Printing, Debinding and Sintering of 15-5PH Stainless Steel Components by Fused Deposition Modeling Additive Manufacturing

Abstract

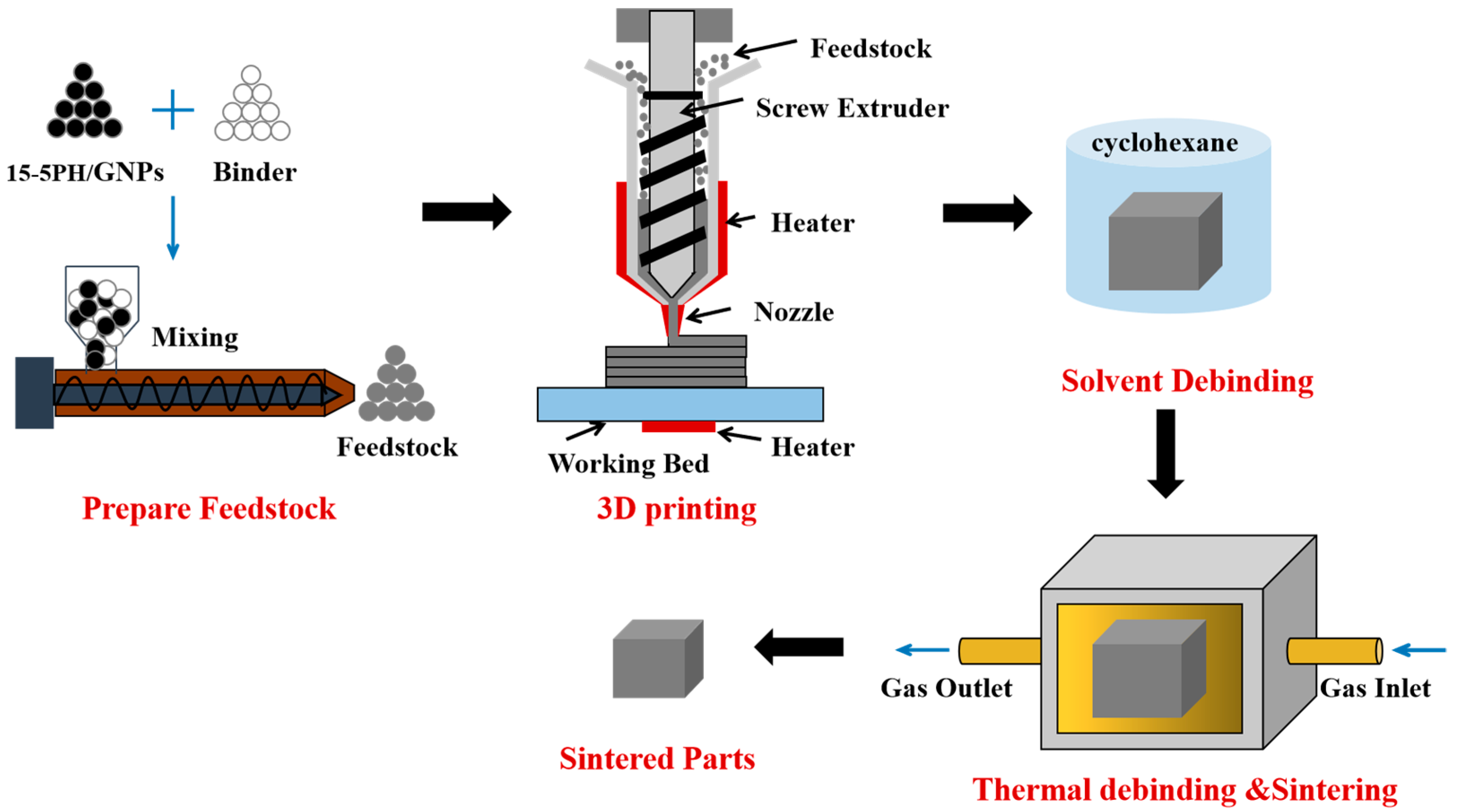

:1. Introduction

2. Experimental Details

2.1. Materials and Preparation of Feedstock

2.2. 3D Printing

2.3. Debinding and Sintering

2.4. Characterization and Test

3. Results and Discussion

3.1. Feedstock Characterization and 3D Printing

3.2. Solvent and Thermal Debinding

3.3. Sintered Parts: Shrinkage, Relative Density, Microstructure and Mechanical Properties

4. Conclusions

- The 15-5PH stainless steel powder is evenly distributed in the granules without agglomeration. The MFR of the granule materials is sensitive to temperature changes, and the fluidity of the granules is the best at 285 °C. The selection of the nozzle diameter and the adaptability of the printer to the viscosity of granules are key to successful printing. The condition of the fan at the nozzle determines the surface quality of the part. The optimum printing parameters are a nozzle diameter 0.8 mm, an extrusion multiplier 180% and the fan shut off at the nozzle.

- Solvent debinding removes soluble components from green parts and provides a pathway for gas diffusion during the thermal debinding process. The solvent debinding rate increases continuously with increasing debinding temperature and time. The debinding rate reaches its maximum at a temperature of 75 °C for 24 h, which is 98.7%. At the same temperature, the debinding rate increment gradually decreases and eventually stabilizes over time. During the thermal debinding process, sintering necks form between the metal powders, preserving the part’s structural integrity. All of the binder was removed and the weight loss was about 10% after debinding.

- The relative density of sintered parts experiences a steady rise with increasing sintering temperature, progressing from 87.26% at 1300 °C to 95.83% at 1390 °C. The microstructure indicates that the parts sintered at 1300 °C contain many pores with large sizes. And the number and size of pores decrease significantly at 1390 °C. The dimensional shrinkage of the sintered parts remains uniform in the X-Y-Z directions. The shrinkage amplifies as the sintering temperature rises, with the range of shrinkage varying from 13.26% to 19.58% within the temperature range of 1300 °C to 1390 °C.

- The hardness and tensile strength of sintered parts increase with increasing temperature, which is mainly related to the density of the part. The hardness of the sintered parts is 87.48 ± 1.03 HRBW at 1300 °C, and it does not change significantly between 1375 °C and 1390 °C. The tensile strength of the sintered parts increases from 567.53 MPa at 1300 °C to 770 MPa at 1390 °C, an increase of 35.68%. The fracture surface of the sintered parts at 1300 °C shows many dissociated sections, while the fracture surface at 1390 °C shows many dimples. The 15-5PH steel parts show brittle fracture with almost no plastic deformation.

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nurhudan, A.I.; Supriadi, S.; Whulanza, Y.; Saragih, A.S. Additive manufacturing of metallic based on extrusion process: A review. J. Manuf. Process. 2021, 66, 228–237. [Google Scholar] [CrossRef]

- Gonzalez-Gutierrez, J.; Cano, S.; Schuschnigg, S.; Kukla, C.; Sapkota, J.; Holzer, C. Additive Manufacturing of Metallic and Ceramic Components by the Material Extrusion of Highly-Filled Polymers: A Review and Future Perspectives. Materials 2018, 11, 840. [Google Scholar] [CrossRef]

- Han, Y.; Zhang, Y.; Jing, H.; Lin, D.; Zhao, L.; Xu, L.; Xin, P. Selective laser melting of low-content graphene nanoplatelets reinforced 316L austenitic stainless steel matrix: Strength enhancement without affecting ductility. Addit. Manuf. 2020, 34, 101381. [Google Scholar] [CrossRef]

- Dong, M.; Zhou, W.; Kamata, K.; Nomura, N. Microstructure and mechanical property of graphene oxide/AlSi10Mg composites fabricated by laser additive manufacturing. Mater. Charact. 2020, 170, 110678. [Google Scholar] [CrossRef]

- Ahmadi, M.; Tabary, S.B.; Rahmatabadi, D.; Ebrahimi, M.; Abrinia, K.; Hashemi, R. Review of selective laser melting of magnesium alloys: Advantages, microstructure and mechanical characterizations, defects, challenges, and applications. J. Mater. Res. Technol. 2022, 19, 1537–1562. [Google Scholar] [CrossRef]

- Tong, Q.; Xue, K.; Wang, T.; Yao, S. Laser sintering and invalidating composite scan for improving tensile strength and accuracy of SLS parts. J. Manuf. Process. 2020, 56, 1–11. [Google Scholar] [CrossRef]

- Olakanmi, E.O.T.; Cochrane, R.F.; Dalgarno, K.W. A review on selective laser sintering/melting (SLS/SLM) of aluminium alloy powders: Processing, microstructure, and properties. Prog. Mater. Sci. 2015, 74, 401–477. [Google Scholar] [CrossRef]

- Murr, L.E.; Gaytan, S.M.; Ramirez, D.A.; Martinez, E.; Hernandez, J.; Amato, K.N.; Shindo, P.W.; Medina, F.R.; Wicker, R.B. Metal Fabrication by Additive Manufacturing Using Laser and Electron Beam Melting Technologies. J. Mater. Sci. Technol. 2012, 28, 1–14. [Google Scholar] [CrossRef]

- Gong, H.; Snelling, D.; Kardel, K.; Carrano, A. Comparison of Stainless Steel 316L Parts Made by FDM- and SLM-Based Additive Manufacturing Processes. JOM 2018, 71, 880–885. [Google Scholar] [CrossRef]

- Santos, E.C.; Shiomi, M.; Osakada, K.; Laoui, T. Rapid manufacturing of metal components by laser forming. Int. J. Mach. Tools Manuf. 2006, 46, 1459–1468. [Google Scholar] [CrossRef]

- Huber, D.; Vogel, L.; Fischer, A. The effects of sintering temperature and hold time on densification, mechanical properties and microstructural characteristics of binder jet 3D printed 17-4 PH stainless steel. Addit. Manuf. 2021, 46, 14. [Google Scholar] [CrossRef]

- Wang, J.; Pan, Z.; Wang, Y.; Wang, L.; Su, L.; Cuiuri, D.; Zhao, Y.; Li, H. Evolution of crystallographic orientation, precipitation, phase transformation and mechanical properties realized by enhancing deposition current for dual-wire arc additive manufactured Ni-rich NiTi alloy. Addit. Manuf. 2020, 34, 101240. [Google Scholar] [CrossRef]

- Azami, M.; Siahsarani, A.; Hadian, A.; Kazemi, Z.; Rahmatabadi, D.; Kashani-Bozorg, S.F.; Abrinia, K. Laser powder bed fusion of Alumina/Fe–Ni ceramic matrix particulate composites impregnated with a polymeric resin. J. Mater. Res. Technol. 2023, 24, 3133–3144. [Google Scholar] [CrossRef]

- Carpenter, K.; Tabei, A. On Residual Stress Development, Prevention, and Compensation in Metal Additive Manufacturing. Materials 2020, 13, 255. [Google Scholar] [CrossRef] [PubMed]

- Mirsayar, M. A generalized criterion for fatigue crack growth in additively manufactured materials—Build orientation and geometry effects. Int. J. Fatigue 2021, 145, 106099. [Google Scholar] [CrossRef]

- Kok, Y.; Tan, X.; Wang, P.; Nai, M.; Loh, N.; Liu, E.; Tor, S. Anisotropy and heterogeneity of microstructure and mechanical properties in metal additive manufacturing: A critical review. Mater. Des. 2018, 139, 565–586. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual Stress in Metal Additive Manufacturing. In Proceedings of the 4th CIRP Conference on Surface Integrity (CSI), Tianjin, China, 11–13 July 2018; pp. 348–353. [Google Scholar]

- Safarian, A.; Subaşi, M.; Karataş, C. The effect of sintering parameters on diffusion bonding of 316L stainless steel in inserted metal injection molding. Int. J. Adv. Manuf. Technol. 2017, 89, 2165–2173. [Google Scholar] [CrossRef]

- Choi, J.-P.; Lee, G.-Y.; Song, J.-I.; Lee, W.-S.; Lee, J.-S. Sintering behavior of 316L stainless steel micro–nanopowder compact fabricated by powder injection molding. Powder Technol. 2015, 279, 196–202. [Google Scholar] [CrossRef]

- Thompson, Y.; Gonzalez-Gutierrez, J.; Kukla, C.; Felfer, P. Fused filament fabrication, debinding and sintering as a low cost additive manufacturing method of 316L stainless steel. Addit. Manuf. 2019, 30, 8. [Google Scholar] [CrossRef]

- Sadaf, M.; Bragaglia, M.; Nanni, F. A simple route for additive manufacturing of 316L stainless steel via Fused Filament Fabrication. J. Manuf. Process. 2021, 67, 141–150. [Google Scholar] [CrossRef]

- Liu, B.; Wang, Y.; Lin, Z.; Zhang, T. Creating metal parts by Fused Deposition Modeling and Sintering. Mater. Lett. 2020, 263, 4. [Google Scholar] [CrossRef]

- Singh, G.; Missiaen, J.-M.; Bouvard, D.; Chaix, J.-M. Copper extrusion 3D printing using metal injection moulding feedstock: Analysis of process parameters for green density and surface roughness optimization. Addit. Manuf. 2020, 38, 15. [Google Scholar] [CrossRef]

- Singh, G.; Missiaen, J.-M.; Bouvard, D.; Chaix, J.-M. Additive manufacturing of 17–4 PH steel using metal injection molding feedstock: Analysis of 3D extrusion printing, debinding and sintering. Addit. Manuf. 2021, 47, 102287. [Google Scholar] [CrossRef]

- Kluczyński, J.; Jasik, K.; Łuszczek, J.; Sarzyński, B.; Grzelak, K.; Dražan, T.; Joska, Z.; Szachogłuchowicz, I.; Płatek, P.; Małek, M. A Comparative Investigation of Properties of Metallic Parts Additively Manufactured through MEX and PBF-LB/M Technologies. Materials 2023, 16, 5200. [Google Scholar] [CrossRef] [PubMed]

- Santamaria, R.; Wang, K.; Salasi, M.; Iannuzzi, M.; Mendoza, M.Y.; Quadir, Z. Stress Corrosion Cracking of 316L Stainless Steel Additively Manufactured with Sinter-Based Material Extrusion. Materials 2023, 16, 4006. [Google Scholar] [CrossRef] [PubMed]

- Sargini, M.I.M.; Masood, S.H.; Palanisamy, S.; Jayamani, E.; Kapoor, A. Additive manufacturing of an automotive brake pedal by metal fused deposition modelling. In Proceedings of the 2nd International Conference on Aspects of Materials Science and Engineering (ICAMSE), Chandigarh, India, 5–6 March 2021; pp. 4601–4605. [Google Scholar]

- Gonzalez-Gutierrez, J.; Arbeiter, F.; Schlauf, T.; Kukla, C.; Holzer, C. Tensile properties of sintered 17-4PH stainless steel fabricated by material extrusion additive manufacturing. Mater. Lett. 2019, 248, 165–168. [Google Scholar] [CrossRef]

- Godec, D.; Cano, S.; Holzer, C.; Gonzalez-Gutierrez, J. Optimization of the 3D Printing Parameters for Tensile Properties of Specimens Produced by Fused Filament Fabrication of 17-4PH Stainless Steel. Materials 2020, 13, 774. [Google Scholar] [CrossRef]

- Ecker, J.V.; Dobrezberger, K.; Gonzalez-Gutierrez, J.; Spoerk, M.; Gierl-Mayer, C.; Danninger, H. Additive Manufacturing of Steel and Copper Using Fused Layer Modelling: Material and Process Development. Powder Met. Prog. 2019, 19, 63–81. [Google Scholar] [CrossRef]

- Ren, L.; Zhou, X.; Song, Z.; Zhao, C.; Liu, Q.; Xue, J.; Li, X. Process Parameter Optimization of Extrusion-Based 3D Metal Printing Utilizing PW–LDPE–SA Binder System. Materials 2017, 10, 305. [Google Scholar] [CrossRef]

- Lengauer, W.; Duretek, I.; Fürst, M.; Schwarz, V.; Gonzalez-Gutierrez, J.; Schuschnigg, S.; Kukla, C.; Kitzmantel, M.; Neubauer, E.; Lieberwirth, C.; et al. Fabrication and properties of extrusion-based 3D-printed hardmetal and cermet components. Int. J. Refract. Met. Hard Mater. 2019, 82, 141–149. [Google Scholar] [CrossRef]

- Singh, P.; Balla, V.K.; Tofangchi, A.; Atre, S.V.; Kate, K.H. Printability studies of Ti-6Al-4V by metal fused filament fabrication (MF3). Int. J. Refract. Met. Hard Mater. 2020, 91, 105249. [Google Scholar] [CrossRef]

- Eickhoff, R.; Antusch, S.; Nötzel, D.; Hanemann, T. New Partially Water-Soluble Feedstocks for Additive Manufacturing of Ti6Al4V Parts by Material Extrusion. Materials 2023, 16, 3162. [Google Scholar] [CrossRef] [PubMed]

- Bose, A.; Reidy, J.P.; Tuncer, N.; Jorgensen, L. Processing of tungsten heavy alloy by extrusion-based additive manufacturing. Int. J. Refract. Met. Hard Mater. 2023, 110, 11. [Google Scholar] [CrossRef]

- Li, S.; Deng, H.; Lan, X.; He, B.; Li, X.; Wang, Z. Developing cost-effective indirect manufacturing of H13 steel from extrusion-printing to post-processing. Addit. Manuf. 2023, 62, 14. [Google Scholar] [CrossRef]

- Palmero, E.M.; Casaleiz, D.; de Vicente, J.; Hernández-Vicen, J.; López-Vidal, S.; Ramiro, E.; Bollero, A. Composites based on metallic particles and tuned filling factor for 3D-printing by Fused Deposition Modeling. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105497. [Google Scholar] [CrossRef]

- Vetter, J.; Huber, F.; Wachter, S.; Körner, C.; Schmidt, M. Development of a Material Extrusion Additive Manufacturing Process of 1.2083 steel comprising FFF Printing, Solvent and Thermal Debinding and Sintering. Procedia CIRP 2022, 113, 341–346. [Google Scholar] [CrossRef]

- Cano, S.; Gonzalez-Gutierrez, J.; Sapkota, J.; Spoerk, M.; Arbeiter, F.; Schuschnigg, S.; Holzer, C.; Kukla, C. Additive manufacturing of zirconia parts by fused filament fabrication and solvent debinding: Selection of binder formulation. Addit. Manuf. 2019, 26, 117–128. [Google Scholar] [CrossRef]

- Kukla, C.; Cano, S.; Kaylani, D.; Schuschnigg, S.; Holzer, C.; Gonzalez-Gutierrez, J. Debinding behaviour of feedstock for material extrusion additive manufacturing of zirconia. Powder Met. 2019, 62, 196–204. [Google Scholar] [CrossRef]

- Tapoglou, N.; Clulow, J.; Patterson, A.; Curtis, D. Characterisation of mechanical properties of 15-5PH stainless steel manufactured through direct energy deposition. CIRP J. Manuf. Sci. Technol. 2022, 38, 172–185. [Google Scholar] [CrossRef]

- Jiang, J.; Zhang, X.; Ma, F.; Dong, S.; Yang, W.; Wu, M.; Chang, G.; Xu, L.; Zhang, C.; Luo, F. Novel phenomena of graphene secondary dispersion and phase transformation in selective laser melting of 15-5PH/graphene composites. Addit. Manuf. 2021, 47, 102207. [Google Scholar] [CrossRef]

- Nong, X.; Zhou, X. Effect of scanning strategy on the microstructure, texture, and mechanical properties of 15-5PH stainless steel processed by selective laser melting. Mater. Charact. 2021, 174, 111012. [Google Scholar] [CrossRef]

- Chen, W.; Xu, L.; Hao, K.; Zhang, Y.; Zhao, L.; Han, Y.; Liu, Z.; Cai, H. Effect of heat treatment on microstructure and performances of additively manufactured 15-5PH stainless steel. Opt. Laser Technol. 2023, 157, 11. [Google Scholar] [CrossRef]

- Wagner, M.A.; Hadian, A.; Sebastian, T.; Clemens, F.; Schweizer, T.; Rodriguez-Arbaizar, M.; Carreño-Morelli, E.; Spolenak, R. Fused filament fabrication of stainless steel structures—from binder development to sintered properties. Addit. Manuf. 2022, 49, 102472. [Google Scholar] [CrossRef]

- Riaz, A.; Töllner, P.; Ahrend, A.; Springer, A.; Milkereit, B.; Seitz, H. Optimization of composite extrusion modeling process parameters for 3D printing of low-alloy steel AISI 8740 using metal injection moulding feedstock. Mater. Des. 2022, 219, 110814. [Google Scholar] [CrossRef]

- Ji, C.; Loh, N.; Khor, K.; Tor, S. Sintering study of 316L stainless steel metal injection molding parts using Taguchi method: Final density. Mater. Sci. Eng. A 2001, 311, 74–82. [Google Scholar] [CrossRef]

| Elements | C | Si | Mn | S | P | Cr | Ni | Cu | Nb | Fe |

|---|---|---|---|---|---|---|---|---|---|---|

| ASTM | ≤0.07 | ≤1.00 | ≤1.00 | ≤0.015 | ≤0.03 | 14.0–15.5 | 3.5–5.5 | 2.5–4.5 | 0.15–0.45 | Bal |

| 15-5PH | 0.015 | 0.59 | 0.52 | 0.004 | 0.03 | 15.22 | 3.98 | 3.85 | 0.35 | Bal |

| Feedstock | 15-5PH Powder | TPE | MAH-g-PP |

|---|---|---|---|

| Content (wt.%) | 90 | 7 | 3 |

| Green Part mass/g | Solvent Debinding/(Δm,%) | Thermal Debinding/(Δm,%) | Total/(Δm,%) |

|---|---|---|---|

| 10.7822 | 6.91% | 3.16% | 10.07% |

| 10.7069 | 6.91% | 3.19% | 10.10% |

| 10.6765 | 6.86% | 3.17% | 10.03% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chang, G.; Zhang, X.; Ma, F.; Zhang, C.; Xu, L. Printing, Debinding and Sintering of 15-5PH Stainless Steel Components by Fused Deposition Modeling Additive Manufacturing. Materials 2023, 16, 6372. https://doi.org/10.3390/ma16196372

Chang G, Zhang X, Ma F, Zhang C, Xu L. Printing, Debinding and Sintering of 15-5PH Stainless Steel Components by Fused Deposition Modeling Additive Manufacturing. Materials. 2023; 16(19):6372. https://doi.org/10.3390/ma16196372

Chicago/Turabian StyleChang, Gaoyuan, Xiaoxun Zhang, Fang Ma, Cheng Zhang, and Luyang Xu. 2023. "Printing, Debinding and Sintering of 15-5PH Stainless Steel Components by Fused Deposition Modeling Additive Manufacturing" Materials 16, no. 19: 6372. https://doi.org/10.3390/ma16196372

APA StyleChang, G., Zhang, X., Ma, F., Zhang, C., & Xu, L. (2023). Printing, Debinding and Sintering of 15-5PH Stainless Steel Components by Fused Deposition Modeling Additive Manufacturing. Materials, 16(19), 6372. https://doi.org/10.3390/ma16196372