Micro-Twinning in IN738LC Manufactured with Laser Powder Bed Fusion

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

- Supplier: VDM Metals (Frankfurt, Germany);

- Gas atomized;

- The D10–D90 range corresponds to 22–49 µm;

- B, P, and S lie below 0.015 wt.%.;

- Mn and Fe lies below 0.05 wt.%.;

- Less than 0.3 wt.% Si are contained within the powder.

| Al | C | Co | Cr | Mo | Nb | Ni | Ta | Ti | W | Zr |

|---|---|---|---|---|---|---|---|---|---|---|

| 3.7 | 0.13 | 9 | 16.3 | 2 | 1.1 | 58.6 | 2 | 3.7 | 2.8 | 0.08 |

2.2. PBF-LB/M Manufacturing

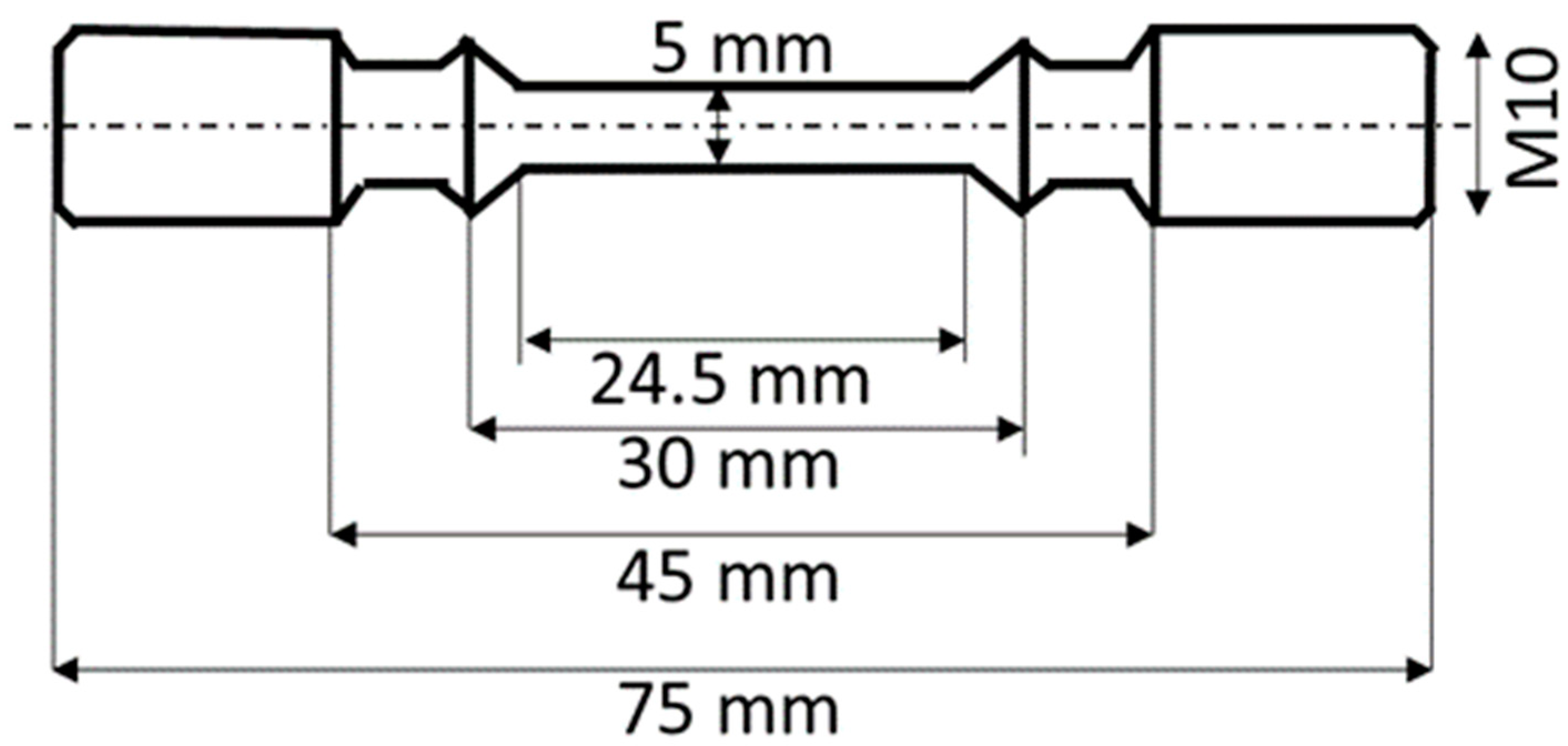

2.3. Creep and Tensile Testing

- Temperature: 850 °C;

- Applied stress: 200 MPa.

- Temperature: 850 °C;

- Strain rate: 0.5%/min when ε < 1.5% (elastic regime);

- Strain rate: 5%/min when ε > 1.5% (plastic regime).

2.4. Relative Density and Microstructure

2.4.1. Relative Density

2.4.2. Scanning Electron Microscopy (SEM)

2.4.3. Transmission Electron Microscopy (TEM)

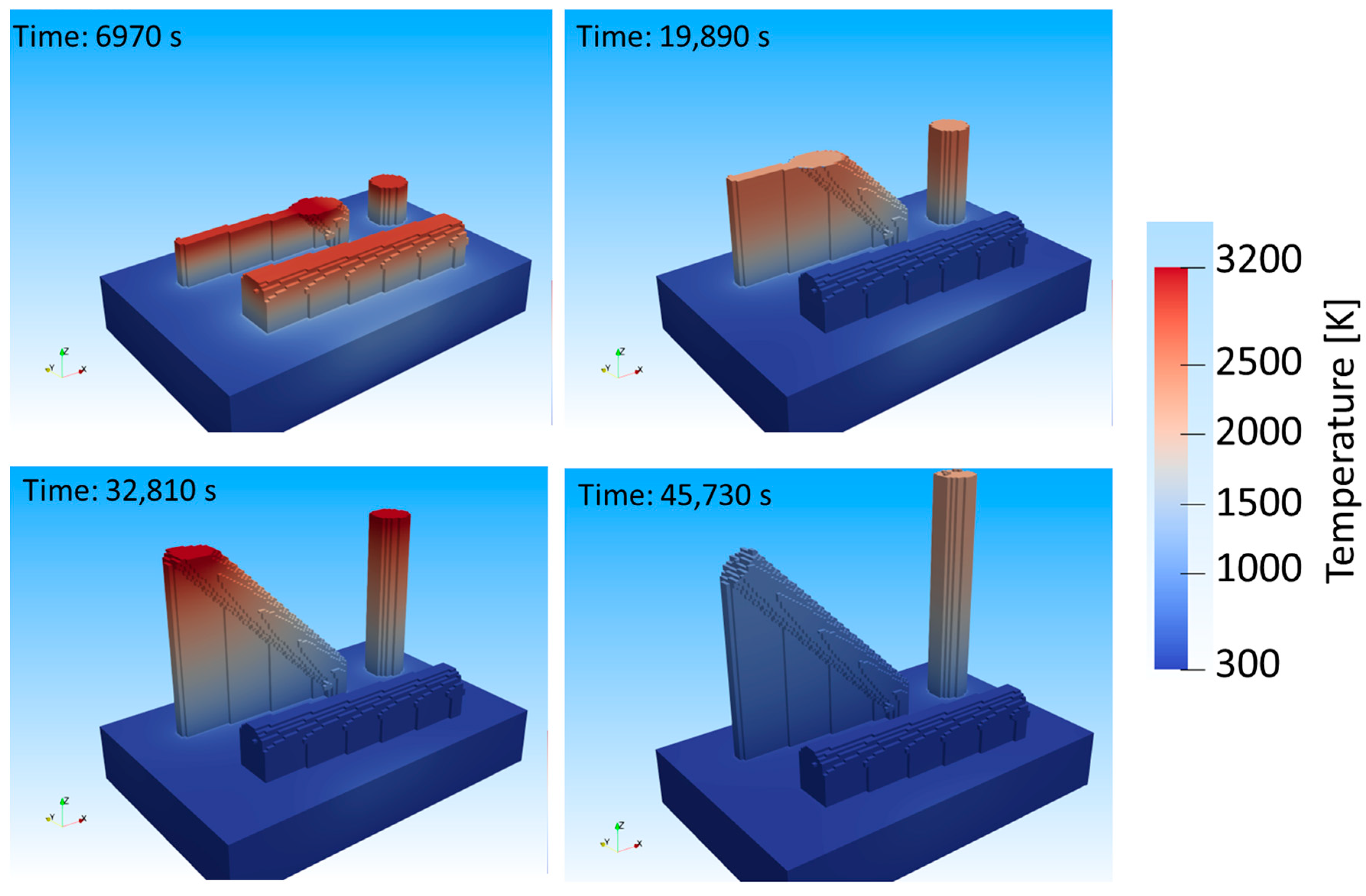

2.5. Numerical Thermal Modelling

- The thermal model used in this study ignores melt pool dynamics and does not resolve scan strategy for the sake of reducing computational effort. Zielinksi et al. showed, that layer-wise thermal models are able to accurately describe the thermal history of parts, while also increasing computational speed [30].

- The volume energy density is applied to 100 layers at a time lasting for a duration corresponding to the build rate and the respective layer volume. After that, the heat source is switched off and allows for the induced heat to diffuse during the recoating time (10 s). Since a group of layers is heated at once, the recoating time is extended accordingly. Following the recoating time, the next 100 layers are exposed to the volume energy density. The process is repeated until the complete samples are numerically built.

- The boiling temperature (i.e., 3200 K) is set as the upper temperature limit.

- In the mushy zone (Tsolidus to Tliquidus), the solution is held constant until the material melts or solidifies.

- The substrate plate acts as a heat sink, with the substrate plate sides exchanging heat with a heat transfer coefficient of 10 , and the substrate plate top exchanges heat with a heat transfer coefficient of 5 .

- The properties , cp and are temperature dependent and were taken from [31].

- is the density;

- cp is the specific heat;

- T is temperature;

- t is time;

- is thermal conductivity;

- Qv is volumetric heat source.

3. Results and Discussion

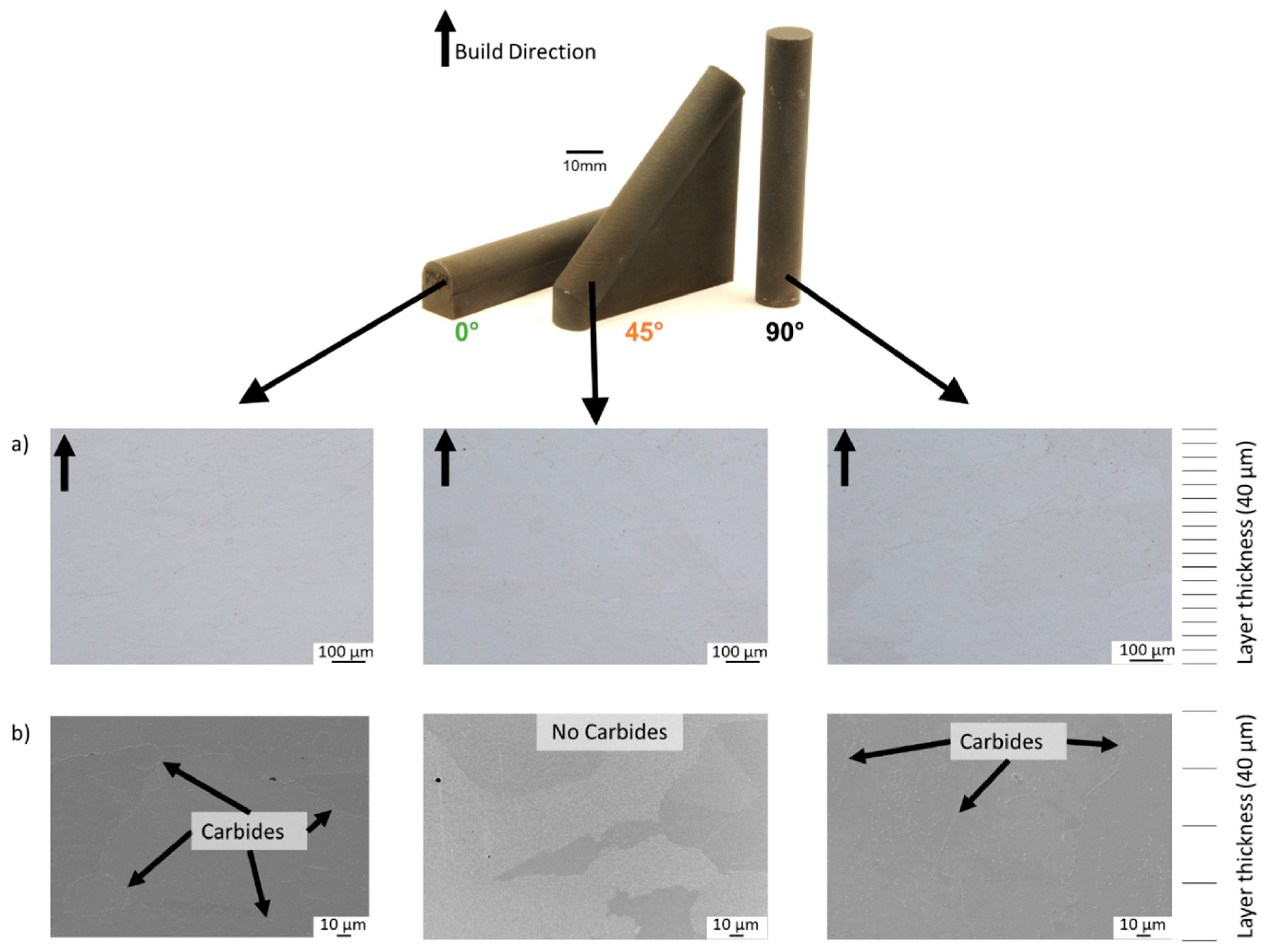

3.1. PBF-LB/M Microstructure

3.2. PBF-LB/M Tensile Properties

3.3. PBF-LB/M Creep Properties

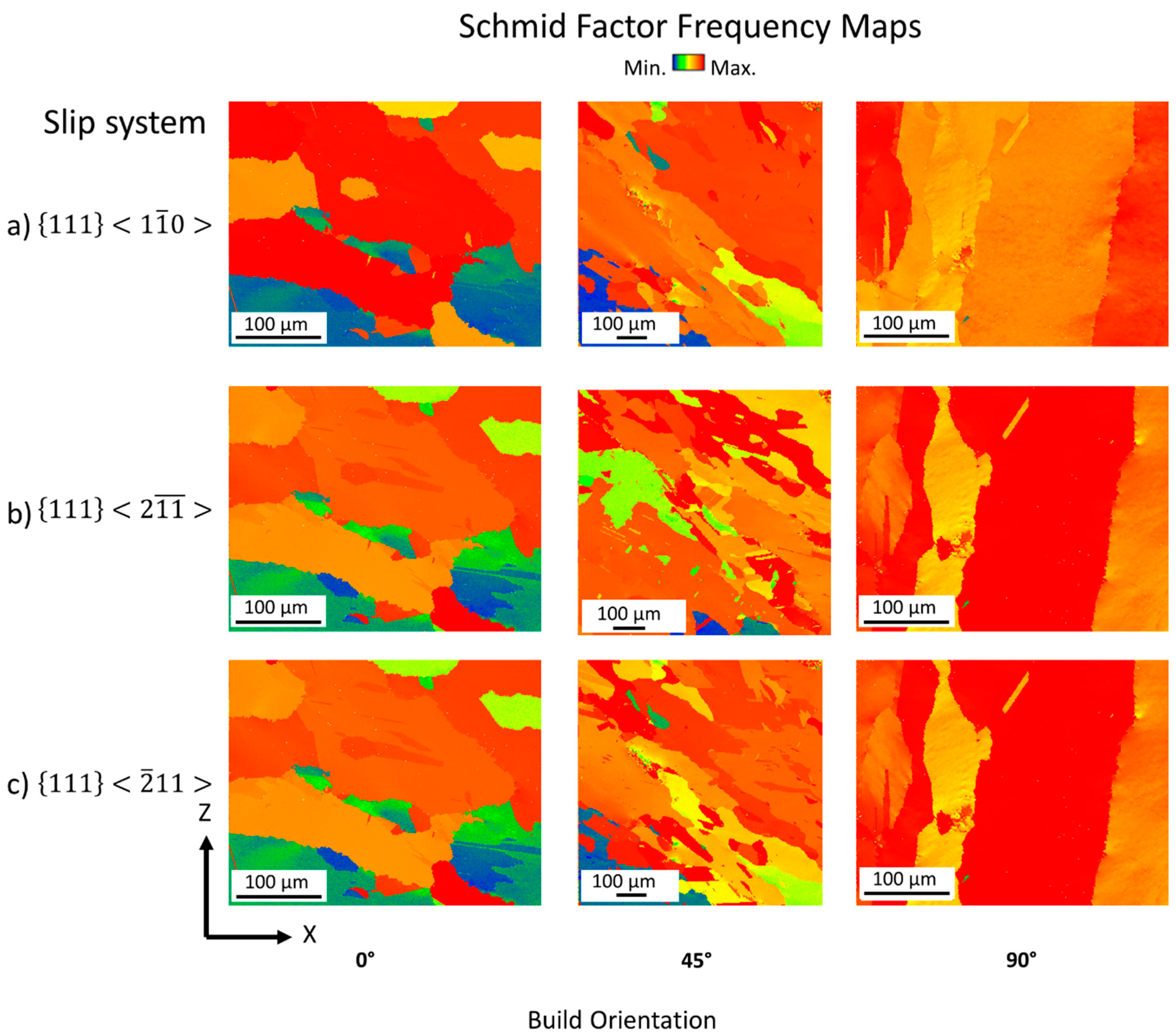

- → fcc slip system

- → slip system when Superlattice Intrinsic Stacking Faults (SISF) and/or micro-twins are present

- → slip system when Superlattice Extrinsic Stacking Faults (SESF) and/or micro-twins are present

4. Conclusions

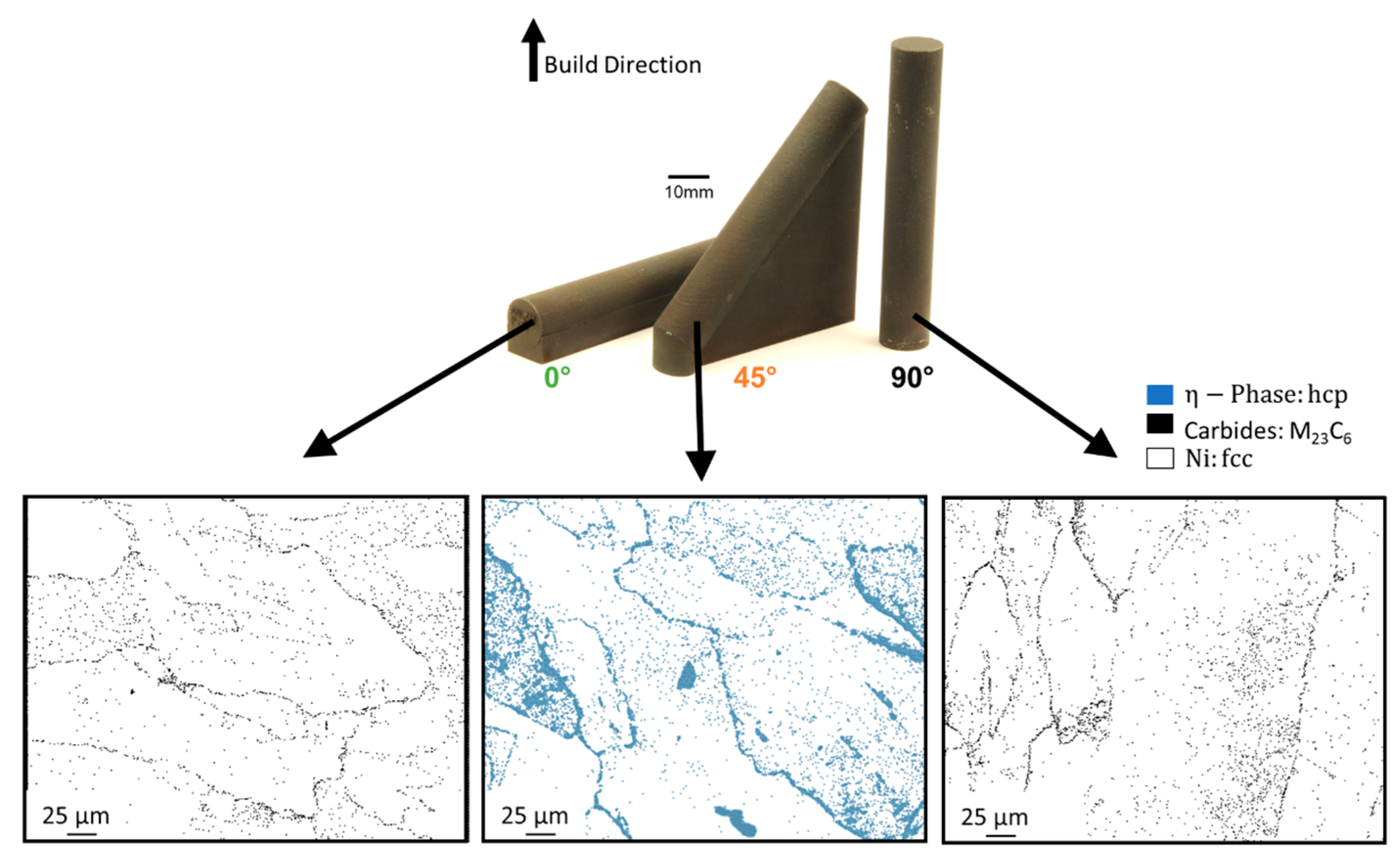

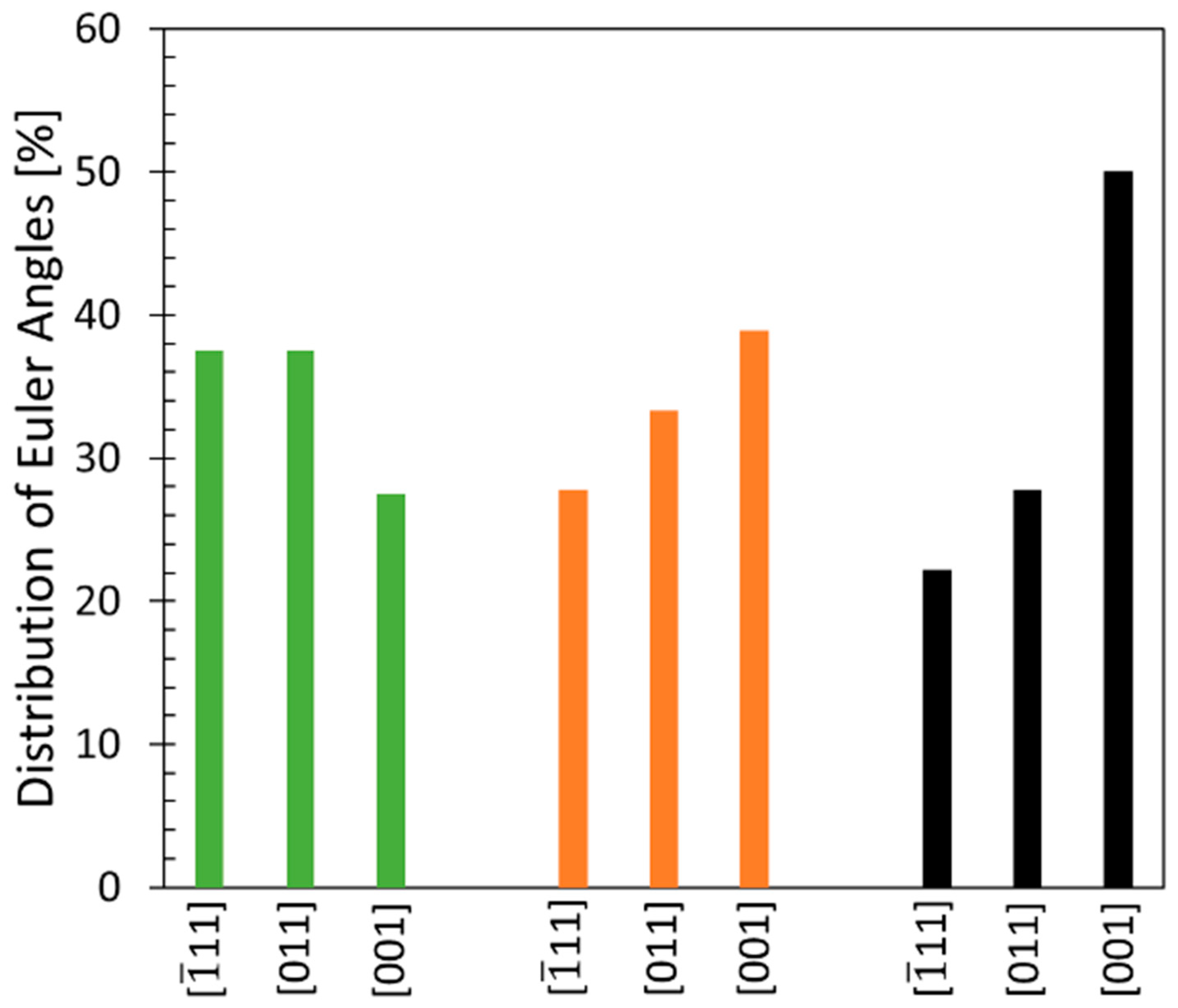

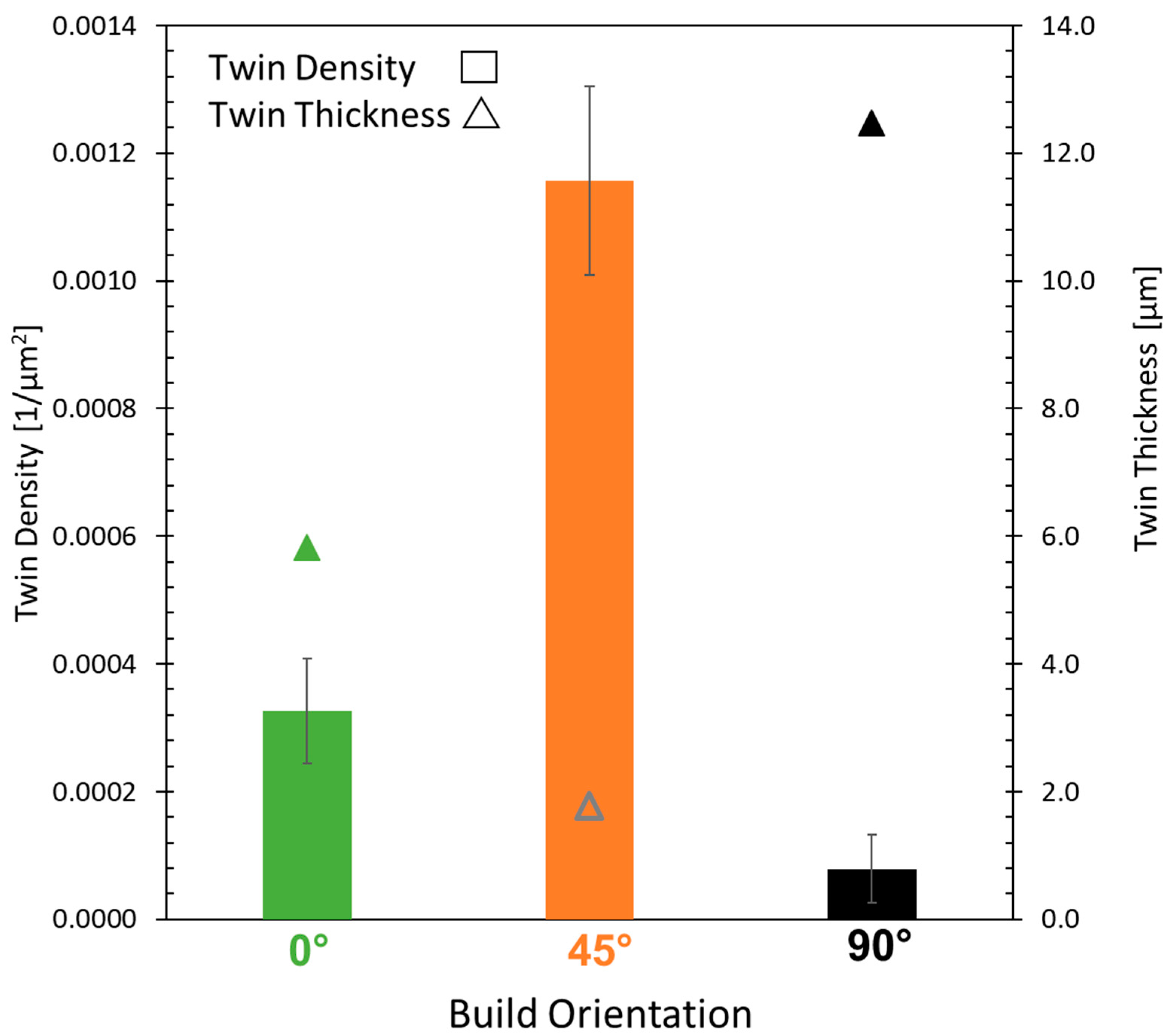

- Solidification conditions differ between the build orientations.

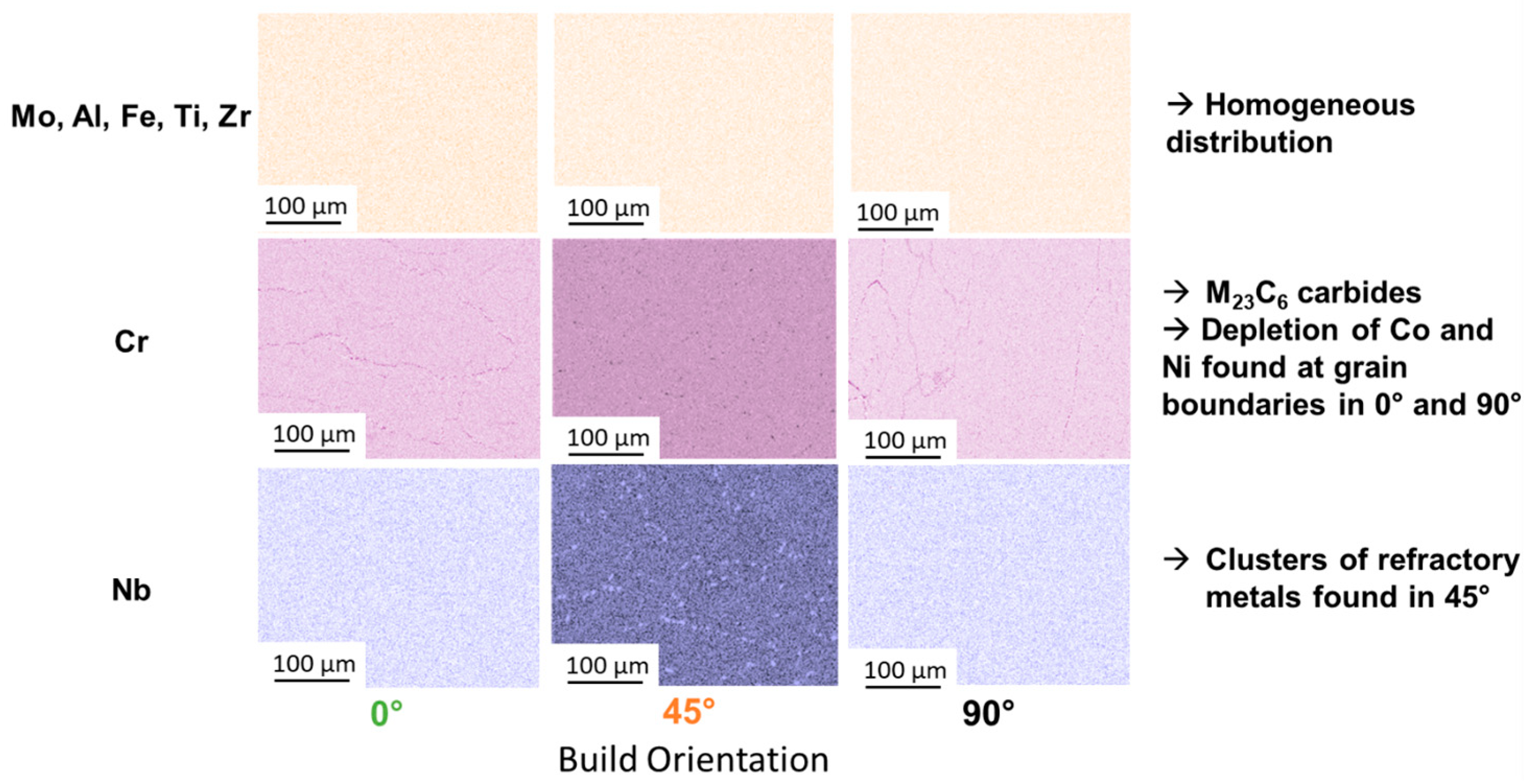

- The differing solidification conditions cause differences in grain size, phase formation and segregation behavior.

- Time to rupture is lowest in 45° compared to the 0° and 90° build orientations.

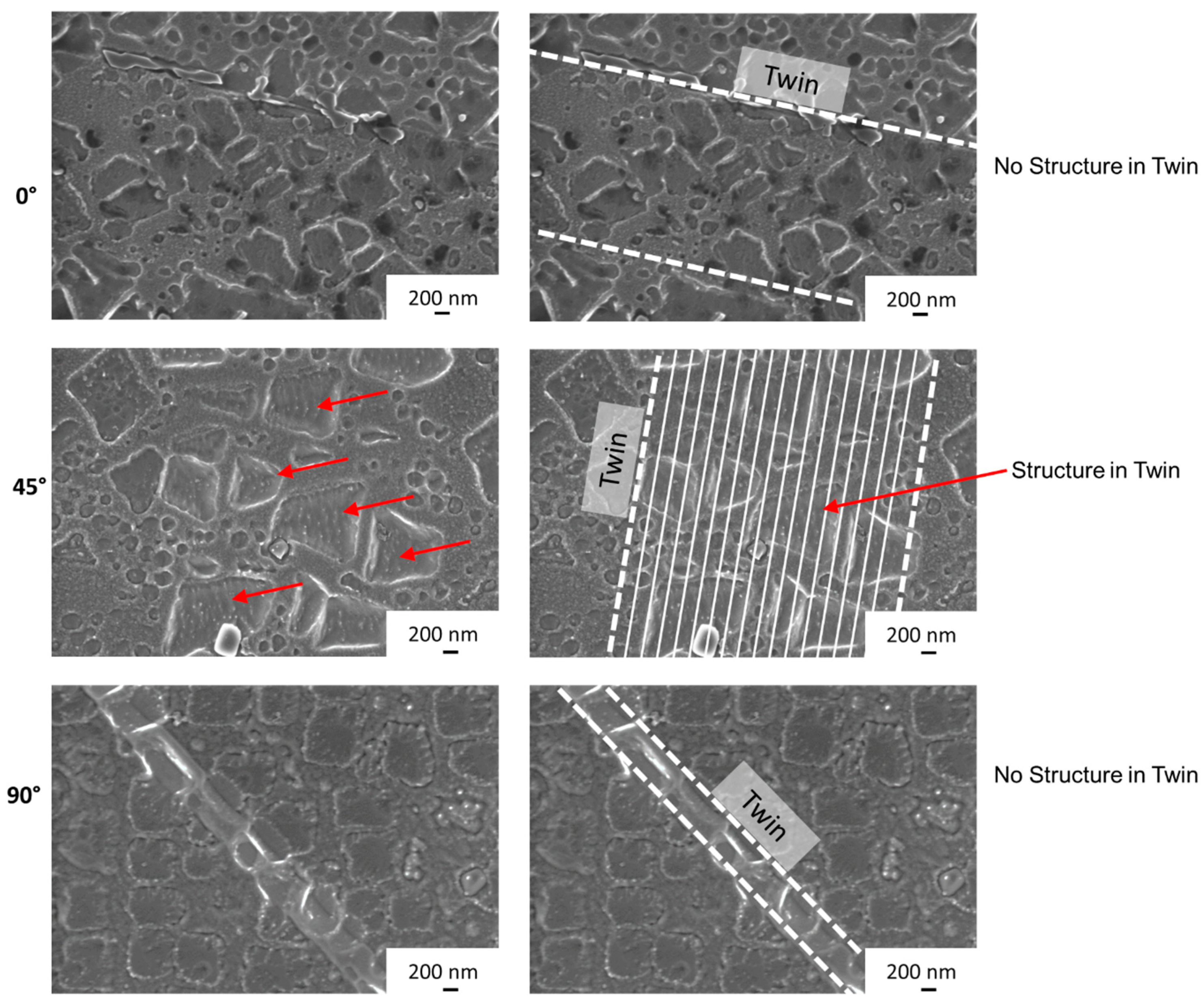

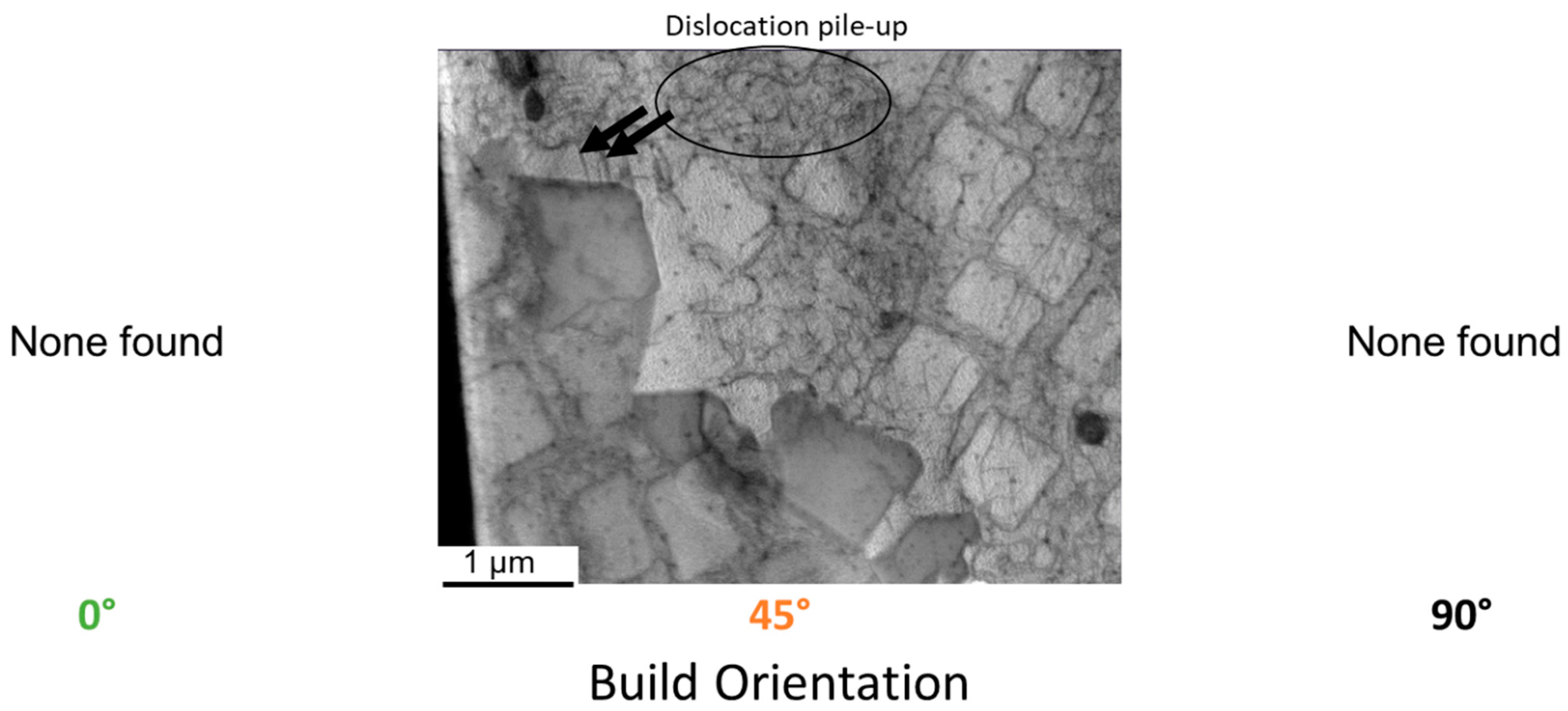

- The 45° build direction exhibits more creep deformation mechanisms compared to the 0° and 90° build directions.

- The differing solidification conditions affect elemental distribution, which in turn affect twin density, and twin thickness.

- The differentiating twin behavior causes an increase in SFE.

- Micro-twins were found for the first time in PBF-LB/M samples.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- DIN EN ISO 17296-3:2016-12; Additive Fertigung_- Grundlagen_- Teil_3: Haupteigenschaften und Entsprechende Prüfverfahren (ISO_17296-3:2014). Beuth Verlag GmbH: Berlin, Germany, 2016.

- DIN EN ISO 17296-4:2016-12; Additive Fertigung_- Grundlagen_- Teil_4: Überblick über die Datenverarbeitung (ISO_17296-4:2014). Deutsche Fassung EN_ISO_17296-4:2016; Beuth Verlag GmbH: Berlin, Germany, 2016.

- DIN EN ISO/ASTM 52900:2017-06; Additive Fertigung_- Grundlagen_- Terminologie (ISO/ASTM 52900:2015). Deutsche Fassung EN_ISO/ASTM 52900:2017; Beuth Verlag GmbH: Berlin, Germany, 2017.

- Herderick, E. Additive Manufacturing of Metals: A Review. Mater. Sci. Technol.Conf. Exhib. 2011, 2, 1413–1425. [Google Scholar]

- Diegel, O.; Nordin, A.; Motte, D. A Practical Guide to Design for Additive Manufacturing; Springer: Singapore, 2019; ISBN 978-981-13-8280-2. [Google Scholar]

- Sanchez, S.; Hyde, C.J.; Ashcroft, I.A.; Ravi, G.A.; Clare, A.T. Multi-laser scan strategies for enhancing creep performance in LPBF. Addit. Manuf. 2021, 41, 101948. [Google Scholar] [CrossRef]

- Rickenbacher, L.; Etter, T.; Hövel, S.; Wegener, K. High temperature material properties of IN738LC processed by selective laser melting (SLM) technology. Rapid Prototyp. J. 2013, 19, 282–290. [Google Scholar] [CrossRef]

- Megahed, S.; Krämer, K.M.; Heinze, C.; Kontermann, C.; Udoh, A.; Weihe, S.; Oechsner, M. Influence of build orientation on the creep behavior of IN738LC manufactured with laser powder bed fusion. Mater. Sci. Eng. A 2023, 2003, 145197. [Google Scholar] [CrossRef]

- Viswanathan, G.B.; Sarosi, P.M.; Whitis, D.H.; Mills, M.J. Deformation mechanisms at intermediate creep temperatures in the Ni-base superalloy René 88 DT. Mater. Sci. Eng. A 2005, 400–401, 489–495. [Google Scholar] [CrossRef]

- Kovarik, L.; Unocic, R.R.; Li, J.; Sarosi, P.; Shen, C.; Wang, Y.; Mills, M.J. Microtwinning and other shearing mechanisms at intermediate temperatures in Ni-based superalloys. Prog. Mater. Sci. 2009, 54, 839–873. [Google Scholar] [CrossRef]

- Ghosh, S.; Weber, G.; Keshavarz, S. Multiscale modeling of polycrystalline nickel-based superalloys accounting for subgrain microstructures. Mech. Res. Commun. 2016, 78, 34–46. [Google Scholar] [CrossRef]

- Kear, B.H.; Oblak, J.M. Deformation modes γ’precipitation hardened nickel-base alloys. J. Phys. Colloques 1974, 35, C7-35–C7-45. [Google Scholar] [CrossRef]

- Barba, D.; Pedrazzini, S.; Vilalta-Clemente, A.; Wilkinson, A.J.; Moody, M.P.; Bagot, P.; Jérusalem, A.; Reed, R.C. On the composition of microtwins in a single crystal nickel-based superalloy. Scr. Mater. 2017, 127, 37–40. [Google Scholar] [CrossRef]

- Smith, T.M.; Unocic, R.R.; Deutchman, H.; Mills, M.J. Creep deformation mechanism mapping in nickel base disk superalloys. Mater. High Temp. 2016, 33, 372–383. [Google Scholar] [CrossRef]

- Freund, L.P.; Messé, O.M.; Barnard, J.S.; Göken, M.; Neumeier, S.; Rae, C.M. Segregation assisted microtwinning during creep of a polycrystalline L12-hardened Co-base superalloy. Acta Mater. 2017, 123, 295–304. [Google Scholar] [CrossRef]

- Smith, T.M.; Esser, B.D.; Antolin, N.; Viswanathan, G.B.; Hanlon, T.; Wessman, A.; Mourer, D.; Windl, W.; McComb, D.W.; Mills, M.J. Segregation and η phase formation along stacking faults during creep at intermediate temperatures in a Ni-based superalloy. Acta Mater. 2015, 100, 19–31. [Google Scholar] [CrossRef]

- Titus, M.S.; Mottura, A.; Babu Viswanathan, G.; Suzuki, A.; Mills, M.J.; Pollock, T.M. High resolution energy dispersive spectroscopy mapping of planar defects in L12-containing Co-base superalloys. Acta Mater. 2015, 89, 423–437. [Google Scholar] [CrossRef]

- Smith, T.M.; Esser, B.D.; Antolin, N.; Carlsson, A.; Williams, R.E.A.; Wessman, A.; Hanlon, T.; Fraser, H.L.; Windl, W.; McComb, D.W.; et al. Phase transformation strengthening of high-temperature superalloys. Nat Commun 2016, 7, 13434. [Google Scholar] [CrossRef]

- Barba, D.; Alabort, E.; Pedrazzini, S.; Collins, D.M.; Wilkinson, A.J.; Bagot, P.; Moody, M.P.; Atkinson, C.; Jérusalem, A.; Reed, R.C. On the microtwinning mechanism in a single crystal superalloy. Acta Mater. 2017, 135, 314–329. [Google Scholar] [CrossRef]

- Sanchez, S.; Gaspard, G.; Hyde, C.J.; Ashcroft, I.A.; Ravi, G.A.; Clare, A.T. The creep behaviour of nickel alloy 718 manufactured by laser powder bed fusion. Mater. Des. 2021, 204, 109647. [Google Scholar] [CrossRef]

- Pegues, J.; Lee, S.; Jensen, S.; Saiz, D.; Whetten, S.; Kustas, A.; Shamsaei, N. Tailoring microstructure and strength through selective remelting in laser powder bed fusion. Mater. Sci. Eng. A 2023, 883, 145412. [Google Scholar] [CrossRef]

- DIN EN ISO 204:2019-04; Metallic Materials—Uniaxial Creep Testing in Tension—Method of Test (ISO 204:2018). Beuth Verlag GmbH: Berlin, Germany, 2019.

- DIN EN ISO 7500-1:2018-06; Metallic Materials—Calibration and Verification of Static Uniaxial Testing Machines—Part 1: Tension/Compression Testing Machines—Calibration and Verification of the Force-Measuring System (ISO 7500-1:2018). Beuth Verlag GmbH: Berlin, Germany, 2018.

- Hu, Y.; Tang, D.; Yang, L.; Lin, Y.; Zhu, C.; Xiao, J.; Yan, C.; Shi, Y. Multi-physics modeling for laser powder bed fusion process of NiTi shape memory alloy. J. Alloys Compd. 2023, 954, 170207. [Google Scholar] [CrossRef]

- Wolfer, A.J.; Aires, J.; Wheeler, K.; Delplanque, J.-P.; Rubenchik, A.; Anderson, A.; Khairallah, S. Fast solution strategy for transient heat conduction for arbitrary scan paths in additive manufacturing. Addit. Manuf. 2019, 30, 100898. [Google Scholar] [CrossRef]

- Moran, T.P.; Warner, D.H.; Phan, N. Scan-by-scan part-scale thermal modelling for defect prediction in metal additive manufacturing. Addit. Manuf. 2021, 37, 101667. [Google Scholar] [CrossRef]

- Liu, B.; Fang, G.; Lei, L. An analytical model for rapid predicting molten pool geometry of selective laser melting (SLM). Appl. Math. Model. 2021, 92, 505–524. [Google Scholar] [CrossRef]

- Duong, E.; Masseling, L.; Knaak, C.; Dionne, P.; Megahed, M. Scan path resolved thermal modelling of LPBF. Addit. Manuf. Lett. 2022, 3, 100047. [Google Scholar] [CrossRef]

- Ji, X.; Wang, Y.; Liang, S.Y. Analytical modeling of temperature evolution in laser powder bed fusion considering the size and shape of the build part. J. Mater. Process. Technol. 2022, 301, 117452. [Google Scholar] [CrossRef]

- Zielinski, J.; Theunissen, J.; Kruse, H.; Rittinghaus, S.; Schleifenbaum, J.H.; Zhu, D.; Megahed, M. Understanding inhomogeneous mechanical properties in PBF-LB/M manufactured parts due to inhomogeneous macro temperature profiles based on process-inherent preheating. J. Manuf. Mater. Process. 2023, 7, 88. [Google Scholar] [CrossRef]

- Inco, The Internactional Nickel Company, Inc. Alloy IN-738 Technical Data. Available online: https://www.nickelinstitute.org/media/1709/in_738alloy_preliminarydata_497_.pdf (accessed on 27 March 2023).

- Aggarangsi, P.; Beuth, J.L. Localized Preheating Approaches for Reducing Residual Stress in Additive Manufacturing. In Proceedings of the 2006 International Solid Freeform Fabrication Symposium, Austin, TX, USA, 14–16 August 2006. [Google Scholar]

- Mercelis, P.; Kruth, J.-P. Residual stresses in selective laser sintering and selective laser melting. Rapid Prototyp. J. 2006, 12, 254–265. [Google Scholar] [CrossRef]

- Risse, J. Additive Fertigung der Nickelbasis-Superlegierung IN738LC Mittels Selektivem Laserstrahlschmelzen; RWTH Aachen University: Aachen, Germany, 2019. [Google Scholar]

- Kunze, K.; Etter, T.; Grässlin, J.; Shklover, V. Texture, anisotropy in microstructure and mechanical properties of IN738LC alloy processed by selective laser melting (SLM). Mater. Sci. Eng. A 2015, 620, 213–222. [Google Scholar] [CrossRef]

- Wang, H.; Zhang, X.; Wang, G.B.; Shen, J.; Zhang, G.Q.; Li, Y.P.; Yan, M. Selective laser melting of the hard-to-weld IN738LC superalloy: Efforts to mitigate defects and the resultant microstructural and mechanical properties. J. Alloys Compd. 2019, 807, 151662. [Google Scholar] [CrossRef]

- Choi, B.G.; Kim, I.S.; Kim, D.H.; Seo, S.M.; Jo, C.Y. ETA Phase Formation During Thermal Exposure and Its Effect on Mechanical Properties in Ni-Base Superalloy GTD 111. In Proceedings of the Superalloys 2004 (Tenth International Symposium), Champion, PA, USA, 19–23 September 2004; TMS: McCandless, MN, USA, 2004; pp. 163–171, ISBN 0-87339-576-X. [Google Scholar]

- Liu, G.; Xiao, X.; Véron, M.; Birosca, S. The nucleation and growth of η phase in nickel-based superalloy during long-term thermal exposure. Acta Mater. 2020, 185, 493–506. [Google Scholar] [CrossRef]

- Bürgel, R.; Jürgen Maier, H.; Niendorf, T. Handbuch Hochtemperatur-Werkstofftechnik; Vieweg+Teubner: Wiesbaden, Germany, 2011; ISBN 978-3-8348-1388-6. [Google Scholar]

- Callister, W.D.; Rethwisch, D.G. Fundamentals of Materials Science and Engineering: An Integrated Approach, 5th ed.; Wiley Binder version; Wiley: Hoboken, NJ, USA, 2015; ISBN 9781119175483. [Google Scholar]

- Egan, A.J.; Xue, F.; Rao, Y.; Sparks, G.; Marquis, E.; Ghazisaeidi, M.; Tin, S.; Mills, M.J. Local Phase Transformation Strengthening at Microtwin Boundaries in Nickel-Based Superalloys. Acta Mater. 2022, 238, 118206. [Google Scholar] [CrossRef]

- Sanchez-Mata, O.; Wang, X.; Muñiz-Lerma, J.A.; Atabay, S.E.; Attarian Shandiz, M.; Brochu, M. Dependence of mechanical properties on crystallographic orientation in nickel-based superalloy Hastelloy X fabricated by laser powder bed fusion. J. Alloys Compd. 2021, 865, 158868. [Google Scholar] [CrossRef]

| Sample Dimensions | Cylinders: Diameter = 13 mm Height = 80 mm |

| PBF-LB/M machine | EOS M290 (Krailling/Munich, Germany) |

| Volume energy density | 69 J/mm3 |

| Layer thickness | 40 µm |

| Heat treatment | Held between 110–1230 °C under argon atmosphere Air cooling Held at 840 °C for 24 h under argon atmosphere Air cooling |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Megahed, S.; Krämer, K.M.; Kontermann, C.; Heinze, C.; Udoh, A.; Weihe, S.; Oechsner, M. Micro-Twinning in IN738LC Manufactured with Laser Powder Bed Fusion. Materials 2023, 16, 5918. https://doi.org/10.3390/ma16175918

Megahed S, Krämer KM, Kontermann C, Heinze C, Udoh A, Weihe S, Oechsner M. Micro-Twinning in IN738LC Manufactured with Laser Powder Bed Fusion. Materials. 2023; 16(17):5918. https://doi.org/10.3390/ma16175918

Chicago/Turabian StyleMegahed, Sandra, Karl Michael Krämer, Christian Kontermann, Christoph Heinze, Annett Udoh, Stefan Weihe, and Matthias Oechsner. 2023. "Micro-Twinning in IN738LC Manufactured with Laser Powder Bed Fusion" Materials 16, no. 17: 5918. https://doi.org/10.3390/ma16175918

APA StyleMegahed, S., Krämer, K. M., Kontermann, C., Heinze, C., Udoh, A., Weihe, S., & Oechsner, M. (2023). Micro-Twinning in IN738LC Manufactured with Laser Powder Bed Fusion. Materials, 16(17), 5918. https://doi.org/10.3390/ma16175918