Life Cycle Assessment of Raw and Fe-Modified Biochars: Contributing to Circular Economy

Abstract

:1. Introduction

2. Methods and Materials

2.1. Software and Scope Definition

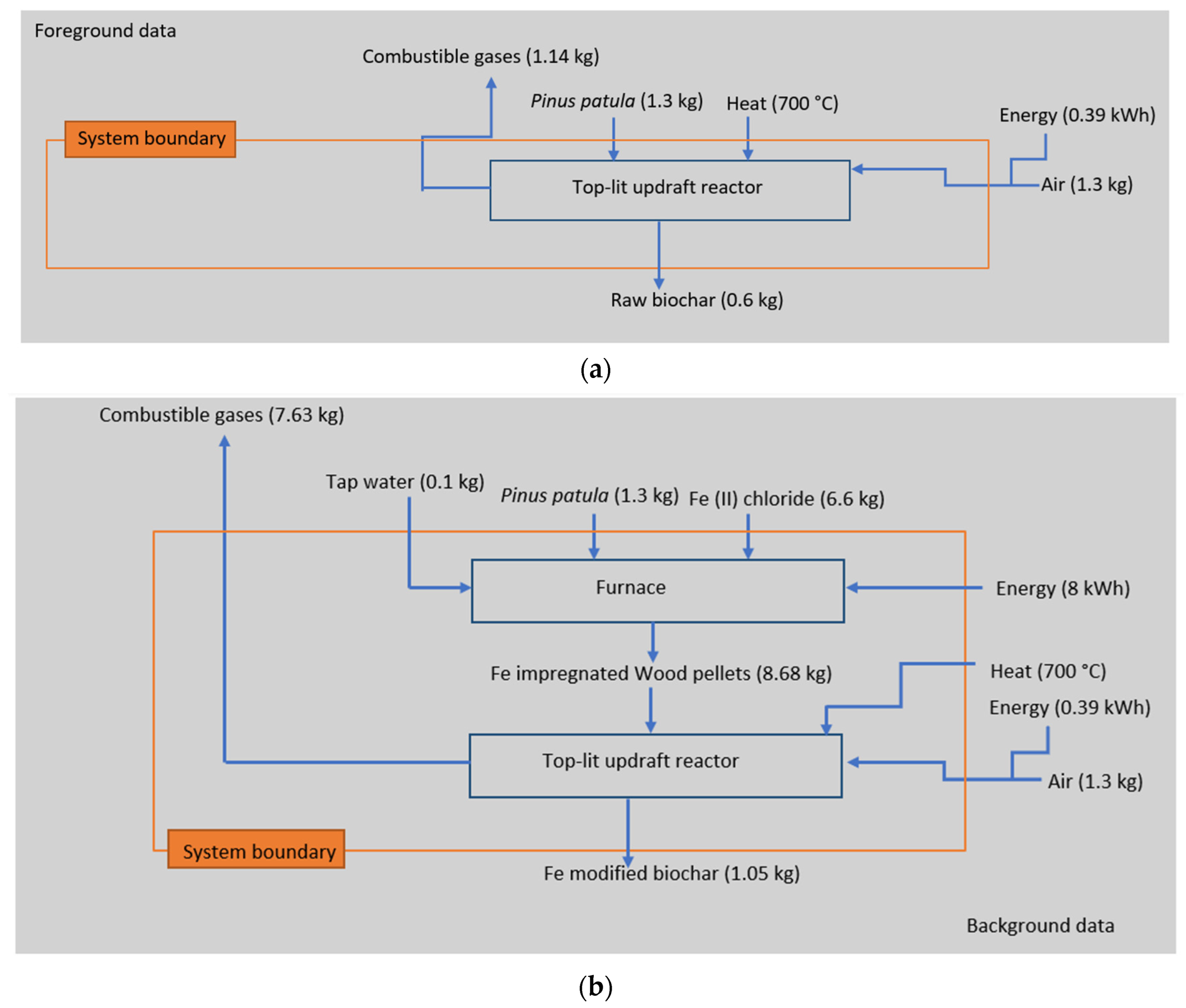

2.2. Inventory Analysis

3. Results and Discussion

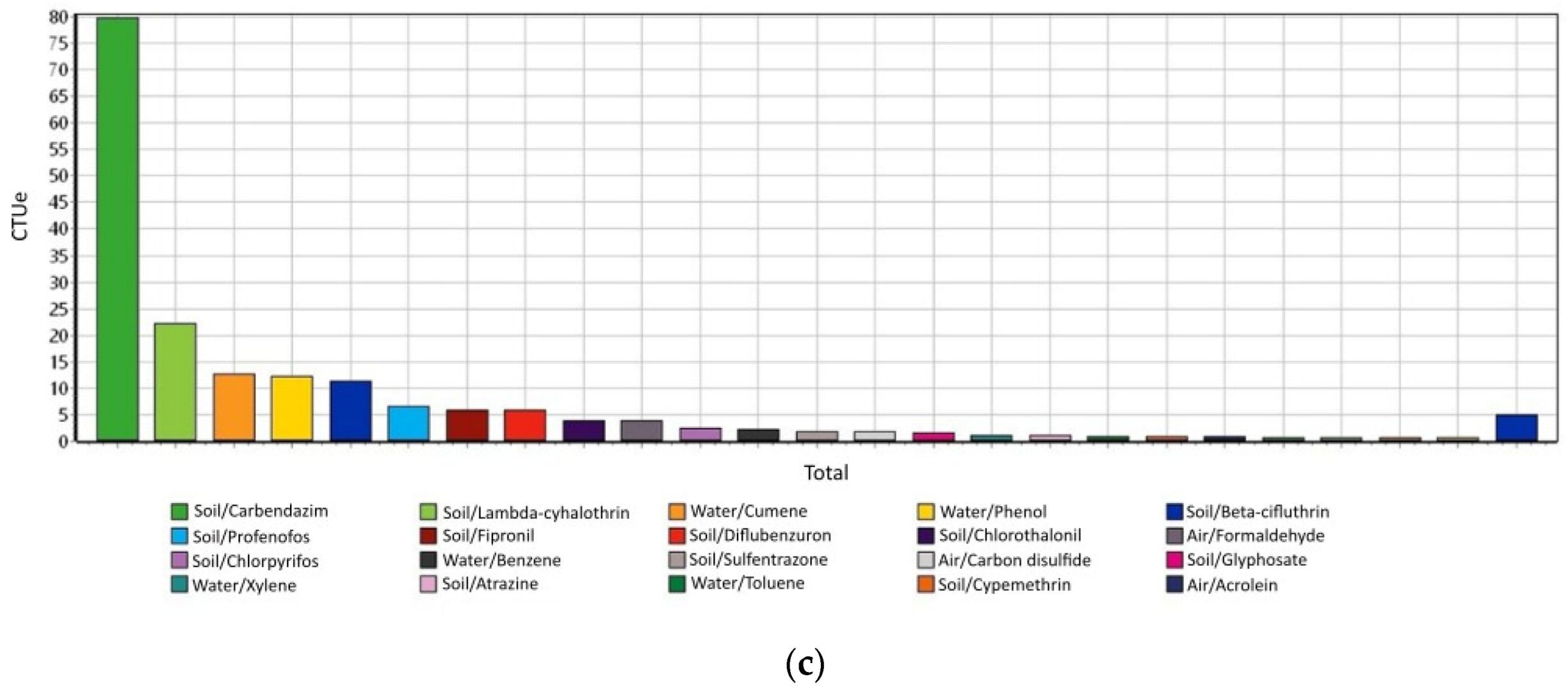

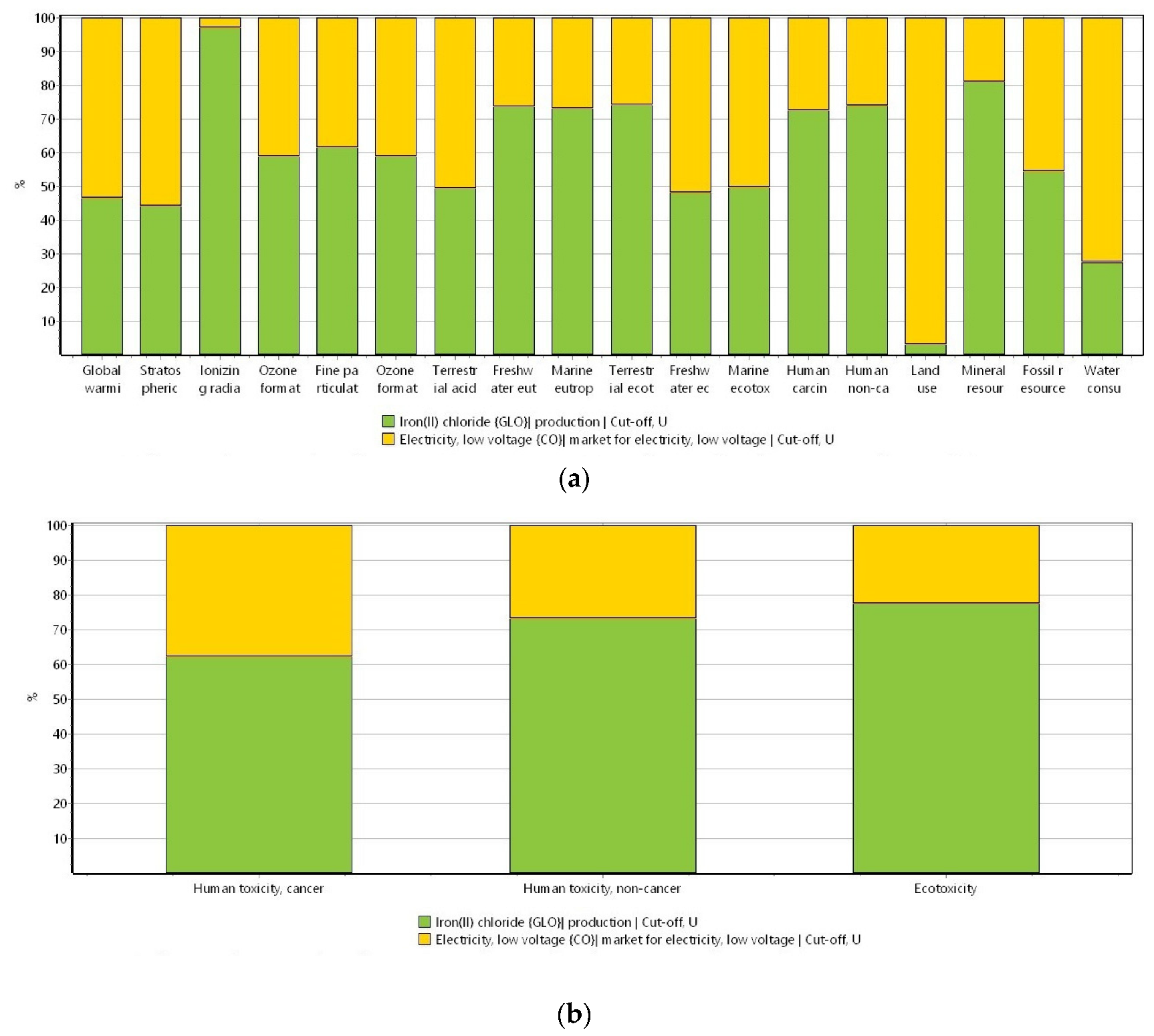

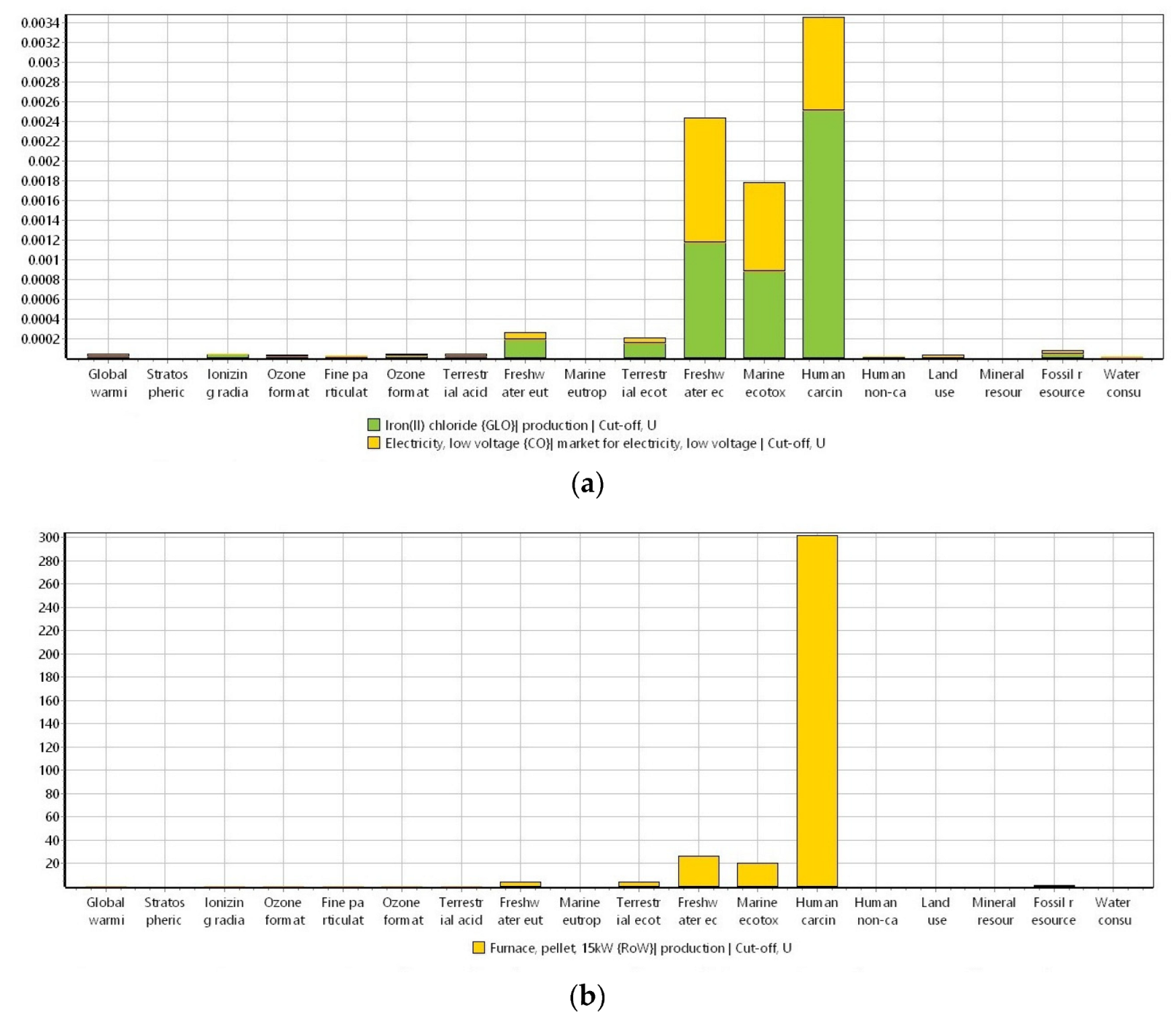

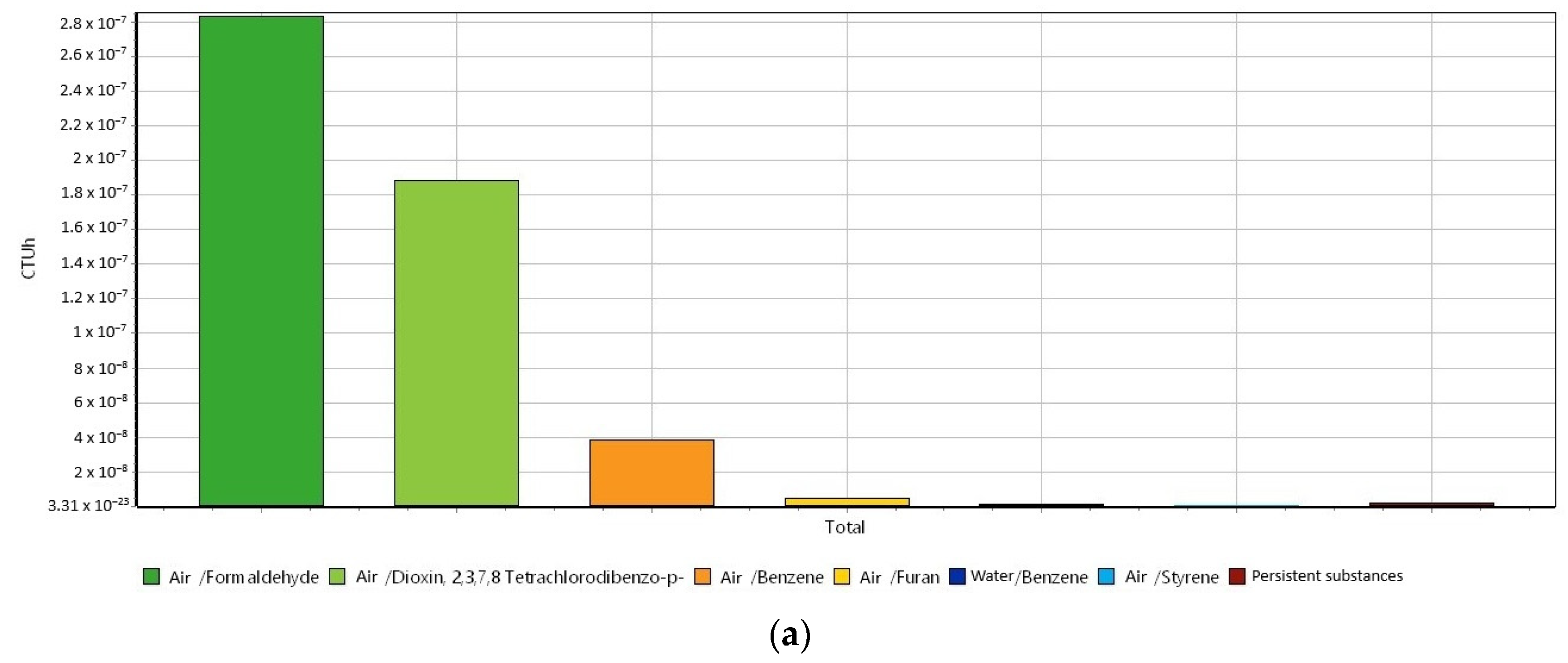

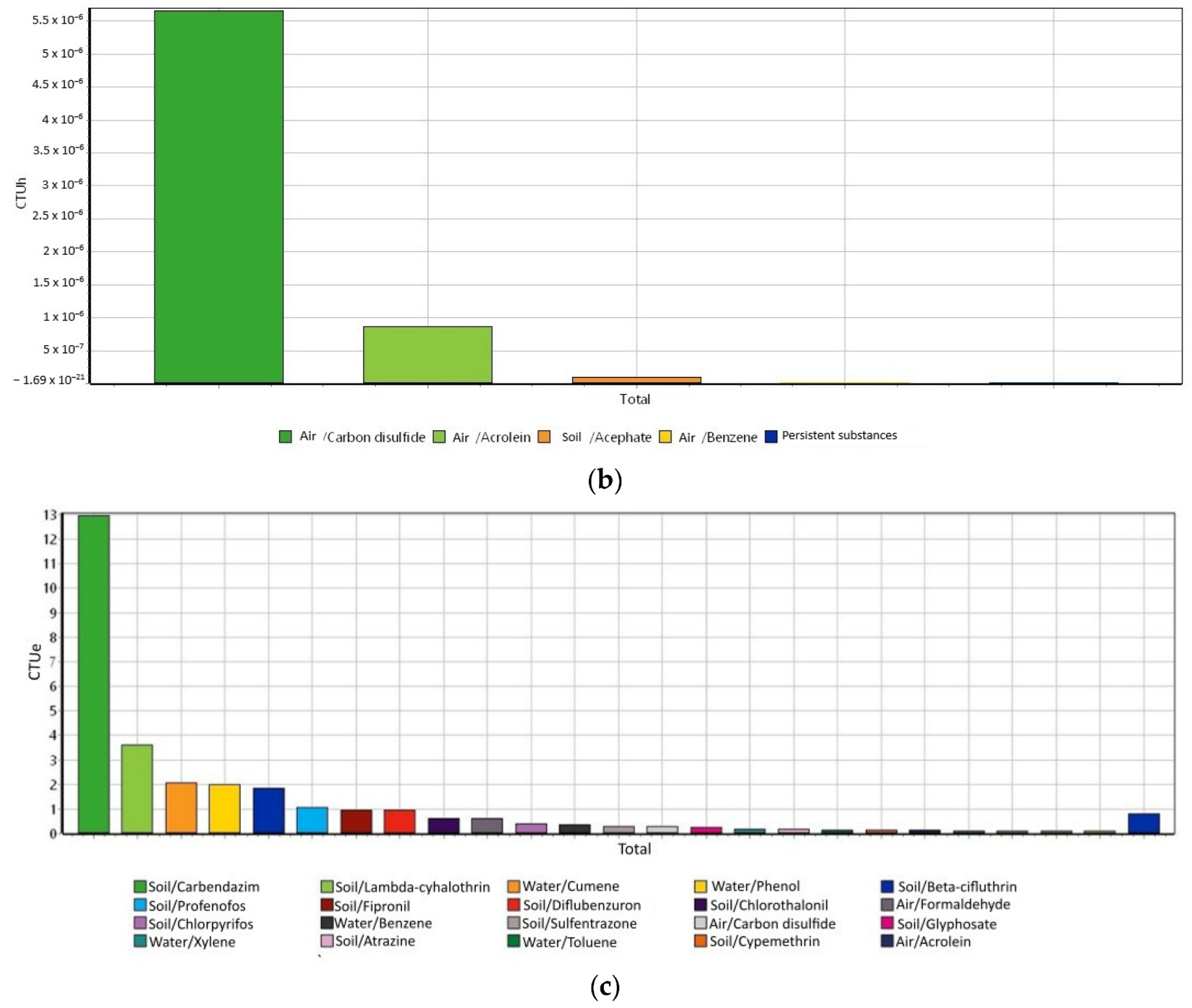

3.1. Impact Assessment

3.2. Impact Interpretation

3.3. Future Perspectives

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tian, W.-W.; Xu, F.; Xing, S.-J.; Wu, R.; Yuan, Z.-Y. Comprehensive Study on the Thermal Decomposition Process of Waste Tobacco Leaves and Stems to Investigate Their Bioenergy Potential: Kinetic, Thermodynamic, and Biochar Analysis. Thermochim. Acta 2023, 723, 179473. [Google Scholar] [CrossRef]

- Murad, H.A.; Ahmad, M.; Bundschuh, J.; Hashimoto, Y.; Zhang, M.; Sarkar, B.; Ok, Y.S. A Remediation Approach to Chromium-Contaminated Water and Soil Using Engineered Biochar Derived from Peanut Shell. Environ. Res. 2022, 204, 112125. [Google Scholar] [CrossRef]

- Nidheesh, P.V.; Gopinath, A.; Ranjith, N.; Praveen Akre, A.; Sreedharan, V.; Suresh Kumar, M. Potential Role of Biochar in Advanced Oxidation Processes: A Sustainable Approach. Chem. Eng. J. 2021, 405, 126582. [Google Scholar] [CrossRef]

- Liu, M.; Almatrafi, E.; Zhang, Y.; Xu, P.; Song, B.; Zhou, C.; Zeng, G.; Zhu, Y. A Critical Review of Biochar-Based Materials for the Remediation of Heavy Metal Contaminated Environment: Applications and Practical Evaluations. Sci. Total Environ. 2022, 806, 150531. [Google Scholar] [CrossRef] [PubMed]

- Mohan, D.; Sarswat, A.; Ok, Y.S.; Pittman, C.U. Organic and Inorganic Contaminants Removal from Water with Biochar, a Renewable, Low Cost and Sustainable Adsorbent—A Critical Review. Bioresour. Technol. 2014, 160, 191–202. [Google Scholar] [CrossRef] [PubMed]

- Yang, C.; Wu, H.; Cai, M.; Li, Y.; Guo, C.; Han, Y.; Zhang, Y.; Song, B. Valorization of Food Waste Digestate to Ash and Biochar Composites for High Performance Adsorption of Methylene Blue. J. Clean. Prod. 2023, 397, 136612. [Google Scholar] [CrossRef]

- Boraah, N.; Chakma, S.; Kaushal, P. Attributes of Wood Biochar as an Efficient Adsorbent for Remediating Heavy Metals and Emerging Contaminants from Water: A Critical Review and Bibliometric Analysis. J. Environ. Chem. Eng. 2022, 10, 107825. [Google Scholar] [CrossRef]

- Wang, J.; Wang, S. Preparation, Modification and Environmental Application of Biochar: A Review. J. Clean. Prod. 2019, 227, 1002–1022. [Google Scholar] [CrossRef]

- Ding, Y.; Li, M.; Zhang, Q.; Zhang, Y.; Xia, Z.; Liu, X.; Wu, N.; Peng, J. Sulfidized State and Formation: Enhancement of Nanoscale Zero-Valent Iron on Biochar (S-NZVI/BC) in Activating Peroxymonosulfate for Acid Red 73 Degradation. J. Environ. Chem. Eng. 2023, 11, 110114. [Google Scholar] [CrossRef]

- Qian, J.; Zhou, X.; Cai, Q.; Zhao, J.; Huang, X. The Study of Optimal Adsorption Conditions of Phosphate on Fe-Modified Biochar by Response Surface Methodology. Molecules 2023, 28, 2323. [Google Scholar] [CrossRef]

- Chu, J.-H.; Kang, J.-K.; Park, S.-J.; Lee, C.-G. Application of Magnetic Biochar Derived from Food Waste in Heterogeneous Sono-Fenton-like Process for Removal of Organic Dyes from Aqueous Solution. J. Water Process Eng. 2020, 37, 101455. [Google Scholar] [CrossRef]

- Chu, J.-H.; Kang, J.-K.; Park, S.-J.; Lee, C.-G. Enhanced Sonocatalytic Degradation of Bisphenol A with a Magnetically Recoverable Biochar Composite Using Rice Husk and Rice Bran as Substrate. J. Environ. Chem. Eng. 2021, 9, 105284. [Google Scholar] [CrossRef]

- Qiu, B.; Shao, Q.; Shi, J.; Yang, C.; Chu, H. Application of Biochar for the Adsorption of Organic Pollutants from Wastewater: Modification Strategies, Mechanisms and Challenges. Sep. Purif. Technol. 2022, 300, 121925. [Google Scholar] [CrossRef]

- Eniola, J.O.; Sizirici, B.; Khaleel, A.; Yildiz, I. Fabrication of Engineered Biochar-Iron Oxide from Date Palm Frond for the Effective Removal of Cationic Dye from Wastewater. J. Water Process Eng. 2023, 54, 104046. [Google Scholar] [CrossRef]

- Sun, M.; Ma, Y.; Yang, Y.; Zhu, X. Effect of Iron Impregnation Ratio on the Properties and Adsorption of KOH Activated Biochar for Removal of Tetracycline and Heavy Metals. Bioresour. Technol. 2023, 380, 129081. [Google Scholar] [CrossRef] [PubMed]

- Hassan, S.R.; Megahed, N.A.; Abo Eleinen, O.M.; Hassan, A.M. Toward a National Life Cycle Assessment Tool: Generative Design for Early Decision Support. Energy Build. 2022, 267, 112144. [Google Scholar] [CrossRef]

- Pryshlakivsky, J.; Searcy, C. Life Cycle Assessment as a Decision-Making Tool: Practitioner and Managerial Considerations. J. Clean. Prod. 2021, 309, 127344. [Google Scholar] [CrossRef]

- Mahmud, R.; Moni, S.M.; High, K.; Carbajales-Dale, M. Integration of Techno-Economic Analysis and Life Cycle Assessment for Sustainable Process Design—A Review. J. Clean. Prod. 2021, 317, 128247. [Google Scholar] [CrossRef]

- Mohd Nasir, A.S.; Mohamed, B.; Li, L.Y. Comparative Life Cycle Assessment of Co-Pyrolysing Sewage Sludge and Wastewater-Grown Microalgae for Biofuel Production. Resour. Conserv. Recycl. 2023, 190, 106780. [Google Scholar] [CrossRef]

- Yadav, G.; Singh, A.; Dutta, A.; Uekert, T.; DesVeaux, J.S.; Nicholson, S.R.; Tan, E.C.D.; Mukarakate, C.; Schaidle, J.A.; Wrasman, C.J.; et al. Techno-Economic Analysis and Life Cycle Assessment for Catalytic Fast Pyrolysis of Mixed Plastic Waste. Energy Environ. Sci. 2023, 1–16. [Google Scholar] [CrossRef]

- Li, H.; Zhao, L. Life Cycle Assessment and Multi-Objective Optimization for Industrial Utility Systems. Energy 2023, 280, 128213. [Google Scholar] [CrossRef]

- Aguiar, G.J.A.; Almeida, L.R.; Fernandes, B.S.; Gavazza, S.; Silva, G.L.; Machado Santos, S. Use of Life Cycle Assessment as a Tool to Evaluate the Environmental Impacts of Textile Effluents: A Systematic Review. Environ. Sci. Pollut. Res. Int. 2023, 30, 76455–76470. [Google Scholar] [CrossRef] [PubMed]

- Mandegari, M.; Ebadian, M.; Saddler, J.J. The Need for Effective Life Cycle Assessment (LCA) to Enhance the Effectiveness of Policies Such as Low Carbon Fuel Standards (LCFS’s). Energy Policy 2023, 181, 113723. [Google Scholar] [CrossRef]

- Arvizu-Piña, V.A.; Armendáriz López, J.F.; García González, A.A.; Barrera Alarcón, I.G. An Open Access Online Tool for LCA in Building’s Early Design Stage in the Latin American Context. A Screening LCA Case Study for a Bioclimatic Building. Energy Build. 2023, 295, 113269. [Google Scholar] [CrossRef]

- Mishra, R.K.; Kumar, D.J.P.; Narula, A.; Chistie, S.M.; Naik, S.U. Production and Beneficial Impact of Biochar for Environmental Application: A Review on Types of Feedstocks, Chemical Compositions, Operating Parameters, Techno-Economic Study, and Life Cycle Assessment. Fuel 2023, 343, 127968. [Google Scholar] [CrossRef]

- Zhu, X.; Labianca, C.; He, M.; Luo, Z.; Wu, C.; You, S.; Tsang, D.C.W. Life-Cycle Assessment of Pyrolysis Processes for Sustainable Production of Biochar from Agro-Residues. Bioresour. Technol. 2022, 360, 127601. [Google Scholar] [CrossRef]

- Hallste Pérez, T.; Rodríguez-Chueca, J.; Pérez Rodríguez, J. Inclusion of Key Social Indices for a Comparative Assessment of the Sustainability of the Life Cycle of Current and Future Electricity Generation in Spain: A Proposed Methodology. Sci. Total Environ. 2023, 899, 165541. [Google Scholar] [CrossRef]

- Razman, K.K.; Hanafiah, M.M.; Mohammad, A.W. An Overview of LCA Applied to Various Membrane Technologies: Progress, Challenges, and Harmonization. Environ. Technol. Innov. 2022, 27, 102803. [Google Scholar] [CrossRef]

- Dastjerdi, B.; Strezov, V.; Rajaeifar, M.A.; Kumar, R.; Behnia, M. A Systematic Review on Life Cycle Assessment of Different Waste to Energy Valorization Technologies. J. Clean. Prod. 2021, 290, 125747. [Google Scholar] [CrossRef]

- Shaheen, J.; Fseha, Y.H.; Sizirici, B. Performance, Life Cycle Assessment, and Economic Comparison between Date Palm Waste Biochar and Activated Carbon Derived from Woody Biomass. Heliyon 2022, 8, e12388. [Google Scholar] [CrossRef]

- Yuan, X.; Cao, Y.; Li, J.; Patel, A.K.; Dong, C.-D.; Jin, X.; Gu, C.; Yip, A.C.K.; Tsang, D.C.W.; Ok, Y.S. Recent Advancements and Challenges in Emerging Applications of Biochar-Based Catalysts. Biotechnol. Adv. 2023, 67, 108181. [Google Scholar] [CrossRef]

- Huang, C.; Mohamed, B.A.; Li, L.Y. Comparative Life-Cycle Assessment of Pyrolysis Processes for Producing Bio-Oil, Biochar, and Activated Carbon from Sewage Sludge. Resour. Conserv. Recycl. 2022, 181, 106273. [Google Scholar] [CrossRef]

- Cheng, H.; Song, Y.; Bolan, N. Biochar for Future and Futuristic Biochar. Pedosphere 2023, in press. [CrossRef]

- Patel, M.R.; Panwar, N.L. Biochar from Agricultural Crop Residues: Environmental, Production, and Life Cycle Assessment Overview. Resour. Conserv. Recycl. Adv. 2023, 19, 200173. [Google Scholar] [CrossRef]

- Cui, Q.; Shao, F. Comparison of Life Cycle Assessment for Laminating and Glazing Processes Based on Simapro. Pigment Resin Technol. 2022, 52, 268–272. [Google Scholar] [CrossRef]

- Generowicz, A.; Gronba-Chyła, A.; Kulczycka, J.; Harazin, P.; Gaska, K.; Ciuła, J.; Ocłoń, P. Life Cycle Assessment for the Environmental Impact Assessment of a City’ Cleaning System. The Case of Cracow (Poland). J. Clean. Prod. 2023, 382, 135184. [Google Scholar] [CrossRef]

- Chen, Y.; Hassan, M.; Nuruzzaman, M.; Zhang, H.; Naidu, R.; Liu, Y.; Wang, L. Iron-Modified Biochar Derived from Sugarcane Bagasse for Adequate Removal of Aqueous Imidacloprid: Sorption Mechanism Study. Environ. Sci. Pollut. Res. 2023, 30, 4754–4768. [Google Scholar] [CrossRef] [PubMed]

- Rubio-Clemente, A.; Gutiérrez, J.; Henao, H.; Melo, A.M.; Pérez, J.F.; Chica, E. Adsorption Capacity of the Biochar Obtained from Pinus Patula Wood Micro-Gasification for the Treatment of Polluted Water Containing Malachite Green Dye. J. King Saud Univ. Eng. Sci. 2021. [Google Scholar] [CrossRef]

- Gutierrez Vanegas, J.; Chica, E.; Pérez, J. Parametric Analysis of a Gasification-Based Cookstove as a Function of Biomass Density, Gasification Behavior, Airflow Ratio, and Design. ACS Omega 2022, 7, 7481–7498. [Google Scholar] [CrossRef]

- Wang, C.; Huang, R.; Sun, R.; Yang, J.; Sillanpää, M. A Review on Persulfates Activation by Functional Biochar for Organic Contaminants Removal: Synthesis, Characterizations, Radical Determination, and Mechanism. J. Environ. Chem. Eng. 2021, 9, 106267. [Google Scholar] [CrossRef]

- Gutiérrez, J.; Rubio-Clemente, A.; Pérez, J.F. Effect of Main Solid Biomass Commodities of Patula Pine on Biochar Properties Produced under Gasification Conditions. Ind. Crops Prod. 2021, 160, 113123. [Google Scholar] [CrossRef]

- Wu, Y.; Su, D. Review of Life Cycle Impact Assessment (LCIA) Methods and Inventory Databases. In Sustainable Product Development: Tools, Methods and Examples; Su, D., Ed.; Springer International Publishing: Cham, Switzerland, 2020; pp. 39–55. [Google Scholar] [CrossRef]

- Rincón, E. Eco-Inidcadores Para Empresas Mexicanas; Universidad Nacional Autónoma de México: Mexico City, Mexico, 2006. [Google Scholar]

- Huijbregts, M.A.J.; Steinmann, Z.J.N.; Elshout, P.M.F.; Stam, G.; Verones, F.; Vieira, M.; Zijp, M.; Hollander, A.; van Zelm, R. ReCiPe2016: A Harmonised Life Cycle Impact Assessment Method at Midpoint and Endpoint Level. Int. J. Life Cycle Assess. 2017, 22, 138–147. [Google Scholar] [CrossRef]

- Ata-Ali, N.; Penadés-Plà, V.; Martínez-Muñoz, D.; Yepes, V. Recycled versus Non-Recycled Insulation Alternatives: LCA Analysis for Different Climatic Conditions in Spain. Resour. Conserv. Recycl. 2021, 175, 105838. [Google Scholar] [CrossRef]

- Ferreira, C.; Ribeiro, J.; Freire, F. A Hazard Classification System Based on Incorporation of REACH Regulation Thresholds in the USEtox Method. J. Clean. Prod. 2019, 228, 856–866. [Google Scholar] [CrossRef]

- Preethi; M., G.; Kumar, G.; Karthikeyan, O.P.; Varjani, S.; J., R.B. Lignocellulosic Biomass as an Optimistic Feedstock for the Production of Biofuels as Valuable Energy Source: Techno-Economic Analysis, Environmental Impact Analysis, Breakthrough and Perspectives. Environ. Technol. Innov. 2021, 24, 102080. [Google Scholar] [CrossRef]

- Greco, G.; Videgain, M.; Di Stasi, C.; Pires, E.; Manyà, J.J. Importance of Pyrolysis Temperature and Pressure in the Concentration of Polycyclic Aromatic Hydrocarbons in Wood Waste-Derived Biochars. J. Anal. Appl. Pyrolysis 2021, 159, 105337. [Google Scholar] [CrossRef]

- Wang, Z.; Bui, Q.; Zhang, B.; Pham, T.L.H. Biomass Energy Production and Its Impacts on the Ecological Footprint: An Investigation of the G7 Countries. Sci. Total Environ. 2020, 743, 140741. [Google Scholar] [CrossRef]

- Zaghden, H.; Barhoumi, B.; Jlaiel, L.; Guigue, C.; Chouba, L.; Touil, S.; Sayadi, S.; Tedetti, M. Occurrence, Origin and Potential Ecological Risk of Dissolved Polycyclic Aromatic Hydrocarbons and Organochlorines in Surface Waters of the Gulf of Gabès (Tunisia, Southern Mediterranean Sea). Mar. Pollut. Bull. 2022, 180, 113737. [Google Scholar] [CrossRef]

- Rubio-Clemente, A.; Chica, E.; Peñuela, G.A. Photolysis of a Mixture of Anthracene and Benzo[a]Pyrene at Ultra-Trace Levels in Natural Water with Disinfection Purposes. J. Environ. Sci. 2020, 92, 79–94. [Google Scholar] [CrossRef]

- Qiao, M.; Qi, W.; Liu, H.; Qu, J. Oxygenated Polycyclic Aromatic Hydrocarbons in the Surface Water Environment: Occurrence, Ecotoxicity, and Sources. Environ. Int. 2022, 163, 107232. [Google Scholar] [CrossRef]

- Madrid, F.; Florido, M.C.; Rubio-Bellido, M.; Villaverde, J.; Morillo, E. Dissipation of a Mix of Priority PAHs in Soils by Using Availability Enhancers. Effect of Aging and Pollutant Interactions. Sci. Total Environ. 2022, 837, 155744. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Liu, Y.; Shao, M.; Lu, S.; Wang, M.; Yuan, B.; Gong, Z.; He, L.; Zeng, L.; Hu, M.; et al. The Contributions of Biomass Burning to Primary and Secondary Organics: A Case Study in Pearl River Delta (PRD), China. Sci. Total Environ. 2016, 569–570, 548–556. [Google Scholar] [CrossRef]

- Ramdugwar, V.; Fernandes, H.; Gadekar, P. Study of Scavengers for Free Formaldehyde Reduction in Phenolic Resins Used in Polychloroprene Based Contact Adhesives. Int. J. Adhes. Adhes. 2022, 115, 103122. [Google Scholar] [CrossRef]

- Environmental Protection Agency. Carbon Disulfide. 2000. Available online: https://www.epa.gov/sites/default/files/2016-09/documents/carbon-disulfide.pdf (accessed on 8 August 2023).

- Printemps, N.; Le Magueresse-Battistoni, B.; Mhaouty-Kodja, S.; Viguié, C.; Michel, C. How to Differentiate General Toxicity-Related Endocrine Effects from Endocrine Disruption: Systematic Review of Carbon Disulfide Data. Int. J. Mol. Sci. 2022, 23, 3153. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Olsen, M.N.P.; Moni, C.; Dieguez-Alonso, A.; de la Rosa, J.M.; Stenrød, M.; Liu, X.; Mao, L. Comparison of Properties of Biochar Produced from Different Types of Lignocellulosic Biomass by Slow Pyrolysis at 600 °C. Appl. Energy Combust. Sci. 2022, 12, 100090. [Google Scholar] [CrossRef]

- Xiao, Y.; Raheem, A.; Ding, L.; Chen, W.-H.; Chen, X.; Wang, F.; Lin, S.-L. Pretreatment, Modification and Applications of Sewage Sludge-Derived Biochar for Resource Recovery—A Review. Chemosphere 2022, 287, 131969. [Google Scholar] [CrossRef]

- Spanu, D.; Binda, G.; Dossi, C.; Monticelli, D. Biochar as an Alternative Sustainable Platform for Sensing Applications: A Review. Microchem. J. 2020, 159, 105506. [Google Scholar] [CrossRef]

- Mandal, A.; Kumar, A.; Singh, N. Sorption Mechanisms of Pesticides Removal from Effluent Matrix Using Biochar: Conclusions from Molecular Modelling Studies Validated by Single-, Binary and Ternary Solute Experiments. J. Environ. Manag. 2021, 295, 113104. [Google Scholar] [CrossRef]

- Olmez, G.M.; Dilek, F.B.; Karanfil, T.; Yetis, U. The Environmental Impacts of Iron and Steel Industry: A Life Cycle Assessment Study. J. Clean. Prod. 2016, 130, 195–201. [Google Scholar] [CrossRef]

- Queiroz, H.M.; Ruiz, F.; Deng, Y.; de Souza, V.S., Jr.; Ferreira, A.D.; Otero, X.L.; de Lima Camêlo, D.; Bernardino, A.F.; Ferreira, T.O. Mine Tailings in a Redox-Active Environment: Iron Geochemistry and Potential Environmental Consequences. Sci. Total Environ. 2022, 807, 151050. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gallego-Ramírez, C.; Chica, E.; Rubio-Clemente, A. Life Cycle Assessment of Raw and Fe-Modified Biochars: Contributing to Circular Economy. Materials 2023, 16, 6059. https://doi.org/10.3390/ma16176059

Gallego-Ramírez C, Chica E, Rubio-Clemente A. Life Cycle Assessment of Raw and Fe-Modified Biochars: Contributing to Circular Economy. Materials. 2023; 16(17):6059. https://doi.org/10.3390/ma16176059

Chicago/Turabian StyleGallego-Ramírez, Carolina, Edwin Chica, and Ainhoa Rubio-Clemente. 2023. "Life Cycle Assessment of Raw and Fe-Modified Biochars: Contributing to Circular Economy" Materials 16, no. 17: 6059. https://doi.org/10.3390/ma16176059