Prediction of Crack Width in RC Piles Exposed to Local Corrosion in Chloride Environment

Abstract

:1. Introduction

2. Localized Corrosion Modeling

2.1. Geometry Model

2.2. Modeling of Corrosion Pits

2.3. Analysis of Crack Width

3. Analysis Results

4. Discussion

5. Conclusions

- (1)

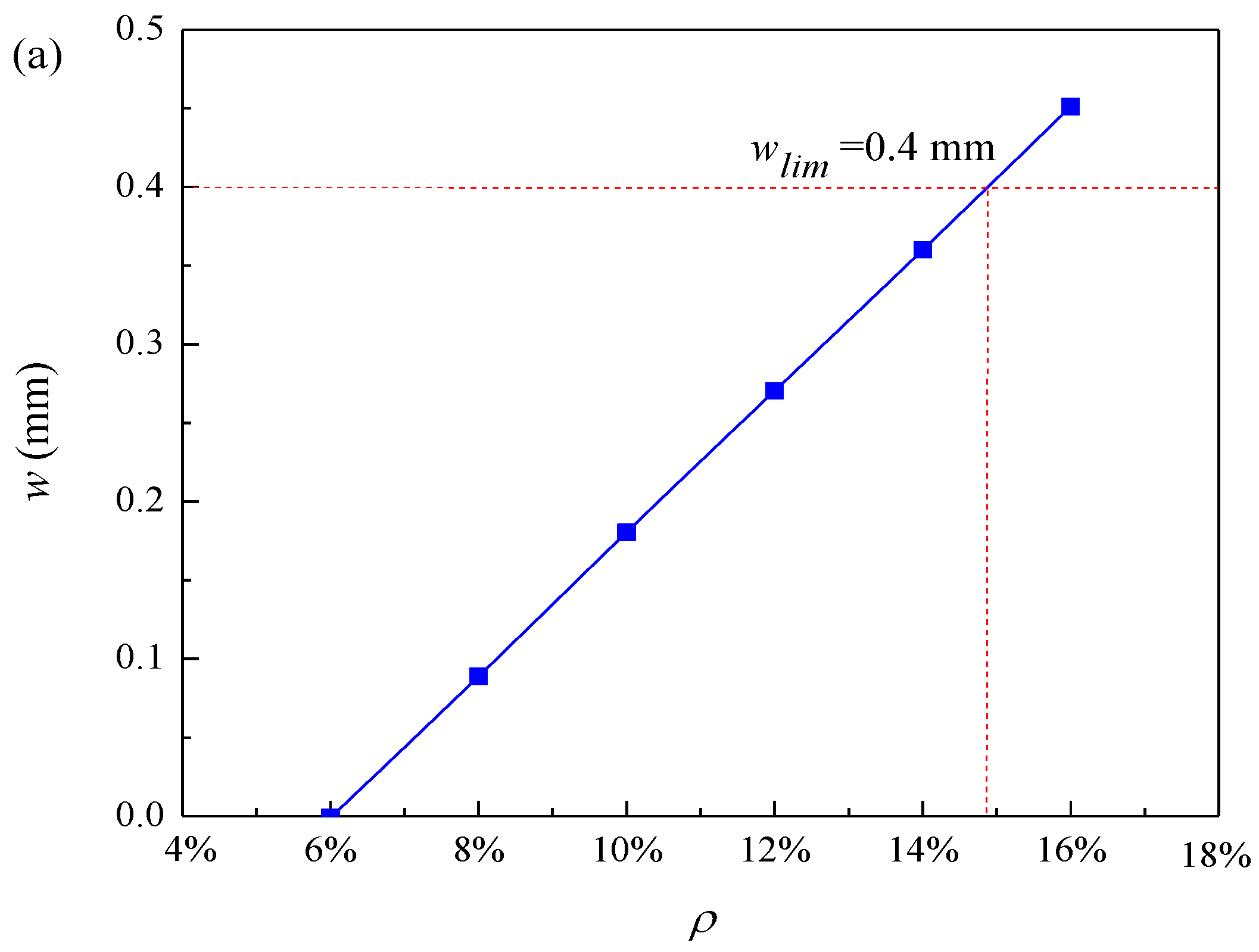

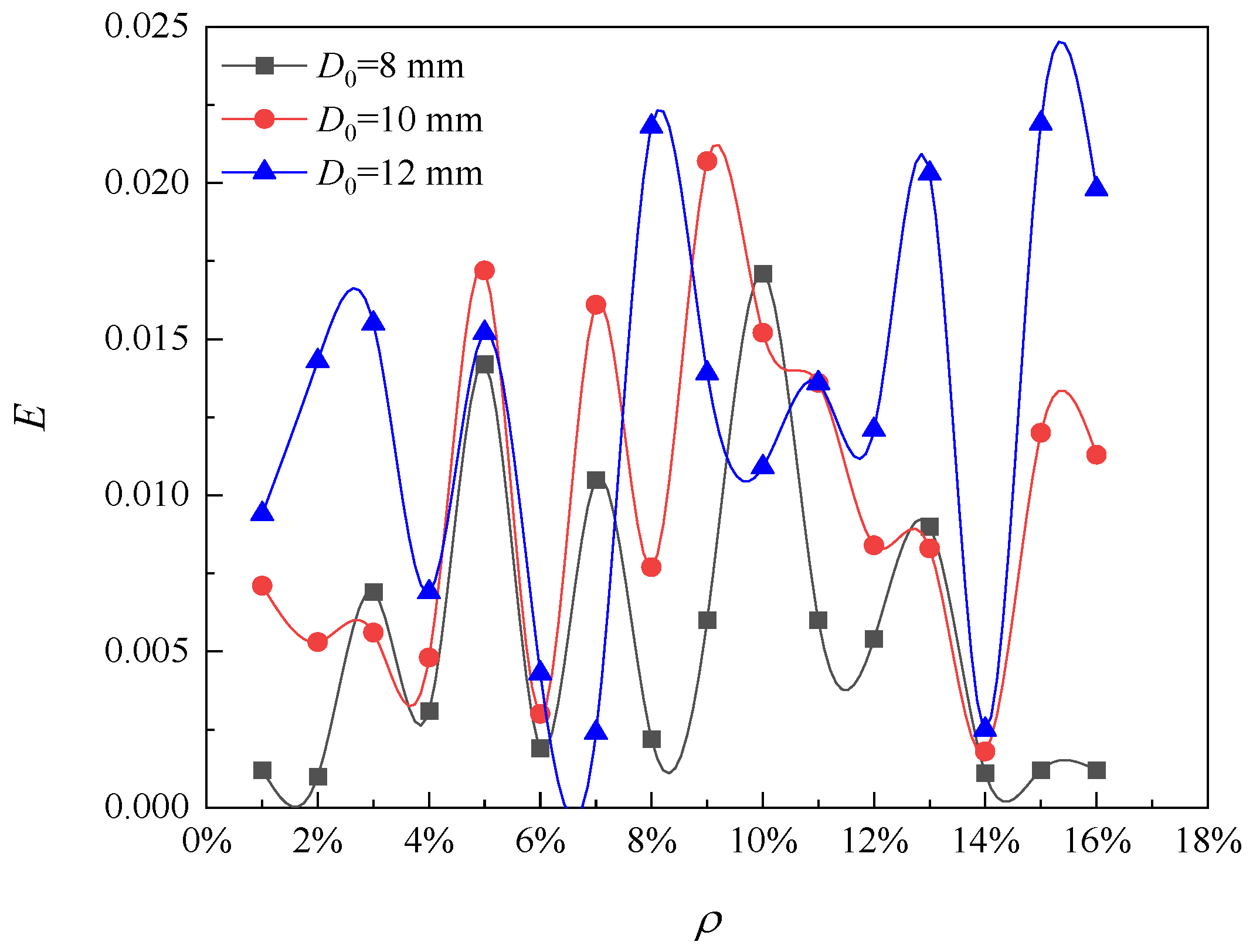

- The radius of the corrosion pit, loss of cross-sectional area of reinforcement, and corrosion pit depth increase as the corrosion level increases. The corrosion depth decreases with the increase in pitting factor and increases with the increase in corrosion pit radius and initial diameter of steel bars. The crack width decreases with the increase in pitting factor and protective layer thickness. During the initial period of the crack, the development rate of corrosion pits is relatively fast, but before reaching the limit crack, the development of the corrosion pits becomes slow.

- (2)

- The required pit depth for reinforcement cracking increases with the increase in the ratio of concrete cover thickness to diameter. The loss of the cross-sectional area of reinforcement and the radius of the corrosion pit increase with the increase in the initial diameter of reinforcement. The loss of the local reinforcement section at the beginning of reinforcement cracking increases with the increase in the ratio of concrete cover thickness to initial diameter and increases with the increase in the pitting factor.

- (3)

- According to the limit crack criterion, the maximum corrosion degree of the reinforced concrete pile is about 15%. The error caused by the discrete method can be ignored. The above analysis results are obtained without considering the influence of concrete characteristics on steel section loss.

- (4)

- The prediction of the durability life of chloride ion corroded piles under the assumption of uniform corrosion is too conservative. In fact, the predicted durability life based on the assumption of uniform corrosion only indicates the beginning of corrosion, and the pile has not yet been adversely affected by the potential inhibition of its function and performance. In order to more accurately predict the time when the crack reaches the limit crack, the durability prediction of piles should be carried out under the assumption of local corrosion, rather than uniform corrosion. When evaluating the durability life of RC piles in actual service, engineers should pay more attention to the local corrosion on the surface of RC piles. This paper proposes a new method to predict the cracking of concrete piles by localized corrosion of chloride in the marine environment. However, the impact of different shapes and spatial distributions of corrosion pits on crack width is currently unclear. If advanced corrosion pit identification technology can be combined to study the impact of different shapes and spatial distributions of corrosion pits on the development of crack width, it will provide effective measures for the durability evaluation of future RC structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhao, Y.X.; Wu, Y.Y.; Jin, W.L. Distribution of millscale on corroded steel bars and penetration of steel corrosion products in concrete. Corros. Sci. 2013, 66, 160–168. [Google Scholar] [CrossRef]

- Chao, Z.M.; Dang, Y.B.; Pan, Y.; Wang, F.Y.; Wang, M.; Zhang, J.; Yang, C.X. Prediction of the shale gas permeability: A data mining approach. Geomech. Energy Environ. 2023, 33, 100435. [Google Scholar] [CrossRef]

- Jang, B.S.; Oh, B.H. Effects of non-uniform corrosion on the cracking and service life of reinforced concrete structures. Cem. Concr. Res. 2010, 40, 1441–1450. [Google Scholar] [CrossRef]

- Cao, C. 3D simulation of localized steel corrosion in chloride contaminated reinforced concrete. Constr. Build. Mater. 2014, 72, 434–443. [Google Scholar] [CrossRef]

- Chen, E.; Berrocal, C.G.; Fernandez, I.; Löfgren, I.; Lundgren, K. Assessment of the mechanical behaviour of reinforcement bars with localized pitting corrosion by digital image correlation. Eng. Struct. 2020, 219, 110936. [Google Scholar] [CrossRef]

- Moreno, E.; Cobo, A.; Palomo, G.; González, N. Mathematical models to predict the mechanical behavior of reinforcements depending on their degree of corrosion and the diameter of the rebars. Constr. Build. Mater. 2014, 61, 156–163. [Google Scholar] [CrossRef]

- Tang, F.J.; Lin, Z.B.; Chen, G.D.; Yi, W.J. Three-dimensional corrosion pit measurement and statistical mechanical degradation analysis of deformed steel bars subjected to accelerated corrosion. Constr. Build Mater. 2014, 70, 104–117. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Z.G.; Zhang, R.B.; Du, X.L. Mesoscopic simulation on flexural behavior of single-way reinforced concrete slab with rebars subjected to localized corrosion. Structures 2021, 31, 815–827. [Google Scholar]

- Xia, N.; Ren, Q.W.; Liang, R.Y.; Payer, J.; Patnaik, A. Nonuniform corrosion-induced stresses in steel-reinforced concrete. J. Eng. Mech. 2012, 138, 338–346. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Hu, B.Y.; Yu, J.; Jin, W.L. Non-uniform distribution of rust layer around steel bar in concrete. Corros. Sci. 2011, 53, 4300–4308. [Google Scholar] [CrossRef]

- Kim, C.-Y.; Kim, J.-K. Numerical analysis of localized steel corrosion in concrete. Constr. Build. Mater. 2008, 22, 1129–1136. [Google Scholar] [CrossRef]

- Li, D.W.; Ren, W.; Li, L.; Guan, X.T.; Mi, X.M. Pitting corrosion of reinforcing steel bars in chloride contaminated concrete. Constr. Build. Mater. 2019, 199, 359–368. [Google Scholar] [CrossRef]

- Darowicki, K.; Mirakowski, A.; Krakowiak, S. Investigation of pitting corrosion of stainless steel by means of acoustic emission and potentiodynamic methods. Corros. Sci. 2003, 45, 1747–1756. [Google Scholar] [CrossRef]

- Kioumarsi, M.M.; Hendriks, M.A.N.; Kohler, J.; Geiker, M.R. The effect of interference of corrosion pits on the failure probability of a reinforced concrete beam. Eng. Struct. 2016, 114, 113–121. [Google Scholar] [CrossRef]

- Vidal, T.; Castel, A.; François, R. Analyzing crack width to predict corrosion in reinforced concrete. Cem. Concr. Res. 2004, 34, 165–174. [Google Scholar] [CrossRef]

- Zhang, W.B.; Shi, D.D.; Shen, Z.Z.; Zhang, J.; Zhao, S.; Gan, L.; Li, Q.M.; Chen, Y.S.; Tang, P. Influence of chopped basalt fibers on the fracture performance of concrete subjected to calcium leaching. Theor. Appl. Fract. Mech. 2023, 125, 103934. [Google Scholar] [CrossRef]

- Zhang, R.J.; Castel, A.; François, R. Concrete cover cracking with reinforcement corrosion of RC beam during chloride-induced corrosion process. Cem. Concr. Res. 2010, 40, 415–425. [Google Scholar] [CrossRef]

- Li, C.Q.; Lawanwisut, W.; Zheng, J.J.; Kijawatworawet, W. Crack width due to corroded bar in reinforced concrete structures. Int. J. Mater. Struct. Reliab. 2005, 3, 87–94. [Google Scholar]

- Zhao, Y.X.; Yu, J.; Jin, W.L. Damage analysis and cracking model of reinforced concrete structures with rebar corrosion. Corros. Sci. 2011, 53, 3388–3397. [Google Scholar] [CrossRef]

- Shao, W.; He, X.Q.; Shi, D.D. Durability life prediction of RC piles subjected to localized corrosion in chloride environments. Eng. Fail. Anal. 2022, 136, 106184. [Google Scholar] [CrossRef]

- Guzmán, S.; Gálvez, J.C. Modelling of concrete cover cracking due to non-uniform corrosion of reinforcing steel. Constr. Build. Mater. 2017, 155, 1063–1071. [Google Scholar] [CrossRef]

- Eliass, E.A.; Fekak, F.E.; Garibaldi, L.; Ahmed, E. A numerical study of pitting corrosion in reinforced concrete structures. J. Build. Eng. 2021, 43, 102789. [Google Scholar]

- Sun, J.; Ding, Z.H.; Huang, Q. Corrosion fatigue life prediction for steel bar in concrete based on fatigue crack propagation and equivalent initial flaw size. Constr. Build. Mater. 2019, 195, 208–217. [Google Scholar] [CrossRef]

- Alonso, C.; Andrade, C.; Rodriguez, J.; Diez, J.M. Factors controlling cracking of concrete affected by reinforcement corrosion. Mater. Struct. 1998, 31, 435–441. [Google Scholar] [CrossRef]

- Stewart, M.G.; Mullard, J.A. Spatial time-dependent reliability analysis of corrosion damage and the timing of first repair for RC structures. Eng. Struct. 2007, 29, 1457–1464. [Google Scholar] [CrossRef]

- Stewart, M.G. Spatial variability of pitting corrosion and its influence on structural fragility and reliability of RC beams in flexure. Struct. Saf. 2004, 26, 453–470. [Google Scholar] [CrossRef]

- Zhao, Y.X.; Karimi, A.R.; Wong, H.S.; Hu, B.Y.; Buenfeld, N.R.; Jin, W.L. Comparison of uniform and non-uniform corrosion induced damage in reinforced concrete based on a Gaussian description of the corrosion layer. Corros. Sci. 2011, 53, 2803–2814. [Google Scholar] [CrossRef]

- Shao, W.; Nie, Y.H.; Liang, F.Y.; Shi, D.D. A novel comprehensive evaluation method for the corrosion initiation life of RC hollow piles in chloride environments. Constr. Build. Mater. 2020, 249, 118801. [Google Scholar] [CrossRef]

| Parameters | Unit | Values | Description | Reference |

|---|---|---|---|---|

| a | mm | 190 | Inner radius of pile | - |

| b | mm | 300 | Outer radius of pile | - |

| D0 | mm | 10 | Initial diameter of steel bar | - |

| c | mm | 50 | Concrete cover thickness | - |

| wlim | mm | 0.4 | Limit crack width | [25] |

| α | - | 5.65 | Pitting factor | [15] |

| K | - | 0.0575 | Slope of curve | [26] |

| α | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|

| ρ | ||||||

| 6% | 76.20 | 60.97 | 50.81 | 43.55 | 38.10 | |

| 7% | 88.82 | 71.06 | 59.21 | 50.75 | 44.41 | |

| 8% | 101.96 | 81.57 | 67.97 | 58.26 | 50.98 | |

| 9% | 115.50 | 92.40 | 76.99 | 66.00 | 57.75 | |

| α | 4 | 5 | 6 | 7 | 8 | |

|---|---|---|---|---|---|---|

| ρ | ||||||

| 6% | 0.08 | 0.03 | - | - | - | |

| 7% | 0.12 | 0.07 | 0.03 | - | - | |

| 8% | 0.16 | 0.12 | 0.07 | 0.03 | - | |

| 9% | 0.21 | 0.17 | 0.12 | 0.07 | 0.03 | |

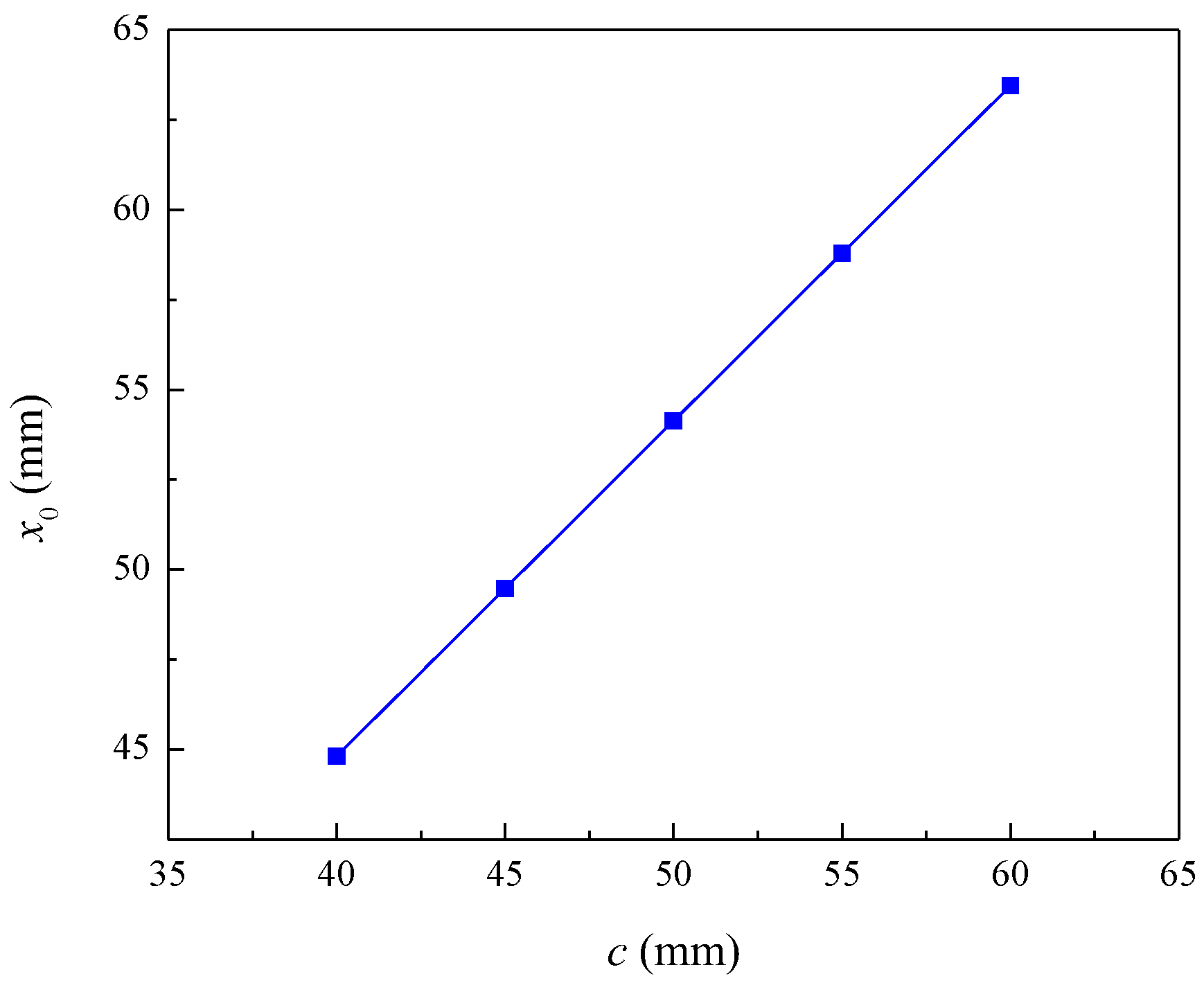

| c | 40 | 45 | 50 | 55 | 60 | |

|---|---|---|---|---|---|---|

| ρ | ||||||

| 6% | 0.05 | 0.02 | - | - | - | |

| 7% | 0.09 | 0.07 | 0.04 | 0.02 | - | |

| 8% | 0.14 | 0.11 | 0.09 | 0.07 | 0.04 | |

| 9% | 0.18 | 0.16 | 0.14 | 0.11 | 0.09 | |

| Corrosion Mode | Method | Model | Durability Life (Years) |

|---|---|---|---|

| Uniform corrosion [28] | Determination method | F(t) = Cth − C(r,t) | 34.8 |

| Reliability method | Pf(t) = P[F(t) ≤ 0] = P[Cth ≤ C(r,t)], Ti = [Pf(t) ≥ Pfmax] | 27.4 | |

| Localized corrosion [20] | Determination method | Tsp,lim = Ti + Tcr + Tcp | 77.60 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shao, W.; He, X.; Shi, D.; Zhu, W. Prediction of Crack Width in RC Piles Exposed to Local Corrosion in Chloride Environment. Materials 2023, 16, 6403. https://doi.org/10.3390/ma16196403

Shao W, He X, Shi D, Zhu W. Prediction of Crack Width in RC Piles Exposed to Local Corrosion in Chloride Environment. Materials. 2023; 16(19):6403. https://doi.org/10.3390/ma16196403

Chicago/Turabian StyleShao, Wei, Xiaoqing He, Danda Shi, and Wenjin Zhu. 2023. "Prediction of Crack Width in RC Piles Exposed to Local Corrosion in Chloride Environment" Materials 16, no. 19: 6403. https://doi.org/10.3390/ma16196403

APA StyleShao, W., He, X., Shi, D., & Zhu, W. (2023). Prediction of Crack Width in RC Piles Exposed to Local Corrosion in Chloride Environment. Materials, 16(19), 6403. https://doi.org/10.3390/ma16196403