Investigation of Sm Addition on Microstructural and Optical Properties of CoFe Thin Films

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Vahaplar, K.; Tari, S.; Tokuc, H.; Okur, S. Effect of Ta buffer layer and thickness on the structural and magnetic properties of Co thin films. J. Vac. Sci. Technol. B 2009, 27, 2112–2116. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Tang, X.; Wei, R.; Zhu, S.; Yang, J.; Song, W.; Dai, J.; Zhu, X.; Sun, Y. Microstructure refinement and magnetization improvement in CoFe thin films by high magnetic field annealing. J. Alloys Compd. 2017, 729, 730–734. [Google Scholar] [CrossRef]

- Mehriz, S.; Sohi, M.H.; Ebrahimi, S.A.S. Study of microstructure and magnetic properties of electrodeposited nanocrystalline CoFeNiCu thin films. Surf. Coat. Technol. 2011, 205, 4757–4763. [Google Scholar] [CrossRef]

- George, E.P.; Gubbi, A.N.; Baker, I.; Robertson, L. Mechanical properties of soft magnetic FeCo alloys. Mater. Sci. Eng. A 2002, 329–331, 325–333. [Google Scholar] [CrossRef]

- Singh, R.K.; Shah, J.; Kotnala, R.K. Magnetic and dielectric properties of rare earth substituted Ni0.5Zn0.5Fe1.95R0.05O4 (R = Pr, Sm and La) ferrite nanoparticles. Mater. Sci. Eng. B 2016, 210, 64–69. [Google Scholar] [CrossRef]

- Tijerina-Rosa, A.; Greneche, J.M.; Fuentes, A.F.; Rodriguez-Hernandez, J.; Menéndez, J.L.; Rodríguez-González, F.J.; Montemayor, S.M. Partial substitution of cobalt by rare-earths (Gd or Sm) in cobalt ferrite: Effect on its microstructure and magnetic properties. Ceram. Int. 2019, 45, 22920–22929. [Google Scholar] [CrossRef]

- Bulai, G.; Diamandescu, L.; Du, I.; Gurlui, S.; Feder, M.; Caltun, O.F. Effect of rare earth substitution in cobalt ferrite bulk materials. J. Magn. Magn. Mater. 2015, 390, 123–131. [Google Scholar] [CrossRef]

- Kayani, Z.N.; Sahar, M.; Riaz, S.; Naseem, S.; Saddiqe, Z. Enhanced magnetic, antibacterial and optical properties of Sm doped ZnO thin films: Role of Sm doping. Opt. Mater. 2020, 108, 110457. [Google Scholar] [CrossRef]

- Li, N.; Li, S.; Zhang, E.; Wang, L. Magnetic property and microstructure of SmCo magnetic recording films. J. Rare Earths 2009, 27, 839–842. [Google Scholar] [CrossRef]

- Rashad, M.M.; Mohamed, R.M.; Shall, H.E. Magnetic properties of nanocrystalline Sm-substituted CoFe2O4 synthesized by citrate precursor method. J. Mater. Process. Technol. 2008, 198, 139–146. [Google Scholar] [CrossRef]

- Apostol, N.G.; Lungu, G.A.; Husanu, M.A.; Costescu, M.R.; Macovei, D.; Teodorescu, C.M. Structure, reactivity, electronic configuration and magnetism of samarium atomic layers deposited on Si(0 0 1) by molecular beam epitaxy. Appl. Surf. Sci. 2013, 267, 106–111. [Google Scholar]

- Hwang, Y.M.; Pan, C.T.; Lu, Y.X.; Jian, S.R.; Chang, H.W.; Juang, J.Y. Influence of post-annealing on the structural and nanomechanical properties of Co thin films. Micromachines 2020, 11, 180. [Google Scholar] [CrossRef] [Green Version]

- Kuru, M.; Sahin, O.; Ozarslan, S.; Ozmetin, A.E. Fabrication and mechanical characterization of rare earth permanent magnet SmCo5 films. J. Alloys Compd. 2017, 694, 726–732. [Google Scholar] [CrossRef]

- Singh, A.K.; Hsu, J.H. Effect of heat treatment on interface driven magnetic properties of CoFe films. J. Magn. Magn. Mater. 2017, 432, 96–101. [Google Scholar] [CrossRef]

- Liu, W.J.; Ou, S.L.; Chang, Y.H.; Chen, Y.T.; Chiang, M.R.; Hsu, S.C.; Chu, C.L. Adhesive characteristic, surface morphology, and optical properties of Co40Fe40V20 films. Opt.-Int. J. Light Electron Opt. 2020, 216, 164587. [Google Scholar] [CrossRef]

- Liu, W.J.; Chen, Y.T.; Chang, Y.H.; Chiang, M.R.; Li, W.H.; Tseng, J.Y.; Chi, P.W.; Wu, T.H. Structure and magnetic properties of Co40Fe40V20 Thin Films. J. Nanosci. Nanotechnol. 2019, 19, 5974–5978. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.J.; Chang, Y.H.; Ou, S.L.; Chen, Y.T.; Li, W.H.; Jhou, T.Y.; Chu, C.C.; Wu, T.H.; Tseng, S.W. Effect of annealing on the structural, magnetic, surface energy and optical properties of Co32Fe30W38 films deposited by direct-current magnetron sputtering. Coatings 2020, 10, 1028. [Google Scholar] [CrossRef]

- Liu, W.J.; Chang, Y.H.; Chiang, C.C.; Chen, Y.T.; Chen, Y.S.; Liao, H.W.; Wu, T.H.; Lin, S.H.; Chi, P.W. Effect of annealing and thickness of Co40Fe40Yb20 thinfilms on various physical properties on a glass substrate. Materials 2022, 15, 8509. [Google Scholar] [CrossRef]

- Liu, W.J.; Chang, Y.H.; Chiang, C.C.; Chen, Y.T.; Liu, Y.C.; Ou, S.L.; Li, S.Y.; Chi, P.W. Co40Fe40Y20 nanofilms’ structural, magnetic, electrical, and nanomechanical characteristics as a function of annealing temperature and thickness. Coatings 2023, 13, 137. [Google Scholar] [CrossRef]

- Liu, W.J.; Chang, Y.H.; Chiang, C.C.; Chen, Y.T.; Liu, Y.C.; Huang, Y.J.; Chi, P.W. The influence of annealing and film thickness on the specific properties of Co40Fe40Y20 Films. Materials 2023, 16, 2490. [Google Scholar] [CrossRef]

- Giridhar, G.; Manepalli, R.K.N.R.; Apparao, G. Thermal and Rheological Measurement Techniques for Nanomaterials Characterization, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2017; pp. 173–195. [Google Scholar]

- Chiu, Y.J.; Shen, C.Y.; Chang, H.W.; Jian, S.R. Characteristics of Iron-Palladium alloy thin films deposited by magnetron sputtering. Results Phys. 2018, 9, 17–22. [Google Scholar] [CrossRef]

- Xi, L.; Du, J.H.; Zhou, J.J.; Ma, J.H.; Li, X.Y.; Wang, Z.; Zuo, Y.L.; Xue, D.S. Soft magnetic property and magnetization reversal mechanism of Sm doped FeCo thin film for high-frequency application. Thin Solid Film. 2012, 520, 5421–5425. [Google Scholar] [CrossRef]

- Ibuki, C.; Sakdanuphab, R. Structural, morphological and adhesion properties of CoFeB thin films deposited by DC magnetron sputtering. Adv. Mat. Res. 2013, 802, 47–52. [Google Scholar] [CrossRef]

- Chaoumead, A.; Sung, Y.M.; Kwak, D.J. The effects of RF sputtering power and gas pressure on structural and electrical properties of ITiO thin film. Adv. Condens. Matter. Phys. 2012, 2012, 651587. [Google Scholar] [CrossRef] [Green Version]

- Das, A.; Palliyan, A.J.; Sahoo, A.K.; Mohanty, J.R.; Gorige, V. Structure, magnetic morphology and magnetization correlations in pulsed laser deposited CoFe2O4 (111) thin films. Thin Solid Films 2023, 770, 139763. [Google Scholar] [CrossRef]

- Cao, Y.; Zhou, C. Thickness dependence of surface roughness and magnetic properties of FeNiCr thin films. J. Magn. Magn. Mater. 2013, 333, 1–7. [Google Scholar] [CrossRef]

- Pookat, G.; Thomas, H.; Thomas, S.; Harthi, S.H.A.; Raghavan, L.; Omari, I.A.A.; Sakthikumar, D.; Ramanujan, R.V.; Anantharaman, M.R. Evolution of structural and magnetic properties of Co–Fe based metallic glass thin films with thermal annealing. Surf. Coat. Technol. 2013, 236, 246–251. [Google Scholar] [CrossRef]

- Abazari, A.M.; Safavi, S.M.; Rezazadeh, G.; Villanueva, L.G. Modelling the size effects on the mechanical properties of micro/nano structures. Senors 2015, 15, 28543–28562. [Google Scholar] [CrossRef] [Green Version]

- Ma, N.; Zheng, W.T.; Wang, X.; Wang, L.L. Effect of Nb-doping on the structure, magnetic, and mechanical properties for Fe-N films synthesized by facing-targets magnetron sputtering. J. Alloys Compd. 2009, 477, 915–919. [Google Scholar] [CrossRef]

- Bhushan, B.; Li, X. Nanomechanical characterisation of solid surfaces and thin films. Int. Mater. Rev. 2003, 48, 125–164. [Google Scholar] [CrossRef]

- Higashino, S.; Miyake, M.; Takahashi, A.; Matamura, Y.; Fujii, H.; Kasada, R.; Hirato, T. Evaluation of the hardness and Young’s modulus of electrodeposited Al–W alloy films by nano-indentation. Surf. Coat. Technol. 2017, 325, 346–351. [Google Scholar] [CrossRef] [Green Version]

- Chu, J.H.; Chen, H.W.; Chan, Y.C.; Duh, J.G.; Lee, J.W.; Jang, J.S.C. Modification of structure and property in Zr-based thin film metallic glass via processing temperature control. Thin Solid Films 2014, 561, 38–42. [Google Scholar] [CrossRef]

- Tayyebi, A.; Rastgoo, A.; Osgouie, K.G. The manufacture and study of the microstructure, mechanical properties, and corrosion behavior of Fe31Cr15Mo14C10B10Si5Ti15 metallic glass thin film, prepared by the magnetic sputtering method. J. Non. Cryst. Solids 2022, 595, 121805. [Google Scholar] [CrossRef]

- Vudayagiri, S.; Junker, M.D.; Skov, A.L. Factors affecting the surface and release properties of thin polydimethylsiloxane films. Polym. J. 2013, 45, 871–878. [Google Scholar] [CrossRef] [Green Version]

- Yu, G.Q.; Tay, B.K.; Sun, Z.; Pan, L.K. Properties of fluorinated amorphous diamond like carbon films by PECVD. Appl. Surf. Sci. 2003, 219, 228–237. [Google Scholar] [CrossRef]

- Tseng, Y.T.; Wu, G.X.; Lin, J.C.; Hwang, Y.R.; Wei, D.H.; Chang, S.Y.; Peng, K.C. Preparation of Co-Fe-Ni alloy micropillar by microanode-guided electroplating. J. Alloys Compd. 2021, 885, 160873. [Google Scholar] [CrossRef]

- Islsm, M.S.; Tong, L.; Falzon, P.J. Influence of metal surface preparation on its surface profile, contact angle, surface energy and adhesion with glass fibre prepreg. Int. J. Adhes. Adhes. 2014, 51, 32–41. [Google Scholar]

- Tavakoli, M.M.; Dastjerdi, H.T.; Zhao, J.; Shulenberger, K.E.; Carbonera, C.; Po, R.; Cominetti, A.; Bianchi, G.; Klein, N.D.; Bawendi, M.G.; et al. Light management in organic photovoltaics processed in ambient conditions using ZnO nanowire and antireflection layer with nanocone array. Small 2019, 15, 1900508. [Google Scholar] [CrossRef]

- KPlancheta; Kot, A.; Gac, J.B.; Zajac, M.; Sikora, M.; Radecka, M.; Zakrzewska, K. Evolution of surface properties of titanium oxide thin films. Appl. Sur. Sci. 2023, 608, 155046. [Google Scholar]

- Hariwal, R.V.; Malik, H.K.; Negi, A.; Asokan, K. Favourable tuning of optical absorbance, bandgap and surface roughness of ZnO thin films by C ion implantation at the critical angle. Appl. Surf. Sci. 2022, 7, 100189. [Google Scholar] [CrossRef]

- Jebathew, A.J.; Karunakaran, M.; Shkir, M.; Algarni, H.; AlFaify, S.; Khan, A.; Alotaibi, N.; Alshahrani, T. High sensitive samarium-doped ZnS thin films for photo-detector applications. Opt. Mater. 2021, 122, 111649. [Google Scholar] [CrossRef]

- Wang, J.; Wu, Y.; Cao, Y.; Li, G.; Liao, Y. Influence of surface roughness on contact angle hysteresis and spreading work. Colloid Polym. Sci. 2020, 298, 1107–1112. [Google Scholar] [CrossRef]

- Liu, T. A facile strategy to simultaneously increase surface roughness and reduce surface energy for the preparation of water-repellent, recyclable and self-cleaning expanded perlite. Colloids Surf. A Physicochem. Eng. Asp. 2022, 655, 130253. [Google Scholar] [CrossRef]

- Bolyachkin, A.S.; Komogortsev, S.V. Power-law behavior of coercivity in nanocrystalline magnetic alloys with grain-size distribution. Scr. Mater. 2018, 152, 55–58. [Google Scholar] [CrossRef]

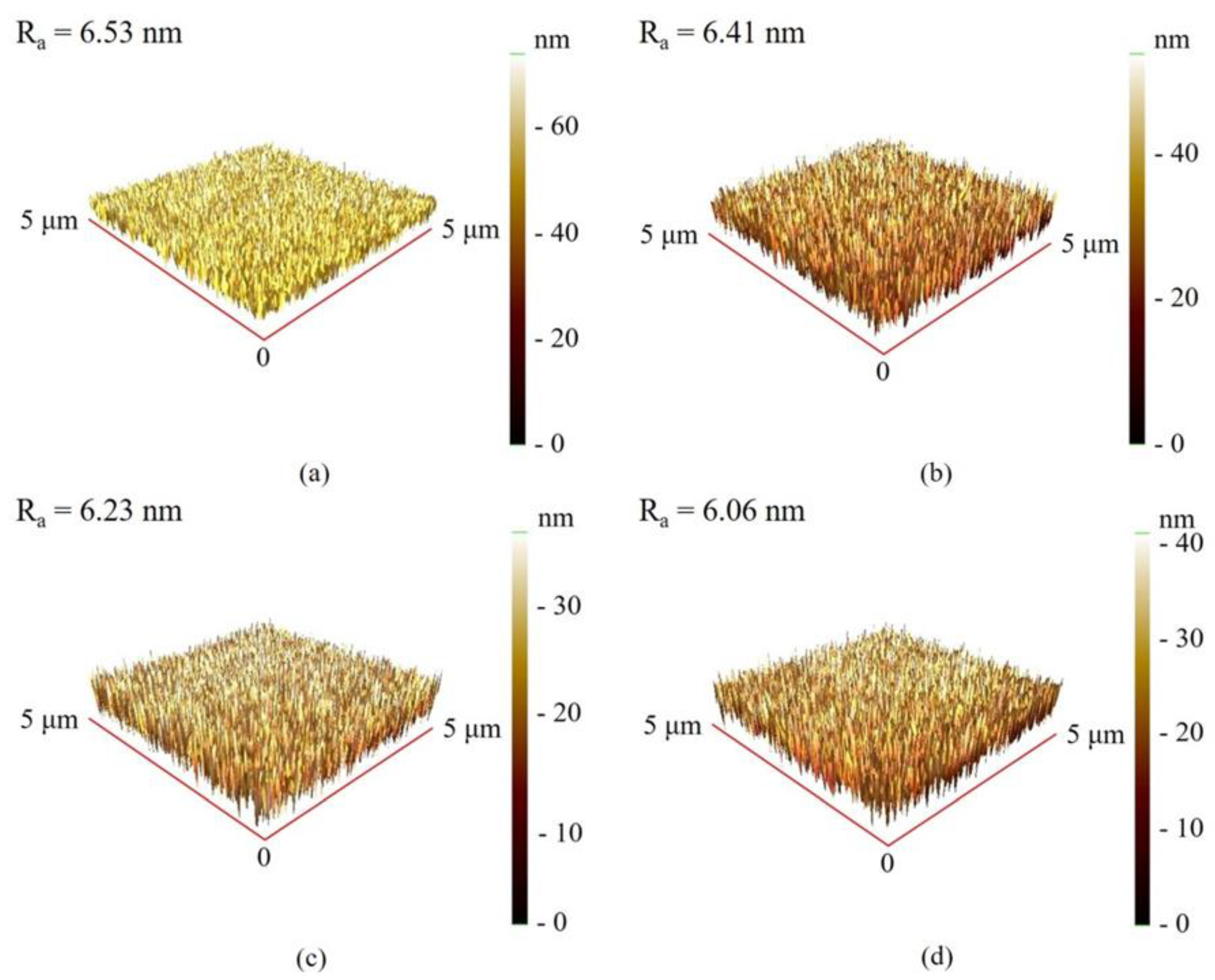

| Materials | Maximum χac (a.u.) | Surface Energy (mJ/mm2) | Transmittance (%) |

|---|---|---|---|

| Glass/Co40Fe40V20 [15,16] 10–100 nm at RT | 0.02–0.04 | 27.8–45.4 | x |

| Glass/Co32Fe30W38 [17] 10–50 nm at RT and annealed conditions | 0.02–0.52 | 22.3–28.4 | x |

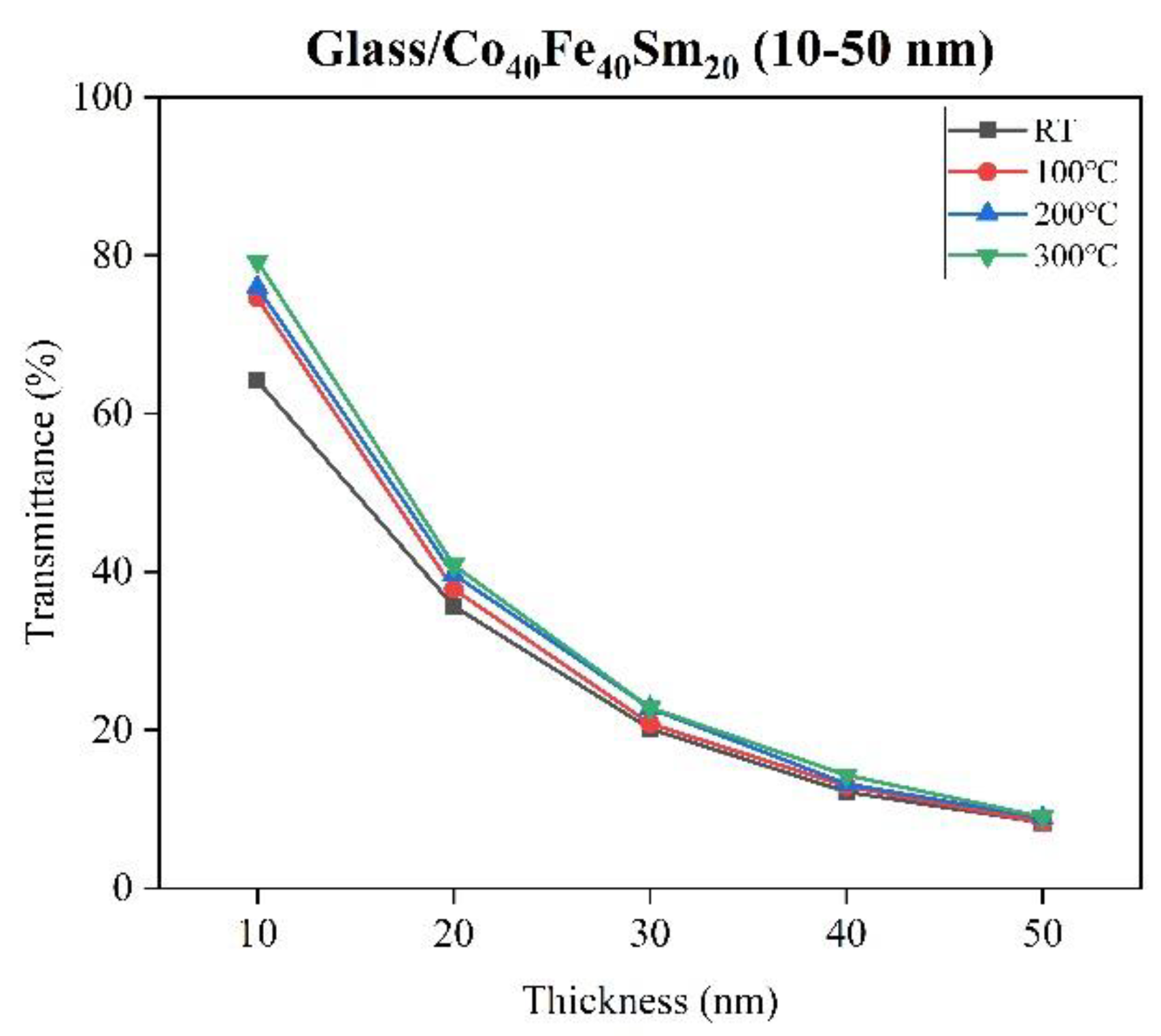

| Glass/Co40Fe40Yb20 [18] 10–50 nm at RT and annealed conditions | 0.04–0.35 | 28.6–34.5 | 22.3–80.5 |

| Si(100)/Co40Fe40Y20 [19] 10–50 nm at RT and annealed conditions | 0.03–0.16 | 22.7–31.1 | x |

| Glass/Co40Fe40Y20 [20] 10–50 nm at RT and annealed conditions | 0.04–0.20 | 23.3–28.7 | 20.1–81.7 |

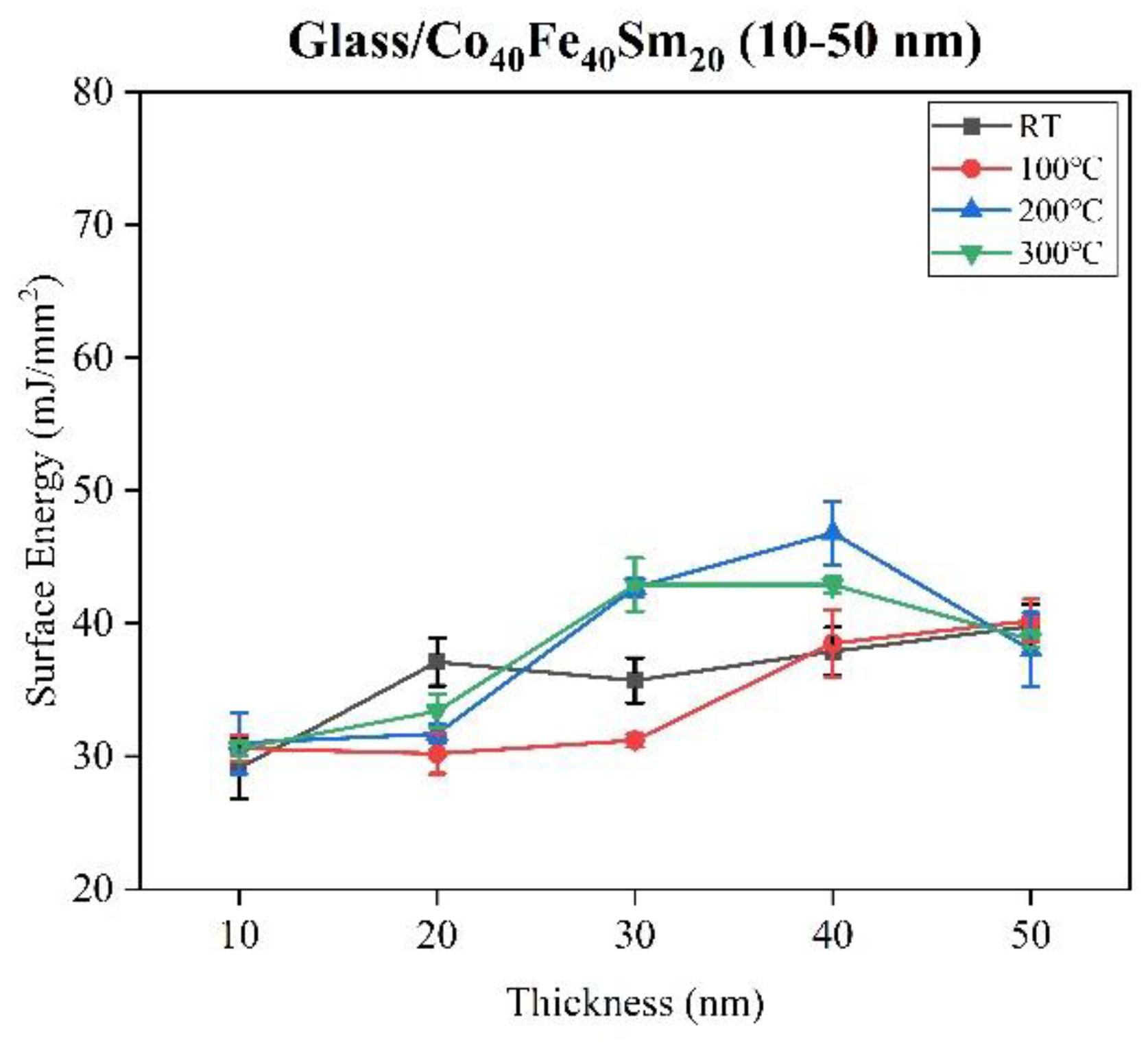

| Glass/Co40Fe40Sm20 10–50 nm at RT and annealed conditions (Current research) | x | 29.1–46.8 | 8.2–79.2 |

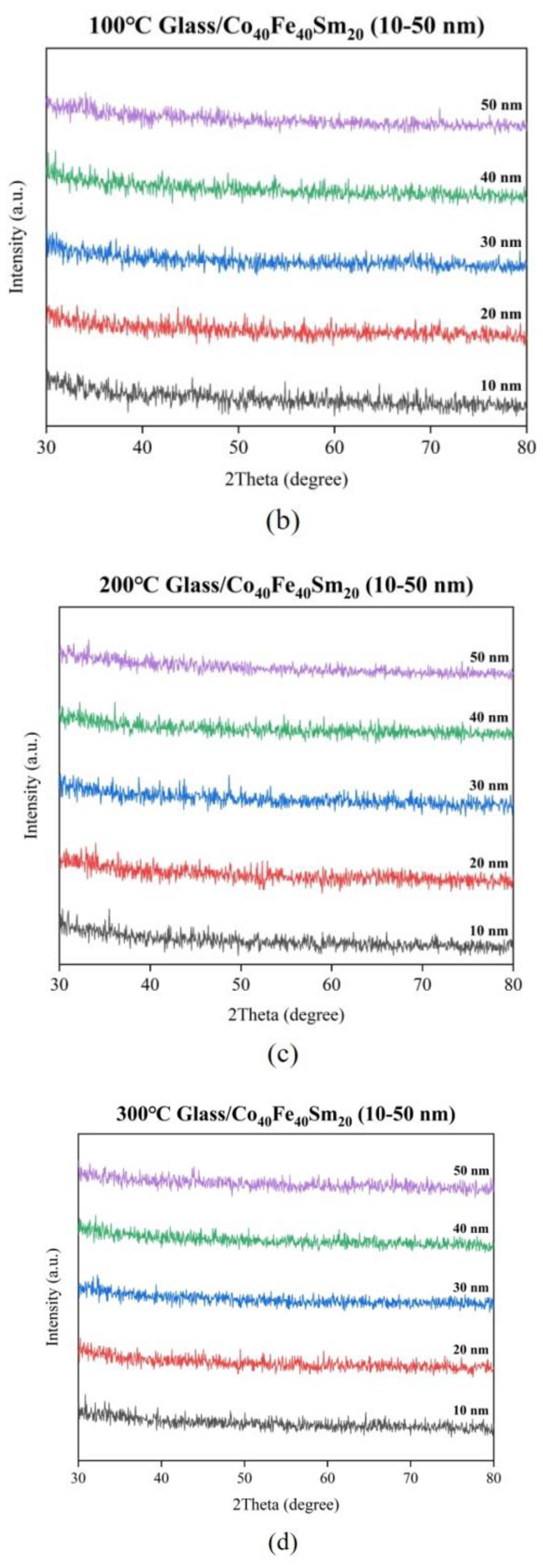

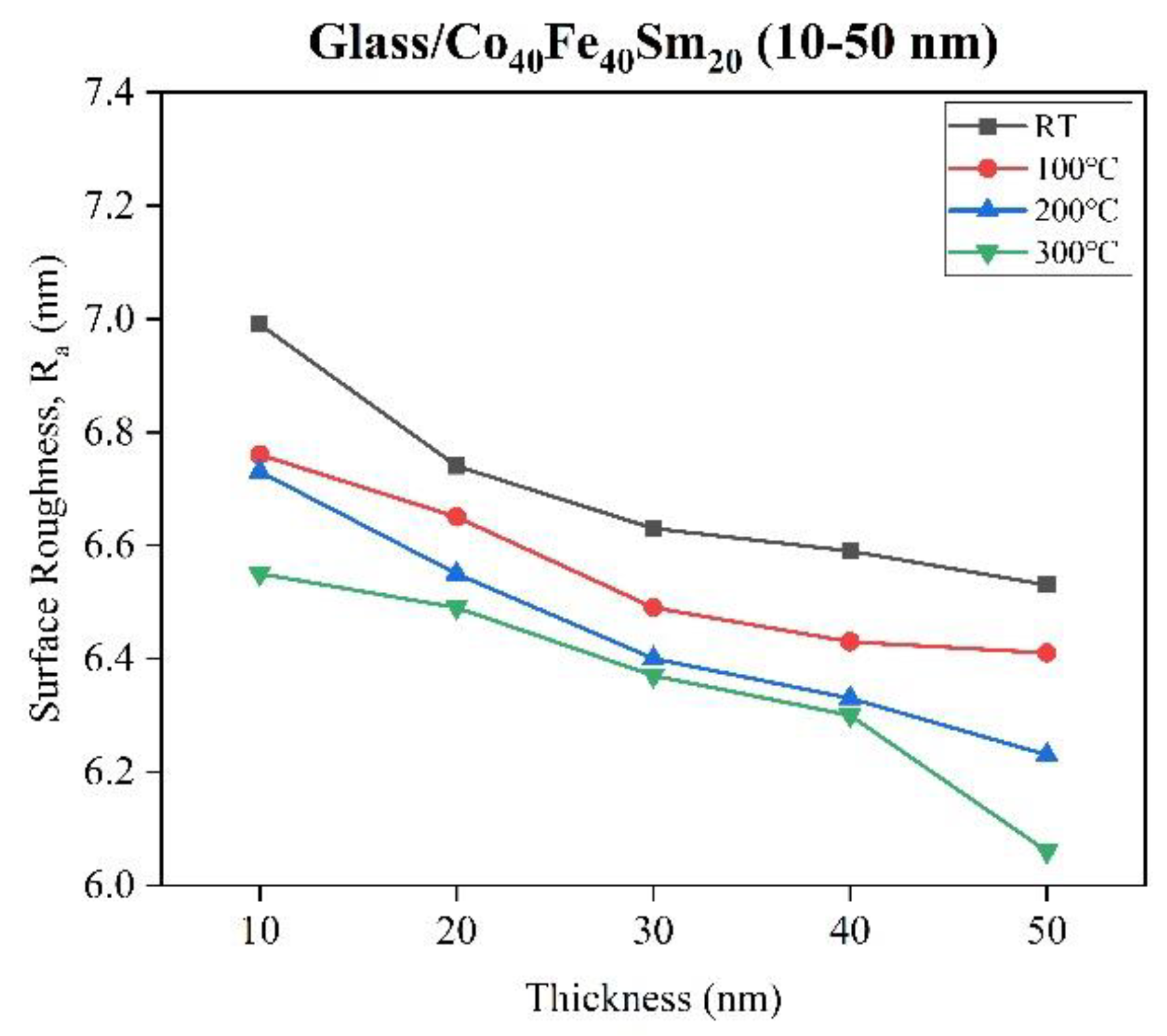

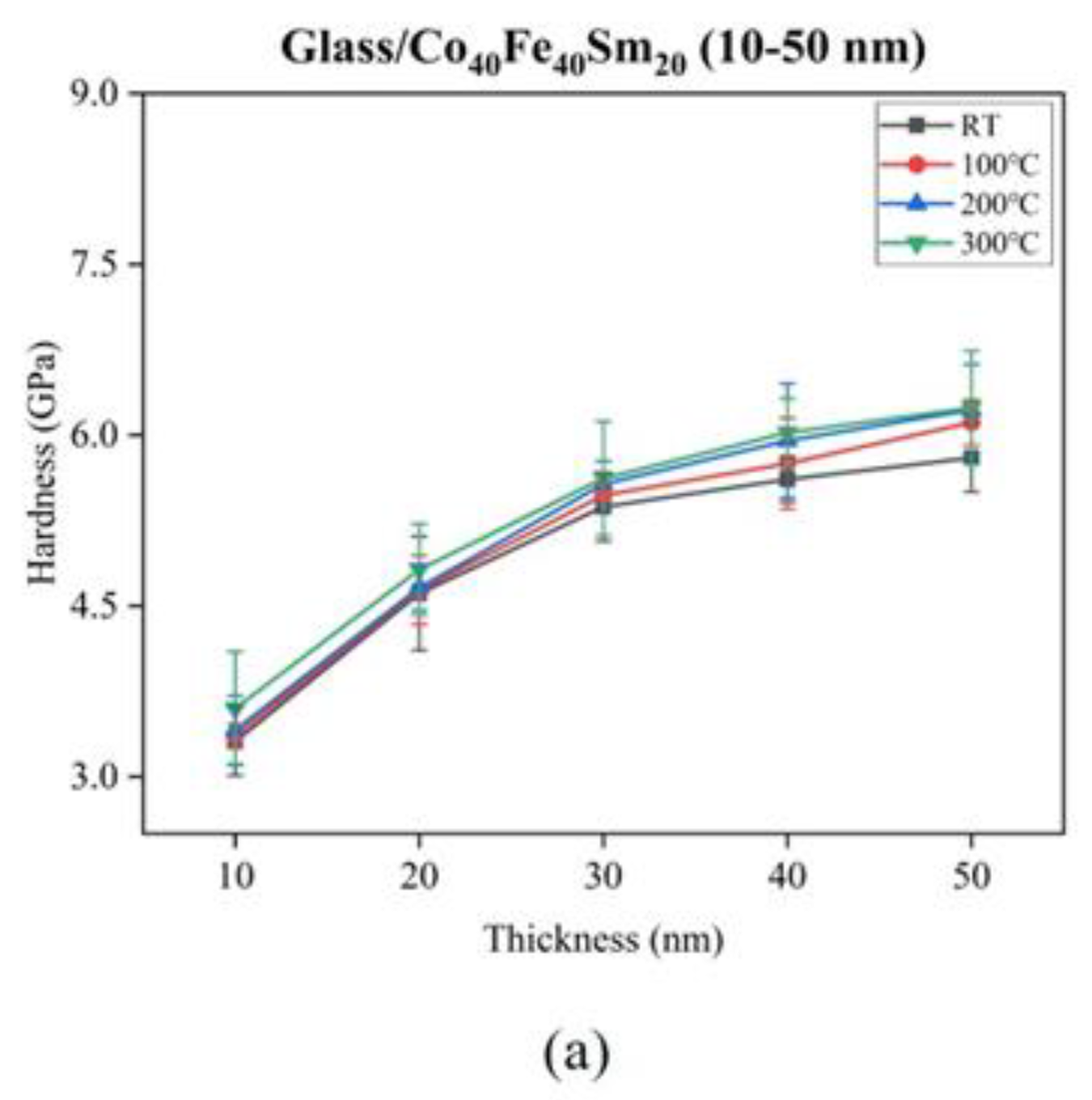

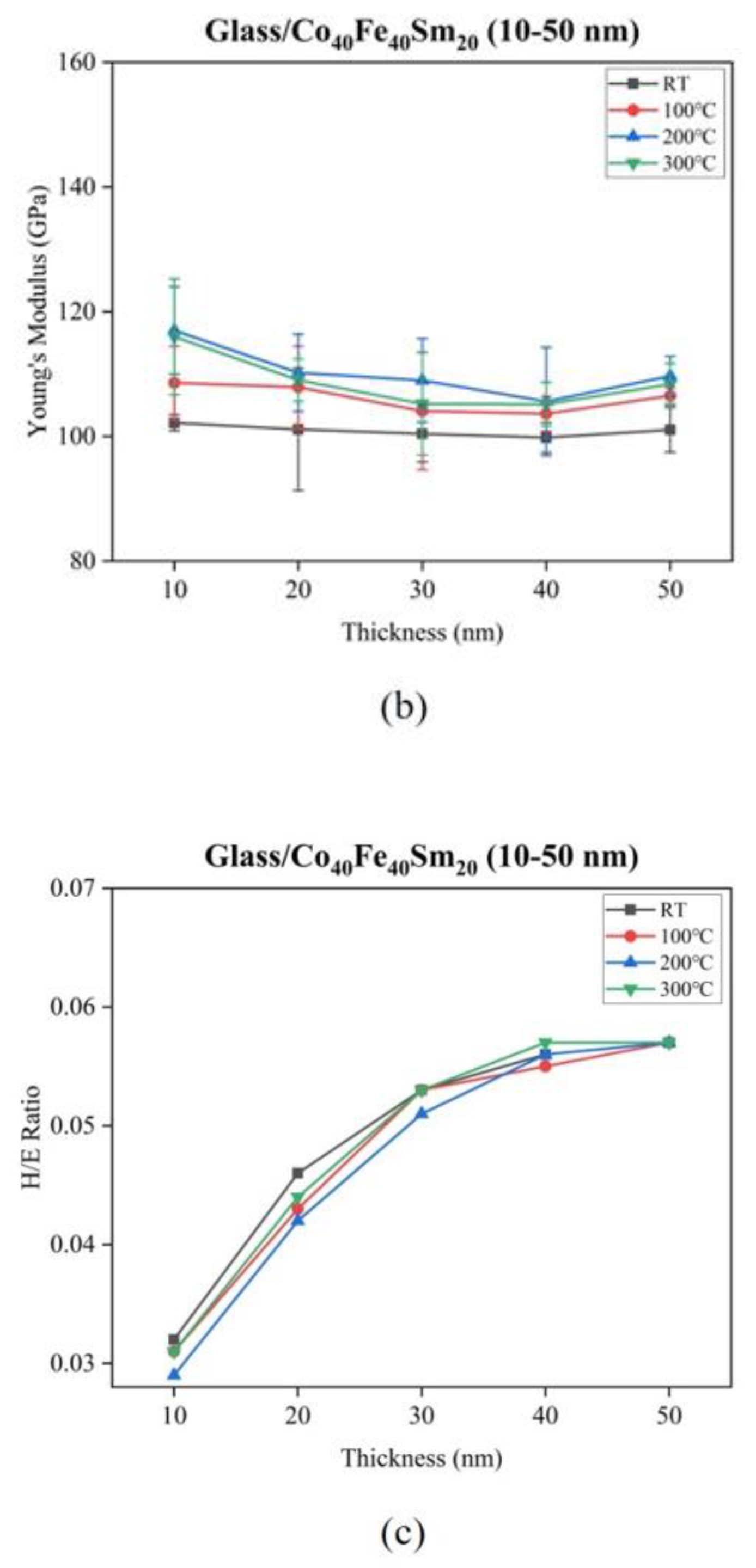

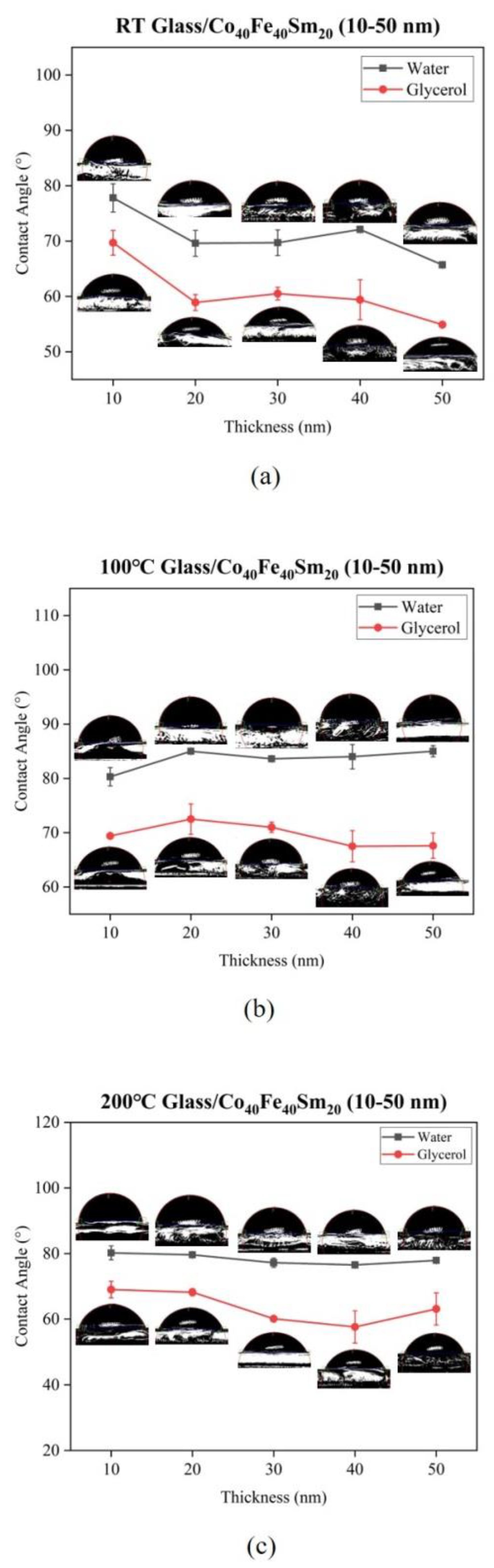

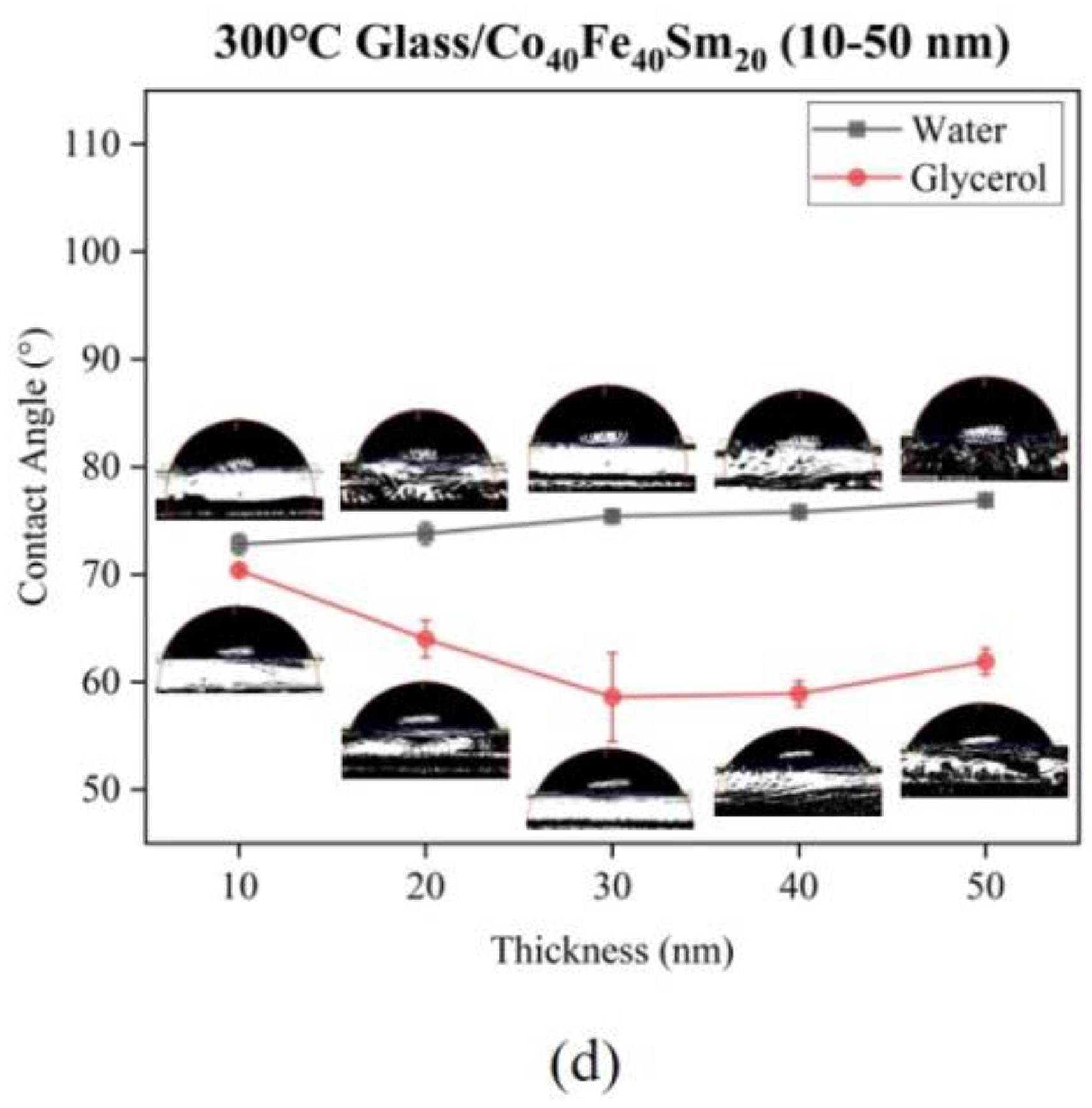

| Ta (°C) | Thickness (nm) | Ra (nm) | H (GPa) | E (GPa) | H/E ratio | SE (mJ/mm2) | Transmittance (%) |

|---|---|---|---|---|---|---|---|

| RT | 10 | 6.99 | 3.31 | 102.17 | 0.032 | 29.1 | 64.16 |

| 20 | 6.74 | 4.61 | 101.12 | 0.046 | 37.1 | 35.66 | |

| 30 | 6.63 | 5.37 | 100.42 | 0.053 | 35.7 | 20.14 | |

| 40 | 6.59 | 5.61 | 99.80 | 0.056 | 37.9 | 12.17 | |

| 50 | 6.53 | 5.80 | 101.05 | 0.057 | 39.8 | 8.28 | |

| 100 | 10 | 6.76 | 3.36 | 108.58 | 0.031 | 30.6 | 74.59 |

| 20 | 6.65 | 4.64 | 107.88 | 0.043 | 30.2 | 37.81 | |

| 30 | 6.49 | 5.47 | 104.07 | 0.053 | 31.2 | 20.81 | |

| 40 | 6.43 | 5.75 | 103.63 | 0.055 | 38.5 | 12.88 | |

| 50 | 6.41 | 6.11 | 106.50 | 0.057 | 40.2 | 8.32 | |

| 200 | 10 | 6.73 | 3.41 | 117.00 | 0.029 | 31.0 | 75.97 |

| 20 | 6.55 | 4.66 | 110.20 | 0.042 | 31.7 | 39.67 | |

| 30 | 6.40 | 5.57 | 108.97 | 0.051 | 42.7 | 22.74 | |

| 40 | 6.33 | 5.95 | 105.60 | 0.056 | 46.8 | 13.18 | |

| 50 | 6.23 | 6.22 | 109.68 | 0.057 | 38.0 | 8.85 | |

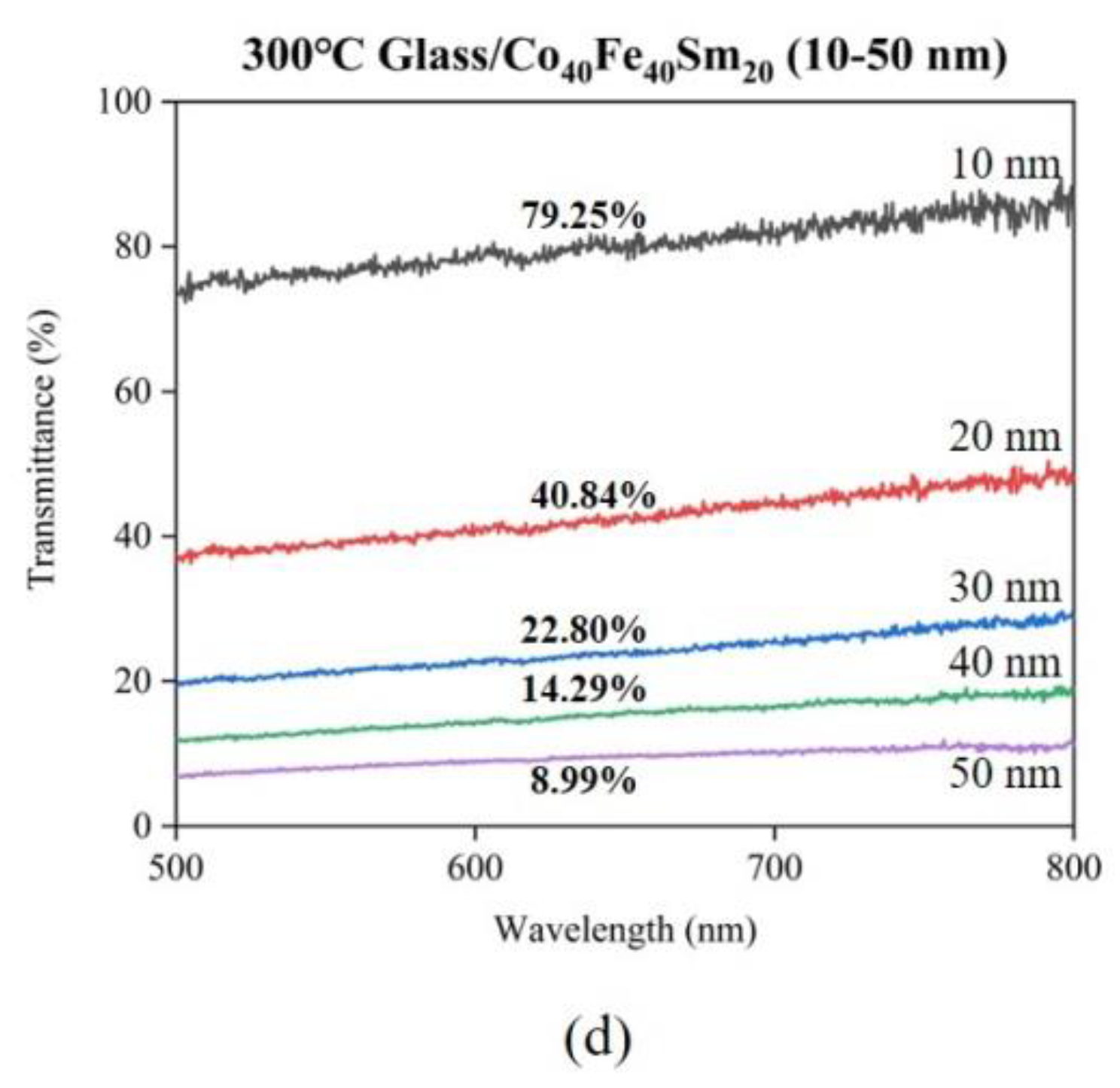

| 300 | 10 | 6.55 | 3.60 | 115.98 | 0.031 | 30.6 | 79.25 |

| 20 | 6.49 | 4.82 | 109.02 | 0.044 | 33.4 | 40.84 | |

| 30 | 6.37 | 5.62 | 105.22 | 0.053 | 42.9 | 22.80 | |

| 40 | 6.30 | 6.02 | 105.16 | 0.057 | 42.9 | 14.29 | |

| 50 | 6.06 | 6.24 | 108.39 | 0.057 | 38.8 | 8.99 |

| Ta (°C) | Hc (kOe) | Ms (emu/cm3) | Mr/Ms |

|---|---|---|---|

| RT | 0.330 | 682.13 | 0.57 |

| 100 | 0.280 | 1076.93 | 0.59 |

| 200 | 0.025 | 1029.24 | 0.20 |

| 300 | 0.030 | 981.13 | 0.46 |

| Materials | Substrate Types | Annealing Temperatures (°C) | Hc (kOe) | Ms (emu/cm3) |

|---|---|---|---|---|

| Co40Fe40Sm20 (40 nm) films | Glass | RT | 0.330 | 682.13 |

| 100 | 0.280 | 1076.93 | ||

| 200 | 0.025 | 1029.24 | ||

| 300 | 0.030 | 981.13 | ||

| Sm37.7Co62.3 (70 nm) films [9] | Glass | RT | 37.938 | 150 |

| Co40Fe40Y20 (50 nm) films [20] | Glass | RT | - | 482 |

| 300 | 610 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, W.-J.; Chang, Y.-H.; Chiang, C.-C.; Lai, J.-X.; Chen, Y.-T.; Chen, H.-L.; Lin, S.-H. Investigation of Sm Addition on Microstructural and Optical Properties of CoFe Thin Films. Materials 2023, 16, 5380. https://doi.org/10.3390/ma16155380

Liu W-J, Chang Y-H, Chiang C-C, Lai J-X, Chen Y-T, Chen H-L, Lin S-H. Investigation of Sm Addition on Microstructural and Optical Properties of CoFe Thin Films. Materials. 2023; 16(15):5380. https://doi.org/10.3390/ma16155380

Chicago/Turabian StyleLiu, Wen-Jen, Yung-Huang Chang, Chia-Chin Chiang, Jian-Xin Lai, Yuan-Tsung Chen, Hsiung-Liang Chen, and Shih-Hung Lin. 2023. "Investigation of Sm Addition on Microstructural and Optical Properties of CoFe Thin Films" Materials 16, no. 15: 5380. https://doi.org/10.3390/ma16155380