Control of Coherent Light through Microperiodic Director Modulation in Nematic Films under Low-Voltage DC Electric Field

Abstract

1. Introduction

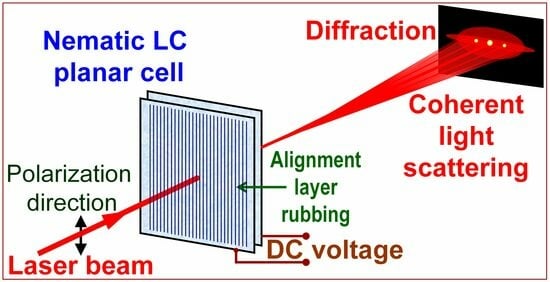

2. Materials and Methods

2.1. NLCs Films

2.2. Electro-Optical Measurements

3. Results and Discussion

3.1. Longitudinal Domain Texture in 5CB Planar Cells under DC Electric Field: Polarizing Optical Microscopy Data

3.1.1. Wide-Formed Electrically-Induced Longitudinal Domains

3.1.2. Narrow-Striped Rubbing-Induced Longitudinal Texture

3.2. Interaction of Coherent Light with LDs in 5CB Planar Films under DC Electric Field

3.2.1. Optical Diffraction by Wide-Formed Electrically-Induced LDs

3.2.2. Coherent Light Scattering/Diffraction by Striped Textures in 5CB Planar Films under DC Electric Field

Diffraction Pattern

Fourier Analysis

3.3. DC Voltage-Dependent Coherent Light Transmittance of 5CB Planar Films

3.3.1. Central-Beam EO Behavior

3.3.2. EO Behavior of Coherently Diffracted and Scattered Light

Voltage-Dependent Fraunhofer Diffraction

Voltage-Dependent CLS

3.3.3. Polarization Dependence

3.4. EO Control of Coherent Light Transmission through LDs in Nematic Films—Physical Mechanism

3.5. Enhancement of the Optical Contrast Ratio of Coherent Light Transmittance of Nematic Films, Electrically-Controlled by Microperiodic Director Modulation

3.6. Applicability of Coherent Light Transmission Electrically Controlled by Spatially-Periodic Director Modulation in Nematic Films under Low-Voltage Static Electric Field

4. Conclusions

Supplementary Materials

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Hinov, H.P. Electro-Optic Effects in Thermotropic Liquid Crystals; Nova Science: New York, NY, USA, 2015. [Google Scholar]

- Buka, A.; Kramer, L. (Eds.) Pattern Formation in Liquid Crystals; Springer: New York, NY, USA, 1996. [Google Scholar]

- Eber, N.; Buka, A.; Krishnamurthy, K.S. Electrically driven structures in bent-core nematics. Liq. Cryst. 2022, 49, 1194–1222. [Google Scholar] [CrossRef]

- Dierking, I. Textures of Liquid Crystals; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2003. [Google Scholar]

- Kyeremah, C.; La, J.; Gharbi, M.A.; Yelleswarapu, C.S. Exploring different textures of a nematic liquid crystal for quantitative Fourier phase contrast microscopy. Opt. Laser Technol. 2022, 147, 107631. [Google Scholar] [CrossRef]

- Zhang, J.; Ostroverkhov, V.; Singer, K.D.; Reshetnyak, V.; Reznikov, Y. Electrically controlled surface diffraction gratings in nematic liquid crystals. Opt. Lett. 2000, 25, 414–416. [Google Scholar] [CrossRef]

- Huang, S.Y.; Huang, B.Y.; Kang, C.C.; Kuo, C.T. Diffraction and polarization properties of electrically-tunable nematic liquid crystal grating. Polymers 2020, 12, 1929. [Google Scholar] [CrossRef] [PubMed]

- Algorri, J.F.; Morawiak, P.; Zografopoulos, D.C.; Bennis, N.; Spadlo, A.; Rodríguez-Cobo, L.; Jaroszewicz, L.R.; Sánchez-Pena, J.M.; Lopez-Higuera, J.M. Multifunctional light beam control device by stimuli-responsive liquid crystal micro-grating structures. Sci. Rep. 2020, 10, 13806. [Google Scholar] [CrossRef]

- Chavel, P.; Sawchuk, A.A.; Strand, T.C.; Tanguay, A.R.; Soffer, B.H. Optical logic with variable-grating-mode liquid-crystal devices. Opt. Lett. 1980, 5, 398–400. [Google Scholar] [CrossRef]

- Soffer, B.H.; Margerum, J.D.; Lackner, A.M.; Boswell, D.; Tanguay, A.R., Jr.; Strand, T.C.; Sawchuk, A.A.; Chavel, P. Variable grating mode liquid crystal device for optical processing computing. Mol. Cryst. Liq. Cryst. 1981, 70, 145–161. [Google Scholar] [CrossRef]

- Tangonan, G.L. Variable-grating-mode liquid crystals for fibre-optic applications. Electron. Lett. 1985, 21, 701–702. [Google Scholar] [CrossRef]

- McManamon, P.F.; Bos, P.J.; Escuti, M.J.; Heikenfeld, J.; Serati, S.; Xie, H.; Watson, E.A. A review of phased array steering for narrow-band electrooptical systems. Proc. IEEE 2009, 97, 1078–1096. [Google Scholar] [CrossRef]

- Morris, R.; Jones, C.; Nagaraj, M. Liquid crystal devices for beam steering applications. Micromachines 2021, 12, 247. [Google Scholar] [CrossRef]

- Weiner, A.M. Femtosecond pulse shaping using spatial light modulators. Rev. Sci. Instrum. 2000, 71, 1929–1960. [Google Scholar] [CrossRef]

- Frumker, E.; Silberberg, Y. Femtosecond pulse shaping using a two-dimensional liquid-crystal spatial light modulator. Opt. Lett. 2007, 32, 1384–1386. [Google Scholar] [CrossRef] [PubMed]

- Zhekova, M.; Maleshkov, G.; Stoyanov, L.; Stefanov, I.; Paulus, G.G.; Dreischuh, A. Formation of multi-spot focal arrays by square-shaped optical vortex lattices. Opt. Commun. 2019, 449, 110–116. [Google Scholar] [CrossRef]

- Stoyanov, L.; Zhekova, M.; Stefanov, A.; Stefanov, I.; Paulus, G.G.; Dreischuh, A. Zeroth- and first-order long range non-diffracting Gauss–Bessel beams generated by annihilating multiple-charged optical vortices. Sci. Rep. 2020, 10, 21981. [Google Scholar] [CrossRef]

- Chen, H.; Tan, G.; Huang, Y.; Weng, Y.; Choi, T.H.; Yoon, T.H.; Wu, S.T. A low voltage LC phase grating with switchable diffraction angles. Sci. Rep. 2017, 7, 39923. [Google Scholar] [CrossRef]

- Katayama, K.; Kato, D.; Nagasaka, K.I.; Miyagawa, M.; Sohn, W.Y.; Lee, K.W. Origin of optical nonlinearity of photo-responsive liquid crystals revealed by transient grating imaging. Sci. Rep. 2019, 9, 5754. [Google Scholar] [CrossRef]

- Shin, Y.; Jiang, Y.; Wang, Q.; Zhou, Z.; Qin, G.; Yang, D.K. Flexoelectric-effect-based light waveguide liquid crystal display for transparent display. Photon. Res. 2022, 10, 407–414. [Google Scholar] [CrossRef]

- Liu, C.; Guo, Z.; Wu, J.; Yuan, D.; Zhou, G.; Tang, B.; Ye, H. Customized design of aperiodic liquid crystal grating for generation of multiple optical patterns. Crystals 2023, 13, 300. [Google Scholar] [CrossRef]

- Zenginoglou, H.M.; Kosmopoulos, J.A. Geometrical optics approach to the nematic liquid crystal grating: Leading term formulas. Appl. Opt. 1989, 28, 3516–3519. [Google Scholar] [CrossRef]

- Zenginoglou, H.; Kosmopoulos, J. Linearized wave-optical approach to the grating effect of a periodically distorted nematic liquid crystal layer. J. Opt. Soc. Am. A 1997, 14, 669–675. [Google Scholar] [CrossRef]

- Zhang, J.; Xiang, Y.; Ding, X.; Hao, L.; Kaur, S.; Mohiuddin, G.; Pal, S.K.; Salamon, P.; Eber, N.; Buka, A. Electric-field-induced patterns in a hockey-stick nematic. J. Mol. Liq. 2022, 366, 120239. [Google Scholar] [CrossRef]

- Kramer, L.; Pesch, W. Electrohydrodynamics in Nematics. In Physical Properties of Liquid Crystals: Nematics; EMIS Datareviews, No. 25; Dunmur, D.A., Fukuda, A., Luckhurst, G.R., Eds.; Inspec: London, UK, 2001; pp. 441–454. [Google Scholar]

- Chillingworth, D.; Golubitsky, M. Symmetry and pattern formation for a planar layer of nematic liquid crystal. J. Math. Phys. 2003, 44, 4201–4219. [Google Scholar] [CrossRef]

- Qiu, X.L.; Ahlers, G. Dynamics of fluctuations below a stationary bifurcation to electroconvection in the planar nematic liquid crystal N4. Phys. Rev. Lett. 2005, 94, 087802. [Google Scholar] [CrossRef]

- Buka, A.; Eber, N.; Pesch, W.; Kramer, L. Convective patterns in liquid crystals driven by electric field. In Self-Assembly, Pattern Formation and Growth Phenomena in Nano-Systems; NATO Science Series II, Mathematica, Physics and Chemistry; Golovin, A.A., Nepomnyashchy, A.A., Eds.; Springer: Dordrecht, The Netherlands, 2006; Volume 218, pp. 55–82. [Google Scholar] [CrossRef]

- Buka, A.; Eber, N.; Pesch, W.; Kramer, L. Isotropic and anisotropic electroconvection. Phys. Rep. 2007, 448, 115–132. [Google Scholar] [CrossRef]

- Krekhov, A.; Pesch, W.; Eber, N.; Toth-Katona, T.A. Buka, Nonstandard electroconvection and flexoelectricity in nematic liquid crystals. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2008, 77, 021705. [Google Scholar] [CrossRef]

- Buka, A.; Toth-Katona, T.; Eber, N.; Krekhov, A.; Pesch, W. The role of flexoelectricity in pattern formation. In Flexoelectricity in Liquid Crystals: Theory, Experiments and Applications; Buka, A., Eber, N., Eds.; World Scientific: Singapore, 2013; Chapter 4; pp. 101–135. [Google Scholar] [CrossRef]

- Krekhov, A.; Decker, W.; Pesch, W.; Eber, N.; Salamon, P.; Fekete, B.; Buka, A. Patterns driven by combined ac and dc electric fields in nematic liquid crystals. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2014, 89, 052507. [Google Scholar] [CrossRef]

- Delev, V.A.; Krekhov, A.P.; Kramer, L. Crossover between flexoelectric stripe patterns and electroconvection in hybrid aligned nematics. Mol. Cryst. Liq. Cryst. 2001, 366, 849–856. [Google Scholar] [CrossRef]

- Kumar, P.; Krishnamurthy, K.S. Gradient flexoelectric switching response in a nematic phenyl benzoate. Liq. Cryst. 2007, 34, 257–266. [Google Scholar] [CrossRef]

- Krishnamurthy, K.S.; Palakurthy, N.B.; Yelamaggad, C.V. Confined electroconvective and flexoelectric instabilities deep in the freedericksz state of nematic CB7CB. J. Phys. Chem. B 2017, 121, 5447–5454. [Google Scholar] [CrossRef]

- Eber, N.; Palomares, L.O.; Salamon, P.; Krekhov, A.; Buka, A. Temporal evolution and alternation of mechanisms of electric-field-induced patterns at ultralow-frequency driving. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2012, 86, 021702. [Google Scholar] [CrossRef]

- Aguirre, L.E.; Anoardo, E.; Eber, N.; Buka, A. Regular structures in 5CB liquid crystals under the joint action of ac and dc voltages. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2012, 85, 041703. [Google Scholar] [CrossRef] [PubMed]

- Toth-Katona, T.; Eber, N.; Buka, A. Temporal response to harmonic driving in electroconvection. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2011, 83, 061704. [Google Scholar] [CrossRef] [PubMed]

- Pesch, W.; Krekhov, A. Optical analysis of spatially periodic patterns in nematic liquid crystals: Diffraction and shadowgraphy. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2013, 87, 052504. [Google Scholar] [CrossRef]

- Xu, M.Y.; Zhou, M.J.; Xiang, Y.; Salamon, P.; Eber, N.; Buka, A. Domain structures as optical gratings controlled by electric field in a bent-core nematic. Opt. Express 2015, 23, 15224–15234. [Google Scholar] [CrossRef] [PubMed]

- Hadjichristov, G.B.; Marinov, Y.G.; Petrov, A.G.; Bruno, E.; Marino, L.; Scaramuzza, N. Electro-optically responsive composites of gold nanospheres in 5CB liquid crystal under direct current and alternating current joint action. J. Appl. Phys. 2014, 115, 083107. [Google Scholar] [CrossRef]

- Hadjichristov, G.B.; Marinov, Y.G. Optical diffraction by using electrically-controlled spatially patterned nematic pentylcyanobiphenyl films under static electric field. Mol. Cryst. Liq. Cryst. 2016, 632, 9–20. [Google Scholar] [CrossRef]

- Li, J.; Wen, C.H.; Gauza, S.; Lu, R.; Wu, S.T. Refractive indices of liquid crystals for display applications. J. Disp. Technol. 2005, 1, 51–61. [Google Scholar] [CrossRef]

- Ratna, B.R.; Shashidhar, R. Dielectric properties of 4’-n-alkyl-4-cyanobipheniyls in their nematic phases. Pramana 1976, 6, 278–283. [Google Scholar] [CrossRef]

- Barnik, M.I.; Blinov, L.M.; Trufanov, A.N.; Umanski, B.A. Flexo-electric domains in liquid crystals. J. Phys. 1978, 39, 417–422. [Google Scholar] [CrossRef]

- Hinov, H.P.; Vistin, L.K. Parallel and cross-like domains due to d.c. and low frequency (<2 Hz) electric fields in nematic liquid crystal layers with negative dielectric anisotropy. J. Phys. 1979, 40, 269–292. [Google Scholar] [CrossRef]

- Bobylev, Y.P.; Chigrinov, V.G.; Pikin, S.A. Threshold flexoelectric effect in nematic liquid crystal. J. Phys. Colloq. 1979, 40, C3-331–C3-333. [Google Scholar] [CrossRef]

- Pikin, S.A. Structural Transformations in Liquid Crystals; Gordon and Breach Science Publishers: New York, USA, 1991. [Google Scholar]

- Hinov, H.P.; Marinov, Y. Theoretical considerations and experimental illustration of the electro-optic behavior of longitudinal flexoelectric domains under the joint action of DC and AC voltages: The case of strong anchoring. Mol. Cryst. Liq. Cryst. 2009, 503, 45–68. [Google Scholar] [CrossRef]

- Marinov, Y.G.; Hinov, H.P. On the threshold characteristics of the flexoelectric domains arising in a homogeneous electric field: The case of anisotropic elasticity. Eur. Phys. J. E Soft Matter 2010, 31, 179–189. [Google Scholar] [CrossRef] [PubMed]

- Hinov, H.P.; Bivas, I.; Mitov, M.D.; Shoumarov, K.; Marinov, Y. A further experimental study of parallel surface-induced flexoelectric domains (PSIFED) (flexo-dielectric walls). Liq. Cryst. 2003, 30, 1293–1317. [Google Scholar] [CrossRef]

- de Gennes, P.G.; Prost, J. The Physics of Liquid Crystals; Clarendon Press: Oxford, UK, 1993. [Google Scholar]

- Hinov, H.P.; Bivas, I.; Mitov, M.D.; Shoumarov, K. Rubbing-induced surface textures in nematic MBBA layers and their behaviour under applied d. c. or a.c. voltages. Liq. Cryst. 2003, 30, 945–959. [Google Scholar] [CrossRef]

- Klein, W.R.; Cook, B.D. Unified approach to ultrasonic light diffraction. IEEE Trans. Sonics Ultrason 1967, SU-14, 123–134. [Google Scholar] [CrossRef]

- Goodman, J.W. Introduction to Fourier Optics, 2nd ed.; Roberts & Co.: Greenwood Village, CO, USA, 2005; p. 80. [Google Scholar]

- Marusii, T.Y.; Reznikov, Y.A.; Reshetnyak, V.Y.; Soskin, M.S.; Khizhnyak, A.I. Scattering of light by nematic liquid crystals in cells with a finite energy of the anchoring of the director to the wails. Sov. Phys. JETP 1986, 64, 502–507. [Google Scholar]

- Val’kov, A.Y.; Romanov, V.P.; Shalaginov, A.N. Fluctuations and light scattering in liquid crystals. Usp. Fiz. Nauk 1994, 164, 149–193. [Google Scholar] [CrossRef]

- Helfrich, W. Conduction-induced alignment of nematic liquid crystals: Basic model and stability considerations. J. Chem. Phys. 1969, 51, 4092–4105. [Google Scholar] [CrossRef]

- Penz, P.A. Voltage-induced vorticity and optical focusing in liquid crystals. Phys. Rev. Lett. 1970, 24, 1405–1409. [Google Scholar] [CrossRef]

- Strazielle, C.; Coles, H.J. Depolarized light scattering studies of the nematogen pentyl cyanobiphenyl. J. Phys. 1979, 40, 895–900. [Google Scholar] [CrossRef]

- Wiersma, D.S.; Muzzi, A.; Colocci, M.; Righini, R. Time-resolved anisotropic multiple light scattering in nematic liquid crystals. Phys. Rev. Lett. 1999, 83, 4321–4324. [Google Scholar] [CrossRef]

- Takase, A.; Sakagami, S.; Nakamizo, M. Light diffraction and light scattering in nematic liquid crystals with a positive dielectric anisotropy. Jpn. J. Appl. Phys. 1975, 14, 228–230. [Google Scholar] [CrossRef]

- Kamanina, N.V.; Vasilenko, N.A. Influence of operating conditions and interface properties on dynamic characteristics of liquid-crystal spatial light modulators. Opt. Quant. Electron. 1997, 29, 1–9. [Google Scholar] [CrossRef]

- Kamanina, N.V.; Berendyaev, V.I. Influence of solid–liquid crystal interface on characteristics of liquid crystal cells. Proc. SPIE 1998, 3292, 134–158. [Google Scholar] [CrossRef]

- Gruler, H.; Scheffer, T.J.; Meier, G. Elastic constants of nematic liquid crystals. Z. Naturforsch. A 1972, 27, 966–976. [Google Scholar] [CrossRef]

- Blinov, L.M.; Chigrinov, V.G. Electrooptic Effects in Liquid Crystal Materials; Springer: New York, NY, USA, 1994; p. 149. [Google Scholar]

- Johnson, R.V.; Tanguay, A.R., Jr. Optical beam propagation method for birefringent phase grating diffraction. Opt. Eng. 1986, 25, 252235. [Google Scholar] [CrossRef]

- Tripathi, P.; Uttam, R.; Kumar, S.; Dabrowski, R.; Dhar, R. Enhancement of the physical parameters due to the dispersion of functionalised gold nanoparticles in a room temperature nematic liquid crystal. Liq. Cryst. 2023, 50, 240–248. [Google Scholar] [CrossRef]

- Shivakumar, U.; Mirzaei, J.; Feng, X.; Sharma, A.; Moreira, P.; Hegmann, T. Nanoparticles: Complex and multifaceted additives for liquid crystals. Liq. Cryst. 2011, 38, 1495–1514. [Google Scholar] [CrossRef]

- Ouskova, E.; Lysenko, D.; Ksondzyk, S.; Cseh, L.; Mehl, G.H.; Reshetnyak, V.; Reznikov, Y. Strong cubic optical nonlinearity of gold nanoparticles suspension in nematic liquid crystal. Mol. Cryst. Liq. Cryst. 2011, 545, 1347–1356. [Google Scholar] [CrossRef]

- Hadjichristov, G.B.; Marinov, Y.G.; Petrov, A.G.; Bruno, E.; Marino, L.; Scaramuzza, N. Electro-optics of nematic/gold nanoparticles composites: The effect from dopants. Mol. Cryst. Liq. Cryst. 2015, 610, 135–148. [Google Scholar] [CrossRef]

- Brouckaert, N.; Podoliak, N.; Orlova, T.; Bankova, D.; De Fazio, A.F.; Kanaras, A.G.; Hovorka, O.; D’Alessandro, G.; Kaczmarek, M. Nanoparticle-induced property changes in nematic liquid crystals. Nanomaterials 2022, 12, 341. [Google Scholar] [CrossRef] [PubMed]

- Qi, H.; Hegmann, T. Formation of periodic stripe patterns in nematic liquid crystals doped with functionalized gold nanoparticles. J. Mater. Chem. 2006, 16, 4197–4205. [Google Scholar] [CrossRef]

- Lesiak, P.; Bednarska, K.; Lewandowski, W.; Wójcik, M.; Polakiewicz, S.; Bagiński, M.; Osuch, T.; Markowski, K.; Orzechowski, K.; Makowski, M.; et al. Self-organized, one-dimensional periodic structures in a gold nanoparticle-doped nematic liquid crystal composite. ACS Nano 2019, 13, 10154–10160. [Google Scholar] [CrossRef]

- Garbovskiy, Y.; Glushchenko, I. Nano-objects and ions in liquid crystals: Ion trapping effect and related phenomena. Crystals 2015, 5, 501–533. [Google Scholar] [CrossRef]

- Wu, S.T.; Efron, U.; Hess, L.D. Birefringence measurements of liquid crystals. Appl. Opt. 1984, 23, 3911–3915. [Google Scholar] [CrossRef]

- Panarin, Y.P.; Panov, V.P.; Kalinovskaya, O.E.; Vij, J.K. On the V-shaped switching in antiferroelectric liquid crystals. Ferroelectrics 2000, 246, 35–42. [Google Scholar] [CrossRef]

- Copic, M.; Maclennan, J.E.; Clark, N.A. Influence of ions on the ‘‘V-shaped’’ electro-optic response of ferroelectric liquid crystals. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2001, 63, 031703. [Google Scholar] [CrossRef]

- Strangi, G.; Versace, C.; Scaramuzza, N.; Bruno, V. Unipolar “V-shaped” switching in chiral smectic C (Sm–C*) liquid crystals bounded by an ion-store film. J. Appl. Phys. 2002, 92, 3630–3635. [Google Scholar] [CrossRef]

- O’Callaghan, M.J. Switching dynamics and surface forces in thresholdless “V-shaped” switching ferroelectric liquid crystals. Phys. Rev. E Stat. Nonlinear Soft Matter Phys. 2003, 67, 011710. [Google Scholar] [CrossRef]

- Blinov, L.M.; Palto, S.P.; Podgornov, F.V.; Moritake, H.; Haase, W. Hysteresis-free electro-optical switching in conductive ferroelectric liquid crystals: Experiments and modelling. Liq. Cryst. 2004, 31, 61–70. [Google Scholar] [CrossRef]

- Engström, D.; Rudquist, P.; Bengtsson, J.; D’have, K.; Galt, S. Analog low-loss full-range phase modulation by utilizing a V-shaped switched ferroelectric liquid-crystal cell in reflective mode. Opt. Lett. 2006, 31, 2906–2908. [Google Scholar] [CrossRef]

- Manjuladevi, V.; Panarin, Y.P.; Song, J.K.; Vij, J.K.; Sadashiva, B.K. V-shaped electro-optic response observed in a chiral ferroelectric smectic liquid crystal. Appl. Phys. Lett. 2008, 93, 093507. [Google Scholar] [CrossRef]

- He, Z.; Gou, F.; Chen, R.; Yin, K.; Zhan, T.; Wu, S.T. Liquid crystal beam steering devices: Principles, recent advances, and future developments. Crystals 2019, 9, 292. [Google Scholar] [CrossRef]

- Jain, A.K.; Deshmukh, R.R. An overview of polymer-dispersed liquid crystals composite films and their applications. In Liquid Crystals and Display Technology; Ghamsari, M.S., Carlescu, I., Eds.; IntechOpen: London, UK, 2020; Chapter 2; pp. 11–78. [Google Scholar] [CrossRef]

- Saeed, M.H.; Zhang, S.; Cao, Y.; Zhou, L.; Hu, J.; Muhammad, I.; Xiao, J.; Zhang, L.; Yang, H. Recent advances in the polymer dispersed liquid crystal composite and its applications. Molecules 2020, 25, 5510. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Miao, Z.; Shen, W. Development of polymer-dispersed liquid crystals: From mode innovation to applications. Compos. Part A Appl. Sci. Manuf. 2022, 163, 107234. [Google Scholar] [CrossRef]

- Zhong, T.; Mandle, R.J.; Goodby, J.W.; Zhang, C.; Zhang, L. Thiol-ene reaction based polymer dispersed liquid crystal composite films with low driving voltage and high contrast ratio. Liq. Cryst. 2020, 47, 2171–2183. [Google Scholar] [CrossRef]

- Shen, W.; Wang, L.; Chen, G.; Li, C.; Zhang, L.; Yang, Z.; Yang, H. A facile route towards controllable electric-optical performance of polymer-dispersed liquid crystal via the implantation of liquid crystalline epoxy network in conventional resin. Polymer 2019, 167, 67–77. [Google Scholar] [CrossRef]

- He, Z.; Yu, P.; Zhang, H.; Zhao, Y.; Zhu, Y.; Guo, Z.; Ma, C.; Zhang, H.; Miao, Z.; Shen, W. Silicon nanostructure-doped polymer/nematic liquid crystal composites for low voltage-driven smart windows. Nanotechnology 2021, 33, 085205. [Google Scholar] [CrossRef] [PubMed]

- Hadjichristov, G.B.; Marinov, Y.G.; Petrov, A.G. Gradient polymer-disposed liquid crystal single layer of large nematic droplets for modulation of laser ligh. Appl. Opt. 2011, 50, 2326–2333. [Google Scholar] [CrossRef]

- Li, J.; Gauzia, S.; Wu, S.T. High temperature-gradient refractive index liquid crystals. Opt. Express 2004, 12, 2002–2010. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hadjichristov, G.B. Control of Coherent Light through Microperiodic Director Modulation in Nematic Films under Low-Voltage DC Electric Field. Materials 2023, 16, 6014. https://doi.org/10.3390/ma16176014

Hadjichristov GB. Control of Coherent Light through Microperiodic Director Modulation in Nematic Films under Low-Voltage DC Electric Field. Materials. 2023; 16(17):6014. https://doi.org/10.3390/ma16176014

Chicago/Turabian StyleHadjichristov, Georgi B. 2023. "Control of Coherent Light through Microperiodic Director Modulation in Nematic Films under Low-Voltage DC Electric Field" Materials 16, no. 17: 6014. https://doi.org/10.3390/ma16176014

APA StyleHadjichristov, G. B. (2023). Control of Coherent Light through Microperiodic Director Modulation in Nematic Films under Low-Voltage DC Electric Field. Materials, 16(17), 6014. https://doi.org/10.3390/ma16176014