Effects of Recycled Polymer on Melt Viscosity and Crystallization Temperature of Polyester Elastomer Blends

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacturing Process of Specimens

2.3. Evaluation Methods

3. Results and Discussion

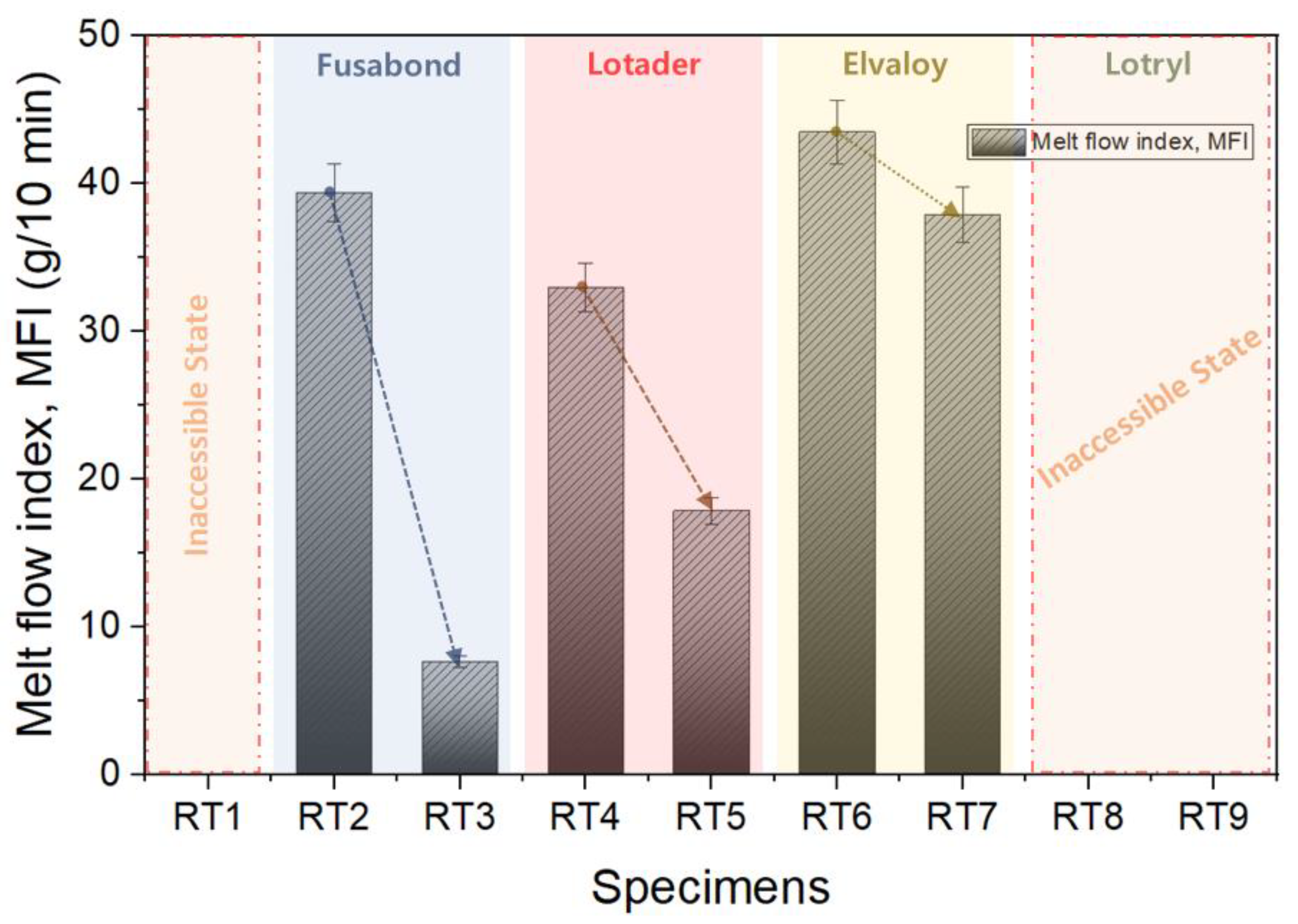

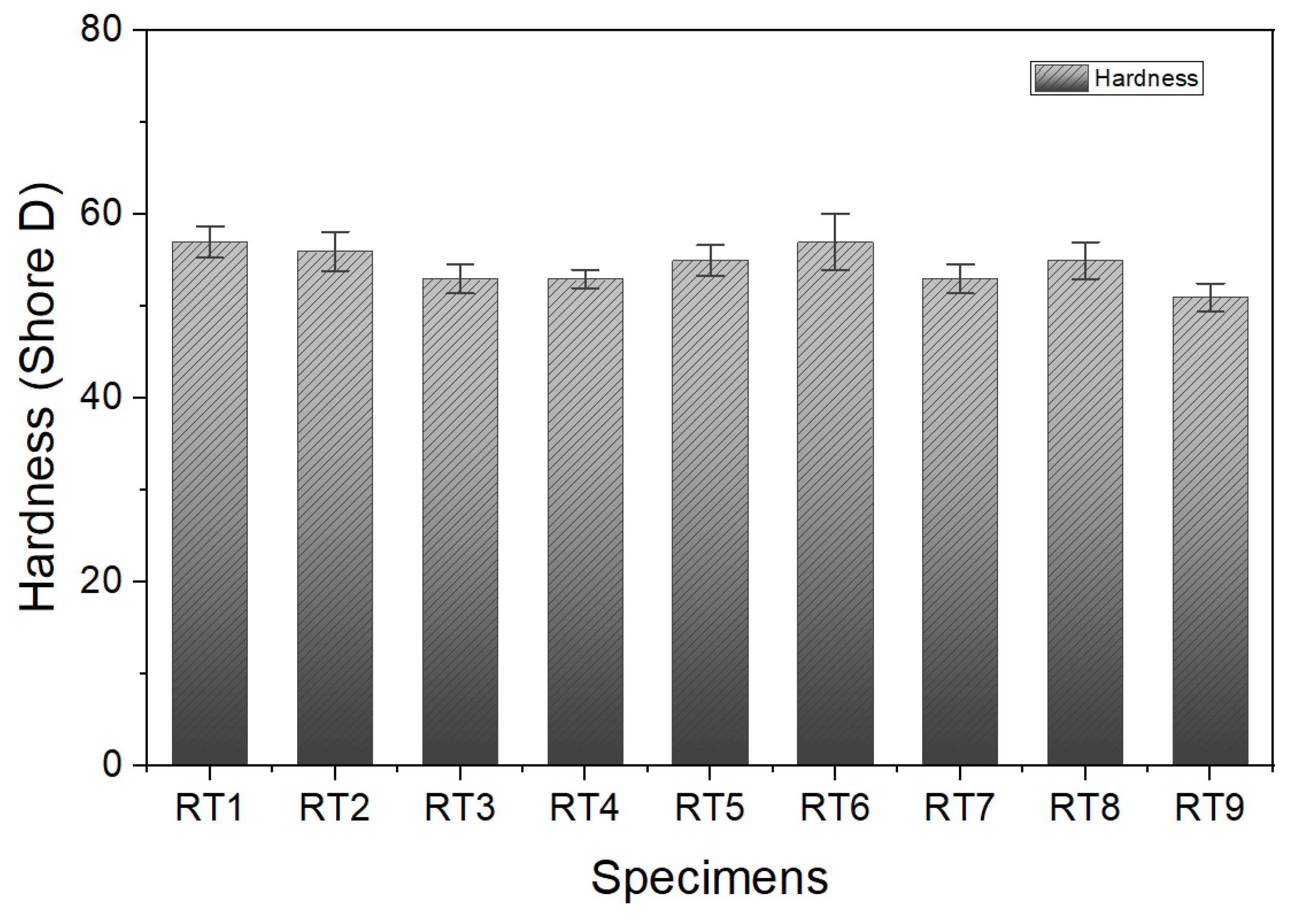

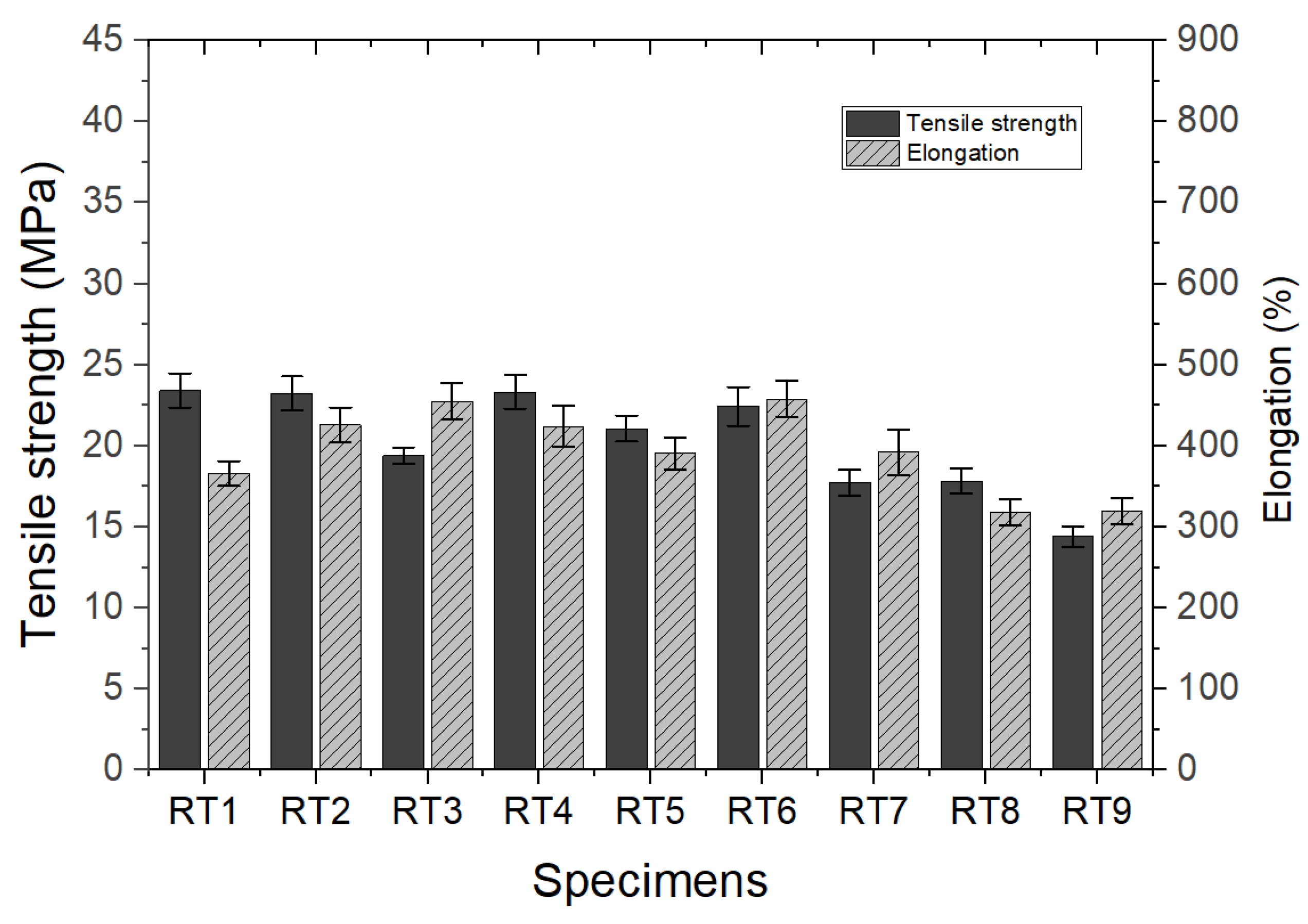

3.1. Measurement of Basic Properties for Fiber Spinning

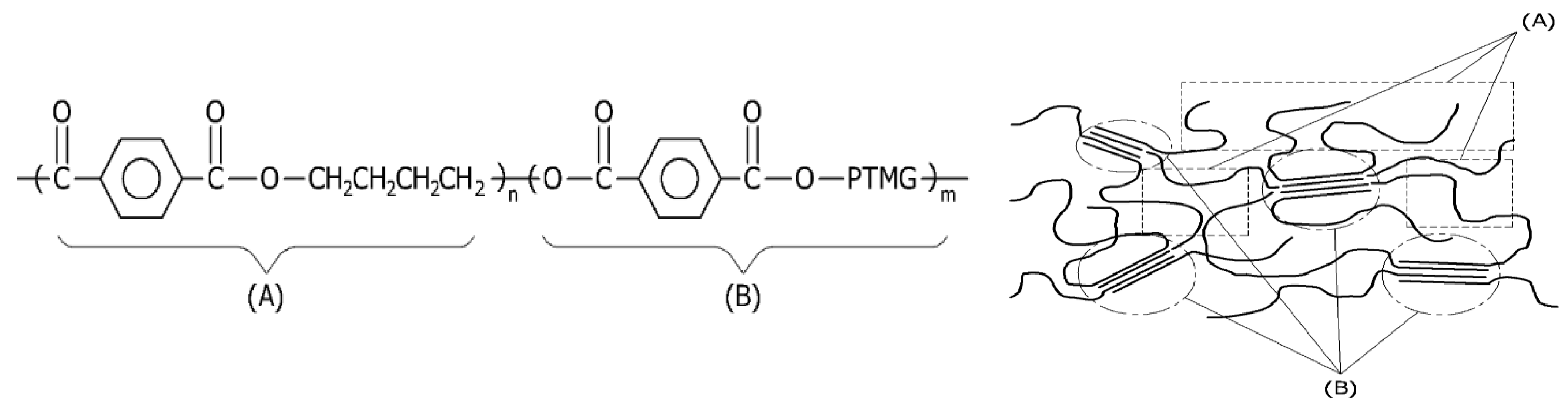

3.1.1. Physical Characterization of TPEE Compositions

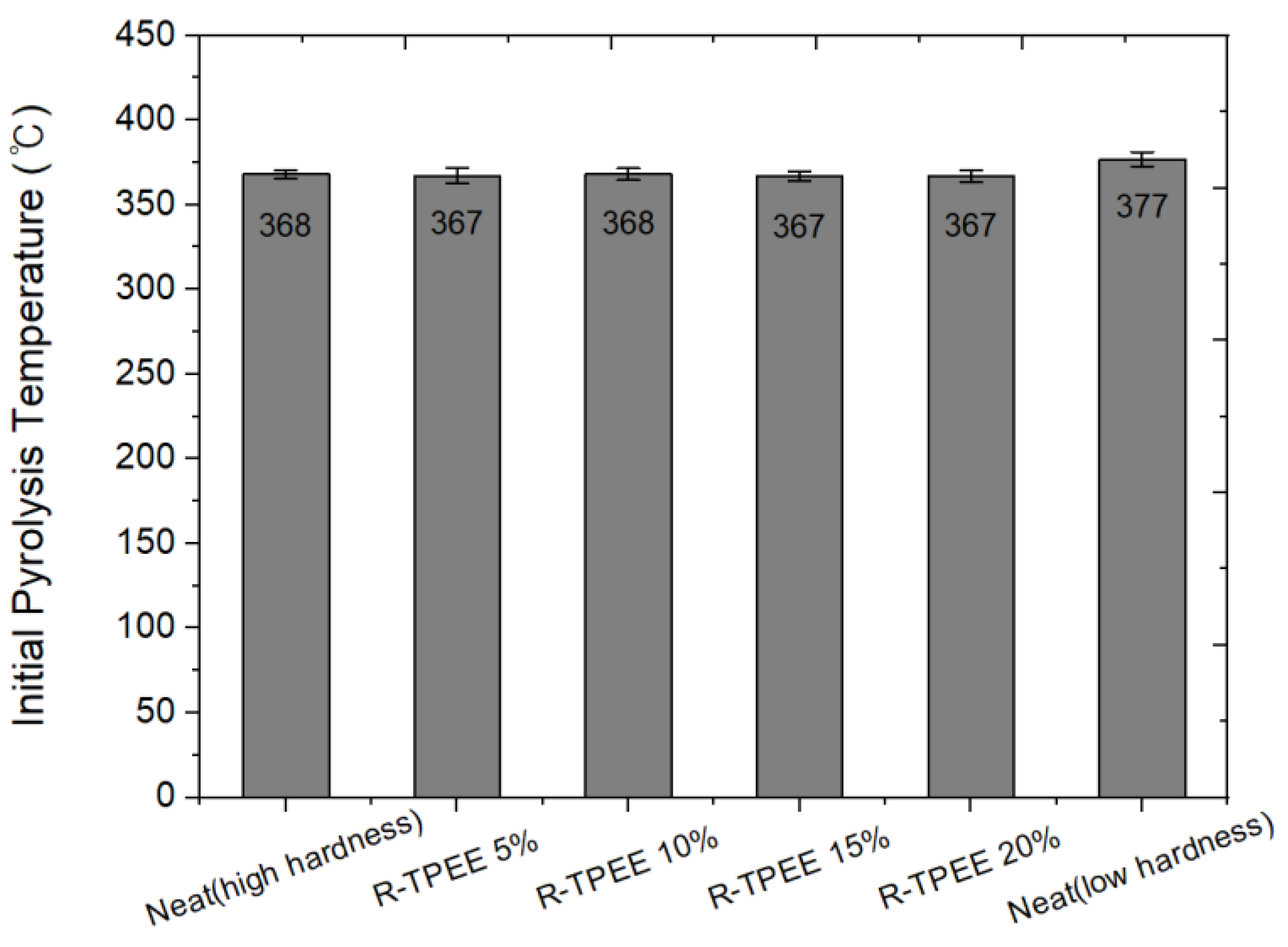

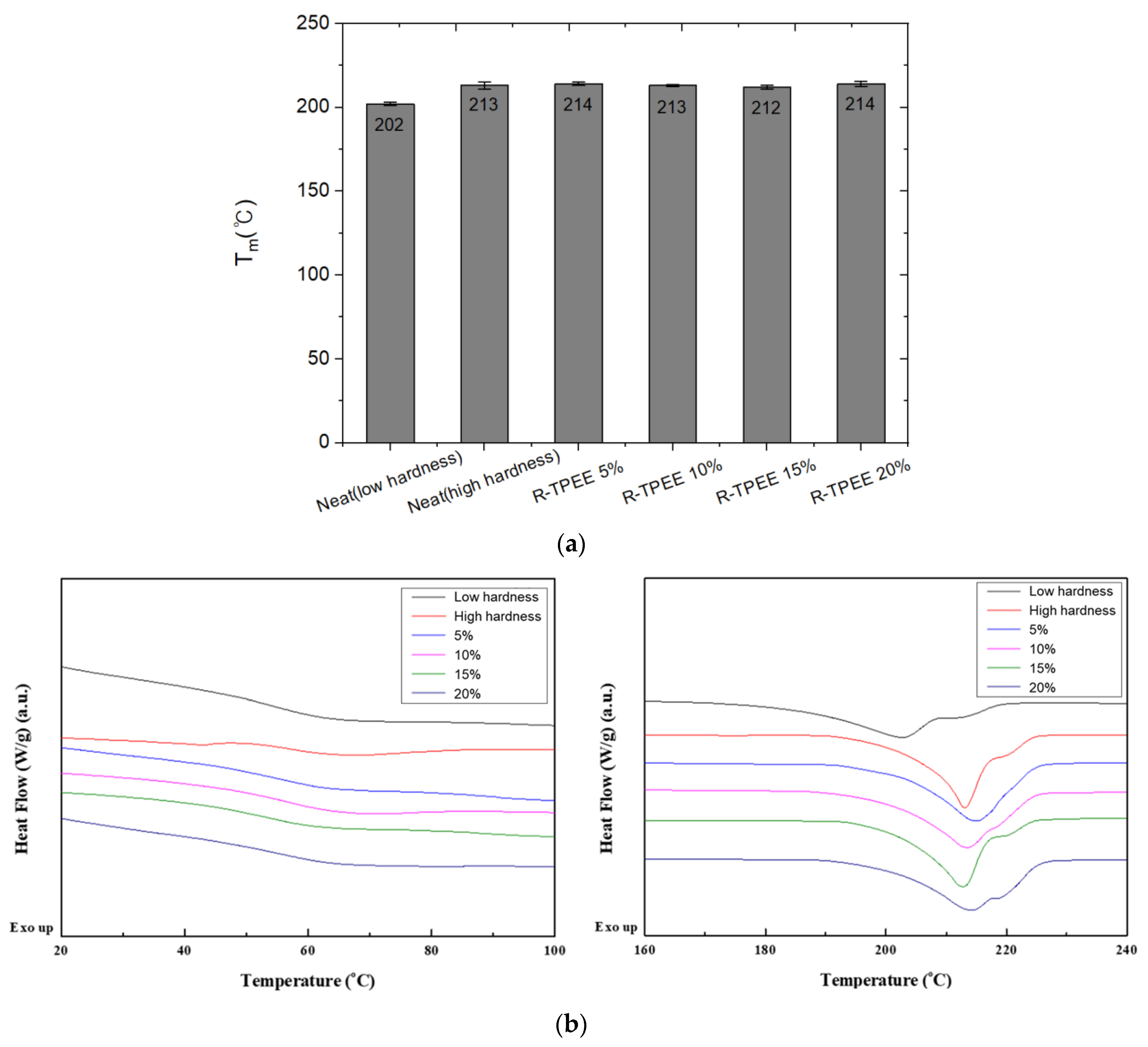

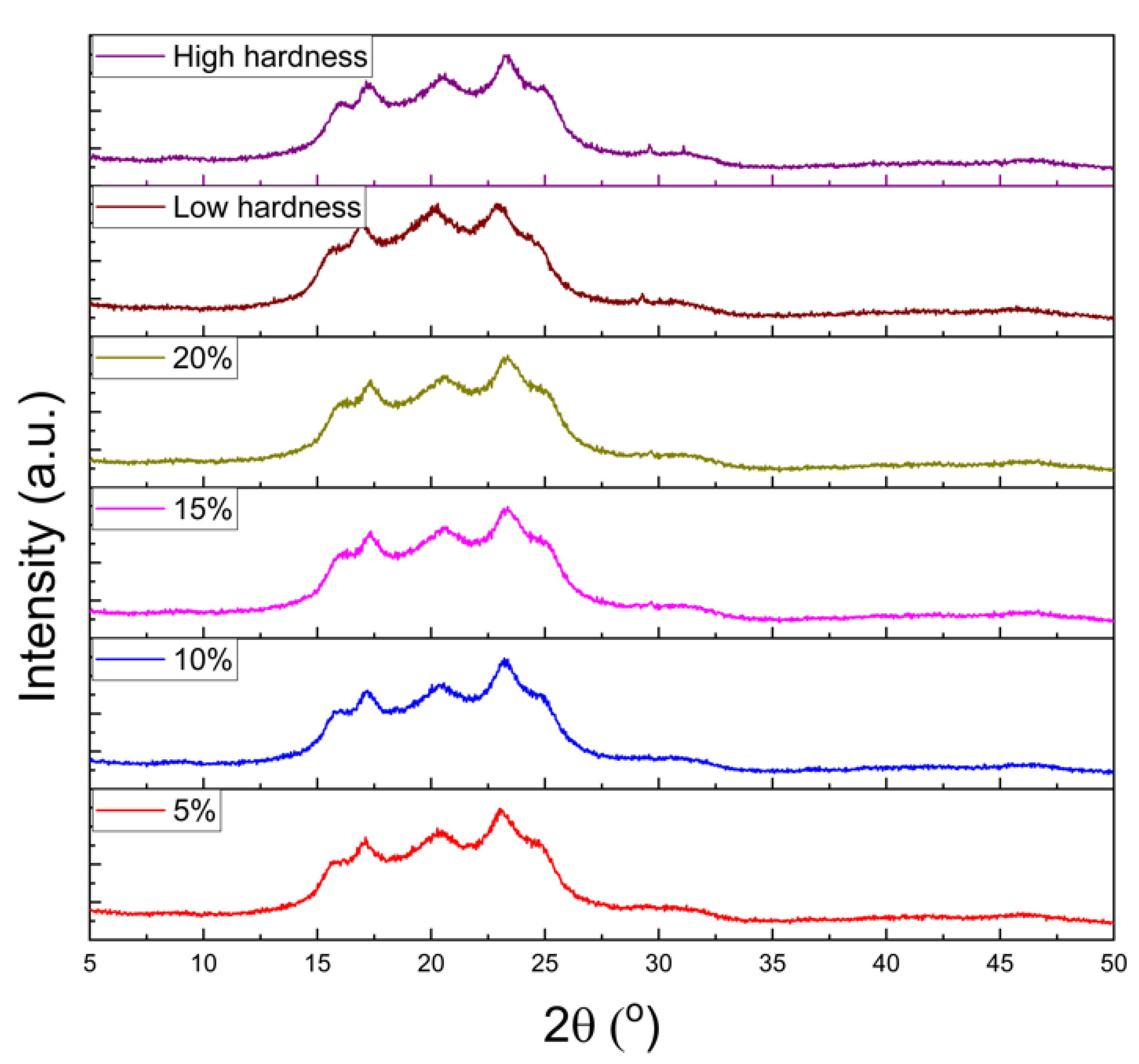

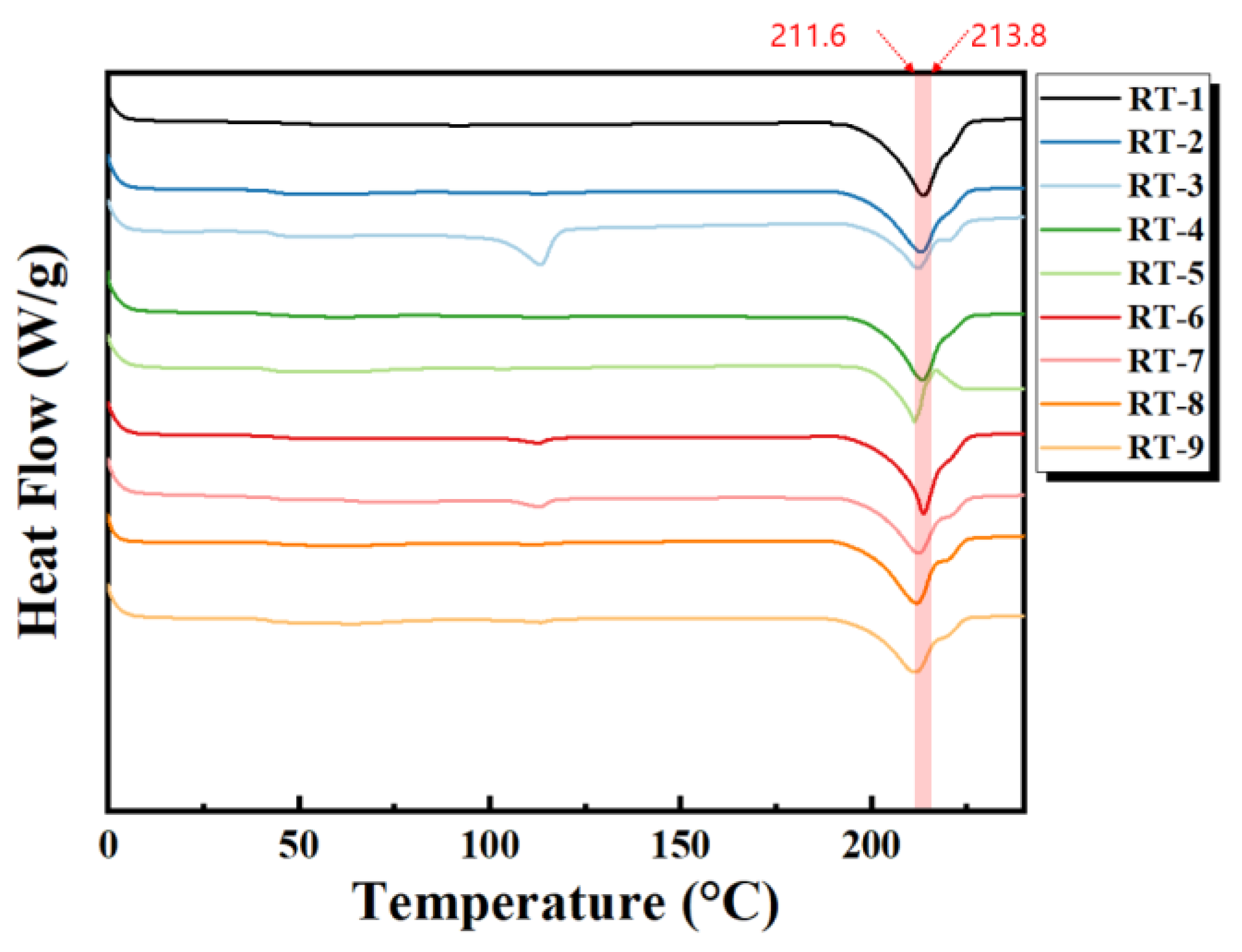

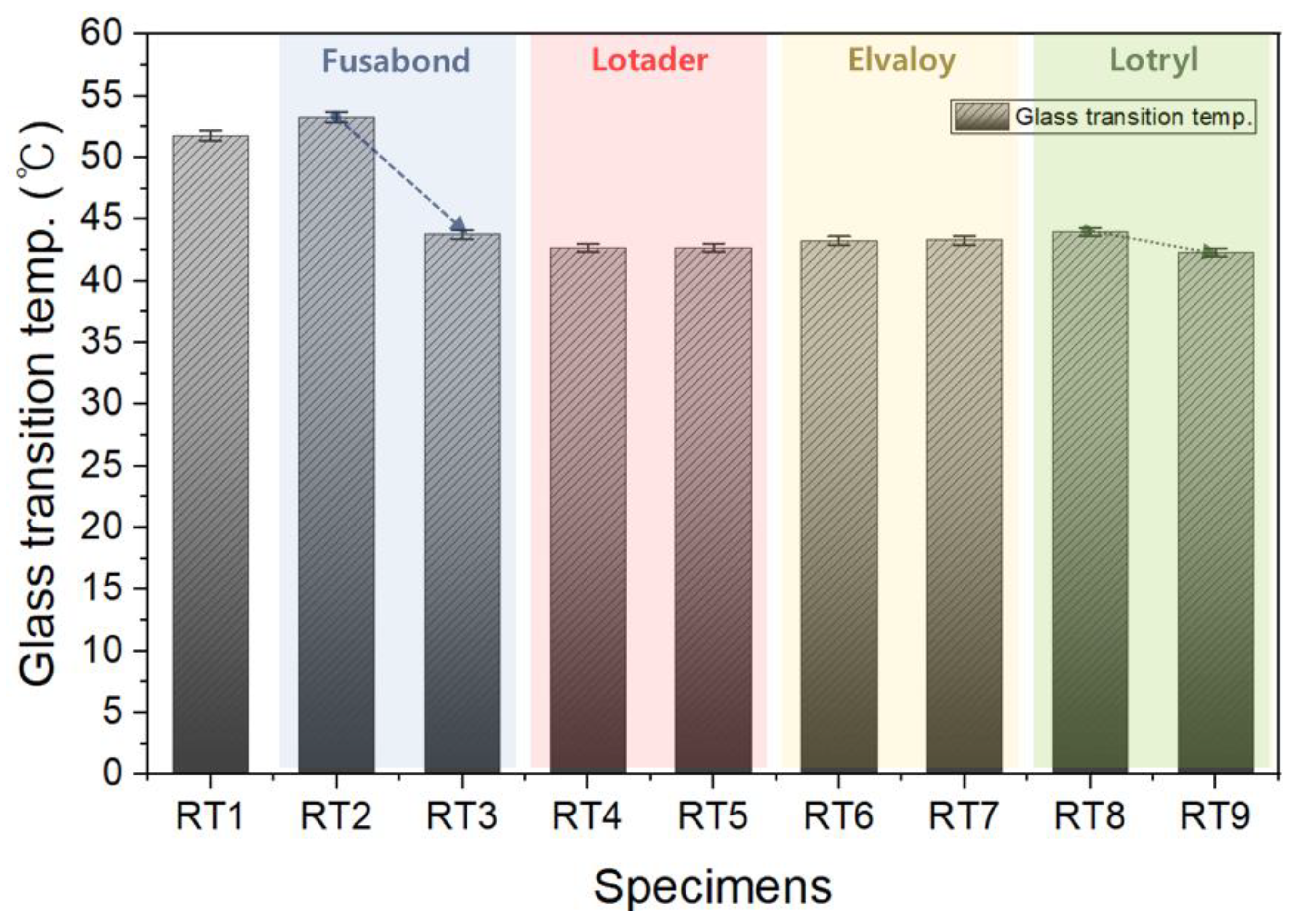

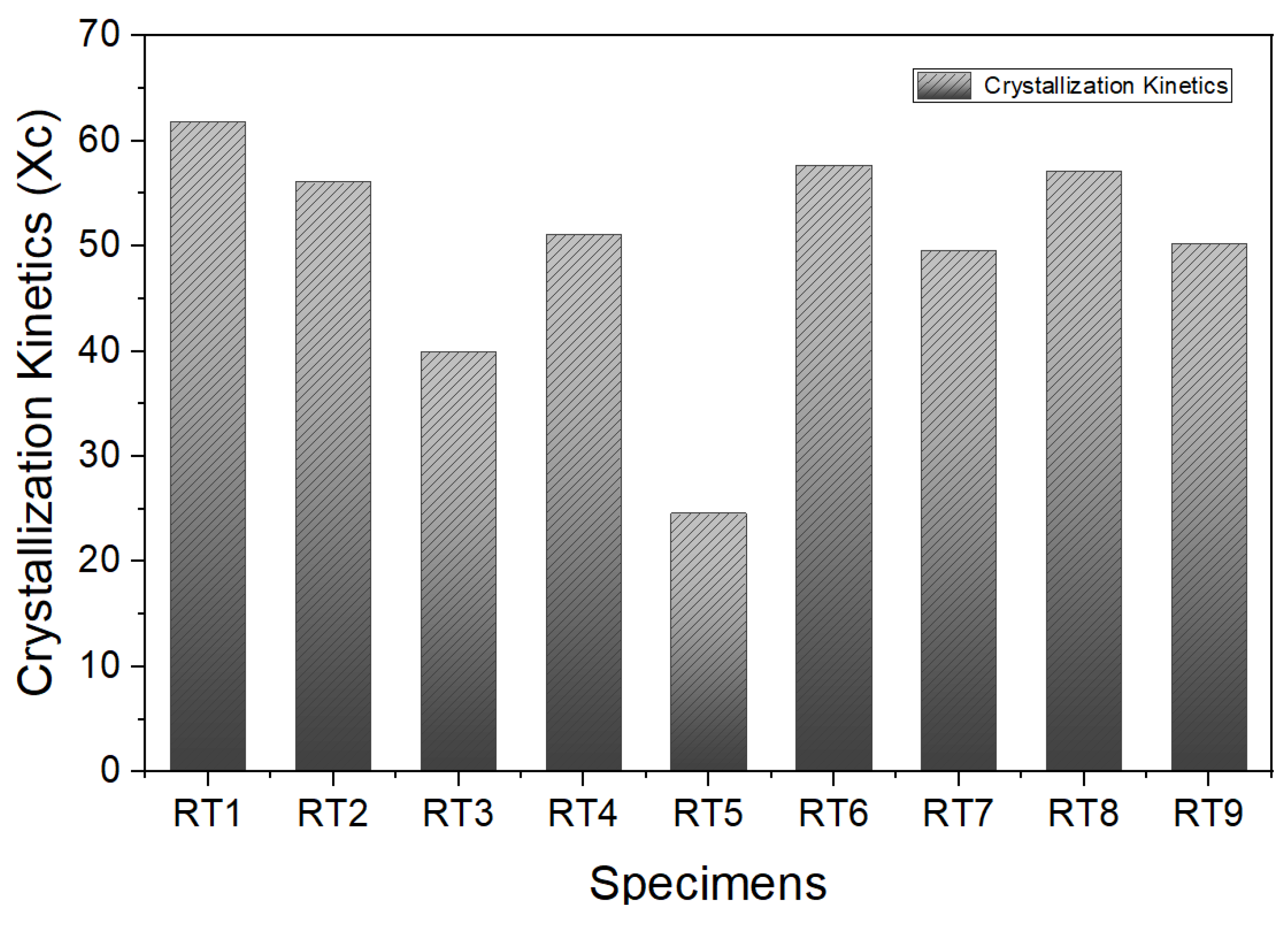

3.1.2. Thermal Properties of TPEE Compositions

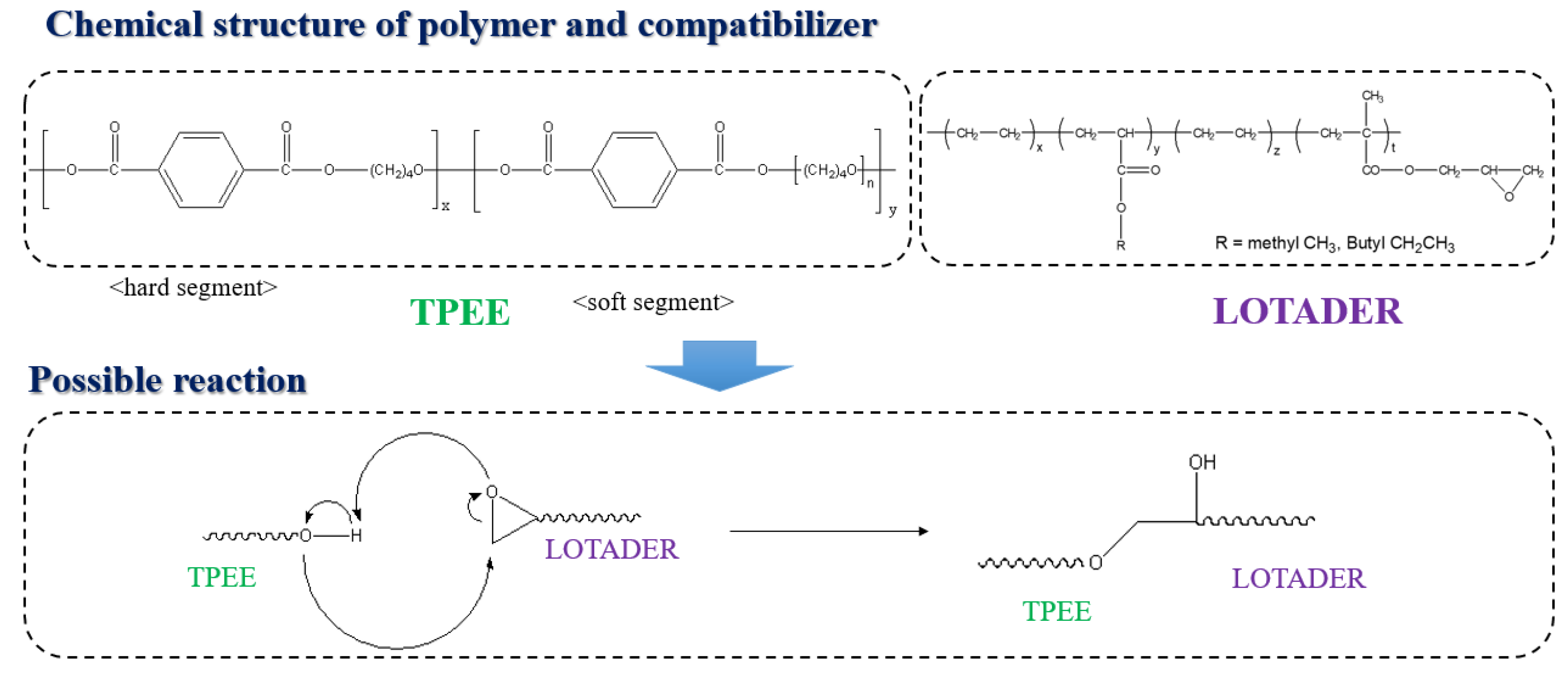

3.2. Characteristic Evaluation by Addition of Compatibilizer

4. Conclusions

- It was confirmed that the addition of recycled resin to the high-hardness resin resulted in a reduction of hardness compared to the raw material. Furthermore, the reduction in hardness remained negligible even when the amount of recycled resin was increased from 5% to 20%.

- The virgin TPEE resin did not significantly increase the melt viscosity index even as the temperature was raised from 220 °C to 240 °C. In contrast, the melt viscosity index increased significantly with the increase in temperature for the specimens containing 20% R-TPEE. This phenomenon is attributed to the increase in the MFI value due to the decrease in the molecular weight of the added R-TPEE, which is believed to potentially lead to poor workability due to excessive flowability during product molding.

- During the MFI evaluation, it was determined that the Elvaloy series compatibilizer showed the most suitability for fiber spinning, and Fusabond and Lotader series compatibilizers can also be used for fiber spinning if the addition amount is controlled.

- The glass transition temperature of the Lotader and Elvaloy series compatibilizers was insufficient even with the change in the amount. Considering their thermal properties, these two series of compatibilizers are suitable for radiation. As a result of the evaluation of the overall characteristics, it is concluded that the Elvaloy-based compatibilizer is optimal for fiber spinning a TPEE composition containing 20% of R-TPEE.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chaiwutthinan, P.; Phutfak, N.; Larpkasemsuk, A. Effects of Thermoplastic Poly(Ether-Ester) Elastomer and Bentonite Nanoclay on Properties of Poly(Lactic Acid). J. Appl. Polym. Sci. 2021, 138, 8–11. [Google Scholar] [CrossRef]

- Ranganathan, P.; Chen, C.-W.; Chou, Y.-L.; Rwei, S.-P.; Ramaraj, S.K. Biomass Chemical Upcycling of Waste RPET for the Fabrication of Formamide-Free TPEE Microcellular Foams via ScCO2 Foaming. J. CO2 Util. 2022, 65, 102199. [Google Scholar] [CrossRef]

- Gloaguen, J.M.; Heim, P.; Gaillard, P.; Lefebvre, J.M. Plasticity of Rubber-Toughened Poly(Methyl Methacrylate): Effect of Rubber Particle Size. Polymer 1992, 33, 4741–4746. [Google Scholar] [CrossRef]

- Dompas, D.; Groeninckx, G. Toughening Behaviour of Rubber-Modified Thermoplastic Polymers Involving Very Small Rubber Particles: 1. A Criterion for Internal Rubber Cavitation. Polymer 1994, 35, 4743–4749. [Google Scholar] [CrossRef]

- Martin, P.; Devaux, J.; Legras, R.; van Gurp, M.; van Duin, M. Competitive Reactions during Compatibilization of Blends of Polybutyleneterephthalate with Epoxide-Containing Rubber. Polymer 2001, 42, 2463–2478. [Google Scholar] [CrossRef]

- Kunimune, N.; Yamada, K.; Leong, Y.W.; Thumsorn, S.; Hamada, H. Influence of the Reactive Processing of Recycled Poly(Ethylene Terephthalate)/Poly(Ethylene-Co-Glycidyl Methacrylate) Blends. J. Appl. Polym. Sci. 2011, 120, 50–55. [Google Scholar] [CrossRef]

- Maris, J.; Bourdon, S.; Brossard, J.-M.; Cauret, L.; Fontaine, L.; Montembault, V. Mechanical Recycling: Compatibilization of Mixed Thermoplastic Wastes. Polym. Degrad. Stab. 2018, 147, 245–266. [Google Scholar] [CrossRef]

- Archibong, F.N.; Sanusi, O.M.; Médéric, P.; Aït Hocine, N. An Overview on the Recycling of Waste Ground Tyre Rubbers in Thermoplastic Matrices: Effect of Added Fillers. Resour. Conserv. Recycl. 2021, 175, 105894. [Google Scholar] [CrossRef]

- Panigrahi, H.; Kumar, D. Jamming Carbonaceous Nanofiller in the Continuous Phase and at the Blend Interface for Phenomenal Improvement in the Overall Physico-Mechanical Properties of Compatibilized Thermoplastic Elastomer. Polymer 2022, 257, 125261. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Du, F.; Wang, X. Thermoplastic Elastomer Based on High Impact Polystyrene/Ethylene-Vinyl Acetate Copolymer/Waste Ground Rubber Tire Powder Composites Compatibilized by Styrene-Butadiene-Styrene Block Copolymer. Mater. Chem. Phys. 2012, 136, 1124–1129. [Google Scholar] [CrossRef]

- Lin, T.A.; Lin, J.-H.; Bao, L. Polypropylene/Thermoplastic Polyurethane Blends: Mechanical Characterizations, Recyclability and Sustainable Development of Thermoplastic Materials. J. Mater. Res. Technol. 2020, 9, 5304–5312. [Google Scholar] [CrossRef]

- Loyens, W.; Groeninckx, G. Ultimate Mechanical Properties of Rubber Toughened Semicrystalline PET at Room Temperature. Polymer 2002, 43, 5679–5691. [Google Scholar] [CrossRef]

- del Mar Castro López, M.; Ares Pernas, A.I.; Abad López, M.J.; Latorre, A.L.; López Vilariño, J.M.; González Rodríguez, M.V. Assessing Changes on Poly(Ethylene Terephthalate) Properties after Recycling: Mechanical Recycling in Laboratory versus Postconsumer Recycled Material. Mater. Chem. Phys. 2014, 147, 884–894. [Google Scholar] [CrossRef]

- Yasar, M.; Celebi, H.; Bayram, G. Role of Formulation Additives on the Properties of Thermoplastic Polyether Ester Elastomer-Based and Carbon Fabric-Reinforced Multilayer Composites. J. Thermoplast. Compos. Mater. 2022, 36, 2757–2776. [Google Scholar] [CrossRef]

- Karaagac, E.; Koch, T.; Archodoulaki, V.-M. The Effect of PP Contamination in Recycled High-Density Polyethylene (RPE-HD) from Post-Consumer Bottle Waste and Their Compatibilization with Olefin Block Copolymer (OBC). Waste Manag. 2021, 119, 285–294. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.H.; Kim, D.-K.; Hong, S.-K.; Han, J.A.; Han, S.W.; Lee, D.H.; Yu, S. Mechanical and Electrical Properties of Impact Polypropylene Ternary Blends for High-Voltage Power Cable Insulation Applications. Compos. Res. 2022, 35, 127–133. [Google Scholar]

- Li, Y.; Xue, B.; Wang, S.; Sun, J.; Li, H.; Gu, X.; Wang, H.; Zhang, S. Photoaging and Fire Performance of Polypropylene Containing Melamine Phosphate. ACS Appl. Polym. Mater. 2020, 2, 4455–4463. [Google Scholar] [CrossRef]

- Papke, N.; Karger-Kocsis, J. Thermoplastic Elastomers Based on Compatibilized Poly(Ethylene Terephthalate) Blends: Effect of Rubber Type and Dynamic Curing. Polymer 2001, 42, 1109–1120. [Google Scholar] [CrossRef]

- Martikka, O.; Kärki, T. Promoting Recycling of Mixed Waste Polymers in Wood-Polymer Composites Using Compatibilizers. Recycling 2019, 4, 6. [Google Scholar] [CrossRef]

- Dike, A.S.; Yilmazer, U. Mechanical, Thermal and Rheological Characterization of Polystyrene/Organoclay Nanocomposites Containing Aliphatic Elastomer Modifiers. Mater. Res. Express 2020, 7, 015055. [Google Scholar] [CrossRef]

- Chung, Y.Y.; Choi, S.-S. Influence of Maleic Anhydride Grafted onto Polyethylene on Pyrolysis Behaviors. Elastomers Compos. 2016, 51, 233–239. [Google Scholar] [CrossRef]

- Monti, M.; Scrivani, M.T.; Kociolek, I.; Larsen, Å.G.; Olafsen, K.; Lambertini, V. Enhanced Impact Strength of Recycled PET/Glass Fiber Composites. Polymers 2021, 13, 1471. [Google Scholar] [CrossRef]

- Malik, N.; Kumar, P.; Shrivastava, S.; Ghosh, S.B. An Overview on PET Waste Recycling for Application in Packaging. Int. J. Plast. Technol. 2017, 21, 1–24. [Google Scholar] [CrossRef]

- De M. Giraldi, A.L.F.; Bartoli, J.R.; Velasco, J.I.; Mei, L.H.I. Glass Fibre Recycled Poly(Ethylene Terephthalate) Composites: Mechanical and Thermal Properties. Polym. Test. 2005, 24, 507–512. [Google Scholar] [CrossRef]

- Karthik, G.; Balaji, K.V.; Venkateshwara, R.; Rahul, B. Eco-Friendly Recycled PET (Polyethylene Terephthalate) Material for Automotive Canopy Strip Application. In Proceedings of the SAE 2015 World Congress & Exhibition, Detroit, MI, USA, 21–23 April 2015; SAE International: Warrendale, PA, USA, 2015. [Google Scholar]

- de Moura Giraldi, A.L.F.; de Jesus, R.C.; Mei, L.H.I. The Influence of Extrusion Variables on the Interfacial Adhesion and Mechanical Properties of Recycled PET Composites. J. Mater. Process. Technol. 2005, 162–163, 90–95. [Google Scholar] [CrossRef]

- Mondadori, N.M.L.; Nunes, R.C.R.; Canto, L.B.; Zattera, A.J. Composites of Recycled PET Reinforced with Short Glass Fiber. J. Thermoplast. Compos. Mater. 2012, 25, 747–764. [Google Scholar] [CrossRef]

- Alqaflah, A.M.; Alotaibi, M.L.; Aldossery, J.N.; Alghamdi, M.S.; Alsewailem, F.D. Preparation and Characterization of Glass Fiber–Reinforced Polyethylene Terephthalate/Linear Low Density Polyethylene (GF-PET/LLDPE) Composites. Polym. Adv. Technol. 2018, 29, 52–60. [Google Scholar] [CrossRef]

- Huang, J.; Wang, J.; Qiu, Y.; Wu, D. Mechanical Properties of Thermoplastic Polyester Elastomer Controlled by Blending with Poly(Butylene Terephthalate). Polym. Test. 2016, 55, 152–159. [Google Scholar] [CrossRef]

- Baltá Calleja, F.J.; Giri, L.; Ezquerra, T.A.; Fakirov, S.; Roslaniec, Z. Microhardness of Condensation Polymers and Copolymers. 1. Coreactive Blends of Polyethylene Terephthalate and Polycarbonates. J. Macromol. Sci. Part B 1997, 36, 655–665. [Google Scholar] [CrossRef]

- Sreekanth, M.S.; Joseph, S.; Mhaske, S.T.; Mahanwar, P.A.; Bambole, V.A. Effects of Mica and Fly Ash Concentration on the Properties of Polyester Thermoplastic Elastomer Composites. J. Thermoplast. Compos. Mater. 2011, 24, 317–331. [Google Scholar] [CrossRef]

- Kadam, P.; Kute, R.; Mhaske, S. Effect of Nano-Alumina Concentration on the Properties of Poly(Vinyl Chloride)/Thermoplastic Polyester Elastomer Blend System. Iran. Polym. J. 2013, 22, 549–560. [Google Scholar] [CrossRef]

- ASTM D 638-14; Standard Test Method for Tensile Properties of Plastics. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D1238-10; Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D2240-15; Standard Test Method for Rubber Property—Durometer Hardness. ASTM International: West Conshohocken, PA, USA, 2015.

- Lee, Y.S.; Yoon, K.H. Determination of Molecular Weight and Molecular Weight Distribution of Polypropylene Using Rheological Properties. Polymer 2014, 38, 735–743. [Google Scholar] [CrossRef]

- Lee, T.Y. Modification of Thermoplastic Polyether-Ester Elastomer (TPEE) for Automotive Applications. 2010. Available online: http://www.riss.kr/search/detail/DetailView.do?p_mat_type=be54d9b8bc7cdb09&control_no=4fe860d55c420903ffe0bdc3ef48d419&outLink=K (accessed on 30 August 2023).

- Lee, Y.; Jeong, J.; Park, J. A Trend of R & D in Enviromental Thermoplastic Elastomer. Elastomers Compos. 2010, 45, 245–249. [Google Scholar]

| Specimen Numbers | RT1 | RT2 | RT3 | RT4 | RT5 | RT6 | RT7 | RT8 | RT9 | |

|---|---|---|---|---|---|---|---|---|---|---|

| Base polymer | TPEE | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 | 100 |

| R-TPEE | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | |

| Initiator | DCP (Dicumyl peroxide) | - | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 | 0.05 |

| Compatilbilizer | Fusabond N525 | - | 10 | 20 | - | - | - | - | - | - |

| Lotader AX8900 | - | - | - | 10 | 20 | - | - | - | - | |

| Elvaloy 3427AC | - | - | - | - | - | 10 | 20 | - | - | |

| Lotryl 30BA02 | - | - | - | - | - | - | - | 10 | 20 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-E.; Lee, J.-W.; Ko, J.-W.; Jo, K.-I.; Park, H.-J.; Chung, I. Effects of Recycled Polymer on Melt Viscosity and Crystallization Temperature of Polyester Elastomer Blends. Materials 2023, 16, 6067. https://doi.org/10.3390/ma16176067

Lee J-E, Lee J-W, Ko J-W, Jo K-I, Park H-J, Chung I. Effects of Recycled Polymer on Melt Viscosity and Crystallization Temperature of Polyester Elastomer Blends. Materials. 2023; 16(17):6067. https://doi.org/10.3390/ma16176067

Chicago/Turabian StyleLee, Ji-Eun, Jin-Woo Lee, Jae-Wang Ko, Kyung-Il Jo, Hyun-Ju Park, and Ildoo Chung. 2023. "Effects of Recycled Polymer on Melt Viscosity and Crystallization Temperature of Polyester Elastomer Blends" Materials 16, no. 17: 6067. https://doi.org/10.3390/ma16176067

APA StyleLee, J.-E., Lee, J.-W., Ko, J.-W., Jo, K.-I., Park, H.-J., & Chung, I. (2023). Effects of Recycled Polymer on Melt Viscosity and Crystallization Temperature of Polyester Elastomer Blends. Materials, 16(17), 6067. https://doi.org/10.3390/ma16176067