The Effects of Compressive Residual Stress on Properties of Kyanite-Coated Zirconia Toughened Alumina Ceramics

Abstract

:1. Introduction

2. Experiments

2.1. Materials

2.2. Characterization

3. Results and Discussion

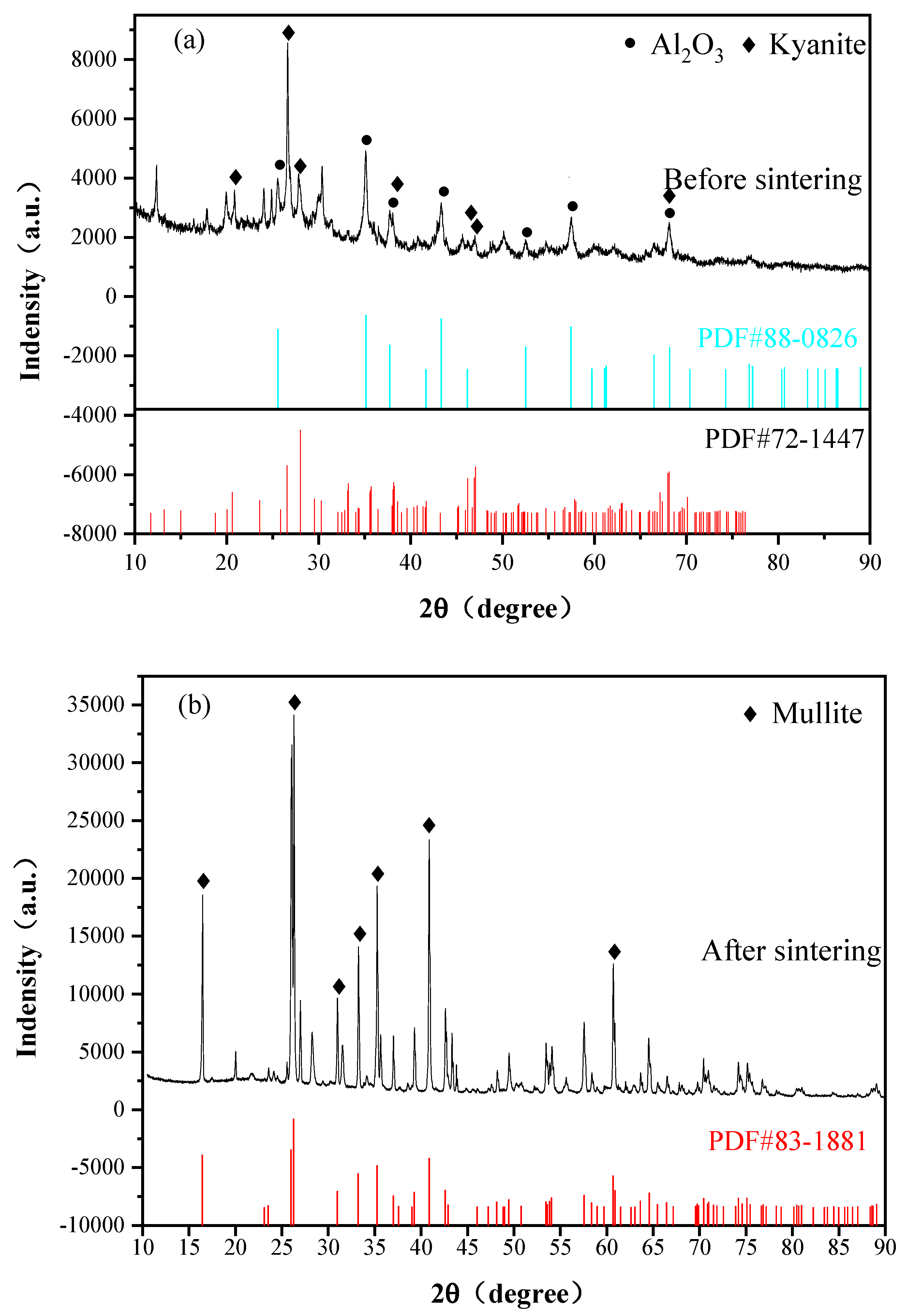

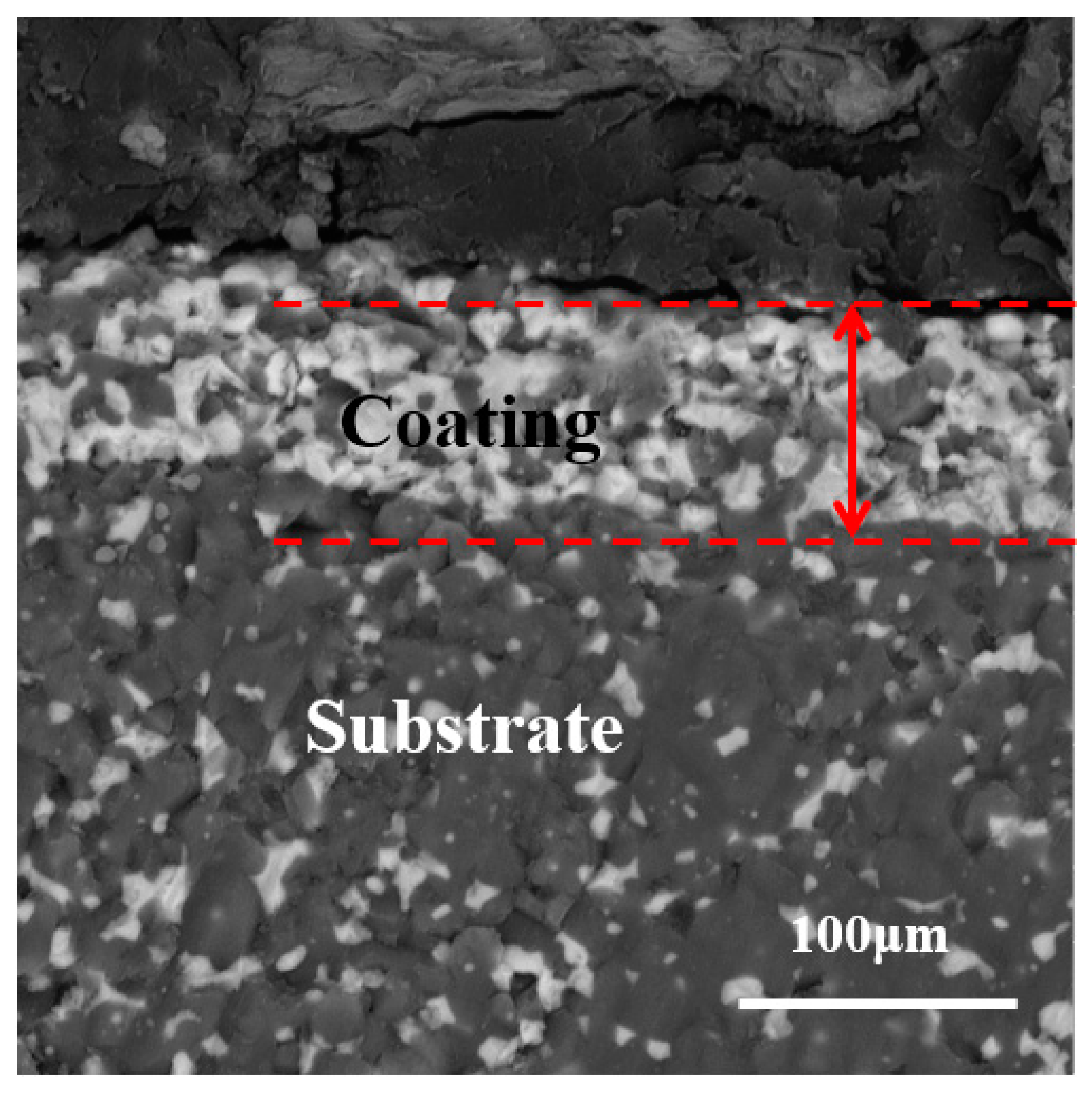

3.1. Microstructure and X-ray Diffraction

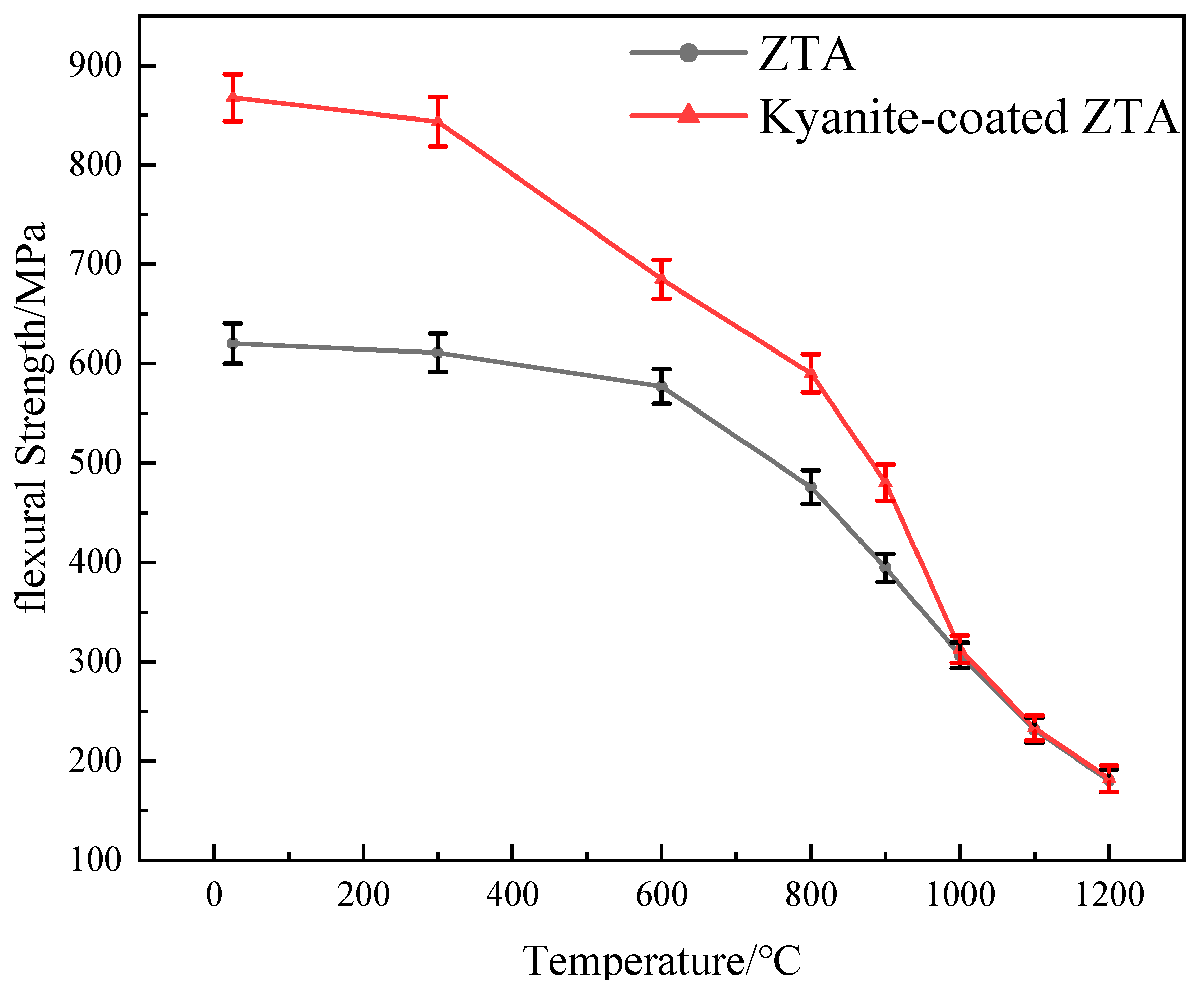

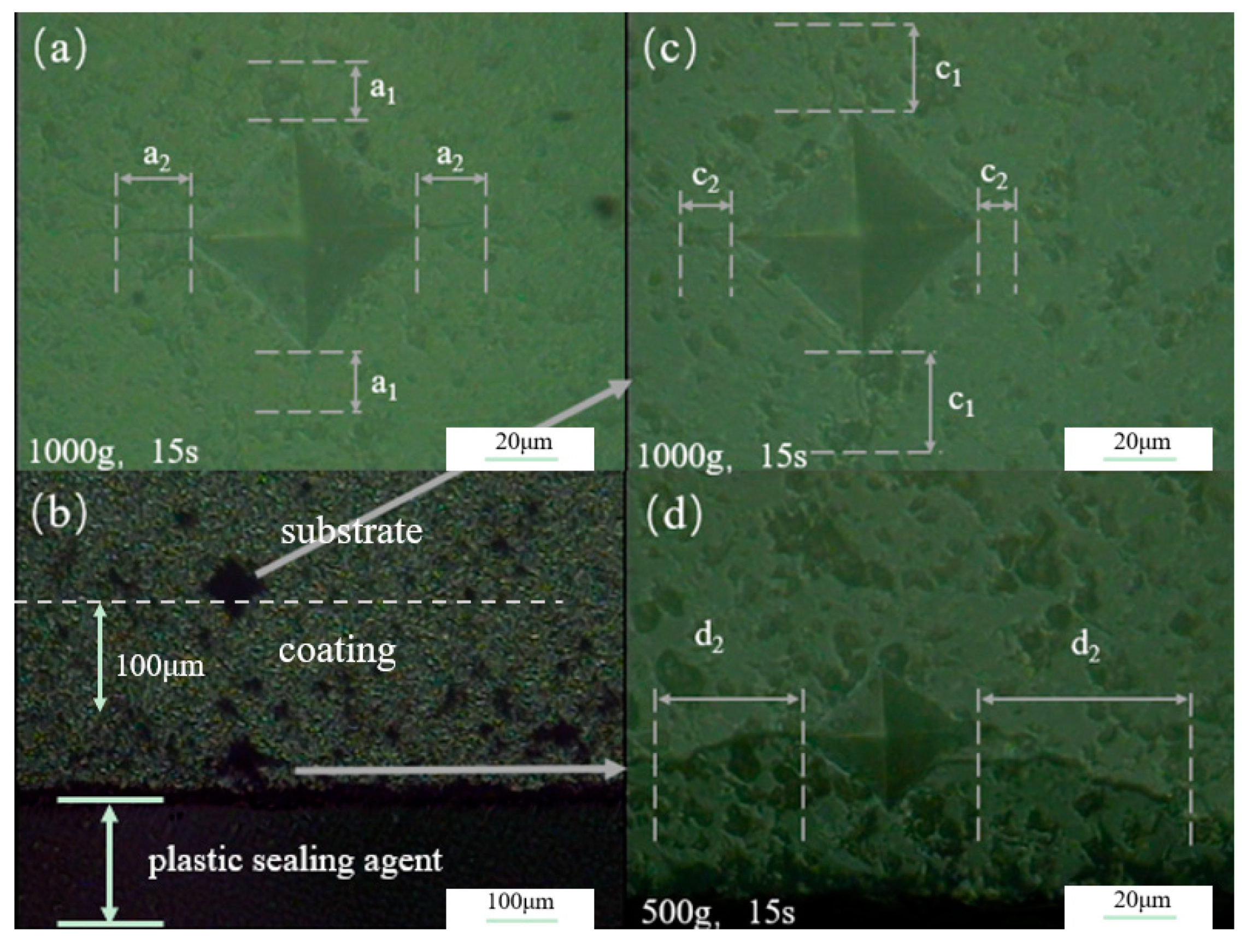

3.2. Mechanical Properties

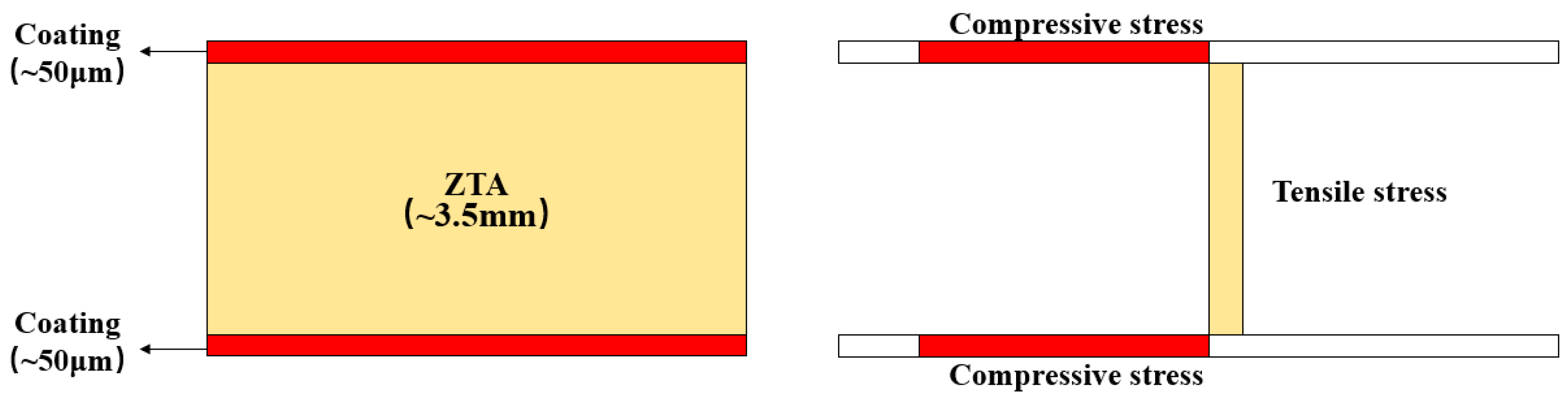

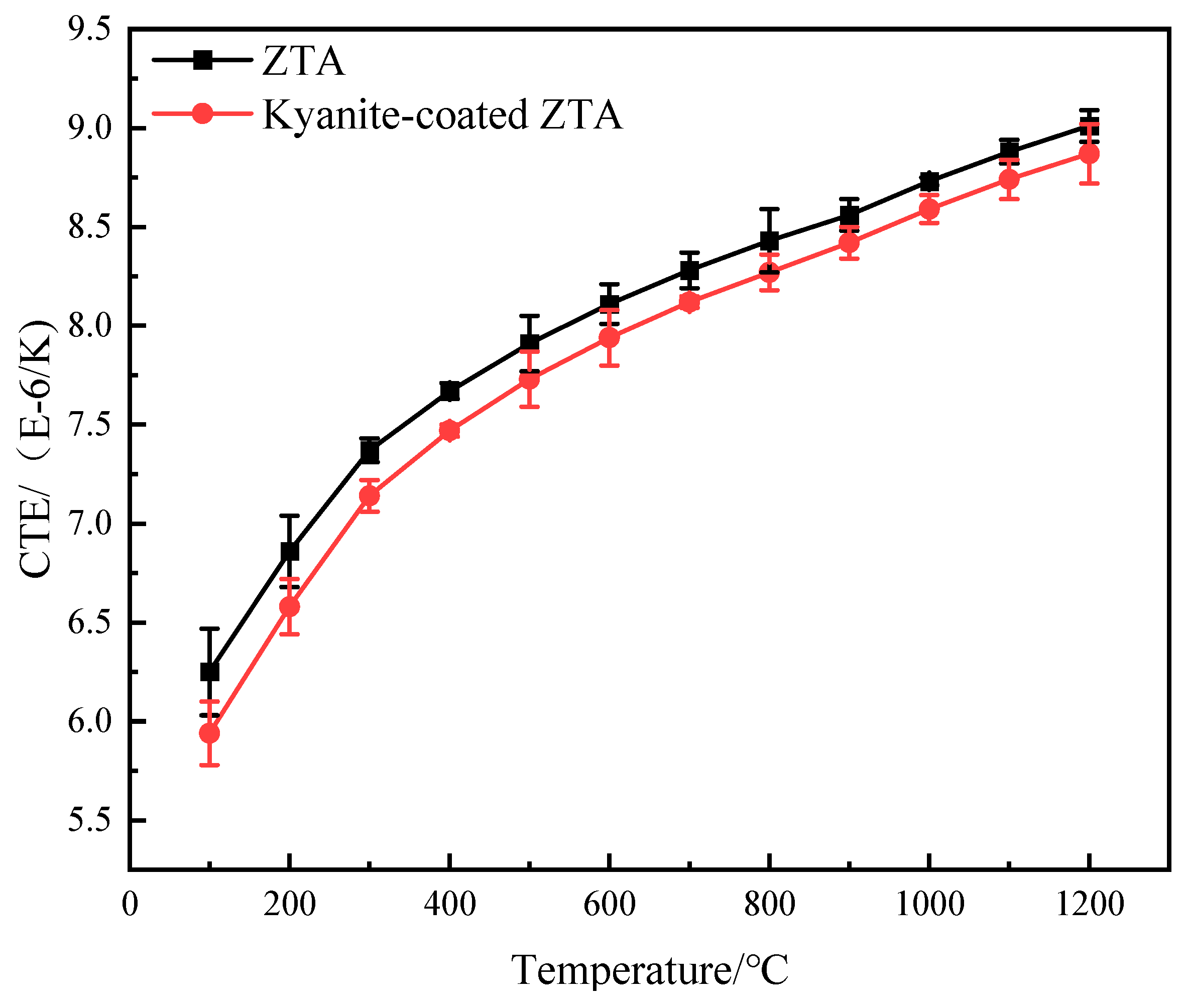

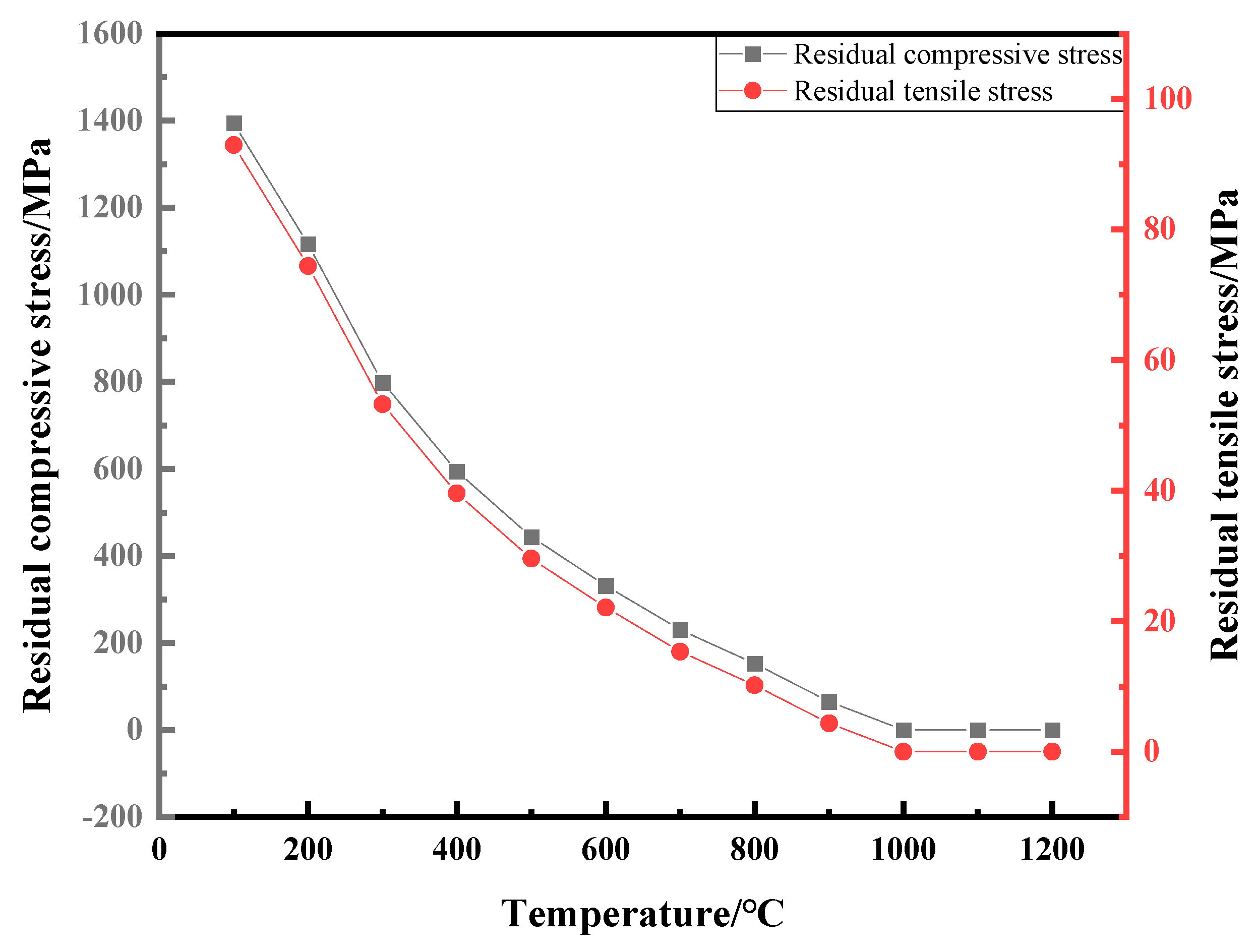

3.3. Analysis of Residual Compressive Stress

| Ef/GPa | Es/GPa | Ec/GPa | R | × 106/K−1 | αc × 106/K−1 | αs × 106/K−1 | ΔT/°C | σc/MPa | σs/MPa |

|---|---|---|---|---|---|---|---|---|---|

| 309.78 | 330.69 | 206.95 | 0.067 | 7.14 | 1.63 | 7.37 | 700 | 798.62 | 53.24 |

| 302.98 | 325.14 | 194.24 | 0.067 | 7.94 | 3.67 | 8.11 | 400 | 331.64 | 22.11 |

| 293.57 | 318.48 | 171.88 | 0.067 | 8.27 | 3.82 | 8.43 | 200 | 152.87 | 10.19 |

| 285.19 | 310.84 | 160.13 | 0.067 | 8.42 | 4.34 | 8.56 | 100 | 65.28 | 4.35 |

| 281.55 | 306.92 | 157.86 | 0.067 | 8.59 | 4.51 | 8.73 | 0 | 0 | 0 |

| 274.11 | 298.35 | 155.85 | 0.067 | 8.74 | 4.72 | 8.88 | −100 | −62.35 | −4.18 |

| 262.39 | 284.62 | 153.79 | 0.067 | 8.87 | 4.98 | 9.01 | −200 | −119.54 | −7.97 |

4. Conclusions

- By utilizing kyanite material with a low thermal expansion coefficient as a coating, the strength of ZTA ceramics experienced a significant improvement of 40% at room temperature. However, as the temperature increases, the strength gradually decreases until it reaches 1000 °C (known as the zero-stress temperature). This decrease can be attributed to the reduction of residual compressive stress in the surface layer as the temperature rises until it reaches 0 at 1000 °C.

- A comparison was made between the flexural strengths of coated and uncoated ZTA specimens at different temperatures. The results show that the zero-stress temperature of the kyanite-coated ZTA ceramics was approximately 1000 °C. Beyond this temperature, the strength of the kyanite-coated ZTA ceramics and ZTA ceramics became similar. This similarity can be attributed to the relaxation of compressive residual stress in the coating.

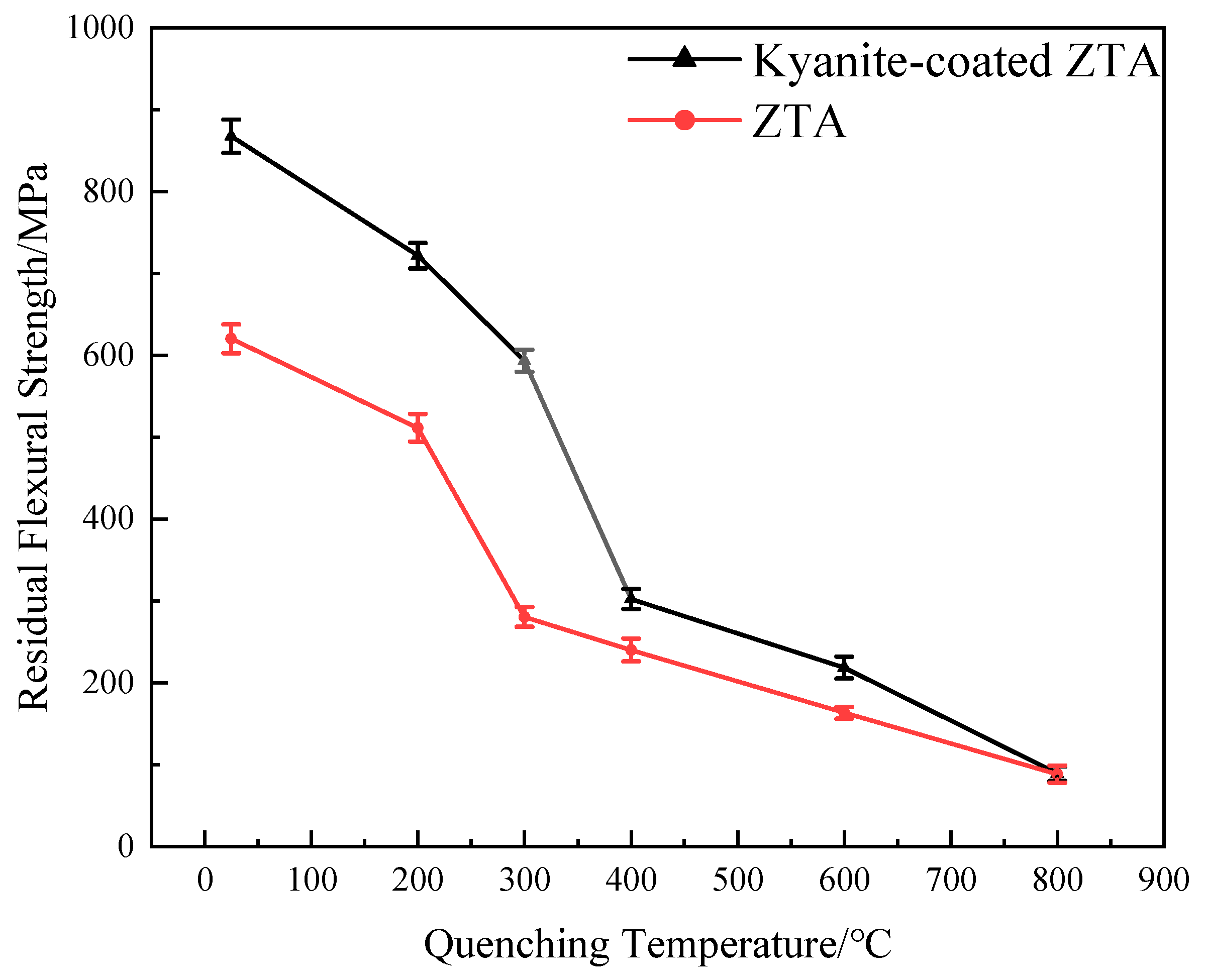

- The residual flexural strength of the quenched kyanite-coated ZTA is found to be higher than that of ZTA up to a temperature of 800 °C. This indicates that the presence of residual compressive stress in the coating improves the material’s resistance to thermal shock. This observation is consistent with the discovery that the quenched kyanite-coated ZTA shows significantly reduced surface crack extension compared to the ZTA.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, B.N.; Hiraga, K.; Morita, K.; Yoshida, H. Effects of heating rate on microstructure and transparency of spark-plasma-sintered alumina. J. Eur. Ceram. Soc. 2009, 29, 323–327. [Google Scholar] [CrossRef]

- Krell, A.; Blank, P.; Ma, H.; Hutzler, T.; Nebelung, M. Processing of high-density submicrometer Al2O3 for new applications. J. Am. Ceram. Soc. 2003, 86, 546–553. [Google Scholar] [CrossRef]

- Mohanty, M. Medical Applications of Alumina Ceramics. Trans. Indian Ceram. Soc. 1995, 54, 200–204. [Google Scholar] [CrossRef]

- Usami, T.; Nakata, K.; Komatsu, M.; Tohnai, I.; Mizutani, H.; Kaneda, T. Application of alumina ceramics to the mandible. Jpn. J. Oral Maxillofac. Surg. 1988, 34, 670–674. [Google Scholar] [CrossRef]

- Majić, M.; Ćurković, L. Fracture Toughness of Alumina Ceramics Determined by Vickers Indentation Technique. Mater. Test. 2012, 54, 228–232. [Google Scholar] [CrossRef]

- Bao, Y.; Kuang, F.; Sun, Y.; Li, Y.; Wan, D.; Shen, Z.; Ma, D.; He, L. A simple way to make pre-stressed ceramics with high strength. J. Mater. 2019, 5, 657–662. [Google Scholar] [CrossRef]

- Sun, Y.; Wu, T.; Bao, Y.; Li, Y.; Wan, D.; Li, K.; He, L. Preparation and strengthening mechanism of prestressed ceramic tile components. Int. J. Appl. Ceram. Technol. 2021, 19, 604–611. [Google Scholar] [CrossRef]

- Yiwang, B.; Yi, S.; Fenghua, K.; Yueming, L.; Detian, W. Development and prospects of high-strength pre-stressed ceramics. J Inorg. Mater. 2020, 35, 399–406. [Google Scholar] [CrossRef]

- ISO 20343; Test Method for Determining Elastic Modulus of Thick Ceramic Coatings at Elevated Temperature. International Organization for Standardization: Geneva, Switzerland, 2017.

- Hao, H.; Li, H.; Wan, D. Flexural strength and thermal shock resistance of mullite/alumina prestressed coating reinforced alumina. J. Inorg. Mater. 2022, 37, 1295–1301. [Google Scholar] [CrossRef]

- Bao, Y. Relative Evaluation of Ceramic Interface Strength Testing and Ceramic Coating Performance. In Proceedings of the 9th Symposium on Inorganic Material Structure, Performance, and Testing Characterization Technology (TEIM2018), Enshi, China, 12 June 2018. [Google Scholar]

- Sainz, M.A.; Serrano, F.J.; Bastida, J.; Caballero, A. Microstructural Evolution and Growth of crystallite size of Mullite during the thermal transformation of kyanite. J. Eur. Ceram. Soc. 1997, 17, 1277–1284. [Google Scholar] [CrossRef]

- Rahbar, N.; Aduda, B.O.; Zimba, J.; Obwoya, S.K.; Nyongesa, F.W.; Yakub, I.; Soboyejo, W.O. Thermal shock resistance of a kyanite-based (aluminosilicate) ceramic. Exp. Mech. 2011, 51, 133–141. [Google Scholar] [CrossRef]

- Tian, W.; Wang, W.; Luo, S. Effect of sintering process on flexural strength of synthetic mullite. Refractory 2000, 34, 325–327. (In Chinese) [Google Scholar]

- Li, H.Y.; Hao, H.; Tian, Y.; Liu, X.G.; Wan, D.; Bao, Y. Temperature dependence of flexural strength and residual stress of Al2O3 reinforced by kyanite coating. Ceram. Int. 2022, 48, 28745–28750. [Google Scholar] [CrossRef]

- Qi, B.; Absi, J.; Tessier-Doyen, N. Experimental and numerical study of the Young’s modulus vs temperature for heterogeneous model materials with polygonal inclusions. Comput. Mater. Sci. 2009, 46, 996–1001. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wu, H.-L.; Li, H.; Cao, D.; Qiu, Y.; Wan, D.; Bao, Y. The Effects of Compressive Residual Stress on Properties of Kyanite-Coated Zirconia Toughened Alumina Ceramics. Materials 2023, 16, 6071. https://doi.org/10.3390/ma16176071

Wu H-L, Li H, Cao D, Qiu Y, Wan D, Bao Y. The Effects of Compressive Residual Stress on Properties of Kyanite-Coated Zirconia Toughened Alumina Ceramics. Materials. 2023; 16(17):6071. https://doi.org/10.3390/ma16176071

Chicago/Turabian StyleWu, Hao-Long, Haiyan Li, Dake Cao, Yan Qiu, Detian Wan, and Yiwang Bao. 2023. "The Effects of Compressive Residual Stress on Properties of Kyanite-Coated Zirconia Toughened Alumina Ceramics" Materials 16, no. 17: 6071. https://doi.org/10.3390/ma16176071

APA StyleWu, H.-L., Li, H., Cao, D., Qiu, Y., Wan, D., & Bao, Y. (2023). The Effects of Compressive Residual Stress on Properties of Kyanite-Coated Zirconia Toughened Alumina Ceramics. Materials, 16(17), 6071. https://doi.org/10.3390/ma16176071