Advanced Injection Molding Methods: Review

Abstract

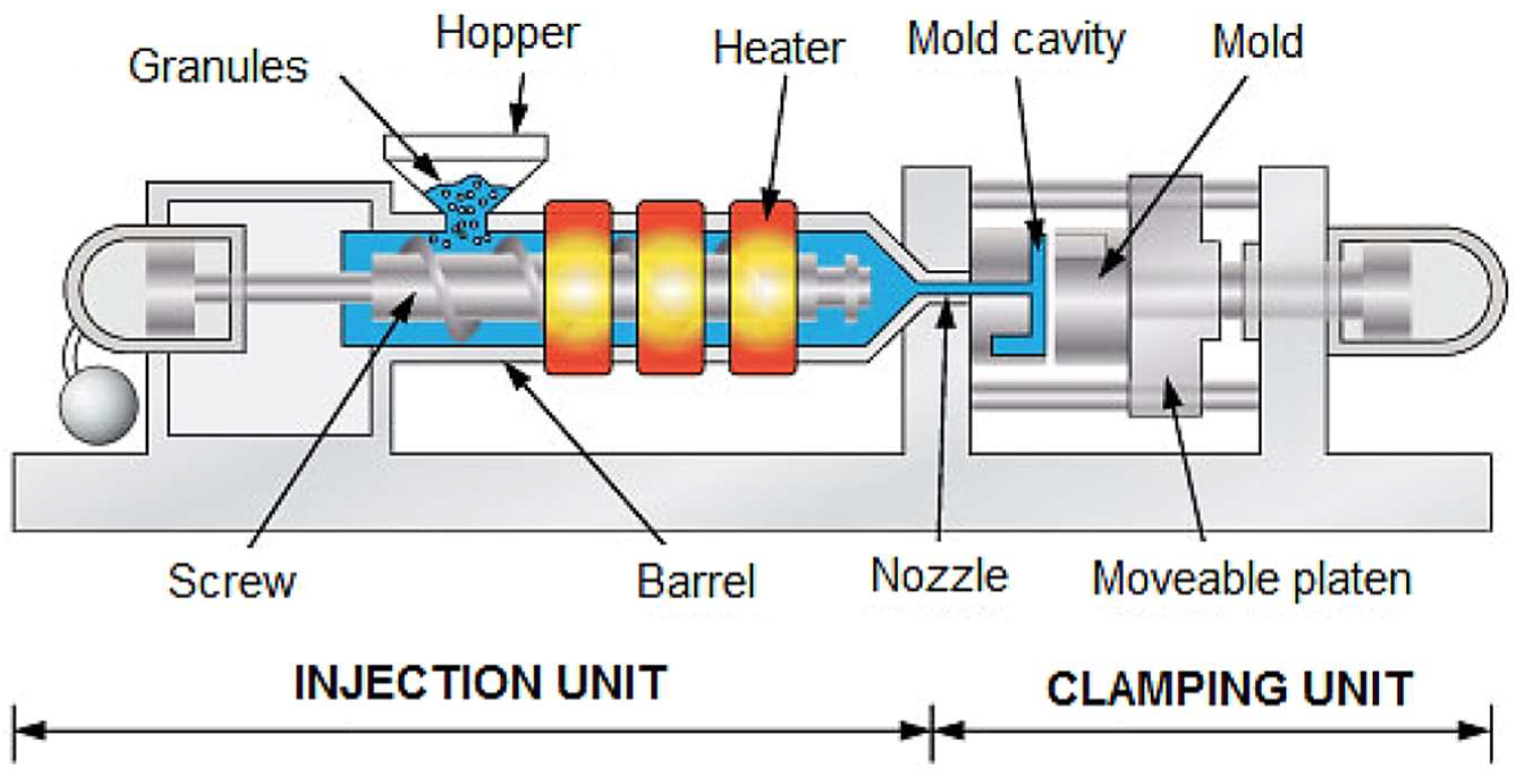

:1. Introduction

2. Materials Used in Injection Molding

2.1. Polypropylene

2.2. Polyethylene

2.3. Polystyrene

2.4. Acrylonitrile-Butadiene-Styrene

2.5. Polyvinyl Chloride

2.6. Polymethyl Methacrylate

2.7. Polyamide

3. Injection Molding Techniques

3.1. Water-Assisted Injection Molding

3.2. Gas-Assisted Injection Molding

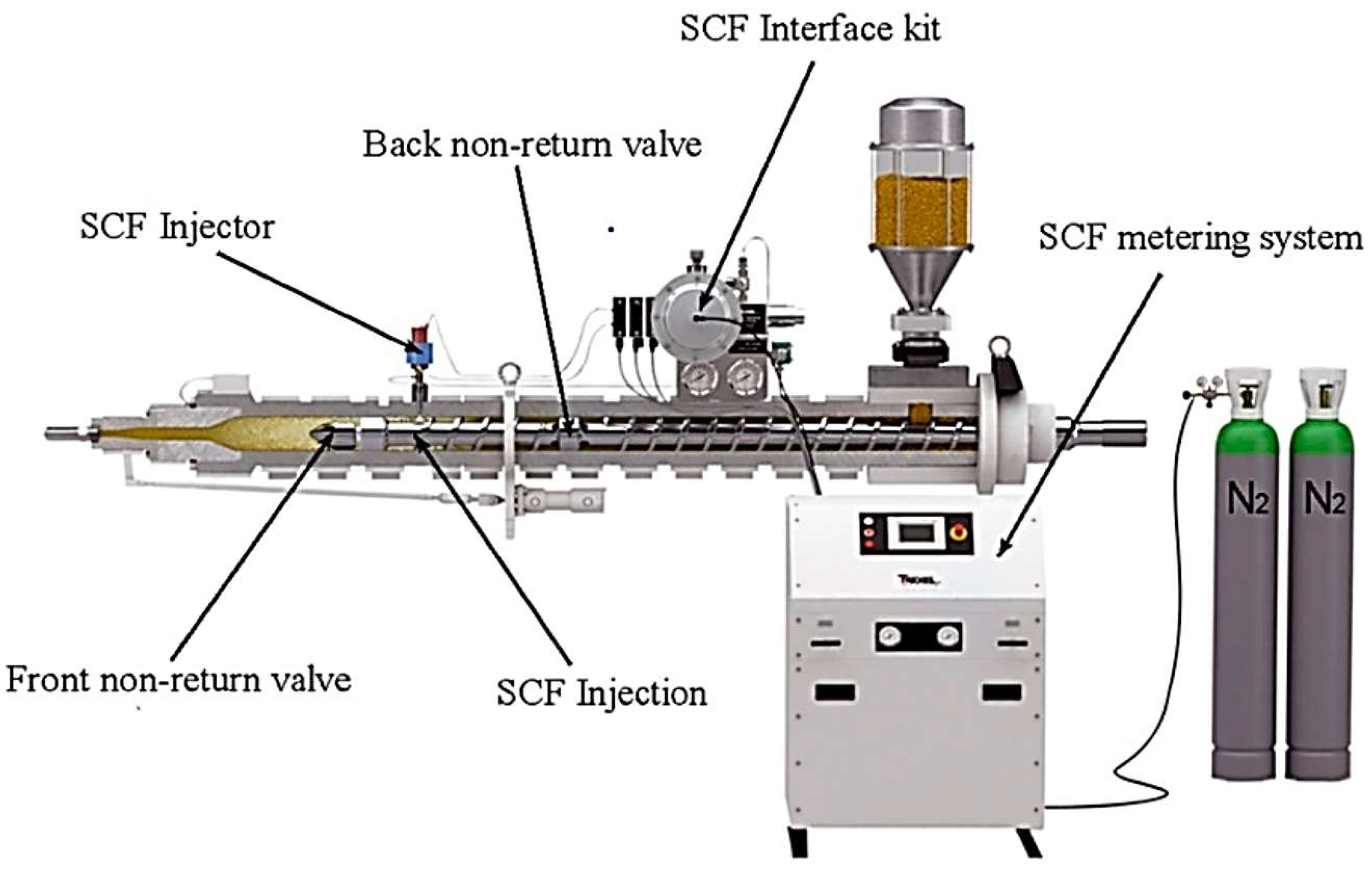

3.3. Microcellular Injection Molding

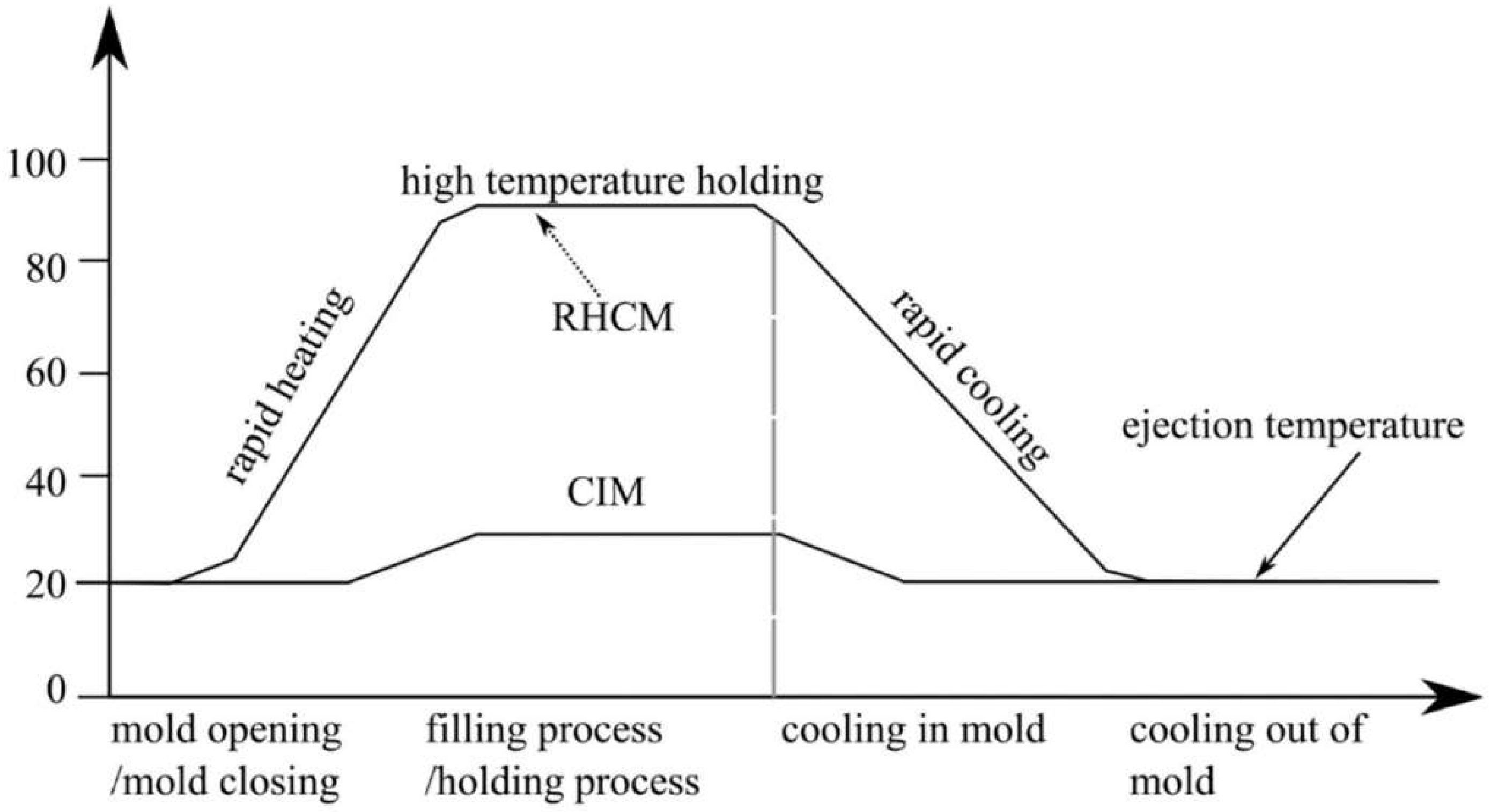

3.4. Variable Mold Temperature Technologies

3.5. Microinjection Molding

3.6. Rapid Thermal Cycling Molding

3.7. Multicomponent Injection Molding

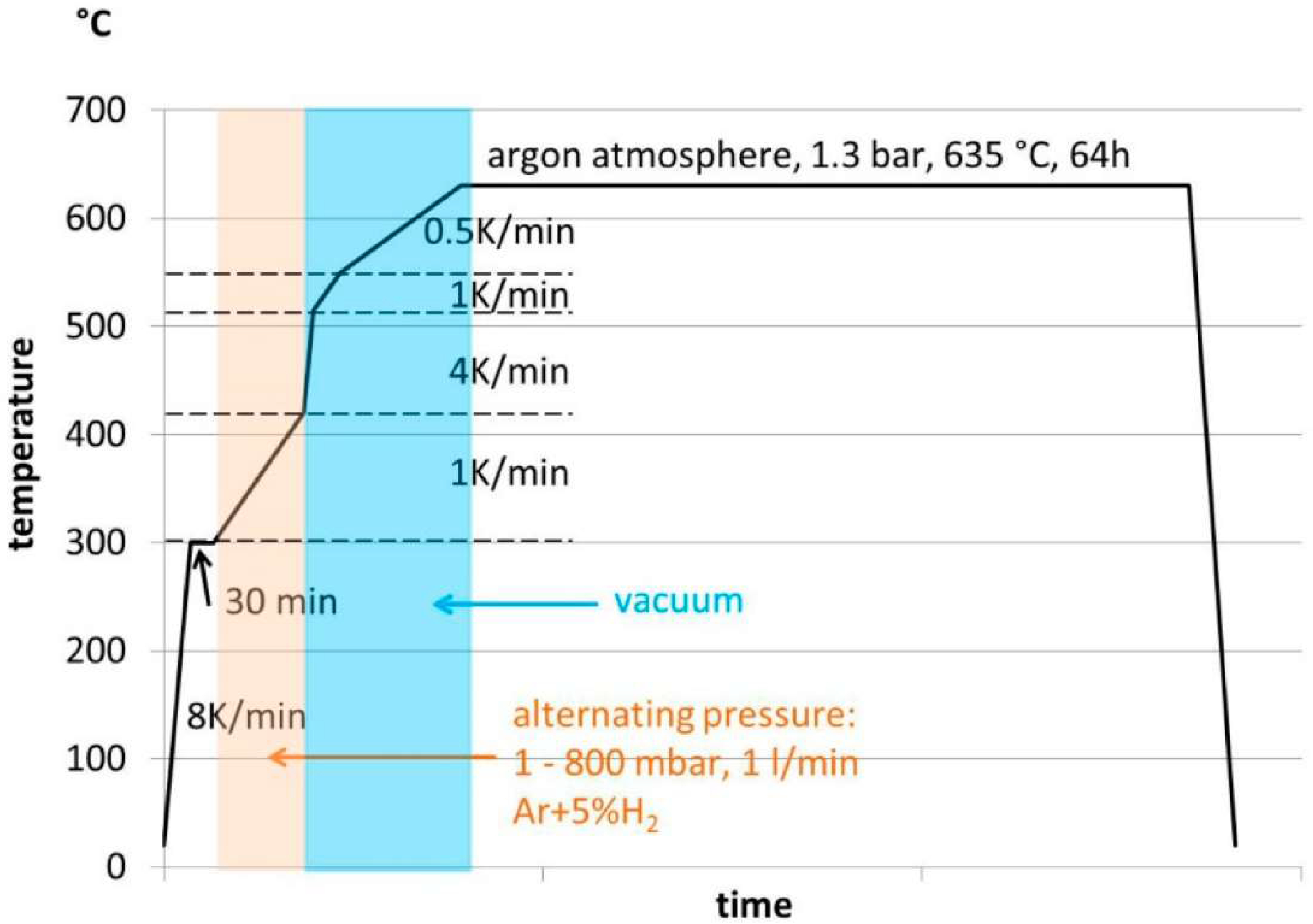

3.8. Metal Injection Molding

3.9. Reaction Injection Molding (RIM)

4. Environmental Impact of Injection Molding Method

5. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Agrawal, A.R.; Pandelidis, I.O.; Pecht, M. Injection-molding process control—A review. Polym. Eng. Sci. 1987, 27, 1345–1357. [Google Scholar] [CrossRef]

- Piotter, V.; Bauer, W.; Benzler, T.; Emde, A. Injection molding of components for microsystems. Microsyst. Technol. 2001, 7, 99–102. [Google Scholar] [CrossRef]

- Zema, L.; Loreti, G.; Melocchi, A.; Maroni, A.; Gazzaniga, A. Injection Molding and its application to drug delivery. J. Control. Release 2012, 159, 324–331. [Google Scholar] [CrossRef]

- Stanek, M.; Manas, D.; Manas, M.; Suba, O. Optimization of injection molding process. Int. J. Math. Comput. Simul. 2011, 5, 413–421. [Google Scholar]

- Krantz, J.; Nieduzak, Z.; Kazmer, E.; Licata, J.; Ferki, O.; Gao, P.; Sobkowicz, M.J.; Masato, D. Investigation of pressure-controlled injection molding on the mechanical properties and embodied energy of recycled high-density polyethylene. Sustain. Mater. Technol. 2023, 36, e00651. [Google Scholar] [CrossRef]

- Frizelle, W.G. 10—Injection Molding Technology. In Applied Plastics Engineering Handbook; Processing, Materials, and Applications Plastics Design Library; William Andrew: Norwich, NY, USA, 2017; pp. 191–202. [Google Scholar]

- Gim, J.; Turng, L.-S. A review of current advancements in high surface quality injection molding: Measurement, influencing factors, prediction, and control. Polym. Test. 2022, 115, 107718. [Google Scholar] [CrossRef]

- Crozier-Bioud, T.; Momeni, V.; Gonzales-Gutierrez, J.; Kukla, C.; Luca, S.; Rolere, S. Current challenges in NdFeB permanent magnets manufacturing by Powder Injection Molding (PIM): A review. Mater. Today Phys. 2023, 34, 101082. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, Y. Process Optimization of the Injection Molding for High Mechanical Performance. In Mechanical Properties of Polycarbonate; Experiment and Modeling for Aeronautical and Aerospace Applications; Elsevier: Amsterdam, The Netherlands, 2019; pp. 133–154. [Google Scholar]

- Peixoto, C.; Valentim, P.T.; Sousa, P.C.; Dias, D.; Araujo, C.; Periera, D.; Machado, C.F.; Pontes, A.J.; Santos, H.; Cruz, S. Injection molding of high-precision optical lenses: A review. Precis. Eng. 2022, 76, 29–51. [Google Scholar] [CrossRef]

- Heaney, D.F.; Greene, C.D. Molding of components in metal injection molding (MIM). In Handbook of Metal Injection Molding; Woodhead Publishing Series in Metals and Surface Engineering; Woodhead Publishing: Sawston, UK, 2019; pp. 105–127. [Google Scholar]

- Greene, J.P. Injection Molding. In Automotive Plastics and Composites; Materials and Processing Plastics Design Library; William Andrew: Norwich, NY, USA, 2021; pp. 241–254. [Google Scholar]

- Proy, J.; Massa, F.; Notta-Cuvier, D.; Lauro, F.; Tison, T.; Spingler, G. Integrating fibers and injection molding process variability in short-natural-fiber-reinforced thermoplastics behavior: A review. Mater. Today Commun. 2021, 29, 102785. [Google Scholar] [CrossRef]

- Cao, P.; Hayat, M.D. Reactive powder metal injection molding. In Feedstock Technology for Reactive Metal Injection Molding Process, Design, and Application; Elsevier: Amsterdam, The Netherlands, 2020; pp. 1–42. [Google Scholar]

- Rajeshkumar, G.; Askash Balaji, B.; Seshadri, S.A. Compression and injection molding techniques. In Cellulose Fibre Reinforced Composites; Interface Engineering, Processing and Performance Woodhead Publishing Series in Composites Science and Engineering; Woodhead Publishing: Sawston, UK, 2023; pp. 165–181. [Google Scholar]

- Vargas-Isaza, C.; Posada-Correa, J.; Briñez-de León, J. Analysis of the Stress Field in Photoelasticity Used to Evaluate the Residual Stresses of a Plastic Injection-Molded Part. Polymers 2023, 15, 3377. [Google Scholar] [CrossRef]

- Sin, L.T.; Tueen, B.S. Injection Molding and Three-Dimensional Printing of Poly(Lactic Acid). In Polylactic Acid: A Practical Guide for the Processing, Manufacturing, and Applications of PLA Plastics Design Library; William Andrew: Norwich, NY, USA, 2019; pp. 325–345. [Google Scholar]

- Jaroschek, C. The Injection Molding Manufacturing Process. In Design of Injection Molded Plastic Parts; Carl Hanser Verlag GmbH & Co. KG: Munich, Germany, 2022; pp. 57–96. [Google Scholar]

- Nofar, M.; Park, C.B. Foam Injection Molding of PLA and Its Compounds. In Polylactide Foams; William Andrew: Norwich, NY, USA, 2018; pp. 151–193. [Google Scholar]

- Luo, L.; Yao, Y.; Gao, F.; Zhao, C. Mixed-effects Gaussian process modeling approach with application in injection molding processes. J. Process Control 2018, 62, 37–43. [Google Scholar] [CrossRef]

- Gao, F.; Yang, Y.; Shao, C. Robust iterative learning control with applications to injection molding process. Chem. Eng. Sci. 2001, 56, 7025–7034. [Google Scholar] [CrossRef]

- Svečko, R.; Kusić, D.; Kek, T.; Sarjaš, A.; Hančič, A.; Grum, J. Acoustic Emission Detection of Macro-Cracks on Engraving Tool Steel Inserts during the Injection Molding Cycle Using PZT Sensors. Sensors 2013, 13, 6365–6379. [Google Scholar] [CrossRef] [PubMed]

- Rizvi, S.J.A.; Singh, A.K.; Bhadu, G.R. Optimization of tensile properties of injection molded α-nucleated polypropylene using response surface methodology. Polym. Test. 2017, 60, 198–210. [Google Scholar] [CrossRef]

- Majumdar, G.; Turng, L.S.; Wang, K.K.; Elsheikhi, S.A.; Elderessi, K.A. Polymer Injection Molding: C-Mold. In Reference Module in Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2016; pp. 1–4. [Google Scholar]

- Xin, L. Reference Module in Materials Science and Materials Engineering. Int. J. Emerg. Technol. 2018, 13, 101–111. [Google Scholar] [CrossRef]

- Zghamg, T.; Chen, K.; Liu, G.; Zheng, X. Injection Molding Peocess Optimalization of Polypropylene using Ortogonal Experimeent Method Basen od Tensile Strength. IOP Conf. Se. Mater. Sci. Eng. 2019, 612, 032102. [Google Scholar]

- Maddah, H.A. Polypropylene as a Promising Plastic: A Review. Am. J. Polym. Sci. 2016, 6, 1–11. [Google Scholar]

- Zainudin, E.S.; Sapuan, S.M. A Review of the Effect of Moulding Parameters on the Performance of Polymeric Composite Injection Moulding. Turk. J. Eng. Environ. Sci. 2006, 30, 23–34. [Google Scholar]

- Ashby, M.F.; Jones, D.R.H. Processing Polymers. Eng. Mat. 2013, 39, 441–455. [Google Scholar]

- Farotti, E.; Natalini, M. Injection molding. Influence of process parameters on mechanical properties of polypropylene polymer. A first study. Procedia Struct. 2018, 8, 256–264. [Google Scholar] [CrossRef]

- Andrzejewski, J.; Barczewski, M.; Szostak, M. Injection Molding of Highly Filled Polypropylene-based Biocomposites. Buckwheat Husk and Wood Flour Filler: A Comparison of Agricultural and Wood Industry Waste Utilization. Polymers 2019, 11, 1881. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Mao, Q.; Jiang, N.; Chen, J. Effects of Injection Molding Parameters on Properties of Insert-Injection Molded Polypropylene Single-Polymer Composites. Polymers 2022, 14, 23. [Google Scholar] [CrossRef] [PubMed]

- Kościuszko, A.; Rojewski, M.; Nowinka, B.; Patalas, F. Post-Molding Shrinkage, Structure and Properties of Cellular Injection-Molded Polypropylene. Materials 2022, 15, 7079. [Google Scholar] [CrossRef]

- Kale, H.P.; Hambire, U.V. Review on Optimization of Injection Molding Process Parameter for Reducing Shrinkage of High Density Polyethylene (HDPE) material. Int. J. Sci. Res. 2015, 4, 2847–2850. [Google Scholar]

- Mizera, A.; Krstulovic-Opara, L.; Krempl, N.; Karhankova, M.; Manas, M.; Sanek, L.; Stoklasek, P.; Grebo, A. Dynamic Behavior of Thermally Affected Injection-Molded High-Density Polyethylene Parts Modified by Accelerated Electrons. Polymers 2022, 14, 4970. [Google Scholar] [CrossRef] [PubMed]

- Gedde, U.W.; Unge, M.; Nilsson, F.; Hedenqvist, M.S. Mass and charge transport in polyethylene—Structure, morphology and properties. Polymer 2023, 266, 125617. [Google Scholar] [CrossRef]

- Yao, Z.; Seong, H.J.; Jang, Y.S. Environmental toxicity and decomposition of polyethylene. Ecotoxicol. Environ. Saf. 2022, 242, 113933. [Google Scholar] [CrossRef]

- Bahlouli, S.; Belaadi, A.; Makhlouf, A.; Alshahrani, H.; Khan, M.K.A.; Jawaid, M. Effect of Fiber Loading on Thermal Properties of Cellulosic Washingtonia Reinforced HDPE Biocomposites. Polymers 2023, 15, 2910. [Google Scholar] [CrossRef]

- Lovato, M.J.; del Valle, L.J.; Puiggalí, J.; Franco, L. Performance-Enhancing Materials in Medical Gloves. J. Funct. Biomater. 2023, 14, 349. [Google Scholar] [CrossRef]

- Kim, M.; Lee, C.H. Hydrogenation of High-Density Polyethylene during Decompression of Pressurized Hydrogen at 90 MPa: A Molecular Perspective. Polymers 2023, 15, 2880. [Google Scholar] [CrossRef]

- Vielma, P.T.; Cervera, A.; Levenfeld, B.; Varez, A. Production of alumina parts by powder injection molding with a binder system based on high density polyethylene. J. Eur. Ceram 2008, 28, 763–771. [Google Scholar] [CrossRef]

- Leyva-Porras, C.; Balderrama-Aguilar, A.; Estrada-Ávila, Y.; Espelosín-Gómez, I.; Mendoza-Duarte, M.; Piñón-Balderrama, C.; Saavedra-Leos, M.Z.; Estrada-Moreno, I. Injection Molding of Low-Density Polyethylene (LDPE) as a Model Polymer: Effect of Molding Parameters on the Microstructure and Crystallinity. Polymers 2021, 13, 3597. [Google Scholar] [CrossRef] [PubMed]

- Meszaros, L.; Tatar, B.; Toth, K.; Foldes, A.; Nagy, K.S.; Jedloxszky-Hajdu, A.; Toth, T.; Molnar, K. Novel, injection molded all-polyethylene composites for potential biomedical implant applications. J. Mater. Res. Technol. 2022, 17, 743–755. [Google Scholar] [CrossRef]

- Kumar Lal, S.; Vasudevan, H. Optimization of Injection Moulding Process Parameters in the Moulding of Low Density Polyethylene (LDPE). Int. J. Eng. Res. Dev. 2013, 7, 35–39. [Google Scholar]

- Khan, Z.A.; Kamaruddin, S.; Siddiquee, A.N. Feasibility study of use of recycled High Density Polyethylene and multi response optimization of injection moulding parameters using combined grey relational and principal component analyses. Mater. Des. 2010, 31, 2925–2931. [Google Scholar] [CrossRef]

- Djurner, K.; Kubat, J.; Rigdahl, M. Influence of high injection moulding pressures on the engineering properties of linear polyethylene. Polymer 1977, 18, 1068–1074. [Google Scholar] [CrossRef]

- Ho, B.T.; Roberts, T.K.; Lucas, S. An overview on biodegradation of polystyrene and modified polystyrene: The microbial approach. Crit. Rev. Biotechnol. 2018, 38, 308–320. [Google Scholar] [CrossRef]

- Maharana, T.; Negi, Y.S.; Mohnaty, B. Review Article: Recycling of Polystyrene. Polym. Plast. Technol. Eng 2007, 46, 729–736. [Google Scholar] [CrossRef]

- Yoon, D.Y.; Sundararajan, P.R.; Flory, P.J. Conformational Characteristics of Polystyrene. Macromolecules 1975, 8, 776–783. [Google Scholar] [CrossRef]

- Chaukura, N.; Gwenzi, W.; Bunhu, T.; Ruziwa, D.T.; Pumure, I. Potential uses and value-added products derived from waste polystyrene in developing countries: A review. Resour. Conserv. Recycl. 2016, 107, 157–165. [Google Scholar] [CrossRef]

- Faravelli, T.; Pinciroli, M.; Pisano, F.; Bozzano, G.; Dente, M.; Ranzi, E. Thermal degradation of polystyrene. J. Anal. Appl. Pyrolysis 2001, 60, 103–121. [Google Scholar] [CrossRef]

- Lerman, M.J.; Lembong, J.; Muramoto, S.; Gillen, G.; Fisher, J.P. The Evolution of Polystyrene as a Cell Culture Material. Tissue Eng. Part B Rev. 2018, 24, 359–372. [Google Scholar] [CrossRef] [PubMed]

- Asandulesa, M.; Solonaru, A.-M.; Resmerita, A.-M.; Honciuc, A. Thermal and Dielectric Investigations of Polystyrene Nanoparticles as a Viable Platform—Toward the Next Generation of Fillers for Nanocomposites. Polymers 2023, 15, 2899. [Google Scholar] [CrossRef] [PubMed]

- Covelli, V.; Cozzolino, A.; Rizzo, P.; Rodriquez, M.; Vestuto, V.; Bertamino, A.; Daniel, C.; Guerra, G. Salicylic Acid Release from Syndiotactic Polystyrene Staple Fibers. Molecules 2023, 28, 5095. [Google Scholar] [CrossRef]

- McKee, G.E.; Kistenmacher, A.; Goerrisssen, H.; Breulmann, M. Synthesis, Properties and Applications of Acrylonitrile–Styrene–Acrylate Polymers. In Modern Styrenic Polymers: Polystyrenes and Styrenic Copolymers; John Wiley & Sons: Hoboken, NJ, USA, 2003; pp. 341–362. [Google Scholar]

- Masato, D.; Sorgato, M.; Babenko, M.; Whiteside, B.; Lucchetta, G. Thin-wall injection molding of polystyrene parts with coated and uncoated cavities. Mater. Des. 2018, 141, 286–295. [Google Scholar] [CrossRef]

- Enomoto, K.; Yasuhara, T.; Ohtake, N.; Kato, K. Injection Molding of Polystyrene Matrix Composites Filled with Vapor Grown Carbon Fiber. JSME Int. J. Ser. A Solid Mech. Mater. Eng. 2003, 46, 353–358. [Google Scholar] [CrossRef]

- Chung, C.-Y.; Hwang, S.-S.; Chen, S.-C.; Lai, M.-C. Effects of Injection Molding Process Parameters on the Chemical Foaming Behavior of Polypropylene and Polystyrene. Polymers 2021, 13, 2331. [Google Scholar] [CrossRef]

- Sadabadi, H.; Ghasemi, M. Effects of Some Injection Molding Process Parameters on Fiber Orientation Tensor of Short Glass Fiber Polystyrene Composites (SGF/PS). J. Reinf. Plast. Compos. 2007, 26, 1729–1741. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Dong, G.; Song, L.; Park, C.B. Lightweight, thermally insulating, and low dielectric microcellular high-impact polystyrene (HIPS) foams fabricated by high-pressure foam injection molding with mold opening. J. Mater. Chem. C 2018, 6, 12294–12305. [Google Scholar] [CrossRef]

- Yausefi, M.; Gholamian, F.; Ghanbaroi, D.; Salavati-Niasari, M. Polymeric nanocomposite materials: Preparation and characterization of star-shaped PbS nanocrystals and their influence on the thermal stability of acrylonitrile–butadiene–styrene (ABS) copolymer. Polyhedron 2011, 30, 1055–1060. [Google Scholar] [CrossRef]

- Rufino, A.F.C.S.; Ribeiro, S.C.; Coutinho, J.A.P.; Silva, F.A.; Freire, M.G. Triblock copolymers as versatile constituents of double stimuli-responsive ionic-liquid-based aqueous biphasic systems. Sep. Purif. Technol. 2023, 317, 123852. [Google Scholar] [CrossRef]

- Anson, M.; Marchese, J.; Garis, E.; Ochoa, N.; Pagliero, C. ABS copolymer-activated carbon mixed matrix membranes for CO2/CH4 separation. J. Membr. Sci. 2004, 243, 19–28. [Google Scholar] [CrossRef]

- Choi, T.S.; Xu, M.; Chung, I.J. Synthesis of exfoliated acrylonitrile–butadiene–styrene copolymer (ABS) clay nanocomposites: Role of clay as a colloidal stabilizer. Polymer 2005, 43, 531–538. [Google Scholar] [CrossRef]

- Yt, C.T.; Lai, C.C.; Wang, F.M.; Hsiao, H.T.; Liu, L.C.; Teng, W.F.; Chang, H.Y.; Chien, G.M.; Chen, C.M. Preparation of acrylonitrile-butadiene-styrene copolymer (ABS)/polylactic acid (PLA) biomass alloys with BaSO4 and their feasible evaluation for the housing of loudspeakers. Matt. Let. 2019, 251, 52–56. [Google Scholar]

- Vishwakarma, S.K.; Pandey, P.; Gupta, N.K. Characterization of ABS Material: A Review. J. Mech. Eng. 2017, 3, 13–16. [Google Scholar]

- Münstedt, H. Rheological Measurements and Structural Analysis of Polymeric Materials. Polymers 2021, 13, 1123. [Google Scholar] [CrossRef]

- Ozcelik, B.; Ozbay, A.; Demirbas, E. Influence of injection parameters and mold materials on mechanical properties of ABS in plastic injection molding. Int. Commun. Heat Mass Transf. 2010, 37, 1359–1365. [Google Scholar] [CrossRef]

- Boronat, T.; Segui, V.J.; Peydro, M.A.; Reig, M.J. Influence of temperature and shear rate on the rheology and processability of reprocessed ABS in injection molding process. J. Mater. Process. Technol. 2009, 209, 2735–2745. [Google Scholar] [CrossRef]

- Rahimi, M.; Esfahanian, M.; Moradi, M. Effect of reprocessing on shrinkage and mechanical properties of ABS and investigating the proper blend of virgin and recycled ABS in injection molding. J. Mater. Process. Technol. 2014, 214, 2359–2365. [Google Scholar] [CrossRef]

- Tranter, J.B.; Refalo, P.; Rochman, A. Towards sustainable injection molding of ABS plastic products. J. Manuf. Process 2017, 29, 399–406. [Google Scholar] [CrossRef]

- Volpato, N.; Solis, M.; Costa, C.A. An analysis of Digital ABS as a rapid tooling material for polymer injection moulding. Int. J. Mater. Prod. Technol. 2015, 52, 3–16. [Google Scholar] [CrossRef]

- Sreedharan, J.; Jeevanantham, A.K. Analysis of Shrinkages in ABS Injection Molding Parts for Automobile Applications. Mat. Tod. Process. 2018, 5, 12744–12749. [Google Scholar] [CrossRef]

- Lay, M.; Thajudin, N.L.N.; Hamid, Z.A.A.; Rusli, A.; Abdulhal, M.K.; Shuib, R.K. Comparison of physical and mechanical properties of PLA, ABS and nylon 6 fabricated using fused deposition modeling and injection molding. Compos. B Eng. 2019, 176, 107341. [Google Scholar] [CrossRef]

- Reddy, V.V.; Krishna, A.V.; Sjogren, A.; Rosen, B.G. Surface characterization and analysis of textured injection moulded PC-ABS automotive interior components. Surf. Topogr. Metrol. Prop. 2023, 11, 014003. [Google Scholar] [CrossRef]

- Lewandowski, K.; Skórczewska, K. A Brief Review of Poly(Vinyl Chloride) (PVC) Recycling. Polymers 2022, 14, 3035. [Google Scholar] [CrossRef]

- Elgharbawy, A.S. Poly Vinyl Chloride Additives and Applications—A Review. J. Risk Anal. Crisis Response 2022, 12, 143–151. [Google Scholar] [CrossRef]

- Lieberzeit, P.; Bekchanov, D.; Mukhamediev, M. Polyvinyl chloride modifications, properties, and applications: Review. Polym. Adv. Technol. 2022, 33, 1809–1820. [Google Scholar] [CrossRef]

- Llado, J.; Sanchez, B. Influence of injection parameters on the formation of blush in injection moulding of PVC. J. Mater. Process. Technol. 2008, 204, 1–7. [Google Scholar] [CrossRef]

- Ahmed, T.; Sharma, P.; Karmaker, C.L.; Nasir, S. Warpage prediction of Injection-molded PVC part using ensemble machine learning algorithm. Mater. Today Proc. 2022, 50, 565–569. [Google Scholar] [CrossRef]

- Tsai, H.-H.; Wu, S.-J.; Liu, J.-W.; Chen, S.-H.; Lin, J.-J. Filling-Balance-Oriented Parameters for Multi-Cavity Molds in Polyvinyl Chloride Injection Molding. Polymers 2022, 14, 3483. [Google Scholar] [CrossRef]

- Ali, U.; Karim, K.J.A.; Buang, N.A. A Review of the Properties and Applications of Poly (Methyl Methacrylate) (PMMA). Polym. Rev. 2015, 55, 678–705. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M. PMMA-Based Nanocomposites for Odontology Applications: A State-of-the-Art. Int. J. Mol. Sci. 2022, 23, 10288. [Google Scholar] [CrossRef]

- Moonprasith, N.; Date, J.; Sako, T.; Kida, T.; Hiraoka, T.; Yamaguchi, M. Segregation Behavior of Miscible PC/PMMA Blends during Injection Molding. Materials 2022, 15, 2994. [Google Scholar] [CrossRef] [PubMed]

- Weng, C.; Ding, T.; Zhou, M.; Liu, J.; Wang, H. Formation Mechanism of Residual Stresses in Micro-Injection Molding of PMMA: A Molecular Dynamics Simulation. Polymers 2020, 12, 1368. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Ding, T.; Wang, W.; Liu, J.; Weng, C. Study on the Effect of Processing Parameters on Residual Stresses of Injection Molded Micro-Pillar Array. Polymers 2022, 14, 3358. [Google Scholar] [CrossRef]

- Zafar, M.S. Prosthodontic Applications of Polymethyl Methacrylate (PMMA): An Update. Polymers 2020, 12, 2299. [Google Scholar] [CrossRef] [PubMed]

- Navidfar, A.; Azdast, T.; Ghavidel, A.K. Influence of processing condition and carbon nanotube on mechanical properties of injection molded multi-walled carbon nanotube/poly(methyl methacrylate) nanocomposites. J. Appl. Polym. Sci. 2016, 133, 43738. [Google Scholar] [CrossRef]

- Ogunsona, E.O.; Codou, A.; Misra, M.; Mohanty, A.K. A critical review on the fabrication processes and performance of polyamide biocomposites from a biofiller perspective. Sustainability 2019, 5, 100014. [Google Scholar] [CrossRef]

- Kondo, M.Y.; Montagna, L.S.; Morfado, G.F.; Castilho, A.L.G.; Batista, L.A.; Botelho, E.C.; Costa, M.L.; Passador, F.R.; Rezende, M.C.; Ribeiro, M.V. Recent advances in the use of Polyamide-based materials for the automotive industry. Polimeros 2022, 32. [Google Scholar] [CrossRef]

- Teixeira, D.; Giovanela, M.; Gonella, L.B.; Crespo, J.S. Influence of injection molding on the flexural strength and surface quality of long glass fiber-reinforced polyamide 6.6 composites. Mater. Des. 2015, 85, 695–706. [Google Scholar] [CrossRef]

- Santos, P.A.; Spinace, M.A.S.; Fermoselli, K.K.G.; Paoli, M.A. Polyamide-6/vegetal fiber composite prepared by extrusion and injection molding. Compos. A Appl. Sci. 2007, 38, 2404–2411. [Google Scholar] [CrossRef]

- Yuan, M.; Turng, L.S. Microstructure and mechanical properties of microcellular injection molded polyamide-6 nanocomposites. Polymer 2005, 46, 7273–7292. [Google Scholar] [CrossRef]

- Chow, W.S.; Ishak, Z.A.M.; Karger-Kocsis, J.; Apostolov, A.A.; Ishiaku, U.S. Compatibilizing effect of maleated polypropylene on the mechanical properties and morphology of injection molded polyamide 6/polypropylene/organoclay nanocomposites. Polymer 2003, 44, 7427–7440. [Google Scholar] [CrossRef]

- Chow, W.S.; Ishak, Z.A.M.; Ishiaku, U.S.; Karger-Kocsis, J.; Apostolov, A.A. The effect of organoclay on the mechanical properties and morphology of injection-molded polyamide 6/polypropylene nanocomposites. J. Appl. Polym. Sci 2003, 91, 175–189. [Google Scholar] [CrossRef]

- Yuan, M.; Turng, L.S.; Gong, S.; Caulfield, D.; Hunt, C.; Spindler, R. Study of injection molded microcellular polyamide-6 nanocomposites. Polym. Eng. Sci. 2004, 44, 673–686. [Google Scholar] [CrossRef]

- Sannen, S.; Kezer, J.; Puyvelde, P. The Influence of Melt and Process Parameters on the Quality and Occurrence of Part Defects in Water-assisted Injection Molded Tubes. Int. Polym. Process. 2013, 26, 551–559. [Google Scholar] [CrossRef]

- Kuang, T.; Wang, J.; Liu, H.; Yuan, Z. Effects of Processing Method and Parameters on the Wall Thickness of Gas-Projectile-Assisted Injection Molding Pipes. Polymers 2023, 15, 1985. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.J.; Chen, W.K. Experimental investigation and numerical simulation of cooling process in water assisted injection moulded parts. Macromol. Eng. 2004, 33, 260–266. [Google Scholar] [CrossRef]

- Liu, S.J.; Wu, Y.C. A Novel High Flow-rate Pin for Water-assisted Injection Molding of Plastic Parts with a More Uniform Residual Wall Thickness Distribution. Int. Polym. Proc. 2006, 21, 436–439. [Google Scholar] [CrossRef]

- Protte, R. Water-assist Injection Molding—An Innovative Process Technology for Productivity Improvement. SPE ANTEC Tech. Paper 2003, 24, 404–408. [Google Scholar]

- Liu, S.J.; Chen, Y.S. Water Assisted Injection Molding of Thermoplastic Materials: Effects of Processing Parameters. Polym. Eng. Sci. 2003, 43, 1806–1817. [Google Scholar] [CrossRef]

- Ahmadzai, A.Z.; Vesh, A.H.B. An experimental investigation on water penetration in the process of water assisted injection molding of polypropylene. J Chem. Tech. Polym. Proc. 2009, 54, 7–8. [Google Scholar] [CrossRef]

- Liu, S.J.; Lin, S.P. Factors affecting the formation of fingering in water-assisted injection-molded thermoplastics. Adv. Polym. Technol. 2006, 25, 98–108. [Google Scholar] [CrossRef]

- Liu, S.J.; Shih, C.C. An Experimental Study of the Water-Assisted Injection Molding of PA-6 Composites. J. Reinf. Plast. Compos. 2008, 27, 985–999. [Google Scholar] [CrossRef]

- Liu, S.J.; Lin, M.J.; Wu, Y.C. An experimental study of the water-assisted injection molding of glass fiber filled poly-butylene-terephthalate (PBT) composites. Compos. Sci. Technol. 2007, 67, 1415–1424. [Google Scholar] [CrossRef]

- Oliviera, D.; Mateus, A.; Carriera, P.; Simoes, F.; Malca, C. Water Assisted Injection Molding for Single and Multi-branched Tubular Components. Procedia Manuf. 2017, 12, 141–149. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, G.; Dai, K.; Jia, Z.; Li, S.; Liu, C.; Chen, J.; Shen, C.; Li, Q. Morphological comparison of isotactic polypropylene molded by water-assisted and conventional injection molding. J. Mater. Sci. 2011, 46, 7830–7838. [Google Scholar] [CrossRef]

- Liu, S.; Lin, C.H. An Experimental Study of Water-Assisted Injection Molding of Plastic Tubes with Dimensional Transitions. Mater. Sci. 2007, 26, 1441–1454. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Kmetty, Á.; Lendvai, L.; Drakopoulos, S.X.; Bárány, T. Water-Assisted Production of Thermoplastic Nanocomposites: A Review. Materials 2015, 8, 72–95. [Google Scholar] [CrossRef]

- Zhang, S.; Cao, W.; Zheng, G.; Jia, Z.; Shen, C. Model and Numerical Simulation for the Second Penetration in Water-assisted Injection Molding. Int. Polym. Process 2013, 26, 560–568. [Google Scholar] [CrossRef]

- Ilinca, F.; Hetu, J.F. Three-dimensional finite element solution of gas-assisted injection moulding. Int. J. Numer. Methods Eng. 2001, 53, 2003–2017. [Google Scholar] [CrossRef]

- Li, Q.; Ouyanf, J.; Yang, B.; Li, X. Numerical simulation of gas-assisted injection molding using CLSVOF method. Appl. Math. Model. 2012, 36, 2262–2274. [Google Scholar] [CrossRef]

- Zheng, G.Q.; Huang, L.; Yang, W.; Yang, B.; Yang, M.B.; Li, Q.; Shen, C.Y. Hierarchical crystalline structure of HDPE molded by gas-assisted injection molding. Polymer 2007, 48, 5486–5492. [Google Scholar] [CrossRef]

- Polynkin, A.; Pittman, J.F.T.; Sienz, J. Gas assisted injection molding of a handle: Three-dimensional simulation and experimental verification. Polym. Eng. Sci. 2005, 45, 1049–1058. [Google Scholar] [CrossRef]

- Parvez, M.A.; Ong, N.S.; Lam, Y.C.; Tor, S.B. Gas-assisted injection molding: The effects of process variables and gas channel geometry. J. Mater. Process. Technol. 2002, 121, 27–35. [Google Scholar] [CrossRef]

- Xin, L.L.; Sharif, S.; Saad, R.M. Gas-Assisted Injection Molding: Case Study on Process Optimization of CD-Rom Tray Manufacturing. Procedia Manuf. 2015, 2, 538–542. [Google Scholar] [CrossRef]

- Li, J.; Liu, W.; Xia, X.; Zhou, H.; Jing, L.; Peng, X.; Jiang, S. Reducing the Burn Marks on Injection-Molded Parts by External Gas-Assisted Injection Molding. Polymers 2021, 13, 4087. [Google Scholar] [CrossRef]

- Chen, S.-C.; Lee, K.-H.; Chang, C.-W.; Hsu, T.-J.; Feng, C.-T. Using Gas Counter Pressure and Combined Technologies for Microcellular Injection Molding of Thermoplastic Polyurethane to Achieve High Foaming Qualities and Weight Reduction. Polymers 2022, 14, 2017. [Google Scholar] [CrossRef]

- Olley, P. An approximation to the PTT viscoelastic model for gas assisted injection moulding simulation. J. Non Newton. Fluid Mech. 2020, 278, 104246. [Google Scholar] [CrossRef]

- Suhot, M.A.; Hassan, M.Z.; Aziz, S.A.; Md Daud, M.Y. Recent Progress of Rice Husk Reinforced Polymer Composites: A Review. Polymers 2021, 13, 2391. [Google Scholar] [CrossRef]

- Hou, J.; Zhao, G.; Wang, G.; Dong, G.; Xu, J. A novel gas-assisted microcellular injection molding method for preparing lightweight foams with superior surface appearance and enhanced mechanical performance. Mater. Des. 2017, 127, 115–125. [Google Scholar] [CrossRef]

- Do, T.T.; Uyen, T.M.T.; Minh, P.S. The Feasibility of an Internal Gas-Assisted Heating Method for Improving the Melt Filling Ability of Polyamide 6 Thermoplastic Composites in a Thin Wall Injection Molding Process. Polymers 2021, 13, 1004. [Google Scholar] [CrossRef]

- Giang, N.T.; Minh, P.S.; Son, T.A.; Uyen, T.M.T.; Nguyen, T.-H.; Dang, H.-S. Study on External Gas-Assisted Mold Temperature Control with the Assistance of a Flow Focusing Device in the Injection Molding Process. Materials 2021, 14, 965. [Google Scholar] [CrossRef]

- The Uyen, T.M.; Truong Giang, N.; Do, T.T.; Anh Son, T.; Son Minh, P. External Gas-Assisted Mold Temperature Control Improves Weld Line Quality in the Injection Molding Process. Materials 2020, 13, 2855. [Google Scholar] [CrossRef] [PubMed]

- Ding, Y.; Hassan, M.H.; Bakker, O.; Hinduja, S.; Bártolo, P. A Review on Microcellular Injection Moulding. Materials 2021, 14, 4209. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Dong, G.; Mu, Y.; Park, C.B. Lightweight and strong microcellular injection molded PP/talc nanocomposite. Compos. Sci. Technol. 2018, 168, 38–46. [Google Scholar] [CrossRef]

- Sun, X.; Kharbas, H.; Peng, J.; Turng, L.S. A novel method of producing lightweight microcellular injection molded parts with improved ductility and toughness. Polymer 2015, 56, 102–110. [Google Scholar] [CrossRef]

- Simon, S.A.; Hain, J.; Sracic, M.W.; Tewani, H.R.; Prabhakar, P.; Osswald, T.A. Mechanical Response of Fiber-Filled Automotive Body Panels Manufactured with the Ku-FizzTM Microcellular Injection Molding Process. Polymers 2022, 14, 4916. [Google Scholar] [CrossRef]

- Chen, S.-C.; Jien, M.-Y.; Hsu, C.-C.; Hwang, S.-S.; Feng, C.-T. Processing Effects on the Through-Plane Electrical Conductivities and Tensile Strengths of Microcellular-Injection-Molded Polypropylene Composites with Carbon Fibers. Polymers 2022, 14, 3251. [Google Scholar] [CrossRef]

- Yang, J.; Xie, J.; Ji, K.; Wang, X.; Jiao, X.; Xu, Z.; Zhao, P. Effect of mold opening on microcellular polyether-ether-ketone fabricated by injection molding. J. Mater. Res. Technol. 2022, 19, 1678–1689. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, J.; Wang, G.; Jiang, L.; Meng, X.; Zhao, G. Microcellular injection molded lightweight, strong and thermally insulating PP/fibrillated-PTFE composite foams with enhanced surface appearance. J. Mater. Res. Technol. 2023, 22, 2933–2943. [Google Scholar] [CrossRef]

- Guzel, K.; Zagres, J.C.; Heim, H.P. In-situ full-field deformation analysis of injection-molded microcellular polycarbonate according to foam morphology patterns. Polym. Test. 2023, 124, 108102. [Google Scholar] [CrossRef]

- Chai, J.; Wang, G.; Zhang, A.; Dong, G.; Li, S.; Shao, J.; Shao, G. Microcellular injection molded lightweight and tough poly (L-lactic acid)/in-situ polytetrafluoroethylene nanocomposite foams with enhanced surface quality and thermally-insulating performance. Int. J. Biol. Macromol. 2022, 215, 57–66. [Google Scholar] [CrossRef] [PubMed]

- Zhao, J.; Wang, G.; Chen, Z.; Huang, Y.; Wang, C.; Zhang, A.; Park, C.B. Microcellular injection molded outstanding oleophilic and sound-insulating PP/PTFE nanocomposite foam. Compos. B Eng. 2021, 215, 108786. [Google Scholar] [CrossRef]

- Hou, J.; Zhao, G.; Wang, G. Polypropylene/talc foams with high weight-reduction and improved surface quality fabricated by mold-opening microcellular injection molding. J. Mater. Res. Technol. 2021, 12, 74–86. [Google Scholar] [CrossRef]

- Yang, C.; Wang, G.; Zhao, J.; Zhao, G.; Zhang, A. Lightweight and strong glass fiber reinforced polypropylene composite foams achieved by mold-opening microcellular injection molding. J. Mater. Res. Technol. 2021, 14, 2920–2931. [Google Scholar] [CrossRef]

- Guo, W.; Yu, Z.; Wei, W.; Meng, Z.; Mao, H.; Hua, L. Effect of film types on thermal response, cellular structure, forming defects and mechanical properties of combined in-mold decoration and microcellular injection molding parts. J. Mater. Res. Technol. 2021, 92, 98–108. [Google Scholar] [CrossRef]

- Yang, Q.; Guo, W.; Meng, Z.; Mao, H.; Hua, L.; Liu, Y. Investigation on forming defects and crystallization of plastic parts in combined in-mold decoration and microcellular injection molding based on a multiphase flow-solid coupled heat transfer model. Int. J. Heat Mass Transf. 2020, 151, 119285. [Google Scholar] [CrossRef]

- Wang, L.; Hikima, Y.; Ishihara, S.; Ohshima, M. Fabrication of lightweight microcellular foams in injection-molded polypropylene using the synergy of long-chain branches and crystal nucleating agents. Polymer 2017, 128, 119–127. [Google Scholar] [CrossRef]

- Yang, J.; Xie, J.; Wang, X.; Jiao, X.; Xu, Z.; Zhao, P. Microcellular injection molding of polyether-ether-ketone. Polymer 2022, 215, 124866. [Google Scholar] [CrossRef]

- Liu, Y.; Guan, Y.; Hu, G.; Zhai, J.; Chen, F.; Lin, J. Study on properties of BF/PP composites and plastic parts manufacturing by mold opening foaming injection molding. Compos. Struct. 2023, 321, 117295. [Google Scholar] [CrossRef]

- Lee, J.; Turning, L.S.; Dougherty, E.; Gorton, P. A novel method for improving the surface quality of microcellular injection molded parts. Polymer 2011, 52, 1436–1446. [Google Scholar] [CrossRef]

- Yu, S.; Kong, W.; Xu, L.; Zou, J.; Han, W.; Liu, Z.; Luo, J.; Xie, Z.; Wu, H.; Zhou, H. Cellular distribution and warpage deformation in double-sided in-mold decoration combined with microcellular injection molding process. J. Mater. Process. Technol. 2023, 317, 117982. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Li, H.; Guan, Y. Research on optimization design of the heating/cooling channels for rapid heat cycle molding based on response surface methodology and constrained particle swarm optimization. Expert Syst. Appl. 2011, 38, 6705–6719. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Li, H.; Guan, Y. Multi-objective optimization design of the heating/cooling channels of the steam-heating rapid thermal response mold using particle swarm optimization. Int. J. Therm. Sci. 2011, 50, 790–802. [Google Scholar] [CrossRef]

- Xiao, C.L.; Huang, H.X. Development of a rapid thermal cycling molding with electric heating and water impingement cooling for injection molding applications. Appl. Therm. Eng. 2014, 73, 712–722. [Google Scholar] [CrossRef]

- Liparoti, S.; Sorrentino, A.; Titomanlio, G. Temperature and pressure evolution in fast heat cycle injection molding. Mat. Manuf. Proc. 2019, 34, 422–430. [Google Scholar] [CrossRef]

- Huang, M.S.; Tai, N.S. Experimental Rapid Surface Heating by Induction for Micro−Injection Molding of Light−Guided Plates. J. Appl. Polym. Sci. 2009, 113, 1345–1354. [Google Scholar] [CrossRef]

- Chen, S.C.; Lin, Y.W.; Chein, R.; Li, H.M. Variable mold temperature to improve surface quality of microcellular injection molded parts using induction heating technology. Adv. Polym. Technol. 2009, 27, 224–232. [Google Scholar] [CrossRef]

- Fischer, C.; Jungmeier, A.; Petres, G.; Drummer, D. Influence of a locally variable mold temperature on injection molded thin-wall components. J. Polym. Eng. 2018, 38, 475–481. [Google Scholar] [CrossRef]

- Wang, Y.; Lee, C. Design and Optimization of Conformal Cooling Channels for Increasing Cooling Efficiency in Injection Molding. Appl. Sci. 2023, 13, 7437. [Google Scholar] [CrossRef]

- Chauhan, V.; Kärki, T.; Varis, J. Optimization of Compression Molding Process Parameters for NFPC Manufacturing Using Taguchi Design of Experiment and Moldflow Analysis. Processes 2021, 9, 1853. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, G.; Wang, G. Formation mechanism of porous structure in plastic parts injected by microcellular injection molding technology with variable mold temperature. Appl. Therm. Eng. 2017, 114, 484–497. [Google Scholar] [CrossRef]

- Giboz, J.; Copponnex, T.; Mele, P. Microinjecition molding of thermoplastic polymers: A review. J. Micromech. Microeng. 2007, 17, 96–106. [Google Scholar] [CrossRef]

- Gao, P.; MacKay, I.; Gruber, A.; Krantz, J.; Piccolo, L.; Lucchetta, G.; Pelaccia, R.; Orazi, L.; Masato, D. Wetting Characteristics of Laser-Ablated Hierarchical Textures Replicated by Micro Injection Molding. Micromachines 2023, 14, 863. [Google Scholar] [CrossRef]

- Ruehl, H.; Guenther, T.; Zimmermann, A. Direct Processing of PVD Hard Coatings via Focused Ion Beam Milling for Microinjection Molding. Micromachines 2023, 14, 294. [Google Scholar] [CrossRef] [PubMed]

- Jiang, S.; Zhang, Y.; Ma, H.; Zha, X.; Peng, X.; Li, J.; Lu, C. Effects of Cavity Thickness on the Replication of Micro Injection Molded Parts with Microstructure Array. Polymers 2022, 14, 5471. [Google Scholar] [CrossRef]

- Babenko, M.; Sweeney, J.; Petkov, P.; Lacan, F.; Bigot, S.; Whiteside, B. Evaluation of heat transfer at the cavity-polymer interface in microinjection moulding based on experimental and simulation study. Appl. Therm. Eng. 2018, 130, 865–876. [Google Scholar] [CrossRef]

- Chang, P.C.; Hwang, S.J.; Lee, H.H.; Huangg, D.Y. Development of an external-type microinjection molding module for thermoplastic polymer. J. Mater. Process. Technol. 2007, 184, 163–172. [Google Scholar] [CrossRef]

- Zhang, N.; Su, Q.; Choi, S.Y.; Gilchrist, M.D. Effects of gate design and cavity thickness on filling, morphology and mechanical properties of microinjection mouldings. Mater. Des. 2015, 83, 835–847. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, Y.; Tan, J.; Feng, S.; Xie, Y.; Li, L. Performance Enhancement of PLA-Based Blend Microneedle Arrays through Shish-Kebab Structuring Strategy in Microinjection Molding. Polymers 2023, 15, 2234. [Google Scholar] [CrossRef]

- Yu, W.; Gu, J.; Li, Z.; Ruan, S.; Chen, B.; Shen, C.; Lee, L.J.; Wang, X. Study on the Influence of Microinjection Molding Processing Parameters on Replication Quality of Polylactic Acid Microneedle Array Product. Polymers 2023, 15, 1199. [Google Scholar] [CrossRef]

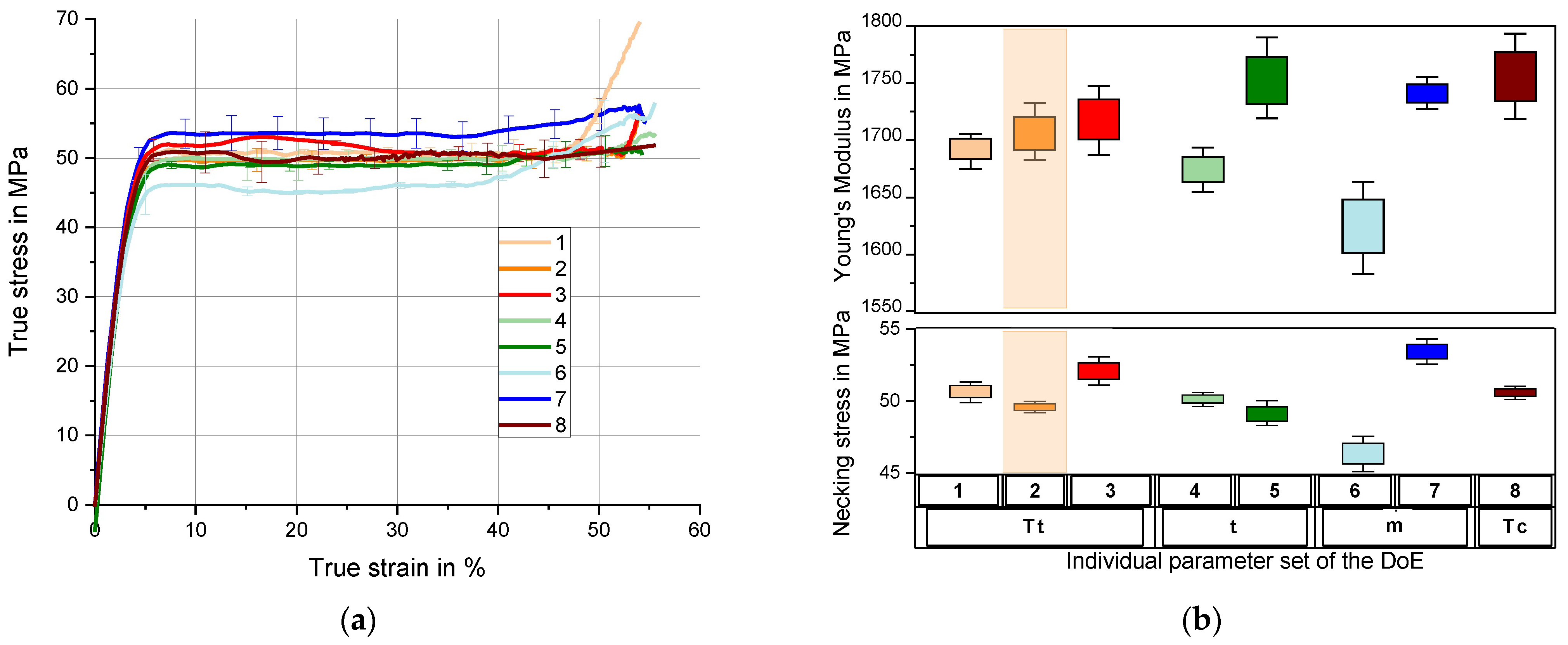

- Erben, J.; Blatonova, K.; Kalous, T.; Capek, L.; Behalek, L.; Boruvka, M.; Chvojka, J. The Injection Molding of Biodegradable Polydioxanone—A Study of the Dependence of the Structural and Mechanical Properties on Thermal Processing Conditions. Polymers 2022, 14, 5528. [Google Scholar] [CrossRef] [PubMed]

- Wu, W.; He, X.; Li, B.; Shan, Z. An Effective Shrinkage Control Method for Tooth Profile Accuracy Improvement of Micro-Injection-Molded Small-Module Plastic Gears. Polymers 2022, 14, 3114. [Google Scholar] [CrossRef] [PubMed]

- Lin, W.-C.; Fan, F.-Y.; Huang, C.-F.; Shen, Y.-K.; Wang, L. Analysis of Melt Front Behavior of a Light Guiding Plate during the Filling Phase of Micro-Injection Molding. Polymers 2022, 14, 3077. [Google Scholar] [CrossRef] [PubMed]

- Uyen, T.M.T.; Do, T.T.; Minh, P.S. Internal Gas-Assisted Mold Temperature Control for Improving the Filling Ability of Polyamide 6 + 30% Glass Fiber in the Micro-Injection Molding Process. Polymers 2022, 14, 2218. [Google Scholar] [CrossRef] [PubMed]

- Weng, C.; Tang, Q.; Li, J.; Nie, L.; Zhai, Z. Application and Optimization of the Thin Electric Heater in Micro-Injection Mold for Micropillars. Nanomaterials 2022, 12, 1751. [Google Scholar] [CrossRef]

- Wu, A.; Pan, L.; Li, B.; He, X.; Jiang, B. Plastic rod as a promising feed material for enhanced performance of ultrasonic plasticization microinjection molding: Plasticization rate, mechanical and thermal properties. Polym. Test. 2023, 118, 107909. [Google Scholar] [CrossRef]

- Zhang, H.; Zhang, N.; Han, W.; Gilchrist, M.; Fang, F. Precision replication of microlens arrays using variotherm-assisted microinjection moulding. Precis. Eng. 2021, 67, 248–261. [Google Scholar] [CrossRef]

- Giboz, J.; Dubelley, F.; Carrier, S.; Tenchine, L.; Molmeret, Y.; Mele, P. Real-time analysis of polymer flow under real processing conditions applied to microinjection molding. J. Manuf. Process 2022, 75, 565–572. [Google Scholar] [CrossRef]

- Liu, Z.; Liu, X.; Li, L.; Zheng, G.; Liu, C.; Qin, Q.; Mi, L. Crystalline structure and remarkably enhanced tensile property of β-isotactic polypropylene via overflow microinjection molding. Polym. Test. 2019, 76, 448–454. [Google Scholar] [CrossRef]

- Scantamburlo, A.; Zanini, F.; Lucchetta, G.; Sorgato, M. Improving the weld lines mechanical properties by combining alternate dynamic packing and rapid heat cycle moulding. Compos. A Appl. Sci. Manuf. 2022, 136, 107239. [Google Scholar] [CrossRef]

- Guilong, W.; Guoqun, Z.; Huiping, L.; Yanjin, G. Analysis of thermal cycling efficiency and optimal design of heating/cooling systems for rapid heat cycle injection molding process. Mater. Des. 2010, 31, 3426–3441. [Google Scholar] [CrossRef]

- Xiao, C.L.; Hahve, C.; Fu, C.M. Multi-objective optimization of heating system for rapid thermal cycling molding mold with internal induction heating. SN Appl. Sci. 2011, 3, 673–687. [Google Scholar] [CrossRef]

- Liparoti, S.; Speranza, V.; Titomanlio, G.; Pantani, R. Effect of Rapid Mold Heating on the Structure and Performance of Injection-Molded Polypropylene. Polymers 2020, 12, 341. [Google Scholar] [CrossRef]

- Yao, D.; Chen, S.C.; Kim, B.H. Rapid thermal cycling of injection molds: An overview on technical approaches and applications. Adv. Polym. Technol. 2009, 27, 233–255. [Google Scholar] [CrossRef]

- Huzaim, N.H.M.; Rahim, S.Z.A.; Musa, L.; Abdellah, A.E.-h.; Abdullah, M.M.A.B.; Rennie, A.; Rahman, R.; Garus, S.; Błoch, K.; Sandu, A.V.; et al. Potential of Rapid Tooling in Rapid Heat Cycle Molding: A Review. Materials 2022, 15, 3725. [Google Scholar] [CrossRef]

- Zhang, M.; Xin, Y. Molecular Mechanism Research into the Replication Capability of Nanostructures Based on Rapid Heat Cycle Molding. Appl. Sci. 2019, 9, 1683. [Google Scholar] [CrossRef]

- Li, J.; Bei, J.; Liu, W.; Xia, X.; Zhou, B.; Peng, X.; Jiang, S. Warpage Prediction of RHCM Crystalline Parts Based on Multi-Layers. Polymers 2021, 13, 1814. [Google Scholar] [CrossRef]

- Xiao, C.L.; Huang, H.X.; Yang, X. Development and application of rapid thermal cycling molding with electric heating for improving surface quality of microcellular injection molded parts. Appl. Therm. Eng. 2016, 100, 478–489. [Google Scholar] [CrossRef]

- Xie, P.; Yang, H.; Zhao, Y.; Yu, W.; Cheng, L.; Yang, W.; Yan, H.; Tan, J. Carbide-bonded graphene coating of mold insert for rapid thermal cycling in injection molding. Appl. Therm. Eng. 2017, 122, 19–26. [Google Scholar] [CrossRef]

- Crema, L.; Sorgato, M.; Luchcetta, G. Thermal optimization of deterministic porous mold inserts for rapid heat cycle molding. Int. J. Heat Mass Transf. 2017, 109, 462–469. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, G.; Li, H.; Guan, Y. Research of thermal response simulation and mold structure optimization for rapid heat cycle molding processes, respectively, with steam heating and electric heating. Mater. Des. 2010, 31, 382–395. [Google Scholar] [CrossRef]

- Piotter, V.; Holstein, N.; Plewa, K.; Ruprecht, R.; Hausselt, J. Replication of micro components by different variants of injection molding. Microsyst. Technol. 2004, 10, 547–551. [Google Scholar] [CrossRef]

- Huang, C.T.; Yeh, C.H.; Tseng, S.C. Geometrical effect and material selelction in multi-component molding (MCM) development. ANTEC 2006, 103493. [Google Scholar]

- Park, H.S.; Anh, D.H. A new approach for molding multi component parts. IJPEM 2010, 11, 291–297. [Google Scholar] [CrossRef]

- Farias, M.A.; Amico, S.C.; Coelho, L.A.F.; Pezzin, S.H. Multi-component nanocomposites of epoxy/silsesquioxane reinforced with carbon fibers and carbon nanotubes processed by resin transfer molding. Polym. Plast. Technol. Mater. 2020, 59, 517–526. [Google Scholar] [CrossRef]

- Scheneider, D.; Hubner, C.; Bourbigot, S. New approach for the efficient attainment of flame retardancy using multi component injection molding. AIP Conf. Proc. 2019, 2055, 070007. [Google Scholar]

- Haberstroh, E.; Lettowsky, C. Multi-component injection moulding of liquid silicone rubber/thermoplastic-combinations. J. Polym. Eng. 2004, 24, 203–214. [Google Scholar] [CrossRef]

- Haberstroh, E.; Ronnewinkel, C. LSR thermoplastic combination parts in two-component injection molding. J. Polym. Eng. 2001, 21, 303–318. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, J.; Zhou, Y.; Saitou, K. Multi-component topology optimization for die casting (MTO-D). Struct. Multidiscip. Optim. 2019, 60, 2265–2279. [Google Scholar] [CrossRef]

- Piotter, V.; Prokop, J.; Ritzhaupt-Kleissl, H.J.; Ruh, A.; Hausselt, J. Multi-component microinjection moulding-trends and developments. J. Adv. Manuf. Technol. 2010, 47, 63–71. [Google Scholar] [CrossRef]

- Bahanan, W.; Fatimah, S.; Song, H.; Lee, E.H.; Kim, D.-J.; Yang, H.W.; Woo, C.H.; Ryu, J.; Widiantara, I.P.; Ko, Y.G. Moldflow Simulation and Characterization of Pure Copper Fabricated via Metal Injection Molding. Materials 2023, 16, 5252. [Google Scholar] [CrossRef] [PubMed]

- Widiantara, I.P.; Putri, R.A.K.; Han, D.I.; Bahanan, W.; Lee, E.H.; Woo, C.H.; Kang, J.-H.; Ryu, J.; Ko, Y.G. Characterization of Green Part of Steel from Metal Injection Molding: An Analysis Using Moldflow. Materials 2023, 16, 2516. [Google Scholar] [CrossRef]

- German, R.M. Progress in Titanium Metal Powder Injection Molding. Materials 2013, 6, 3641–3662. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Duretek, I.; Kukla, C.; Poljšak, A.; Bek, M.; Emri, I.; Holzer, C. Models to Predict the Viscosity of Metal Injection Molding Feedstock Materials as Function of Their Formulation. Metals 2016, 6, 129. [Google Scholar] [CrossRef]

- Viswanath, D.S.; Ghosh, T.K.; Prasad, D.H.; Dutt, N.V.K.; Rani, K.Y. Viscosity of solutions and mixtures. In Viscosity of Liquids—Theory, Estimation, Experiment, and Data, 1st ed.; Viswanath, D.S., Ghosh, T.K., Prasad, D.H., Dutt, N.V.K., Rani, K.Y., Eds.; Springer: Dordrecht, The Netherlands, 2007; pp. 407–434. [Google Scholar]

- Royer, A.; Barrière, T.; Gelin, J.-C. Development and Characterization of a Metal Injection Molding Bio Sourced Inconel 718 Feedstock Based on Polyhydroxyalkanoates. Metals 2016, 6, 89. [Google Scholar] [CrossRef]

- Ibrahim, M.H.I.; Mohd Amin, A.; Asmawi, R.; Mustafa, N. Influences of Restaurant Waste Fats and Oils (RWFO) from Grease Trap as Binder on Rheological and Solvent Extraction Behavior in SS316L Metal Injection Molding. Metals 2016, 6, 19. [Google Scholar] [CrossRef]

- Yang, D.-Y.; Kim, Y.; Hur, M.Y.; Lee, H.J.; Kim, Y.-J.; Lim, T.-S.; Kim, K.-B.; Yang, S. Control of the Nano-Particle Weight Ratio in Stainless Steel Micro and Nano Powders by Radio Frequency Plasma Treatment. Metals 2015, 5, 2058–2069. [Google Scholar] [CrossRef]

- Lu, Z.; Huang, Z.; Jiang, S.; Liu, W.; Zhang, K. Influencing Factors for the Microstructure and Mechanical Properties of Micro Porous Titanium Manufactured by Metal Injection Molding. Metals 2016, 6, 83. [Google Scholar] [CrossRef]

- Lin, C.-M.; Wu, J.-J.; Tan, C.-M. Processing Optimization for Metal Injection Molding of Orthodontic Braces Considering Powder Concentration Distribution of Feedstock. Polymers 2020, 12, 2635. [Google Scholar] [CrossRef]

- Wolff, M.; Schaper, J.G.; Suckert, M.R.; Dahms, M.; Feyerabend, F.; Ebel, T.; Willumeit-Römer, R.; Klassen, T. Metal Injection Molding (MIM) of Magnesium and Its Alloys. Metals 2016, 6, 118. [Google Scholar] [CrossRef]

- Wittemann, F.; Maertens, R.; Bernath, A.; Hohberg, M.; Kärger, L.; Henning, F. Simulation of Reinforced Reactive Injection Molding with the Finite Volume Method. J. Compos. Sci. 2018, 2, 5. [Google Scholar] [CrossRef]

- Tran, N.T.; Seefried, A.; Gehde, M. Investigation of the Influence of Fiber Content, Processing Conditions and Surface Roughness on the Polymer Filling Behavior in Thermoset Injection Molding. Polymers 2023, 15, 1244. [Google Scholar] [CrossRef]

- Nagel, J.; Heinrich, G. Temperature transitions on the surface of a thermoplastic melt during injection moulding and its use for chemical reactions. Int. J. Heat Mass Transf. 2012, 55, 6890–6896. [Google Scholar] [CrossRef]

- Gomes, N.; Fonte, C.P.; Sousa, C.C.; Mateus, A.J.; Bartolo, P.J.; Dias, M.M.; Lopes, J.C.; Santos, R.J. Real time control of mixing in Reaction Injection Moulding. Chem. Eng. Res. Des. 2016, 105, 31–43. [Google Scholar] [CrossRef]

- Seo, D.; Youn, J.R. Numerical analysis on reaction injection molding of polyurethane foam by using a finite volume method. Polymer 2005, 46, 6482–6493. [Google Scholar] [CrossRef]

- Yacoub, F.; MacGregor, J.F. Analysis and optimization of a polyurethane reaction injection molding (RIM) process using multivariate projection methods. Chemometr. Intell. Lab. Syst. 2003, 65, 17–33. [Google Scholar] [CrossRef]

- Lehmenkühler, P.; Stommel, M. Influence of the Reaction Injection Moulding Process on the Thermomechanical Behaviour of Fast Curing Polyurethane. J. Manuf. Mater. Process. 2022, 6, 53. [Google Scholar] [CrossRef]

- Pun, K.F.; Hui, I.K.; Lewis, W.G.; Lau, H.C.W. A multiple-criteria environmental impact assessment for the plastic injection molding process: A methodology. J. Clean. Prod. 2003, 11, 41–49. [Google Scholar] [CrossRef]

- Elduque, A.; Javierre, C.; Elduque, D.; Fernández, Á. LCI Databases Sensitivity Analysis of the Environmental Impact of the Injection Molding Process. Sustainability 2015, 7, 3792–3800. [Google Scholar] [CrossRef]

- Bordon, P.; Elduque, D.; Paz, R.; Javierre, C.; Kusic, D.; Monzon, M. Analysis of processing and environmental impact of polymer compounds reinforced with banana fiber in an injection molding process. J. Clean. Prod. 2022, 379, 134476. [Google Scholar] [CrossRef]

- Elduque, A.; Elduque, D.; Claveria, I.; Jacierre, C. Influence of material and injection molding machine’s selection on the electricity consumption and environmental impact of the injection molding process: An experimental approach. Int. J. Precis. Eng. Manuf. Green Technol. 2018, 5, 13–28. [Google Scholar] [CrossRef]

- Roufi, K.; Manoharan, S.; Etheridge, T.; Paul, B.K.; Haapala, K.R. Cost and Environmental Impact Assessment of Stainless Steel Microreactor Plates using Binder Jetting and Metal Injection Molding Processes. Procedia Manuf. 2020, 48, 311–319. [Google Scholar] [CrossRef]

- Choi, A.C.K.; Haebernick, H.; Lai, W.H. Manufacturing processes modelling for environmental impact assessment. J. Mater. Process. Technol. 1997, 70, 231–238. [Google Scholar] [CrossRef]

- Matarrese, P.; Fontana, A.; Srlini, M.; Diviani, L.; Specht, I.; Maggi, A. Estimating energy consumption of injection moulding for environmental-driven mould design. J. Clean. Prod. 2017, 168, 1505–1512. [Google Scholar] [CrossRef]

- Guinee, J.; Gorree, M.; Heijungs, R.; Hyppes, G.; Kleijn, R.; Koning, A.; Huijbregts, M. Handbook on Life Cycle Assessment Operational Guide to the ISO Standards; Part III: Scientific Background; Kluwer Academic Publishers: Doedrecht, The Netherlands, 2002. [Google Scholar]

- Czap, N.V.; Czap, H.J. An experimental investigation of revealed environmental concern. Ecol. Econ. 2010, 69, 2033–2041. [Google Scholar] [CrossRef]

- Plastic Europe. Plastics—The Fact 2013, an Analysis of European Latest Plastics Production, Demand and Waste Data; Plastic Europe: Brussels, Belgium, 2013. [Google Scholar]

- Yam, R.; Mak, D. A cleaner production of rice husk-blended polypropylene ecocomposite by gas-assisted injection molding. J. Clean. Prod. 2014, 62, 277–284. [Google Scholar] [CrossRef]

- Lucchetta, G.; Bariani, P.F. Sustainable design of injection moulded parts by material intensity reduction. CIRP Ann. 2010, 59, 33–36. [Google Scholar] [CrossRef]

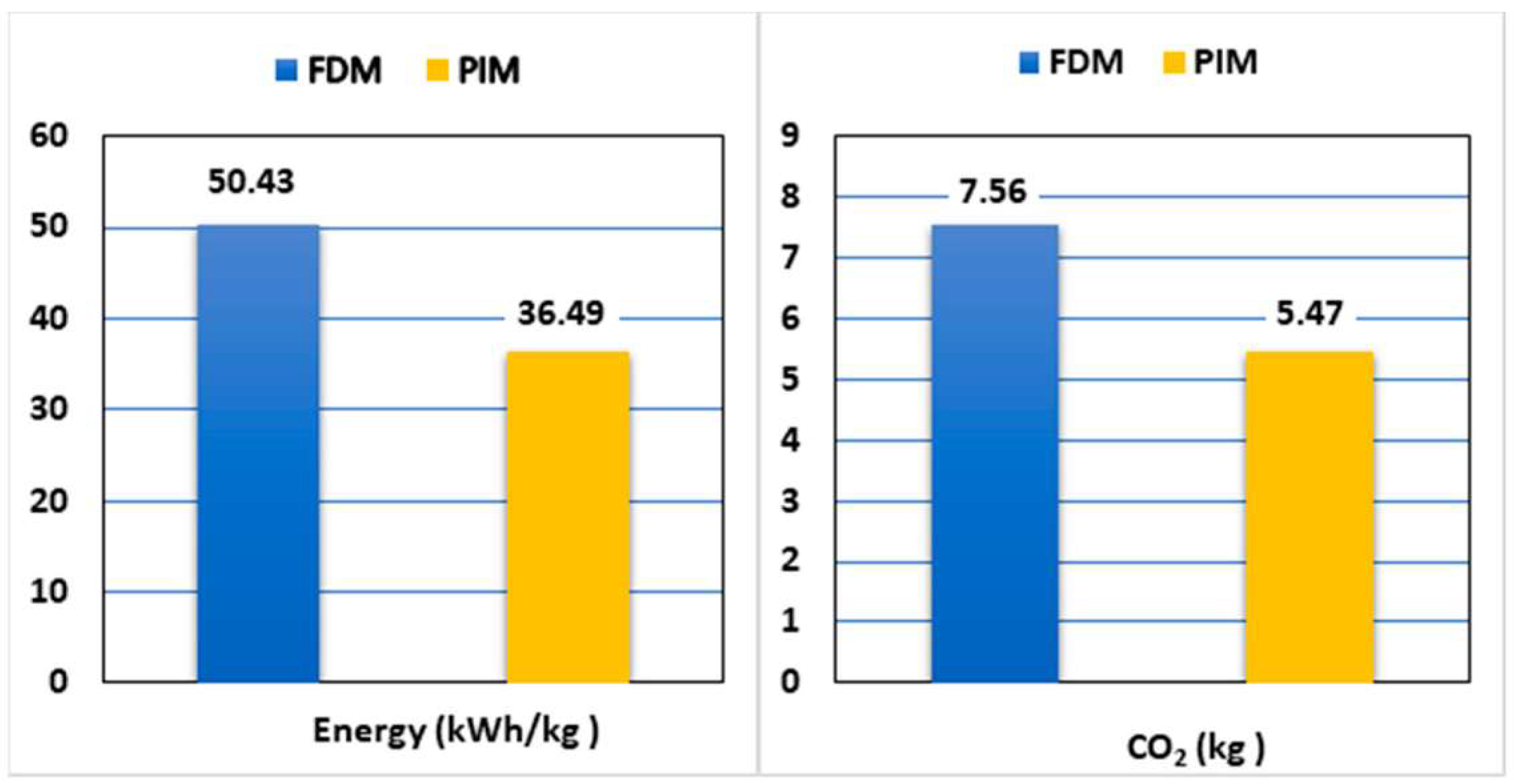

- Enemuoh, E.U.; Menta, V.G.; Abutunis, A.; O’Brien, S.; Kaya, L.I.; Rapinac, J. Energy and Eco-Impact Evaluation of Fused Deposition Modeling and Injection Molding of Polylactic Acid. Sustainability 2021, 13, 1875. [Google Scholar] [CrossRef]

| Parameters | Low Level | High Level |

|---|---|---|

| Melt injection time | 1 s | 3 s |

| Gas delay time | 1 s | 3 s |

| Melt temperature | 220 °C | 240 °C |

| Mold temperature | 50 °C | 70 °C |

| Gas injection pressure | 5 MPa | 7 MPa |

| Processing Parameters | Material | |

|---|---|---|

| PP | PMMA | |

| Shot size (mm) | 10 | 10 |

| Nozzle temperature (°C) | 230 | 230 |

| Injection velocity (mm/s) | 158 | 158 |

| Packing pressure (MPa) | 130 | 130 |

| Packing time (s) | 3 | 3 |

| Mold temperature (°C) | 80 | 80 |

| Cooling time (s) | 30 | 25 |

| Injection Molding Method | References |

|---|---|

| Water-assisted injection molding | [97,98,99,100,101,102,103,104,105,106,107,108,109,110,111] |

| Gas-assisted injection molding | [112,113,114,115,116,117,118,119,120,121,122,123,124,125] |

| Microcellular injection molding | [126,127,128,129,130,131,132,133,134,135,136,137,138,139,140,141,142,143,144] |

| Variable mold temperature technologies | [145,146,147,148,149,150,151,152,153,154] |

| Microinjection molding | [155,156,157,158,159,160,161,162,163,164,165,166,167,168,169,170,171,172] |

| Rapid thermal cycling molding | [173,174,175,176,177,178,179,180,181,182,183,184] |

| Multicomponent injection molding | [185,186,187,188,189,190,191,192,193] |

| Metal injection molding | [194,195,196,197,198,199,200,201,202,203,204] |

| Reaction injection molding | [205,206,207,208,209,210,211] |

| Method | Disadventage | Adventage | Application |

|---|---|---|---|

| WAIM | Not for multicavity molds and transparent parts. | Thiner walls, better surface quality. | Pipes, chers, and rattan baskets. |

| GAIM | Complicated rheology model and mold. | Reduce warpage, lower clamping force, thin wall. Reduce cost of raw material. | Lightwidth products. |

| Microcellular IM | Aspect | Reduce mass and material consumption, enviromental friendly. | Aviation, automotive, and medical industries. |

| VMTT | Cost of equpment, longe cycle time. | Very good quality product. | Automotive, households. |

| MM | Parting line and degating issue. | Able to produce 0.1 g components. | Microbearings and pistons, biodegradable implants, endoscopics, and surgery. |

| RTCM | Long cycle time. | Good quality. | High gloss elements. |

| Multicomponent | Complicated mold and injection machine. | Multicolor and multifunction elements. | Swimming googles, protectors, elements for the car body, table tennis racket |

| Metal IM | High initial investment, size of parts. | Wide range of complicated shapes is able to produce. | commercial, medical, dental, and firearms industry. |

| RIM | Slow cycle time, expensive row matelials. | High density surface on low density core. | Automotive bumpers, spoilers, and fenders. |

| Parameter | Specification |

|---|---|

| Nozzle diameter | 0.4 mm |

| Outer shell speed | 15 mm/s |

| 100% infill speed | 50 mm/s |

| Speed without extrusion | 80 mm/s |

| Material flow rate | 2.5 mm3/s |

| Factor | Level |

|---|---|

| Injection pressure | 25.5 MPa |

| Nozzle temperature | 185 °C |

| Barrel temperature | 176.7 °C |

| Plate temperature | 121.1 °C |

| Injection time | 11 s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Czepiel, M.; Bańkosz, M.; Sobczak-Kupiec, A. Advanced Injection Molding Methods: Review. Materials 2023, 16, 5802. https://doi.org/10.3390/ma16175802

Czepiel M, Bańkosz M, Sobczak-Kupiec A. Advanced Injection Molding Methods: Review. Materials. 2023; 16(17):5802. https://doi.org/10.3390/ma16175802

Chicago/Turabian StyleCzepiel, Mateusz, Magdalena Bańkosz, and Agnieszka Sobczak-Kupiec. 2023. "Advanced Injection Molding Methods: Review" Materials 16, no. 17: 5802. https://doi.org/10.3390/ma16175802

APA StyleCzepiel, M., Bańkosz, M., & Sobczak-Kupiec, A. (2023). Advanced Injection Molding Methods: Review. Materials, 16(17), 5802. https://doi.org/10.3390/ma16175802