A Review of Solar-Coupled Phase Change Materials in Buildings

Abstract

:1. Introduction

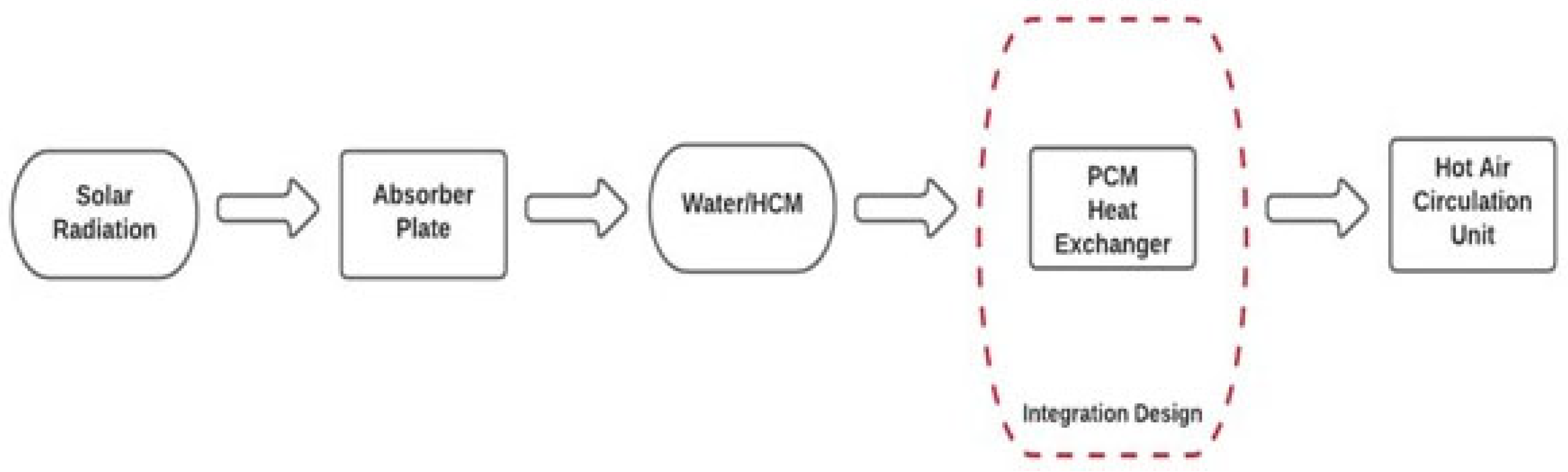

2. Configurations of SPCMS

2.1. Active Arrangements

2.2. Passive Arrangements

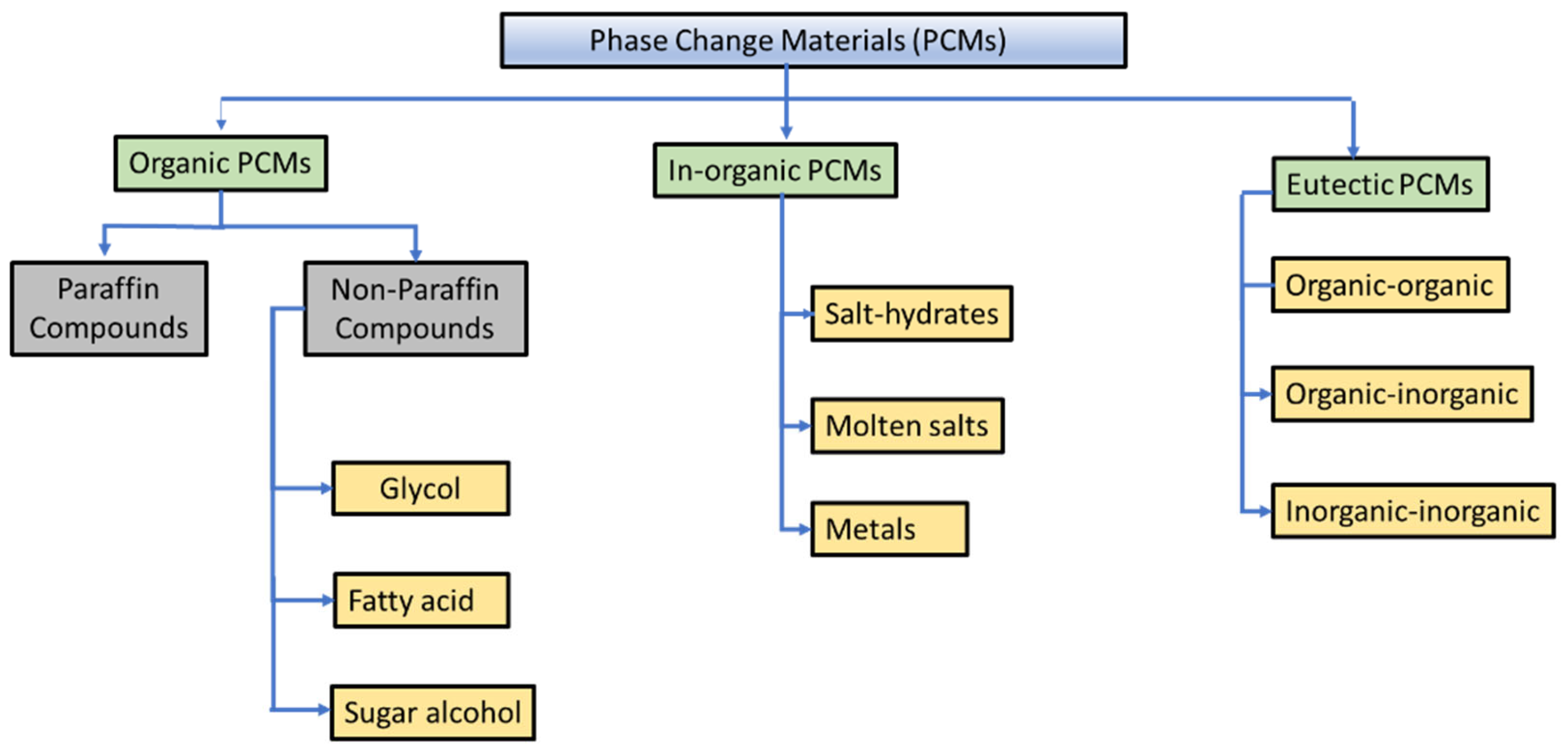

2.3. Type of PCMs Used in SPCMS

3. Key Performance Indicators (KPIs) for SPCMSs

3.1. Technical/Thermophysical Indicators

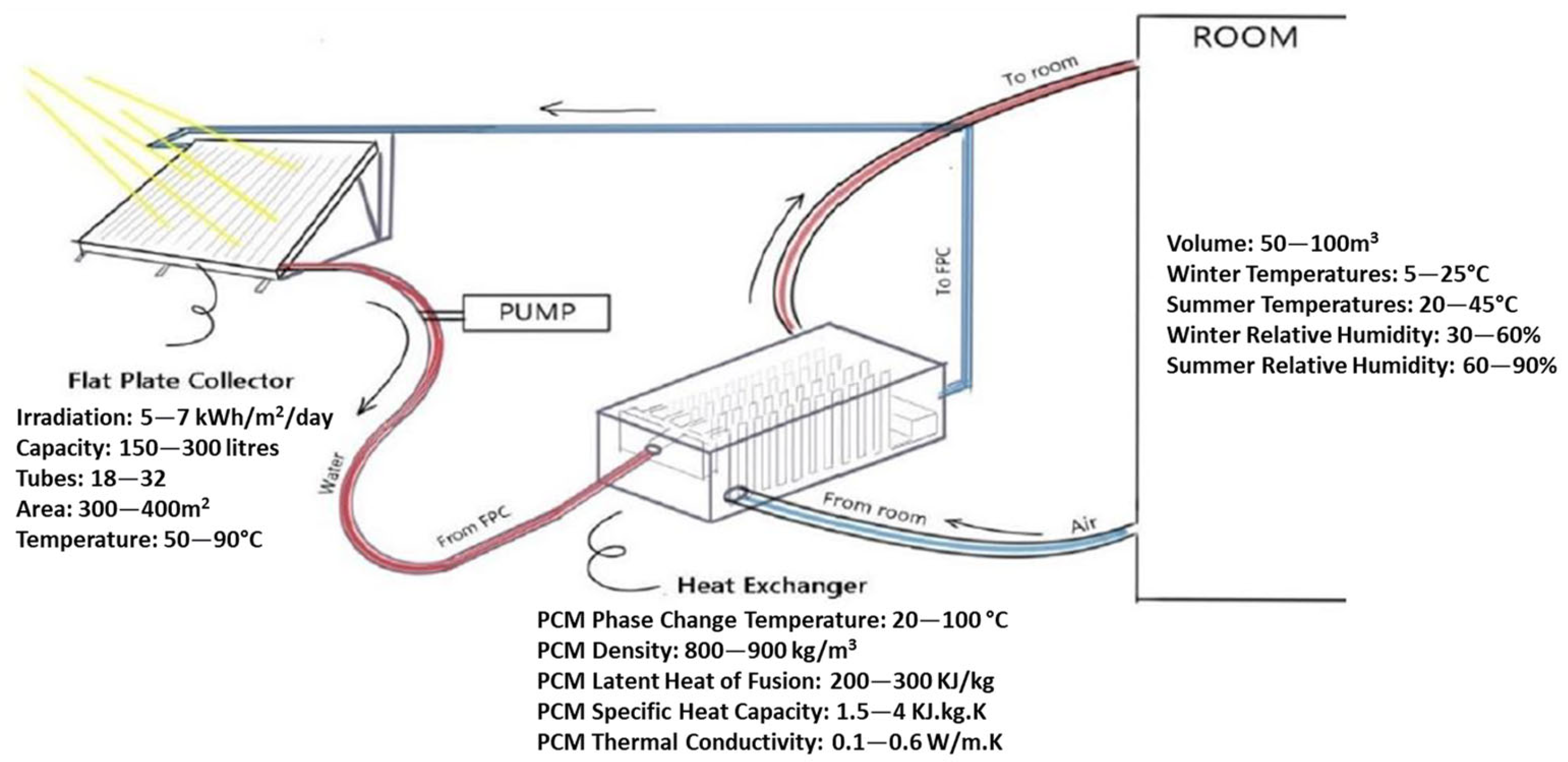

- Transition temperature of a PCM: The transition temperature of a PCM should be within the operating range of the system in an optimal manner [48]. The pull of heat during charging and the push of heat during discharging should be made equal by ensuring an equivalent ΔT between the phase change temperature and the supply and demand of the HTF. Generally, the applications involving heating requirements employ PCMs that have a phase change temperature in the range of 20–100 °C, except for solar thermal electricity, where a phase change temperature in the range of 400–1000 °C is required. On the other hand, cooling applications usually require a PCM with a phase change temperature in the range of −20–20 °C. PCMs with a phase transition temperature in the range of 21–28 °C are preferred for providing thermal comfort in residential buildings.

- Density of a PCM: A high-density PCM is recommended when storing a higher energy content in a specified volume. In this way, the volume of the thermal storage can be reduced significantly [48]. The density difference between the solid and liquid phases should be kept minimal to avoid ullage, but this will reduce free convective heat transfer, especially during melting. The density of paraffin wax usually lies in the range of 800–900 .

- Latent heat of fusion of a PCM: A higher value for the latent heat of fusion is preferred. A high latent heat results in more energy storage [49]. The latent heat of fusion for paraffin wax is between 200–300 kJ/kg, whereas for metallic PCMs, its value is found to be in the range of 25–100 kJ/kg.

- Specific heat of a PCM: The specific heat of a PCM should also be high. A higher value for specific heat, again, corresponds to higher-density energy storage, which is desirable [48]. The entire objective of using PCMs is to maximize latent heat transfer while minimizing sensible heat transfer.

- Thermal conductivity: The thermal conductivity of a PCM should be as high as possible. However, the main reason for the limited commercial success of PCMs both in active and passive setups is their inherently low thermal conductivity. Various techniques can be used to increase a PCM’s thermal conductivity, including the use of graphite powder, carbon nanotubes, graphene, honeycomb fillers, aluminum matrices, carbon fibers, nanoparticles, fins, and heat pipes [50]. For instance, the thermal conductivity of paraffin wax was found to increase from 0.21 W/m.K to 4.09 W/m.K when using a composite of paraffin with aluminum powder [50].

- Inter tube distance in a PCM heat exchanger: Heat exchangers with several tubes are recommended to improve the thermal conductivity of SPCMSs. The distance between the tubes of such heat exchangers plays a significant role in overall thermal performance. Intuitively, as the distance between the tubes decreases, the system becomes more compact, resulting in better performance and increasing the area of contact between the HTF and PCM. This compactness not only reduces the loss of heat to the surrounding area but also generates space for more tubes [51].

- Insulation of SPCMSs: The transfer of energy from the PCM to the desired medium occurs with the loss of energy to the surroundings. Minimizing such heat loss will result in the significantly better thermal performance of the system. Polyurethane and wood are commonly used for insulating a SPCMSs [52].

- Circulation flow rate: Useful heat gain is found to increase with the increase in the flow rate of the HTF, which, consequently, causes an increase in heat transfer to the facility in which the system is employed [53]. Normally, HTF flows at a rate of 2–15 L/minute in a SPCMS.

- Cascaded PCM arrangement: Using two PCMs with different transition temperatures results in higher thermal conductivity and, consequently, better performance [54,55]. This technique maintains a consistent ΔT between the HTF and the phase change temperatures of the PCM. An increase of approximately 5% was reported when using cascaded latent heat storage [55]. Usually, no more than three cascaded PCMs are used in an SPCM-based heat exchanger.

- Internal fins: Another archetype for performance improvement comes in the form of an internal fin structure. The use of fins increases thermal conductivity by increasing the effective heat transfer area, thereby increasing the heat transfer rate. Numerical models are used to optimize the number of fins, their diameters, and the length of fins for better performance. Jia et al. [56] found an optimum length-to-radius ratio of 0.75. The authors used a total of six fins and found more than a 50% reduction in discharging time (3600 s using fins compared to 7700 s without using fins).

- PCM layer thickness: PCM layer thickness is an essential indicator of an SPCMS design. PCMs with greater thicknesses tend to increase the overall volume of the system, whereas a small PCM thickness results in performance degradation. Therefore, optimal layer thickness must be carefully selected. Numerical-simulation-based techniques lead to such optimized PCM layer thicknesses [57]. A PCM thickness of 0.01 m was found to produce the best results under the operating conditions of the thermal system under investigation [57].

- Solar irradiation and climatic conditions: Atmospheric conditions are one of the most critical parameters to be considered when designing SPCMSs because several parameters, such as transition temperature, the mass of a PCM, the estimated solar irradiation, etc., are dependent on the climate of a particular place [58].

3.2. Economic Indicators

4. Conclusions and Future Recommendations

- The thermal conductivity of PCMs, despite obtaining several improvements through various techniques, is still the main constraint that limits the efficiency of SPCMSs and, thus, needs to be investigated further. Nano-modified PCMs, along with more efficient finned configurations, can be explored further to fully explore their potential for enhancing thermal characteristics.

- Research should be conducted to a) increase the density of PCMs and b) decrease the volume of the system and, thus, increase energy storage for compact domestic applications linked with solar thermal energy.

- The configuration and geometry of tubes exchanging heat with PCMs need to be explored further so that complete charging and discharging can be achieved within a shorter timespan without depositing hard water sediments over the long term, as has been observed in most studies.

- Substantial energy savings can be achieved in buildings with PCM incorporation, as has been shown in this review. However, it is imperative to take great care when selecting a PCM for a particular application by considering their phase change temperature, thermal stability, and compatibility. Most importantly, it is vital to ensure the setup is not toxic or corrosive, as this would be in close contact with humans.

- Due to unpredictable weather fluctuations, these systems should be tested under real conditions in pilot studies instead of simulated conditions for more accurate results.

- Focused research on the prevention of energy losses should be performed, especially considering usage with fluctuating solar water temperatures.

- The freezing of solar water at night under rare conditions, in which the temperatures are below subzero, is a major research gap that must be further investigated to mitigate operational risks.

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations and Nomenclature

| SPCMS | Solar PCM system |

| PCM | Phase change material |

| TES | Thermal energy storage |

| HVAC | Heating, ventilation, and air-conditioning |

| PTTS | Passive thermal storage system |

| DP-SAH | Double-pass solar air heater |

| CPV | Concentrated photovoltaic |

| HTF | Heat transfer fluid |

| DHW | Domestic hot water |

| Source term | |

| Density (kgm−3) | |

| Thermal expansion coefficient (K−1) | |

| T | Temperature (K) |

| k | Thermal conductivity (Wm−1 K −1) |

| h | Enthalpy (Jkg−1) |

| Cp | Specific heat (Jkg−1K−1) |

| Latent heat of fusion (kJkg−1) | |

| Source term for momentum | |

| t | Time (min, second) |

References

- Hu, Y.; Heiselberg, P.K.; Johra, H.; Guo, R. Experimental and numerical study of a PCM solar air heat exchanger and its ventilation preheating effectiveness. Renew. Energy 2019, 145, 106–115. [Google Scholar] [CrossRef]

- Zhao, J.; Ji, Y.; Yuan, Y.; Zhang, Z.; Lu, J. Seven Operation Modes and Simulation Models of Solar Heating System with PCM Storage Tank. Energies 2017, 10, 2128. [Google Scholar] [CrossRef]

- Jamar, A.; Majid, Z.; Azmi, W.; Norhafana, M.; Razak, A. A review of water heating system for solar energy applications. Int. Commun. Heat Mass Transf. 2016, 76, 178–187. [Google Scholar] [CrossRef]

- Selvaraj, D.A.; Victor, K. Design and Performance of Solar PV Integrated Domestic Vapor Absorption Refrigeration System. Int. J. Photoenergy 2021, 2021, 1–10. [Google Scholar] [CrossRef]

- Xu, H.; Sze, J.Y.; Romagnoli, A.; Py, X. Selection of Phase Change Material for Thermal Energy Storage in Solar Air Conditioning Systems. Energy Procedia 2017, 105, 4281–4288. [Google Scholar] [CrossRef]

- Yang, Y.K.; Kim, M.Y.; Chung, M.H.; Park, J.C. PCM cool roof systems for mitigating urban heat island—An experimental and numerical analysis. Energy Build. 2019, 205, 109537. [Google Scholar] [CrossRef]

- Souayfane, F.; Fardoun, F.; Biwole, P.-H. Phase change materials (PCM) for cooling applications in buildings: A review. Energy Build. 2016, 129, 396–431. [Google Scholar] [CrossRef]

- Mettawee, E.-B.S.; Assassa, G.M. Experimental study of a compact PCM solar collector. Energy 2006, 31, 2958–2968. [Google Scholar] [CrossRef]

- Iten, D.C. Air-Multiple PCMs for the Free Cooling and Ventilation of Buildings Air-Multiple PCMs for the Free Cooling and Ventilation of Buildings. Ph.D. Thesis, Coventry University, Coventry, UK, 2015. [Google Scholar]

- Meng, E.; Cai, R.; Sun, Z.; Yang, J.; Wang, J. Experimental study of the passive and active performance of real-scale composite PCM room in winter. Appl. Therm. Eng. 2021, 185, 116418. [Google Scholar] [CrossRef]

- Nasef, H.; Nada, S.; Hassan, H. Integrative passive and active cooling system using PCM and nanofluid for thermal regulation of concentrated photovoltaic solar cells. Energy Convers. Manag. 2019, 199, 112065. [Google Scholar] [CrossRef]

- Gholamibozanjani, G.; Farid, M. A comparison between passive and active PCM systems applied to buildings. Renew. Energy 2020, 162, 112–123. [Google Scholar] [CrossRef]

- Kousksou, T.; Bruel, P.; Cherreau, G.; Leoussoff, V.; El Rhafiki, T. PCM storage for solar DHW: From an unfulfilled promise to a real benefit. Sol. Energy 2011, 85, 2033–2040. [Google Scholar] [CrossRef]

- Haillot, D.; Franquet, E.; Gibout, S.; Bédécarrats, J.-P. Optimization of solar DHW system including PCM media. Appl. Energy 2013, 109, 470–475. [Google Scholar] [CrossRef]

- Salih, S.M.; Jalil, J.M.; Najim, S.E. Experimental and numerical analysis of double-pass solar air heater utilizing multiple capsules PCM. Renew. Energy 2019, 143, 1053–1066. [Google Scholar] [CrossRef]

- Mao, Q.; Yang, M. Study on heat transfer performance of a solar double-slope PCM glazed roof with different physical parameters. Energy Build. 2020, 223, 110141. [Google Scholar] [CrossRef]

- Navarro, L.; de Gracia, A.; Castell, A.; Cabeza, L.F. Experimental study of an active slab with PCM coupled to a solar air collector for heating purposes. Energy Build. 2016, 128, 12–21. [Google Scholar] [CrossRef]

- Kong, X.; Wang, L.; Li, H.; Yuan, G.; Yao, C. Experimental study on a novel hybrid system of active composite PCM wall and solar thermal system for clean heating supply in winter. Sol. Energy 2020, 195, 259–270. [Google Scholar] [CrossRef]

- Dordelly, J.C.F.; El Mankibi, M.; Roccamena, L.; Remion, G.; Landa, J.A. Experimental analysis of a PCM integrated solar chimney under laboratory conditions. Sol. Energy 2019, 188, 1332–1348. [Google Scholar] [CrossRef]

- Ke, W.; Ji, J.; Xu, L.; Yu, B.; Tian, X.; Wang, J. Numerical study and experimental validation of a multi-functional dual-air-channel solar wall system with PCM. Energy 2021, 227, 120434. [Google Scholar] [CrossRef]

- Esen, M. Thermal performance of a solar-aided latent heat store used for space heating by heat pump. Sol. Energy 2000, 69, 15–25. [Google Scholar] [CrossRef]

- Saffari, M.; de Gracia, A.; Ushak, S.; Cabeza, L.F. Passive cooling of buildings with phase change materials using whole-building energy simulation tools: A review. Renew. Sustain. Energy Rev. 2017, 80, 1239–1255. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Buddhi, D. PCM thermal storage in buildings: A state of art. Renew. Sustain. Energy Rev. 2007, 11, 1146–1166. [Google Scholar] [CrossRef]

- Voelker, C.; Kornadt, O.; Ostry, M. Temperature reduction due to the application of phase change materials. Energy Build. 2008, 40, 937–944. [Google Scholar] [CrossRef]

- Jeong, S.-G.; Wi, S.; Chang, S.J.; Lee, J.; Kim, S. An experimental study on applying organic PCMs to gypsum-cement board for improving thermal performance of buildings in different climates. Energy Build. 2019, 190, 183–194. [Google Scholar] [CrossRef]

- Shukla, N.; Fallahi, A.; Kosny, J. Performance characterization of PCM impregnated gypsum board for building applications. Energy Procedia 2012, 30, 370–379. [Google Scholar] [CrossRef]

- Shen, Y.; Liu, S.; Zeng, C.; Zhang, Y.; Li, Y.; Han, X.; Yang, L.; Yang, X. Experimental thermal study of a new PCM-concrete thermal storage block (PCM-CTSB). Constr. Build. Mater. 2021, 293, 123540. [Google Scholar] [CrossRef]

- Entrop, A.G.; Brouwers, H.J.H.; Reinders, A. Experimental research on the use of micro-encapsulated Phase Change Materials to store solar energy in concrete floors and to save energy in Dutch houses. Sol. Energy 2011, 85, 1007–1020. [Google Scholar] [CrossRef]

- Mahdaoui, M.; Hamdaoui, S.; Msaad, A.A.; Kousksou, T.; El Rhafiki, T.; Jamil, A.; Ahachad, M. Building bricks with phase change material (PCM): Thermal performances. Constr. Build. Mater. 2021, 269, 121315. [Google Scholar] [CrossRef]

- Muthuvelan, T.; Panchabikesan, K.; Munisamy, R.; Nibhanupudi, K.M.; Ramalingam, V. Experimental investigation of free cooling using phase change material-filled air heat exchanger for energy efficiency in buildings. Adv. Build. Energy Res. 2018, 12, 139–149. [Google Scholar] [CrossRef]

- Li, S.; Zhu, N.; Hu, P.; Lei, F.; Deng, R. Numerical study on thermal performance of PCM Trombe Wall. Energy Procedia 2019, 158, 2441–2447. [Google Scholar] [CrossRef]

- Kośny, J. PCM-Enhanced Building Components; An Application of Phase Change Materials in Building Envelopes and Internal Structures; Springer International Publishing: Cham, Switzerland, 2015. [Google Scholar] [CrossRef]

- Duan, S.; Wang, L.; Zhao, Z.; Zhang, C. Experimental study on thermal performance of an integrated PCM Trombe wall. Renew. Energy 2021, 163, 1932–1941. [Google Scholar] [CrossRef]

- Silva, T.; Vicente, R.; Rodrigues, F.; Samagaio, A.; Cardoso, C. Development of a window shutter with phase change materials: Full scale outdoor experimental approach. Energy Build. 2015, 88, 110–121. [Google Scholar] [CrossRef]

- Chan, A. Energy and environmental performance of building façades integrated with phase change material in subtropical Hong Kong. Energy Build. 2011, 43, 2947–2955. [Google Scholar] [CrossRef]

- Choi, Y.; Mae, M.; Kim, H.B. Thermal performance improvement method for air-based solar heating systems. Sol. Energy 2019, 186, 277–290. [Google Scholar] [CrossRef]

- Gutherz, J.M.; Schiler, M.E. A Passive Solar Heating System for the Perimeter Zone of Office Buildings. Energy Sources 1991, 13, 39–54. [Google Scholar] [CrossRef]

- Mousavi, S.; Rismanchi, B.; Brey, S.; Aye, L. PCM embedded radiant chilled ceiling: A state-of-the-art review. Renew. Sustain. Energy Rev. 2021, 151, 1601. [Google Scholar] [CrossRef]

- Bouzennada, T.; Mechighel, F.; Filali, A.; Ghachem, K.; Kolsi, L. Numerical investigation of heat transfer and melting process in a PCM capsule: Effects of inner tube position and Stefan number. Case Stud. Therm. Eng. 2021, 27, 101306. [Google Scholar] [CrossRef]

- Bouzennada, T.; Mechighel, F.; Ismail, T.; Kolsi, L.; Ghachem, K. Heat transfer and fluid flow in a PCM-filled enclosure: Effect of inclination angle and mid-separation fin. Int. Commun. Heat Mass Transf. 2020, 124, 105280. [Google Scholar] [CrossRef]

- Bodin, N.B.; Semenov, A.S.; Shchegolkov, A.V.; Shchegolkovand, A.V.; Popova, A.A. Nanomodified heat accumulating mate-rials for energy saving in industrial processes. Eco. Env. Cons. 2016, 22, 2155–2162. [Google Scholar]

- Shchegolkov, A.; Dyachkova, T.; Semenov, A. The heat storage material based on paraffin-modified multilayer carbon nanotubes with Nickel-zinc ferrite. IOP Conf. Series Mater. Sci. Eng. 2017, 312, 012023. [Google Scholar] [CrossRef]

- Yu, S.; Jeong, S.-G.; Chung, O.; Kim, S. Bio-based PCM/carbon nanomaterials composites with enhanced thermal conductivity. Sol. Energy Mater. Sol. Cells 2014, 120, 549–554. [Google Scholar] [CrossRef]

- Kenisarin, M.; Mahkamov, K.; Kahwash, F.; Makhkamova, I. Enhancing thermal conductivity of paraffin wax 53–57 °C using expanded graphite. Sol. Energy Mater. Sol. Cells 2019, 200, 110026. [Google Scholar] [CrossRef]

- Choi, D.H.; Lee, J.; Hong, H.; Kang, Y.T. Thermal conductivity and heat transfer performance enhancement of phase change materials (PCM) containing carbon additives for heat storage application. Int. J. Refrig. 2014, 42, 112–120. [Google Scholar] [CrossRef]

- Mazhar, A.R.; Shukla, A.; Liu, S. Numerical analysis of rectangular fins in a PCM for low-grade heat harnessing. Int. J. Therm. Sci. 2020, 152, 106306. [Google Scholar] [CrossRef]

- Luo, J.; Zou, D.; Wang, Y.; Wang, S.; Huang, L. Battery thermal management systems (BTMs) based on phase change material (PCM): A comprehensive review. Chem. Eng. J. 2022, 430, 132741. [Google Scholar] [CrossRef]

- Javadi, F.; Metselaar, H.; Ganesan, P. Performance improvement of solar thermal systems integrated with phase change materials (PCM), a review. Sol. Energy 2020, 206, 330–352. [Google Scholar] [CrossRef]

- Arıcı, M.; Bilgin, F.; Nižetić, S.; Karabay, H. PCM integrated to external building walls: An optimization study on maximum activation of latent heat. Appl. Therm. Eng. 2020, 165, 114560. [Google Scholar] [CrossRef]

- Mettawee, E.-B.S.; Assassa, G.M. Thermal conductivity enhancement in a latent heat storage system. Sol. Energy 2007, 81, 839–845. [Google Scholar] [CrossRef]

- Wang, P.; Yao, H.; Lan, Z.; Peng, Z.; Huang, Y.; Ding, Y. Numerical investigation of PCM melting process in sleeve tube with internal fins. Energy Convers. Manag. 2016, 110, 428–435. [Google Scholar] [CrossRef]

- Baniassadi, A.; Sajadi, B.; Amidpour, M.; Noori, N. Economic optimization of PCM and insulation layer thickness in residential buildings. Sustain. Energy Technol. Assess. 2016, 14, 92–99. [Google Scholar] [CrossRef]

- Chopra, K.; Tyagi, V.; Pandey, A.; Sharma, R.K.; Sari, A. PCM integrated glass in glass tube solar collector for low and medium temperature applications: Thermodynamic & techno-economic approach. Energy 2020, 198, 117238. [Google Scholar] [CrossRef]

- Velmurugan, K.; Kumarasamy, S.; Wongwuttanasatian, T.; Seithtanabutara, V. Review of PCM types and suggestions for an applicable cascaded PCM for passive PV module cooling under tropical climate conditions. J. Clean. Prod. 2021, 293, 126065. [Google Scholar] [CrossRef]

- Shamsi, H.; Boroushaki, M.; Geraei, H. Performance evaluation and optimization of encapsulated cascade PCM thermal storage. J. Energy Storage 2017, 11, 64–75. [Google Scholar] [CrossRef]

- Jia, X.; Zhai, X.; Cheng, X. Thermal performance analysis and optimization of a spherical PCM capsule with pin-fins for cold storage. Appl. Therm. Eng. 2019, 148, 929–938. [Google Scholar] [CrossRef]

- Allouhi, A.; Msaad, A.A.; Amine, M.B.; Saidur, R.; Mahdaoui, M.; Kousksou, T.; Pandey, A.; Jamil, A.; Moujibi, N.; Benbassou, A. Optimization of melting and solidification processes of PCM: Application to integrated collector storage solar water heaters (ICSSWH). Sol. Energy 2018, 171, 562–570. [Google Scholar] [CrossRef]

- Barzin, R.; Chen, J.J.; Young, B.R.; Farid, M.M. Application of weather forecast in conjunction with price-based method for PCM solar passive buildings—An experimental study. Appl. Energy 2016, 163, 9–18. [Google Scholar] [CrossRef]

- Lu, S.; Gao, J.; Tong, H.; Yin, S.; Tang, X.; Jiang, X. Model establishment and operation optimization of the casing PCM radiant floor heating system. Energy 2020, 193, 116814. [Google Scholar] [CrossRef]

- Mehrpooya, M.; Hemmatabady, H.; Ahmadi, M.H. Optimization of performance of Combined Solar Collector-Geothermal Heat Pump Systems to supply thermal load needed for heating greenhouses. Energy Convers. Manag. 2015, 97, 382–392. [Google Scholar] [CrossRef]

- Mazhar, A.R.; Liu, S.; Shukla, A. Numerical investigation of the heat transfer enhancement using corrugated pipes in a PCM for grey water harnessing. Therm. Sci. Eng. Prog. 2021, 23, 100909. [Google Scholar] [CrossRef]

- Afshan, M.E.; Selvakumar, A.; Velraj, R.; Rajaraman, R. Effect of aspect ratio and dispersed PCM balls on the charging performance of a latent heat thermal storage unit for solar thermal applications. Renew. Energy 2020, 148, 876–888. [Google Scholar] [CrossRef]

- Saafi, K.; Daouas, N. Energy and cost efficiency of phase change materials integrated in building envelopes under Tunisia Mediterranean climate. Energy 2019, 187, 115987. [Google Scholar] [CrossRef]

- Zhu, N.; Wu, M.; Hu, P.; Xu, L.; Lei, F.; Li, S. Performance study on different location of double layers SSPCM wallboard in office building. Energy Build. 2018, 158, 23–31. [Google Scholar] [CrossRef]

- Jin, X.; Medina, M.A.; Zhang, X. Numerical analysis for the optimal location of a thin PCM layer in frame walls. Appl. Therm. Eng. 2016, 103, 1057–1063. [Google Scholar] [CrossRef]

- Heim, D.; Clarke, J.A. Numerical modelling and thermal simulation of PCM & ndash; gypsum composites with ESP-r. Energy Build. 2004, 36, 795–805. [Google Scholar] [CrossRef]

- Sovetova, M.; Memon, S.A.; Kim, J. Thermal performance and energy efficiency of building integrated with PCMs in hot desert climate region. Sol. Energy 2019, 189, 357–371. [Google Scholar] [CrossRef]

- Qu, Y.; Zhou, D.; Xue, F.; Cui, L. Multi-factor analysis on thermal comfort and energy saving potential for PCM-integrated buildings in summer. Energy Build. 2021, 241, 110966. [Google Scholar] [CrossRef]

- Alam, M.; Jamil, H.; Sanjayan, J.; Wilson, J. Energy saving potential of phase change materials in major Australian cities. Energy Build. 2014, 78, 192–201. [Google Scholar] [CrossRef]

- Wang, H.; Lu, W.; Wu, Z.; Zhang, G. Parametric analysis of applying PCM wallboards for energy saving in high-rise lightweight buildings in Shanghai. Renew. Energy 2020, 145, 52–64. [Google Scholar] [CrossRef]

- Zhao, J.; Ji, Y.; Yuan, Y.; Zhang, Z.; Lu, J. Energy-Saving Analysis of Solar Heating System with PCM Storage Tank. Energies 2018, 11, 237. [Google Scholar] [CrossRef]

- Devaux, P.; Farid, M.M. Benefits of PCM underfloor heating with PCM wallboards for space heating in winter. Appl. Energy 2017, 191, 593–602. [Google Scholar] [CrossRef]

- Calise, F.; Cappiello, F.L.; D’accadia, M.D.; Vicidomini, M. Dynamic modelling and thermoeconomic analysis of micro wind turbines and building integrated photovoltaic panels. Renew. Energy 2020, 160, 633–652. [Google Scholar] [CrossRef]

- Panayiotou, G.; Kalogirou, S.; Tassou, S. Evaluation of the application of Phase Change Materials (PCM) on the envelope of a typical dwelling in the Mediterranean region. Renew. Energy 2016, 97, 24–32. [Google Scholar] [CrossRef]

- Mi, X.; Liu, R.; Cui, H.; Memon, S.A.; Xing, F.; Lo, Y. Energy and economic analysis of building integrated with PCM in different cities of China. Appl. Energy 2016, 175, 324–336. [Google Scholar] [CrossRef]

- Solgi, E.; Memarian, S.; Moud, G.N. Financial viability of PCMs in countries with low energy cost: A case study of different climates in Iran. Energy Build. 2018, 173, 128–137. [Google Scholar] [CrossRef]

- Kosny, J.; Shukla, N.; Fallahi, A. Cost Analysis of Simple Phase Change Material-Enhanced Building Envelopes in in Southern U.S. Climates. Report. 1 January 2013; Golden, Colorado. Available online: https://digital.library.unt.edu/ark:/67531/metadc838307/ (accessed on 25 July 2023).

- Souayfane, F.; Biwole, P.H.; Fardoun, F.; Achard, P. Energy performance and economic analysis of a TIM-PCM wall under different climates. Energy 2019, 169, 1274–1291. [Google Scholar] [CrossRef]

- Yun, B.Y.; Park, J.H.; Yang, S.; Wi, S.; Kim, S. Integrated analysis of the energy and economic efficiency of PCM as an indoor decoration element: Application to an apartment building. Sol. Energy 2020, 196, 437–447. [Google Scholar] [CrossRef]

- Figueiredo, A.; Vicente, R.; Lapa, J.; Cardoso, C.; Rodrigues, F.; Kämpf, J. Indoor thermal comfort assessment using different constructive solutions incorporating PCM. Appl. Energy 2017, 208, 1208–1221. [Google Scholar] [CrossRef]

| Subject | Overview | Outcome | References |

|---|---|---|---|

| PCM storage for solar DHW |

|

| [13,14] |

| DP-SAH equipped with capsules of PCM |

|

| [15] |

| Solar double-slope PCM glazed roof |

|

| [16] |

| Active-slab-containing PCM integrated into solar air collector |

|

| [17] |

| Preheating of ventilation air using a solar PCM |

|

| [1] |

| Hybrid PCM system using an active composite wall |

|

| [18] |

| PCM-integrated solar chimney |

|

| [19] |

| Dual-air-channel PCM system with solar wall |

|

| [20] |

| Solar-aided PCM-based space heating |

|

| [21] |

| Subject | Overview | Outcome | Reference |

|---|---|---|---|

| PCM in gypsum Boards |

|

| [24,25,26] |

| PCM in Concrete |

|

| [27,28] |

| PCM in Bricks |

|

| [29] |

| PCM based Free Cooling |

|

| [30] |

| PCM Trombe wall |

|

| [31,32,33] |

| PCM Shutter |

|

| [34] |

| PCM after Mosaic Tiles |

|

| [35] |

| Air-based Heating System |

|

| [36] |

| PCM in Ceilings |

|

| [37,38] |

| PCM in capasules |

|

| [39,40] |

| PCM | Melting Temperature (°C) | Thermal Conductivity (W/m K) | Heat of Fusion (kJ/kg) | Density (kg/m3) |

|---|---|---|---|---|

| Polyglycol E400 | 8 | 0.187 | 99.6 | 1125 |

| Paraffin C15 | 10 | - | 205 | - |

| n-Pentadecane | 10 | - | 193.9 | 770 |

| Caprylic acid (fatty acid) | 16 | 0.149 | 148.5 | 901 |

| Paraffin C16 | 16.7 | - | 237.1 | - |

| Glycerin (organic) | 17.9 | 0.143 | 198.7 | - |

| n-Heptadecane (organic) | 19 | 0.21 | 240 | 760 |

| OM 21 | 22 | 0.14 | 174 | 891 |

| HS 22 | 23 | 0.56 | 167.6 | 1540 |

| HS 24 | 26 | 0.55 | - | 1510 |

| Lactic acid | 26 | - | 184 | - |

| n-Octadecane | 28 | 0.148 | 244 | 774 |

| HS 29 | 29 | 0.382 | 190 | 1530 |

| OM 32 | 33 | 0.145 | 157 | 870 |

| Capric acid | 32 | 0.153 | 152.7 | 878 |

| Lauric acid | 42 | 0.147 | 178 | 870 |

| Paraffin C20 | 36.7 | - | 246 | - |

| OM 35 | 35 | 0.16 | 171 | 870 |

| PCM | Site | Energy Savings (kW/Year) | Payback Period (Year) | Reference |

|---|---|---|---|---|

| BioPCM@ ™ M91 | Nicosia | 20.567 | 14.5 | [74] |

| PCM27 | Hong Kong | 3798.34 | 30.09 | [75] |

| PCM23 | Australia | 4833.33 | - | [75] |

| PCM29 | Iran | 2969.65 | 42 | [76] |

| PCM-enhanced insulation | Miami | 19,954 | 7 | [77] |

| TIM-PCM | Paris | 668.8 | 22 | [78] |

| n-hexadecane | Seoul | 326.36 | 6.88 | [79] |

| n-heptadecane | Seoul | 312.18 | 6.80 | [79] |

| n-octadecane | Seoul | 205.37 | 8.38 | [79] |

| 25# Paraffin | China | - | 3.32 | [18] |

| Dupon Energain | Aveiro | - | 41 | [80] |

| BioPCM® M51 | Aveiro | - | 18 | [80] |

| BioPCM® M91 | Aveiro | - | 26 | [80] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aziz, S.; Talha, T.; Mazhar, A.R.; Ali, J.; Jung, D.-W. A Review of Solar-Coupled Phase Change Materials in Buildings. Materials 2023, 16, 5979. https://doi.org/10.3390/ma16175979

Aziz S, Talha T, Mazhar AR, Ali J, Jung D-W. A Review of Solar-Coupled Phase Change Materials in Buildings. Materials. 2023; 16(17):5979. https://doi.org/10.3390/ma16175979

Chicago/Turabian StyleAziz, Shahid, Tariq Talha, Abdur Rehman Mazhar, Junaid Ali, and Dong-Won Jung. 2023. "A Review of Solar-Coupled Phase Change Materials in Buildings" Materials 16, no. 17: 5979. https://doi.org/10.3390/ma16175979

APA StyleAziz, S., Talha, T., Mazhar, A. R., Ali, J., & Jung, D.-W. (2023). A Review of Solar-Coupled Phase Change Materials in Buildings. Materials, 16(17), 5979. https://doi.org/10.3390/ma16175979