Full Characterization of Self-Compacting Concrete Containing Recycled Aggregates and Limestone

Abstract

:1. Introduction

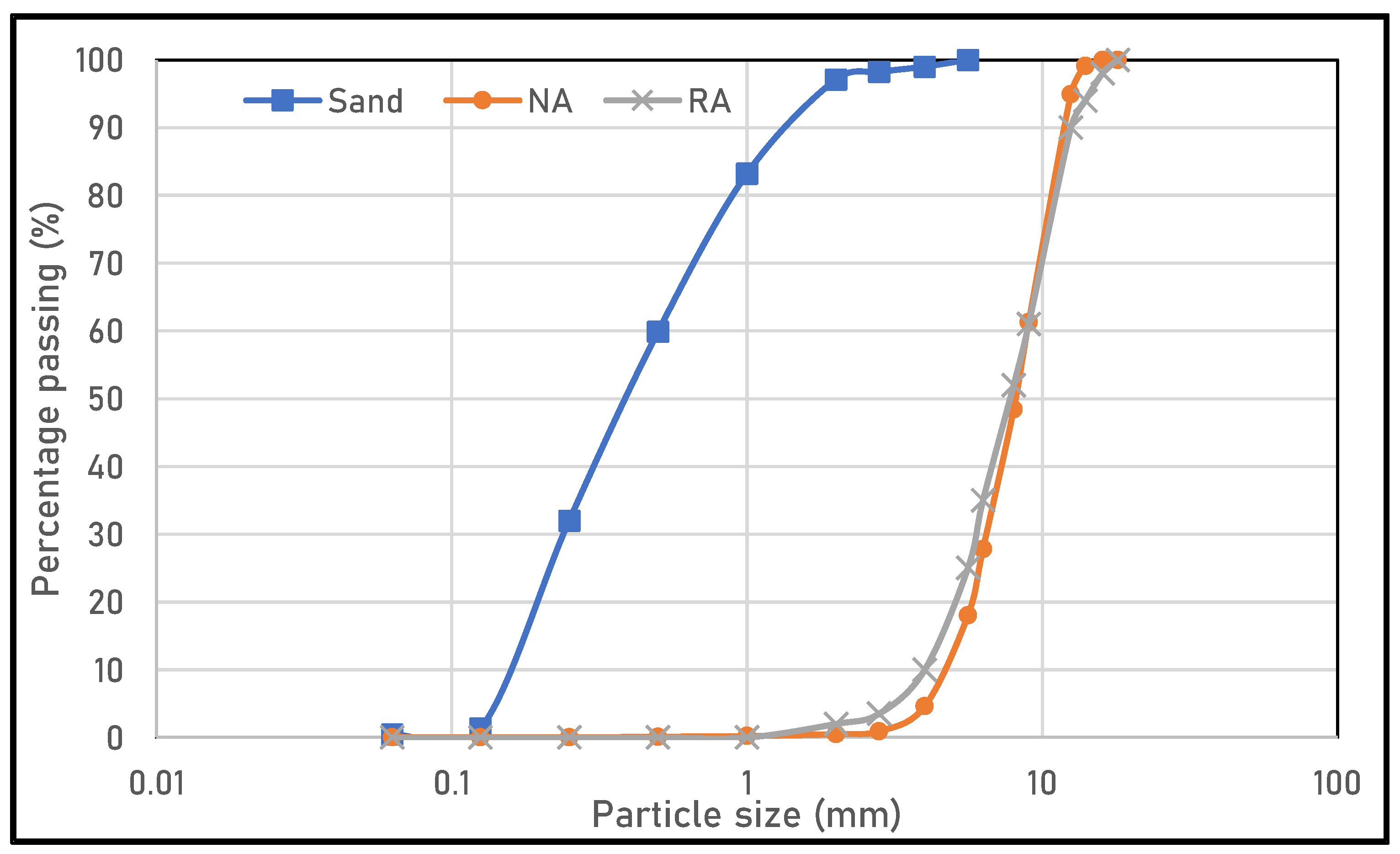

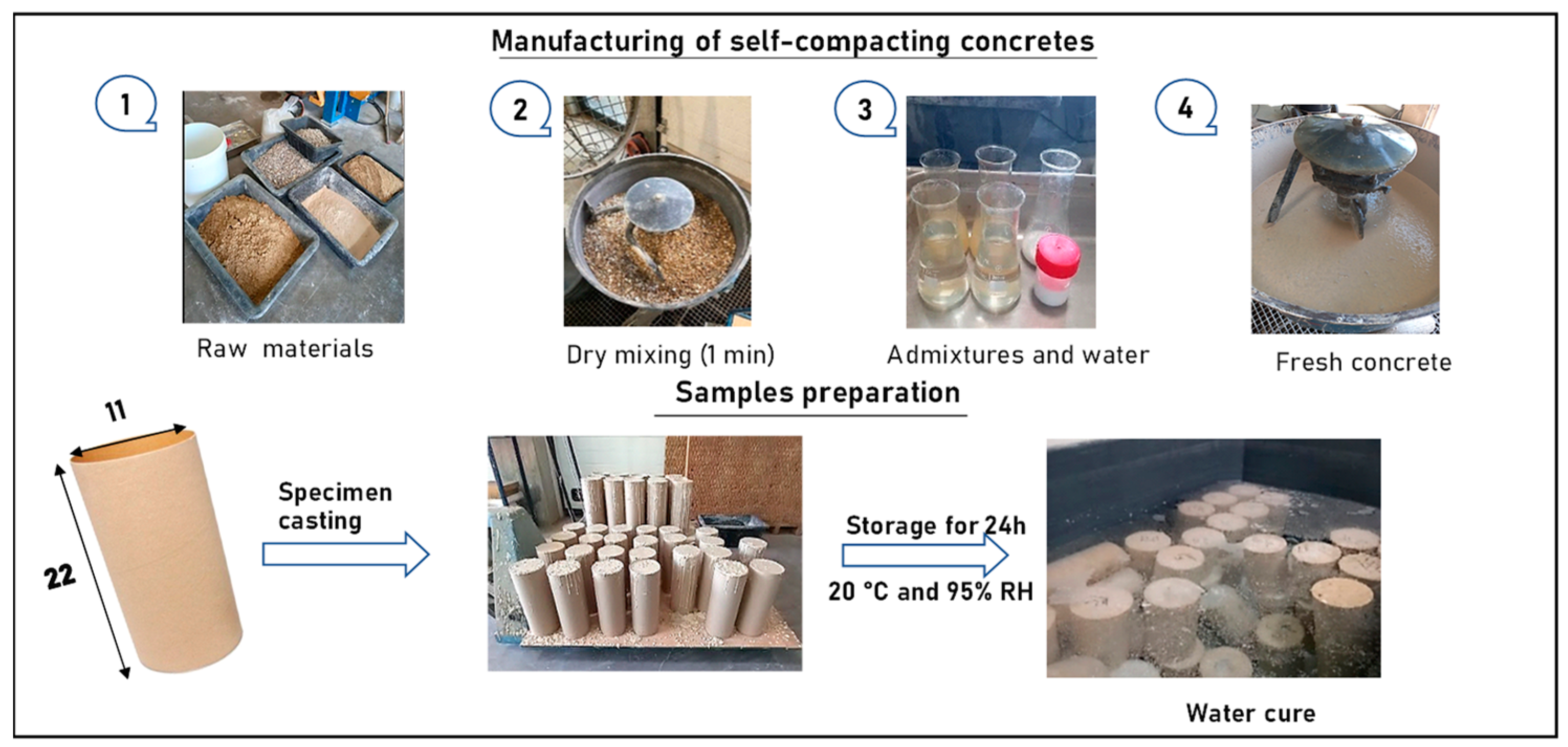

2. Materials and Methods

3. Results and Discussion

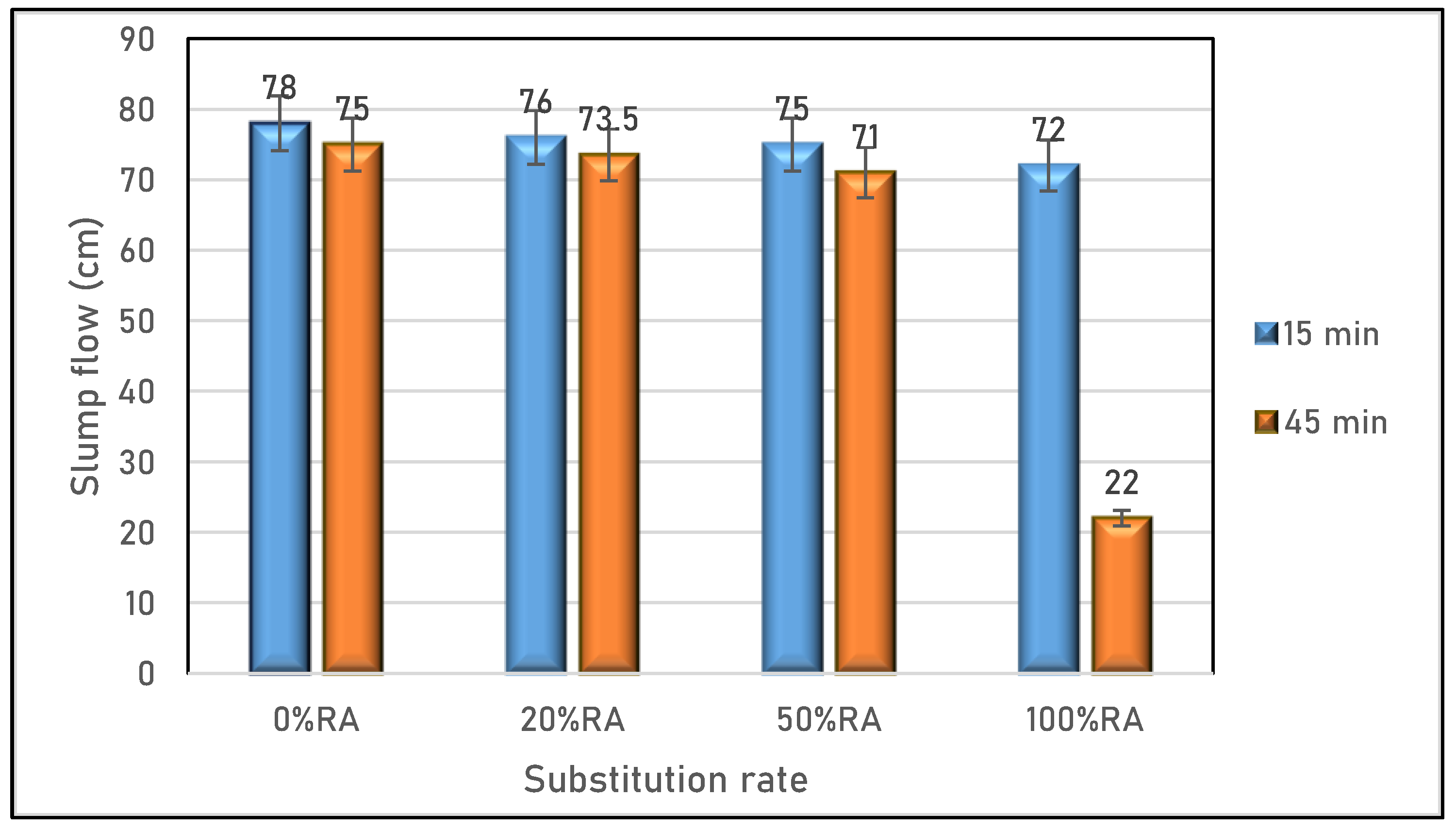

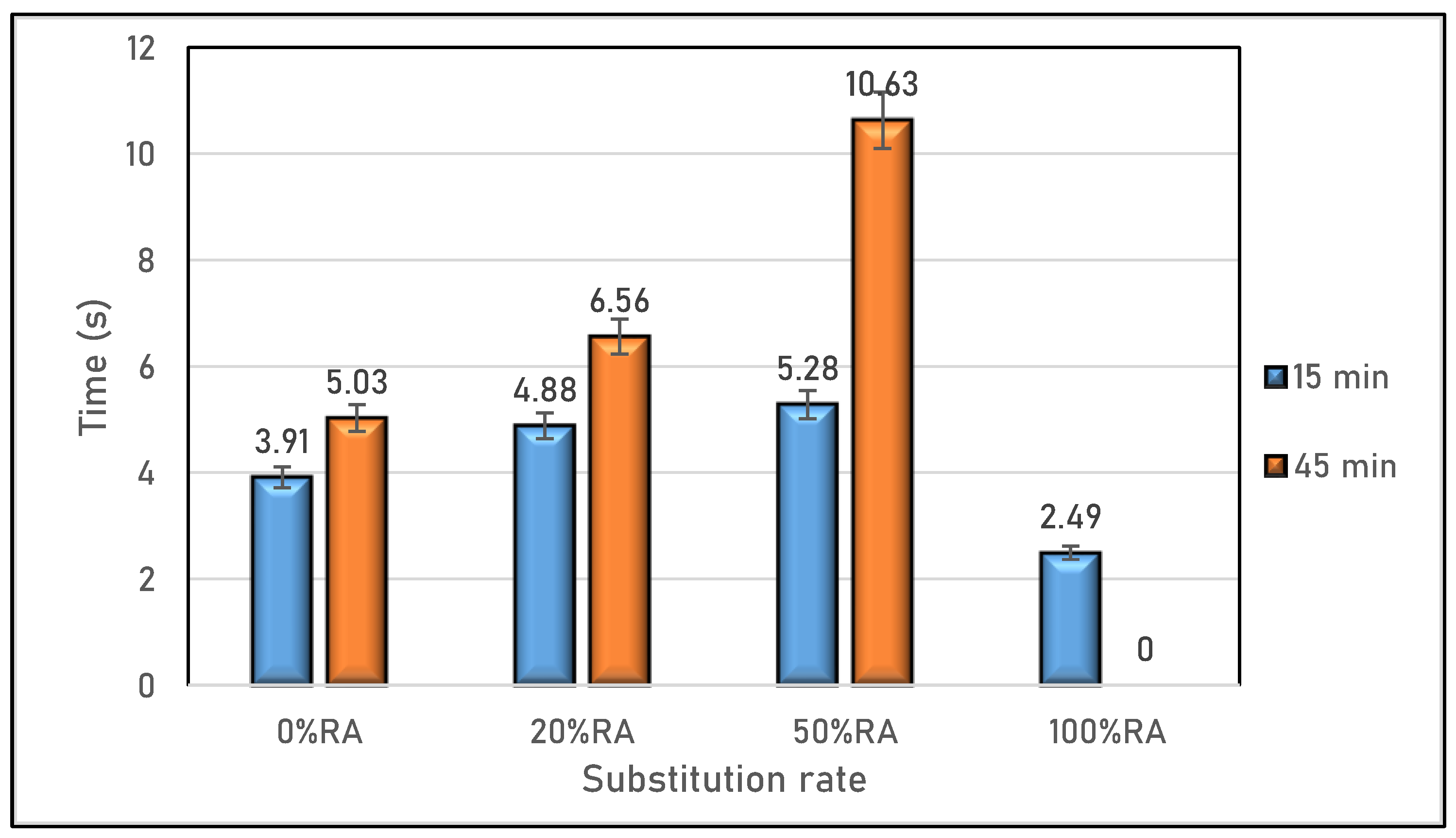

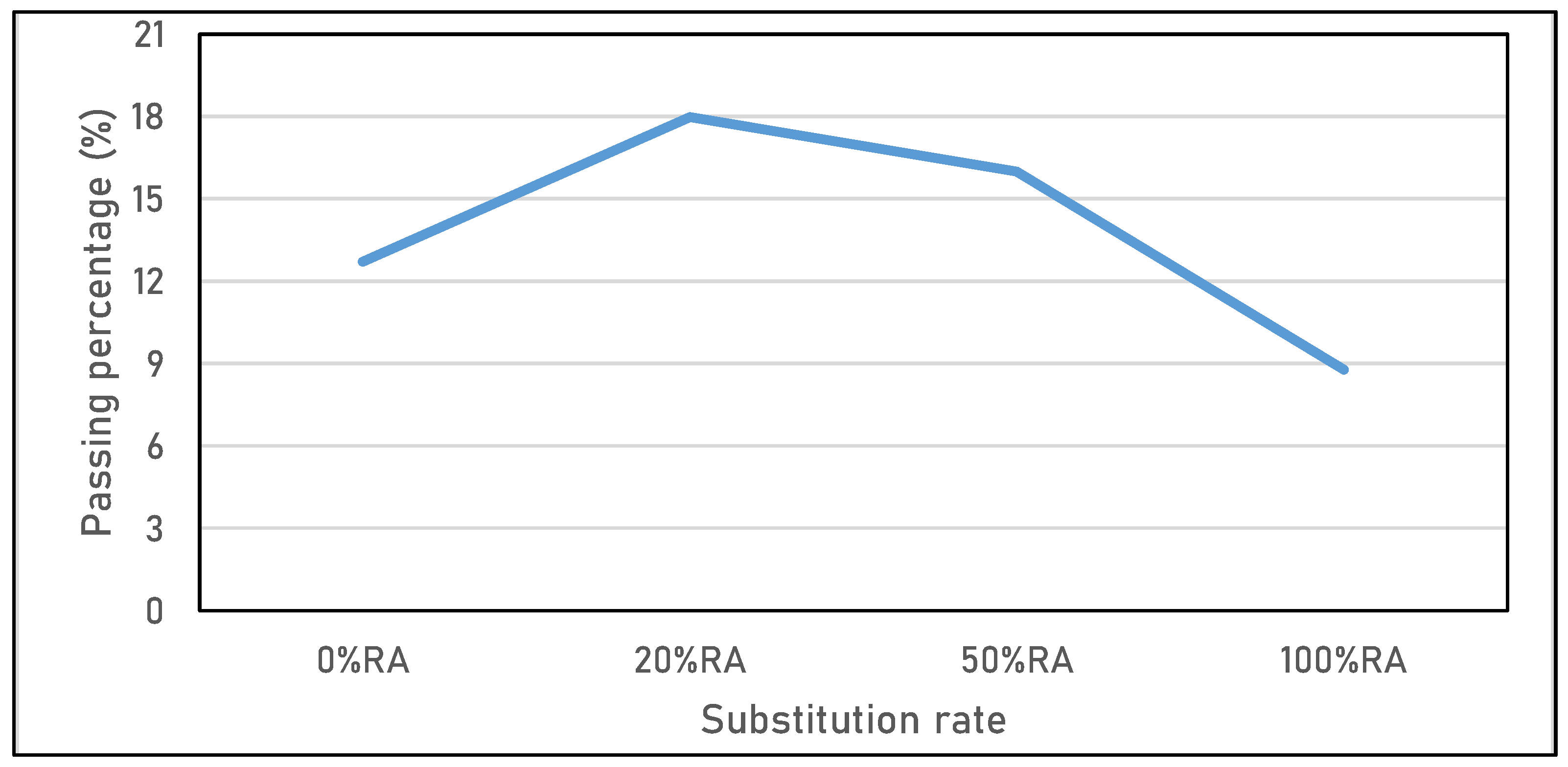

3.1. Fresh State

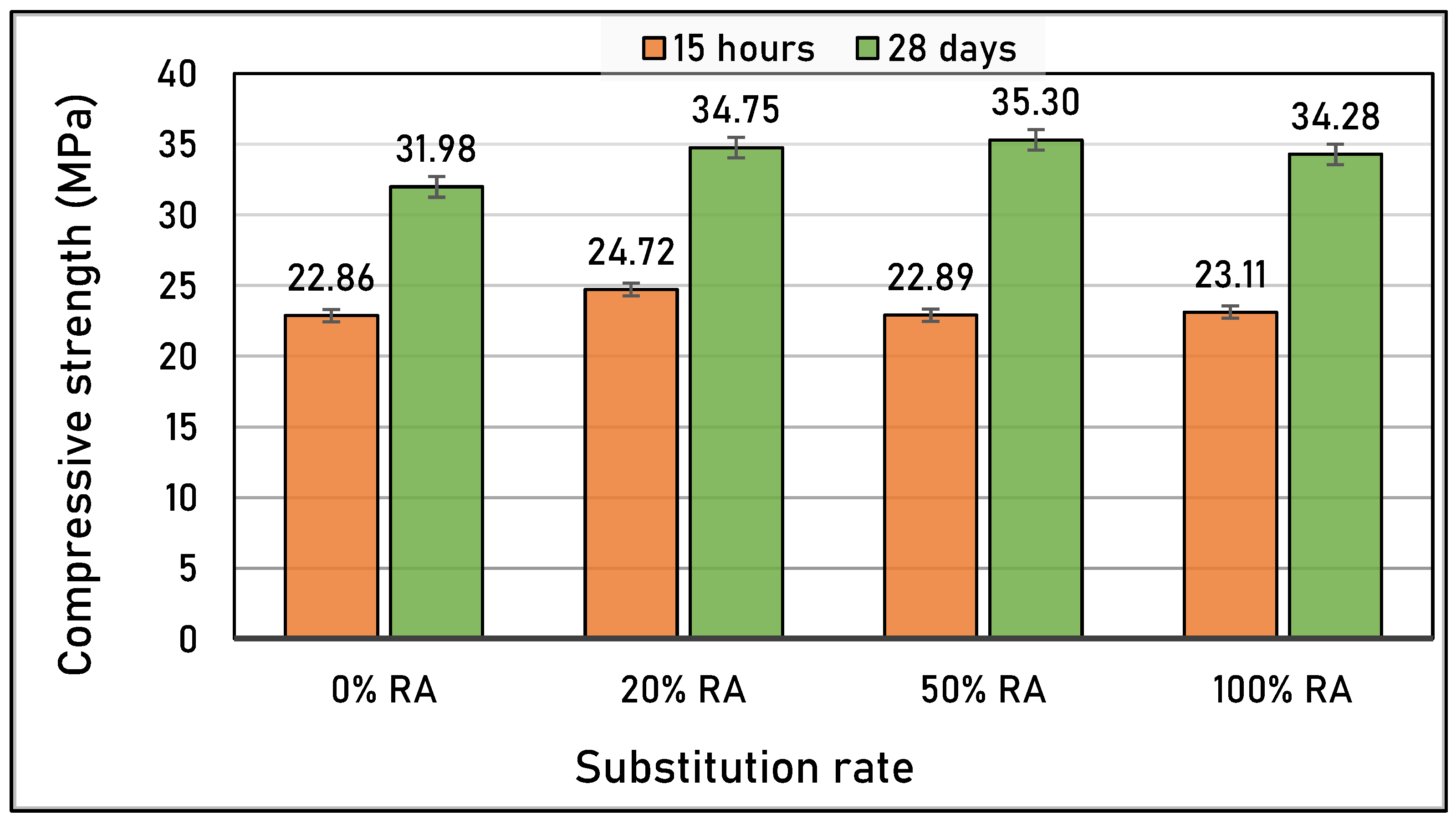

3.2. Hardened State

3.3. Durability

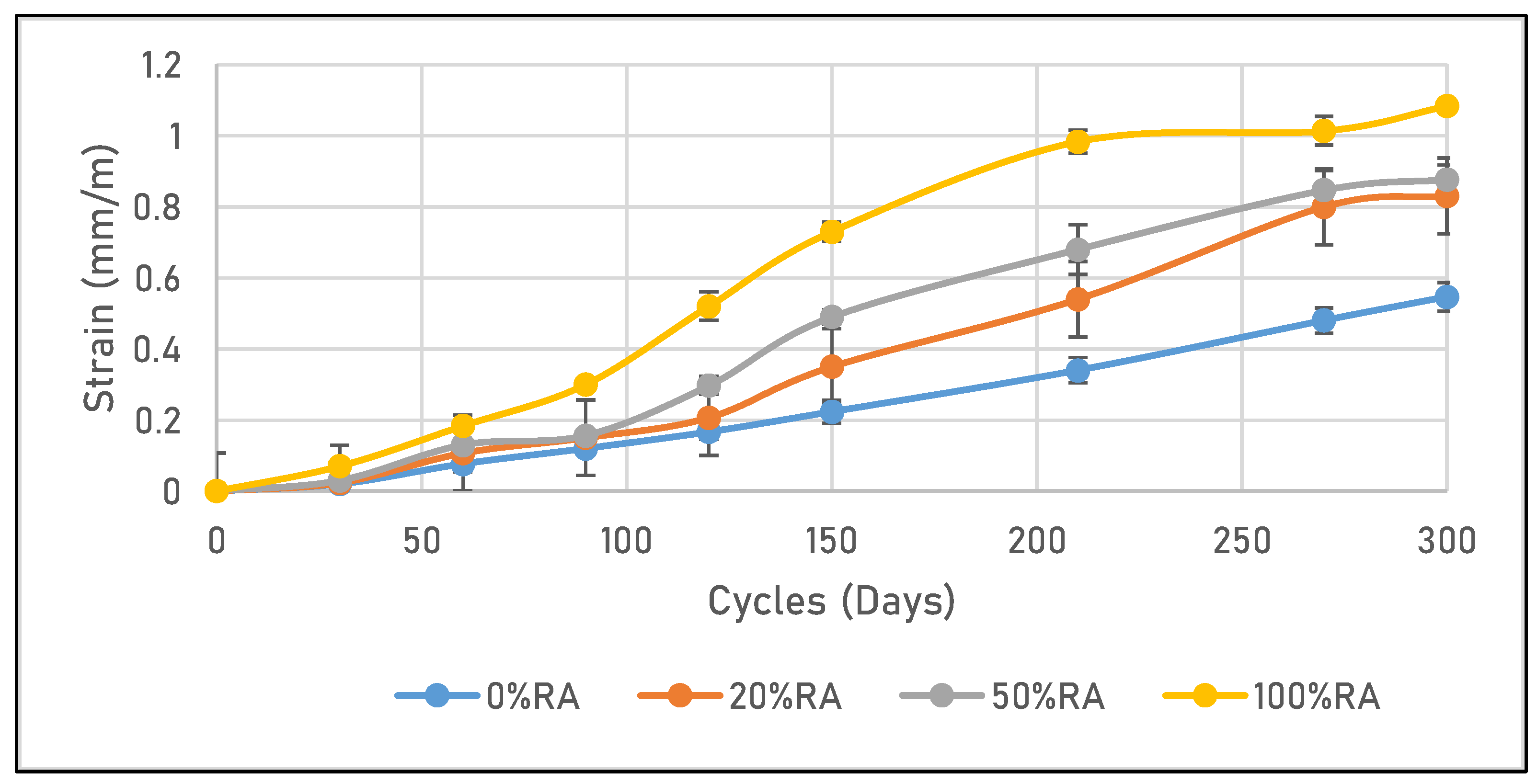

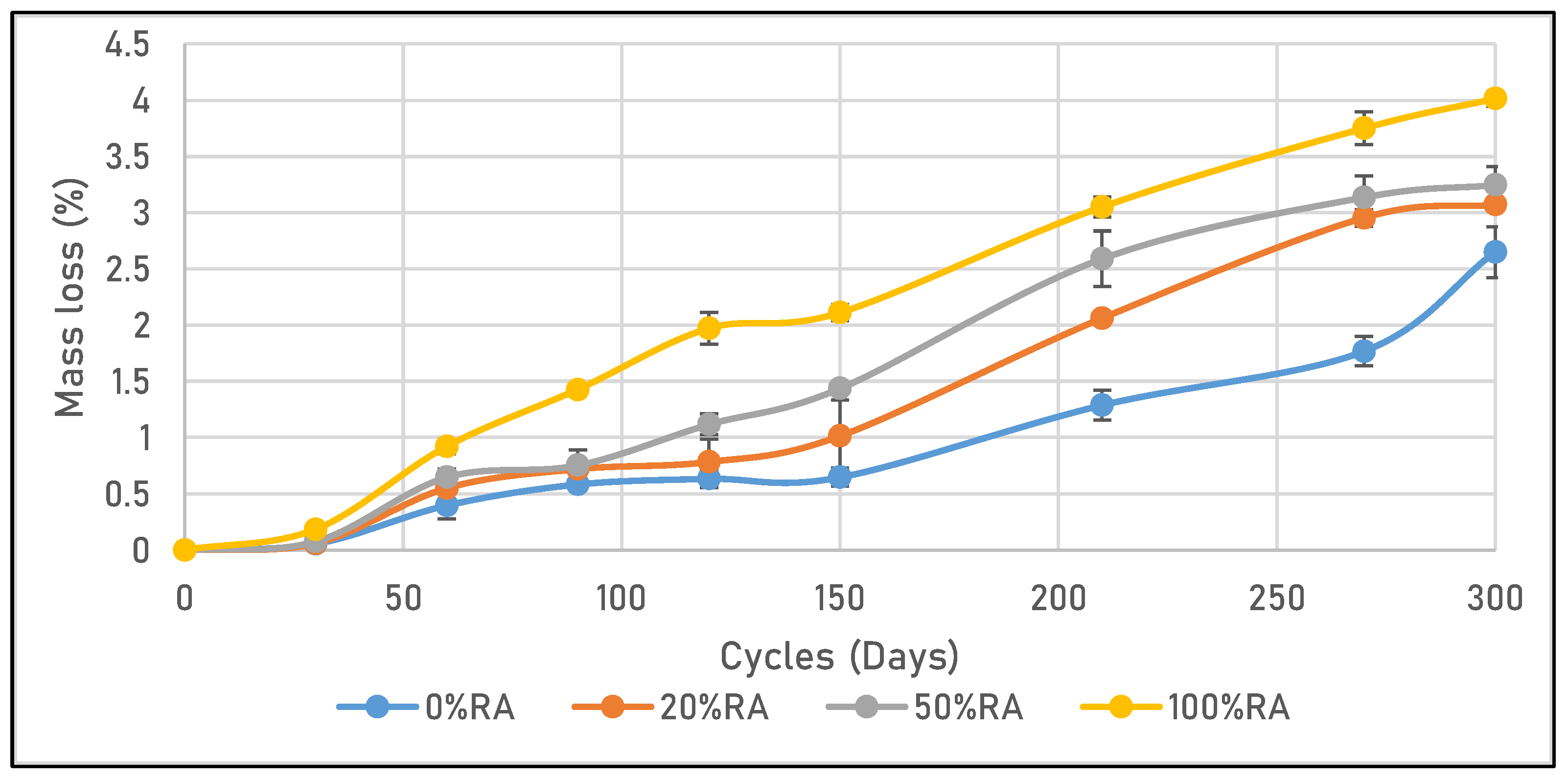

3.3.1. Freeze–Thaw Results

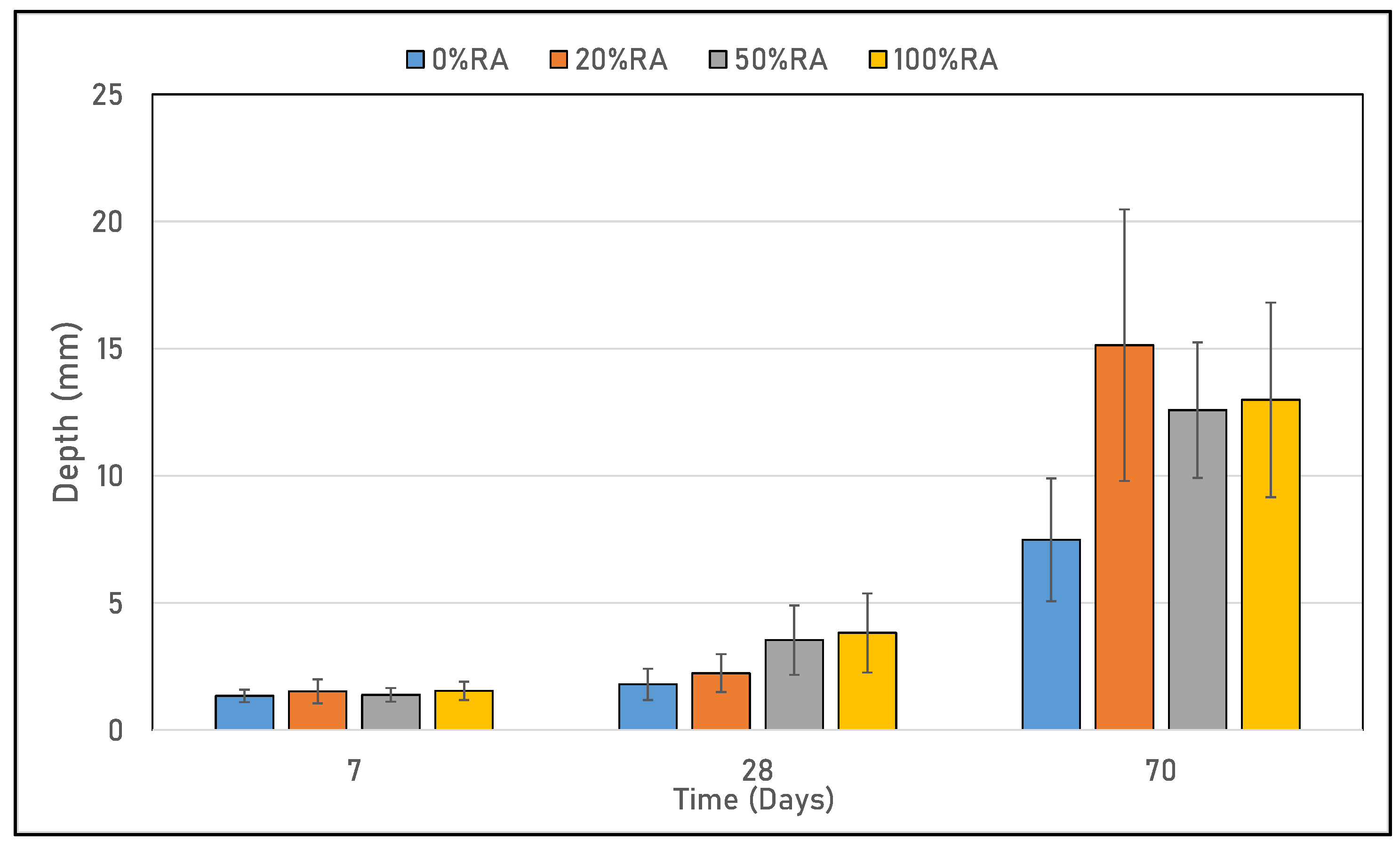

3.3.2. Accelerated Carbonation

4. Conclusions

- The use of recycled aggregates reduces the time required to maintain consistency due to the fine particles present in the aggregates and their significant water absorption.

- The sieve stability of the 20%RA and 50%RA self-compacting concretes was greatly modified by the granular discontinuity, in contrast to homogeneous aggregate mix designs such as 0%RA and 100%RA.

- The recycled aggregates do not affect either the mechanical compressive strength or the binder hydration, as demonstrated by TG analyses.

- The self-compacting concretes tested exhibit good freeze–thaw resistance, and the difference between them is strongly related to the porosity. The 0%RA presents a quasi-linear behavior, and this increases with the higher replacement rate by 45%, 54%, and 110% for 20%RA, 50%RA, and 100%RA, respectively.

- The developed self-compacting concretes have a carbonation rate of 0.96 mm/day0.5 for the 0%RA and about 1.8 mm/day0.5 for the other mix designs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M. Readily Implementable Techniques Can Cut Annual CO 2 Emissions from the Production of Concrete by over 20%. Environ. Res. Lett. 2016, 11, 074029. [Google Scholar] [CrossRef]

- Federation de l’Industrie du Béton. Available online: https://www.fib.org/industrie-du-beton-chiffres-cles/ (accessed on 10 February 2023).

- Ordener, L. Empreinte Carbone du Béton: Origines et Conséquences. Les Emissions de GES du la Transition Écologique et Solidaire. Available online: https://www.concretedispatch.eu/blog/empreinte-carbone-beton/#:~:text= (accessed on 10 February 2023).

- De Andrade Salgado, F.; de Andrade Silva, F. Recycled Aggregates from Construction and Demolition Waste towards an Application on Structural Concrete: A Review. J. Build. Eng. 2022, 52, 104452. [Google Scholar] [CrossRef]

- Mefteh, H.; Kebaïli, O.; Oucief, H.; Berredjem, L.; Arabi, N. Influence of Moisture Conditioning of Recycled Aggregates on the Properties of Fresh and Hardened Concrete. J. Clean. Prod. 2013, 54, 282–288. [Google Scholar] [CrossRef]

- Levy, S.M.; Helene, P. Durability of Recycled Aggregates Concrete: A Safe Way to Sustainable Development. Cem. Concr. Res. 2004, 34, 1975–1980. [Google Scholar] [CrossRef]

- Sivamani, J.; Renganathan, N.T. Effect of Fine Recycled Aggregate on the Strength and Durability Properties of Concrete Modified through Two-Stage Mixing Approach. Environ. Sci. Pollut. Res. 2022, 29, 85869–85882. [Google Scholar] [CrossRef] [PubMed]

- ISWA REPORT: ISWA at a Glance International Solid Waste Association AUT; ISWA: Viena, Austria, 2015; Available online: https://www.iswa.org/ (accessed on 10 February 2023).

- EPA. Advancing Sustainable Materials Management: 2015 Fact Sheet Assessing Trends in Material Generation, Recycling, Composting, Combustion with Energy; EPA: Washington, DC, USA, 2018.

- Huang, B.; Wang, X.; Kua, H.; Geng, Y.; Bleischwitz, R.; Ren, J. Construction and Demolition Waste Management in China through the 3R Principle. Resour. Conserv. Recycl. 2018, 129, 36–44. [Google Scholar] [CrossRef]

- European Environment Agency. EU as a Recycling Society—Present Recycling Levels of Municipal Waste and Construction & Demolition Waste in the EU; European Environment Agency: Copenhagen, Denmark, 2009. [Google Scholar]

- Tejas, S.; Pasla, D. Assessment of Mechanical and Durability Properties of Composite Cement-Based Recycled Aggregate Concrete. Constr. Build. Mater. 2023, 387, 131620. [Google Scholar] [CrossRef]

- Jadon, S.; Kumar, S. Stone Dust and Recycled Concrete Aggregates in Concrete Construction: An Efficient Way of Sustainable Development. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Raut, S.; Olcun, S.; Butler, L.J. Evaluating the Use of Limestone Calcined Clay Cement and Recycled Concrete Aggregates for Reducing the Carbon Footprint of Concrete Structures. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Santos, S.; da Silva, P.R.; de Brito, J. Self-Compacting Concrete with Recycled Aggregates—A Literature Review. J. Build. Eng. 2019, 22, 349–371. [Google Scholar] [CrossRef]

- Arabi, N.; Meftah, H.; Amara, H.; Kebaïli, O.; Berredjem, L. Valorization of Recycled Materials in Development of Self-Compacting Concrete: Mixing Recycled Concrete Aggregates—Windshield Waste Glass Aggregates. Constr. Build. Mater. 2019, 209, 364–376. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Skaf, M.; Santamaría, A.; Hernández-Bagaces, J.J.; Ortega-López, V. Temporal Flowability Evolution of Slag-Based Self-Compacting Concrete with Recycled Concrete Aggregate. J. Clean. Prod. 2021, 299, 126890. [Google Scholar] [CrossRef]

- Revilla-Cuesta, V.; Skaf, M.; Serrano-López, R.; Ortega-López, V. Models for Compressive Strength Estimation through Non-Destructive Testing of Highly Self-Compacting Concrete Containing Recycled Concrete Aggregate and Slag-Based Binder. Constr. Build. Mater. 2021, 280, 122454. [Google Scholar] [CrossRef]

- Güneyisi, E.; Gesoğlu, M.; Algın, Z.; Yazıcı, H. Effect of Surface Treatment Methods on the Properties of Self-Compacting Concrete with Recycled Aggregates. Constr. Build. Mater. 2014, 64, 172–183. [Google Scholar] [CrossRef]

- Saif, M.S.; Shanour, A.S.; Abdelaziz, G.E.; Elsayad, H.I.; Shaaban, I.G.; Tayeh, B.A.; Hammad, M.S. Influence of Blended Powders on Properties of Ultra-High Strength Fibre Reinforced Self Compacting Concrete Subjected to Elevated Temperatures. Case Stud. Constr. Mater. 2023, 18, e01793. [Google Scholar] [CrossRef]

- Amara, H.; Arabi, N.; Arnaud, P. Unconventional Tools for the Study of the Flow Properties of Concrete Equivalent Mortar Based on Recycled Concrete Aggregates. Environ. Sci. Pollut. Res. 2021, 29, 26739–26758. [Google Scholar] [CrossRef]

- Rabehi, R.; Rabehi, M.; Omrane, M. Study of the Durability of Self-Compacting Concrete Made from Recycled Gravel. J. Eng. Exact Sci. 2023, 9, 1–12. [Google Scholar] [CrossRef]

- Damme, H. Van Concrete Material Science: Past, Present, and Future Innovations. Cem. Concr. Res. 2018, 112, 5–24. [Google Scholar] [CrossRef]

- Zhu, W.; Gibbs, J.C. Use of Different Limestone and Chalk Powders in Self-Compacting Concrete. Cem. Concr. Res. 2005, 35, 1457–1462. [Google Scholar] [CrossRef]

- Valcuende, M.; Marco, E.; Parra, C.; Serna, P. Influence of Limestone Filler and Viscosity-Modifying Admixture on the Shrinkage of Self-Compacting Concrete. Cem. Concr. Res. 2012, 42, 583–592. [Google Scholar] [CrossRef]

- Kopecskó, K. Self-Compacting Concrete Produced with Limestone Waste. IOP Conf. Ser. Mater. Sci. Eng. 2018, 442, 012006. [Google Scholar] [CrossRef]

- Salman, A.; Akinpelu, M.; Yahaya, I.; Salami, H. Workability and Strengths of Ternary Cementitious Concrete Incorporating Calcined Clay and Limestone Powder. Mater. Today Proc. 2023, 86, 51–58. [Google Scholar] [CrossRef]

- Alyousef, R.; Abbass, W.; Aslam, F.; Gillani, S.A.A. Characterization of High-Performance Concrete Using Limestone Powder and Supplementary Fillers in Binary and Ternary Blends under Different Curing Regimes. Case Stud. Constr. Mater. 2023, 18, e02058. [Google Scholar] [CrossRef]

- NF EN 206; Béton—Spécification, Performances, Production et Conformité. Afnor: Saint-Denis, France, 2013.

- EN 12350-8; Essai Pour Béton Frais—Partie 8: Béton Auto-Plaçant—Essai d’étalement Au Cône d’Abrams. Afnor: Saint-Denis, France, 2010.

- NF EN 12350-11; Essai Pour Béton Frais—Partie 11: Béton Auto-Plaçant—Essai de Stabilité Au Tamis. Afnor: Saint-Denis, France, 2010.

- NF EN 12390-3; Essais Pour Béton Durci—Partie 3: Résistance à La Compression Des Éprouvettes. Afnor: Saint-Denis, France, 2019.

- AFPC-AFREM. Durabilité Des Bétons: Méthodes Recommandées pour la Mesure des Grandeurs Associées à la Durabilité; Institut National des Sciences Appliquées: Toulouse, France, 2009. [Google Scholar]

- NF P 18-424; Essai de Gel Sur Béton Durci. Afnor: Saint-Denis, France, 2008.

- XP P18-458; Essai Pour Béton Durci—Essai de Carbonatation Accélérée—Mesure de l’épaisseur de Béton Carbonaté. Afnor: Saint-Denis, France, 2022.

- Kebaïli, O.; Mouret, M.; Arabi, N.; Cassagnabere, F. Adverse Effect of the Mass Substitution of Natural Aggregates by Air-Dried Recycled Concrete Aggregates on the Self-Compacting Ability of Concrete: Evidence and Analysis through an Example. J. Clean. Prod. 2015, 87, 752–761. [Google Scholar] [CrossRef]

- Manzi, S.; Mazzotti, C.; Chiara Bignozzi, M. Self-Compacting Concrete with Recycled Concrete Aggregate: Study of the Long-Term Properties. Constr. Build. Mater. 2017, 157, 582–590. [Google Scholar] [CrossRef]

- Liu, J.; Ma, K.; Shen, J.; Zhu, J.; Long, G.; Xie, Y.; Liu, B. Influence of Recycled Concrete Aggregate Enhancement Methods on the Change of Microstructure of ITZs in Recycled Aggregate Concrete. Constr. Build. Mater. 2023, 371, 130772. [Google Scholar] [CrossRef]

- Xuan, D.X.; Shui, Z.H.; Wu, S.P. Influence of Silica Fume on the Interfacial Bond between Aggregate and Matrix in Near-Surface Layer of Concrete. Constr. Build. Mater. 2009, 23, 2631–2635. [Google Scholar] [CrossRef]

- Nadesan, M.S.; Dinakar, P. Micro-Structural Behavior of Interfacial Transition Zone of the Porous Sintered Fly Ash Aggregate. J. Build. Eng. 2018, 16, 31–38. [Google Scholar] [CrossRef]

- Lee, G.C.; Choi, H.B. Study on Interfacial Transition Zone Properties of Recycled Aggregate by Micro-Hardness Test. Constr. Build. Mater. 2013, 40, 455–460. [Google Scholar] [CrossRef]

- Zhang, H.; Zhao, Y.; Meng, T.; Shah, S.P. Surface Treatment on Recycled Coarse Aggregates with Nanomaterials. J. Mater. Civ. Eng. 2016, 28, 04015094. [Google Scholar] [CrossRef]

- Otieno, M.; Ikotun, J.; Ballim, Y. Experimental Investigations on the Influence of Cover Depth and Concrete Quality on Time to Cover Cracking Due to Carbonation-Induced Corrosion of Steel in RC Structures in an Urban, Inland Environment. Constr. Build. Mater. 2019, 198, 172–181. [Google Scholar] [CrossRef]

- Fawzy, A.; Elshami, A.; Ahmad, S. Investigating the Effects of Recycled Aggregate and Mineral Admixtures on the Mechanical Properties and Performance of Concrete. Materials 2023, 16, 5134. [Google Scholar] [CrossRef] [PubMed]

- Boukhelf, F.; Targino, D.L.L.; Benzaama, M.H.; de Lima Babadopulos, L.F.A.; El Mendili, Y. Insight into the Behavior of Mortars Containing Glass Powder: An Artificial Neural Network Analysis Approach to Classify the Hydration Modes. Materials 2023, 16, 943. [Google Scholar] [CrossRef] [PubMed]

- Zeng, H.; Li, Y.; Zhang, J.; Chong, P.; Zhang, K. Effect of Limestone Powder and Fly Ash on the PH Evolution Coefficient of Concrete in a Sulfate-Freeze–Thaw Environment. J. Mater. Res. Technol. 2022, 16, 1889–1903. [Google Scholar] [CrossRef]

- Younsi, A. Long-Term Carbon Dioxide Sequestration by Concretes with Supplementary Cementitious Materials under Indoor and Outdoor Exposure: Assessment as per a Standardized Model. J. Build. Eng. 2022, 51, 104306. [Google Scholar] [CrossRef]

- Andrade, C.; Sanjuán, M. Updating Carbon Storage Capacity of Spanish Cements. Sustainability 2018, 10, 4806. [Google Scholar] [CrossRef]

- Otieno, M.; Ikotun, J.; Ballim, Y. Experimental Investigations on the Effect of Concrete Quality, Exposure Conditions and Duration of Initial Moist Curing on Carbonation Rate in Concretes Exposed to Urban, Inland Environment. Constr. Build. Mater. 2020, 246, 118443. [Google Scholar] [CrossRef]

- Tang, B.; Fan, M.; Yang, Z.; Sun, Y.; Yuan, L. A Comparison Study of Aggregate Carbonation and Concrete Carbonation for the Enhancement of Recycled Aggregate Pervious Concrete. Constr. Build. Mater. 2023, 371, 130797. [Google Scholar] [CrossRef]

- FD P 18-480; Béton—Justification de la Durabilité des Ouvrages en Béton par Méthode Performantielle. Afnor: Saint-Denis, France, 2022.

- Oliva Rivera, A.; Suchorzewski, J.; Malaga, K. Potential of CO2-Storage in Recycled Concrete Aggregates by Accelerated Carbonation. In International RILEM Conference on Synergising Expertise towards Sustainability and Robustness of Cement-Based Materials and Concrete Structures; Springer: Berlin/Heidelberg, Germany, 2023; pp. 604–615. [Google Scholar]

| 0%RA | 20%RA | 50%RA | 100%RA | |

|---|---|---|---|---|

| Sand 0/4 | 786 | 786 | 786 | 786 |

| Natural aggregate 4/12.5 | 726 | 580.8 | 361 | - |

| Recycled aggregate 4/14 | - | 145.2 | 361 | 726 |

| Blanc CEM I-52.5 R | 320 | 320 | 320 | 320 |

| Limestone | 160 | 160 | 160 | 160 |

| Efficient water | 161.81 | 161.81 | 161.81 | 179 |

| Total water | 168 | 168 | 168 | 185.19 |

| Superplasticizer | 4.8 | 4.8 | 4.8 | 4.8 |

| Set accelerator | 3.80 | 3.80 | 3.80 | 3.80 |

| Water-repellent | 0.78 | 0.78 | 0.78 | 0.78 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guessoum, M.; Boukhelf, F.; Khadraoui, F. Full Characterization of Self-Compacting Concrete Containing Recycled Aggregates and Limestone. Materials 2023, 16, 5842. https://doi.org/10.3390/ma16175842

Guessoum M, Boukhelf F, Khadraoui F. Full Characterization of Self-Compacting Concrete Containing Recycled Aggregates and Limestone. Materials. 2023; 16(17):5842. https://doi.org/10.3390/ma16175842

Chicago/Turabian StyleGuessoum, Meriem, Fouad Boukhelf, and Fouzia Khadraoui. 2023. "Full Characterization of Self-Compacting Concrete Containing Recycled Aggregates and Limestone" Materials 16, no. 17: 5842. https://doi.org/10.3390/ma16175842

APA StyleGuessoum, M., Boukhelf, F., & Khadraoui, F. (2023). Full Characterization of Self-Compacting Concrete Containing Recycled Aggregates and Limestone. Materials, 16(17), 5842. https://doi.org/10.3390/ma16175842