Experimental Research on Application of Waste Concrete Powder–Waste Brick Powder–Cement Grout for Foundation Reinforcement in Mining Goaf

Abstract

:1. Introduction

2. State of the Art

3. Experimental Materials and Schedules

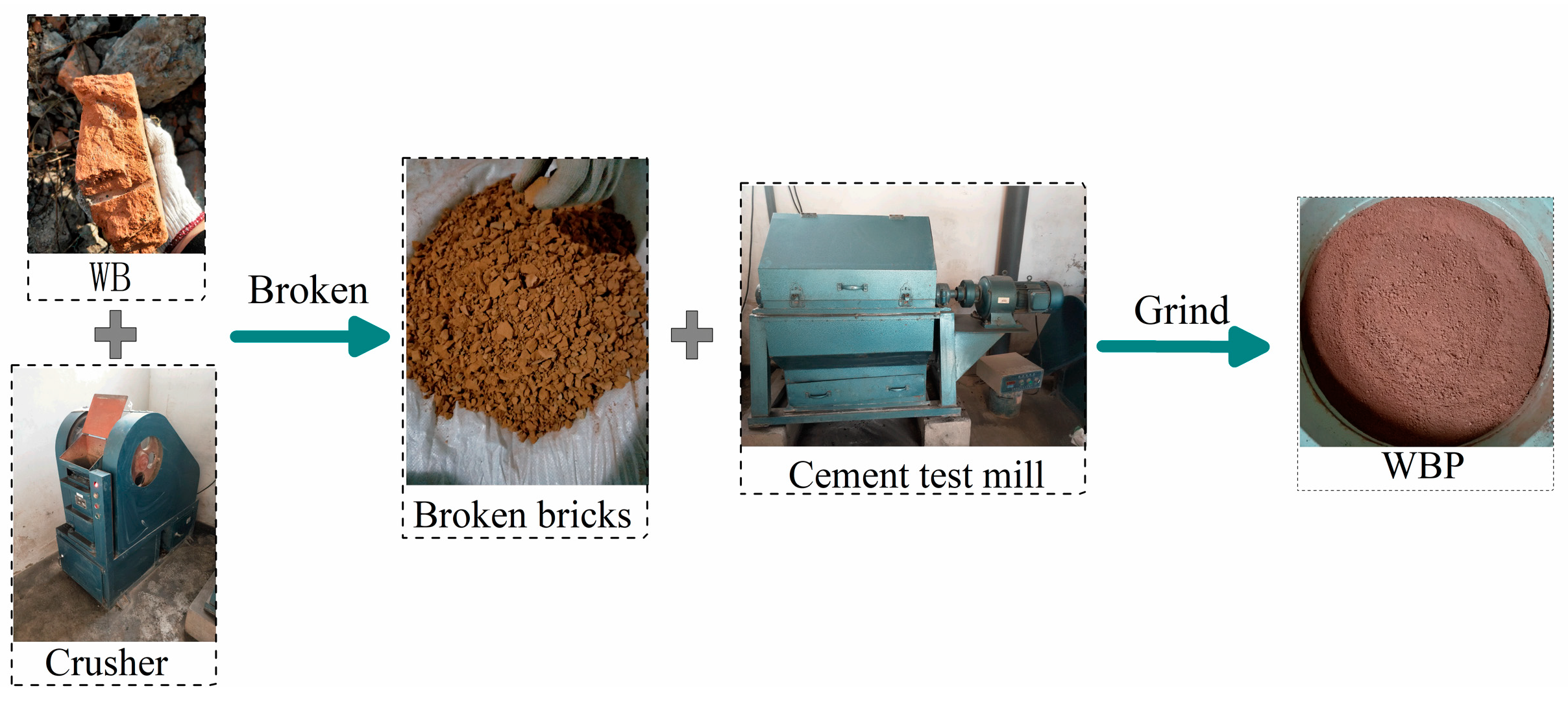

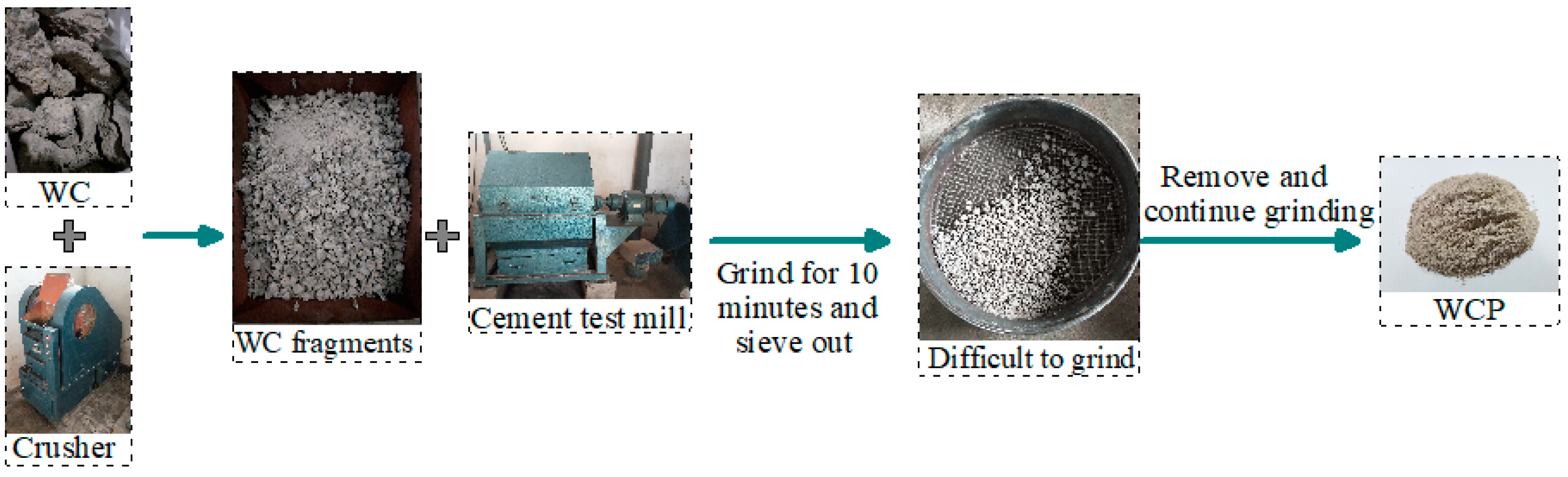

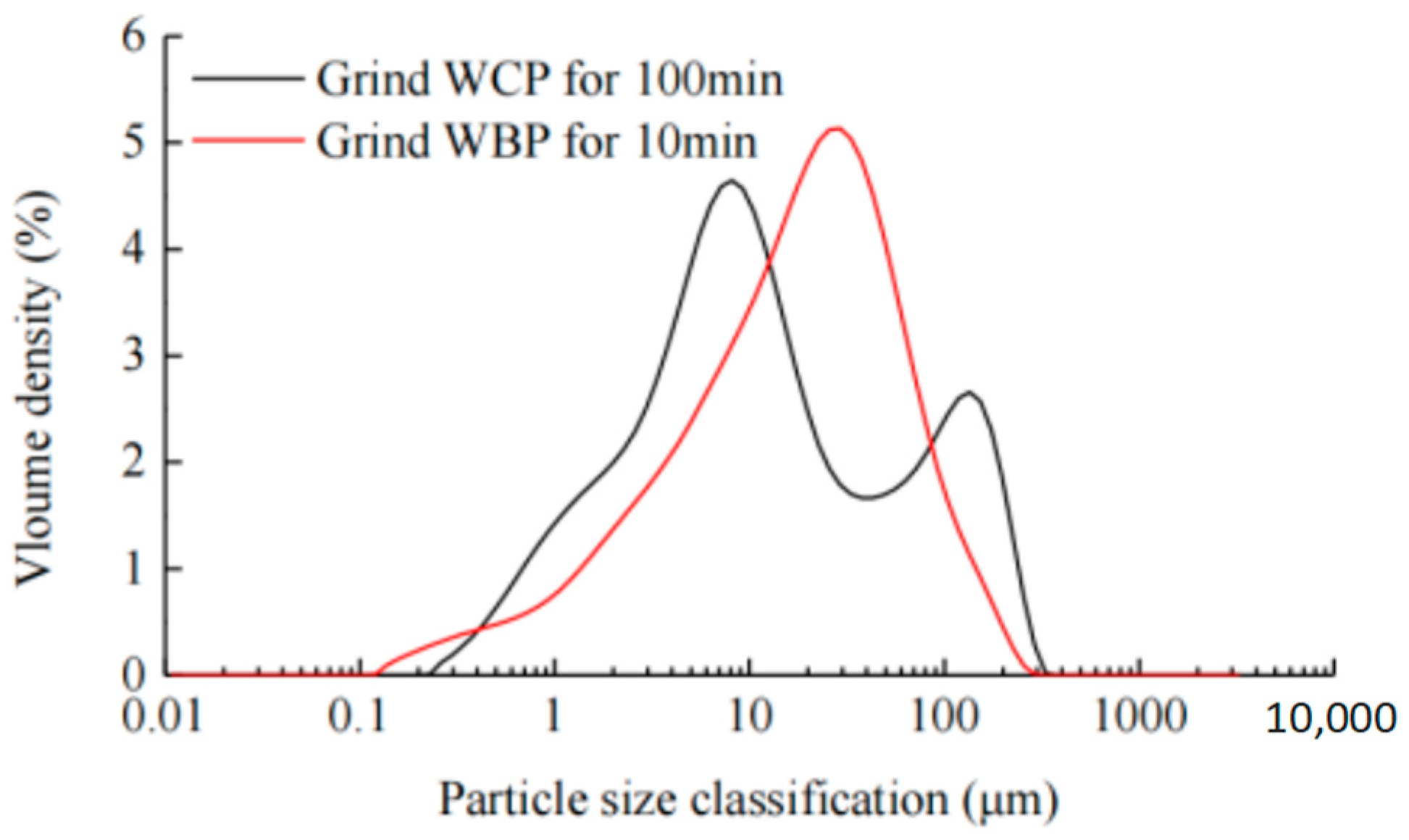

3.1. Raw Materials

3.2. Test Scheme Design of BCP Cement Grout

3.2.1. Test Purpose

3.2.2. Test Contents and Methods

- (1)

- Viscosity

- (2)

- Setting time

- (3)

- Water precipitation rate

- (4)

- Stone rate

- (5)

- Compressive strength

3.2.3. Test Scheme Design

4. Results and Discussion

4.1. Characteristic Analysis of BCP Cement Grout

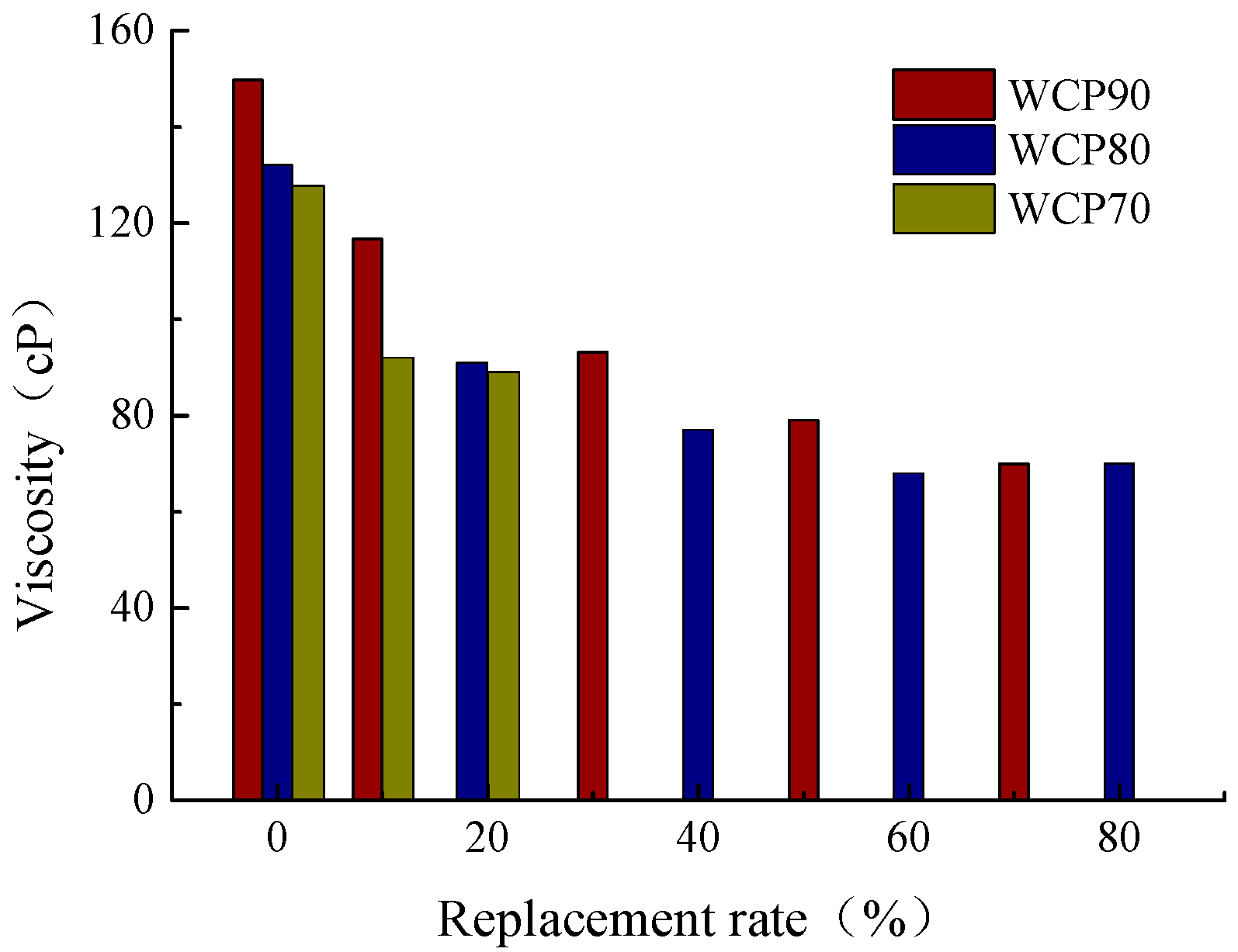

4.1.1. Viscosity

4.1.2. Water Separation Rate and Stone Rate

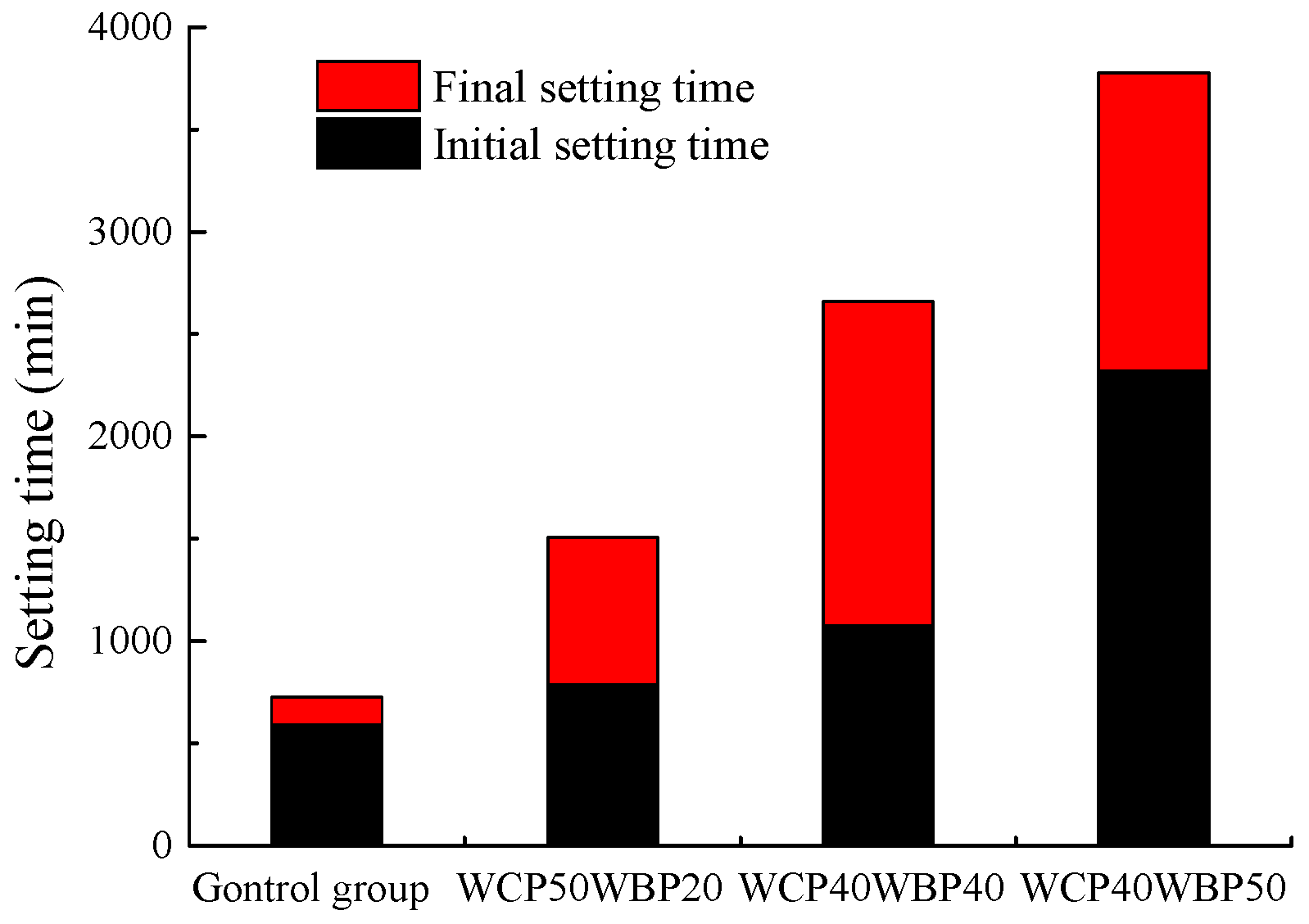

4.1.3. Setting Time

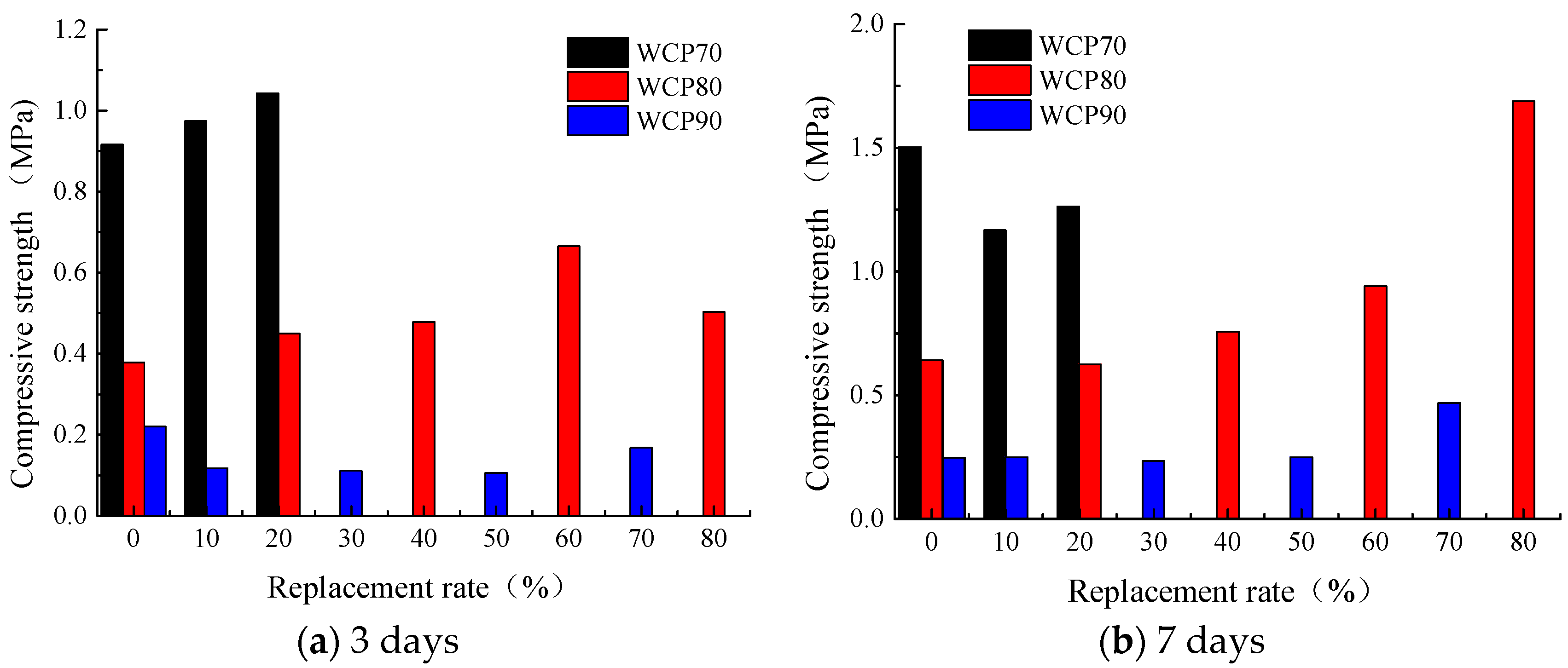

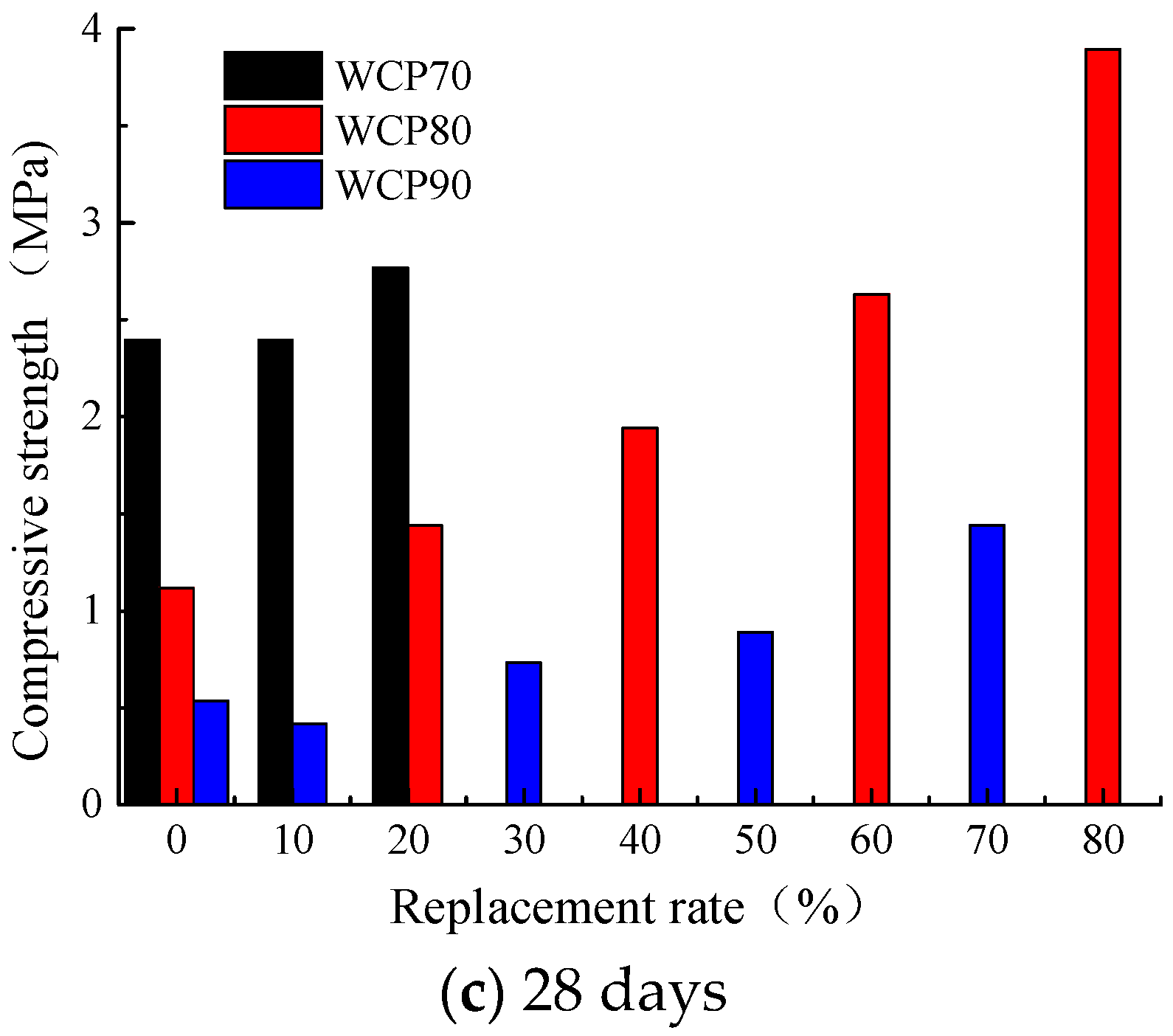

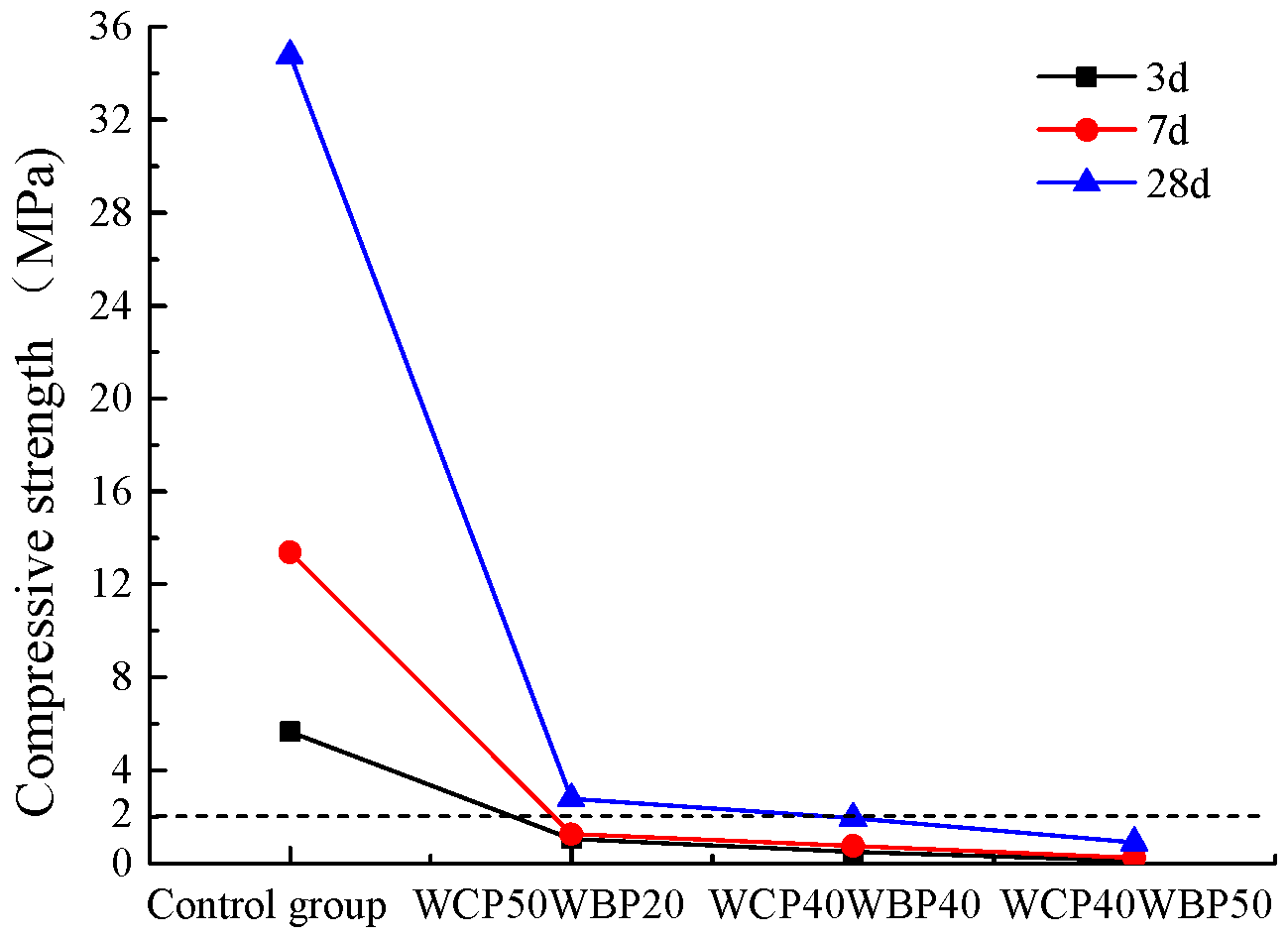

4.1.4. Compressive Strength

4.2. Micro Mechanism of BCP Cement Grout

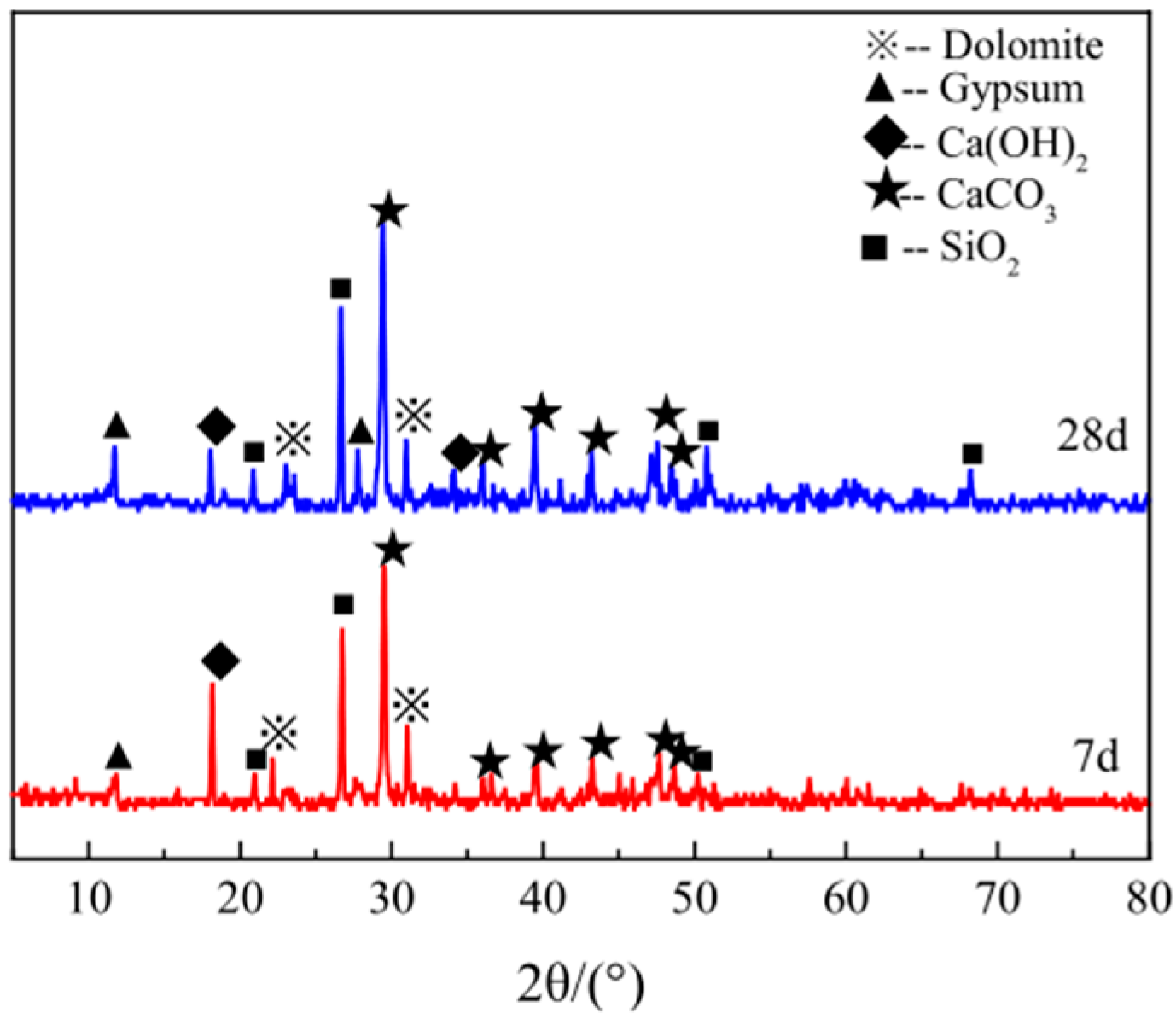

4.2.1. XRD

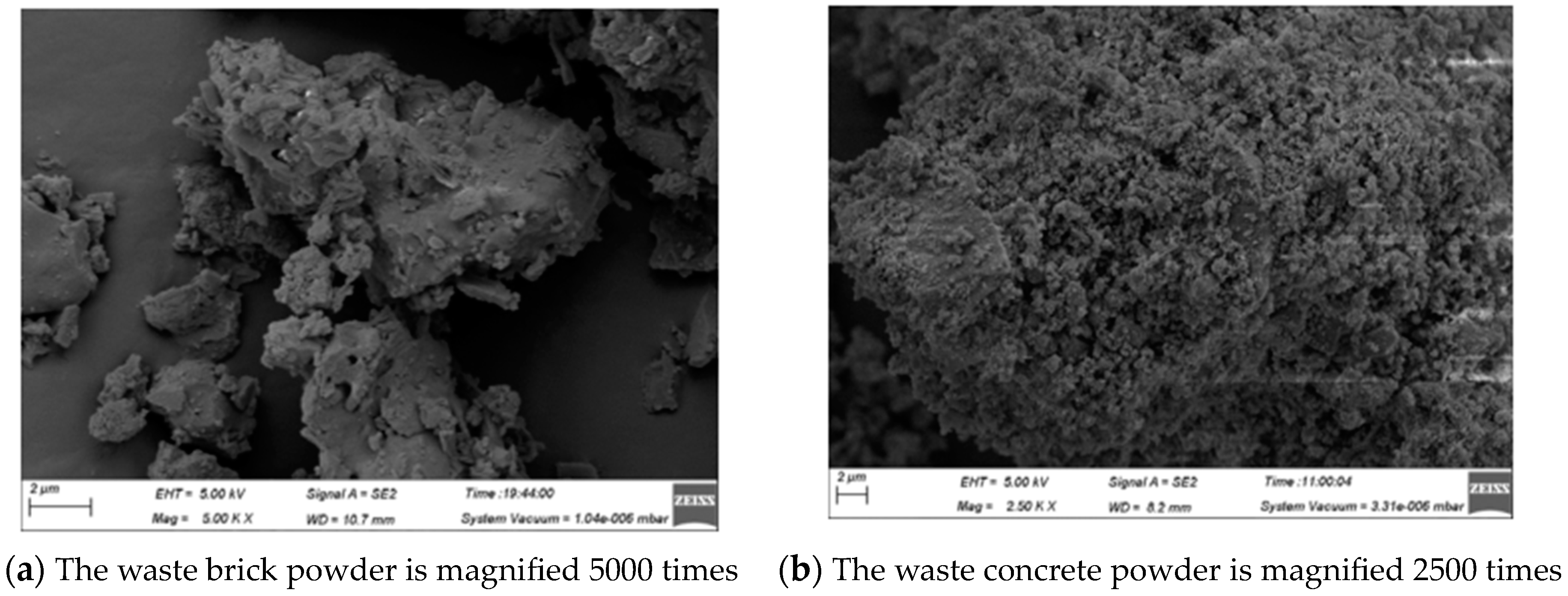

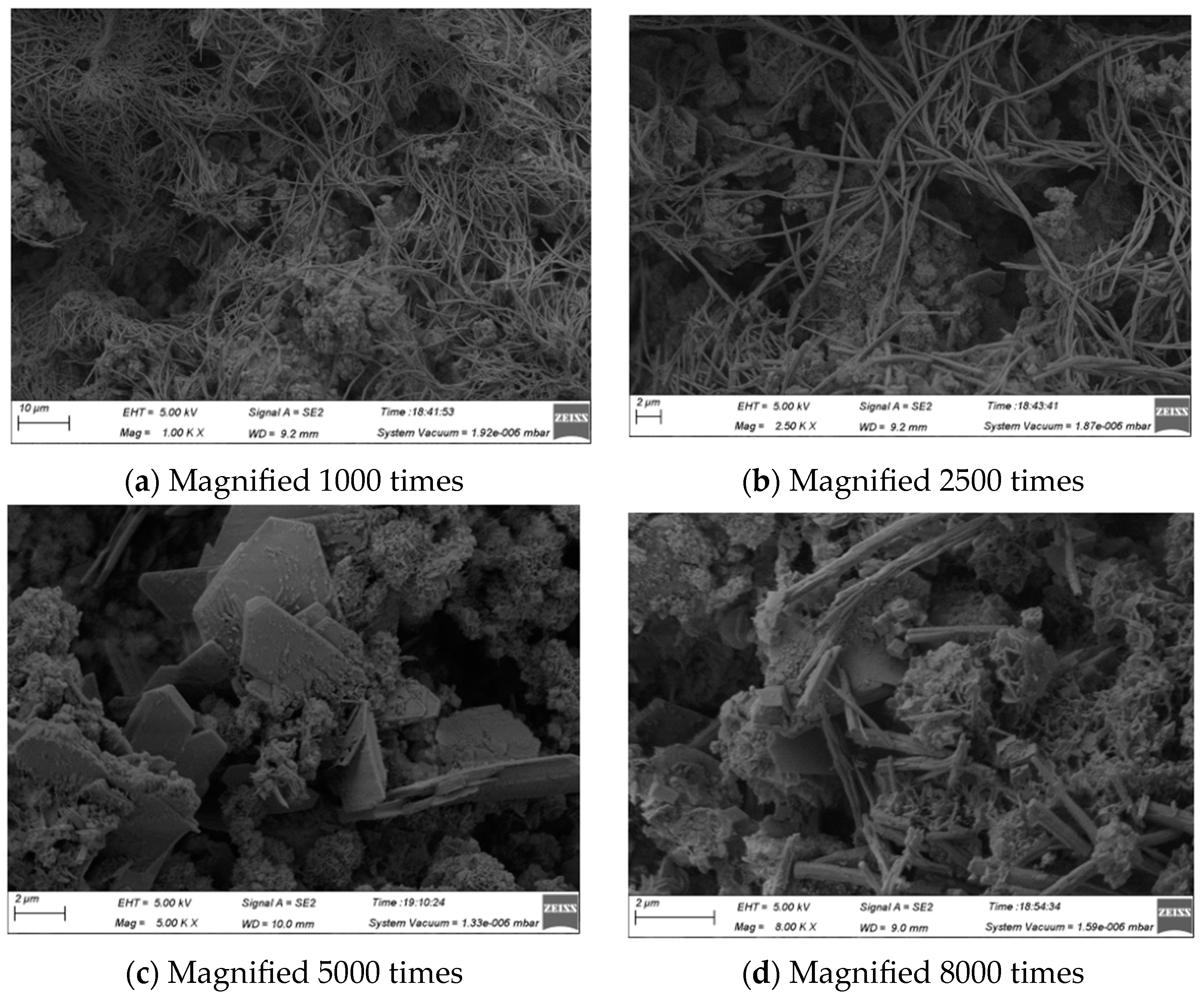

4.2.2. SEM

5. Conclusions

- (1)

- Macroscopic performances: In terms of viscosity, the WCP cement slurry and BCP cement slurry are higher, while WBP cement slurry is the lowest and has the best fluidity. In terms of the water separation rate and stone rate, the water separation rate of the three groups is much lower than that of the control group, and the stone rate is much higher than that of the control group. Among them, the water separation rate of the WCP group is the lowest (about 5%), and the stone rate is the highest (up to 95%). In terms of setting time, the WBP group has higher initial setting time and final setting time. In terms of compressive strength, the 3-day compressive strength of the WBP group is much lower than that of the WCP group and BCP group, the 7-day compressive strength is slightly lower than that of the WCP group and BCP group, and the 28-day compressive strength is basically the same or even slightly higher than that of the WCP group and BCP group.

- (2)

- Microscopic performances: The XRD analysis shows that there are few crystal phases in the WBP group. As the main raw material of this group is brick powder, the number of diffraction peaks of SiO2 is the largest, and the peak strength is the largest. The crystal phase types in the WCP group and BCP group are basically the same, but the diffraction peaks of CaCO3 crystal in the WCP group are the strongest and the number of diffraction peaks is the largest. The SEM analysis shows that the AFt generated from the hydration of samples in the WCP group and WBP group is in the form of short columns or short needles interspersed between gel, while the AFt of samples in the BCP group is in the form of large radial fibers, indicating that the composite action of the two kinds of powders will affect the microscopic morphology of ettringite to some extent.

- (3)

- Economic and environmental performances: Through calculation, the unit cost of pure cement slurry is 261.91 yuan/t, and the three kinds of slurries have significant economic and environmental characteristics compared with pure cement slurry. Due to the long grinding time of waste concrete powder, WCP cement grout is the most expensive of the three kinds of grout, at 182.55 yuan/t, but the stone rate is the highest. WBP cement slurry is the cheapest, at 92.77 yuan/t, with the best economic and environmental performances. BCP cement slurry has a medium economic performance, at 154.83 yuan/t, but it can fully utilize the performance advantages of waste concrete powder and waste brick powder, and no other additives need to be consumed during application.

- (4)

- Limitations: This experiment mainly studied the basic properties of the slurry and the compressive strength of the stone body. However, the internal environment of the mined-out areas is complex, and the buildings have a service life of 50–70 years. Therefore, it is necessary to conduct further research on the durability of the slurry material in the goaf field.

- (5)

- Prospects: Indoor model tests should also be conducted to study the diffusion radius of grout with different ratios in different mined-out areas. The mechanical properties of the stone body in the model test should be tested by taking the cores and the relationship between the compressive strength of the stone body after grouting, and the compressive strength of the indoor pouring specimen should be studied.

- (6)

- Recommendations: The BCP cement grout equipped in this experiment has significant economic and environmental characteristics compared to pure cement grout, which is consistent with sustainable development strategies. Construction professionals or policymakers should encourage and promote the use of new materials in terms of policy, which has significant strategic significance in solving the technical problems of goaf reinforcement and promoting ecological restoration.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ren, L.W.; Li, B.; Zou, Y.F.; Dun, Z.L.; Yang, W.F. Experimental study on performance of waste solid material in coal mine goaf ground grouting improvement. Coal Sci. Technol. 2023. [Google Scholar] [CrossRef]

- Zhou, X.Z.; Zheng, Y.H.; Zhang, Y.X.; Zhan, B.; Zheng, J.J. An experimental study of chloride diffusivity of cement paste mixed with fly ash and slag. J. Zhejiang Univ. Technol. 2023, 51, 127–130. [Google Scholar]

- Ao, X.F.; Wang, X.L.; Zhu, X.B.; Zhou, Z.; Zhang, X. Grouting simulation and stability analysis of coal mine goaf considering hydromechaical coupling. J. Comput. Civ. Eng. 2017, 31, 04016069. [Google Scholar] [CrossRef]

- Wang, Z.S.; Deng, K.Z. Multi Dimension Analysis on Time—Variation Features of Residual Subsidence in Abandoned Goaf. Coal Sci. Technol. 2010, 38, 97–100. [Google Scholar]

- Zhu, D.F.; Tu, S.H.; Wang, F.T.; Ma, H.S. Stability evaluation on pillar system of room and pillar mining in goaf at shallow depth seam. J. China Coal Soc. 2018, 43, 390–397. [Google Scholar]

- Zhai, J.Y.; Fan, S.F.; Yan, Z.X.; Yuan, Y.Z.; Zhu, H.Y.; Zhang, Q.X. Study on the engineering characteristics and application of construction waste expansive soil backfill foundation. J. Xi’an Univ. Arch. Tech. (Nat. Sci. Ed.) 2020, 52, 321–327. [Google Scholar]

- Rong, K.W.; Lan, W.T.; Li, H.Y. Industrial experiment of goaf filling using the filling materials based on hemihydrate phosphogypsum. Minerals 2020, 10, 324–340. [Google Scholar] [CrossRef]

- Du, X.Y.; Chen, X.; Zhou, M.K.; Zhang, H.Y.; Yang, Y.; Wang, Y.D. Effects of Sulfate-Containing Solid Wastes on Hydration of Portland Cement. Bull. Chin. Ceram. Soc. 2023, 42, 1710–1720. [Google Scholar]

- Pantazopoulos, I.; Markou, A.I.N.; Christodoulou, D.N.; Droudakis, A.I.; Atmatzidis, D.K.; Antiohos, S.K.; Chaniotakis, E. Development of microfine cement grouts by pulverizing ordinary cements. Cem. Concr. Compos. 2012, 34, 593–603. [Google Scholar] [CrossRef]

- Markou, I.N.; Droudakis, A.I. Factors affecting engineering properties of microfine cement grouted sands. Geotech. Geol. Eng. 2013, 31, 1041–1058. [Google Scholar] [CrossRef]

- Li, Z.F.; Zhang, J.; Li, S.C.; Gao, Y.F.; Liu, C.; Qi, Y.H. Effect of different gypsums on the workability and mechanical properties of red mud-slag based grouting materials. J. Clean. Prod. 2020, 245, 118759. [Google Scholar] [CrossRef]

- Borden, R.H.; Krizek, R.J.; Baker, W.H. Creep Behavior of Silicate-Grouted Sand: Grouting in Geotechnical Engineering; ASCE: Reston, UK, 2011. [Google Scholar]

- Schneider, M.; Romer, M.; Tschudin, M.; Bolio, H. Sustainable cement production-present and future. Cem. Concr. Res. 2011, 41, 642–650. [Google Scholar] [CrossRef]

- Kwon, E.; Ahn, J.; Cho, B.; Park, D. A study on development of recycled cement made from waste cementitious powder. Constr. Build. Mater. 2015, 83, 174–180. [Google Scholar] [CrossRef]

- Zhang, Y.S.; He, X.F.; Zhu, L.L.; Wang, M.L. Study and application of cement-fly ash grouting material. J. Henan Polytech. Univ. (Nat. Sci.) 2010, 29, 674–679. [Google Scholar]

- Perez-Garcia, F.; Rubio-Cintas, M.D.; Parron-Rubio, M.E.; Garcia-Manrique, J.M. Advances in the analysis of properties behaviour of cement-based grouts with high substitution of cement with blast furnace slags. Materials 2020, 13, 561–574. [Google Scholar] [CrossRef]

- Zhu, X.X.; Zhang, Q.; Zhang, W.Q.; Shao, J.L.; Wang, Z.Y.; Wu, X.T. Experimental study on the basic properties of a green new coal mine grouting reinforcement material. ACS Omega 2020, 5, 16722–16732. [Google Scholar] [CrossRef]

- Lin, C.J.; Dai, W.J.; Li, Z.F.; Wang, Y.S. Study on the inorganic synthesis from recycled cement and solid waste gypsum system: Application in grouting materials. Constr. Build. Mater. 2020, 251, 118930. [Google Scholar] [CrossRef]

- Balkis, A.P. Properties and performance of a high volume fly ash grout. Mar. Georesources Geotechnol. 2020, 38, 73–82. [Google Scholar] [CrossRef]

- Sanchez-cotte, E.H.; Fuentes, L.; Martinez-Argurlles, G.; Quintana, H.A.R.; Walubita, L.F.; Cantero-Durango, J.M. Influence of recycled concrete aggregates from different sources in hot mix asphalt design. Constr. Build. Mater. 2020, 259, 120427. [Google Scholar] [CrossRef]

- Zhou, W.J.; Zhang, Z.W.; Xu, Y.B. Mechanical and Frost Resistance of Inorganic Binder Stabilized Construction Waste Recycled Aggregate. Mater. Rep. 2020, 34, 234–236. [Google Scholar]

- Kim, H.S.; Lee, S.H.; Kim, B. Properties of extrusion concrete panel using waste concrete powder. Appl. Sci. 2017, 7, 910–923. [Google Scholar] [CrossRef]

- Zheng, C.C.; Lou, C.; Du, G.; Li, X.; Liu, Z.; Li, L. Mechanical properties of recycled concrete with demolished waste concrete aggregate and clay brick aggregate. Results Phys. 2018, 9, 1317–1322. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Ma, Z.M.; Sui, T.B.; Akbarnezhad, A.; Duan, Z. Mechanical properties of concrete mixed with recycled powder produced from construction and demolish waste. J. Clean. Prod. 2018, 188, 720–731. [Google Scholar] [CrossRef]

- He, X.Y.; Zheng, Z.Q.; Yang, J.; Su, Y.; Wang, T.W.; Strnadel, B. Feasibility of incorporating autoclaved aerated concrete waste for cement replacement in sustainable building materials. J. Clean. Prod. 2020, 250, 119451–119455. [Google Scholar] [CrossRef]

- Cao, W.Q.; Huang, L.; Gao, Q.; Bao, T.T.; Li, F.A.; Li, Y. Experimental study on the basic mechanical properties of recycled brick aggregate masonry. J. Railw. Sci. Eng. 2019, 16, 384–390. [Google Scholar]

- Chen, J.; Zhang, S.M.; Wang, Y.Y.; Geng, Y. Axial compressive behavior of recycled concrete filled steel tubular stub columns with the inclusion of crushed brick. Structures 2020, 26, 271–283. [Google Scholar] [CrossRef]

- Ortega, J.M.; Letelier, V.; Solas, C.; Moriconi, G.; Climent, M.A.; Sanchez, I. Long-term effects of waste brick powder addition in the microstructure and service properties of mortars. Constr. Build. Mater. 2018, 182, 691–702. [Google Scholar] [CrossRef]

- Irki, I.; Debieb, F.; Ouzadid, S.; Dilmi, H.L.; Settari, C.; Boukhelkhel, D. Effect of blaine fineness of recycling brick powder replacing cementitious materials in self compacting mortar. J. Adhes. Sci. Technol. 2018, 32, 963–975. [Google Scholar] [CrossRef]

- Letelier, V.; Ortega, J.M.; Munoz, P.; Tarela, E.; Moriconi, G. Influence of waste brick powder in the mechanical properties of recycled aggregate concrete. Sustainability 2018, 10, 1037–1052. [Google Scholar] [CrossRef]

- Tang, Z.J.; Deng, M.; Mo, L.W.; Lv, L.M.; Liu, G.H. Modification of MgO Expansive Agent by Waste Brick Powder and Its Effect on Performance of Mortars. Bull. Chin. Ceram. Soc. 2017, 36, 3958–3963. [Google Scholar]

- Che, F.; Xu, S.W.; Zhang, H. Experimental Study on Working and Mechanical Performance of Concrete with Waste Clay Brick Powder. Railw. Eng. 2016, 56, 139–142. [Google Scholar]

- Huang, H.; Guo, M.X.; Zhang, W.; Yang, S.L. Mechanical property and microstructure of geopolymer concrete based on fly ash and slag. J. Harbin Inst. Technol. 2022, 54, 74–84. [Google Scholar]

- Chen, W.; Xiong, C.B.; Cai, G.Y.; Shen, M. Experimental investigation on the effect of recycled clay brick powder on the performance of foamed concrete. Mag. Concr. Res. 2019, 71, 1206–1207. [Google Scholar]

- Cachim, P.B. Mechanical properties of brick aggregate concrete. Constr. Build. Mater. 2009, 23, 1292–1297. [Google Scholar] [CrossRef]

- Yang, F.L.; Zhao, Y.S. Research on the Influence of Mixing Ratio Parameters of Recycled Clay Brick Aggregate Concrete on Its Performance. China Concr. Cem. Prod. 2019, 2, 63–66. [Google Scholar]

- Dun, Z.L.; Wang, M.Q.; Zou, Y.F.; Ren, L.W. Laboratory Tests on Performance of Waste-Clay-Brick-Powder Cement Grouting Materials for Ground Improvement in Mine Goaf. Adv. Eng. Mater. 2022, 24, 2101575. [Google Scholar] [CrossRef]

- Dun, Z.L.; Wang, M.Q.; Ren, L.W.; Dun, Z.Y. Tests Research on Grouting Materials of Waste-Concrete-Powder Cement for Goaf Ground Improvement. Adv. Mater. Sci. Eng. 2021, 2021, 9598418. [Google Scholar] [CrossRef]

- GB/T 17671-1999; Method of Testing Cements—Determination of Strength. State Bureau of Quality and Technical Supervision: Beijing, China, 1999.

- GB/T 1346-2011; Test Methods for Water Requirement of Normal Consistency, Setting Time and Soundness of the Portland Cement. Standardization Administration of China: Beijing, China, 2011.

- GB 51180-2016; Technical Code for Ground Treatment of Buildings in Coal Mine Goaf. Ministry of Housing and Urban Rural Development of the People’s Republic of China: Beijing, China, 2016.

| Indicators | Specific Surface Area m2/kg | Setting Time Min | Compressive Strength MPa | Flexural Strength MPa | |||

|---|---|---|---|---|---|---|---|

| Initial Setting | Final Setting | 7 d | 28 d | 7 d | 28 d | ||

| results | 412 | 167 | 233 | 23 | 52 | 4.9 | 7.3 |

| Raw Materials | Chemical Composition (%) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | Al2O3 | MgO | Fe2O3 | SO3 | K2O | Na2O | TiO2 | |

| cement | 59.49 | 19.41 | 6.49 | 4.05 | 3.4 | 4.33 | 0.96 | 0.61 | 0.5 |

| waste concrete powder | 62.76 | 20.244 | 4.996 | 5.511 | 2.84 | 0.62 | 1.121 | 0.583 | 0.36 |

| waste brick powder | 8.008 | 60.99 | 16.379 | 2.631 | 5.697 | 0.344 | 2.786 | 1.868 | 0.778 |

| Group Numbers | Cement Content (%) | Brick Powder Content (%) | Concert Powder Content (%) |

|---|---|---|---|

| WCP70 | 30 | 0 | 70 |

| WCP60WBP10 | 30 | 10 | 60 |

| WCP50WBP20 | 30 | 20 | 50 |

| WCP80 | 20 | 0 | 80 |

| WCP60WBP20 | 20 | 20 | 60 |

| WCP40WBP40 | 20 | 40 | 40 |

| WCP20WBP60 | 20 | 60 | 20 |

| WCP90 | 10 | 0 | 90 |

| WCP80WBP10 | 10 | 10 | 80 |

| WCP60WBP30 | 10 | 30 | 60 |

| WCP40WBP50 | 10 | 50 | 40 |

| WCP20WBP70 | 10 | 70 | 20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Wang, M.; Wang, H.; Dun, Z.; Ren, L. Experimental Research on Application of Waste Concrete Powder–Waste Brick Powder–Cement Grout for Foundation Reinforcement in Mining Goaf. Materials 2023, 16, 6075. https://doi.org/10.3390/ma16186075

Wang Y, Wang M, Wang H, Dun Z, Ren L. Experimental Research on Application of Waste Concrete Powder–Waste Brick Powder–Cement Grout for Foundation Reinforcement in Mining Goaf. Materials. 2023; 16(18):6075. https://doi.org/10.3390/ma16186075

Chicago/Turabian StyleWang, Yan, Mengqi Wang, Hui Wang, Zhilin Dun, and Lianwei Ren. 2023. "Experimental Research on Application of Waste Concrete Powder–Waste Brick Powder–Cement Grout for Foundation Reinforcement in Mining Goaf" Materials 16, no. 18: 6075. https://doi.org/10.3390/ma16186075

APA StyleWang, Y., Wang, M., Wang, H., Dun, Z., & Ren, L. (2023). Experimental Research on Application of Waste Concrete Powder–Waste Brick Powder–Cement Grout for Foundation Reinforcement in Mining Goaf. Materials, 16(18), 6075. https://doi.org/10.3390/ma16186075