Effect of Trap Behavior on the Reliability Instability of Metamorphic Buffer in InAlAs/InGaAs MHEMT on GaAs

Abstract

:1. Introduction

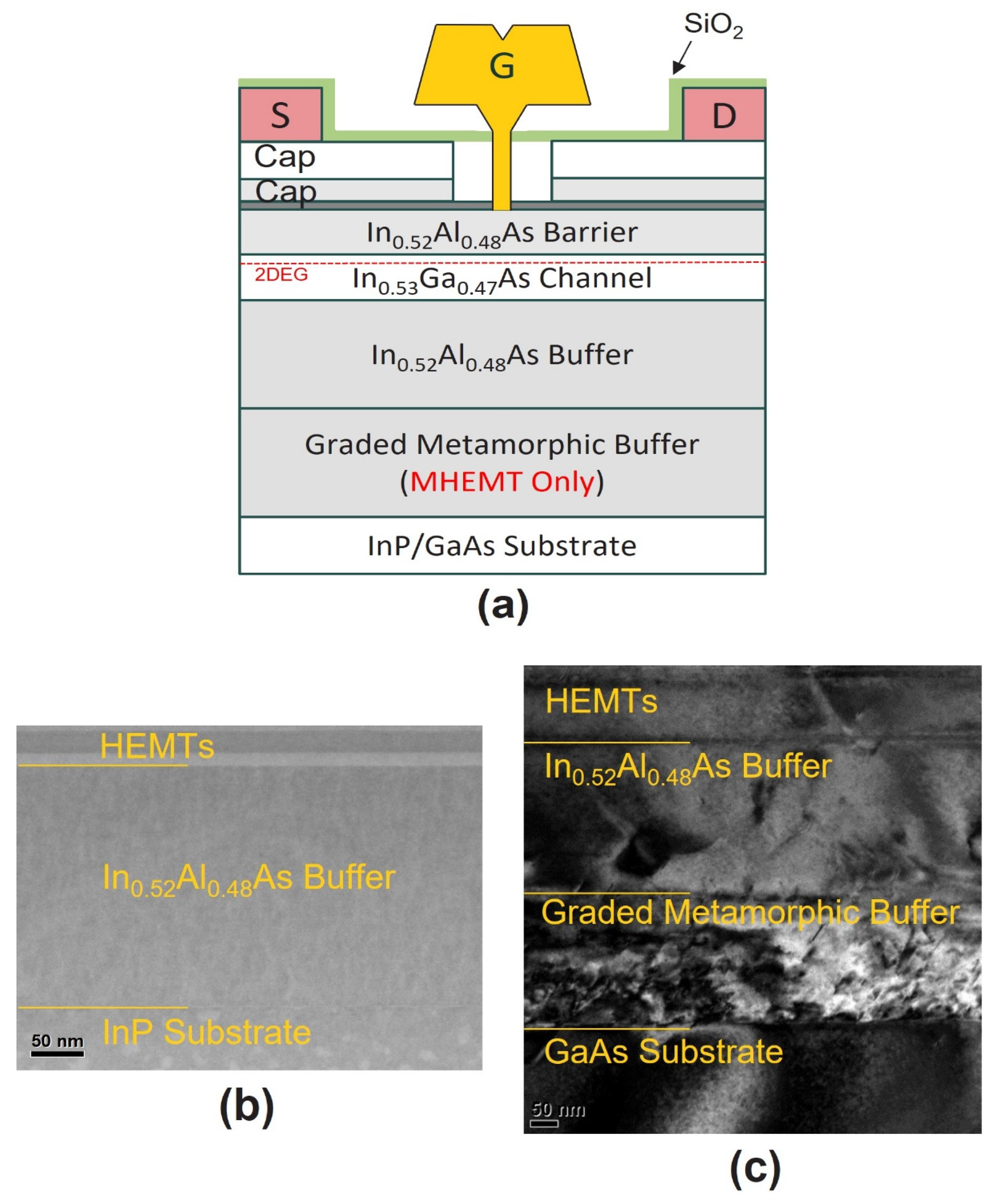

2. Experimental Details

3. Results and Discussion

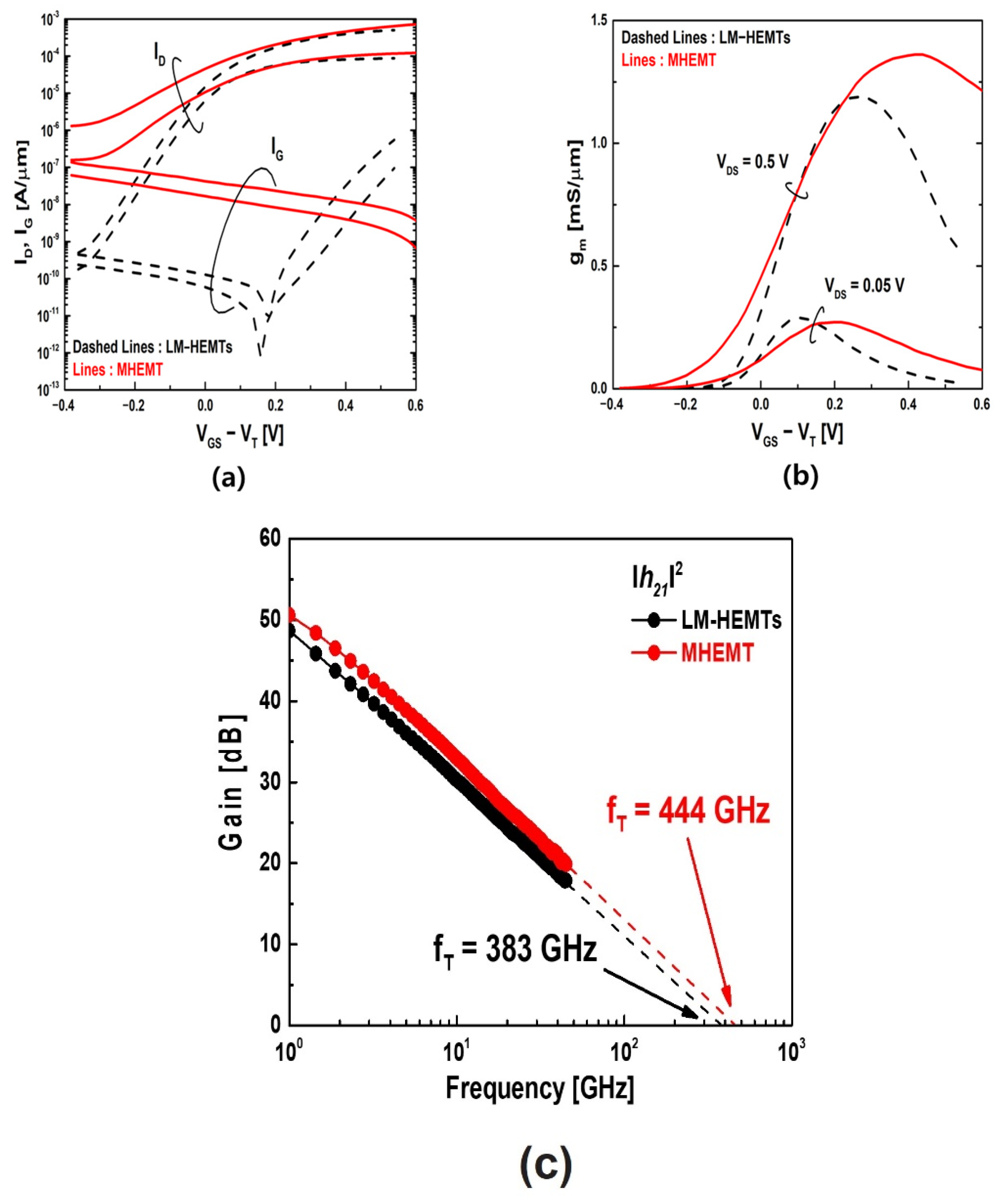

3.1. Devices Characteristics

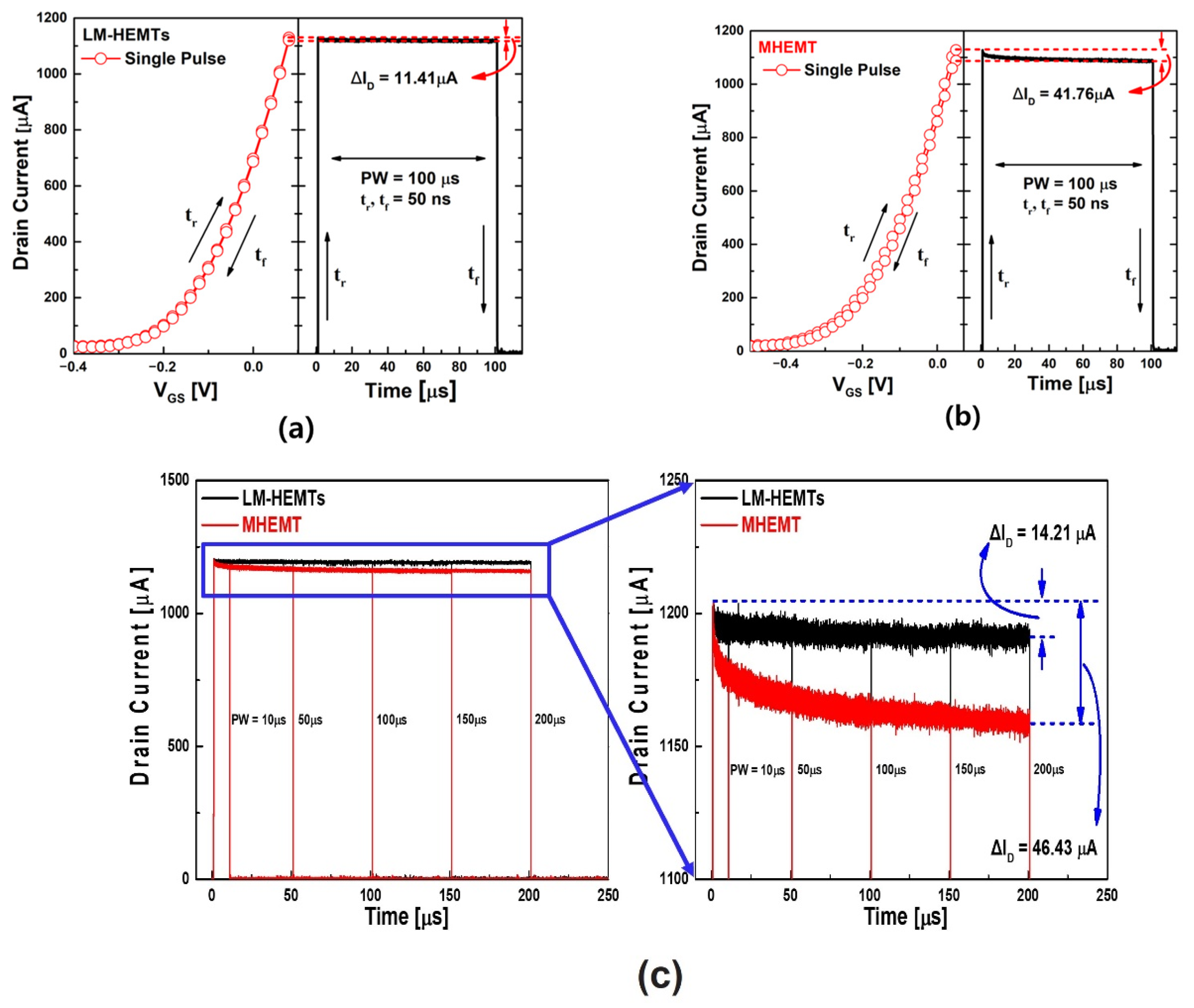

3.2. Fast Transient Charging Effect with Pulse I–V

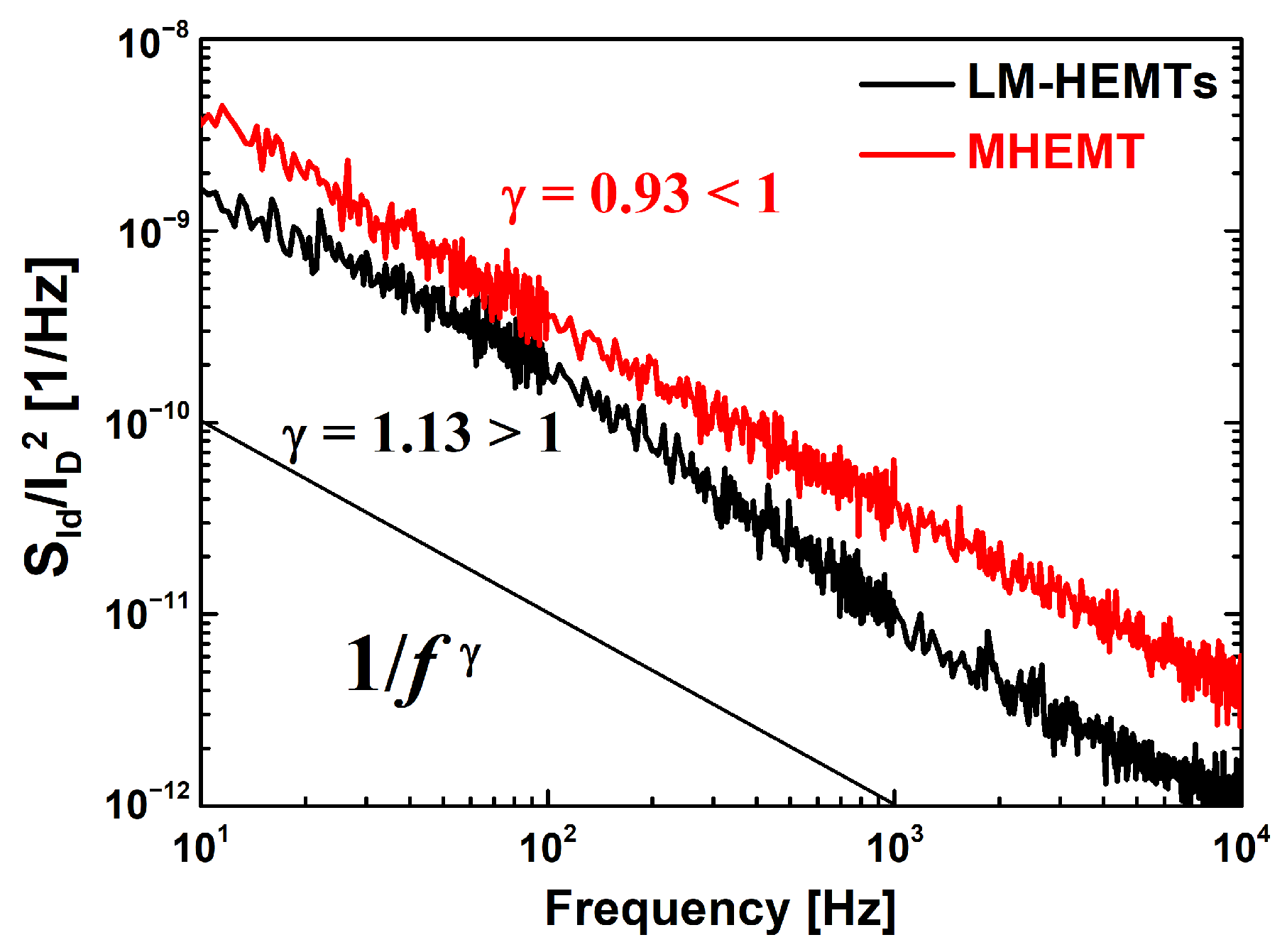

3.3. 1/f (Low-Frequency) Noise

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Del Alamo, J.A. Nanometre-Scale Electronics with III–V Compound Semiconductors. Nature 2011, 479, 317–323. [Google Scholar] [CrossRef]

- Jo, H.B.; Yun, S.W.; Kim, J.G.; Yun, D.Y.; Lee, I.G.; Kim, D.H.; Kim, T.W.; Kim, S.K.; Yun, J.; Kim, T.; et al. Lg = 19 Nm In0.8Ga0.2As Composite-Channel HEMTs with FT = 738 GHz and Fmax = 492 GHz. In Proceedings of the Technical Digest—International Electron Devices Meeting, IEDM, San Francisco, CA, USA, 12–18 December 2020; pp. 8.4.1–8.4.4. [Google Scholar] [CrossRef]

- Lai, R.; Mei, X.B.; Deal, W.R.; Yoshida, W.; Kim, Y.M.; Liu, P.H.; Lee, J.; Uyeda, J.; Radisic, V.; Lange, M.; et al. Sub 50 Nm InP HEMT Device with Fmax Greater than 1 THz. In Proceedings of the Technical Digest—International Electron Devices Meeting, IEDM, Washington, DC, USA, 10–12 December 2007; pp. 609–611. [Google Scholar] [CrossRef]

- Kim, D.H.; Del Alamo, J.A.; Chen, P.; Ha, W.; Urteaga, M.; Brar, B. 50-Nm E-Mode In0.7Ga0.3As PHEMTs on 100-Mm InP Substrate with Fmax > 1 THz. In Proceedings of the Technical Digest—International Electron Devices Meeting, IEDM, San Francisco, CA, USA, 6–8 December 2010. [Google Scholar] [CrossRef]

- Kim, D.H.; Brar, B.; Del Alamo, J.A. F T = 688 GHz and f Max = 800 GHz in L g = 40 Nm In 0.7Ga 0.3As MHEMTs with g m-Max > 2.7 MS/Μm. In Proceedings of the Technical Digest—International Electron Devices Meeting, IEDM, Washington, DC, USA, 5–7 December 2011. [Google Scholar] [CrossRef]

- Leuther, A.; Tessmann, A.; Doria, P.; Ohlrogge, M.; Seelmann-Eggebert, M.; Masler, H.; Schlechtweg, M.; Ambacher, O. 20 Nm Metamorphic HEMT Technology for Terahertz Monolithic Integrated Circuits. In Proceedings of the European Microwave Week 2014: “Connecting the Future”, EuMW 2014—Conference Proceedings; EuMIC 2014: 9th European Microwave Integrated Circuits Conference, Rome, Italy, 6–7 October 2014; pp. 84–87. [Google Scholar] [CrossRef]

- Lavrukhin, D.V.; Yachmenev, A.E.; Galiev, R.R.; Khabibullin, R.A.; Ponomarev, D.S.; Fedorov, Y.V.; Maltsev, P.P. MHEMT with a Power-Gain Cut-off Frequency of f Max = 0.63 THz on the Basis of a In0.42Al0.58As/In0.42Ga0.58As/In0.42Al0.58As/GaAs Nanoheterostructure. Semiconductors 2014, 48, 69–72. [Google Scholar] [CrossRef]

- Chou, Y.C.; Grundbacher, R.; Leung, D.; Lai, R.; Liu, P.H.; Kan, Q.; Biedenbender, M.; Wojtowicz, M.; Eng, D.; Oki, A. Physical Identification of Gate Metal Interdiffusion in GaAs PHEMTs. IEEE Electron. Device Lett. 2004, 25, 64–66. [Google Scholar] [CrossRef]

- Dammann, M.; Leuther, A.; Quay, R.; Meng, M.; Konstanzer, H.; Jantz, W.; Mikulla, M. Reliability of 70 Nm Metamorphic HEMTs. Microelectron. Reliab. 2004, 44, 939–943. [Google Scholar] [CrossRef]

- Suemitsu, T. Recent Achievements in the Reliability of InP-Based HEMTs. Thin Solid Film. 2007, 515, 4378–4383. [Google Scholar] [CrossRef]

- Meneghesso, G.; Zanoni, E. Failure Modes and Mechanisms of InP-Based and Metamorphic High Electron Mobility Transistors. Microelectron. Reliab. 2002, 42, 685–708. [Google Scholar] [CrossRef]

- Mertens, S.D.; Del Alamo, J.A. A Model for Hydrogen-Induced Piezoelectric Effect in InP HEMTs and GaAs PHEMTs; A Model for Hydrogen-Induced Piezoelectric Effect in InP HEMTs and GaAs PHEMTs. IEEE Trans. Electron. Devices 2002, 49, 1849. [Google Scholar] [CrossRef]

- Dammann, M.; Leuther, A.; Benkhelifa, F.; Feltgen, T.; Jantz, W. Reliability and Degradation Mechanism of AlGaAs/InGaAs and InAlAs/InGaAs HEMTs. Phys. Status Solidi (A) 2003, 195, 81–86. [Google Scholar] [CrossRef]

- Canali, C.; Castaldo, F.; Fantini, F.; Ogliari, D.; Umena, L.; Zanoni, E. Gate Metallization “Sinking” into the Active Channel in Ti/W/Au Metallized Power MESFET’s. IEEE Electron. Device Lett. 1986, 7, 185–187. [Google Scholar] [CrossRef]

- Douglas, E.A.; Chen, K.H.; Chang, C.Y.; Leu, L.C.; Lo, C.F.; Chu, B.H.; Ren, F.; Pearton, S.J. InAlAs/InGaAs MHEMT Degradation during DC and Thermal Stressing. In Proceedings of the IEEE International Reliability Physics Symposium Proceedings, Anaheim, CA, USA, 2–6 May 2010; pp. 818–821. [Google Scholar] [CrossRef]

- Dammann, M.; Benkhelifa, F.; Meng, M.; Jantz, W. Reliability of Metamorphic HEMTs for Power Applications. Microelectron. Reliab. 2002, 42, 1569–1573. [Google Scholar] [CrossRef]

- Ajayan, J.; Nirmal, D.; Mathew, R.; Kurian, D.; Mohankumar, P.; Arivazhagan, L.; Ajitha, D. A Critical Review of Design and Fabrication Challenges in InP HEMTs for Future Terahertz Frequency Applications. Mater. Sci. Semicond. Process. 2021, 128, 105753. [Google Scholar] [CrossRef]

- Chou, Y.C.; Leung, D.; Lai, R.; Grundbacher, R.; Barsky, M.; Kan, Q.; Tsai, R.; Wojtowicz, M.; Eng, D.; Tran, L.; et al. Reliability Investigation of 0.07-Μm InGaAs-InAlAs-InP HEMT MMICs with Pseudomorphic In0.75Ga0.25As Channel. IEEE Electron. Device Lett. 2003, 24, 378–380. [Google Scholar] [CrossRef]

- Chen, K.H.; Chang, C.Y.; Leu, L.C.; Lo, C.F.; Chu, B.H.; Pearton, S.J.; Ren, F. Degradation of 150 Nm Mushroom Gate InAlAs/InGaAs Metamorphic High Electron Mobility Transistors during Dc Stressing and Thermal Storage. J. Vac. Sci. Technol. B Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2010, 28, 365. [Google Scholar] [CrossRef]

- Tateno, Y.; Nakata, K.; Oya, A.; Matsuda, K.; Komatsu, Y.; Osada, S.; Hirata, M.; Ishiyama, S.; Yoda, T.; Nitta, A.; et al. Investigation of the Failure Mechanism of InGaAs-PHEMT under High Temperature Operating Life Tests. In Proceedings of the IEEE International Reliability Physics Symposium Proceedings, Monterey, CA, USA, 21–25 March 2021. [Google Scholar] [CrossRef]

- Borgarino, M.; Menozzi, R.; Baeyens, Y.; Cova, P.; Fantini, F. Hot Electron Degradation of the DC and RF Characteristics of AlGaAs/InGaAs/GaAs PHEMT’s. IEEE Trans. Electron. Devices 1998, 45, 366–372. [Google Scholar] [CrossRef]

- Hisaka, T.; Nogami, Y.; Sasaki, H.; Hasuike, A.; Yoshida, N.; Hayashi, K.; Sonoda, T.; Villanueva, A.A.; Del Alamo, J.A. Degradation Mechanism of PHEMT under Large Signal Operation. In Proceedings of the Technical Digest—GaAs IC Symposium (Gallium Arsenide Integrated Circuit), San Diego, CA, USA, 9–12 November 2003; pp. 67–70. [Google Scholar] [CrossRef]

- Meneghesso, G.; De Bortoli, E.; Sala, D.; Zanoni, E. Failure Mechanisms of AlGaAs/InGaAs Pseudomorphic Hemt’s: Effects Due to Hot Electrons and Modulation of Trapped Charge. Microelectron. Reliab. 1997, 37, 1121–1129. [Google Scholar] [CrossRef]

- Huang, Y.; Li, S.; Hong, X. The Gate Metal Degradation Mechanism and Electromigration Evaluation of PHEMT Devices. In Proceedings of the ICQR2MSE 2011—Proceedings of 2011 International Conference on Quality, Reliability, Risk, Maintenance, and Safety Engineering, Xi’an, China, 17–19 June 2011; pp. 370–373. [Google Scholar] [CrossRef]

- Leoni, R.E.; Hwang, J.C.M. Mechanisms for Output Power Expansion and Degradation of PHEMT’s during High-Efficiency Operation. IEEE Trans. Electron. Devices 1999, 46, 1608–1613. [Google Scholar] [CrossRef]

- Lubyshev, D.; Liu, W.K.; Stewart, T.R.; Cornfeld, A.B.; Fang, X.M.; Xu, X.; Specht, P.; Kisielowski, C.; Naidenkova, M.; Goorsky, M.S.; et al. Strain Relaxation and Dislocation Filtering in Metamorphic High Electron Mobility Transistor Structures Grown on GaAs Substrates. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. Process. Meas. Phenom. 2001, 19, 1510. [Google Scholar] [CrossRef]

- Young, C.D.; Zhao, Y.; Heh, D.; Choi, R.; Lee, B.H.; Bersuker, G. Pulsed Id-Vg Methodology and Its Application to Electron-Trapping Characterization and Defect Density Profiling. IEEE Trans. Electron. Devices 2009, 56, 1322–1329. [Google Scholar] [CrossRef]

- Kwon, H.M.; Kim, D.H.; Kim, T.W. Impact of Fast and Slow Transient Charging Effect on Reliability Instability in In0.7Ga0.3As Quantum-Well MOSFETs with High-κ Dielectrics. Jpn. J. Appl. Phys. 2020, 59, 110903. [Google Scholar] [CrossRef]

- Young, C.D.; Heh, D.; Neugroschel, A.; Choi, R.; Lee, B.H.; Bersuker, G. Electrical Characterization and Analysis Techniques for the High-κ Era. Microelectron. Reliab. 2007, 47, 479–488. [Google Scholar] [CrossRef]

- Lee, B.H.; Young, C.D.; Choi, R.; Sim, J.H.; Bersuker, G.; Kang, C.Y.; Harris, R.; Brown, G.A.; Matthews, K.; Song, S.C.; et al. Intrinsic Characteristics of High-k Devices and Implications of Fast Transient Charging Effects (FTCE). In Proceedings of the Technical Digest—International Electron Devices Meeting, IEDM, San Francisco, CA, USA, 13–15 December 2004; pp. 859–862. [Google Scholar] [CrossRef]

- Shin, K.Y.; Shin, J.W.; Chakraborty, S.; Amir, W.; Shin, C.S.; Kim, T.W. Trap Behavior of Metamorphic HEMTs with Pulsed IV and 1/f Noise Measurement. In Proceedings of the European Solid-State Device Research Conference, Milan, Italy, 19–22 September 2022; pp. 324–327. [Google Scholar] [CrossRef]

- Amir, W.; Shin, J.W.; Shin, K.Y.; Chakraborty, S.; Cho, C.Y.; Kim, J.M.; Lee, S.T.; Hoshi, T.; Tsutsumi, T.; Sugiyama, H.; et al. Performance Enhancement of AlGaN/GaN HEMT via Trap-State Improvement Using O2 Plasma Treatment. IEEE Trans. Electron. Devices 2023, 70, 2988–2993. [Google Scholar] [CrossRef]

- Boutchacha, T.; Ghibaudo, G.; Guégan, G.; Haond, M. Low Frequency Noise Characterization of 0.25 Μm Si CMOS Transistors. J. Non-Cryst. Solids 1997, 216, 192–197. [Google Scholar] [CrossRef]

- Han, I.S.; Kwon, H.M.; Bok, J.D.; Kwon, S.K.; Jung, Y.J.; Choi, W.I.; Choi, D.S.; Lim, M.G.; Chung, Y.S.; Lee, J.H.; et al. Effect of Nitrogen Concentration on Low-Frequency Noise and Negative Bias Temperature Instability of p-Channel Metal-Oxide-Semiconductor Field-Effect Transistors with Nitrided Gate Oxide. Jpn. J. Appl. Phys. 2011, 50, 10PB03. [Google Scholar] [CrossRef]

- Hooge, F.N.; Kleinpenning, T.G.M.; Vandamme, L.K.J. Experimental Studies on 1/f Noise. Rep. Prog. Phys. 1981, 44, 479. [Google Scholar] [CrossRef]

- Vandamme, L.K.J.; Hooge, F.N. On the Additivity of Generation-Recombination Spectra Part 3: The McWhorter Model for 1/f Noise in MOSFETs. Phys. B Condens. Matter 2005, 357, 507–524. [Google Scholar] [CrossRef]

- Amir, W.; Shin, J.W.; Shin, K.Y.; Kim, J.M.; Cho, C.Y.; Park, K.H.; Hoshi, T.; Tsutsumi, T.; Sugiyama, H.; Matsuzaki, H.; et al. A Quantitative Approach for Trap Analysis between Al0.25Ga0.75N and GaN in High Electron Mobility Transistors. Sci. Rep. 2021, 11, 22401. [Google Scholar] [CrossRef]

- Ghibaudo, G.; Roux, O.; Nguyen-Duc, C.; Balestra, F.; Brini, J. Improved Analysis of Low Frequency Noise in Field-Effect MOS Transistors. Phys. Status Solidi (A) 1991, 124, 571–581. [Google Scholar] [CrossRef]

- Viktorovitch, P.; Rojo-Romeo, P.; Leclercq, J.L.; Letartre, X.; Tardy, J.; Oustric, M.; Gendry, M. Low Frequency Noise Sources in InAlAs/InGaAs MODFET’s. IEEE Trans. Electron. Devices 1996, 43, 2085–2100. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shin, K.-Y.; Shin, J.-W.; Amir, W.; Chakraborty, S.; Shim, J.-P.; Lee, S.-T.; Jang, H.; Shin, C.-S.; Kwon, H.-M.; Kim, T.-W. Effect of Trap Behavior on the Reliability Instability of Metamorphic Buffer in InAlAs/InGaAs MHEMT on GaAs. Materials 2023, 16, 6138. https://doi.org/10.3390/ma16186138

Shin K-Y, Shin J-W, Amir W, Chakraborty S, Shim J-P, Lee S-T, Jang H, Shin C-S, Kwon H-M, Kim T-W. Effect of Trap Behavior on the Reliability Instability of Metamorphic Buffer in InAlAs/InGaAs MHEMT on GaAs. Materials. 2023; 16(18):6138. https://doi.org/10.3390/ma16186138

Chicago/Turabian StyleShin, Ki-Yong, Ju-Won Shin, Walid Amir, Surajit Chakraborty, Jae-Phil Shim, Sang-Tae Lee, Hyunchul Jang, Chan-Soo Shin, Hyuk-Min Kwon, and Tae-Woo Kim. 2023. "Effect of Trap Behavior on the Reliability Instability of Metamorphic Buffer in InAlAs/InGaAs MHEMT on GaAs" Materials 16, no. 18: 6138. https://doi.org/10.3390/ma16186138

APA StyleShin, K.-Y., Shin, J.-W., Amir, W., Chakraborty, S., Shim, J.-P., Lee, S.-T., Jang, H., Shin, C.-S., Kwon, H.-M., & Kim, T.-W. (2023). Effect of Trap Behavior on the Reliability Instability of Metamorphic Buffer in InAlAs/InGaAs MHEMT on GaAs. Materials, 16(18), 6138. https://doi.org/10.3390/ma16186138