Research and Development of Self-Waterproofing Concrete for Tunnel Lining Structure and Its Impermeability and Crack Resistance Characteristics

Abstract

:1. Introduction

2. Benchmark Mix Design

2.1. Test Raw Materials and Performance Indicators

2.2. Calculation of Benchmark Mix Proportion and Indoor Trial Mixing Test

3. Research on the Significance of Factors Influencing the Permeability and Crack Resistance of Concrete Based on Orthogonal Design

3.1. Design of Orthogonal Experimental Scheme

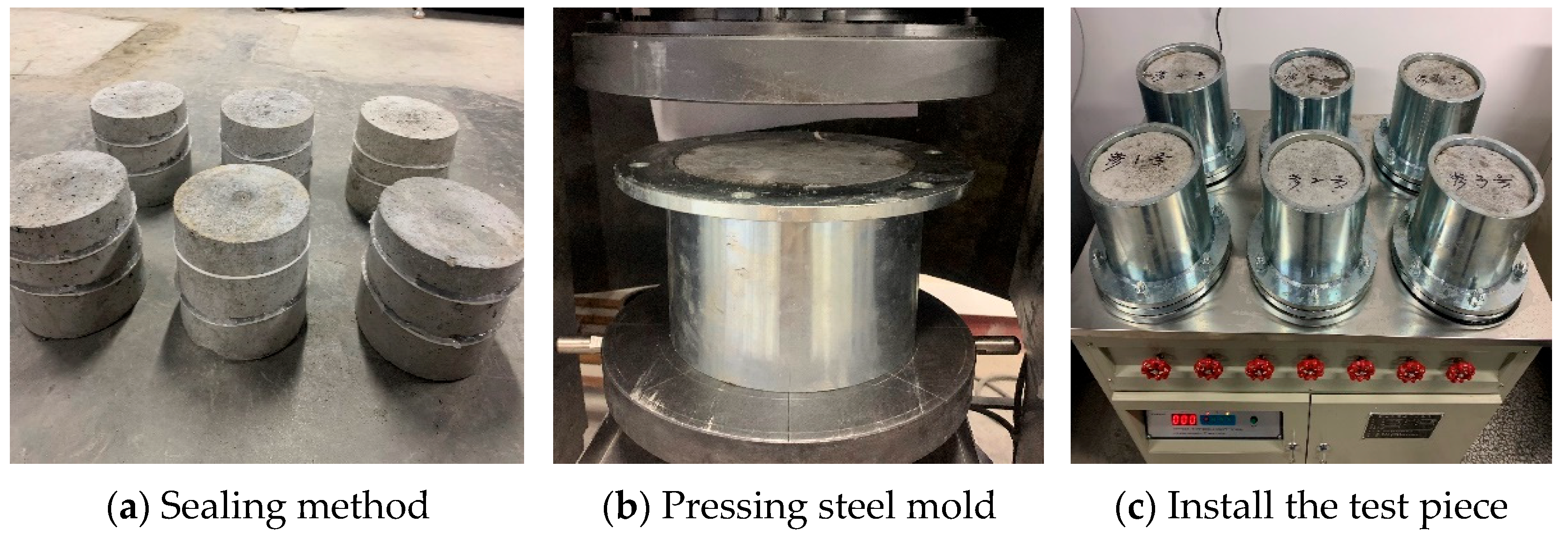

3.2. Laboratory Test of Concrete Mechanics and Impermeability

3.2.1. Concrete Compressive Strength Test

3.2.2. Concrete Splitting Tensile Strength Test

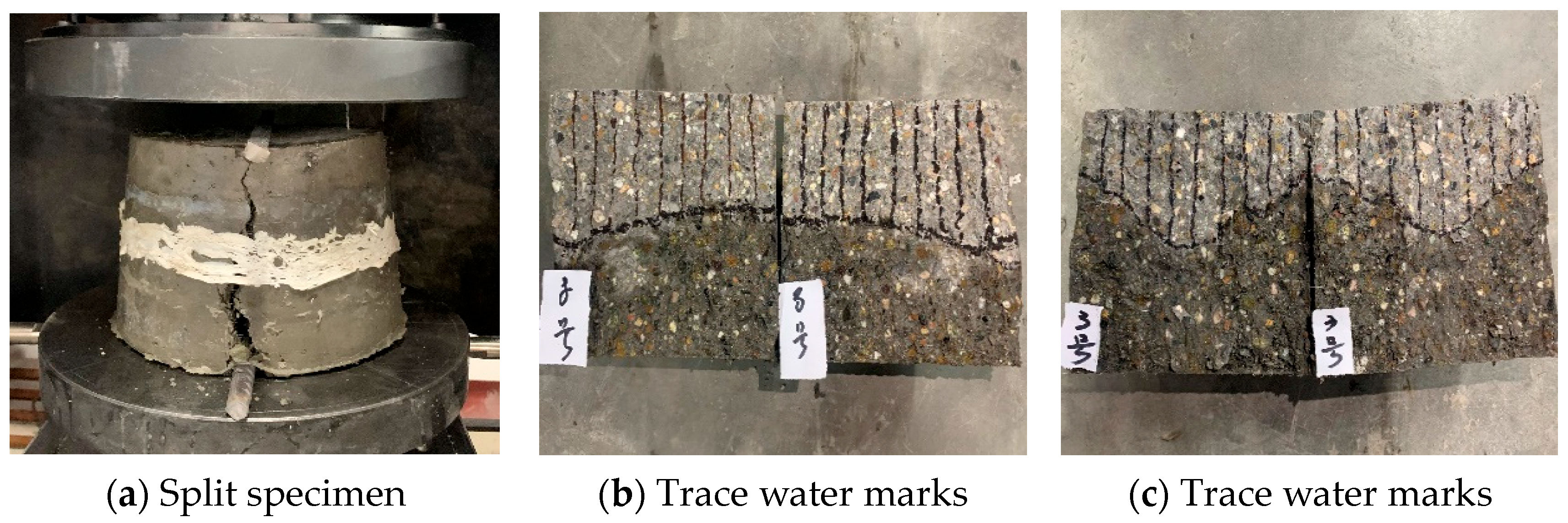

3.2.3. Concrete Impermeability Performance Test

3.3. Calculation and Analysis of Orthogonal Test Results

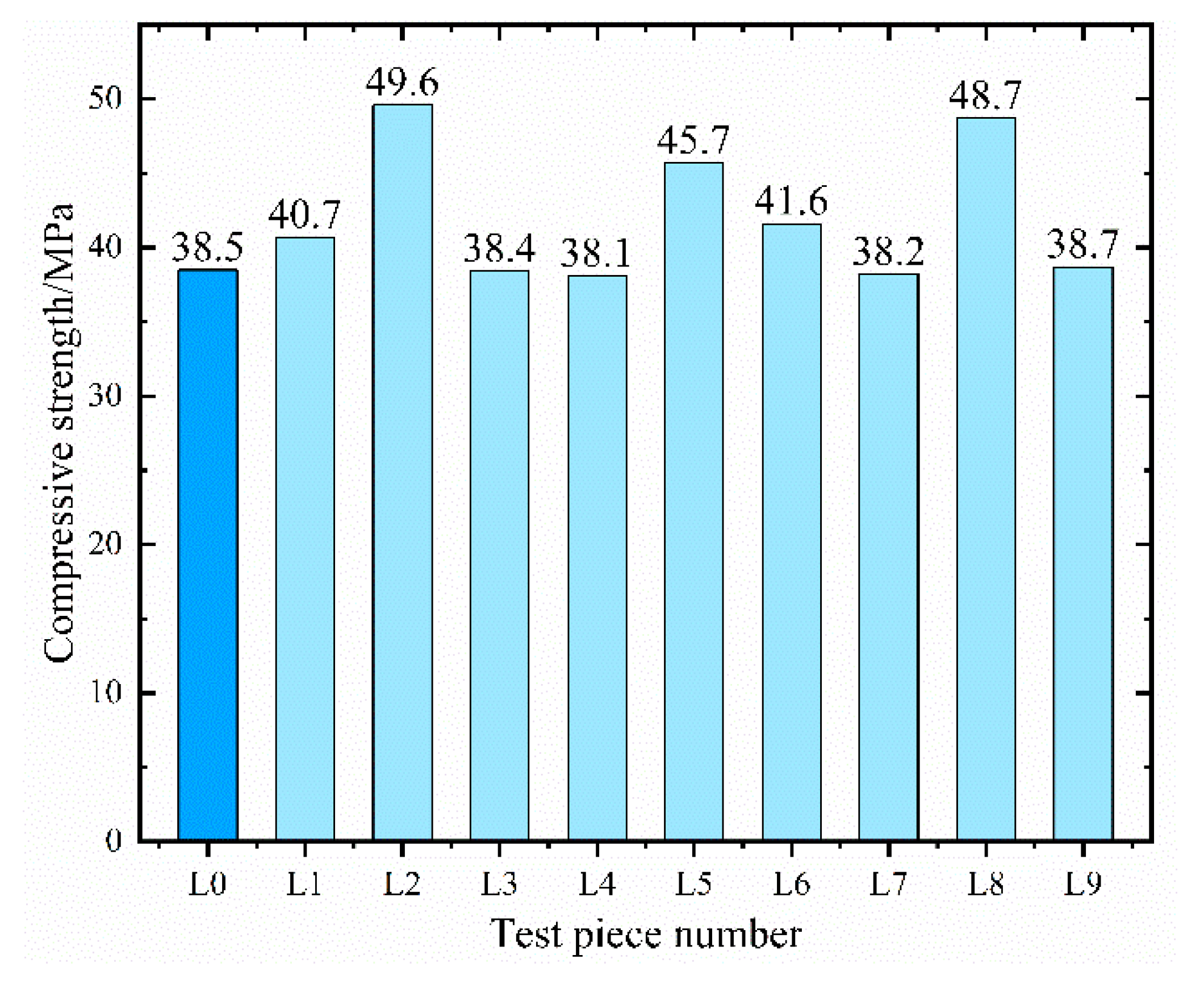

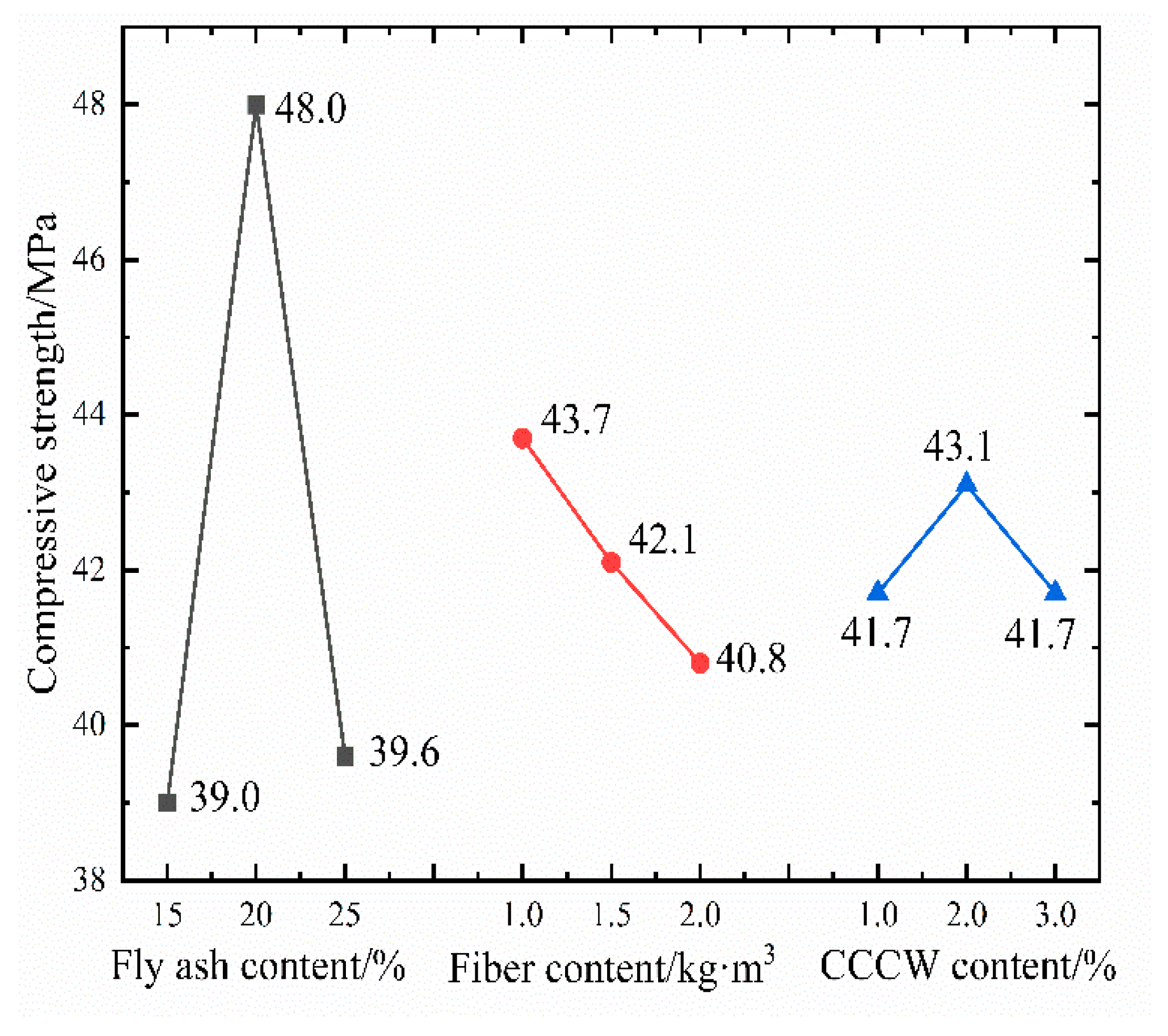

3.3.1. Compressive Strength Test Results and Analysis

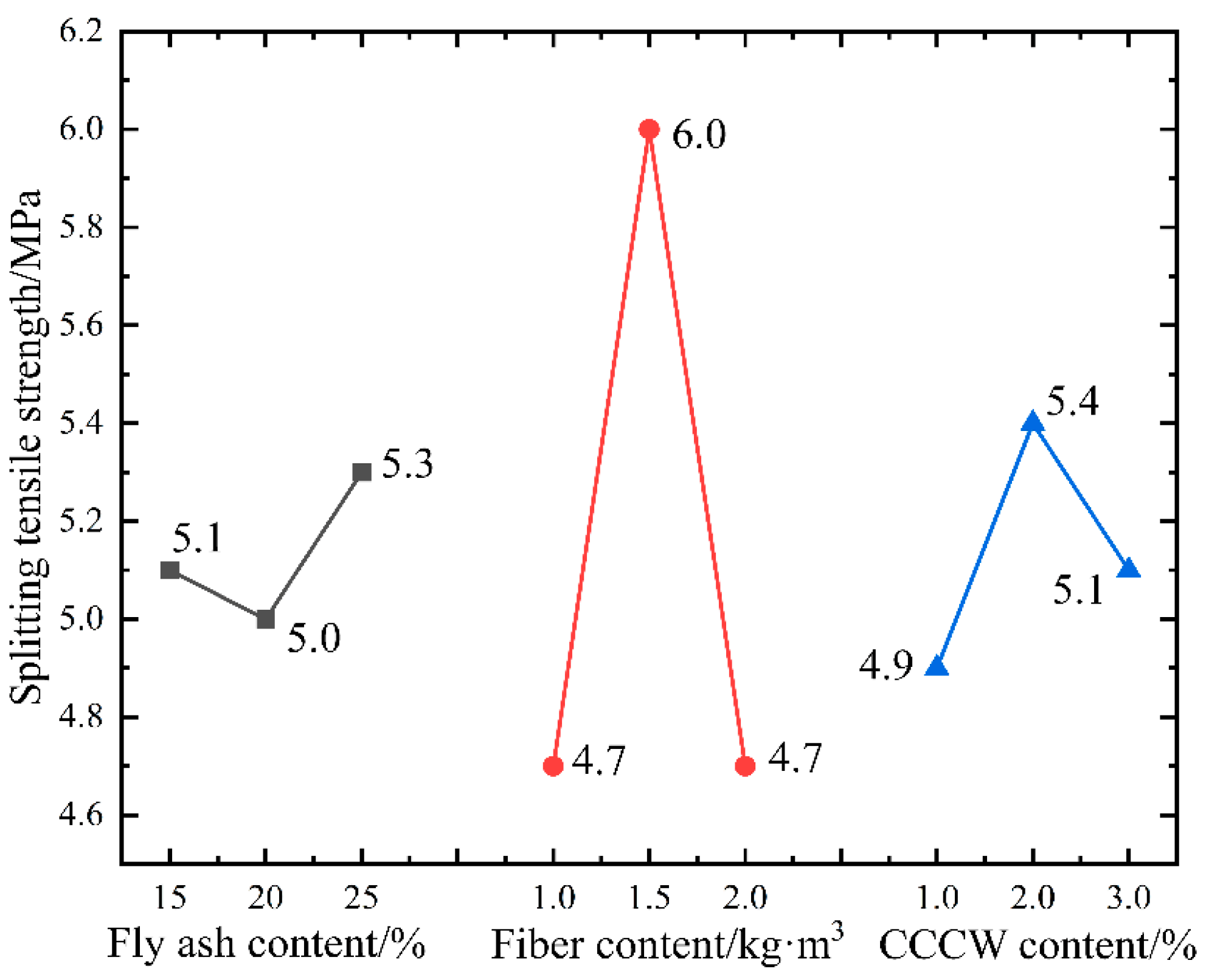

3.3.2. Splitting Tensile Strength Test Results and Analysis

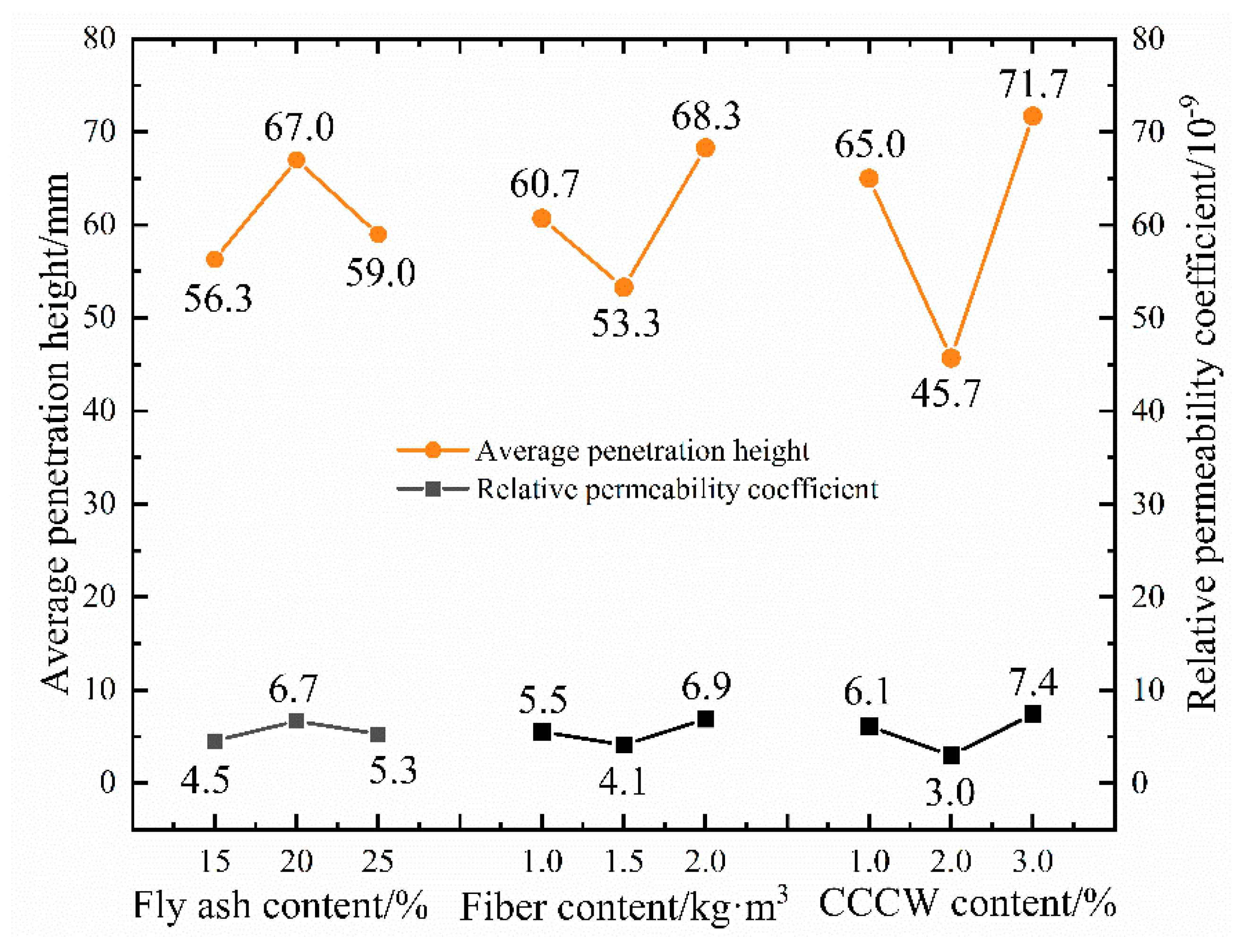

3.3.3. Results and Analysis of Impermeability Performance Test

3.3.4. Comprehensive Scoring of Multiple Indicator Problems

4. Microscopic Mechanism Analysis of the Effect of Composite Modified Materials on the Properties of Concrete

4.1. SEM Scanning Electron Microscopy Analysis

4.1.1. SEM Scanning Electron Microscope Test Plan

4.1.2. SEM Scanning Electron Microscope Test Results and Analysis

- (1)

- Microscopic Morphological Characteristics of Concrete Matrix at 28 Days of Age

- (2)

- Microscopic Morphological Characteristics of the Transition Zone between Fiber and Concrete Matrix at 28 Days of Age

4.2. XRD Diffraction Phase Analysis

4.2.1. XRD Diffraction Test Plan

4.2.2. XRD Diffraction Test Results and Analysis

5. Conclusions

- (1)

- The relative impact of the three materials on concrete’s compressive strength is: fly ash > polypropylene fiber > CCCW. The optimal combination of these three components (A2B1C2) resulted in a compressive strength of 49.8 MPa, a 29.3% increase compared to standard C35 concrete;

- (2)

- The influence of the three materials on the splitting tensile strength of the concrete is as follows: polypropylene fiber > CCCW > fly ash. The optimal combination for crack resistance (A3B2C2) resulted in a tensile strength of 6.31 MPa, representing a 56% improvement over the control concrete;

- (3)

- The effect of the three materials on the concrete’s impermeability is: CCCW > polypropylene fiber > fly ash. The optimal combination for impermeability (A1B2C2) decreased permeability by 63.6% compared to the control concrete. Moreover, A1B2C2 also provided the optimal solution in the multi-indicator analysis;

- (4)

- The 28-day-old control concrete exhibited numerous internal voids and crack defects and a low bonding strength between the polypropylene fibers and the concrete matrix. The incorporation of either fly ash or CCCW led to a substantial improvement in the concrete’s microstructure, resulting in a denser distribution of hydration products and improved fiber-to-matrix bonding characteristics;

- (5)

- The addition of fly ash and CCCW effectively enhanced the cement hydration reaction and increased the crystallinity of the hydration products. The secondary hydration reaction of the fly ash and the complex precipitation reaction of the CCCW materials consumed a portion of the Ca(OH)2, which improved the structure of the aggregate interface transition layer, ultimately augmenting the concrete’s strength and durability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Gao, C.; Zhou, Z.; Yang, W.; Lin, C.; Li, L.; Wang, J. Model Test and Numerical Simulation Research of Water Leakage in Operating Tunnels Passing through Intersecting Faults. Tunn. Undergr. Space Technol. 2019, 94, 103134. [Google Scholar] [CrossRef]

- Yang, W.; Fang, Z.; Wang, H.; Li, L.; Shi, S.; Ding, R.; Bu, L.; Wang, M. Analysis on Water Inrush Process of Tunnel with Large Buried Depth and High Water Pressure. Processes 2019, 7, 134. [Google Scholar] [CrossRef] [Green Version]

- Lu, D.; Huo, Y.; Jiang, Z.; Zhong, J. Carbon Nanotube Polymer Nanocomposites Coated Aggregate Enabled Highly Conductive Concrete for Structural Health Monitoring. Carbon 2023, 206, 340–350. [Google Scholar] [CrossRef]

- Shen, D.; Liu, X.; Zeng, X.; Zhao, X.; Jiang, G. Effect of Polypropylene Plastic Fibers Length on Cracking Resistance of High Performance Concrete at Early Age. Constr. Build. Mater. 2020, 244, 117874. [Google Scholar] [CrossRef]

- Xiao, H.; Liu, R.; Zhang, F.; Liu, M.; Li, H. Role of Nano-SiO2 in Improving the Microstructure and Impermeability of Concrete with Different Aggregate Gradations. Constr. Build. Mater. 2018, 188, 537–545. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E. Innovative Carboxylic Acid Waterproofing Admixture for Self-Sealing Watertight Concretes. Constr. Build. Mater. 2018, 171, 817–824. [Google Scholar] [CrossRef]

- Zheng, J.; Wang, X. Influence of Fly Ash on Early-Age Cracking Behavior of High-Flowing Concrete. J. Cent. South Univ. Technol. 2009, 16, 312–319. [Google Scholar] [CrossRef]

- Cheng, Y.; Huang, F.; Liu, R.; Hou, J.; Li, G. Test Research on Effects of Waste Ceramic Polishing Powder on the Permeability Resistance of Concrete. Mater. Struct. 2016, 49, 729–738. [Google Scholar] [CrossRef]

- Omran, A.; Soliman, N.; Xie, A.; Davidenko, T.; Tagnit-Hamou, A. Field Trials with Concrete Incorporating Biomass-Fly Ash. Constr. Build. Mater. 2018, 186, 660–669. [Google Scholar] [CrossRef]

- Liu, D.; Zhang, W.; Tang, Y.; Jian, Y.; Lai, Y. Orthogonal Experimental Study on Concrete Properties of Machine-Made Tuff Sand. Materials 2022, 15, 3516. [Google Scholar] [CrossRef]

- Lee, H.K.; Lee, K.M.; Kim, B.G. Autogenous Shrinkage of High-Performance Concrete Containing Fly Ash. Mag. Concr. Res. 2003, 55, 507–515. [Google Scholar] [CrossRef]

- Gao, Y.; Zhang, H.; Tang, S.; Liu, H. Study on Early Autogenous Shrinkage and Crack Resistance of Fly Ash High-Strength Lightweight Aggregate Concrete. Mag. Concr. Res. 2013, 65, 906–913. [Google Scholar] [CrossRef]

- Shen, D.; Wang, W.; Li, Q.; Yao, P.; Jiang, G. Early-Age Behaviour and Cracking Potential of Fly Ash Concrete under Restrained Condition. Mag. Concr. Res. 2020, 72, 246–261. [Google Scholar] [CrossRef]

- Lee, K.M.; Lee, H.K.; Lee, S.H.; Kim, G.Y. Autogenous Shrinkage of Concrete Containing Granulated Blast-Furnace Slag. Cem. Concr. Res. 2006, 36, 1279–1285. [Google Scholar] [CrossRef]

- Shen, D.; Jiao, Y.; Gao, Y.; Zhu, S.; Jiang, G. Influence of Ground Granulated Blast Furnace Slag on Cracking Potential of High Performance Concrete at Early Age. Constr. Build. Mater. 2020, 241, 117839. [Google Scholar] [CrossRef]

- Mazloom, M.; Ramezanianpour, A.A.; Brooks, J.J. Effect of Silica Fume on Mechanical Properties of High-Strength Concrete. Cem. Concr. Compos. 2004, 26, 347–357. [Google Scholar] [CrossRef]

- Akcay, B.; Tasdemir, M.A. Performance Evaluation of Silica Fume and Metakaolin with Identical Finenesses in Self Compacting and Fiber Reinforced Concretes. Constr. Build. Mater. 2018, 185, 436–444. [Google Scholar] [CrossRef]

- Zhuang, S.; Wang, Q.; Luo, T. Modification of Ultrafine Blast Furnace Slag with Steel Slag as a Novel High-Quality Mineral Admixture to Prepare High-Strength Concrete. J. Build. Eng. 2023, 71, 106501. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, C.; Sun, W. Fly Ash Effects: I. The Morphological Effect of Fly Ash. Cem. Concr. Res. 2003, 33, 2023–2029. [Google Scholar] [CrossRef]

- Desmettre, C.; Charron, J.-P. Water Permeability of Reinforced Concrete with and without Fiber Subjected to Static and Constant Tensile Loading. Cem. Concr. Res. 2012, 42, 945–952. [Google Scholar] [CrossRef]

- Yang, L.; Yao, Z.; Xue, W.; Wang, X.; Kong, W.; Wu, T. Preparation, Performance Test and Microanalysis of Hybrid Fibers and Microexpansive High-Performance Shaft Lining Concrete. Constr. Build. Mater. 2019, 223, 431–440. [Google Scholar] [CrossRef]

- Liu, F.; Ding, W.; Qiao, Y. An Experimental Investigation on the Integral Waterproofing Capacity of Polypropylene Fiber Concrete with Fly Ash and Slag Powder. Constr. Build. Mater. 2019, 212, 675–686. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.; Zhang, H. Combined Effect of Polypropylene Fiber and Silica Fume on Mechanical Properties of Concrete Composite Containing Fly Ash. J. Reinf. Plast. Compos. 2011, 30, 1349–1358. [Google Scholar] [CrossRef]

- Wang, H.L.; Yuan, L. Experimental Study on Impermeability Performance of Chopped Basalt Fiber Reinforced Concrete. Adv. Mater. Res. 2013, 834–836, 726–729. [Google Scholar] [CrossRef]

- Zheng, K.; Yang, X.; Chen, R.; Xu, L. Application of a Capillary Crystalline Material to Enhance Cement Grout for Sealing Tunnel Leakage. Constr. Build. Mater. 2019, 214, 497–505. [Google Scholar] [CrossRef]

- Joa, B.W.; Sikandar, M.A.; Baloch, Z.; Asad Khan, R.M. Effect of Incorporation of Self Healing Admixture (SHA) on Physical and Mechanical Properties of Mortars. J. Ceram. Process. Res. 2015, 16, S138–S143. [Google Scholar]

- Lu, D.; Wang, D.; Zhong, J. Highly Conductive and Sensitive Piezoresistive Cement Mortar with Graphene Coated Aggregates and Carbon Fiber. Cem. Concr. Compos. 2022, 134, 10473. [Google Scholar] [CrossRef]

- Fakhri, M.; Amoosoltani, E.; Aliha, M.R.M. Crack Behavior Analysis of Roller Compacted Concrete Mixtures Containing Reclaimed Asphalt Pavement and Crumb Rubber. Eng. Fract. Mech. 2017, 180, 43–59. [Google Scholar] [CrossRef]

- Fakhri, M.; Saberi, K.F. The Effect of Waste Rubber Particles and Silica Fume on the Mechanical Properties of Roller Compacted Concrete Pavement. J. Clean. Prod. 2016, 129, 521–530. [Google Scholar] [CrossRef]

- Shariati, M.; Kamyab, H.; Habibi, M.; Ahmadi, S.; Naghipour, M.; Gorjinezhad, F.; Mohammadirad, S.; Aminian, A. Sulfuric Acid Resistance of Concrete Containing Coal Waste as a Partial Substitute for Fine and Coarse Aggregates. Fuel 2023, 348, 128311. [Google Scholar] [CrossRef]

- Lu, F.; Wang, H.; Wang, L.; Zhao, K.; Zhang, J. Degradation Law and Service Life Prediction Model of Tunnel Lining Concrete Suffered Combined Effects of Sulfate Attack and Drying–Wetting Cycles. Materials 2022, 15, 4435. [Google Scholar] [CrossRef]

- Mehrabi, P.; Shariati, M.; Kabirifar, K.; Jarrah, M.; Rasekh, H.; Trung, N.T.; Shariati, A.; Jahandari, S. Effect of Pumice Powder and Nano-Clay on the Strength and Permeability of Fiber-Reinforced Pervious Concrete Incorporating Recycled Concrete Aggregate. Constr. Build. Mater. 2021, 287, 122652. [Google Scholar] [CrossRef]

- Toghroli, A.; Mehrabi, P.; Shariati, M.; Trung, N.T.; Jahandari, S.; Rasekh, H. Evaluating the Use of Recycled Concrete Aggregate and Pozzolanic Additives in Fiber-Reinforced Pervious Concrete with Industrial and Recycled Fibers. Constr. Build. Mater. 2020, 252, 118997. [Google Scholar] [CrossRef]

- Fakhri, M.; Yousefian, F.; Amoosoltani, E.; Aliha, M.R.M.; Berto, F. Combined Effects of Recycled Crumb Rubber and Silica Fume on Mechanical Properties and Mode I Fracture Toughness of Self-compacting Concrete. Fatigue Fract. Eng. Mater. Struct. 2021, 44, 2659–2673. [Google Scholar] [CrossRef]

- Azarsa, P.; Gupta, R.; Azarsa, P.; Biparva, A. Durability and Self-Sealing Examination of Concretes Modified with Crystalline Waterproofing Admixtures. Materials 2021, 14, 6508. [Google Scholar] [CrossRef] [PubMed]

- Halbiniak, J.; Katzer, J.; Major, M.; Langier, B.; Major, I. An Example of Harnessing Crushed Ceramic Pots for the Production of Watertight Concrete. Struct. Concr. 2021, 22, 39. [Google Scholar] [CrossRef]

- Huang, L.; Yang, H.; Yao, S.; Li, B. Preparation Method of Waterproof Concrete for Secondary Lining of Tunnel. Concrete 2014, 5, 144–147. [Google Scholar]

- Ma, W.B.; Chai, J.F.; Han, Z.L.; Ma, Z.G.; Guo, X.X.; Zou, W.H.; An, Z.L.; Li, T.F.; Niu, Y.B. Research on Design Parameters and Fatigue Life of Tunnel Bottom Structure of Single-Track Ballasted Heavy-Haul Railway Tunnel with 40-Ton Axle Load. Math. Probl. Eng. 2020, 2020, 3181480. [Google Scholar] [CrossRef]

- JGJ55-2011; Specification for Mix Proportion Design of Ordinary Concrete. China Construction Industry Press: Beijing, China, 2011.

- GB/T50081-2019; Standard for Test Methods of Concrete Physical and Mechanical Properties. China Construction Industry Press: Beijing, China, 2019.

- GB/T50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. China Construction Industry Press: Beijing, China, 2009.

- Cho, Y.K.; Jung, S.H.; Choi, Y.C. Effects of Chemical Composition of Fly Ash on Compressive Strength of Fly Ash Cement Mortar. Constr. Build. Mater. 2019, 204, 255–264. [Google Scholar] [CrossRef]

- Yan, N.; Tang, Q.; Zhang, Y.; Sun, G. Action Time-Effect and Mechanism of Low-Calcium Fly Ash in Cement-Based Composites. Crystals 2021, 11, 681. [Google Scholar] [CrossRef]

- Yu, J.; Li, G.; Leung, C.K.Y. Hydration and Physical Characteristics of Ultrahigh-Volume Fly Ash-Cement Systems with Low Water/Binder Ratio. Constr. Build. Mater. 2018, 161, 509–518. [Google Scholar] [CrossRef]

- Shaaban, I.G.; Rizzuto, J.P.; El-Nemr, A.; Bohan, L.; Ahmed, H.; Tindyebwa, H. Mechanical Properties and Air Permeability of Concrete Containing Waste Tires Extracts. J. Mater. Civ. Eng. 2021, 33, 04020472. [Google Scholar] [CrossRef]

- Yang, J.; Wang, T.; He, X.; Su, Y.; Dai, F.; Xiong, L.; Zhao, R.; Duan, X. Preparation and Experimental Investigations of Low-Shrinkage Commercial Concrete for Tunnel Annular Secondary Lining Engineering. Materials 2022, 15, 6848. [Google Scholar] [CrossRef] [PubMed]

- Jiao, H.; Chen, X.; Yang, X.; Wang, Y.; Yang, Y.; Chen, X.; Yang, L.; Yu, J. Quantifying Computed Tomography of Basalt Fiber-Reinforced Concrete under Unconfined Compression. Crystals 2022, 12, 360. [Google Scholar] [CrossRef]

- Cui, K.; Liang, K.; Jiang, T.; Zhang, J.; Lau, D.; Chang, J. Understanding the Role of Carbon Nanotubes in Low-Carbon Concrete: From Experiment to Molecular Dynamics. Cem. Concr. Compos. 2023, 142, S0958–S9465. [Google Scholar] [CrossRef]

- Hu, X.; Xiao, J.; Zhang, Z.; Wang, C.; Long, C.; Dai, L. Effects of CCCW on Properties of Cement-Based Materials: A Review. J. Build. Eng. 2022, 50, 104184. [Google Scholar] [CrossRef]

- Guiming, W.; Jianying, Y. Self-Healing Action of Permeable Crystalline Coating on Pores and Cracks in Cement-Based Materials. J. Wuhan Univ. Technol.-Mat. Sci. Ed. 2005, 20, 89–92. [Google Scholar] [CrossRef]

- Wang, C.; Xiao, J.; Long, C.; Zhang, Q.; Shi, J.; Zhang, Z. Influences of the Joint Action of Sulfate Erosion and Cementitious Capillary Crystalline Waterproofing Materials on the Hydration Products and Properties of Cement-Based Materials: A Review. J. Build. Eng. 2023, 68, 106061. [Google Scholar] [CrossRef]

- Banthia, N.; Gupta, R. Influence of Polypropylene Fiber Geometry on Plastic Shrinkage Cracking in Concrete. Cem. Concr. Res. 2006, 36, 1263–1267. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.-F. Water Impermeability of Fly Ash Concrete Composites Containing Silica Fume and Polypropylene Fiber. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2013, 227, 259–264. [Google Scholar] [CrossRef]

- He, W.; Xue, W.; Tang, B. Methods for Optimizing Design of Experiments and Data Analysis; Chemical Industry Press: Beijing, China, 2012. [Google Scholar]

- Cui, K.; Lu, D.; Jiang, T.; Zhang, J.; Jiang, Z.; Zhang, G.; Chang, J.; Lau, D. Understanding the Role of Carbon Nanotubes in Low Carbon Sulfoaluminate Cement-Based Composite. J. Clean. Prod. 2023, 416, S0959–S6526. [Google Scholar] [CrossRef]

- Liu, X.; Ni, C.; Meng, K.; Zhang, L.; Liu, D.; Sun, L. Strengthening Mechanism of Lightweight Cellular Concrete Filled with Fly Ash. Constr. Build. Mater. 2020, 251, 118954. [Google Scholar] [CrossRef]

- Lu, D.; Shi, X.; Zhong, J. Interfacial Bonding between Graphene Oxide Coated Carbon Nanotube Fiber and Cement Paste Matrix. Cem. Concr. Compos. 2022, 134, 104802. [Google Scholar] [CrossRef]

- Lu, D.; Ma, L.-P.; Zhong, J.; Tong, J.; Liu, Z.; Ren, W.; Cheng, H.-M. Growing Nanocrystalline Graphene on Aggregates for Conductive and Strong Smart Cement Composites. ACS Nano 2023, 17, 3587–3597. [Google Scholar] [CrossRef] [PubMed]

- Phoo-ngernkham, T.; Phiangphimai, C.; Intarabut, D.; Hanjitsuwan, S.; Damrongwiriyanupap, N.; Li, L.; Chindaprasirt, P. Low Cost and Sustainable Repair Material Made from Alkali-Activated High-Calcium Fly Ash with Calcium Carbide Residue. Constr. Build. Mater. 2020, 247, 118543. [Google Scholar] [CrossRef]

- Li, W.; Yi, Y. Use of Carbide Slag from Acetylene Industry for Activation of Ground Granulated Blast-Furnace Slag. Constr. Build. Mater. 2020, 238, 117713. [Google Scholar] [CrossRef]

- Guo, W.; Zou, S.; Pu, S.; Zhou, Y. Study on the Physical and Chemical Properties of Cement-Based Grout Containing Coal–Fly Ash. Materials 2022, 15, 8804. [Google Scholar] [CrossRef]

- Jiang, T.; Cui, K.; Chang, J. Development of Low-Carbon Cement: Carbonation of Compounded C2S by β-C2S and γ-C2S. Cem. Concr. Compos. 2023, 139, 105071. [Google Scholar] [CrossRef]

| Number | Requirement of Normal Consistency/% | Stability | Fineness/% | Setting Time/min | Flexural Strength/MPa | Compressive Strength/MPa | |||

|---|---|---|---|---|---|---|---|---|---|

| P·O 42.5 | 26.7 | Qualified | 1.3 | Initial set | Final set | 3 d | 28 d | 3 d | 28 d |

| 170 | 235 | 3.68 | 7.24 | 17.5 | 52.3 | ||||

| Test Items | Technical Requirements | Test Results | |

|---|---|---|---|

| Appearance | Homogeneous, no lumps | Homogeneous, no lumps | |

| Water content/% | ≤1.5 | 0.0 | |

| Fineness, 0.63 mm sieve residue/% | ≤5.0 | 1.2 | |

| Chloride ion content/% | ≤0.1 | 0.05 | |

| Water reduction rate/% | <8.0 | 7.0 | |

| Gas content/% | ≤3.0 >−90 - | 2.0 −75 - | |

| Difference in setting time | Initial setting/min | ||

| Final coagulation/h | |||

| Test Items | Technical Requirement | Detection Result |

|---|---|---|

| Tensile strength/MPa | 350–537 | 469 |

| Elongation at break/% | ≤30 | 28.4 |

| Elastic modulus/MPa | ≥4000 | 4236 |

| Density/g·cm−3 | 0.91 | 0.91 |

| Diameter/mm | 18–78 | 32.7 |

| Melting point/°C | 169 | 169 |

| Raw Material | Cement | Fine Aggregate | Coarse Aggregate | Water | Water-Reducing Agent |

|---|---|---|---|---|---|

| Consumption per cubic meter/kg·m−3 | 400 | 712 | 1112 | 176 | 0.8 |

| 1 | 1.78 | 2.78 | 0.44 | 0.002 |

| Raw Material | Cement | Fine Aggregate | Coarse Aggregate | Water | Water-Reducing Agent |

|---|---|---|---|---|---|

| Consumption per cubic meter/kg·m−3 | 400 | 748 | 1076 | 176 | 0.8 |

| 1 | 1.87 | 2.69 | 0.44 | 0.002 |

| Factor | A Fly Ash Content | B Fiber Content | C CCCW Content | |

|---|---|---|---|---|

| Level | ||||

| 1 | 15% | 1.0 kg/m3 | 1.0% | |

| 2 | 20% | 1.5 kg/m3 | 2.0% | |

| 3 | 25% | 2.0 kg/m3 | 3.0% | |

| Number | Water–Binder Ratio | Cement | Medium Sand | Gravel | Water | Water-Reducing Agent | Fly Ash | Fiber | CCCW |

|---|---|---|---|---|---|---|---|---|---|

| L-0 | 0.44 | 400 | 748 | 1076 | 176 | 0.8 | 0 | 0 | 0 |

| L-1 | 0.44 | 336 | 748 | 1076 | 176 | 0.8 | 60 | 1.0 | 4.0 |

| L-2 | 0.44 | 312 | 748 | 1076 | 176 | 0.8 | 80 | 1.5 | 8.0 |

| L-3 | 0.44 | 288 | 748 | 1076 | 176 | 0.8 | 100 | 2.0 | 12.0 |

| L-4 | 0.44 | 328 | 748 | 1076 | 176 | 0.8 | 60 | 1.5 | 12.0 |

| L-5 | 0.44 | 316 | 748 | 1076 | 176 | 0.8 | 80 | 2.0 | 4.0 |

| L-6 | 0.44 | 292 | 748 | 1076 | 176 | 0.8 | 100 | 1.0 | 8.0 |

| L-7 | 0.44 | 332 | 748 | 1076 | 176 | 0.8 | 60 | 2.0 | 8.0 |

| L-8 | 0.44 | 308 | 748 | 1076 | 176 | 0.8 | 80 | 1.0 | 12.0 |

| L-9 | 0.44 | 296 | 748 | 1076 | 176 | 0.8 | 100 | 1.5 | 4.0 |

| Test Piece Number | A Fly Ash Content/% | B Fiber Content/kg·m3 | C CCCW Content/% | Compressive Strength/MPa |

|---|---|---|---|---|

| L1 | 15 | 1.0 | 1.0 | 40.7 |

| L2 | 20 | 1.5 | 2.0 | 49.6 |

| L3 | 25 | 2.0 | 3.0 | 38.4 |

| L4 | 15 | 1.5 | 3.0 | 38.1 |

| L5 | 20 | 2.0 | 1.0 | 45.7 |

| L6 | 25 | 1.0 | 2.0 | 41.6 |

| L7 | 15 | 2.0 | 2.0 | 38.2 |

| L8 | 20 | 1.0 | 3.0 | 48.7 |

| L9 | 25 | 1.5 | 1.0 | 38.7 |

| K1 | 117 | 131 | 125.1 | A > B > C |

| K2 | 144 | 126.4 | 129.4 | |

| K3 | 118.7 | 122.3 | 125.2 | |

| k1 | 39.0 | 43.7 | 41.7 | |

| k2 | 48.0 | 42.1 | 43.1 | |

| k3 | 39.6 | 40.8 | 41.7 | |

| R | 9.0 | 2.9 | 1.4 |

| Source of Variance | Sum of Squares of Variation | Degree of Freedom | Mean Square | F Value | p Value | Significance |

|---|---|---|---|---|---|---|

| A | 152.4 | 2 | 76.2 | 66.8 | 0.01 | Significant impact |

| B | 12.6 | 2 | 6.3 | 5.5 | 0.15 | Has a certain impact |

| C | 4.0 | 2 | 2.0 | 1.8 | 0.36 | No effect |

| Error | 2.3 | 2 | 1.1 |

| Test Piece Number | A Fly Ash Content/% | B Fiber Content/kg·m3 | C CCCW Content/% | Tensile Strength/MPa |

|---|---|---|---|---|

| L1 | 15 | 1.0 | 1.0 | 4.59 |

| L2 | 20 | 1.5 | 2.0 | 6.29 |

| L3 | 25 | 2.0 | 3.0 | 4.99 |

| L4 | 15 | 1.5 | 3.0 | 5.92 |

| L5 | 20 | 2.0 | 1.0 | 4.26 |

| L6 | 25 | 1.0 | 2.0 | 5.10 |

| L7 | 15 | 2.0 | 2.0 | 4.85 |

| L8 | 20 | 1.0 | 3.0 | 4.54 |

| L9 | 25 | 1.5 | 1.0 | 5.86 |

| K1 | 15.35 | 14.22 | 14.72 | B > C > A |

| K2 | 15.09 | 18.07 | 16.24 | |

| K3 | 15.95 | 14.11 | 15.44 | |

| k1 | 5.1 | 4.7 | 4.9 | |

| k2 | 5.0 | 6.0 | 5.4 | |

| k3 | 5.3 | 4.7 | 5.1 | |

| R | 0.3 | 1.3 | 0.5 |

| Source of Variance | Sum of Squares of Variation | Degree of Freedom | Mean Square | F Value | p Value | Significance |

|---|---|---|---|---|---|---|

| A | 0.13 | 2 | 0.06 | 1.55 | 0.39 | No effect |

| B | 3.39 | 2 | 1.70 | 40.85 | 0.02 | Significant impact |

| C | 0.39 | 2 | 0.19 | 4.64 | 0.18 | Has a certain impact |

| Error | 0.08 | 2 | 0.04 |

| Test Piece Number | A Fly Ash Content/% | B Fiber Content/kg·m3 | C CCCW Content/% | Penetration Height/mm |

|---|---|---|---|---|

| L1 | 15 | 1.0 | 1.0 | 62 |

| L2 | 20 | 1.5 | 2.0 | 46 |

| L3 | 25 | 2.0 | 3.0 | 79 |

| L4 | 15 | 1.5 | 3.0 | 58 |

| L5 | 20 | 2.0 | 1.0 | 77 |

| L6 | 25 | 1.0 | 2.0 | 42 |

| L7 | 15 | 2.0 | 2.0 | 49 |

| L8 | 20 | 1.0 | 3.0 | 78 |

| L9 | 25 | 1.5 | 1.0 | 56 |

| K1 | 169 | 182 | 195 | C > B > A |

| K2 | 201 | 160 | 137 | |

| K3 | 177 | 205 | 215 | |

| k1 | 56.3 | 60.7 | 65.0 | |

| k2 | 67.0 | 53.3 | 45.7 | |

| k3 | 59.0 | 68.3 | 71.7 | |

| R | 10.7 | 15.0 | 26.0 |

| Source of Variance | Sum of Squares of Variation | Degree of Freedom | Mean Square | F Value | p Value | Significance |

|---|---|---|---|---|---|---|

| A | 184.9 | 2 | 92.4 | 10.95 | 0.08 | Impact |

| B | 337.6 | 2 | 168.8 | 19.99 | 0.05 | Significant impact |

| C | 1094.2 | 2 | 547.1 | 64.79 | 0.02 | Significant impact |

| Error | 16.9 | 2 | 8.4 |

| Number | A | B | C | Test Indicators | Comprehensive Score | ||

|---|---|---|---|---|---|---|---|

| 1 * | 2 ** | 3 ** | |||||

| L1 | 15 | 1.0 | 1.0 | 40.7 | 4.59 | 88 | 251.8 |

| L2 | 20 | 1.5 | 2.0 | 49.6 | 6.29 | 104 | 300.5 |

| L3 | 25 | 2.0 | 3.0 | 38.4 | 4.99 | 71 | 209.2 |

| L4 | 15 | 1.5 | 3.0 | 38.1 | 5.92 | 92 | 263.8 |

| L5 | 20 | 2.0 | 1.0 | 45.7 | 4.26 | 73 | 216.0 |

| L6 | 25 | 1.0 | 2.0 | 41.6 | 5.10 | 108 | 303.5 |

| L7 | 15 | 2.0 | 2.0 | 38.2 | 4.85 | 101 | 283.7 |

| L8 | 20 | 1.0 | 3.0 | 48.7 | 4.54 | 72 | 215.7 |

| L9 | 25 | 1.5 | 1.0 | 38.7 | 5.86 | 94 | 269.0 |

| K1 | 799.4 | 771.1 | 736.8 | A: Fly ash content/%; B: Fiber content/kg·m3; C: CCCW content/%; 1 *: Compressive strength value/MPa; 2 **: Splitting tensile strength value/MPa; 3 **: 150—Penetration height/mm; | |||

| K2 | 732.2 | 833.4 | 887.8 | ||||

| K3 | 781.7 | 708.9 | 688.7 | ||||

| k1 | 266.5 | 257.0 | 245.6 | ||||

| k2 | 244.1 | 277.8 | 295.9 | ||||

| k3 | 260.6 | 236.3 | 229.6 | ||||

| R | 22.4 | 41.5 | 66.4 | ||||

| Source of Variance | Sum of Squares of Variation | Degree of Freedom | Mean Square | F Value | p Value | Significance |

|---|---|---|---|---|---|---|

| A | 807.84 | 2 | 403.92 | 9.71 | 0.09 | Impact |

| B | 2581.82 | 2 | 1290.91 | 31.02 | 0.03 | Significant impact |

| C | 7193.00 | 2 | 3596.50 | 86.42 | 0.01 | Significant impact |

| Error | 83.23 | 2 | 41.61 |

| Factor Level Combination | Compressive Strength/MPa | Tensile Strength/MPa | Penetration Height/mm | Comprehensive Score |

|---|---|---|---|---|

| Benchmark concrete | 38.5 | 4.03 | 121 | 101.8 |

| A2B1C2 | 49.8 | 5.53 | 52 | 283.7 |

| A3B2C2 | 41.3 | 6.31 | 47 | 293.9 |

| A1B2C2 | 43.3 | 5.98 | 44 | 301.6 |

| Number | Water–Binder Ratio | Cement | Grit | Stone | Water | Water-Reducing Agent | Fly Ash | Polypropylene Fiber | CCCW |

|---|---|---|---|---|---|---|---|---|---|

| SEM-1 | 0.44 | 400 | 748 | 1076 | 176 | 0.8 | 0 | 1.5 | 0 |

| SEM-2 | 0.44 | 340 | 748 | 1076 | 176 | 0.8 | 60 | 1.5 | 0 |

| SEM-3 | 0.44 | 392 | 748 | 1076 | 176 | 0.8 | 0 | 1.5 | 8.0 |

| SEM-4 | 0.44 | 332 | 748 | 1076 | 176 | 0.8 | 60 | 1.5 | 8.0 |

| Number | Water–Binder Ratio | Cement | Grit | Stone | Water | Water-Reducing Agent | Fly Ash | Polypropylene Fiber |

|---|---|---|---|---|---|---|---|---|

| XRD-1 | 0.44 | 400 | 748 | 1076 | 176 | 0.8 | 0 | 0 |

| XRD-2 | 0.44 | 340 | 748 | 1076 | 176 | 0.8 | 60 | 0 |

| XRD-3 | 0.44 | 392 | 748 | 1076 | 176 | 0.8 | 0 | 8.0 |

| XRD-4 | 0.44 | 332 | 748 | 1076 | 176 | 0.8 | 60 | 8.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Zhou, A.; Wu, Y.; Deng, L.; Zhu, K.; Lu, F. Research and Development of Self-Waterproofing Concrete for Tunnel Lining Structure and Its Impermeability and Crack Resistance Characteristics. Materials 2023, 16, 5557. https://doi.org/10.3390/ma16165557

Li H, Zhou A, Wu Y, Deng L, Zhu K, Lu F. Research and Development of Self-Waterproofing Concrete for Tunnel Lining Structure and Its Impermeability and Crack Resistance Characteristics. Materials. 2023; 16(16):5557. https://doi.org/10.3390/ma16165557

Chicago/Turabian StyleLi, Huayun, Anxiang Zhou, Yangfan Wu, Lai Deng, Kaicheng Zhu, and Feng Lu. 2023. "Research and Development of Self-Waterproofing Concrete for Tunnel Lining Structure and Its Impermeability and Crack Resistance Characteristics" Materials 16, no. 16: 5557. https://doi.org/10.3390/ma16165557

APA StyleLi, H., Zhou, A., Wu, Y., Deng, L., Zhu, K., & Lu, F. (2023). Research and Development of Self-Waterproofing Concrete for Tunnel Lining Structure and Its Impermeability and Crack Resistance Characteristics. Materials, 16(16), 5557. https://doi.org/10.3390/ma16165557