Freeze–Thaw Durability of Basalt Fibre Reinforced Bio-Based Unsaturated Polyester Composite

Abstract

:1. Introduction

2. Materials

2.1. Bio-Based Resin

2.2. Oil-Based Resin

2.3. Basalt Fibre

2.4. Production of Composite Plates

3. Methods

3.1. Freeze–Thaw Environment

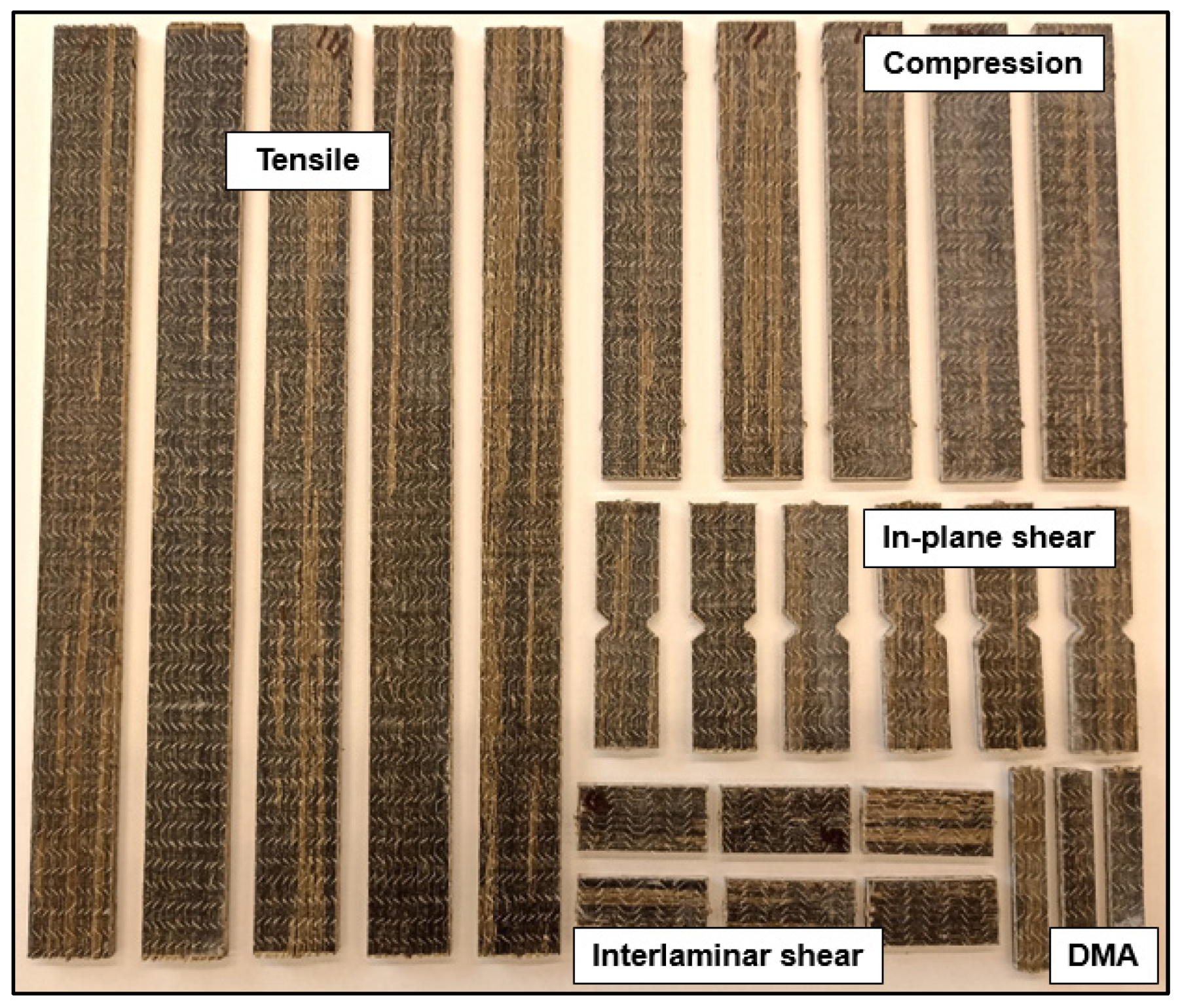

3.2. Experimental Characterisation

4. Results and Discussion

4.1. Initial Characterisation

4.2. Water Absorption

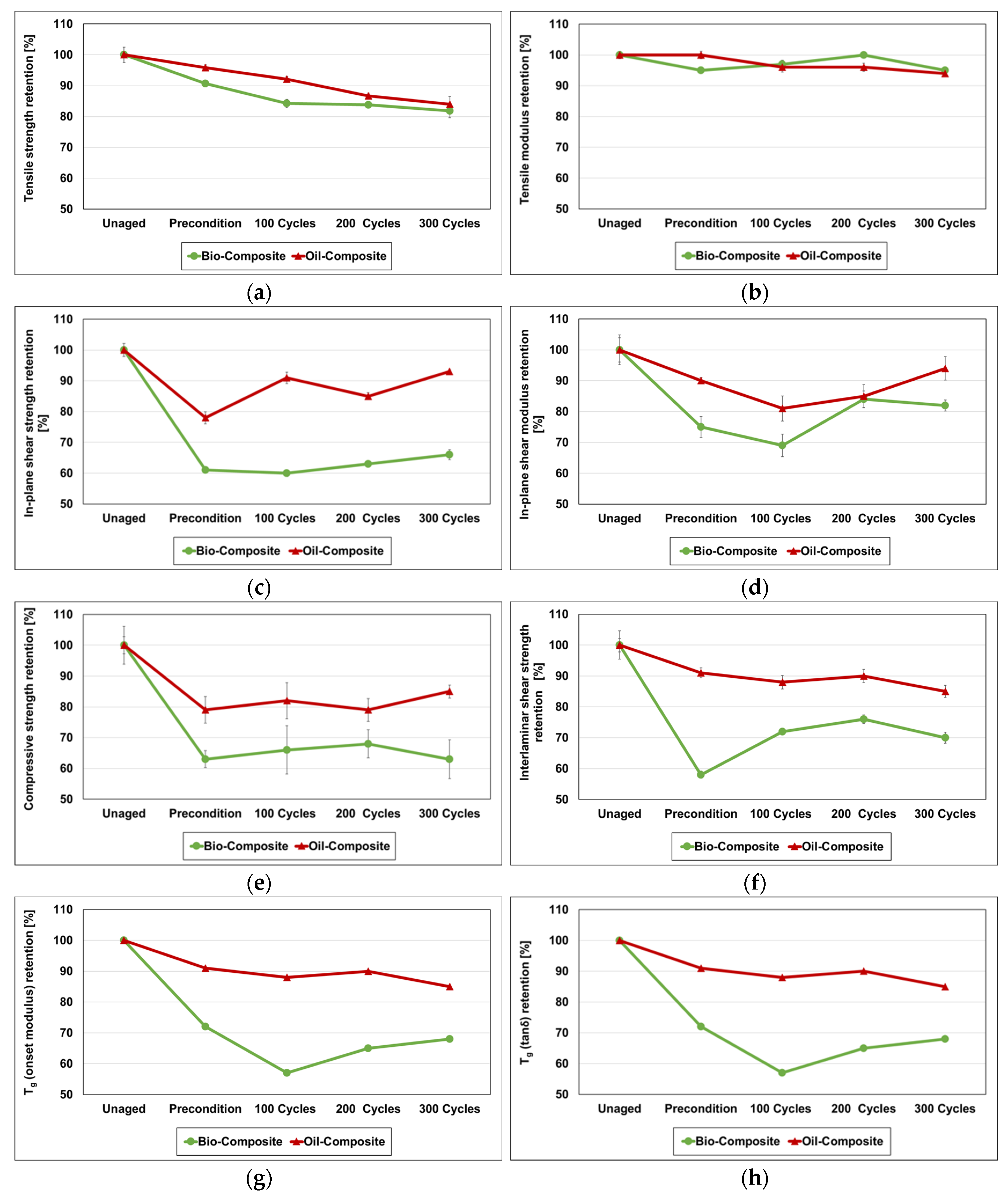

4.3. Tensile Properties

4.4. In-Plane Shear Properties

| Bio-Composite | Oil-Composite | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Property | Parameter | Preconditioning | 100 Cycle | 200 Cycle | 300 Cycle | Preconditioning | 100 Cycle | 200 Cycle | 300 Cycle |

| Tensile strength | [MPa] | 487.3 | 452.4 | 450.0 | 439.4 | 558.5 | 536.8 | 505.2 | 489.6 |

| SD | 11.0 | 13.0 | 7.3 | 21.5 | 10.2 | 10.3 | 9.7 | 25.8 | |

| CV [%] | 2.3 | 2.9 | 1.6 | 4.9 | 1.8 | 1.9 | 1.9 | 5.3 | |

| R [%] | 91 | 84 | 84 | 82 | 96 | 92 | 87 | 84 | |

| Tensile modulus | [GPa] | 26.5 | 27.1 | 27.9 | 26.3 | 27.9 | 26.6 | 26.8 | 26.0 |

| SD | 0.4 | 0.6 | 0.4 | 0.3 | 0.6 | 0.8 | 0.7 | 0.5 | |

| CV [%] | 1.8 | 2.4 | 1.3 | 1.0 | 2.2 | 2.9 | 2.4 | 2.0 | |

| R [%] | 95 | 97 | 100 | 95 | 100 | 96 | 96 | 94 | |

| In-plane shear strength | [MPa] | 26.6 | 26.2 | 27.5 | 29.0 | 33.5 | 38.9 | 36.5 | 39.9 |

| SD | 0.4 | 1.0 | 0.8 | 1.4 | 1.6 | 1.6 | 1.0 | 0.5 | |

| CV [%] | 1.4 | 3.7 | 2.9 | 4.8 | 4.9 | 4.1 | 2.7 | 1.3 | |

| R [%] | 61 | 60 | 63 | 66 | 78 | 91 | 85 | 93 | |

| In-plane shear modulus | [MPa] | 2.0 | 1.9 | 2.3 | 2.2 | 2.8 | 2.5 | 2.6 | 2.9 |

| SD | 0.2 | 0.2 | 0.2 | 0.1 | 0.1 | 0.3 | 0.2 | 0.2 | |

| CV [%] | 9.1 | 10.7 | 6.4 | 4.4 | 2.3 | 10.1 | 8.9 | 8.1 | |

| R [%] | 75 | 69 | 84 | 82 | 90 | 81 | 85 | 84 | |

| Compressive strength | [MPa] | 90.0 | 94.3 | 97.5 | 90.8 | 124.6 | 128.3 | 124.4 | 133.3 |

| SD | 7.1 | 20.1 | 11.6 | 18.0 | 12.2 | 16.5 | 10.4 | 6.6 | |

| CV [%] | 7.9 | 21.3 | 11.9 | 19.9 | 9.8 | 12.8 | 8.4 | 5.0 | |

| R [%] | 63 | 66 | 68 | 63 | 79 | 82 | 79 | 85 | |

| Interlaminar shear strength | [MPa] | 9.1 | 11.3 | 11.9 | 11.3 | >14.2 | 16.4 | 15.7 | 16.1 |

| SD | 0.4 | 0.3 | 1.2 | 0.6 | 0.6 | 0.8 | 0.8 | 0.7 | |

| CV [%] | 4.1 | 3.0 | 10.3 | 5.1 | 4.0 | 4.7 | 4.8 | 4.3 | |

| R [%] | 58 | 72 | 76 | 70 | 81 | 94 | 90 | 92 | |

| Tg,onset | [°C] | 49.6 | 39.4 | 44.6 | 46.8 | 64.5 | 62.5 | 63.7 | 59.9 |

| R [%] | 72 | 57 | 65 | 68 | 91 | 88 | 90 | 85 | |

| Tg,tan(δ) | [°C] | 73.5 | 76.8 | 76.6 | 77.0 | 87.6 | 89.0 | 89.0 | 85.7 |

| R [%] | 75 | 78 | 78 | 78 | 93 | 95 | 95 | 91 | |

4.5. Compressive Strength

4.6. Interlaminar Shear Strength (ILSS)

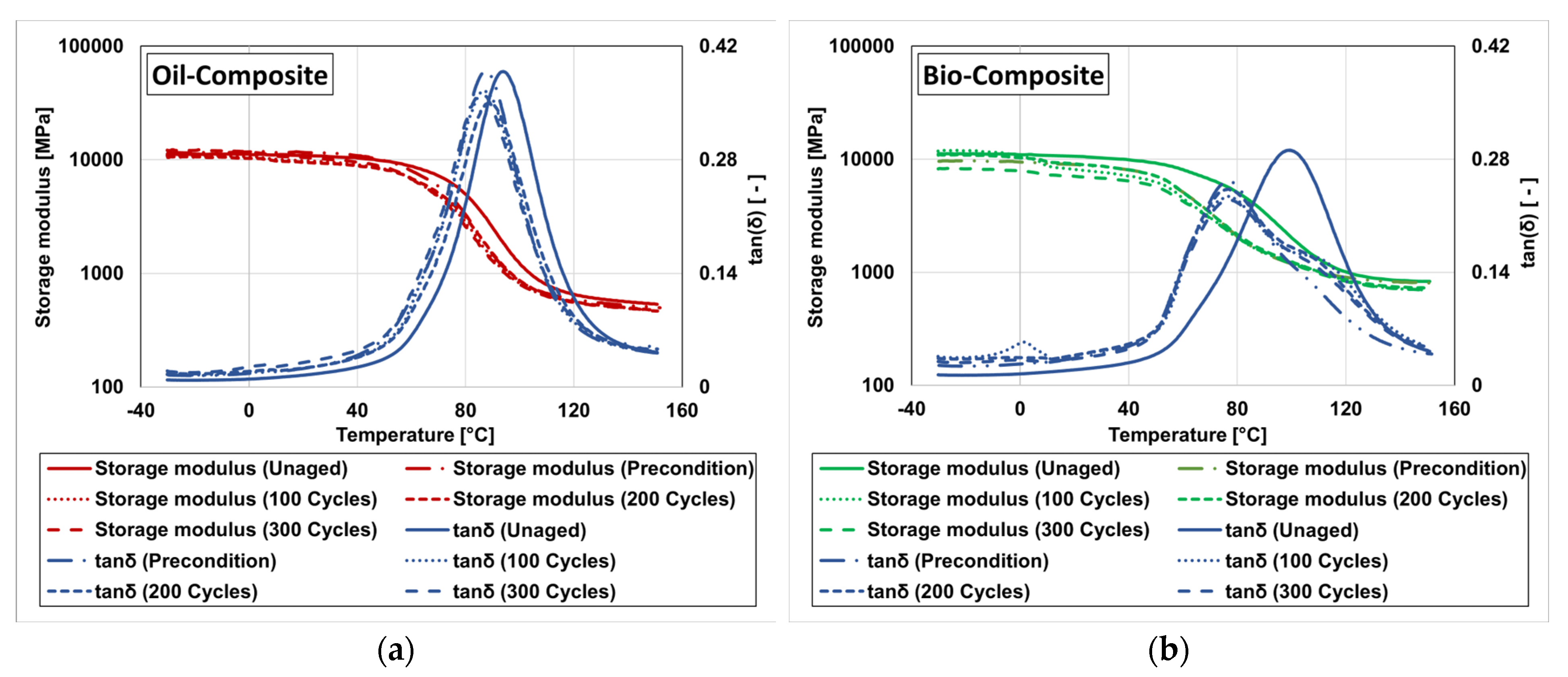

4.7. Dynamic Mechanical Analysis (DMA)

4.8. Scanning Electron Microscopy (SEM)

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Yu, Y.; Liu, Y.; Zhang, M.; Li, L.; Ma, L.; Sun, Y.; Wang, W. A Review on Basalt Fiber Composites and Their Applications in Clean Energy Sector and Power Grids. Polymers 2022, 14, 2376. [Google Scholar] [CrossRef] [PubMed]

- Sousa, J.M.; Correia, J.R.; Cabral-Fonseca, S.; Diogo, A.C. Effects of thermal cycles on the mechanical response of pultruded GFRP profiles used in civil engineering applications. Compos. Struct. 2014, 116, 720–731. [Google Scholar] [CrossRef] [Green Version]

- Wegmann, S.; Rytka, C.; Diaz-Rodenas, M.; Werlen, V.; Schneeberger, C.; Ermanni, P.; Caglar, B.; Gomez, C.; Michaud, V. A life cycle analysis of novel lightweight composite processes: Reducing the environmental footprint of automotive structures. J. Clean. Prod. 2022, 330, 129808. [Google Scholar] [CrossRef]

- Dudley, B. BP Statistical Review of World Energy 2018. Energy Economic, Centre for Energy Economics Research and Policy. British Petroleum. 2018. Volume 5. Available online: https://www.bp.com/en/global/corporate/energy-economics/statistical-review-of-world-energy/electricity.html (accessed on 16 June 2023).

- Chang, B.P.; Mohanty, A.K.; Misra, M. Studies on durability of sustainable biobased composites: A review. RSC Adv. 2020, 10, 17955–17999. [Google Scholar] [CrossRef] [PubMed]

- Monaldo, E.; Nerilli, F.; Vairo, G. Basalt-Based Fiber-Reinforced Materials and Structural Applications in Civil Engineering. Compos. Struct. 2019, 214, 246–263. [Google Scholar] [CrossRef]

- Mugahed Amran, Y.H.; Alyousef, R.; Rashid, R.S.M.; Alabduljabbar, H.; Hung, C.-C. Properties and applications of FRP in strengthening RC structures: A review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- Chakartnarodom, P.; Prakaypan, W.; Ineure, P.; Kongkajun, N.; Chuankrerkkul, N. Feasibility Study of Using Basalt Fibers as the Reinforcement Phase in Fiber-Cement Products. Key Eng. Mater. 2018, 766, 252–257. [Google Scholar] [CrossRef]

- Gutnikov, S.; Manylov, M.; Lipatov, Y.; Lazoryak, B.; Pokholok, K. Effect of the reduction treatment on the basalt continuous fiber crystallization properties. J. Non-Cryst. Solids 2013, 368, 45–50. [Google Scholar] [CrossRef]

- Gadow, R.; Weichand, P. Novel Intermediate Temperature Ceramic Composites, Materials and Processing for Siloxane Based Basalt Fiber Composites. Key Eng. Mater. 2014, 611–612, 382–390. [Google Scholar] [CrossRef]

- Deák, T.; Czigány, T. Chemical Composition and Mechanical Properties of Basalt and Glass Fibers: A Comparison. Text. Res. J. 2009, 79, 645–651. [Google Scholar] [CrossRef]

- Benmokrane, B.; Elgabbas, F.; Ahmed, E.A.; Cousin, P. Characterization and comparative durability study of glass/vinylester, basalt/vinylester, and basalt/epoxy FRP bars. J. Compos. Constr. 2015, 19, 04015008. [Google Scholar] [CrossRef]

- Chowdhury, I.R.; O’Dowd, N.P.; Comer, A.J. Experimental study of hygrothermal ageing effects on failure modes of non-crimp basalt fibre-reinforced epoxy composite. Compos. Struct. 2021, 275, 114415. [Google Scholar] [CrossRef]

- Dhand, V.; Mittal, G.; Rhee, K.Y.; Park, S.-J.; Hui, D. A short review on basalt fiber reinforced polymer composites. Compos. Part B Eng. 2015, 73, 166–180. [Google Scholar] [CrossRef]

- Lebedev, M.; Startsev, O.; Kychkin, A. The effects of aggressive environments on the mechanical properties of basalt plastics. Heliyon 2020, 6, e03481. [Google Scholar] [CrossRef]

- Lopresto, V.; Leone, C.; De Iorio, I. Mechanical characterisation of basalt fibre reinforced plastic. Compos. Part B Eng. 2011, 42, 717–723. [Google Scholar] [CrossRef]

- Hofmann, M.; Garrido, M.; Machado, M.; Correia, J.R.; Bordado, J.C. Development of high-performance partially biobased thermoset polyester using renewable building blocks from isosorbide, 1,3-propanediol, and fumaric acid. J. Appl. Polym. Sci. 2022, 139, e53029. [Google Scholar] [CrossRef]

- Gonzalez, M.N.G.; Levi, M.; Turri, S. Development of polyester binders for the production of sustainable polyurethane coatings: Technological characterization and life cycle assessment. J. Clean. Prod. 2017, 164, 171–178. [Google Scholar] [CrossRef]

- González, M.N.G.; Börjesson, P.; Levi, M.; Turri, S. Development and life cycle assessment of polyester binders con-taining 2,5-furandicarboxylic acid and their polyurethane coatings. J. Polym. Environ. 2018, 26, 3626–3637. [Google Scholar] [CrossRef] [Green Version]

- Suriano, R.; Gonzalez, M.N.G.; Turri, S. Environmental Profile and Technological Validation of New High-Tg Unsatu-rated Polyesters from Fully Bio-Based Monomers and Reactive Diluents. J. Polym. Environ. 2021, 29, 1122–1133. [Google Scholar] [CrossRef]

- Hofmann, M.A.; Shahid, A.T.; Garrido, M.; Ferreira, M.J.; Correia, J.R.; Bordado, J.C. Biobased Thermosetting Polyester Resin for High-Performance Applications. ACS Sustain. Chem. Eng. 2022, 10, 3442–3454. [Google Scholar] [CrossRef]

- Hofmann, M.; Shahid, A.T.; Machado, M.; Garrido, M.; Bordado, J.C.; Correia, J.R. GFRP biocomposites produced with a novel high-performance bio-based unsaturated polyester resin. Compos. Part A Appl. Sci. Manuf. 2022, 161, 107098. [Google Scholar] [CrossRef]

- Hofmann, M.; Machado, M.; Shahid, A.; Dourado, F.; Garrido, M.; Bordado, J.C.; Correia, J.R. Pultruded carbon fibre reinforced polymer strips produced with a novel bio-based thermoset polyester for structural strengthening. Compos. Sci. Technol. 2023, 234, 109936. [Google Scholar] [CrossRef]

- Zaman, A.; Gutub, S.A.; Wafa, M.A. A review on FRP composites applications and durability concerns in the construction sector. J. Reinf. Plast. Compos. 2013, 32, 1966–1988. [Google Scholar] [CrossRef]

- Karbhari, V.M. E-Glass/Vinylester Composites in Aqueous Environments: Effects on Short-Beam Shear Strength. J. Compos. Constr. 2004, 8, 148–156. [Google Scholar] [CrossRef]

- Shi, J.-W.; Zhu, H.; Wu, G.; Wu, Z.-S. Tensile behavior of FRP and hybrid FRP sheets in freeze–thaw cycling environments. Compos. Part B Eng. 2014, 60, 239–247. [Google Scholar] [CrossRef]

- Shi, J.-W.; Cao, W.-H.; Chen, L.; Li, A.-L. Durability of wet lay-up BFRP single-lap joints subjected to freeze–thaw cycling. Constr. Build. Mater. 2020, 238, 117664. [Google Scholar] [CrossRef]

- Liu, Q.; Shaw, M.T.; Parnas, R.S.; McDonnell, A.-M. Investigation of basalt fiber composite aging behavior for applications in transportation. Polym. Compos. 2006, 27, 475–483. [Google Scholar] [CrossRef]

- Li, H.; Xian, G.; Lin, Q.; Zhang, H. Freeze-thaw resistance of unidirectional-fiber-reinforced epoxy composites. J. Appl. Polym. Sci. 2012, 123, 3781–3788. [Google Scholar] [CrossRef]

- ASTM D7792/D7792M-15; Standard Practice for Freeze/Thaw Conditioning of Pultruded Fiber Reinforced Polymer (FRP) Composites Used in Structural Designs. ASTM International: West Conshohocken, PA, USA, 2015.

- Aniskevich, K.; Korkhov, V.; Faitelsone, J.; Jansons, J. Mechanical properties of pultruded glass fiber reinforced plastic after freeze–thaw cycling. J. Reinf. Plast. Compos. 2012, 31, 1554–1563. [Google Scholar] [CrossRef]

- Wu, H.-C.; Fu, G.; Gibson, R.F.; Yan, A.; Warnemuende, K.; Anumandla, V. Durability of FRP composite bridge deck materials under freeze-thaw and low temperature conditions. J. Bridge Eng. 2006, 11, 443–451. [Google Scholar] [CrossRef] [Green Version]

- Mcisaac, A. The Effects of Bio Content and Type of Resin on FRP Wet Layup Tensile and Bond Strength to Concrete and Durability under Freeze-Thaw Cycles. M.Sc. Thesis, Queen’s University, Kingston, ON, Canada, 2017. [Google Scholar]

- Di Ludovico, M.; Piscitelli, F.; Prota, A.; Lavorgna, M.; Mensitieri, G.; Manfredi, G. Improved mechanical properties of CFRP laminates at elevated temperatures and freeze–thaw cycling. Constr. Build. Mater. 2012, 31, 273–283. [Google Scholar] [CrossRef]

- Kim, H.-Y.; Park, Y.-H.; You, Y.-J.; Moon, C.-K. Short-term durability test for GFRP rods under various environmental conditions. Compos. Struct. 2008, 83, 37–47. [Google Scholar] [CrossRef]

- ISO 16620-4; Plastics—Biobased Content—Part 4: Determination of Biobased Mass Content. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 6721-11; Plastics—Determination of dynamic mechanical properties—Part 11: Glass transition temperature. International Organization for Standardization: Geneva, Switzerland, 2019.

- ISO 527-4; Plastics—Determination of tensile properties—Part 4: Test conditions for isotropic and orthotropic fibre-reinforced plastic composites. International Organization for Standardization: Geneva, Switzerland, 2023.

- ASTM D5379/D5379M; Standard Test Method for Shear Properties of Composite Materials by the V-Notched Beam Method. ASTM International: West Conshohocken, PA, USA, 2019.

- ASTM D6641/D6641M; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture. ASTM International: West Conshohocken, PA, USA, 2016.

- ISO 14130; Fibre-reinforced plastic composites—Determination of apparent interlaminar shear strength by short-beam method. International Organization for Standardization: Geneva, Switzerland, 1997.

- Fonseca, A.C.; Lopes, I.M.; Coelho, J.F.; Serra, A.C. Synthesis of unsaturated polyesters based on renewable monomers: Structure/properties relationship and crosslinking with 2-hydroxyethyl methacrylate. React. Funct. Polym. 2015, 97, 1–11. [Google Scholar] [CrossRef]

- Sousa, J.; Garrido, M.; Correia, J.; Cabral-Fonseca, S. Hygrothermal ageing of pultruded GFRP profiles: Comparative study of unsaturated polyester and vinyl ester resin matrices. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106193. [Google Scholar] [CrossRef]

- Sun, W.; Vassilopoulos, A.P.; Keller, T. Effect of temperature on kinking failure mode of non-slender glass fi-ber-reinforced polymer specimens. Compos. Struct. 2015, 133, 178–190. [Google Scholar] [CrossRef]

- Grammatikos, S.; Zafari, B.; Evernden, M.; Mottram, J.; Mitchels, J. Moisture uptake characteristics of a pultruded fibre reinforced polymer flat sheet subjected to hot/wet aging. Polym. Degrad. Stab. 2015, 121, 407–419. [Google Scholar] [CrossRef] [Green Version]

| Properties | Bio-UPR | Oil-UPR | Standard (No. of Specimens) | |

|---|---|---|---|---|

| Tg | Onset E’ modulus [°C] | 70.6 | 75.3 | ISO 6721-11 [37] (2) |

| tan(δ) [°C] | 103.6 | 102.4 | ||

| Tension | σt [MPa] | 43.5 ± 3.4 (7.8%) | 45.3 ± 3.3 (7.3%) | ISO 527-4 [38] (10) |

| Et [GPa] | 3.3 ± 0.03 (0.9%) | 3.3 ± 0.1 (3.4%) | ||

| εt (m/m) [%] | 1.6 ± 0.1 (8.8%) | 1.7 ± 0.2 (11.7%) | ||

| In-plane shear | σ12 [MPa] | 49.0 ± 3.4 (6.9%) | 54.1 ± 2.5 (4.7%) | ASTM D5379/D5379M [39] (8) |

| G12 [GPa] | 1.6 ± 0.1 (8.4%) | 1.3 ± 0.1 (10.8%) | ||

| Properties | Parameter | Bio-Composite | Oil-Composite |

|---|---|---|---|

| Tg | Onset E’ [°C] | 69.2 | 70.9 |

| tan(δ) [°C] | 98.2 | 93.8 | |

| Tension | σt [MPa] | 537.1 ± 23.6 (4.4%) | 583.0 ± 10.7 (1.8%) |

| Et [GPa] | 27.8 ± 0.3 (1.1%) | 27.8 ± 0.6 (2.2%) | |

| Compression | σc [MPa] | 143.3 ± 7.2 (5.0%) | 157.1 ± 17.2 (10.9%) |

| In-plane shear | τ12 [MPa] | 43.8 ± 0.7 (1.6%) | 42.8 ± 1.8 (4.2%) |

| G12 [GPa] | 2.7 ± 0.2 (7.9%) | 3.1 ± 0.3 (9.2%) | |

| Interlaminar shear | σsbs [MPa] | 15.7 ± 1.2 (7.6%) | 17.5 ± 1.6 (9.2%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shahid, A.T.; Hofmann, M.; Garrido, M.; Correia, J.R.; Rosa, I.C. Freeze–Thaw Durability of Basalt Fibre Reinforced Bio-Based Unsaturated Polyester Composite. Materials 2023, 16, 5411. https://doi.org/10.3390/ma16155411

Shahid AT, Hofmann M, Garrido M, Correia JR, Rosa IC. Freeze–Thaw Durability of Basalt Fibre Reinforced Bio-Based Unsaturated Polyester Composite. Materials. 2023; 16(15):5411. https://doi.org/10.3390/ma16155411

Chicago/Turabian StyleShahid, Abu T., Mateus Hofmann, Mário Garrido, João R. Correia, and Inês C. Rosa. 2023. "Freeze–Thaw Durability of Basalt Fibre Reinforced Bio-Based Unsaturated Polyester Composite" Materials 16, no. 15: 5411. https://doi.org/10.3390/ma16155411

APA StyleShahid, A. T., Hofmann, M., Garrido, M., Correia, J. R., & Rosa, I. C. (2023). Freeze–Thaw Durability of Basalt Fibre Reinforced Bio-Based Unsaturated Polyester Composite. Materials, 16(15), 5411. https://doi.org/10.3390/ma16155411