Numerical Study of Step Drill Structure on Machining Damage in Drilling of CFRP/Ti Stacks

Abstract

:1. Introduction

2. Numerical Setup

2.1. Modeling for the CFRP

2.2. Modeling for the Titanium Alloy

2.3. Modeling for the Interface Layer

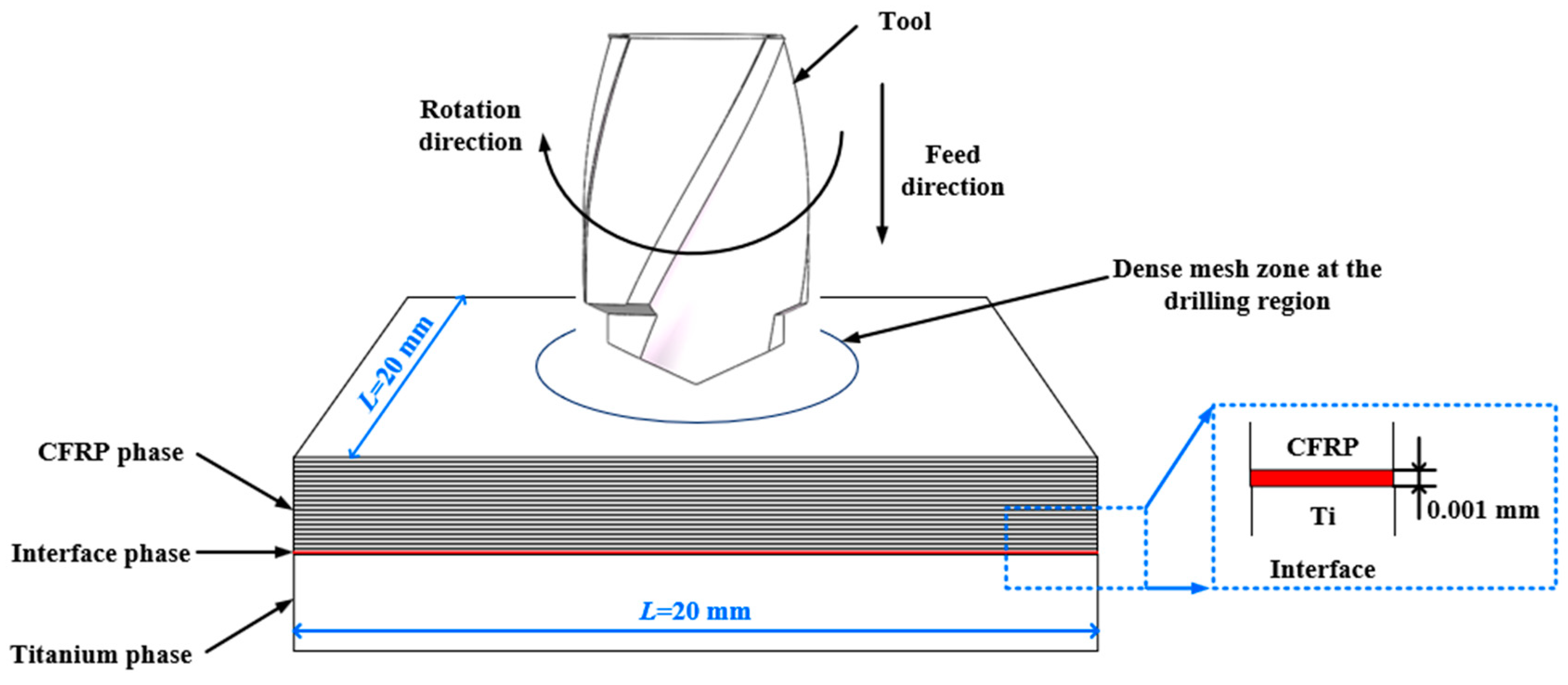

2.4. Geometrical Modelling for Drilling of Stacks

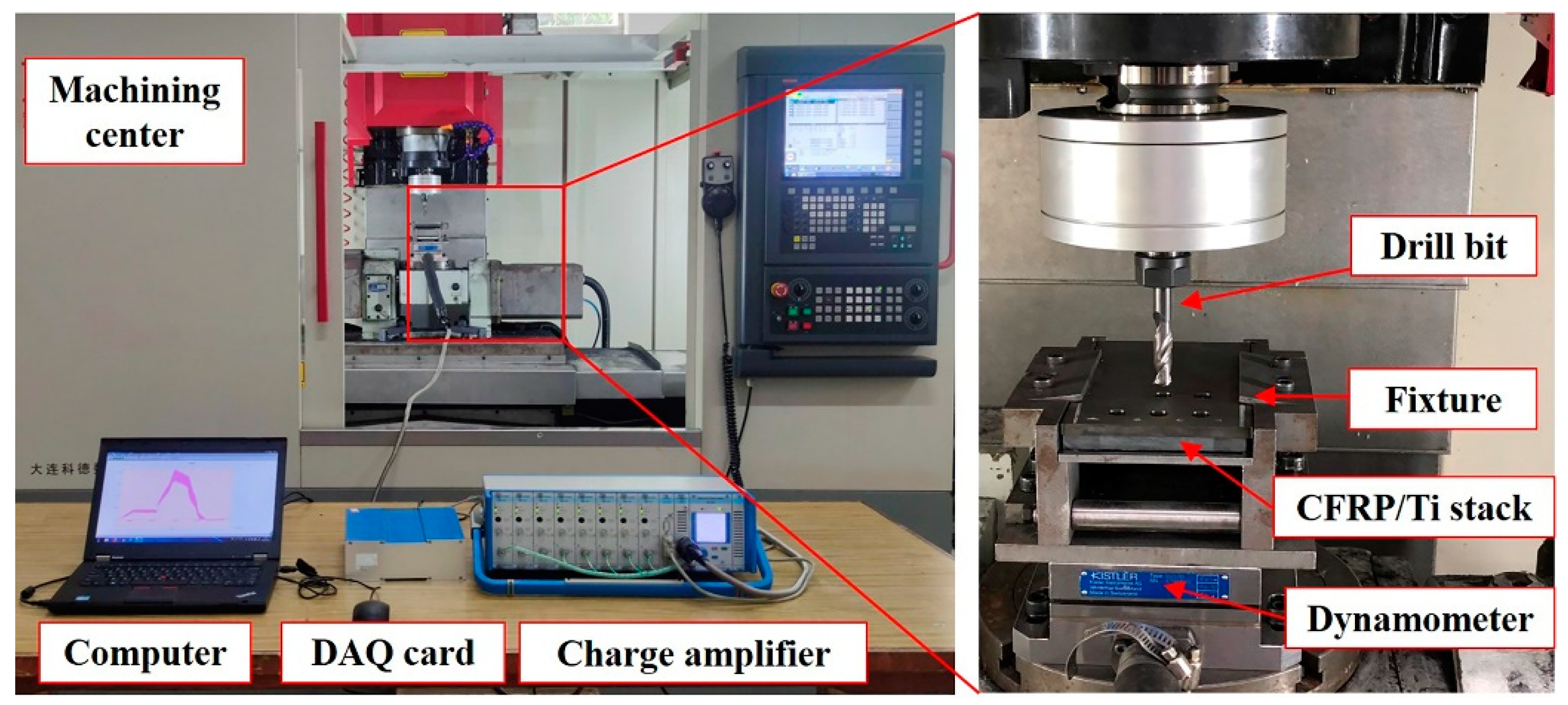

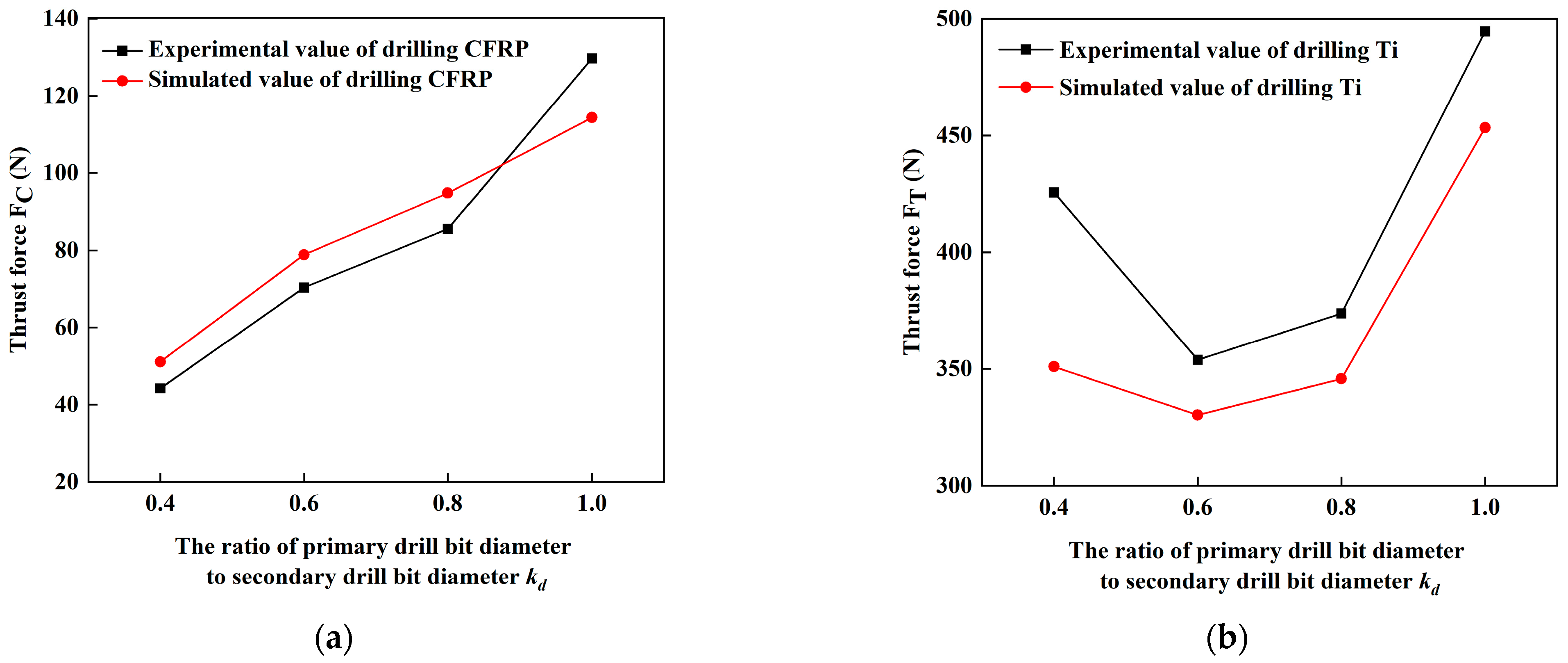

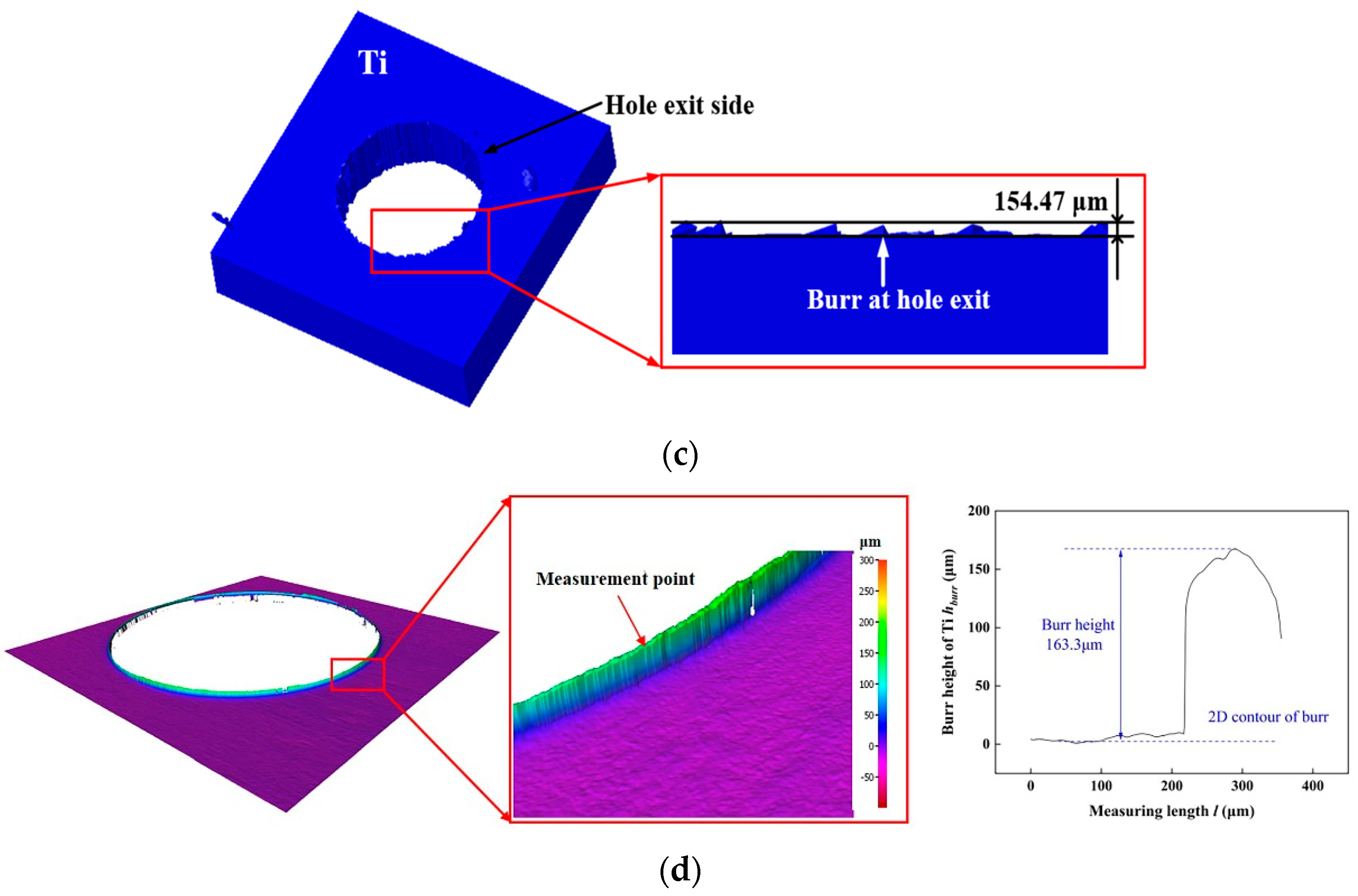

2.5. Experiment Validation of CFRP/Ti Stacks Drilling Model

3. Numerical Result and Discussion

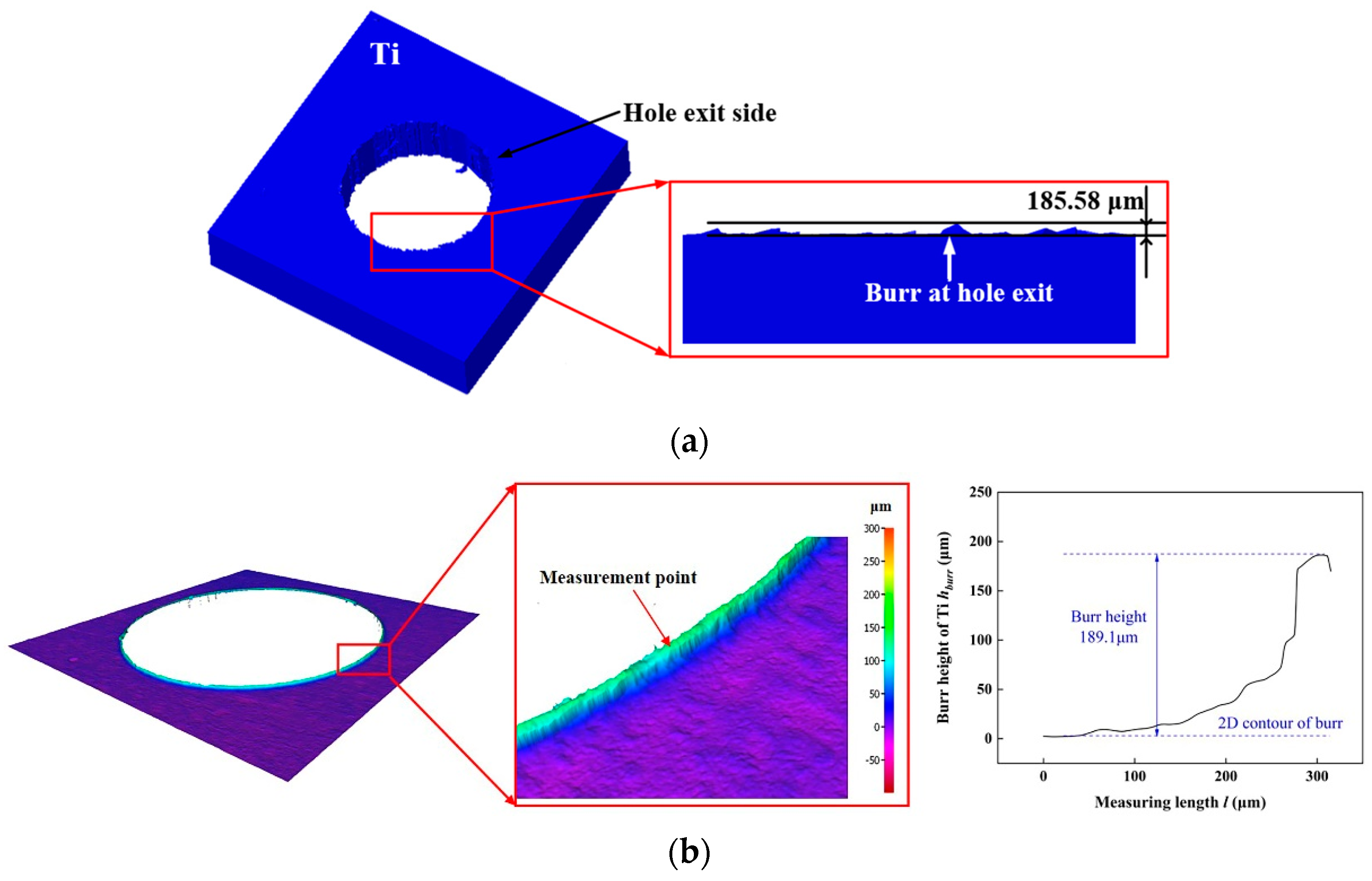

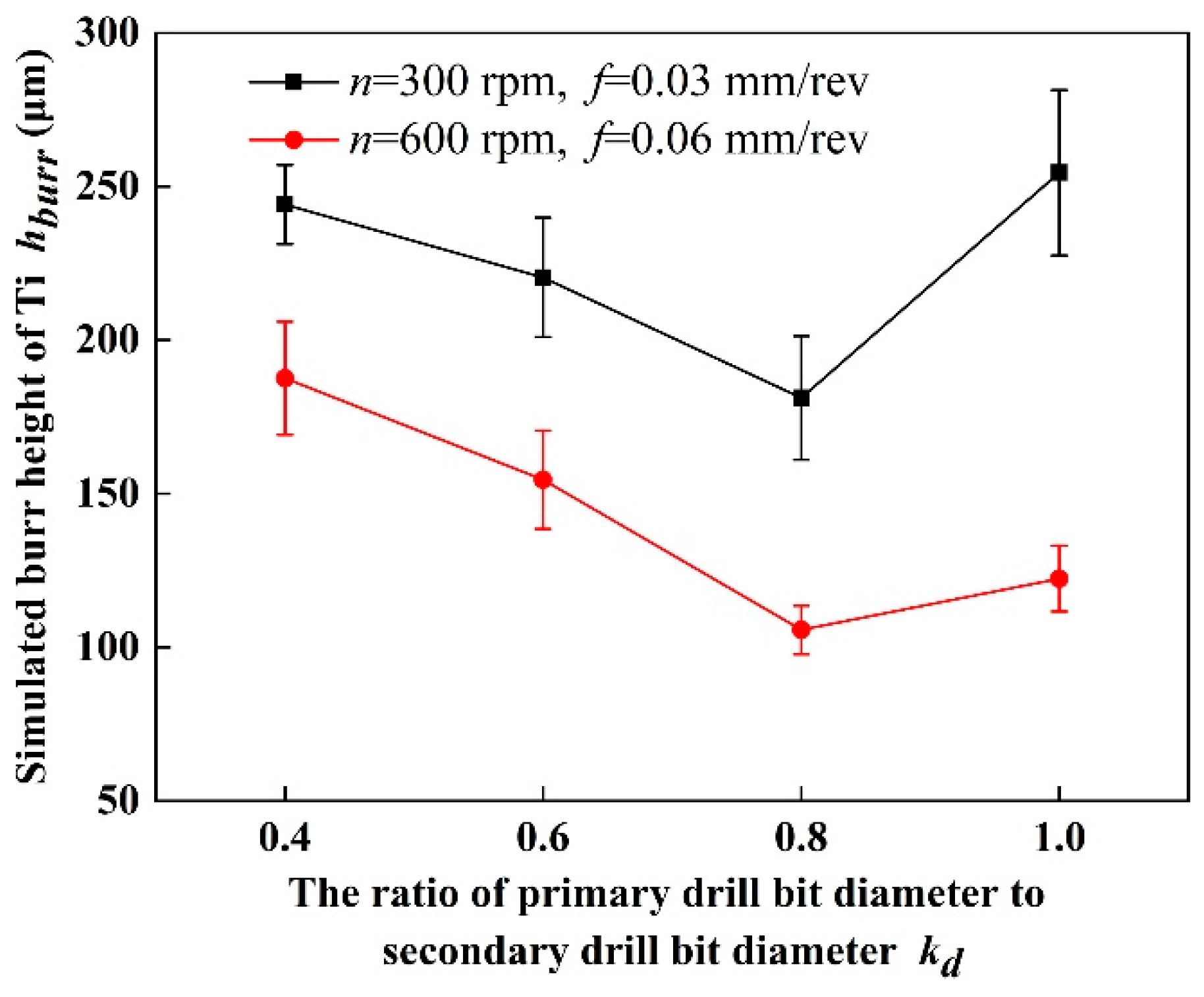

3.1. Effect of Step Drill Structure on the Titanium Alloy Burr at Hole Exit

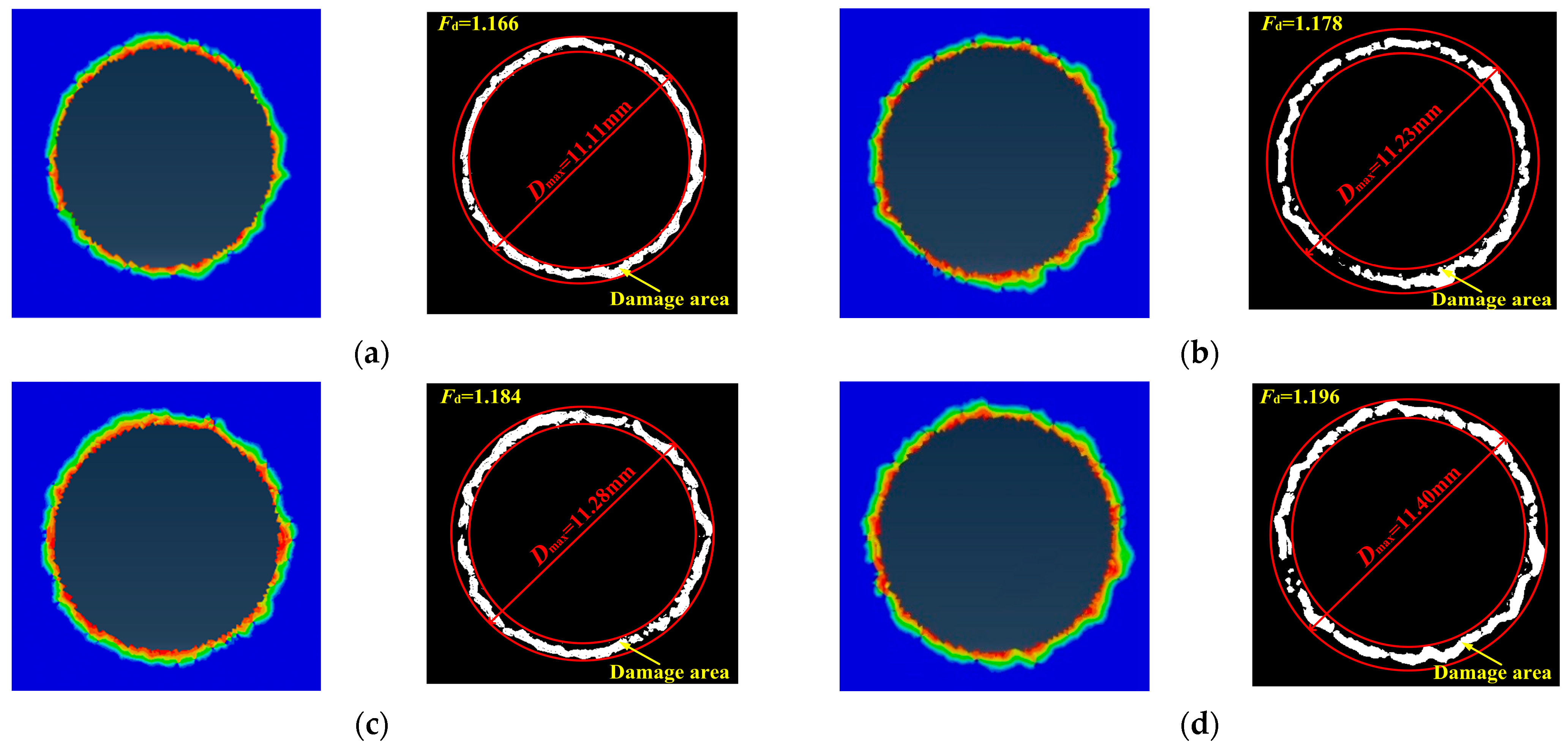

3.2. Effect of Step Drill Structure on the Delamination Damage of CFRP

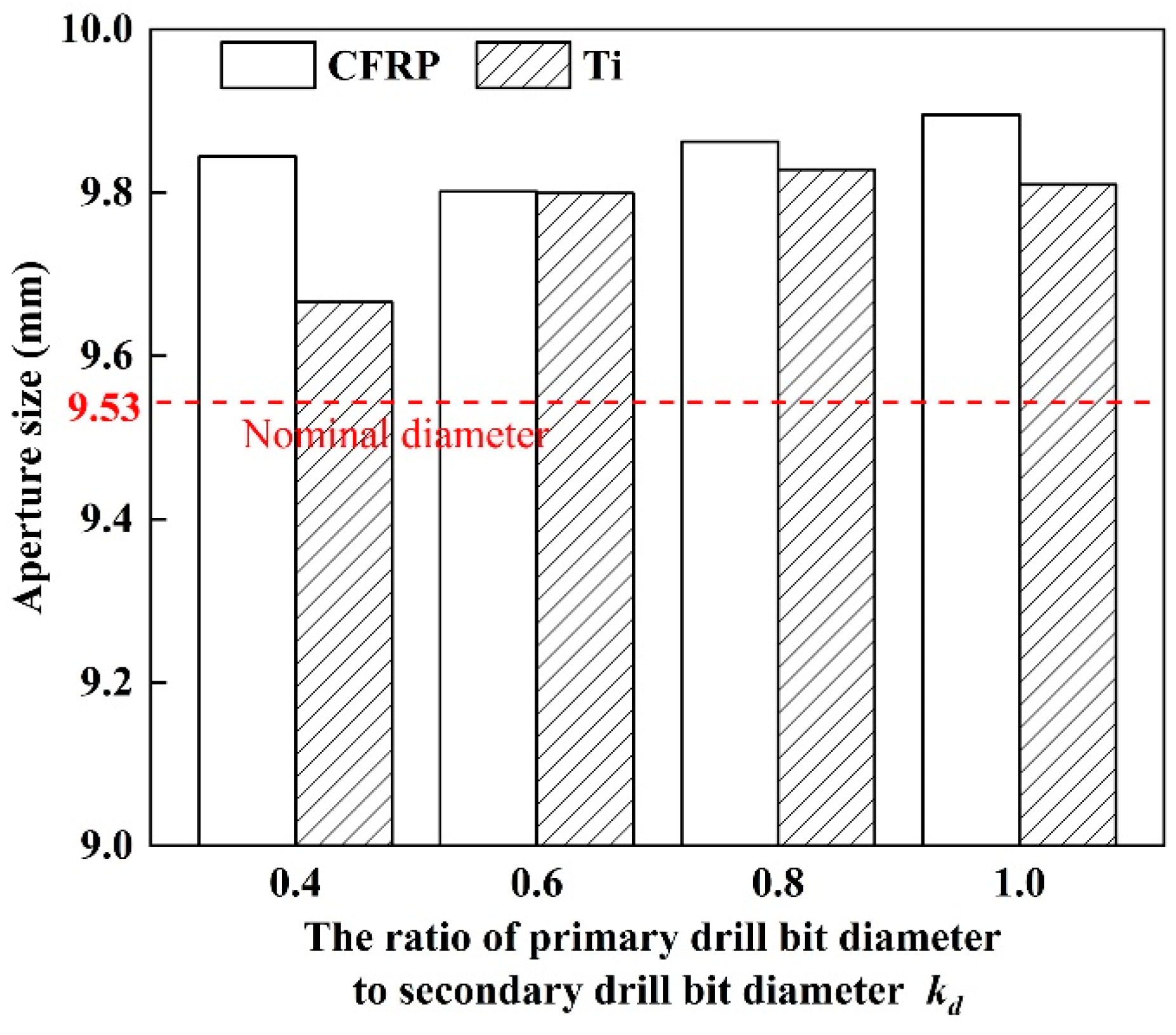

3.3. Effect of Step Drill Structure on the Aperture Size

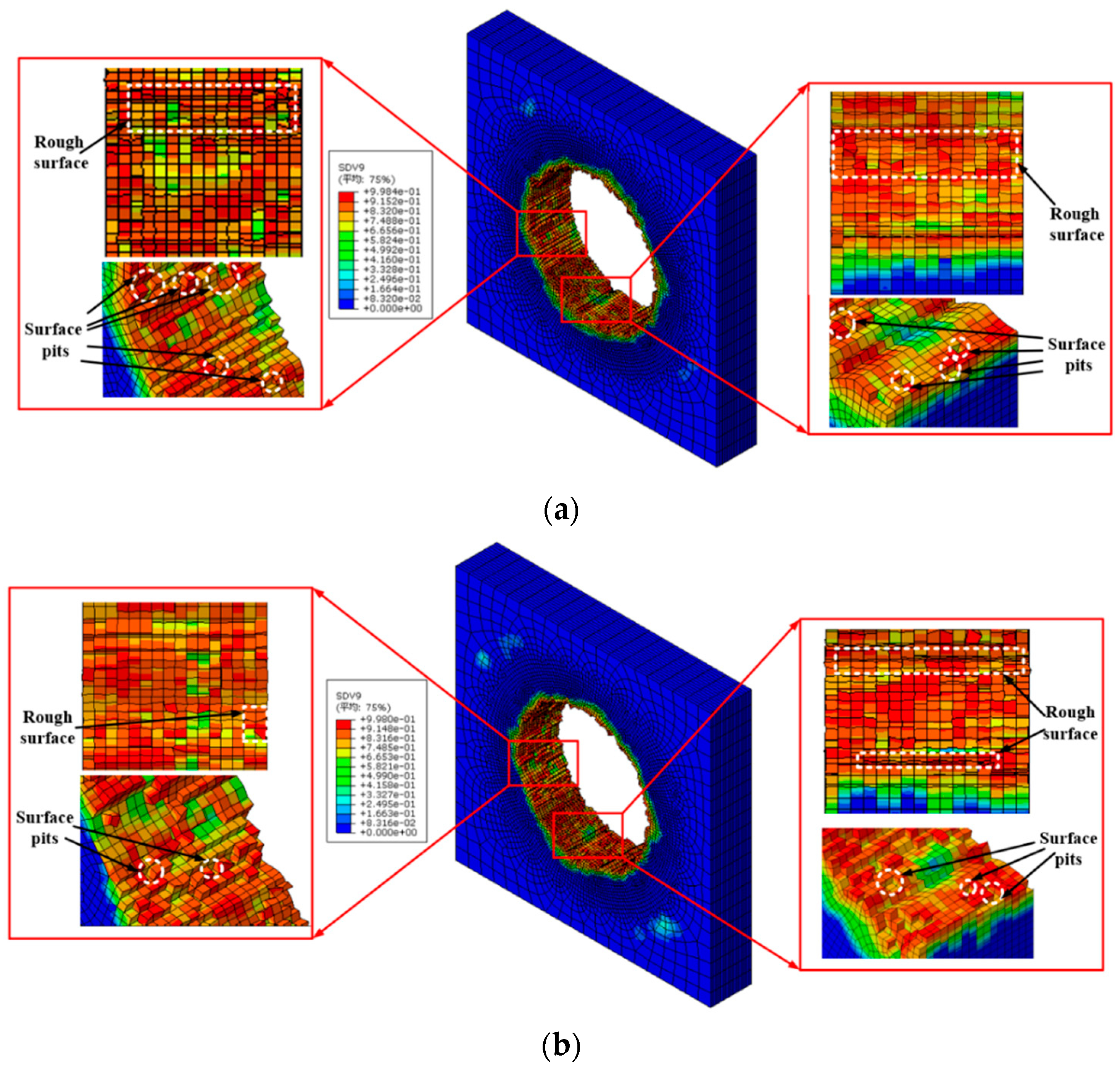

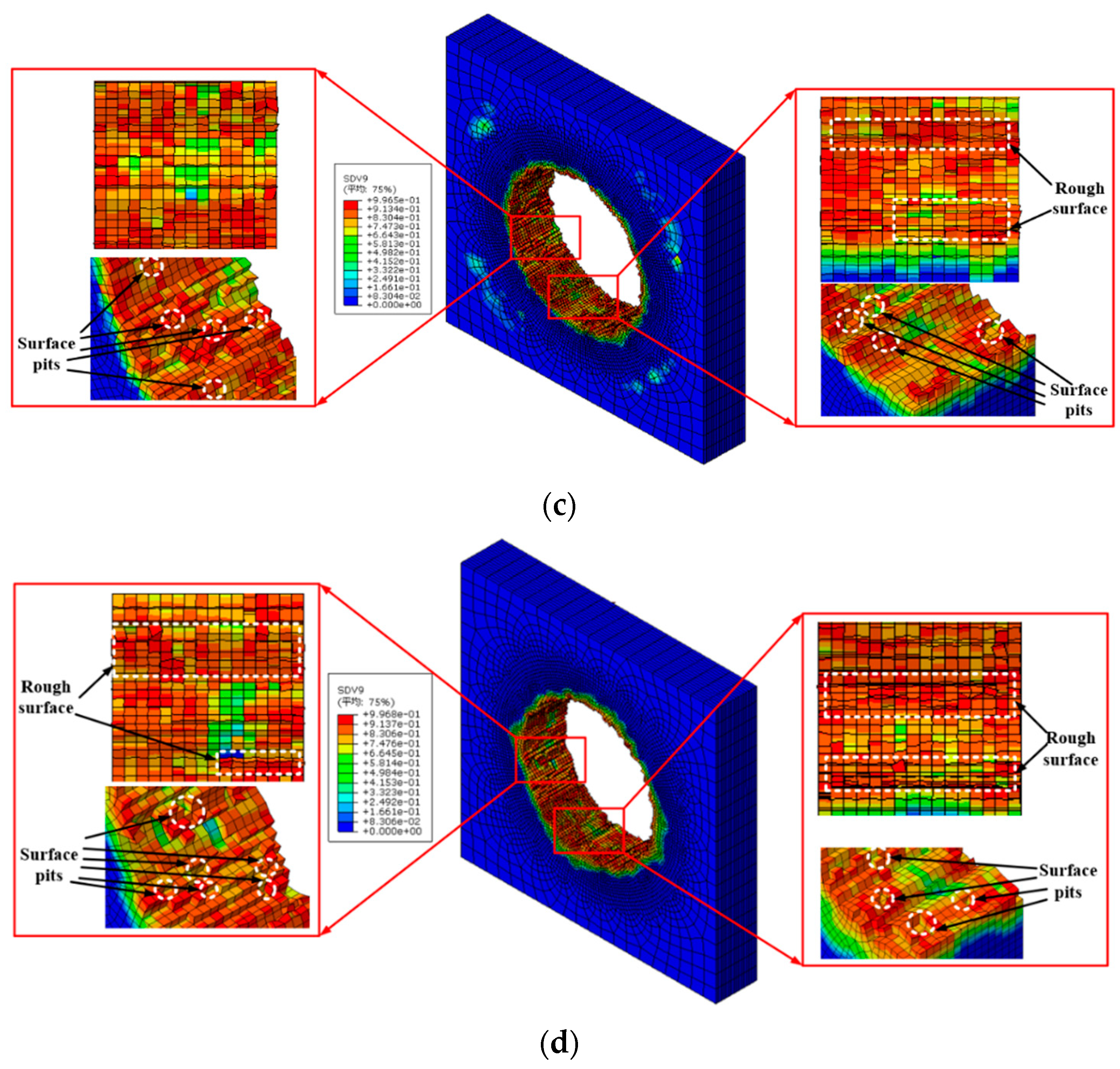

3.4. Effect of Step Drill Structure on the Hole Wall Quality

4. Conclusions

- (1)

- Thrust force and the maximum height of the titanium alloy exit burrs are selected as two indicators to verify the accuracy of the simulation model. The proposed simulation model is found to accurately predicted thrust force and burrs of Ti which are in the maximum error of 15.59% and 3.71% respectively. Based on this result, the reliability of the simulation model results has been verified.

- (2)

- The structure of step drill is confirmed to have significant effect on reducing the height of the titanium alloy burr at hole exit. When the stacking sequence is CFRP to Ti, the height of the titanium alloy burr at hole exit decreases first and then increases with the rising of kd. When kd is 0.6, the height of the titanium alloy burr at hole exit is the lower.

- (3)

- When the stacking sequence is CFRP to Ti, the delamination damage of the CFRP in this stacking sequence is less affected by the change in step drill structure. The results show that as drilling from CFRP to Ti, the support of Ti can offset part of the punching on the CFRP by step drill, which makes the delamination factor only increase by 2.57% with kd increases from 0.4 to 1.0.

- (4)

- The aperture accuracy is related to the structure of step drill. The aperture size decreases first and then increases with the rising of kd. When kd is 0.6, the aperture size deviation is the smallest and the aperture accuracy is the best.

- (5)

- The structure of step drill has a certain impact on the quality of the hole wall. Fewer pit defects on the hole wall surface of CFRP layer occurs as drilling with step drill. Especially when kd is 0.6, the quality of the hole wall surface is better.

Author Contributions

Funding

Conflicts of Interest

References

- Abidin, N.M.Z.; Sultan, M.T.H.; Hua, L.S.; Basri, A.A.; Md Shah, A.U.; Safri, S.N.A. A brief review of computational analysis and experimental models of composite materials for aerospace applications. J. Reinf. Plast. Compos. 2019, 38, 1031–1039. [Google Scholar] [CrossRef]

- Choi, J.Y.; Jeon, J.H.; Lyu, J.H.; Park, J.; Kim, G.Y.; Chey, S.Y.; Quan, Y.-J.; Bhandari, B.; Prusty, B.G.; Ahn, S.-H. Current Applications and Development of Composite Manufacturing Processes for Future Mobility. Int. J. Precis. Eng. Manuf. Green Technol. 2022, 10, 269–291. [Google Scholar] [CrossRef]

- Das, T.K.; Ghosh, P.; Das, N.C. Preparation, development, outcomes, and application versatility of carbon fiber-based polymer composites: A review. Adv. Compos. Hybrid Mater. 2019, 2, 214–233. [Google Scholar] [CrossRef]

- Jones, C.E.; Norman, P.J.; Burt, G.M.; Hill, C.; Allegri, G.; Yon, J.M.; Hamerton, I.; Trask, R.S. A Route to Sustainable Aviation: A Roadmap for the Realization of Aircraft Components With Electrical and Structural Multifunctionality. IEEE Trans. Transp. Electrif. 2021, 7, 3032–3049. [Google Scholar] [CrossRef]

- Zheng, H.; Zhang, W.J.; Li, B.W.; Zhu, J.J.; Wang, C.H.; Song, G.J.; Wu, G.S.; Yang, X.P.; Huang, Y.D.; Ma, L.C. Recent advances of interphases in carbon fiber-reinforced polymer composites: A review. Compos. Part B Eng. 2022, 233, 109639. [Google Scholar] [CrossRef]

- Xu, J.; Ji, M.; Davim, J.P.; Chen, M.; El Mansori, M.; Krishnaraj, V. Comparative study of minimum quantity lubrication and dry drilling of CFRP/titanium stacks using TiAIN and diamond coated drills. Compos. Struct. 2020, 234, 111727. [Google Scholar] [CrossRef]

- Ge, J.; Chen, G.; Su, Y.; Zou, Y.; Ren, C.; Qin, X.; Wang, G. Effect of cooling strategies on performance and mechanism of helical milling of CFRP/Ti-6Al-4 V stacks. Chin. J. Aeronaut. 2022, 35, 388–403. [Google Scholar] [CrossRef]

- An, Q.L.; Zhong, B.F.; Wang, X.F.; Zhang, H.Z.; Sun, X.F.; Chen, M. Effects of drilling strategies for CFRP/Ti stacks on static mechanical property and fatigue behavior of open-hole CFRP laminates. J. Manuf. Process. 2021, 64, 409–420. [Google Scholar] [CrossRef]

- Jia, Z.Y.; Fu, R.; Niu, B.; Qian, B.W.; Bai, Y.; Wang, F.J. Novel drill structure for damage reduction in drilling CFRP composites. Int. J. Mach. Tools Manuf. 2016, 110, 55–65. [Google Scholar] [CrossRef]

- SenthilKumar, M.; Prabukarthi, A.; Krishnaraj, V. Study on Tool Wear and Chip Formation During Drilling Carbon Fiber Reinforced Polymer (CFRP)/Titanium Alloy (Ti6Al4V) Stacks. Procedia Eng. 2013, 64, 582–592. [Google Scholar] [CrossRef]

- Shi, R.P.; Wang, C.Y.; Wang, X. Preliminary Study on Carbon Fibre Composites Cutting Technology and Cutting Tools. Mater. Sci. Forum 2012, 723, 25–29. [Google Scholar]

- Baon, F.; Sambruno, A.; Batista, M.; Fernandez-Vidal, S.R.; Salguero, J. Study of the one-shot drilling of CFRP/Ti6Al4V stacks with a double tip angle cutting-tool geometry. In Proceedings of the International ESAFORM Conference on Material Forming, Vitoria-Gasteiz, Spain, 8–10 May 2019. [Google Scholar]

- Liu, L.P.; Lian, B.; Zhou, C.G.; Duan, K.H.; Zhu, X.M.; Xia, P.F. Research on drilling CFRP laminate with a thin woven glass fiber surface layer using plane rake-faced twist drill. Int. J. Adv. Manuf. Technol. 2021, 117, 1781–1796. [Google Scholar] [CrossRef]

- Alonso, U.; Calamaz, M.; Girot, F.; Iriondo, E. Influence of flute number and stepped bit geometry when drilling CFRP/Ti6Al4V stacks. J. Manuf. Process. 2019, 39, 356–370. [Google Scholar] [CrossRef]

- Wang, F.J.; Zhao, M.; Fu, R.; Liu, X.; Qiu, S.; Yan, J.B.; Zhang, B.Y. Replaceable drill bit with compound step and sawtooth structures for damages and drilling-cost reduction of CFRP composite. J. Manuf. Process. 2022, 81, 1018–1027. [Google Scholar] [CrossRef]

- Brinksmeier, E.; Janssen, R. Drilling of multi-layer composite materials consisting of carbon fiber reinforced plastics (CFRP), titanium and aluminum alloys. Cirp Ann. Manuf. Technol. 2002, 51, 87–90. [Google Scholar] [CrossRef]

- Leng, X.L.; Li, P.N.; Niu, Q.L.; Qiu, X.Y.; Li, C.P. Tool wear of step drill drilling CFRP/ TC4 stack. Aerosp. Mater. Technol. 2018, 48, 86–90. (In Chinese) [Google Scholar]

- Leng, X.L.; Li, P.N.; Niu, Q.L.; Qiu, X.Y.; Xu, L. Drilling force and hole quality of step drill drilling of carbon fiber composite. Aerosp. Mater. Technol. 2018, 48, 89–94. (In Chinese) [Google Scholar]

- Diaz-Alvarez, A.; Diaz-Alvarez, J.; Santiuste, C.; Miguelez, M.H. Experimental and numerical analysis of the influence of drill point angle when drilling biocomposites. Compos. Struct. 2019, 209, 700–709. [Google Scholar] [CrossRef]

- Wang, H.T.; Huang, S.T.; Zhang, P.; Xv, L.F. Finite element analysis on influence which tool structure impose on delamination damage of CFRP/Al stacks. Tool Eng. 2018, 52, 60–64. (In Chinese) [Google Scholar]

- Isbilir, O.; Ghassemieh, E. Numerical investigation of the effects of drill geometry on drilling induced delamination of carbon fiber reinforced composites. Compos. Struct. 2013, 105, 126–133. [Google Scholar] [CrossRef]

- Yi, Y.P.; Xv, Z.F.; Wang, H. Stiffness degradation methodology for low-velocity impact simulation in composite laminate. Chin. Q. Mech. 2012, 33, 469–475. (In Chinese) [Google Scholar]

- Rentsch, R.; Pecat, O.; Brinksmeier, E. Macro and micro process modeling of the cutting of carbon fiber reinforced plastics using FEM. Procedia Eng. 2011, 10, 1823–1828. [Google Scholar] [CrossRef]

- Johnson, G.R. A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperature. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983. [Google Scholar]

- Ji, C.H.; Li, Y.H.; Qin, X.D.; Zhao, Q.; Sun, D.; Jin, Y. 3D FEM simulation of helical milling hole process for titanium alloy Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2015, 81, 1733–1742. [Google Scholar] [CrossRef]

- Xu, J.; Lin, T.; Li, L.; Ji, M.; Davim, J.P.; Geier, N.; Chen, M. Numerical study of interface damage formation mechanisms in machining CFRP/Ti6Al4V stacks under different cutting sequence strategies. Compos. Struct. 2022, 285, 115236. [Google Scholar] [CrossRef]

- Xu, J.Y.; El Mansori, M. Cutting Modeling of Hybrid CFRP/Ti Composite with Induced Damage Analysis. Materials 2016, 9, 22. [Google Scholar] [CrossRef]

| Mechanical Property | Value |

|---|---|

| Density, ρ (Kg/m3) | 1470 |

| Longitudinal modulus, E1 (GPa) | 116 |

| Transverse modulus, E2 (GPa) | 8.5 |

| Transverse modulus, E3 (GPa) | 8.5 |

| Poisson ratio, υ12 | 0.32 |

| Poisson ratio, υ13 | 0.32 |

| Poisson ratio, υ23 | 0.46 |

| Shear modulus in 1–2 plane, G12 (GPa) | 3.26 |

| Shear modulus in 1–3 plane, G13 (GPa) | 3.26 |

| Shear modulus in 2–3 plane, G23 (GPa) | 2.91 |

| Shear strength in 1–2 plane, S12 (MPa) | 79 |

| Shear strength in 1–3 plane, S13 (MPa) | 79 |

| Shear strength in 2–3 plane, S23 (MPa) | 79 |

| Longitudinal tensile strength, XT (MPa) | 1950 |

| Longitudinal compressive strength, XC (MPa) | 1480 |

| Transverse tensile strength, YT (MPa) | 48 |

| Transverse compressive strength, YC (MPa) | 200 |

| Transverse tensile strength, ZT (MPa) | 48 |

| Transverse compressive strength, ZC (MPa) | 200 |

| JC constitutive model | A (MPa) | B (MPa) | C | n | m |

| 860 | 683 | 0.035 | 0.47 | 1 | |

| JC damage criteria | D1 | D2 | D3 | D4 | D5 |

| −0.09 | 0.25 | −0.5 | 0.014 | 3.87 |

| Mechanical Property | Value |

|---|---|

| Knn (Gpa) | 2 |

| Kss (Gpa) | 1.5 |

| Ktt (Gpa) | 1.5 |

| (Mpa) | 60 |

| (Mpa) | 90 |

| (Mpa) | 90 |

| kd | Point Angle of Primary Drill Bit (°) | Point Angle of Secondary Drill Bit (°) | Tool Diameter (mm) | |

|---|---|---|---|---|

| 1 | 0.4 | 130 | 130 | 9.53 |

| 2 | 0.6 | 130 | 130 | 9.53 |

| 3 | 0.8 | 130 | 130 | 9.53 |

| 4 | 1.0 | 130 | - | 9.53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, C.; Zhao, Q.; Wang, A.; Zhang, J.; Qu, Q.; Shi, Z. Numerical Study of Step Drill Structure on Machining Damage in Drilling of CFRP/Ti Stacks. Materials 2023, 16, 6039. https://doi.org/10.3390/ma16176039

Chen C, Zhao Q, Wang A, Zhang J, Qu Q, Shi Z. Numerical Study of Step Drill Structure on Machining Damage in Drilling of CFRP/Ti Stacks. Materials. 2023; 16(17):6039. https://doi.org/10.3390/ma16176039

Chicago/Turabian StyleChen, Chen, Qing Zhao, Aixu Wang, Jing Zhang, Qing Qu, and Zhanli Shi. 2023. "Numerical Study of Step Drill Structure on Machining Damage in Drilling of CFRP/Ti Stacks" Materials 16, no. 17: 6039. https://doi.org/10.3390/ma16176039

APA StyleChen, C., Zhao, Q., Wang, A., Zhang, J., Qu, Q., & Shi, Z. (2023). Numerical Study of Step Drill Structure on Machining Damage in Drilling of CFRP/Ti Stacks. Materials, 16(17), 6039. https://doi.org/10.3390/ma16176039