Magnetic Properties of the Soft Magnetic Composites Prepared Using Mixtures of Carbonyl Iron, FeSiCr, and FeSiAl Alloy Powders

Abstract

:1. Introduction

2. Experimental Procedure

3. Results and Discussion

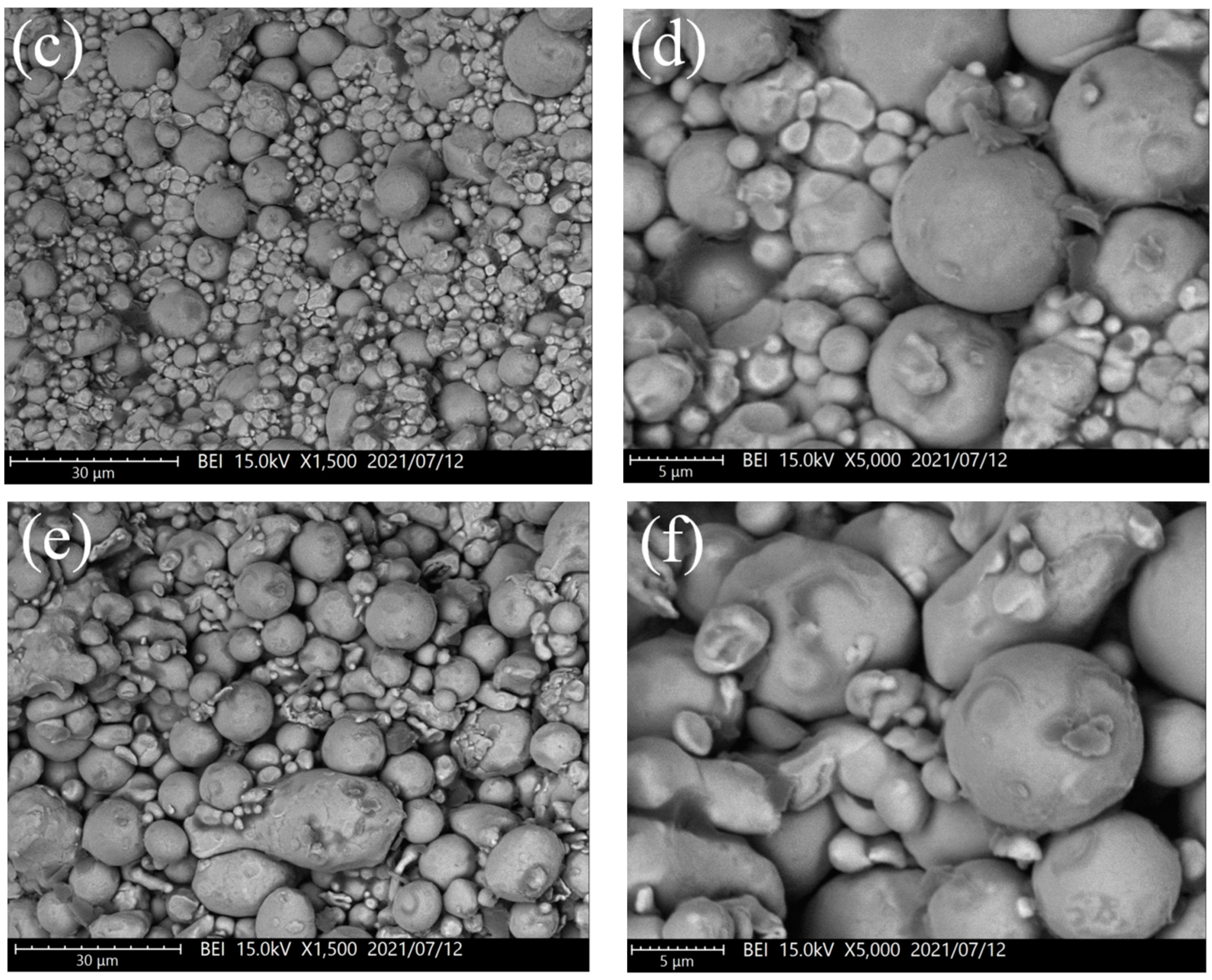

3.1. Carbonyl Iron Powder, FeSiCr Alloy Powder, and Annealed Alloy Powder

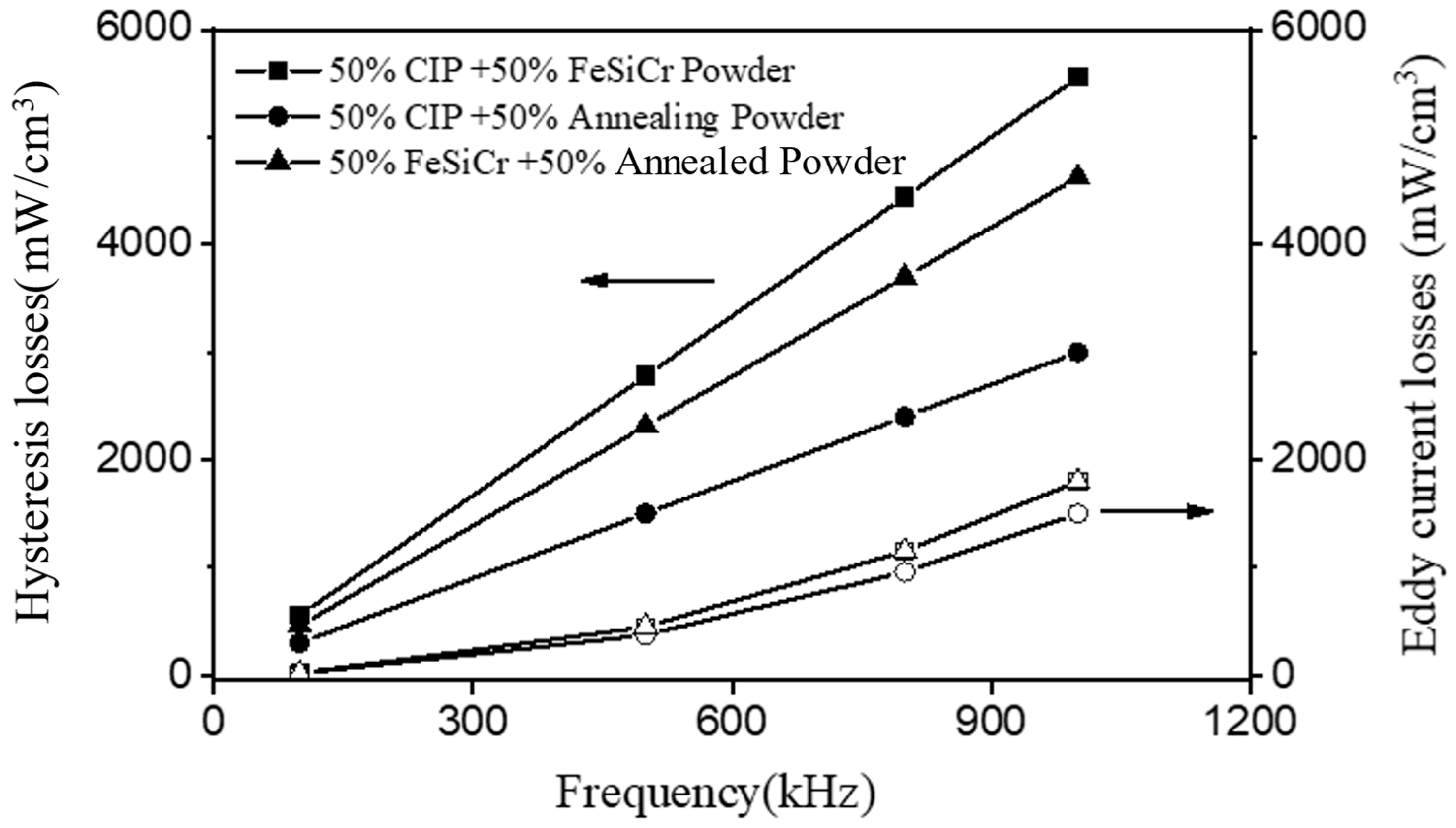

3.2. Binary Mixtures of Carbonyl Iron Powder, FeSiCr Alloy Powder, and Annealed Alloy Powder

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shokrollahi, H.; Janghorban, K. Soft magnetic composite materials (SMCs). J. Mater. Process. Tech. 2007, 189, 1–12. [Google Scholar] [CrossRef]

- Lu, S.; Wang, M.; Zhankui, Z. Recent advances and future developments in Fe-based amorphous soft magnetic composites. J. Non-Cryst. Solids 2023, 616, 122440. [Google Scholar] [CrossRef]

- Perigo, E.A.; Weidenfeller, B.; Kollar, P.; Fuzer, J. Past, present, and future of soft magnetic composites. Appl. Phy. Rev. 2018, 5, 031301. [Google Scholar] [CrossRef]

- Lefebvre, L.; Pelletier, S.; Gélinas, C. Effect of electrical resistivity on core losses in soft magnetic iron powder materials. J. Magn. Magn. Mater. 1997, 176, L93–L96. [Google Scholar] [CrossRef]

- Hsiang, H.I.; Chen, C.H.; Chen, C.C. Magnetic properties of FeSiCr alloy powder coils made by gel casting process. J. Mater. Sci. Mater. Electron. 2021, 32, 14584–14591. [Google Scholar] [CrossRef]

- Konda, S.; Yoshida, Y.; Ichinokura, O. Eddy current loss evaluation of magnetic powder core based on electric and magnetic networks. AIP Adv. 2017, 7, 056678. [Google Scholar] [CrossRef]

- Fan, L.F.; Hsiang, H.I.; Hung, J.J. Silane surface modification effects on the electromagnetic properties of phosphatized iron-based SMCs. Appl. Surf. Sci. 2018, 433, 133–138. [Google Scholar] [CrossRef]

- Hsiang, H.I.; Fan, L.F.; Ho, K.T. Relationship between the microstructure and magnetic properties of Fe–Si–Cr powder cores. IEEE Trans. Magn. 2018, 54, 2000407. [Google Scholar] [CrossRef]

- Hasegawa, R. Advances in amorphous and nanocrystalline magnetic materials. J. Magn. Magn. Mater. 2006, 304, 187–191. [Google Scholar] [CrossRef]

- Long, J.; McHenry, M. Nanocrystalline material development for high-power inductors. J. Appl. Phys. 2008, 103, 07E705. [Google Scholar] [CrossRef]

- Fan, L.F.; Hsiang, H.I.; Hung, J.J. Effects of the sodium stearate addition on the corrosion resistance and electromagnetic properties of phosphatized iron-based SMCs. J. Magn. Magn. Mater. 2019, 490, 165532. [Google Scholar]

- Hsiang, H.I.; Chuang, K.H.; Lee, W.H. FeSiCr alloy powder to carbonyl iron powder mixing ratio effects on the magnetic properties of the iron-based alloy powder cores prepared using screen printing. Materials 2021, 14, 1034. [Google Scholar] [CrossRef] [PubMed]

- Hsiang, H.I.; Wu, L.C.; Chen, C.C.; Lee, W.H. Power molding inductors prepared using amorphous FeSiCr alloy powder, carbonyl iron powder, and silicone resin. Materials 2022, 15, 3681. [Google Scholar] [CrossRef] [PubMed]

- Hsiang, H.I.; Fan, L.F.; Hung, J.J. Phosphoric acid addition effect on the microstructure and magnetic properties of iron-based soft magnetic composites. J. Magn. Magn. Mater. 2018, 447, 1–8. [Google Scholar] [CrossRef]

- Sergueeva, A.V.; Song, C.; Valiev, R.Z.; Mukherjee, A.K. Structure and properties of amorphous and nanocrystalline NiTi prepared by severe plastic deformation and annealing. Mater. Sci. Eng. A 2003, 339, 159–165. [Google Scholar] [CrossRef]

- Kaido, C.; Ogawa, T.; Arita, Y.; Yamasaki, J.; Shishido, Y. Hysteresis and domain behaviors analysis of high purity Fe-(5, 6) wt% Si alloys. J. Magn. Soc. Jpn. 2007, 31, 316–321. [Google Scholar] [CrossRef]

- Saito, T.; Takemoto, S.; Iriyama, T. Resistivity and core size dependencies of eddy current loss for Fe-Si compressed cores. IEEE Trans. Magn. 2005, 41, 3301–3303. [Google Scholar] [CrossRef]

- Hanejko, F.G.; Phan, H.G. Powder Metallurgy Materials for AC Magnetic Applications. In Proceedings of the 96 World Congress, Orlando, FL, USA, 16–21 June 1996; PM TEC: Washangton, DC, USA, 1996. [Google Scholar]

- Pošković, E.; Franchini, F.; Ferraris, L.; Fracchia, E.; Bidulska, J.; Carosio, F.; Bidulsky, R.; Actis Grande, M. Recent advances in multi-functional coatings for soft magnetic composites. Materials 2021, 14, 6844. [Google Scholar] [CrossRef] [PubMed]

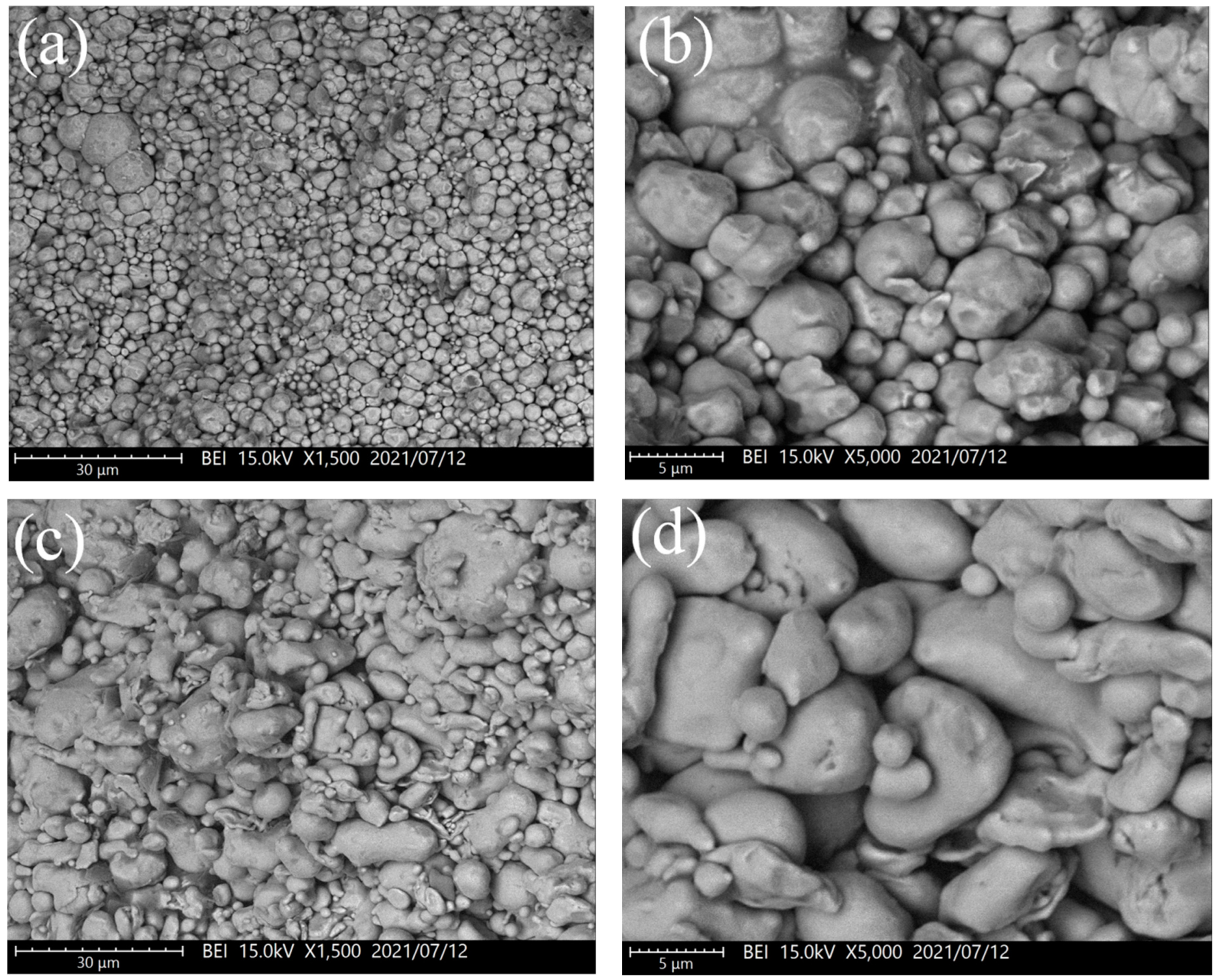

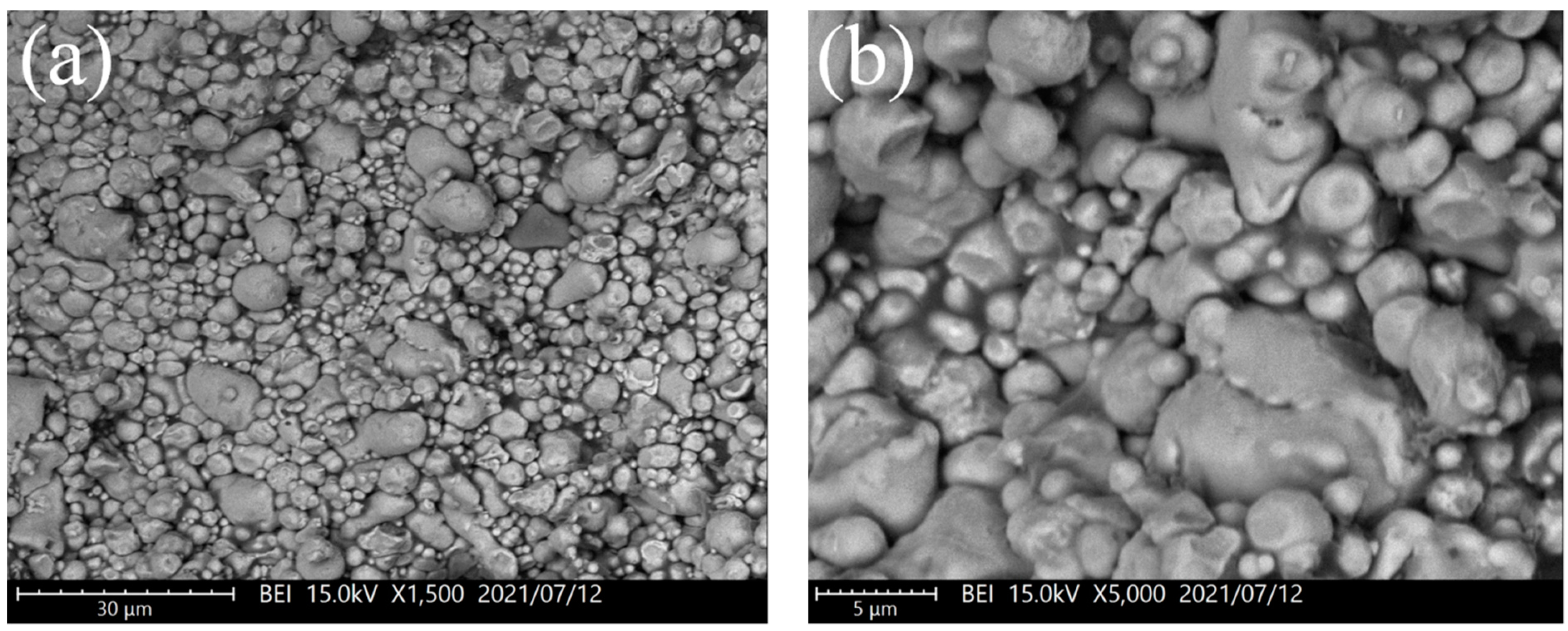

| Powder Type | FeSiCr Alloy Powder | Carbonyl Iron Powder | Annealed Powder |

|---|---|---|---|

| Particle Size (µm) | D10 = 4.1, D50 = 9.4, D90 = 20.4 | D10 = 2.5, D50 = 4.4, D90 = 6.9 | D10 = 5.8, D50 = 9.1, D90 = 13.0 |

| Powder Shape | Irregular | Nearly Spherical | Nearly Spherical |

| True Density (g/cc) | 7.8 | 7.7 | 7.0 |

| Tap Density (g/cc) | 4.4 | 4.6 | 4.2 |

| Chemical Compositions (wt%) | Fe: 91.8 | Fe: >99.5 | Fe: 86.5 |

| Cr: 4.5 | C: 0.01 | Si: 7.0 | |

| Si: 3.5 | O: 0.28 | Al: 6.5 |

| Sample | Compacted Density (Relative Compacted Density) | Permeability |

|---|---|---|

| Carbonyl iron powder | 6.2 g/cm3 (92.4%) | 27.3 |

| FeSiCr alloy powder | 5.9 g/cm3 (87.0%) | 31.0 |

| Annealed FeSiAl powder | 4.9 g/cm3 (79.2%) | 23.4 |

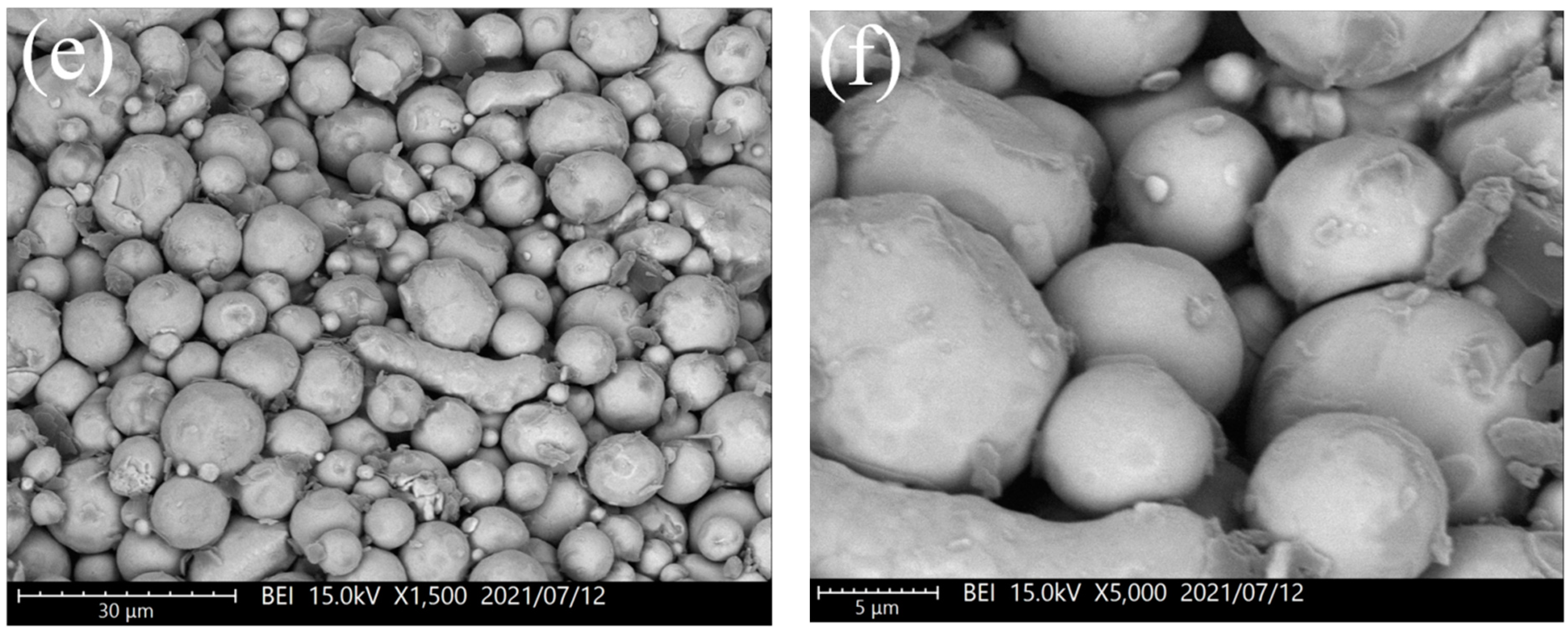

| Powder | Carbonyl Iron Powder | FeSiCr Powder | Annealed Powder |

|---|---|---|---|

| Core losses (mW/cm3) | |||

| 100 kHz | 534 | 630 | 666 |

| 500 kHz | 3025 | 3476 | 4163 |

| 800 kHz | 5289 | 5964 | 7250 |

| 1000 kHz | 6817 | 7739 | 9531 |

| Hysteresis losses (mW/cm3) | |||

| 100 kHz | 536 | 619 | 705 |

| 500 kHz | 2682 | 3095 | 3526 |

| 800 kHz | 4291 | 4952 | 5642 |

| 1000 kHz | 5364 | 6190 | 7053 |

| Eddy current losses (mW/cm3) | |||

| 100 kHz | 15 | 16 | 25 |

| 500 kHz | 375 | 400 | 625 |

| 800 kHz | 960 | 1024 | 1600 |

| 1000 kHz | 1500 | 1600 | 2500 |

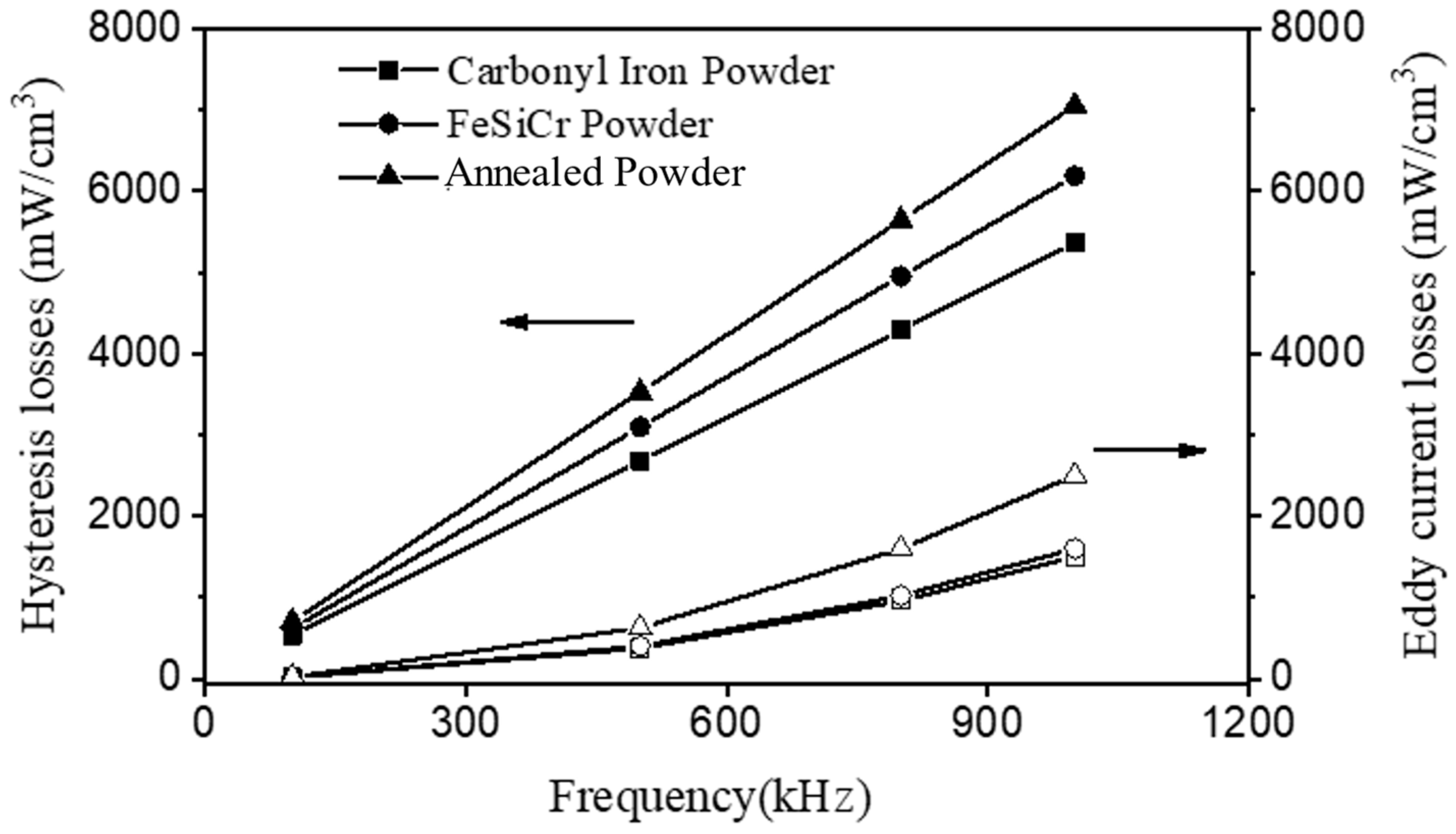

| Sample | Compacted Density (Relative Compacted Densities) | Permeability |

|---|---|---|

| Carbonyl iron and FeSiCr alloy powders | 6.0 g/cm3 (88.9%) | 31.9 |

| Carbonyl iron and annealed FeSiAl alloy powders | 6.0 g/cm3 (93.2%) | 35.3 |

| FeSiCr and annealed FeSiAl alloy powders | 5.8 g/cm3 (89.6%) | 34.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hsiang, H.-I.; Fan, L.-F. Magnetic Properties of the Soft Magnetic Composites Prepared Using Mixtures of Carbonyl Iron, FeSiCr, and FeSiAl Alloy Powders. Materials 2023, 16, 6033. https://doi.org/10.3390/ma16176033

Hsiang H-I, Fan L-F. Magnetic Properties of the Soft Magnetic Composites Prepared Using Mixtures of Carbonyl Iron, FeSiCr, and FeSiAl Alloy Powders. Materials. 2023; 16(17):6033. https://doi.org/10.3390/ma16176033

Chicago/Turabian StyleHsiang, Hsing-I, and Liang-Fang Fan. 2023. "Magnetic Properties of the Soft Magnetic Composites Prepared Using Mixtures of Carbonyl Iron, FeSiCr, and FeSiAl Alloy Powders" Materials 16, no. 17: 6033. https://doi.org/10.3390/ma16176033

APA StyleHsiang, H.-I., & Fan, L.-F. (2023). Magnetic Properties of the Soft Magnetic Composites Prepared Using Mixtures of Carbonyl Iron, FeSiCr, and FeSiAl Alloy Powders. Materials, 16(17), 6033. https://doi.org/10.3390/ma16176033