Recycled Fine and Coarse Aggregates’ Contributions to the Fracture Energy and Mechanical Properties of Concrete

Abstract

:1. Introduction

Background

2. Materials and Methods

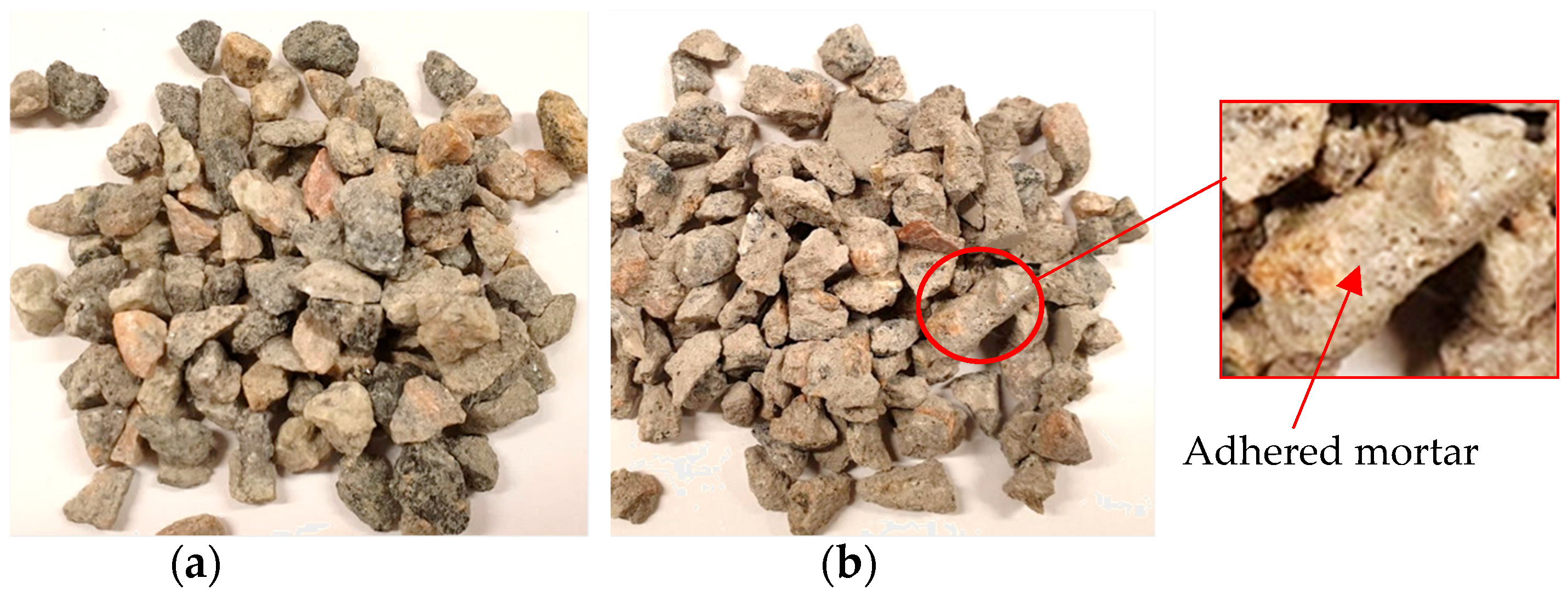

2.1. Testing Aggregate Properties

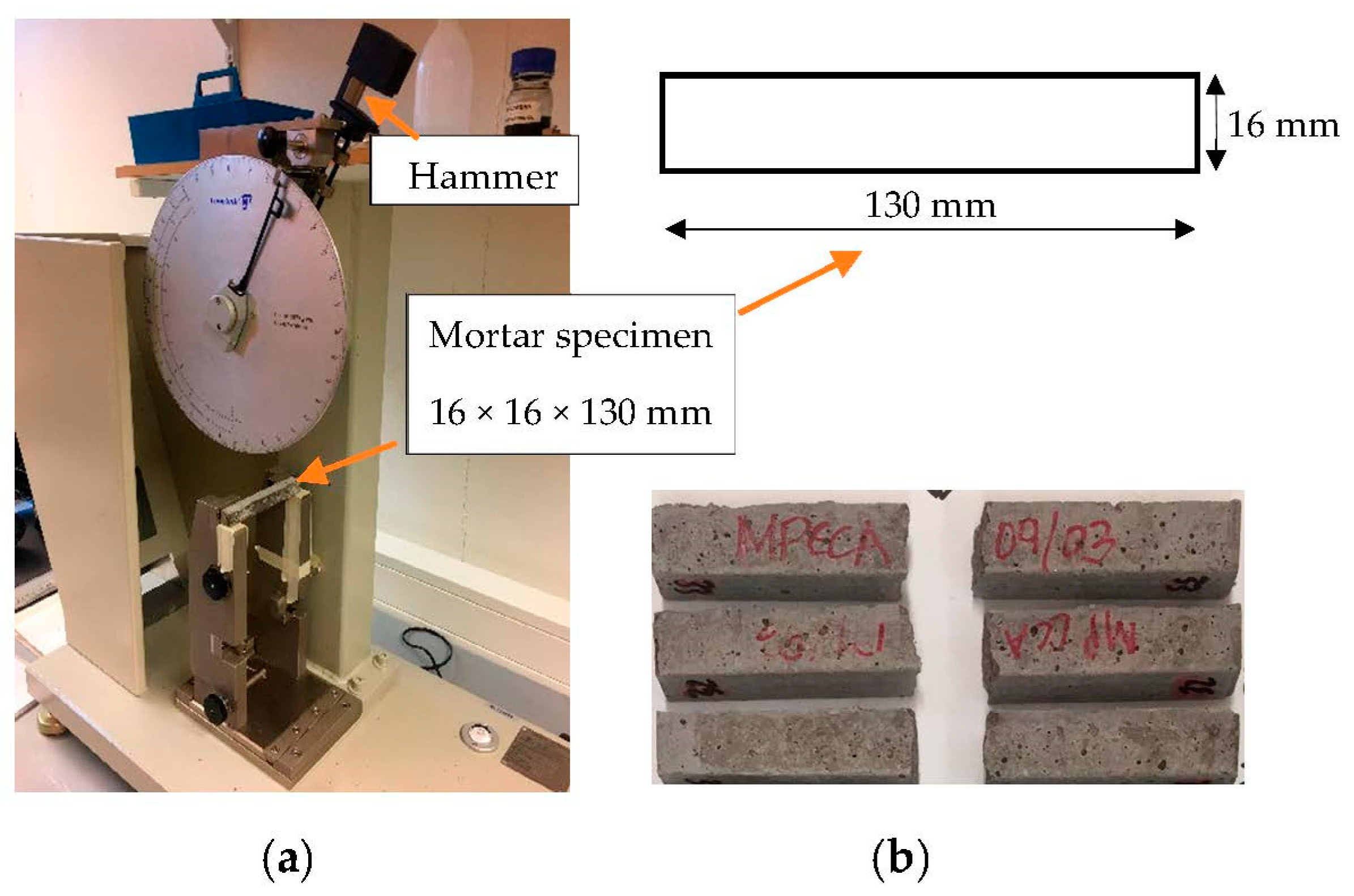

2.2. Testing Cement Mortar

2.3. Testing Concrete

3. Results

- The mechanical performance of the aggregates, reported using the elastic modulus;

- The properties of the fine aggregates, with the mortar’s mechanical and Charpy energy properties;

- The properties of the coarse aggregates, with the mechanical properties and fracture energy of the concrete.

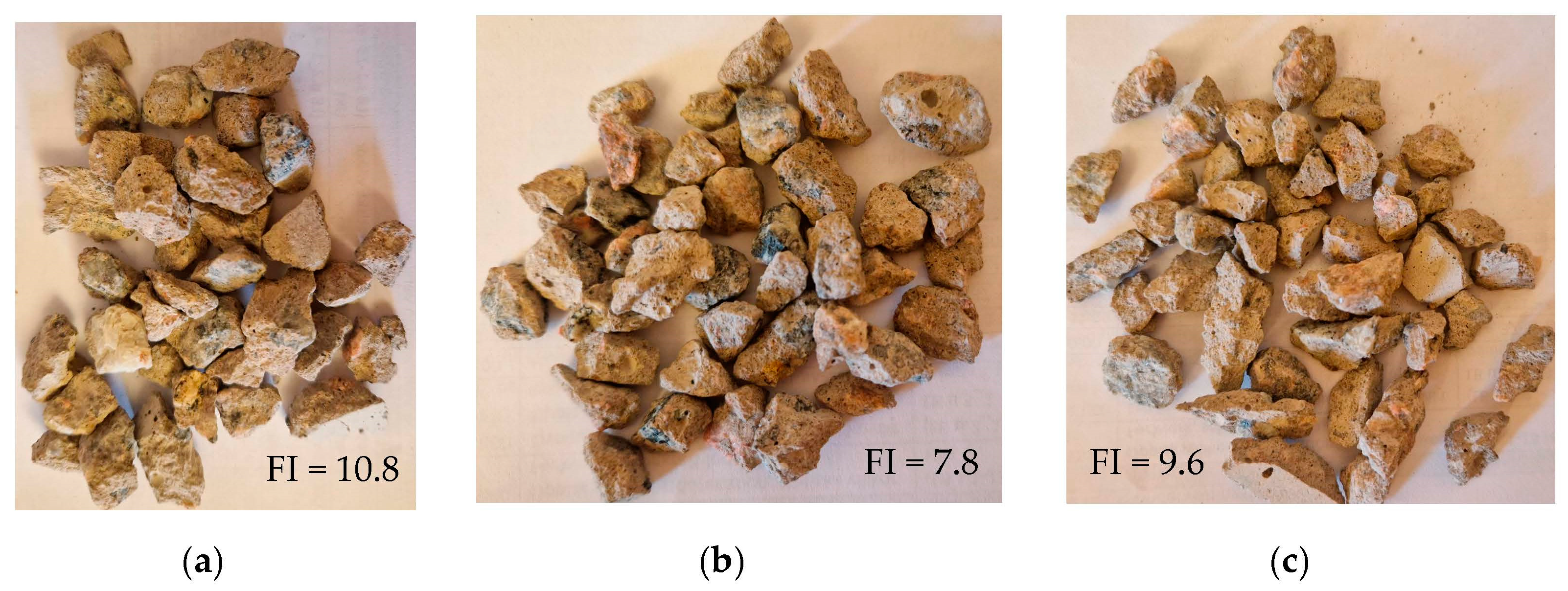

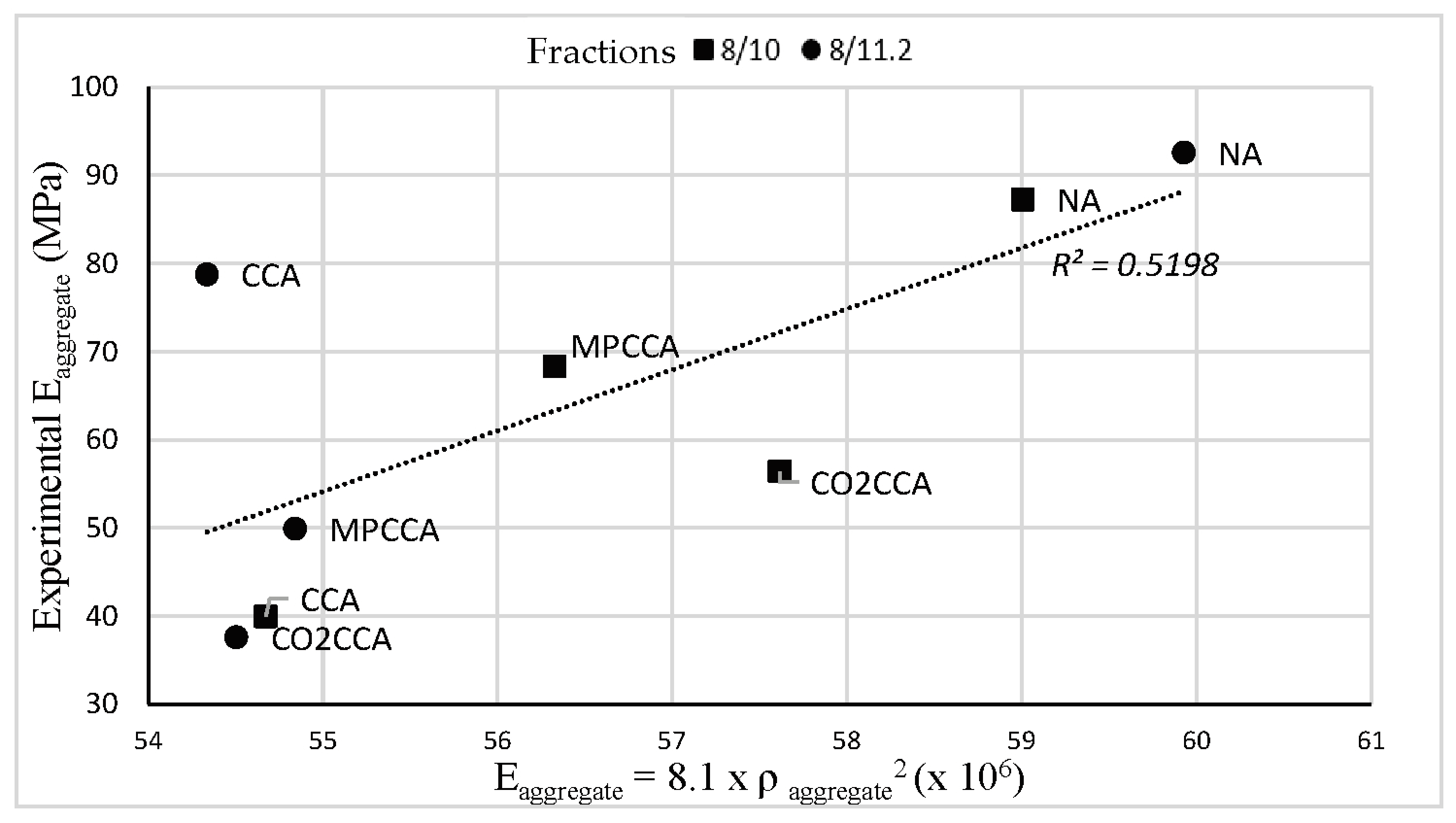

3.1. The Physical and Mechanical Properties of the Coarse Aggregates

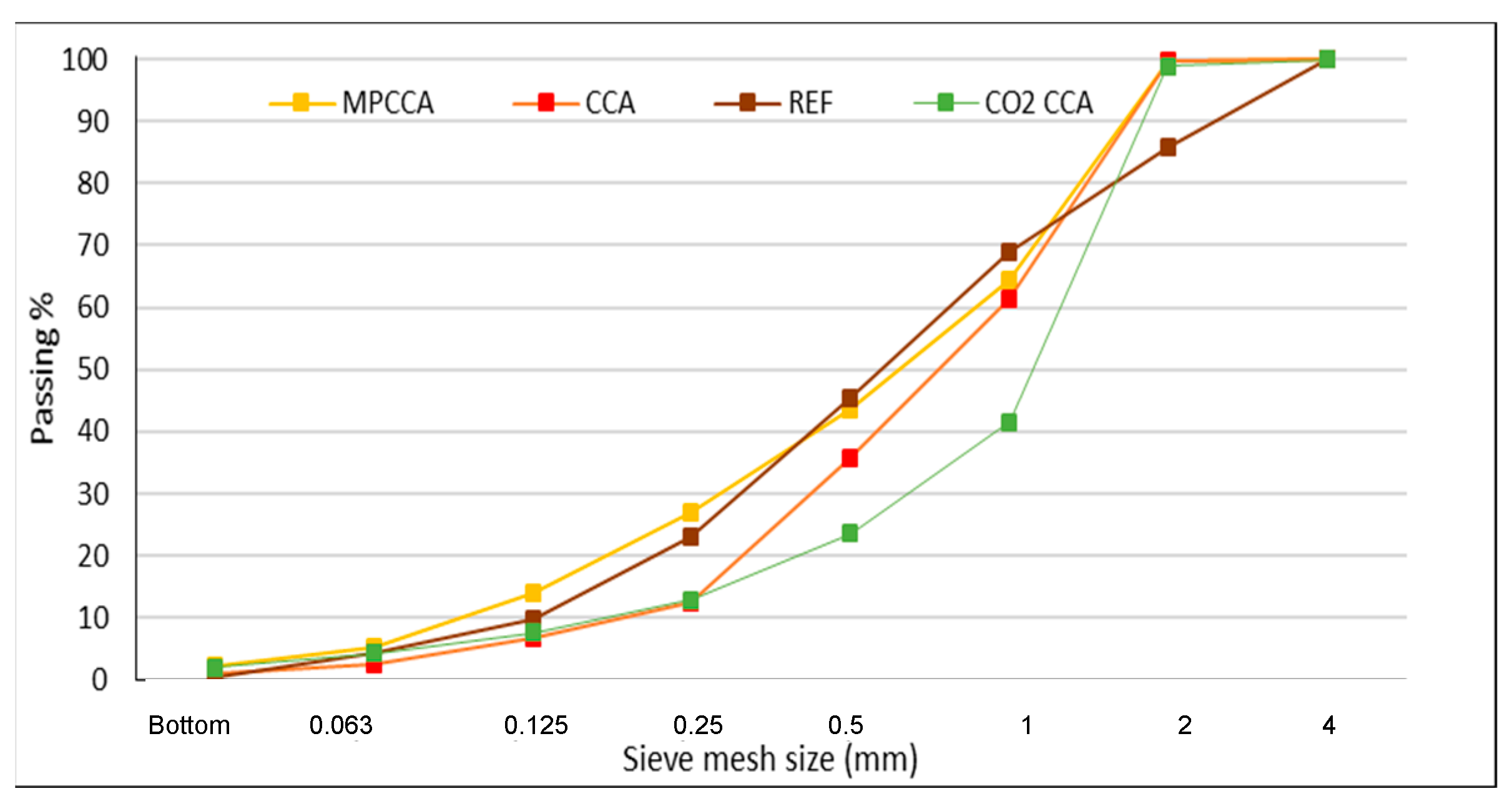

3.2. Physical Properties of Fine Aggregates

| Properties | Fine Aggregate Fractions (mm) | |||||||

|---|---|---|---|---|---|---|---|---|

| 0/4 | 0.5/4 | 0/4 | 0/8 | |||||

| CCA | MPCCA | CO2CCA | CCA | MPCCA | CO2CCA | NA | NA | |

| Apparent density (kg/m3) | 2677 | 2718 | 2752 | 2656 | 2637 | 2639 | 2701 | 2701 |

| Flakiness index (%) | 5.90 | 5.2 | 5.6 | 6.5 | 5 | 5.08 | 1.8 | 4.5 |

| Unit weight (kg/m3) | 1415 | 1385 | 1567 | 1314 | 1268 | 1263 | 1748 | 1837 |

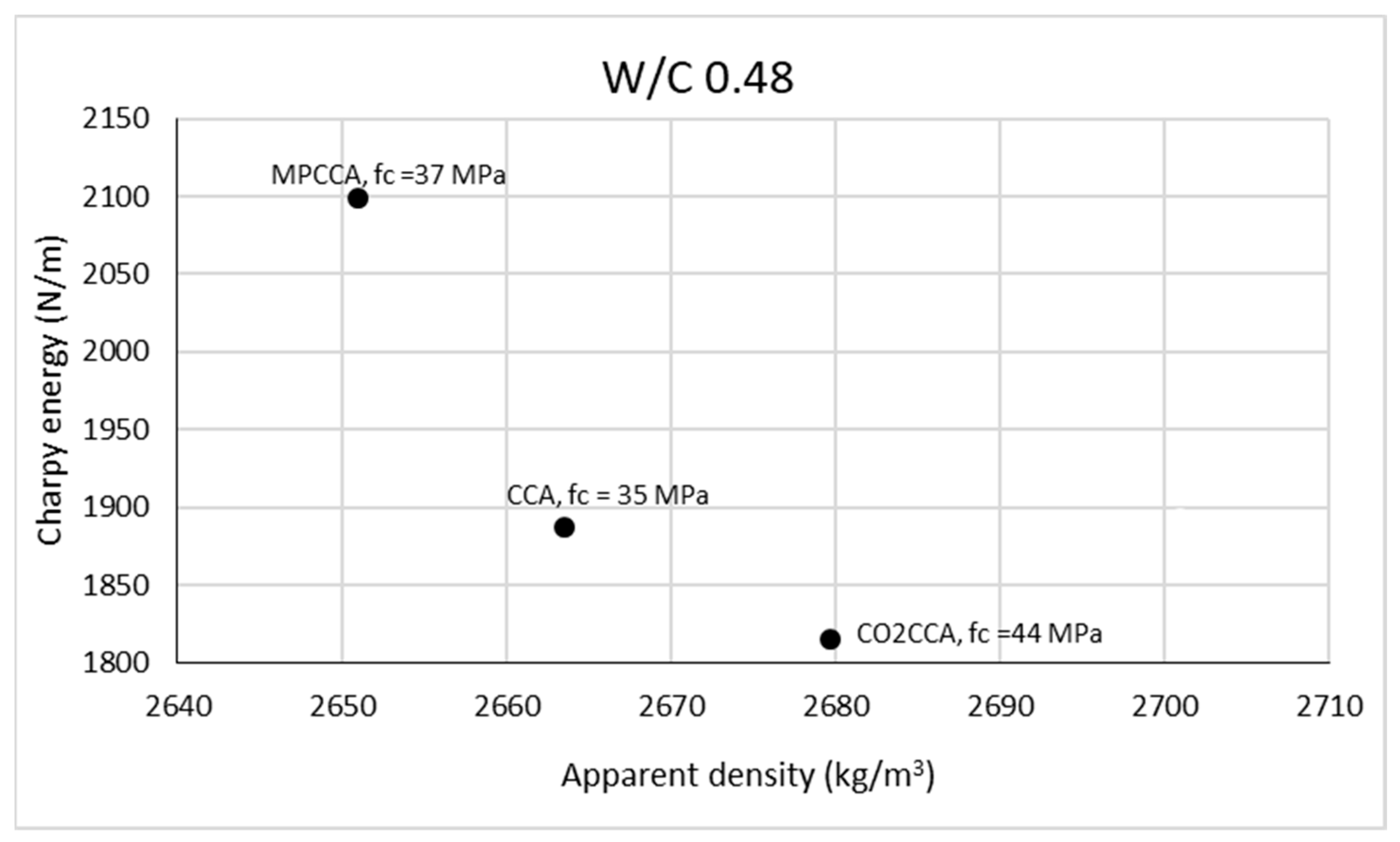

3.3. Mechanical Properties and Charpy Energy of Mortar

- Densified aggregates result in lower Charpy energy values;

- The Charpy energy has an inverse relationship to the compressive strength of mortar. Higher Charpy energies are observed for mortars with lower compressive strengths.

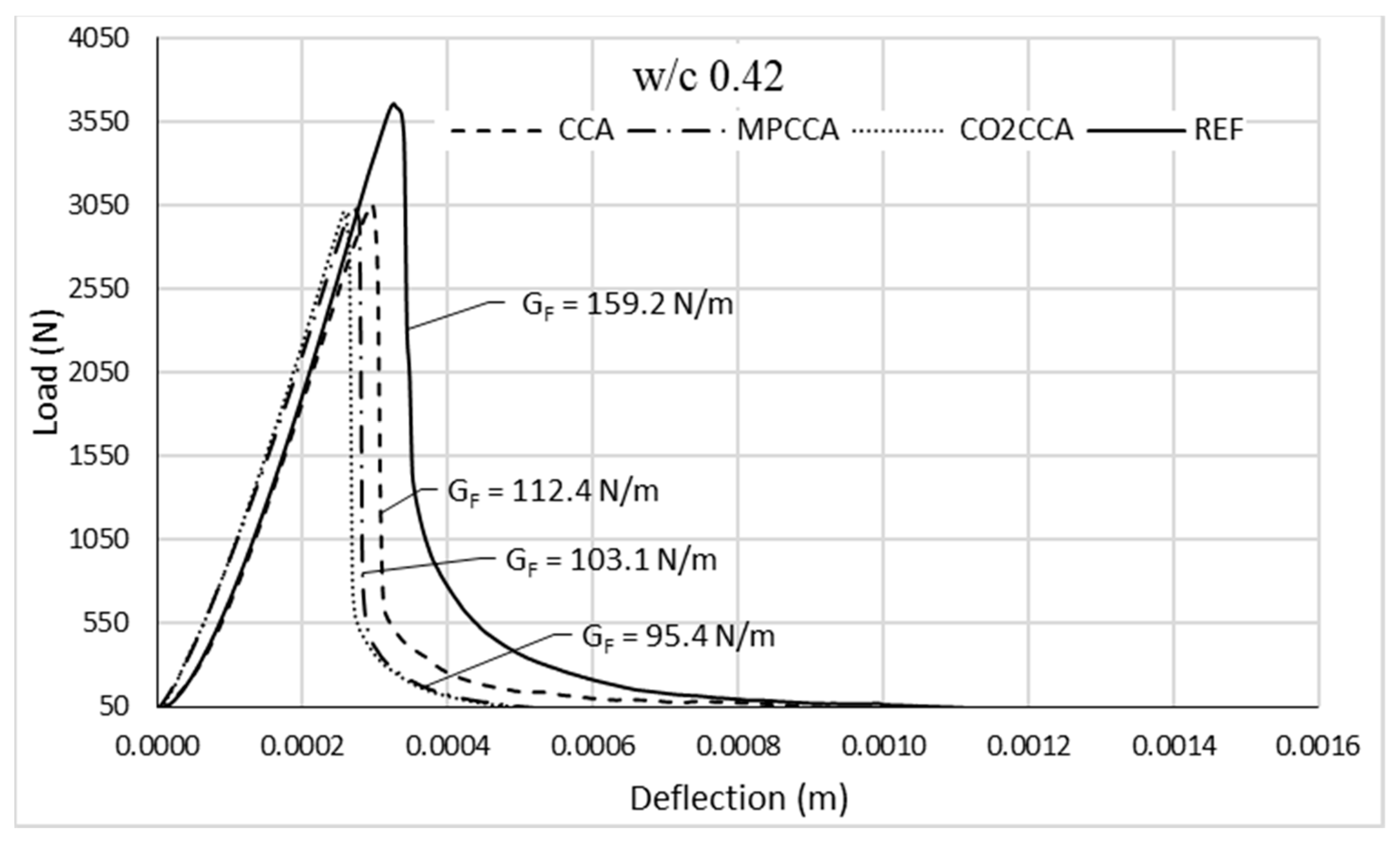

3.4. Mechanical and Fracture Mechanical Properties of Concrete

4. Analysis of Results

4.1. Effect of Aggregate Shape on Fracture Energy

4.2. The Effect of the Elastic Modulus of an Aggregate on Concrete

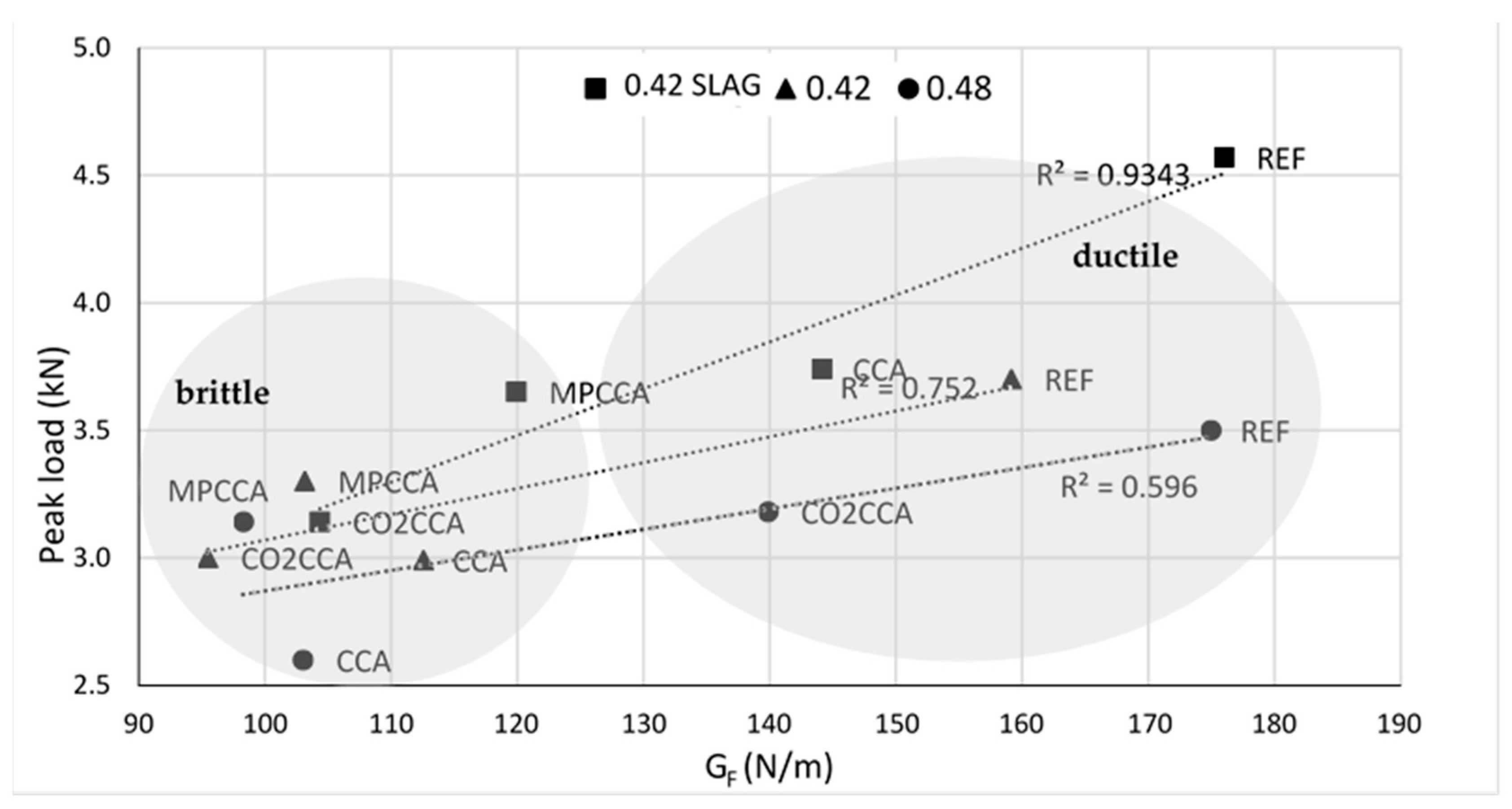

4.3. Fracture Energy

The Aggregate’s Effect on Fracture Energy

4.4. The Aggregate’s Influence on Compressive Strength

5. Conclusions

- The CCA concrete achieves 70% of the fracture energy value of the reference concrete independent of the w/c ratio, and this value increases to 80% for mixes with the addition of GGBS.

- Mortar mixes containing aggregates treated with accelerated carbonation, CO2CCA showed high compressive strength values, low Charpy energy values and ductile behavior. Concrete mixes containing CO2CCA aggregates showed lower fracture energy values than the reference concrete. Thus, CO2CCA aggregates fit concrete with high w/c ratios.

- The MPCCA concrete showed a lower fracture energy than the reference concrete due to the loss of the aggregate’s flakiness following mechanical pre-processing. Mixes containing mechanically pre-processed aggregates show more brittle behavior and higher compressive strength values which fit normal–high-strength concrete.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Göransson, M. Replacements for Natural Aggreagtes—Compilation and Recommendations for the Use of Natural Aggregates; Geological Survey of Sweden: Uppsala, Sweden, 2015. [Google Scholar]

- Svenska Miljö Emissions Data (SMED). Waste in Sweden 2018, Generation and Handling; Naturvårdsverket: Stockholm, Sweden, 2010. (In Swedish) [Google Scholar]

- Ernst, W.; Lynn, P.; Nathan, M.; Chris, H.; Ozawa, M.L. Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar]

- Carpenter, A. CO2 abatement in the iron and steel industry. IEA Clean Coal Cent. 2012, 25, 193. [Google Scholar]

- Kou, S.-C.; Poon, C.S.; Agrela, F. Comparisons of natural and recycled aggregate concretes prepared with the addition of different mineral admixtures. Cem. Concr. Compos. 2011, 33, 788–795. [Google Scholar] [CrossRef]

- Sadagopan, M. Recycling of Concrete in New Structural Concrete. Ph.D. Thesis, Högskolan i Borås, Borås, Sweden, 2021. [Google Scholar]

- Hansen, T.C.; Narud, H. Strength of recycled concrete made from crushed concrete coarse aggregate. Concr. Int.-Des. Constr. 1983, 5, 79–83. [Google Scholar]

- Sadagopan, M.; Malaga, K.; Nagy, A. Improving recycled aggregate quality by mechanical pre-processing. Materials 2020, 13, 4342. [Google Scholar] [CrossRef]

- Katz, A. Treatments for the Improvement of Recycled Aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Fang, X.; Xuan, D.; Poon, C.S. Empirical modelling of CO2 uptake by recycled concrete aggregates under accelerated carbonation conditions. Mater. Struct. 2017, 50, 200. [Google Scholar] [CrossRef]

- Wu, J.; Zhang, Y.; Zhu, P.; Feng, J.; Hu, K. Mechanical Properties and ITZ Microstructure of Recycled Aggregate Concrete Using Carbonated Recycled Coarse Aggregate. J. Wuhan Univ. Technol. Sci. Ed. 2018, 33, 648–653. [Google Scholar] [CrossRef]

- Poon, C.; Shui, Z.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Pepe, M.; Toledo Filho, R.D.; Koenders, E.A.; Martinelli, E. Alternative processing procedures for recycled aggregates in structural concrete. Constr. Build. Mater. 2014, 69, 124–132. [Google Scholar] [CrossRef]

- Hillerborg, A. The theoretical basis of a method to determine the fracture energy GF of concrete. Mater. Struct. 1985, 18, 291–296. [Google Scholar] [CrossRef]

- Karihaloo, B. Fracture Mechanics and Structural Concrete; Longman Scientific & Technical: London, UK, 1995. [Google Scholar]

- Butler, L.; West, J.S.; Tighe, S.L. Effect of recycled concrete coarse aggregate from multiple sources on the hardened properties of concrete with equivalent compressive strength. Constr. Build. Mater. 2013, 47, 1292–1301. [Google Scholar] [CrossRef]

- Kazemian, F.; Rooholamini, H.; Hassani, A. Mechanical and fracture properties of concrete containing treated and untreated recycled concrete aggregates. Constr. Build. Mater. 2019, 209, 690–700. [Google Scholar] [CrossRef]

- Xiao, J.; Tang, Y.; Chen, H.; Zhang, H.; Xia, B. Effects of recycled aggregate combinations and recycled powder contents on fracture behavior of fully recycled aggregate concrete. J. Clean. Prod. 2022, 366, 132895. [Google Scholar] [CrossRef]

- Casuccio, M.; Torrijos, M.; Giaccio, G.; Zerbino, R. Failure mechanism of recycled aggregate concrete. Constr. Build. Mater. 2008, 22, 1500–1506. [Google Scholar] [CrossRef]

- Ishiguro, S.; Stanzl-Tschegg, S.E.; Tschegg, E.K.; Travnicek, R. Mode I fracture behaviour of recycled concrete. In Fracture Mechanics of Concrete Structures, Proceedings FRAMCOS-2; Wittmann, H.F., Ed.; AEDIFICATIO Publishers: Freiburg, Germany, 1995; pp. 145–154. [Google Scholar]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson Education: Upper Saddle River, NJ, USA, 2013. [Google Scholar]

- Darwin, D.; Barham, S.; Kozul, R.; Luan, S. Fracture energy of high-strength concrete. ACI Mater. J. 2001, 98, 410–417. [Google Scholar]

- Wu, K.-R.; Chen, B.; Yao, W.; Zhang, D. Effect of coarse aggregate type on mechanical properties of high-performance concrete. Cem. Concr. Res. 2001, 31, 1421–1425. [Google Scholar] [CrossRef]

- Tasdemir, C.; Tasdemir, M.A.; Lydon, F.D.; Barr, B.I. Effects of silica fume and aggregate size on the brittleness of concrete. Cem. Concr. Res. 1996, 26, 63–68. [Google Scholar] [CrossRef]

- Rocco, C.; Elices, M. Effect of aggregate shape on the mechanical properties of a simple concrete. Eng. Fract. Mech. 2009, 76, 286–298. [Google Scholar] [CrossRef]

- Teng, S.; Liu, Y.; Lim, T.Y.D. Determination of fracture energy of ultra high strength concrete. Eng. Fract. Mech. 2014, 131, 602–615. [Google Scholar] [CrossRef]

- Donza, H.; Cabrera, O.; Irassar, E. High-strength concrete with different fine aggregate. Cem. Concr. Res. 2002, 32, 1755–1761. [Google Scholar] [CrossRef]

- Alexander, M.; Mindess, S. Aggregates in Concrete, 1st ed.; CRC Press: Boca Raton, FL, USA, 2010. [Google Scholar]

- Kim, J.-K.; Lee, C.-S.; Park, C.-K.; Eo, S.-H. The fracture characteristics of crushed limestone sand concrete. Cem. Concr. Res. 1997, 27, 1719–1729. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Behaviour of cementitious mortars containing different kinds of recycled aggregate. Constr. Build. Mater. 2009, 23, 289–294. [Google Scholar] [CrossRef]

- Saleem, M.M.; Ahmad, Z.; Hayat, S. Predicting compressive strength of concrete using impact modulus of toughness. Case Stud. Constr. Mater. 2021, 14, e00518. [Google Scholar] [CrossRef]

- Akono, A.-T.; Chen, J.; Zhan, M.; Shah, S.P. Basic creep and fracture response of fine recycled aggregate concrete. Constr. Build. Mater. 2021, 266, 121107. [Google Scholar] [CrossRef]

- Ismail, S.; Ramli, M. Mechanical strength and drying shrinkage properties of concrete containing treated coarse recycled concrete aggregates. Constr. Build. Mater. 2014, 68, 726–739. [Google Scholar] [CrossRef]

- Bui, N.K.; Satomi, T.; Takahashi, H. Mechanical properties of concrete containing 100% treated coarse recycled concrete aggregate. Constr. Build. Mater. 2018, 163, 496–507. [Google Scholar] [CrossRef]

- Mohammed, S.I.; Najim, K.B. Mechanical strength, flexural behavior and fracture energy of Recycled Concrete Aggregate self-compacting concrete. Structures 2020, 23, 34–43. [Google Scholar] [CrossRef]

- SS-EN 933-1:2012; Tests for Geometrical Properties of Aggregates-Part 1: Determination of Particle Size Distribution-Sieving. Swedish Standards Institute: Stockholm, Sweden, 2012.

- SS-EN 933-3:2012; Tests for Geometrical Properties of Aggregates-Part 3: Determination of Particle Shape-Flakiness Index. Swedish Standards Institute: Stockholm, Sweden, 2012.

- Stenlid, L. Method to determine the flakiness index of fine aggregate. In SBUF 12270; Teknik, S.S.A., Ed.; Svenska Byggbranschens Utvecklingsfond: Stockholm, Sweden, 2011. (In Swedish) [Google Scholar]

- SS-EN 1097-6:2013; Tests for Mechanical and Physical Properties of Aggregates-Part 6: Determination of Particle Density And Water Absorption. Swedish Standards Institute: Stockholm, Sweden, 2013.

- ASTM C29/29M-17a; Standard Test Method for Bulk Density (“Unit Weight”) and Voids in Aggregate. ASTM International: West Conshohocken, PA, USA, 2017.

- BS 812-110:1990; Testing Aggregates-Methods for Determination Of Aggregate Crushing Value (ACV). British Standards Institution: London, UK, 1990.

- SS-EN ISO 179-1:2010; Plastics-Determination of Charpy Impact Properties-Part 1: Non-Instrumented Impact Test. Swedish Standards Institute: Stockholm, Sweden, 2010.

- SS-EN 1015-11:2019; Methods of Test for Mortar For Masonry-Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. Swedish Standards Institute: Stockholm, Sweden, 2019.

- SS-EN 12390-13:2021; Testing Hardened Concrete-Part 13: Determination of Secant Modulus of Elasticity in Compression. Swedish Standards Institute: Stockholm, Sweden, 2021.

- Esping, O.; Löfgren, I.; Lindvall, A. Betongtekniska Möjligheter med Mineraliska Tillsatsmaterial; Bygg & Teknik: Tyresö, Sweden, 2011. (In Swedish) [Google Scholar]

- SS-EN 12390-3:2002; Testing Hardened Concrete-Part 3: Compressive Strength of Test Specimens. Swedish Standards Institute: Stockholm, Sweden, 2002.

- SS-EN 12390-6:2009; Testing Hardened Concrete-Part 6: Tensile Splitting Strength of Test Specimens. Swedish Standards Institute: Stockholm, Sweden, 2009.

- Rilem, D.R. Determination of the fracture energy of mortar and concrete by means of three-point bend tests on notched beames. Mater. Struct. 1985, 18, 285–290. [Google Scholar]

- Müller-Rochholz, J. Determination of the elastic properties of lightweight aggregate by ultrasonic pulse velocity measurement. Int. J. Cem. Compos. Lightweight Concr. 1979, 1, 87–90. [Google Scholar] [CrossRef]

- Kong, D.; Lei, T.; Zheng, J.; Ma, C.; Jiang, J.; Jiang, J. Effect and mechanism of surface-coating pozzalanics materials around aggregate on properties and ITZ microstructure of recycled aggregate concrete. Constr. Build. Mater. 2010, 24, 701–708. [Google Scholar] [CrossRef]

| Mixes | 0.48 CEM II | 0.42 CEM II | 0.42 SLAG 30% GGBS, CEM II | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Concrete and Mortar Mix Series | REF | CCA | MP CCA | CO2CCA | REF | CCA | MP CCA | CO2CCA | REF | CCA | MP CCA | CO2CCA |

| Concrete Recipes (kg/m3) | ||||||||||||

| Aggregate type | NA | CCA | MP CCA | CO2 CCA | NA | CCA | MP CCA | CO2 CCA | NA | CCA | MP CCA | CO2 CCA |

| 8/10 | 729 | 708 | 708 | 708 | - | - | - | - | - | - | - | - |

| 8/11.2 | - | - | - | - | 729 | 728 | 728 | 728 | 729 | 728 | 728 | 728 |

| 0/8 | 845 | - | - | - | 845 | - | - | - | 845 | - | - | - |

| 0.5/4 | - | 550 | 157 | 550 | - | 530 | 141 | 530 | - | 530 | 141 | 530 |

| 0/4 | - | 314 | 708 | 314 | - | 314 | 703 | 314 | - | 314 | 703 | 314 |

| Water absorption water | - | 44 | 36 | 37 | - | 44 | 36 | 37 | - | 44 | 36 | 37 |

| CEM II | 490 | 490 | 343 | |||||||||

| GGBS (k = 0.8) | - | - | 149 | |||||||||

| Mixing water | 234 | 205.8 | 194.1 | |||||||||

| Superplasticizer | 3.7 | 5 | 3.7 | |||||||||

| Mortar Recipes (kg/m3) | ||||||||||||

| Aggregate type | NA | CCA | MP CCA | CO2 CCA | NA | CCA | MP CCA | CO2 CCA | NA | CCA | MP CCA | CO2 CCA |

| 0.5/4 | - | 1008 | 283 | 1008 | - | 1001 | 1310 | 1001 | - | 1001 | 1310 | 1001 |

| 0/4 | 1574 | 566 | 1291 | 566 | 1574 | 572 | 264 | 572 | 1574 | 572 | 264 | 572 |

| Properties | Fraction 8/10 w/c 0.48 | Fraction 8/11.2 w/c 0.42 | ||||||

|---|---|---|---|---|---|---|---|---|

| NA | CCA | MP CCA | CO2CCA | NA | CCA | MP CCA | CO2CCA | |

| Apparent density, ρaggregate (kg/m3) | 2699 | 2598 | 2637 | 2667 | 2720 | 2590 | 2602 | 2594 |

| Flakiness index (%) | 9.51 | 8 | 7.7 | 8 | 19 | 10.4 | 7.8 | 9.6 |

| ACV (%) | 27 | 29 | 30 | 30 | 26 | 24 | 29 | 27 |

| Unit weight (kg/m3) | 1529 | 1267 | 1298 | 1295 | 1487 | 1326 | 1349 | 1319 |

| Mortar Properties | Mortar Mixes | |||

|---|---|---|---|---|

| REF | CCA | MPCCA | CO2CCA | |

| fc (MPa) | 43.9 | 35.1 | 37.8 | 44.8 |

| Emortar (GPa) | 29.2 | 23.7 | 22.0 | 22.0 |

| Charpy Energy (N/m) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.48 | 0.42 | 0.42 SLAG | |||||||||

| REF | CCA | MP CCA | CO2 CCA | REF | CCA | MP CCA | CO2 CCA | REF | CCA | MP CCA | CO2 CCA |

| 1893 | 1888 | 2099 | 1816 | 1877 | 1855 | 1959 | 1865 | 1974 | 1885 | 1984 | 1899 |

| fc (MPa) | Econcrete (GPa) | ft (MPa) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| REF | CCA | MP CCA | CO2CCA | REF | CCA | MP CCA | CO2CCA | REF | CCA | MP CCA | CO2CCA | |

| 0.48 | 39.7 | 38.2 | 39.6 | 39.1 | 26.9 | 22.6 | 25.2 | 25.5 | 3.2 | 4.1 | 3.0 | 3.2 |

| 0.42 | 48.4 | 43.3 | 49.4 | 48.0 | 29.7 | 23.4 | 23.3 | 23.8 | 3.1 | 4.0 | 3.3 | 2.9 |

| 0.42 SLAG | 59.6 | 53.7 | 52.4 | 52.0 | 36.4 | 27.1 | 29.5 | 29.4 | 4.4 | 3.1 | 4.4 | 3.9 |

| Fracture Parameters | Concrete Mixes | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.48 | 0.42 | 0.42 SLAG | ||||||||||

| REF | CCA | MP CCA | CO2CCA | REF | CCA | MP CCA | CO2CCA | REF | CCA | MP CCA | CO2CCA | |

| Peak load Pmax (kN) | 3.50 | 2.60 | 3.14 | 3.18 | 3.70 | 2.99 | 3.30 | 3.00 | 4.57 | 3.74 | 3.65 | 3.14 |

| Deflection δ0 × 10−3 (mm) | 2 | 1.4 | 0.9 | 2 | 1.5 | 1.5 | 0.9 | 0.9 | 1.1 | 1.3 | 1.1 | 1.5 |

| Fracture energy GF (N/m) | 174.87 | 103.01 | 101.77 | 140.01 | 159.26 | 112.44 | 103.16 | 95.43 | 175.95 | 144.04 | 119.91 | 104.35 |

| Time to failure (s) | 463 | 156.3 | 320.7 | 459.7 | 344.3 | 310.0 | 150.7 | 162.6 | 212.7 | 267.7 | 203.7 | 333.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sadagopan, M.; Rivera, A.O.; Malaga, K.; Nagy, A. Recycled Fine and Coarse Aggregates’ Contributions to the Fracture Energy and Mechanical Properties of Concrete. Materials 2023, 16, 6437. https://doi.org/10.3390/ma16196437

Sadagopan M, Rivera AO, Malaga K, Nagy A. Recycled Fine and Coarse Aggregates’ Contributions to the Fracture Energy and Mechanical Properties of Concrete. Materials. 2023; 16(19):6437. https://doi.org/10.3390/ma16196437

Chicago/Turabian StyleSadagopan, Madumita, Alexander Oliva Rivera, Katarina Malaga, and Agnes Nagy. 2023. "Recycled Fine and Coarse Aggregates’ Contributions to the Fracture Energy and Mechanical Properties of Concrete" Materials 16, no. 19: 6437. https://doi.org/10.3390/ma16196437