Bearing Capacity and Deformation of the Tandem Compound Piles Improved Foundation: A Parametric Study

Abstract

:1. Introduction

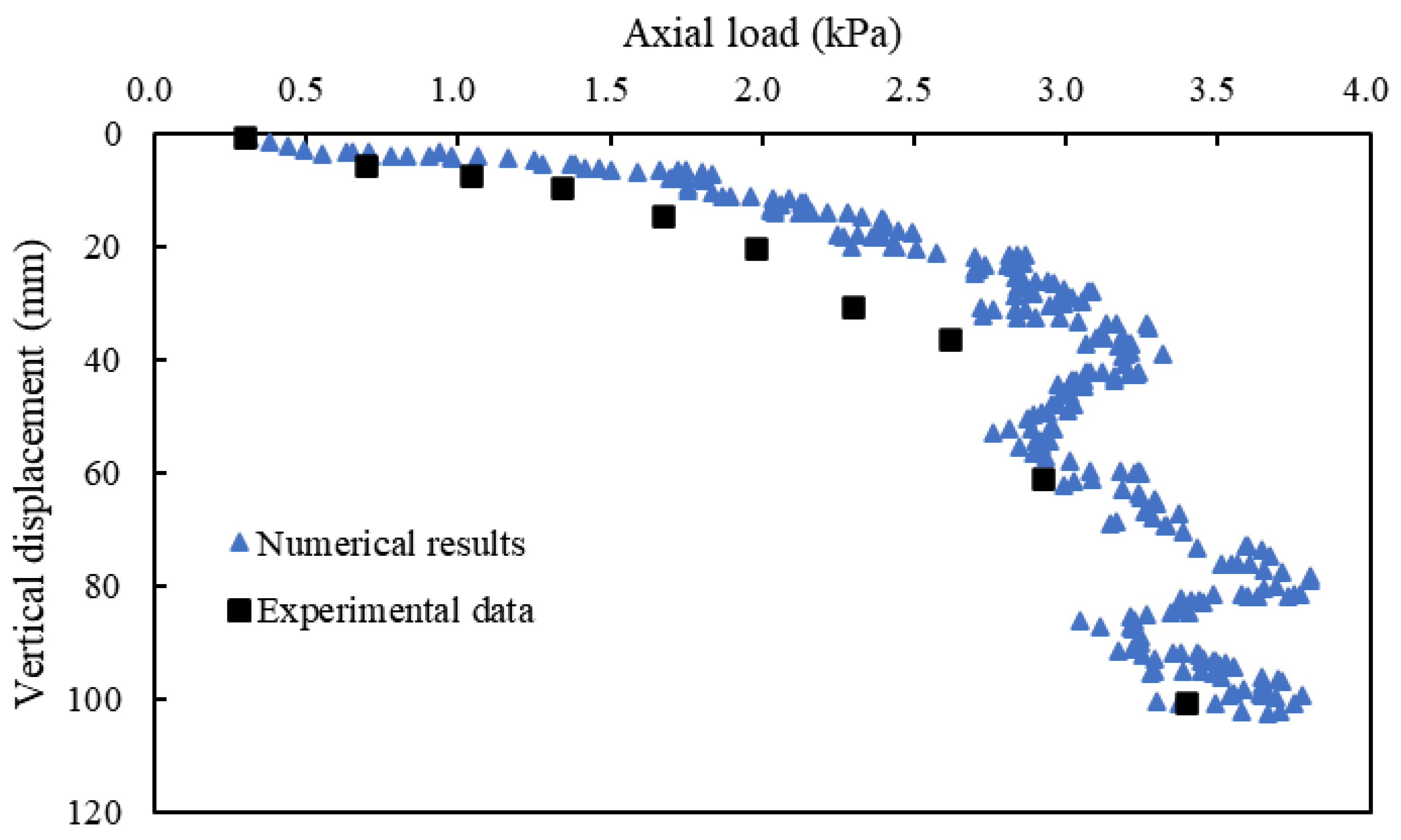

2. Coupled Discrete-Continuum Numerical Method

3. Parametric Study

3.1. Cushion Thickness and Modulus

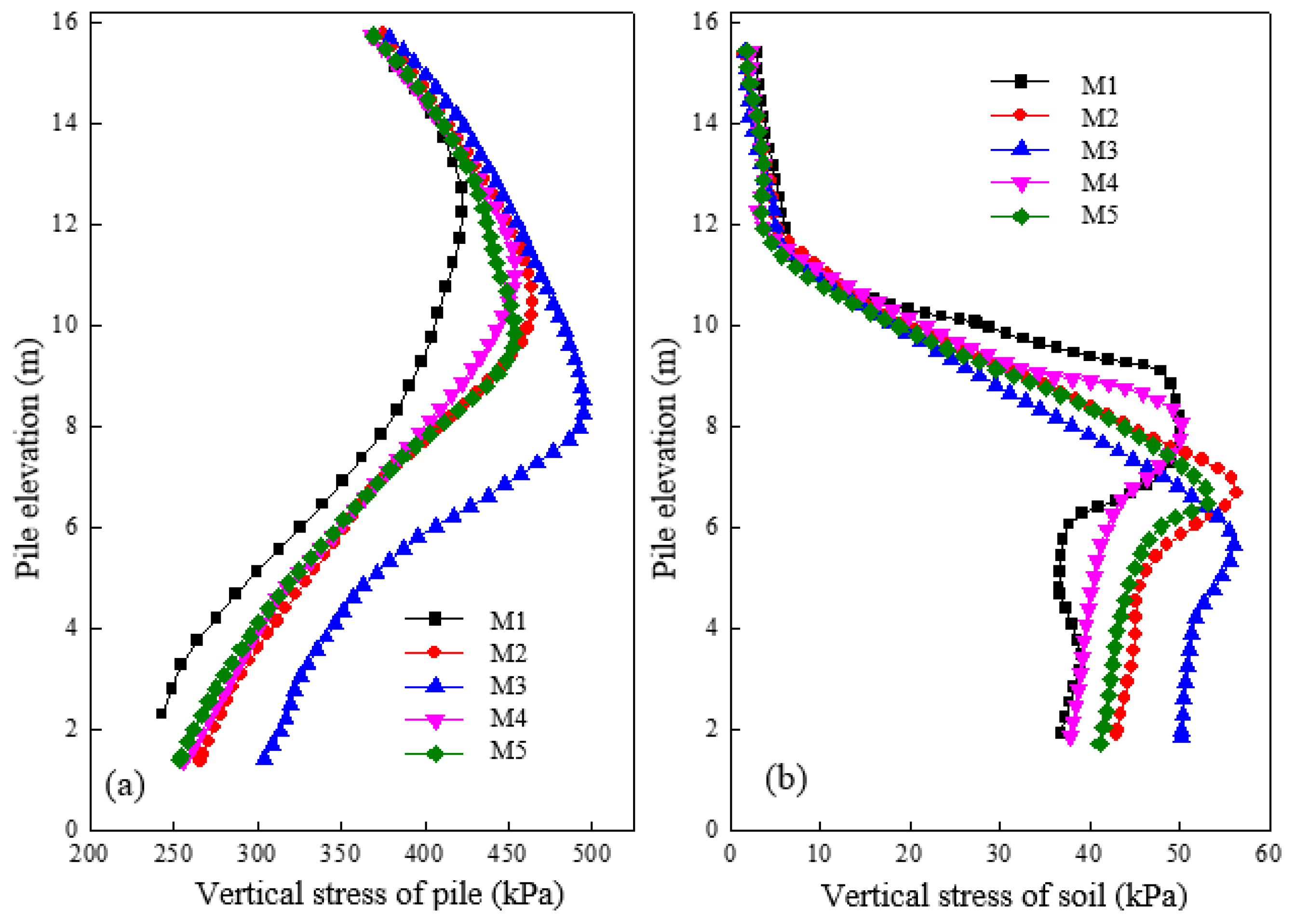

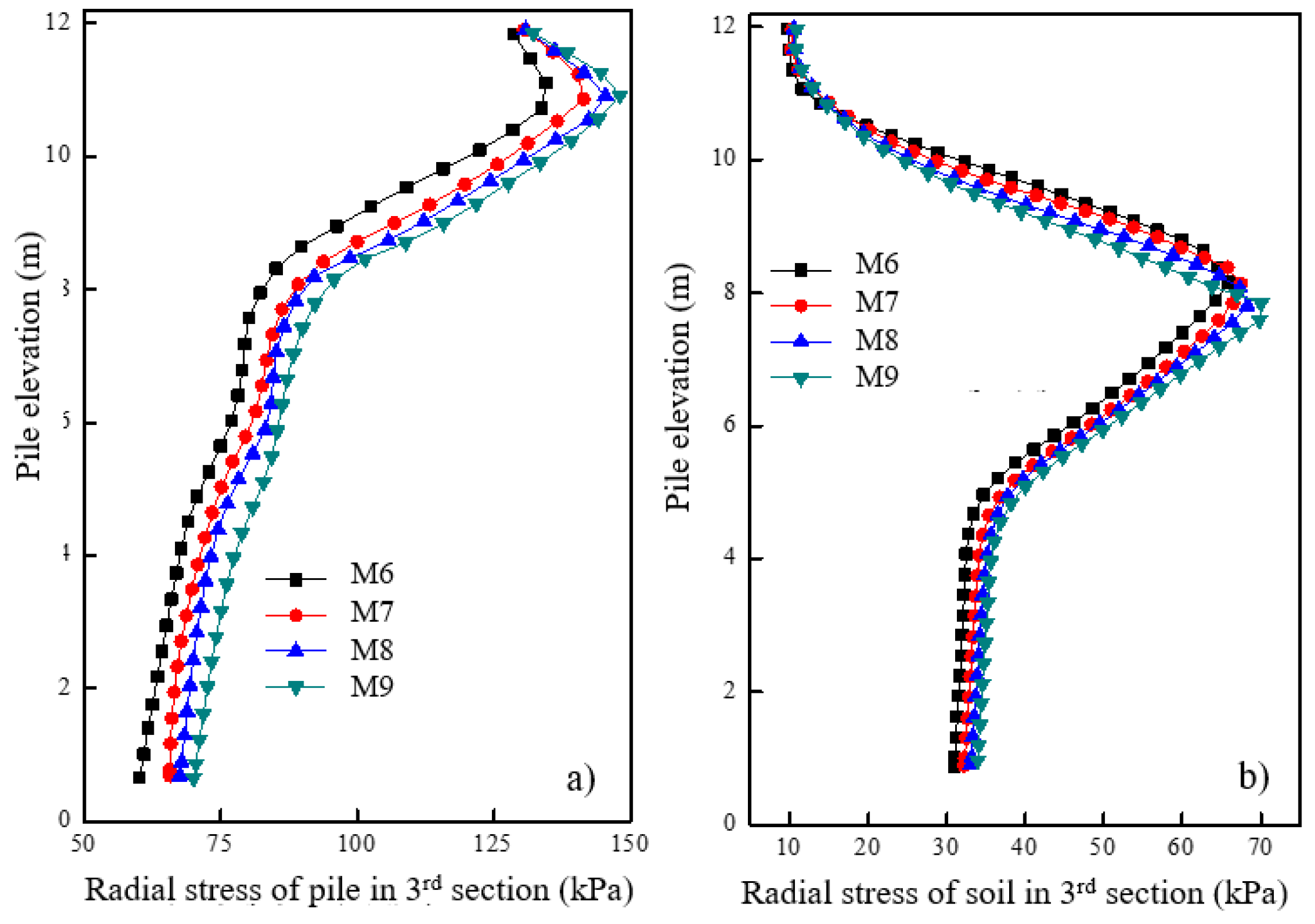

3.2. Pile Parameter

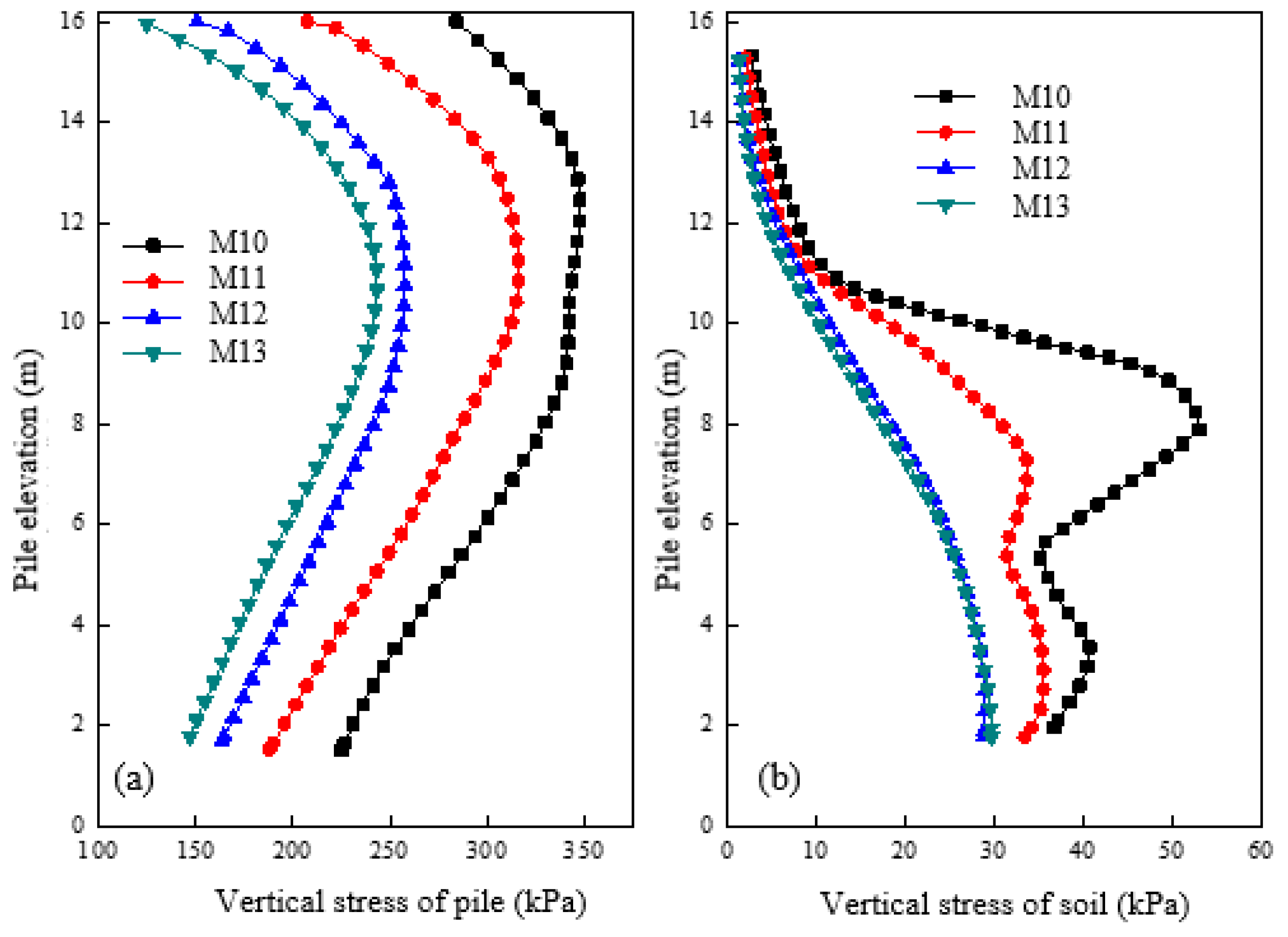

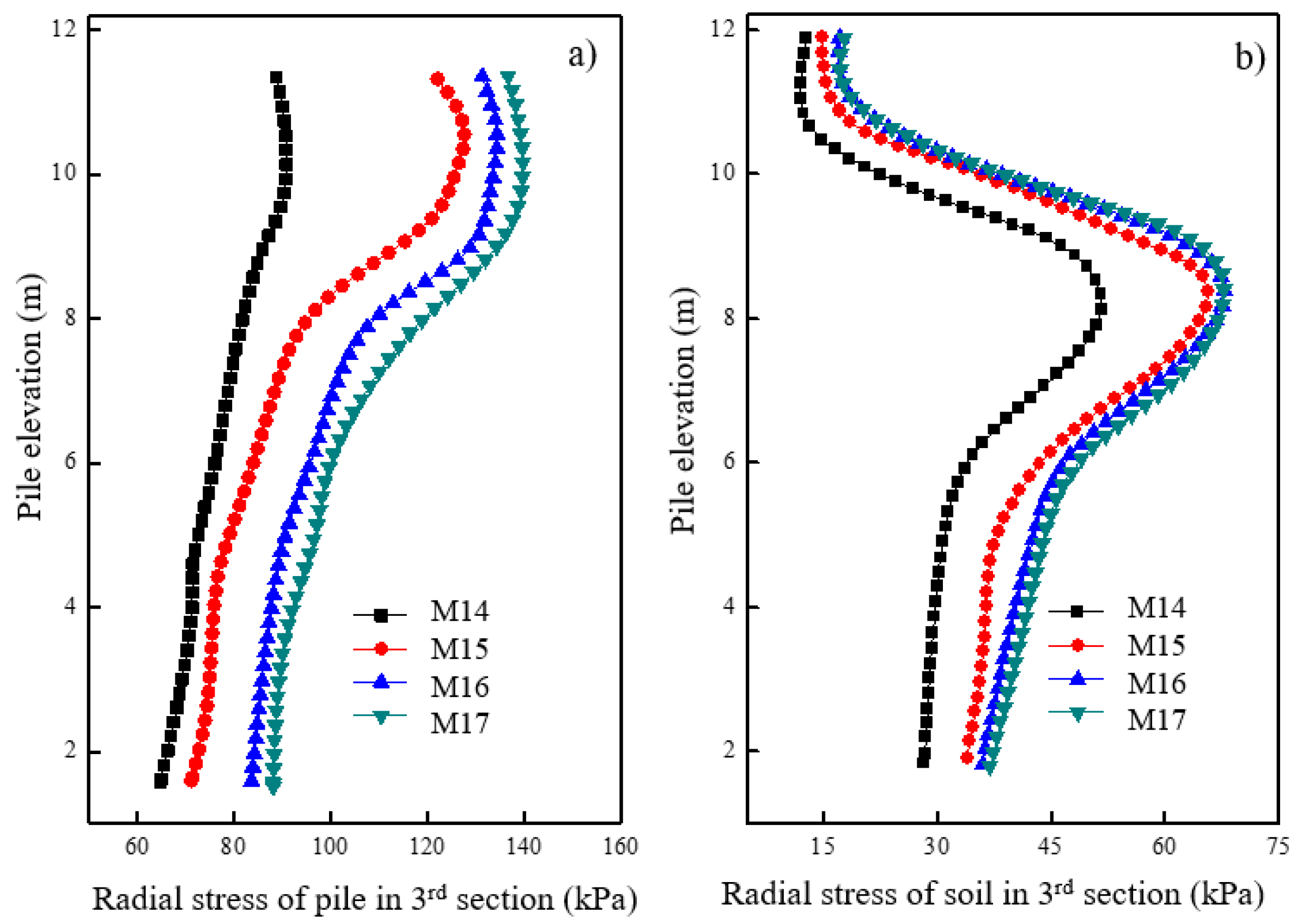

3.3. Soil Modulus

4. Results and Discussion

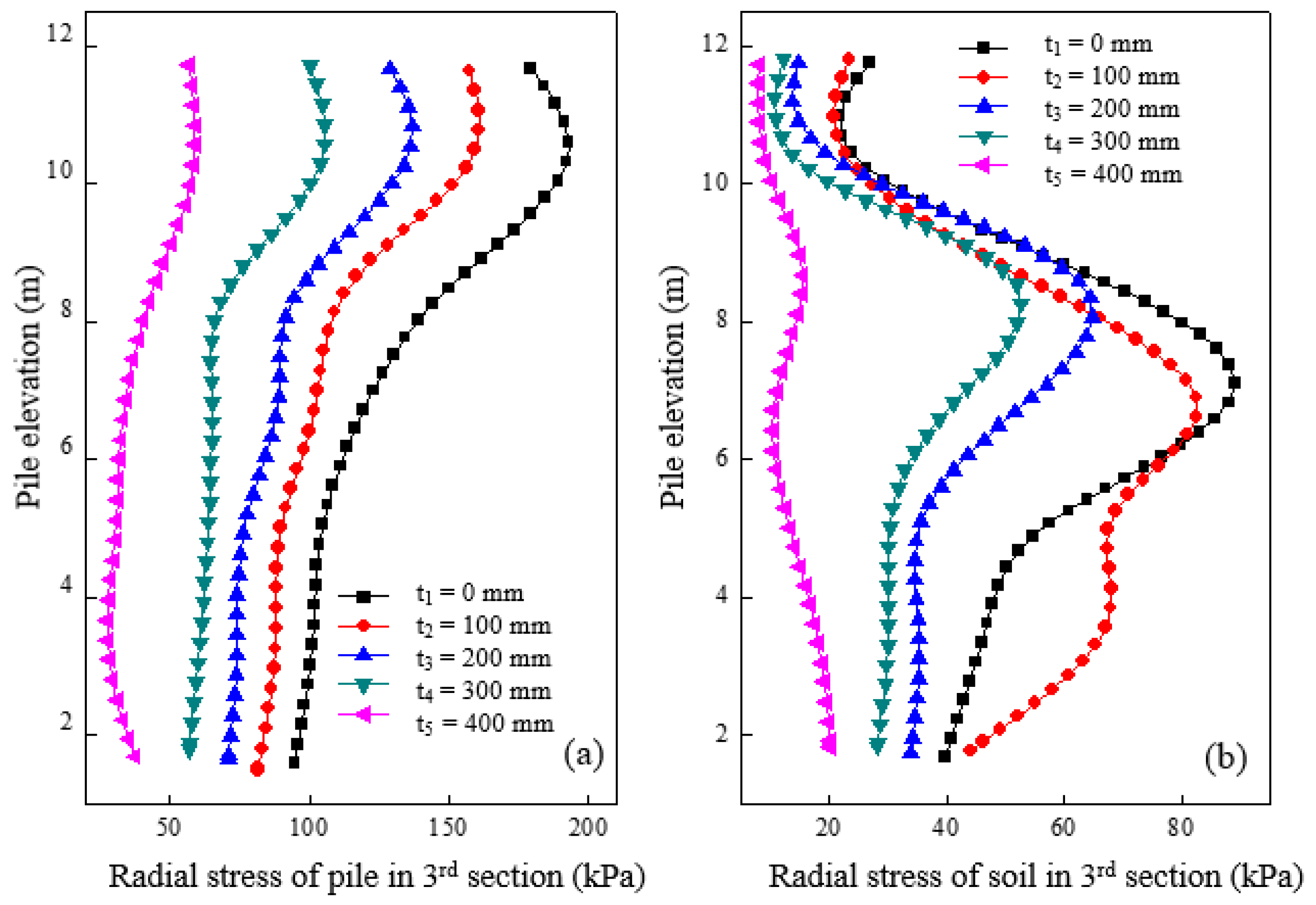

4.1. Effect of Cushion Thickness and Modulus

4.2. Effect of Pile Parameter

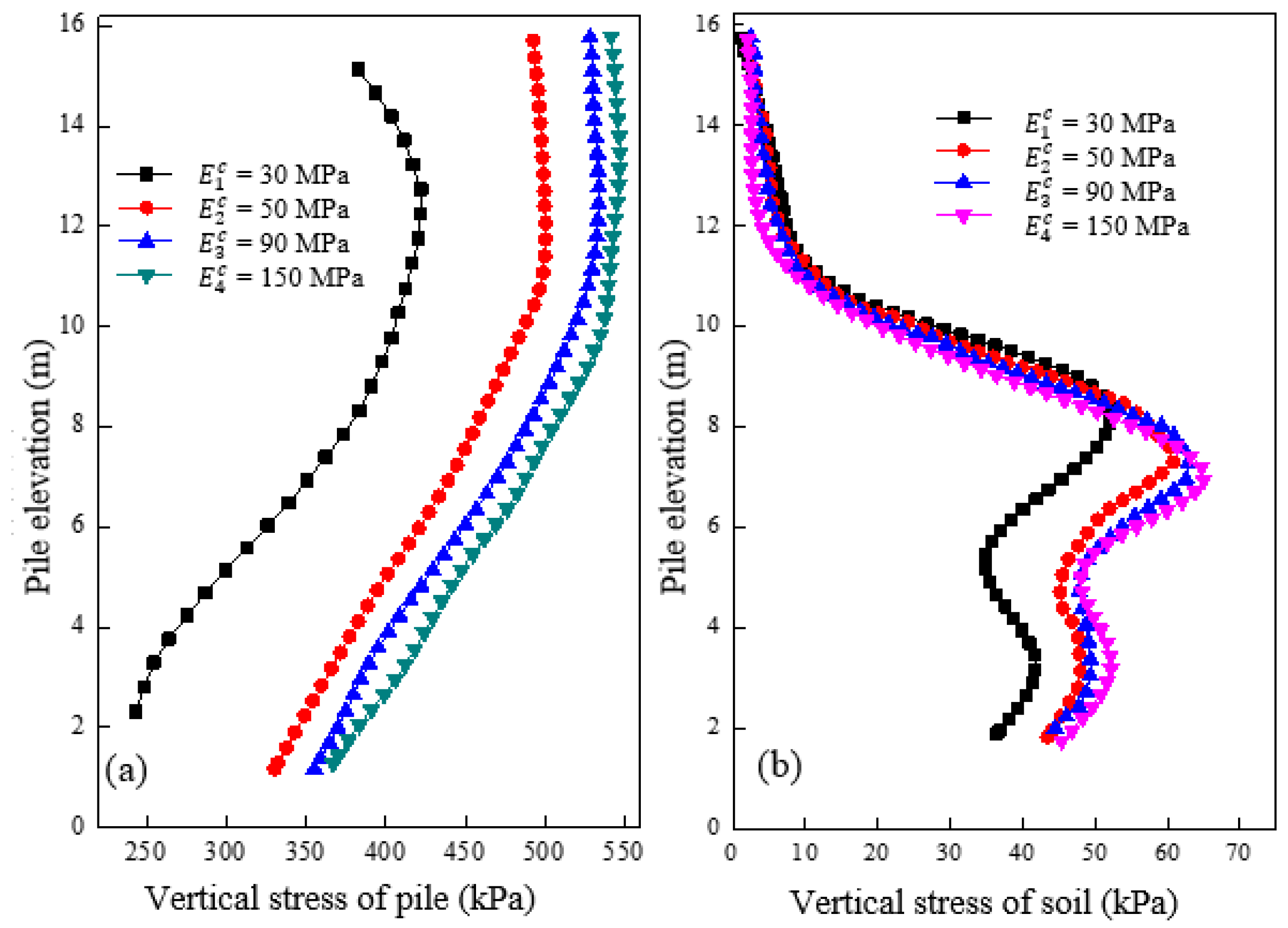

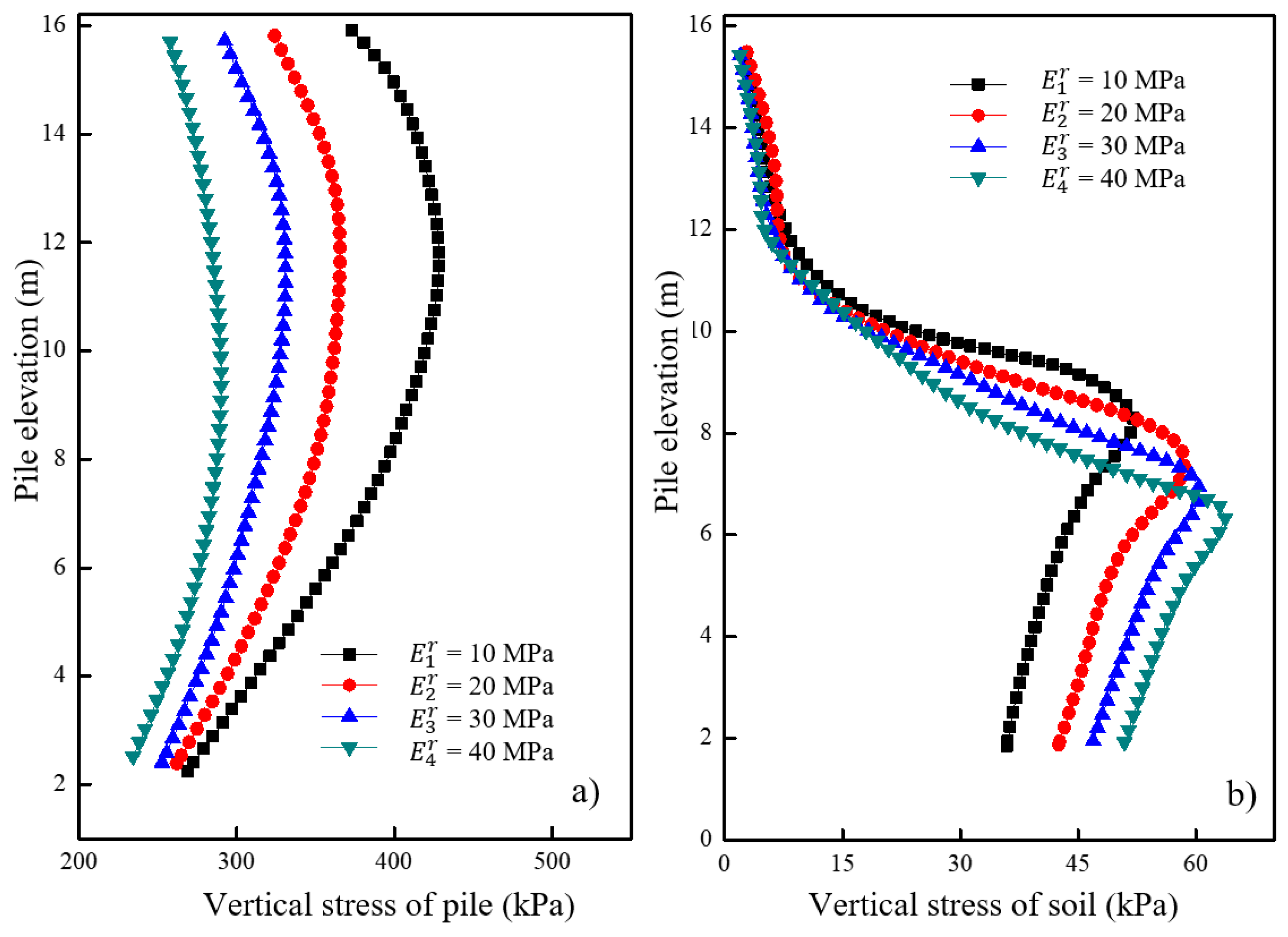

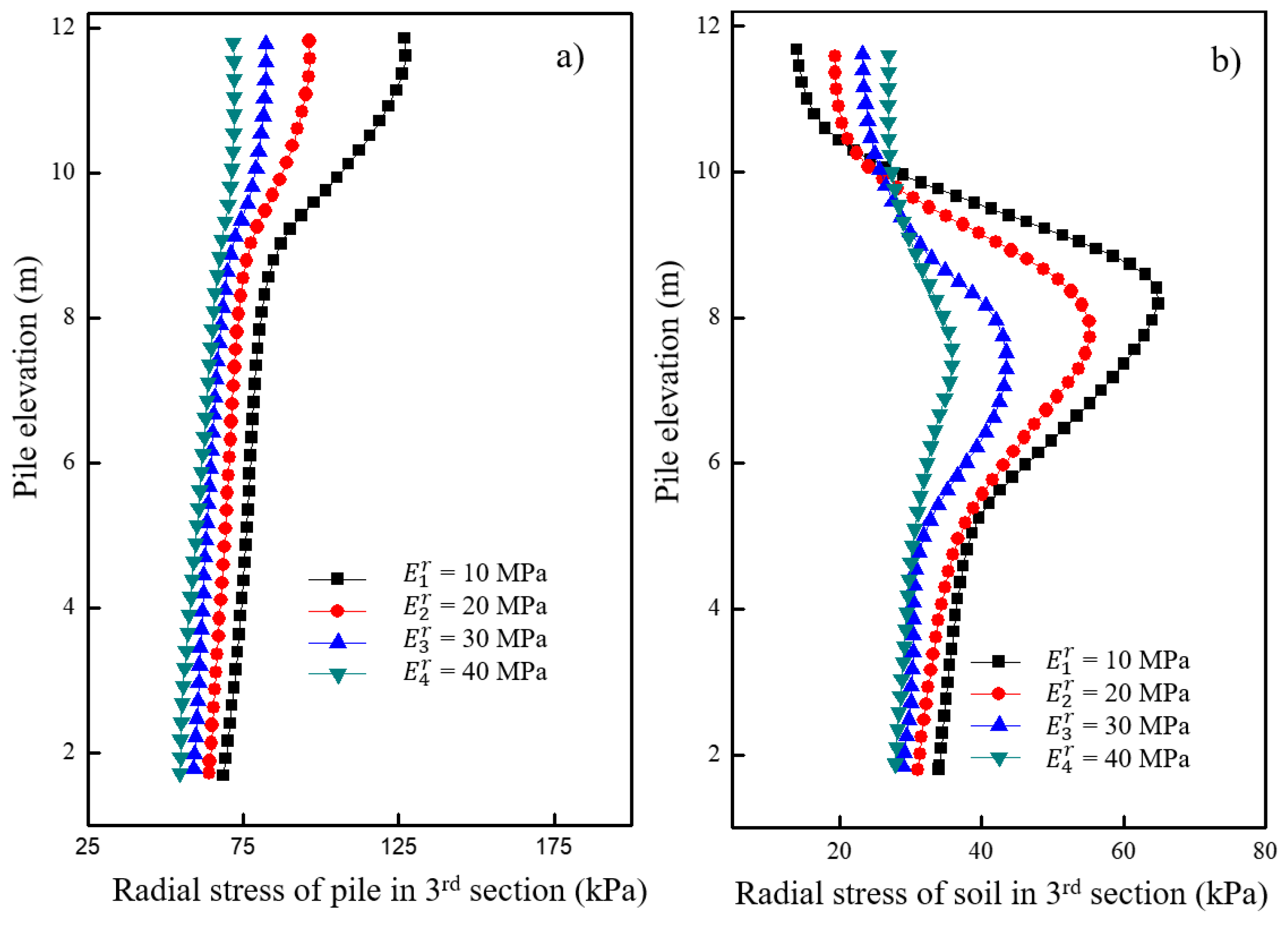

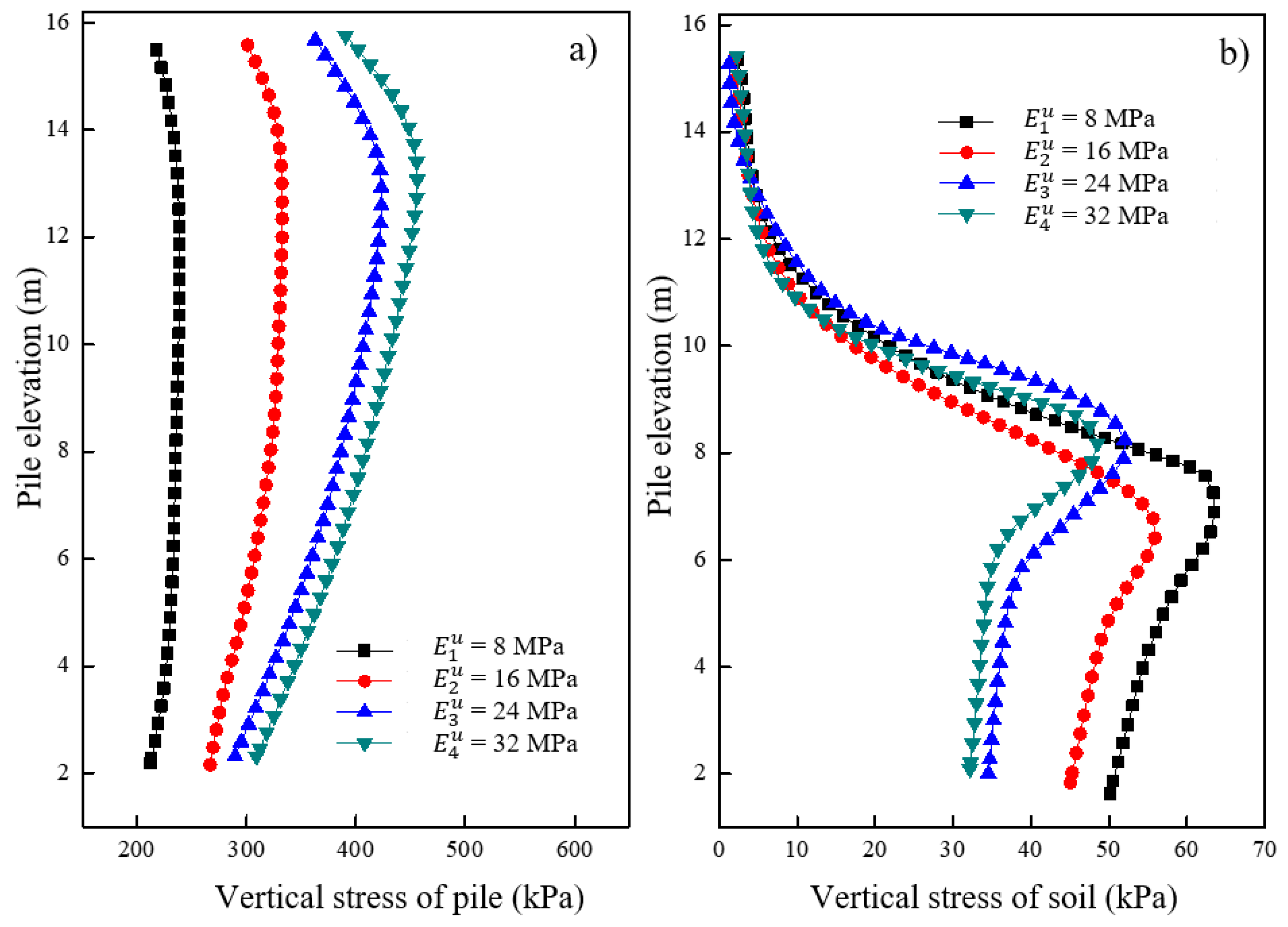

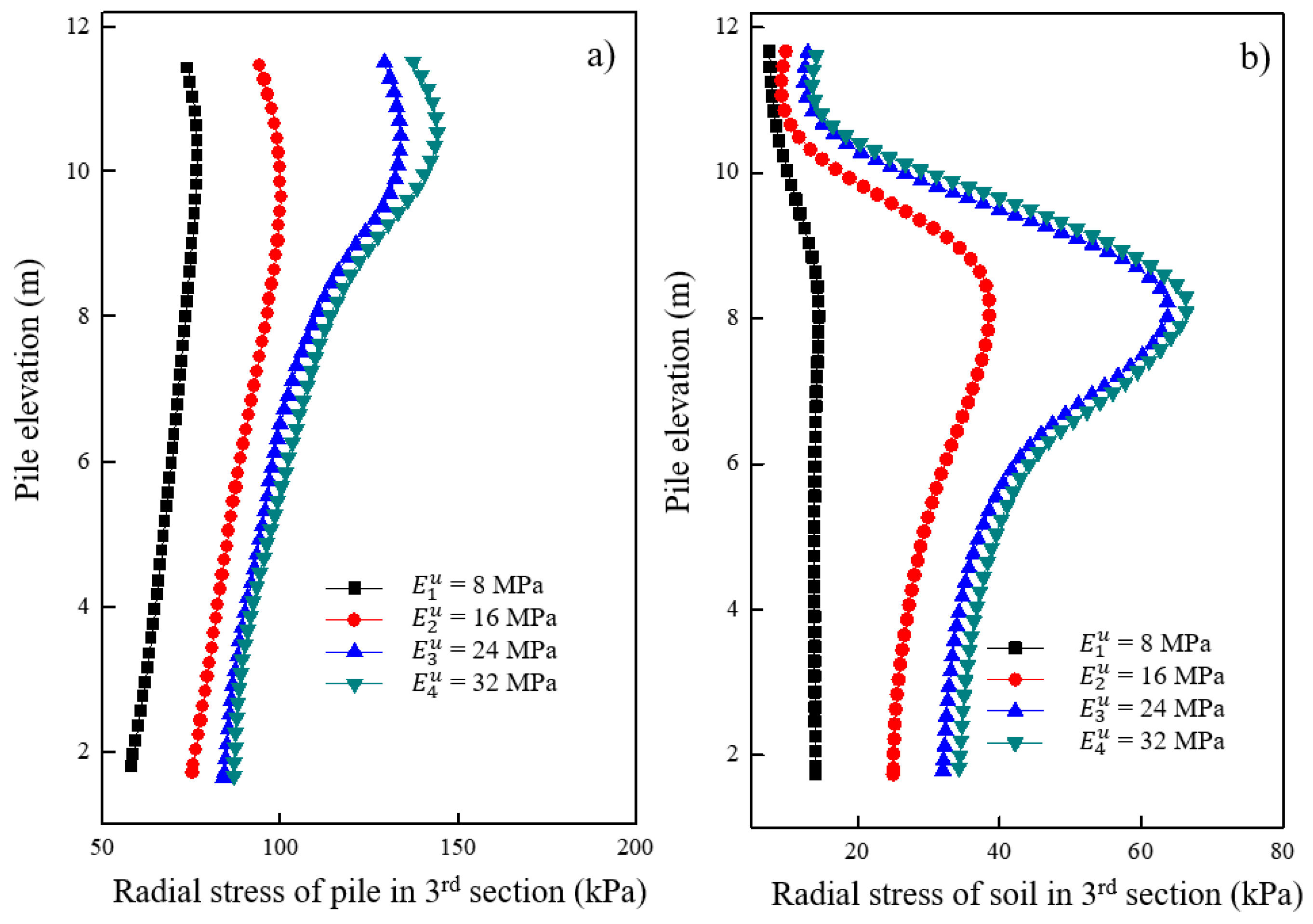

4.3. Effect of Soil Modulus

5. Limitations and Recommendations

6. Conclusions

- (1)

- In foundations without a cushion, the stress level of the pile was higher. However, utilizing a thick cushion did not fully exploit the bearing capacity of the pile. Therefore, it is necessary to determine an appropriate cushion thickness (e.g., 200–300 mm) and modulus (e.g., 90 MPa) to fully utilize the bearing capacity;

- (2)

- Increasing the length and concrete strength of the concrete pile section, or modulus of the reinforced soil, effectively enhanced the bearing capacity. However, the impact of increasing the pile modulus on the bearing capacity was limited;

- (3)

- The pile diameter inversely affected the vertical and radial stress of the pile, with larger diameters resulting in lower stress levels. However, the influence of pile diameter on the bearing capacity of the pile became insignificant once the pile diameter exceeded 1.2 m. The pile spacing should not be less than twice the pile diameter;

- (4)

- A higher modulus of the underlying stratum resulted in increased vertical and radial stress in the pile, larger settlements on the top of the pile, and increased vertical deformation. Moreover, a critical modulus of the underlying stratum, 24 MPa, was observed in affecting the feature of pile and soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sivapriya, S.; James, J. Numerical study on static behaviour of a stone column under uniformly distributed load. AIP Conf. Proc. 2019, 2161, 020058. [Google Scholar]

- Jamshidi Chenari, R.; Karimpour Fard, M.; Jamshidi Chenari, M.; Shamsi Sosahab, J. Physical and numerical modeling of stone column behavior in loose sand. Int. J. Civ. Eng. 2019, 17, 231–244. [Google Scholar] [CrossRef]

- Deb, K. A mathematical model to study the soil arching effect in stone column-supported embankment resting on soft foundation soil. Appl. Math. Model. 2010, 34, 3871–3883. [Google Scholar] [CrossRef]

- Guetif, Z.; Bouassida, M.; Debats, J. Improved soft clay characteristics due to stone column installation. Comput. Geotech. 2007, 34, 104–111. [Google Scholar] [CrossRef]

- Zhang, L.; Xu, Z.; Zhao, H.; Zhou, S. A Three-Dimensional Discrete Element Modeling to Cyclic Response of Geosynthetic-Encased Stone Column. Int. J. Geosynth. Ground Eng. 2021, 7, 75. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, L.; Zhou, S. Influence of encasement length and geosynthetic stiffness on the performance of stone column: 3D DEM-FDM coupled numerical investigation. Comput. Geotech. 2021, 132, 103993. [Google Scholar] [CrossRef]

- Xu, F.; Moayedi, H.; Foong, L.K.; Moghadam, M.J.; Zangeneh, M. Laboratory and numerical analysis of geogrid encased stone columns. Measurement 2021, 169, 108369. [Google Scholar] [CrossRef]

- Farah, R.E.; Nalbantoglu, Z. Behavior of geotextile-encased single stone column in soft soils. Arab. J. Sci. Eng. 2020, 45, 3877–3890. [Google Scholar] [CrossRef]

- Hasan, M.; Samadhiya, N.K. Performance of geosynthetic-reinforced granular piles in soft clays: Model tests and numerical analysis. Comput. Geotech. 2017, 87, 178–187. [Google Scholar] [CrossRef]

- Ji, M.; Wang, J.; Zheng, J.-J.; Zheng, Y. Contribution of geosynthetic to the shear strength of geosynthetic encased stone columns. Geosynth. Int. 2023, 1–14. [Google Scholar] [CrossRef]

- Wehr, J. The undrained cohesion of the soil as a criterion for column installation with a depth vibrator. In Installation Effects in Geotechnical Engineering; Taylor & Francis Group: London, UK, 2013; pp. 241–244. [Google Scholar]

- Castro, J. Modeling stone columns. Materials 2017, 10, 782. [Google Scholar] [CrossRef]

- Zhao, Y.L.; Yang, T.; Tong, Y.; Wang, J.; Luan, J.H.; Jiao, Z.B.; Chen, D.; Yang, Y.; Hu, A.; Liu, C.T.; et al. Heterogeneous precipitation behavior and stacking-fault-mediated deformation in a CoCrNi-based medium-entropy alloy. Acta Mater. 2017, 138, 72–82. [Google Scholar] [CrossRef]

- Zhang, D.; Huang, X. Proceedings of GeoShanghai 2018 International Conference: Tunnelling and Underground Construction; Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- McCabe, B.A.; Nimmons, G.J.; Egan, D. A review of field performance of stone columns in soft soils. Proc. Inst. Civ. Eng. Geotech. Eng. 2009, 162, 323–334. [Google Scholar] [CrossRef]

- Gu, M.; Cai, X.; Mo, H.; Wang, Q. Unconfined compressive behavior of column with geogrid-encased recycled aggregate: Test and simulation. Constr. Build. Mater. 2023, 400, 132528. [Google Scholar] [CrossRef]

- Gao, J.; Zhang, Y.; Wang, C.; Yuan, C. Behavior characteristics of geosynthetic-encased stone column under cyclic loading. Transp. Geotech. 2021, 28, 100554. [Google Scholar] [CrossRef]

- Malik, P.; Mishra, S.K. A comprehensive review of soil strength improvement using geosynthetics. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Zhang, L.; Peng, B.; Xu, Z.; Zhou, S. Shear performance of geosynthetic-encased stone column based on 3D-DEM simulation. Comput. Geotech. 2022, 151, 104952. [Google Scholar] [CrossRef]

- Lo, S.R.; Zhang, R.; Mak, J. Geosynthetic-encased stone columns in soft clay: A numerical study. Geotext. Geomembr. 2010, 28, 292–302. [Google Scholar] [CrossRef]

- Yoo, C.; Lee, D. Performance of geogrid-encased stone columns in soft ground: Full-scale load tests. Geosynth. Int. 2012, 19, 480–490. [Google Scholar] [CrossRef]

- Yoo, C.; Abbas, Q. Performance of geosynthetic-encased stone column-improved soft clay under vertical cyclic loading. Soils Found. 2019, 59, 1875–1890. [Google Scholar] [CrossRef]

- Imam, R.; Zarei, M.; Ghafarian, D. Relative contribution of various deformation mechanisms in the settlement of floating stone column-supported foundations. Comput. Geotech. 2021, 134, 104109. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, M. Deformation analysis of geotextile-encased stone columns. Int. J. Geomech. 2015, 15, 04014053. [Google Scholar] [CrossRef]

- Shahraki, M.; Rafiee-Dehkharghani, R.; Behnia, K. Three-dimensional Finite Element modeling of stone column-improved soft saturated ground. Civ. Eng. Infrastruct. J. 2018, 51, 389–403. [Google Scholar]

- Tan, X.; Hu, Z.; Cao, M.; Chen, C. 3D discrete element simulation of a geotextile-encased stone column under uniaxial compression testing. Comput. Geotech. 2020, 126, 103769. [Google Scholar] [CrossRef]

- Cheng, Y.; Cai, X.; Mo, H.; Gu, M. Numerical Analysis on the Behavior of Floating Geogrid-Encased Stone Column Improved Foundation. Buildings 2023, 13, 1609. [Google Scholar] [CrossRef]

- Ou Yang, F.; Fan, G.; Wang, K.; Yang, C.; Lyu, W.; Zhang, J. A large-scale shaking table model test for acceleration and deformation response of geosynthetic encased stone column composite ground. Geotext. Geomembr. 2021, 49, 1407–1418. [Google Scholar] [CrossRef]

- Gniel, J.; Bouazza, A. Construction of geogrid encased stone columns: A new proposal based on laboratory testing. Geotext. Geomembr. 2010, 28, 108–118. [Google Scholar] [CrossRef]

- Guo, Y.; Zhao, M.; Fu, G.; Li, Y.; Yu, P. Bearing Capacity of the New Composite Foundation with Discrete Material-Concrete Compound Piles. Geotech. Geol. Eng. 2017, 35, 1439–1451. [Google Scholar] [CrossRef]

- Itasca. FLAC3D 6.0 Document; Itasca Consulting Group: Minneapolis, MN, USA, 2018. [Google Scholar]

- Park, K.; Felippa, C.; DeRuntz, J. Stabilization of staggered solution procedures for fluid-structure interaction analysis. Comput. Methods Fluid-Struct. Interact. Probl. 1977, 26, 51. [Google Scholar]

- Wang, T.; Zhou, W.; Chen, J.; Xiao, X.; Li, Y.; Zhao, X. Simulation of hydraulic fracturing using particle flow method and application in a coal mine. Int. J. Coal Geol. 2014, 121, 1–13. [Google Scholar] [CrossRef]

- Trung Ngo, N.; Indraratna, B.; Rujikiatkamjorn, C. A hybrid DEM-FDM approach for load-deformation analysis of stone columns. In From Fundamentals to Applications in Geotechnics; IOS Press: Amsterdam, The Netherlands, 2015; pp. 1256–1264. [Google Scholar]

- Tan, X.; Hu, Z.; Chen, C.; Zhao, M. 3D DEM-FDM Coupled Analysis of the Behavior of an Isolated Geogrid-Encased Stone Column under Axial Loading. J. Geotech. Geoenviron. Eng. 2021, 147, 04021028. [Google Scholar] [CrossRef]

- Ngo, N.T.; Tung, T.M. Coupled Discrete-Continuum Method for Studying Load-Deformation of a Stone Column Reinforces Rail Track Embankments. Procedia Eng. 2016, 142, 139–145. [Google Scholar] [CrossRef]

- Indraratna, B.; Ngo, N.T.; Rujikiatkamjorn, C.; Sloan, S.W. Coupled discrete element–finite difference method for analysing the load-deformation behaviour of a single stone column in soft soil. Comput. Geotech. 2015, 63, 267–278. [Google Scholar] [CrossRef]

- Breugnot, A.; Lambert, S.; Villard, P.; Gotteland, P. A Discrete/continuous Coupled Approach for Modeling Impacts on Cellular Geostructures. Rock Mech. Rock Eng. 2015, 49, 1831–1848. [Google Scholar] [CrossRef]

- Żywica, G.; Breńkacz, Ł.; Bagiński, P. Interactions in the Rotor-Bearings-Support Structure System of the Multi-stage ORC Microturbine. J. Vib. Eng. Technol. 2018, 6, 369–377. [Google Scholar] [CrossRef]

- Wang, R.; Yang, H.; Ni, P.; Zhao, C.; Guo, C.; Ma, H.; Dong, P.; Liang, H.; Tang, M. Model test and numerical simulation of a new prefabricated double-row piles retaining system in silty clay ground. Undergr. Space 2023, 13, 262–280. [Google Scholar] [CrossRef]

- Gu, M.; Cui, J.; Yuan, J.; Wu, Y.; Li, Y.; Mo, H. The stress and deformation of stone column-improved soft clay by discrete element modelling. Eur. J. Environ. Civ. Eng. 2022, 26, 1544–1560. [Google Scholar] [CrossRef]

| size/mm | 60~40 | 40~20 | 20~10 | 10~5 | 5~2 | 2~1 | 1~0.5 | <0.5 |

| Percentage finer/% | 60 | 20 | 10 | 5 | 3 | 2 | 0 | 0 |

| Pile Sections | Values | |

|---|---|---|

| Concrete section | E1 = 2.55 × 104 MPa | v1 = 0.17 |

| Middle section | E2 = 2.0 × 104 MPa | v2 = 0.2 |

| Granular column | = 6.0 × 104 kN/m | = 130 N |

| = 1.0 × 104 kN/m | = 130 N | |

| Description | Unite Weight (kN/m3) | Elastic Modulus (MPa) | Poisson Ratio | Cohesion (kPa) | Friction Angle (°) |

|---|---|---|---|---|---|

| Cushion | 21.8 | 30 | 0.30 | 0 | 45 |

| Reinforced soil | 17.0 | 10 | 0.35 | 12 | 10 |

| Underlying stratum | 20.5 | 24 | 0.30 | 30 | 26 |

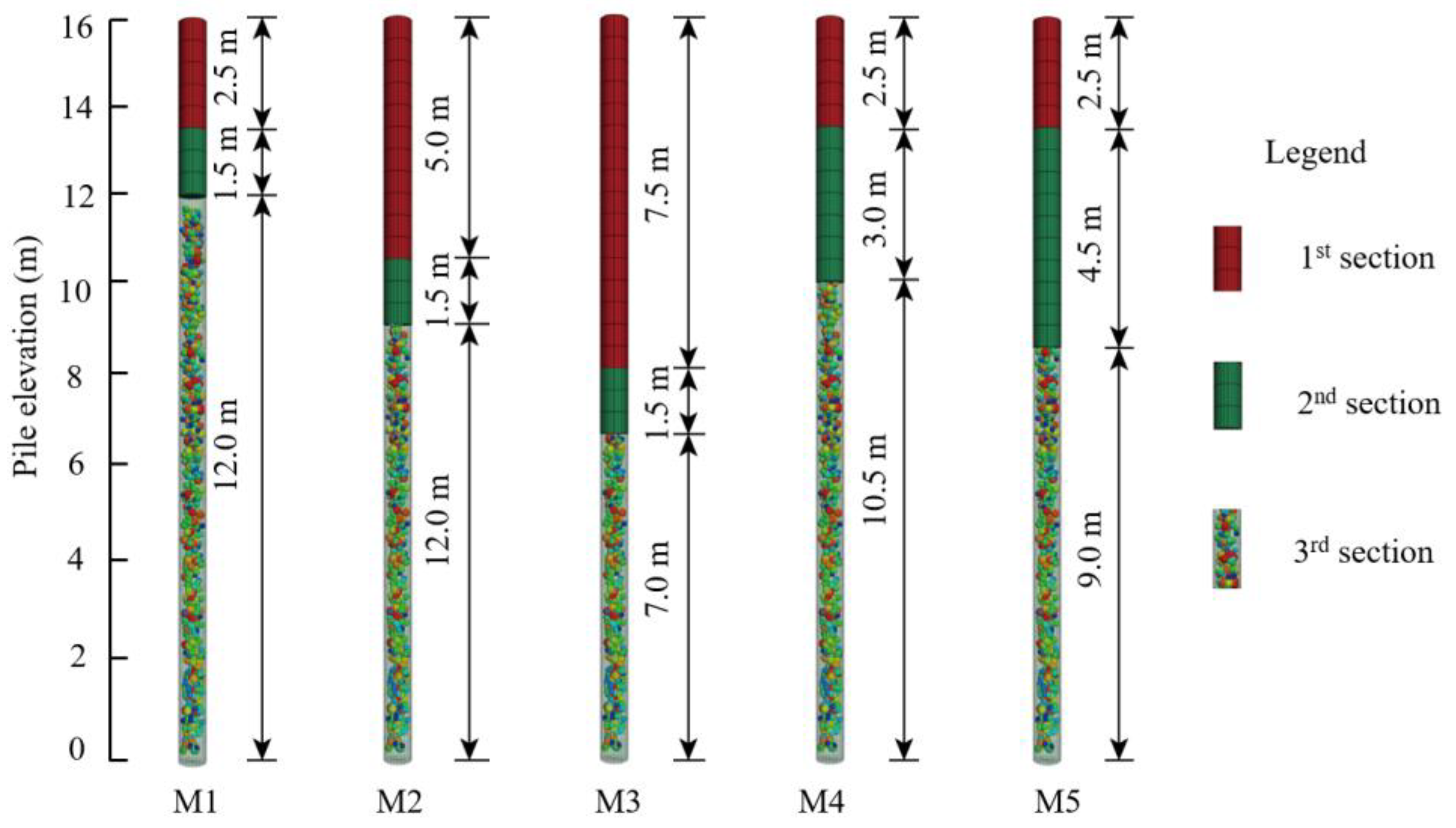

| Pile Section | Length (m) | Concrete Strength | Pile Diameter (m) | Pile Spacing (m) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concrete section | 2.5 | 5.0 | 7.5 | 2.5 | 2.5 | C15 | C20 | C30 | C40 | 0.6 | 0.9 | 1.2 | 1.5 | 1.2 | 1.8 | 2.4 | 3.0 |

| Middle section | 1.5 | 1.5 | 1.5 | 3.0 | 4.5 | ||||||||||||

| Granular column | 12 | 9.5 | 7 | 10.5 | 9 | ||||||||||||

| Model description | M1 | M2 | M3 | M4 | M5 | M6 | M7 | M8 | M9 | M10 | M11 | M12 | M13 | M14 | M15 | M16 | M17 |

| Description | Cushion | Pile Parameter | Soil Modulus | |||||

|---|---|---|---|---|---|---|---|---|

| Thickness | Modulus | Length | Concrete Strength | Diameter | Spacing | Reinforced Area | Underlying Stratum | |

| Recommended value | 200–300 mm | 90 MPa | - | - | 1.2 m | 1.8 m | - | 24 MPa |

| Influence on vertical stress of pile | Decreasing 33.13% | Increasing 54.06% | - | Slightly | Decreasing 59.24% | Increasing 61.35% | Negative correlation | Increasing 220.88% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, Y.; Cai, X.; Gu, M. Bearing Capacity and Deformation of the Tandem Compound Piles Improved Foundation: A Parametric Study. Materials 2023, 16, 5737. https://doi.org/10.3390/ma16175737

Guo Y, Cai X, Gu M. Bearing Capacity and Deformation of the Tandem Compound Piles Improved Foundation: A Parametric Study. Materials. 2023; 16(17):5737. https://doi.org/10.3390/ma16175737

Chicago/Turabian StyleGuo, Youlin, Xiaocong Cai, and Meixiang Gu. 2023. "Bearing Capacity and Deformation of the Tandem Compound Piles Improved Foundation: A Parametric Study" Materials 16, no. 17: 5737. https://doi.org/10.3390/ma16175737

APA StyleGuo, Y., Cai, X., & Gu, M. (2023). Bearing Capacity and Deformation of the Tandem Compound Piles Improved Foundation: A Parametric Study. Materials, 16(17), 5737. https://doi.org/10.3390/ma16175737