Ultrasonic-Assisted Surface Finishing of STAVAX Mold Steel Using Lab-Made Polishing Balls on a 5-Axis CNC Machining Center

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- Good corrosion resistance

- Excellent polishability

- Good wear resistance

- Good machinability

- Good stability in hardening

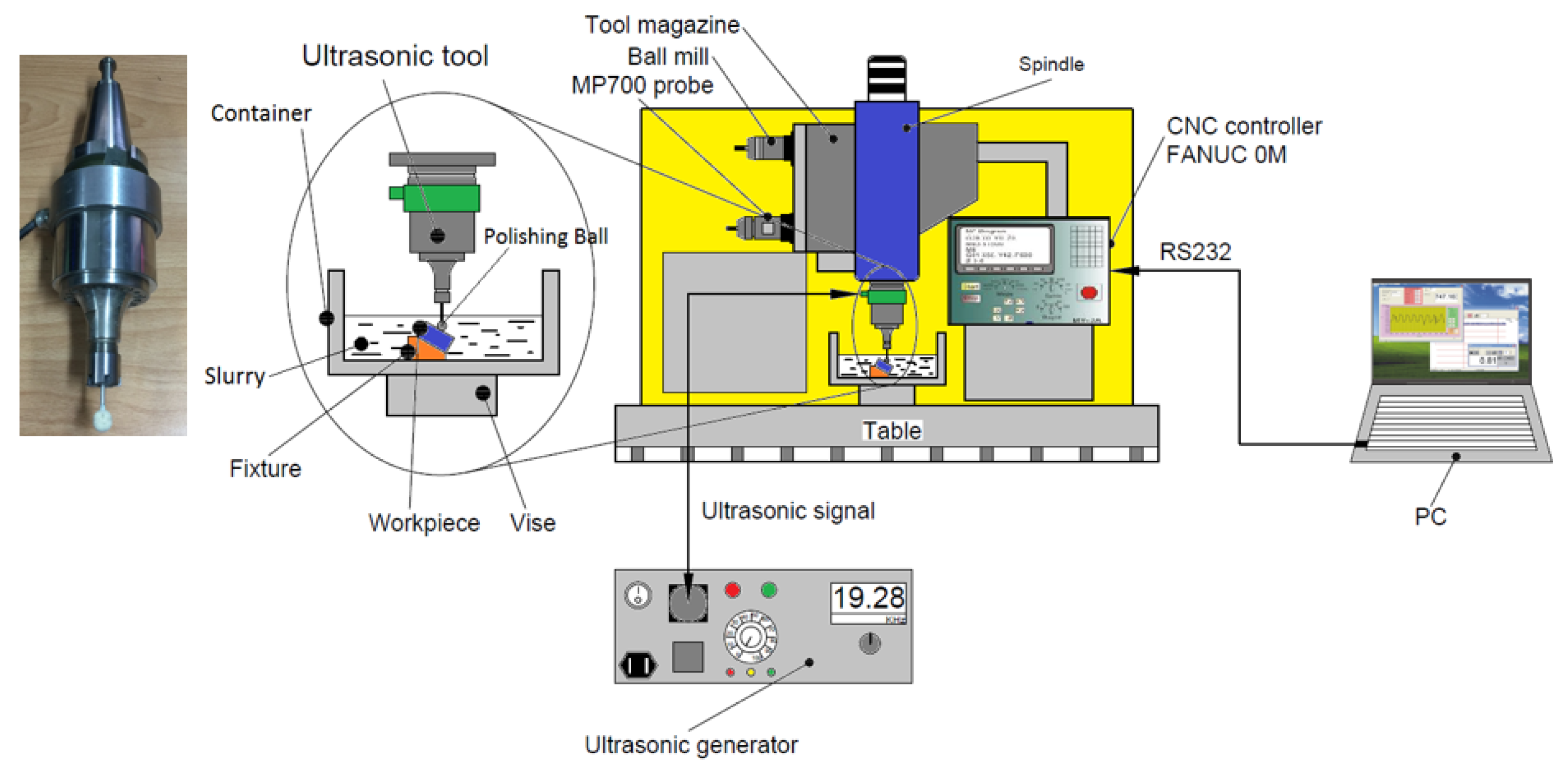

2.2. Experimental Setups on a 5-Axis Machining Center

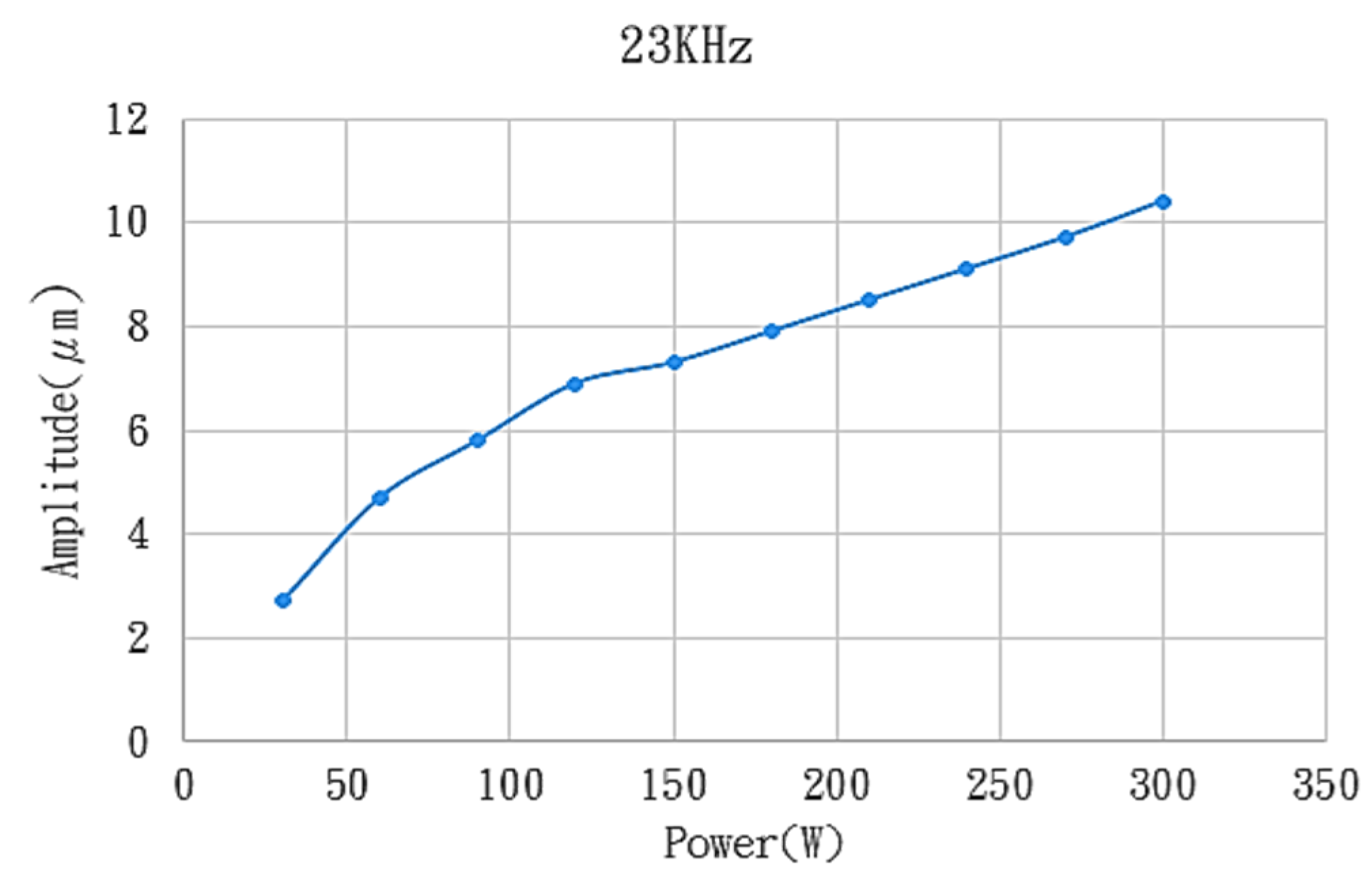

2.3. Specification and Investigation of the Used Ultrasonic Tool

3. Results

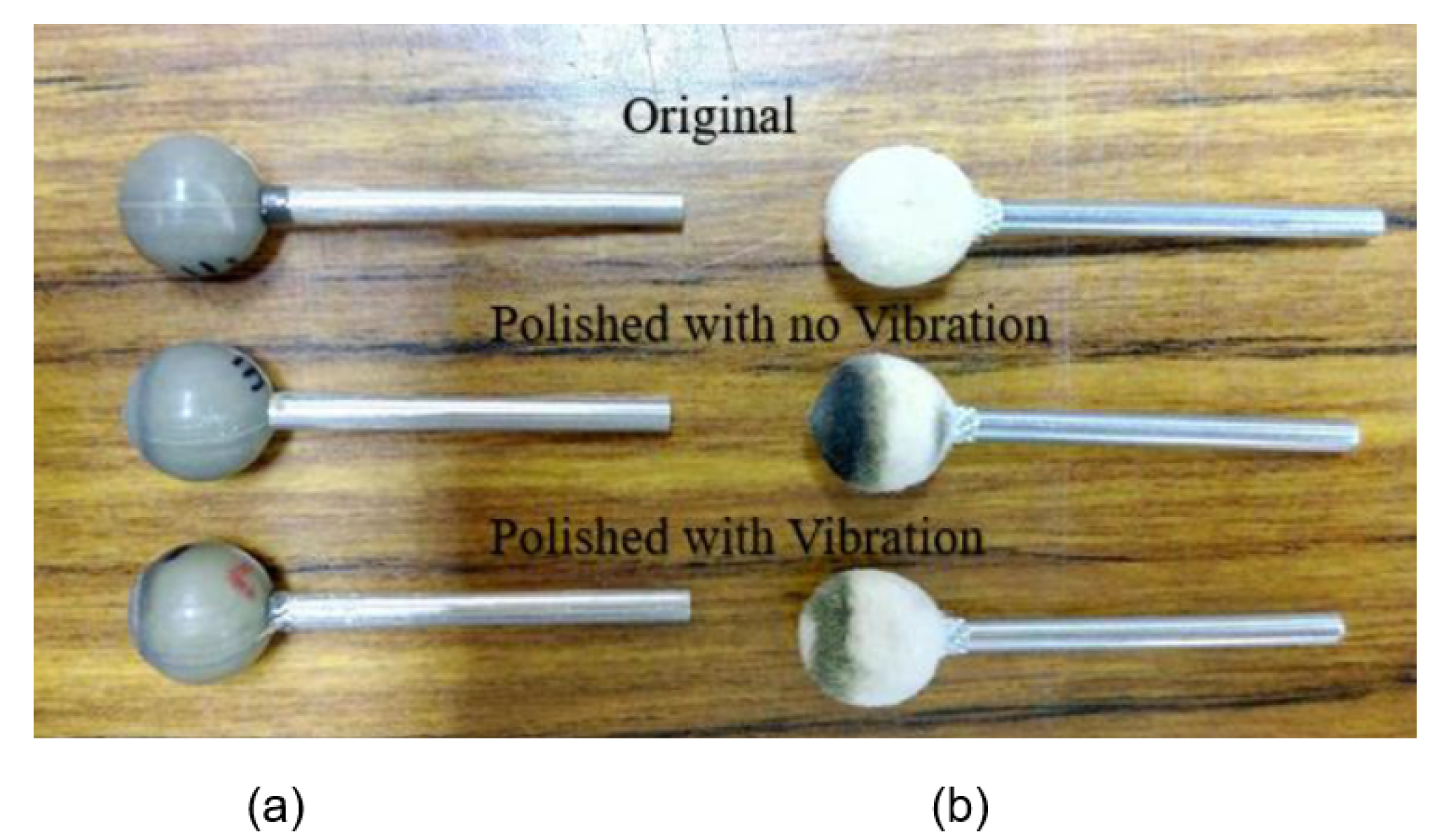

3.1. Development of the Lab-Made Polishing Balls

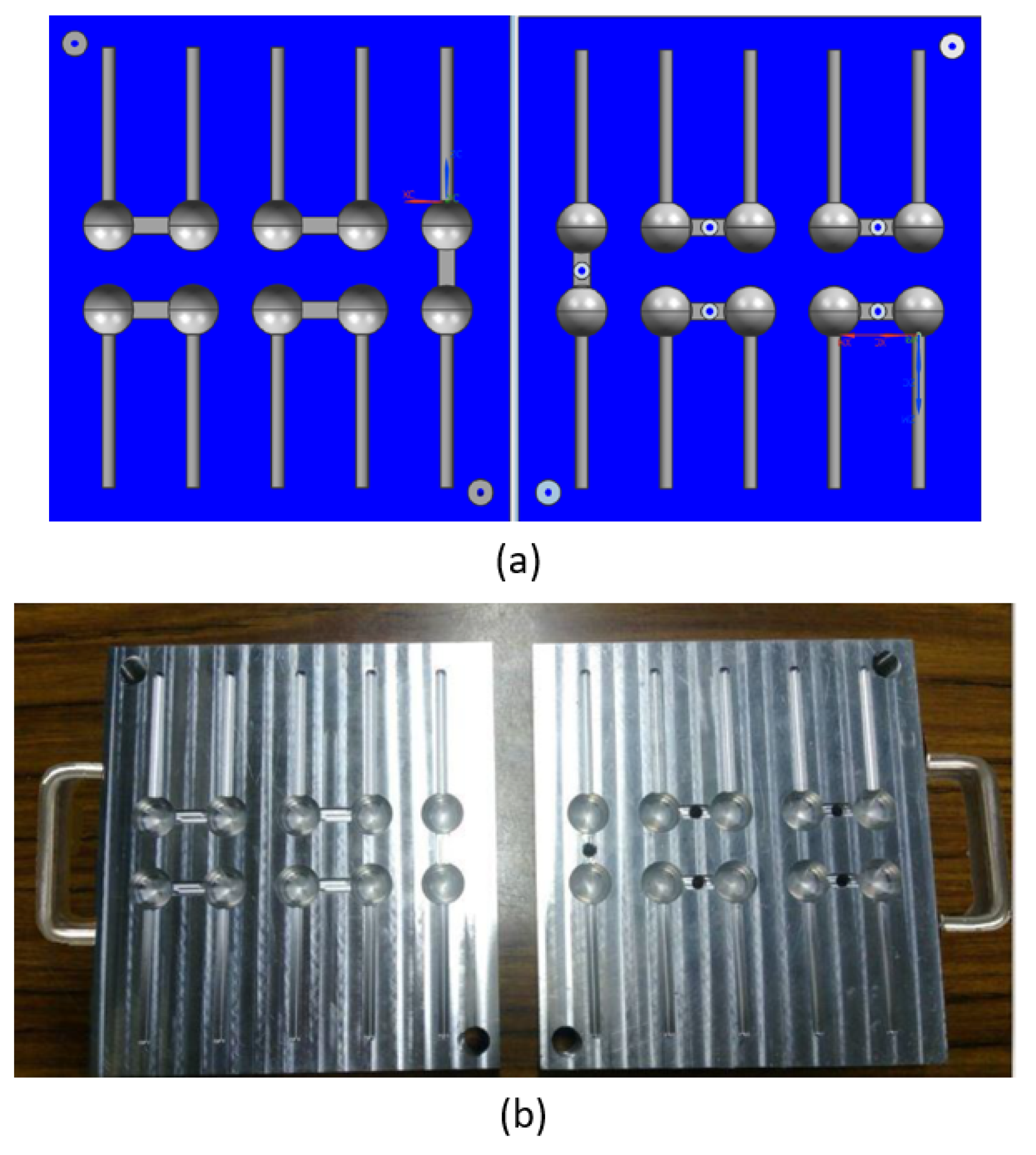

3.1.1. Design and Fabrication of the Mold for the Lab-Made Polishing Balls

3.1.2. Configuration and Fabrication of the Lab-Made Polishing Balls

3.2. Processing Parameters for the Ultrasonic Tool

3.3. Effects of Different Passes on the Surface Roughness Improvement

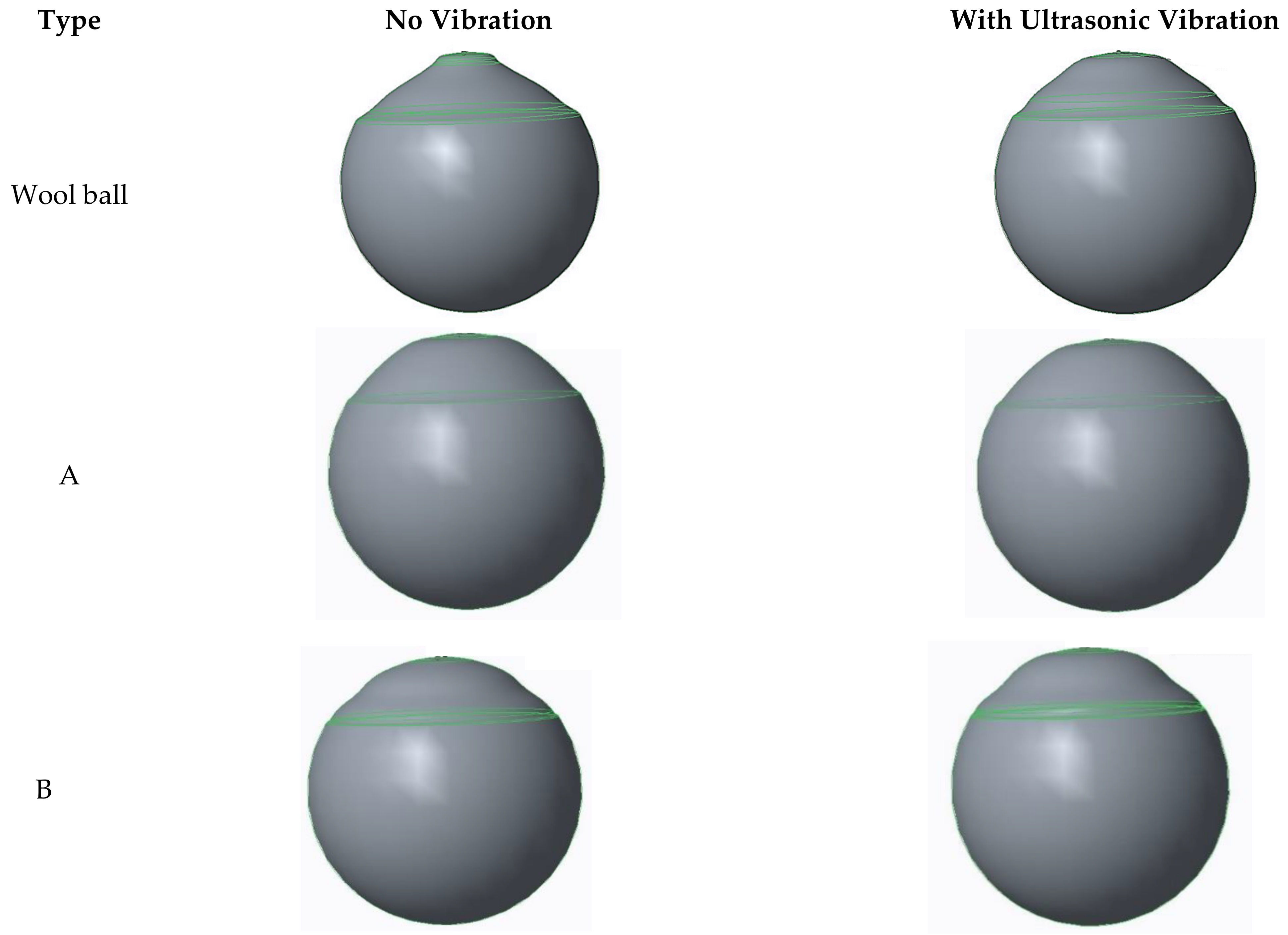

3.4. Volumetric Wear Improvement of the Lab-Made Polishing Balls

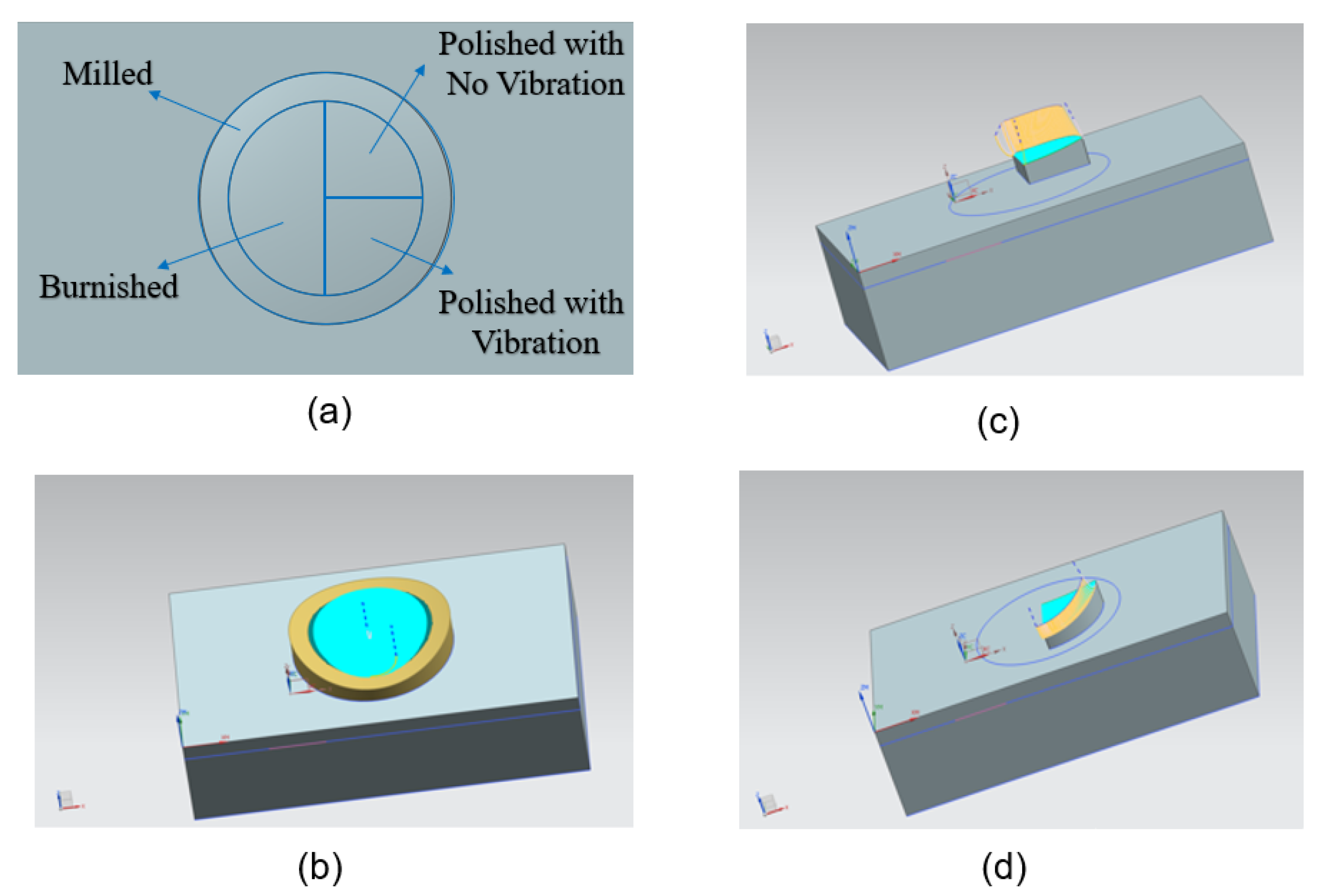

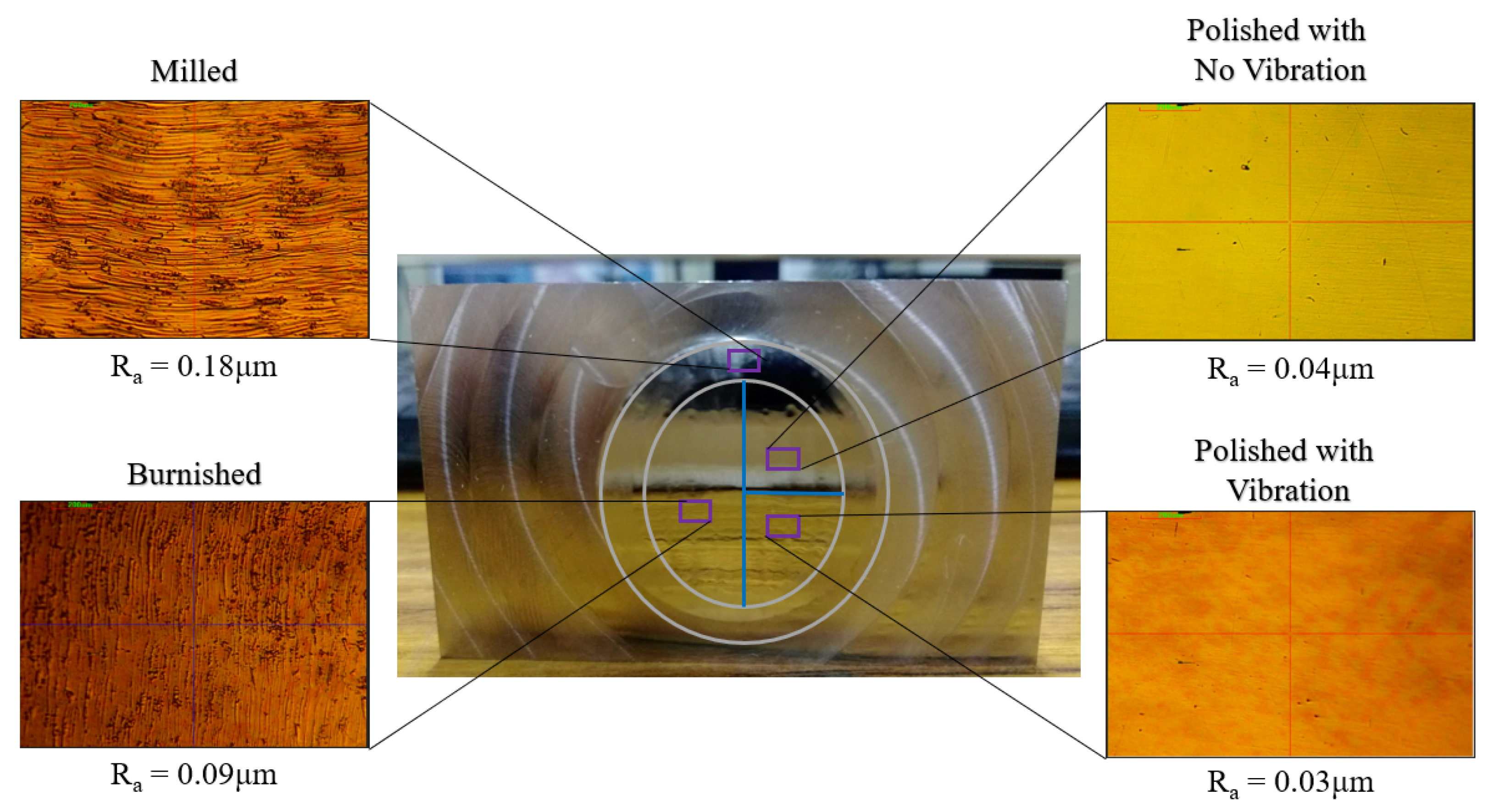

3.5. Application to the Surface Finishing of a Test Carrier with Saddle Surface

4. Discussion

- Based on the experimental results of the multiple passes of ball polishing on the surface roughness improvement, in general, the more the passes used the better the improvement on the surface roughness. However, the results of the type E-C-B and type E-C-B-A showed a very small difference (0.016 μm) on the surface roughness. This implied that the variation in the same concentration of the abrasive with different grain size had no obvious influence on the surface roughness improvement. To reduce the polishing time, the surface roughness of Ra 0.04 μm on average was achieved by utilizing a number of Type E-C-B passes.

- The volumetric wear of the lab-made polishing balls can be reduced by about 13% to 65% using ultrasonic vibration-assisted polishing. The mechanism for the reduction in the volumetric wear might be that the total sliding path had been reduced due to the intermittent contact between the vibrating polishing ball and the surface of the workpiece.

- A constant force polishing process is suggested to be implemented regarding the wear of the polishing ball.

- The diameter of the lab-made polishing balls was 12 mm. Considering the efficiency of polishing, different diameters of the polishing balls could be designed and fabricated to adapt the curvature of the workpiece. The cylindrical polishing pads with different diameters can also be utilized for a plane surface or a smoothed curved surface with small curvature in the future.

5. Conclusions

- Five types of NBR-based blanks for the polishing balls, Type A to Type E, have been made after NBR, aluminum oxide (Al2O3) abrasive, and some additives have been homogenously mixed by a blending machine. Five kinds of polishing balls with the diameter of 12 mm have been fabricated by the thermal forming processes using the lab-made molds, and some mechanical properties have been tested.

- The effects of multiple polishing passes on the surface roughness improvement for the lab-made polishing balls has been investigated in this study. The multiple polishing process E-C-B-A resulted in the best outcome with a surface roughness of Ra 0.027 um on average.

- According to the experimental results, the suitable combination of the ultrasonic vibration-assisted polishing parameters using the lab-made polishing balls was as follows: amplitude of 10 μm, frequency of 23 kHz, spindle speed of 5000 rpm, feed rate of 60 mm/min, stepover of 20 μm, depth of penetration of 180 μm, and polishing pass of E-C-B-A.

- The volumetric wear of the Lab-made polishing balls is less than that of conventional wool polishing balls. The improvement in the volumetric wear of the ultrasonic vibration-assisted polishing of the Lab-made polishing balls ranges from 12.64% (Type A) to 65.48% (Type E), based on the calculation of the constructed CAD models of the used polishing balls.

- The proposed suitable ball polishing parameters for a plane surface have been applied to the surface finishing of a test carrier with a saddle surface. The surface roughness improvement in the 3D test object on the burnished surface was about 50%, and that of the vibration-assisted ball-polished surface using the suggested E-C-B-A passes of the lab-made polishing balls was about 83%, compared with the fine-milled surface.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lionetto, F. Ultrasound for Material Characterization and Processing. Materials 2021, 14, 3891. [Google Scholar] [CrossRef] [PubMed]

- Ultrasound. Available online: https://en.wikipedia.org/wiki/Ultrasound (accessed on 26 June 2023).

- Zou, Y.; Guo, S.; Li, H.; Deng, X. Investigation on cutting performance in ultrasonic assisted helical milling of Ti6Al4V alloy by various parameters and cooling strategies. J. Adv. Manuf. Technol. 2023, 126, 5123–5138. [Google Scholar] [CrossRef]

- Zhang, Y.; Yuan, Z.; Fang, B.; Gao, L.; Chen, Z.; Su, G. Study on the mechanism of burr formation by simulation and experiment in ultrasonic vibration-assisted micromilling. Micromachines 2023, 14, 625. [Google Scholar] [CrossRef] [PubMed]

- Júnior, M.; França, T.; Fortulan, C.; da Silva, R.; Foschini, C. Green ceramic machining benefits through ultrasonic-assisted turning: An experimental investigation. J. Adv. Manuf. Technol. 2022, 118, 3091–3104. [Google Scholar] [CrossRef]

- Airao, J.; Nirala, C.; Bertolini, R.; Krolczyk, G.; Khanna, N. Sustainable cooling strategies to reduce tool wear, power consumption and surface roughness during ultrasonic assisted turning of Ti-6Al-4V. Tribol. Int. 2022, 169, 107494. [Google Scholar] [CrossRef]

- Wang, D.; Liang, Q.; Xu, D. Research on damage characteristics of ultrasonic vibration-assisted grinding of a C/ SIC Composite material. Sensors 2023, 23, 224. [Google Scholar] [CrossRef] [PubMed]

- Ma, Y.; Yin, Y.; Zhang, J.; Huo, J. Effects of processing parameters on the surface quality of wrought Ni-based superalloy by ultrasonic-assisted electrochemical grinding. J. Adv. Manuf. Technol. 2022, 121, 7851–7865. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, D.; Fang, Y. Research on chip mechanism of Inconel 718 with ultrasonic assisted drilling by step drill. J. Adv. Manuf. Technol. 2023, 126, 2579–2594. [Google Scholar] [CrossRef]

- Zhou, H.; Feng, Y.; Xu, W.; Zhou, Z.; Qin, Y.; Jia, X. Experimental research on new hole-making method assisted with asynchronous mixed frequency vibration in TiBw/TC4 composites. J. Adv. Manuf. Technol. 2023, 125, 543–561. [Google Scholar] [CrossRef]

- Kumar, A.; Deb, S.; Paul, S. Ultrasonic-assisted abrasive micro-deburring of micromachined metallic alloys. J. Manuf. Process. 2021, 66, 595–607. [Google Scholar] [CrossRef]

- Kumar, A.; Deb, S.; Paul, S. Burr removal from high-aspect-ratio micro-pillars using ultrasonic-assisted abrasive micro-deburring. J. Micromech. Microeng. 2022, 32, 055010. [Google Scholar] [CrossRef]

- Zhang, J.; Yuan, H.; Feng, L.; Zhang, J.; Chen, X.; Xiao, J.; Xu, J. Enhanced machinability of Ni-based single crystal superalloy by vibration-assisted diamond cutting. Precis. Eng. 2023, 79, 300–309. [Google Scholar] [CrossRef]

- Juri, A.; Zhang, Y.; Kotousov, A.; Yin, L. Zirconia responses to edge chipping damage induced in conventional and ultrasonic vibration-assisted diamond machining. J. Mater. Res. Technol. 2021, 13, 573–589. [Google Scholar] [CrossRef]

- Muttamara, A.; Nakwong, P. Enhancing wire-EDM performance with Zinc-coated brass wire electrode and ultrasonic vibration. Micromachines 2023, 14, 862. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Li, J.; Xing, Q.; Zhang, Q. Research on ultrasonic vibration–assisted electrical discharge machining SiCp/Al composite. J. Adv. Manuf. Technol. 2022, 121, 2095–2113. [Google Scholar] [CrossRef]

- Cheng, Z.; Qin, S.; Fang, Z. Numerical modeling and experimental study on the material removal process using ultrasonic vibration-assisted abrasive water jet. Front. Mater. 2022, 9, 895271. [Google Scholar] [CrossRef]

- Dominguez-Caballero, J.; Ayvar-Soberanis, S.; Kim, J.; Roy, A.; Li, L.; Curtis, D. Hybrid simultaneous laser- and ultrasonic-assisted machining of Ti-6Al-4V alloy. J. Adv. Manuf. Technol. 2023, 125, 1903–1916. [Google Scholar] [CrossRef]

- Kim, J.; Zani, L.; Abdul-Kadir, A.; Roy, A.; Baxevanakis, K.; Jones, L.; Silberschmidt, V. Hybrid turning of micro-SiCp/AA2124 composites: A comparative study of laser and- ultrasonic vibration-assisted machining. J. Manuf. Process. 2023, 86, 109–125. [Google Scholar] [CrossRef]

- Chen, Y.; Yi, J.; Wang, Z.; Zhou, W.; Deng, H. Experimental study on ultrasonic-assisted electrolyte plasma polishing of SUS304 stainless steel. J. Adv. Manuf. Technol. 2023, 124, 2835–2846. [Google Scholar] [CrossRef]

- Liang, Y.; Zhang, C.; Chen, X.; Zhang, T.; Yu, T.; Zhao, J. Modeling and analysis of the material removal rate for ultrasonic vibration–assisted polishing of optical glass BK7. J. Adv. Manuf. Technol. 2022, 118, 627–639. [Google Scholar] [CrossRef]

- Tsai, M.; Lin, Y.; Ho, J.; Yang, J. Ultrasonic-assisted innovative polyurethane tool to polish mold steel. Int. J. Autom. Technol. 2019, 13, 174–184. [Google Scholar] [CrossRef]

- Shiou, F.; Tsegaw, A. Ultraprecision surface finishing processes. Int. J. Autom. Technol. 2019, 13, 199–206. [Google Scholar]

- Bertolini, R.; Andrea, G.; Tamil Alagan, N.; Bruschi, S. Tool wear reduction in ultrasonic vibration-assisted turning of SiC-reinforced metal-matrix composite. Wear 2023, 523, 204785. [Google Scholar] [CrossRef]

- Witte, J.; Huebler, D.; Schroepfer, D.; Boerner, A.; Kannengiesser, T. Wear behavior of innovative niobium carbide cutting tools in ultrasonic-assisted finishing milling. Wear 2023, 522, 204722. [Google Scholar] [CrossRef]

- ISO 21920-2:2021; Geometrical Product Specifications (GPS)—Surface Texture: Profile—Part 2: Terms, Definitions and Surface Texture Parameters. International Organization for Standarization: Geneva, Switzerland, 2021. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:21920:-2:ed-1:v2:en (accessed on 16 August 2023).

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Functional Importance of Surface Texture Parameters. Materials 2021, 14, 5326. [Google Scholar] [CrossRef] [PubMed]

- Vinod, V.; Varghese, S.; Kuriakose, B. Aluminum Powder Filled Nitrile Rubber Composites. J. Appl. Polym. Sci. 2004, 91, 3156–3161. [Google Scholar] [CrossRef]

- Alhareb, A.; Akil, H.; Ahmad, Z. Poly(methyl methacrylate) denture base composites enhancement by various combinations of nitrile butadiene rubber/treated ceramic fillers. J. Thermoplast. Compos. Mater. 2015, 30, 1069–1090. [Google Scholar] [CrossRef]

- Ding, Z.L. Automated Surface Finish of Mirror-Like Stainless Mold Steel Using Ultrasonic Ball Polishing Process. Master’s Thesis, National Taiwan University of Science and Technology, Taipei, Taiwan, 13 June 2016. (In Chinese). [Google Scholar]

- STAVAX ESR. Available online: https://www.assab.com/app/uploads/sites/133/2020/04/Stavax_ESR_PH-EN.pdf (accessed on 28 June 2023).

- KLI Technology Co., Ltd. Available online: http://www.toolingmachine.biz/?atc-ultrasonic-tool-holder-auth-bt-type,40 (accessed on 29 June 2023).

| Composition | C | Si | Mn | Cr | V |

|---|---|---|---|---|---|

| % | 0.38 | 0.9 | 0.5 | 13.6 | 0.3 |

| Model | Specification |

|---|---|

| Holder Type | BT40 |

| Holder Weight | 3.5 KG |

| Input Power | 110 V 220 V AC 50/60 H |

| Maximum Output | 300W |

| Tool Speed | Max 6000 RPM |

| Tool Interface | ER-11 |

| Ultrasonic Power | 100~220 V |

| Operation Frequency | 18~27 KHz |

| Vibration Average | <20 μm |

| Type | A | B | C | D | E |

|---|---|---|---|---|---|

| Abrasive size (μm) | 0.05 μm | 0.3 μm | 1 μm | 3 μm | 3 μm |

| Concentration (%) | 20% | 20% | 30% | 20% | 40% |

| Type | A | B | C | D | E |

|---|---|---|---|---|---|

| Hardness (HAS, Shore) | 65 HAS | 63 HAS | 66 HAS | 64 HAS | 66 HAS |

| Yielding strength (N/mm2) | 9.516 N/mm2 | 8.07 N/mm2 | 9.68 N/mm2 | 6.84 N/mm2 | 10.67 N/mm2 |

| Static coefficient of friction | 0.98 | 0.96 | 0.74 | 0.61 | 0.6 |

| Factor | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| A. Amplitude (μm) | 6 | 10 | --- |

| B. Frequency (KHz) | 18 | 20 | 23 |

| C. Spindle Speed (rpm) | 1000 | 3000 | 5000 |

| D. Abrasive Diameter (μm) | 0.05 | 0.3 | 1 |

| E. Feed Rate (mm/min) | 20 | 40 | 60 |

| F. Stepover (μm) | 20 | 40 | 60 |

| G. Depth of Penetration (μm) | 60 | 120 | 180 |

| H. Abrasive Concentration | 1:10 | 1:20 | 1:30 |

| Factor | Level |

|---|---|

| A. Amplitude (μm) | 10 |

| B. Frequency (KHz) | 23 |

| C. Spindle Speed (rpm) | 5000 |

| D. Abrasive Diameter (μm) | 0.3 |

| E. Feed Rate (mm/min) | 60 |

| F. Stepover (μm) | 20 |

| G. Depth of Penetration (μm) | 180 |

| H. Abrasive Concentration | 1:10 |

| No. of Pass | Test 1 (μm) | Test 2 (μm) | Test 3 (μm) | Mean (μm) |

|---|---|---|---|---|

| Burnished | 0.13 | 0.13 | 0.13 | 0.130 |

| E | 0.08 | 0.08 | 0.08 | 0.080 |

| D | 0.10 | 0.90 | 0.90 | 0.093 |

| E-A | 0.08 | 0.07 | 0.07 | 0.073 |

| E-C | 0.07 | 0.07 | 0.06 | 0.067 |

| E-C-B | 0.04 | 0.05 | 0.04 | 0.043 |

| E-C-B-A | 0.02 | 0.03 | 0.03 | 0.027 |

| Factor | Level |

|---|---|

| A. Amplitude (μm) | 10 |

| B. Frequency (KHz) | 23 |

| C. Spindle Speed (rpm) | 5000 |

| D. Feed Rate (mm/min) | 60 |

| E. Stepover (μm) | 20 |

| F. Depth of Penetration (μm) | 180 |

| G. No. of Passes | E-C-B-A |

| Volumetric Wear | Wool Ball | A: 0.05 μm (20%) | B: 0.3 μm (20%) | C: 1 μm (30%) | D: 3 μm (20%) | E: 3 μm (40%) |

|---|---|---|---|---|---|---|

| Volumetric wear with no vibration (mm3) (%) | 33.5847 4% | 4.7157 0.56% | 7.9067 0.94% | 12.5347 1.5% | 11.1427 0.6% | 17.197 2% |

| Volumetric wear with vibration (mm3) (%) | 13.9207 1.66% | 4.1557 0.49% | 5.8127 0.69% | 5.6557 0.67% | 4.7537 0.57% | 6.0907 0.73% |

| Improvement (%) | 58.55% | 12.64% | 26.48% | 60.07% | 57.33% | 64.58% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shiou, F.-J.; Pan, J.-N.; Ding, Z.-L.; Lin, S.-P. Ultrasonic-Assisted Surface Finishing of STAVAX Mold Steel Using Lab-Made Polishing Balls on a 5-Axis CNC Machining Center. Materials 2023, 16, 5888. https://doi.org/10.3390/ma16175888

Shiou F-J, Pan J-N, Ding Z-L, Lin S-P. Ultrasonic-Assisted Surface Finishing of STAVAX Mold Steel Using Lab-Made Polishing Balls on a 5-Axis CNC Machining Center. Materials. 2023; 16(17):5888. https://doi.org/10.3390/ma16175888

Chicago/Turabian StyleShiou, Fang-Jung, Jian-Nan Pan, Zhao-Li Ding, and Sun-Peng Lin. 2023. "Ultrasonic-Assisted Surface Finishing of STAVAX Mold Steel Using Lab-Made Polishing Balls on a 5-Axis CNC Machining Center" Materials 16, no. 17: 5888. https://doi.org/10.3390/ma16175888

APA StyleShiou, F.-J., Pan, J.-N., Ding, Z.-L., & Lin, S.-P. (2023). Ultrasonic-Assisted Surface Finishing of STAVAX Mold Steel Using Lab-Made Polishing Balls on a 5-Axis CNC Machining Center. Materials, 16(17), 5888. https://doi.org/10.3390/ma16175888