Enhancing Fatigue Life and Strength of Adhesively Bonded Composite Joints: A Comprehensive Review

Abstract

:1. Introduction

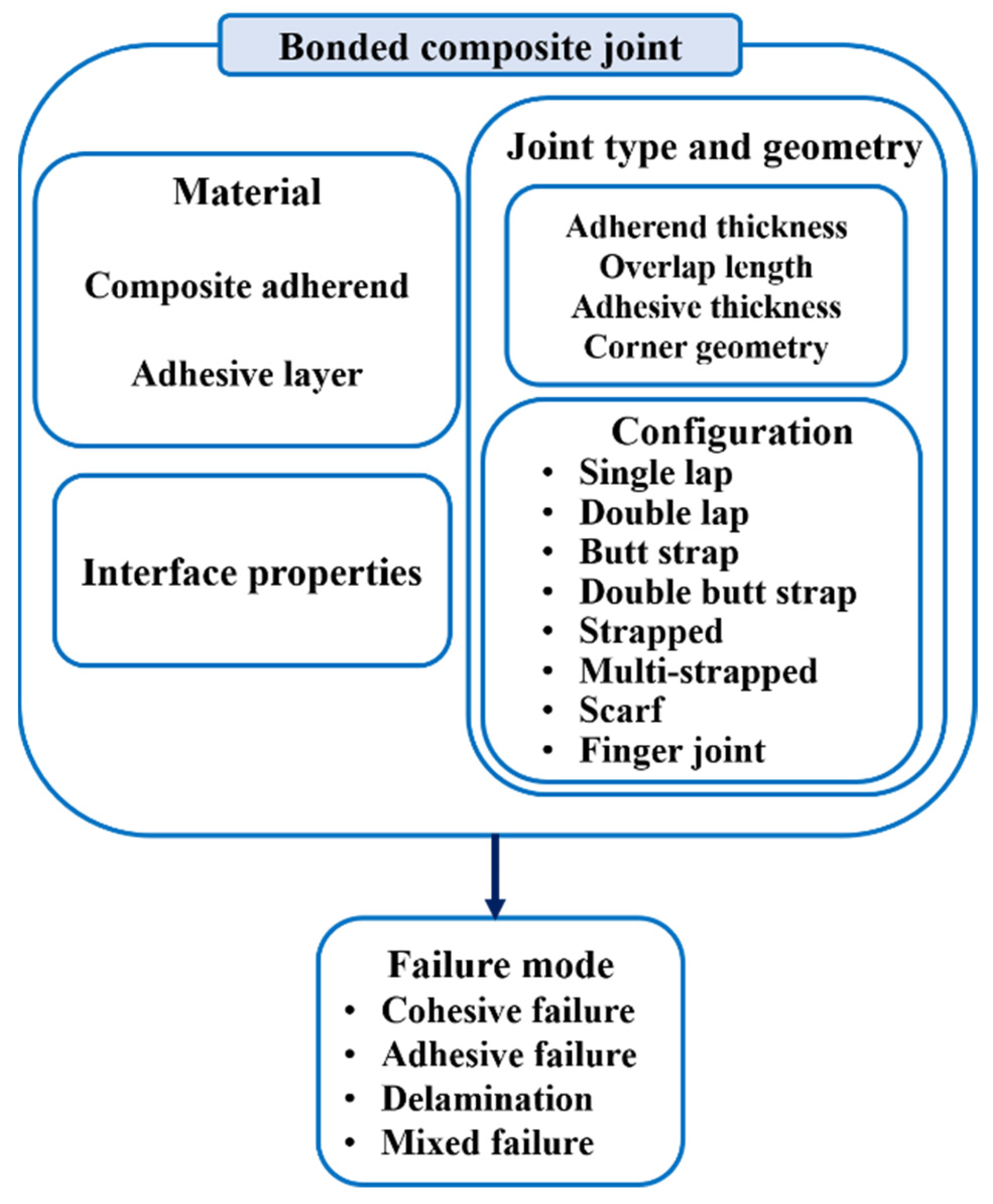

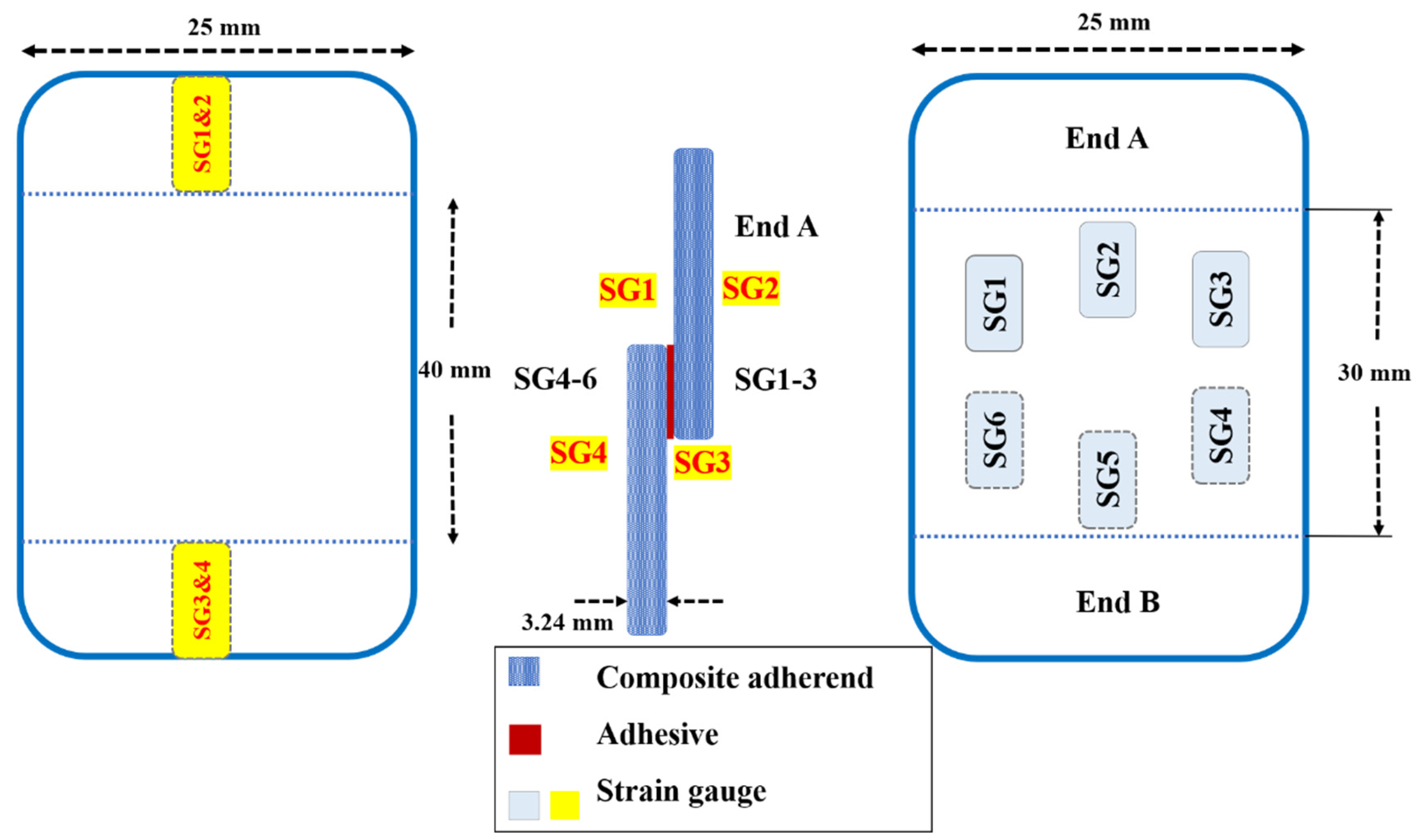

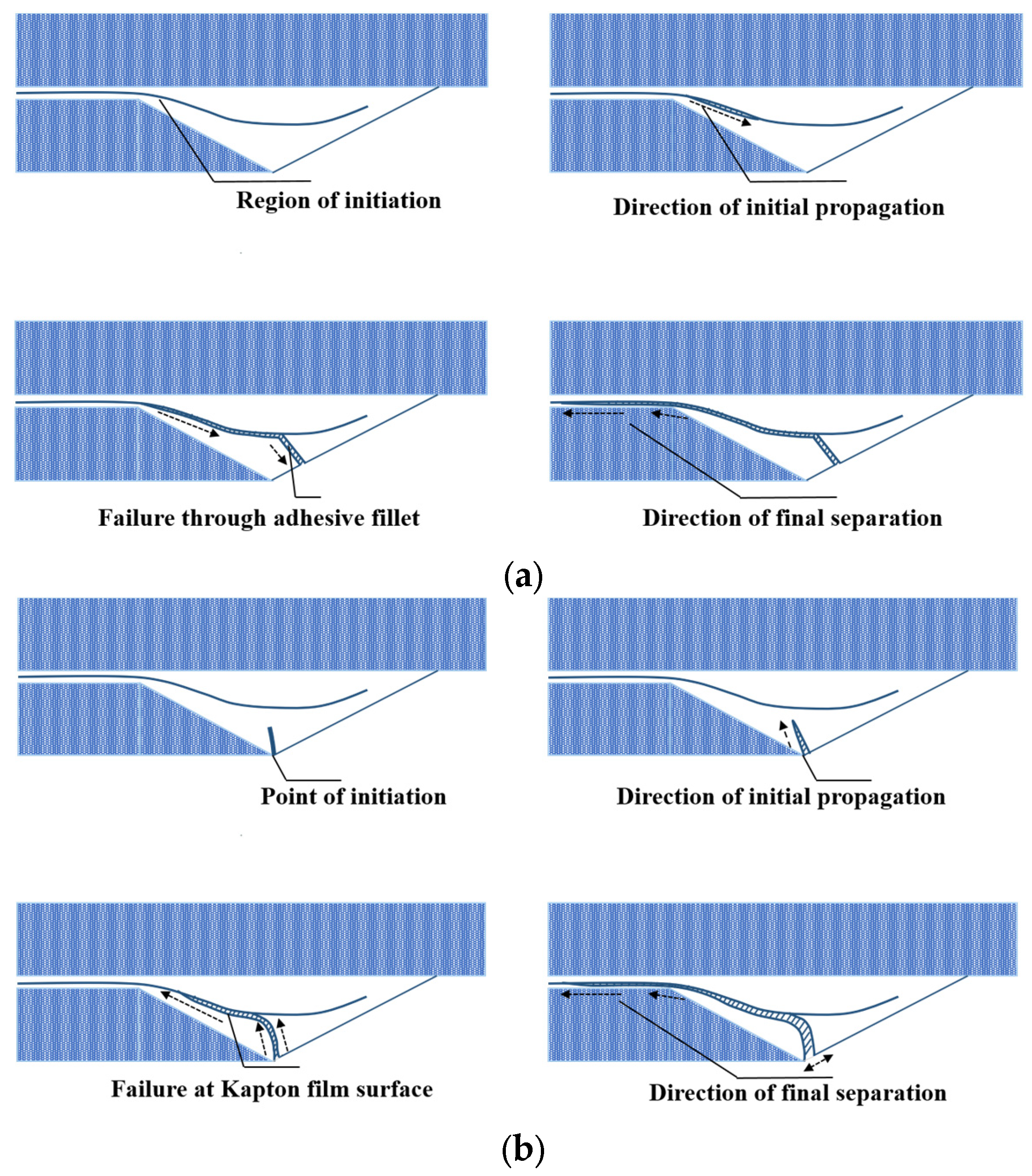

2. Crack Initiation Inspection

3. Joint Configuration and Geometry

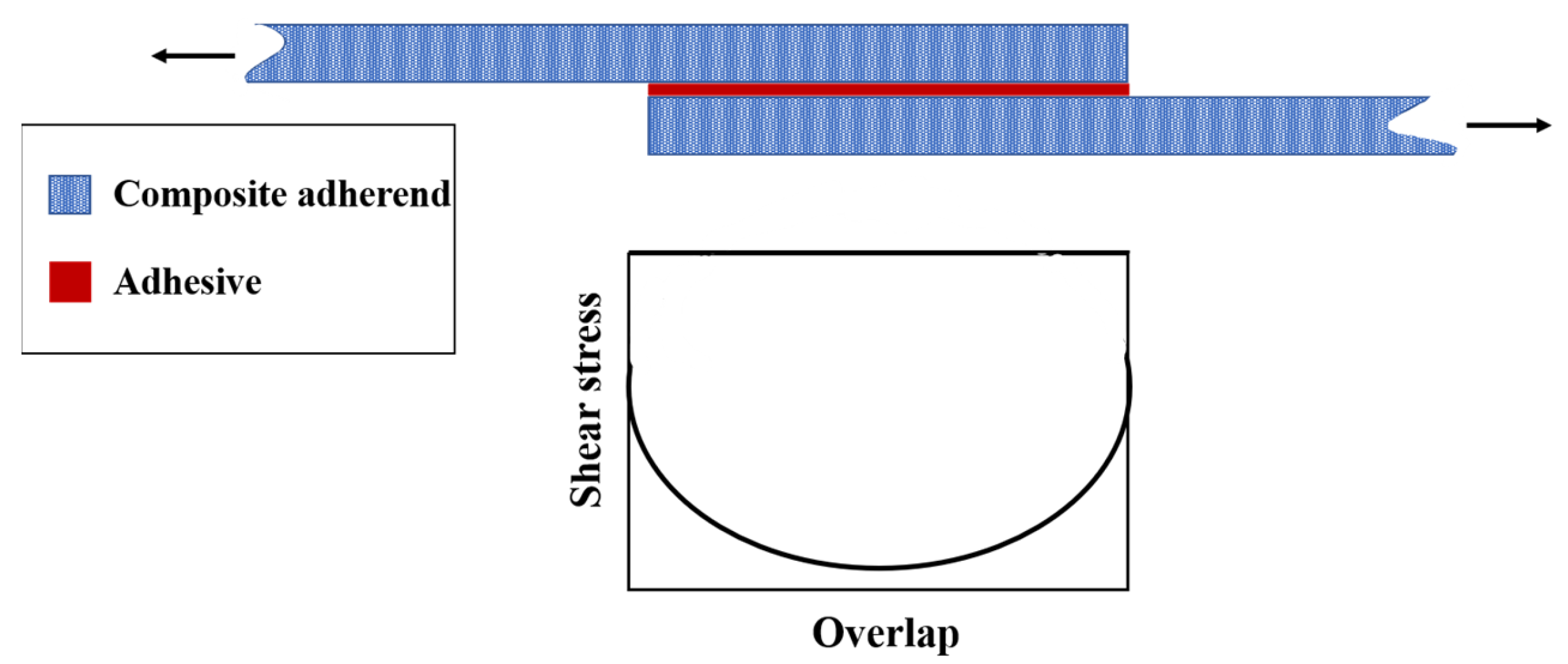

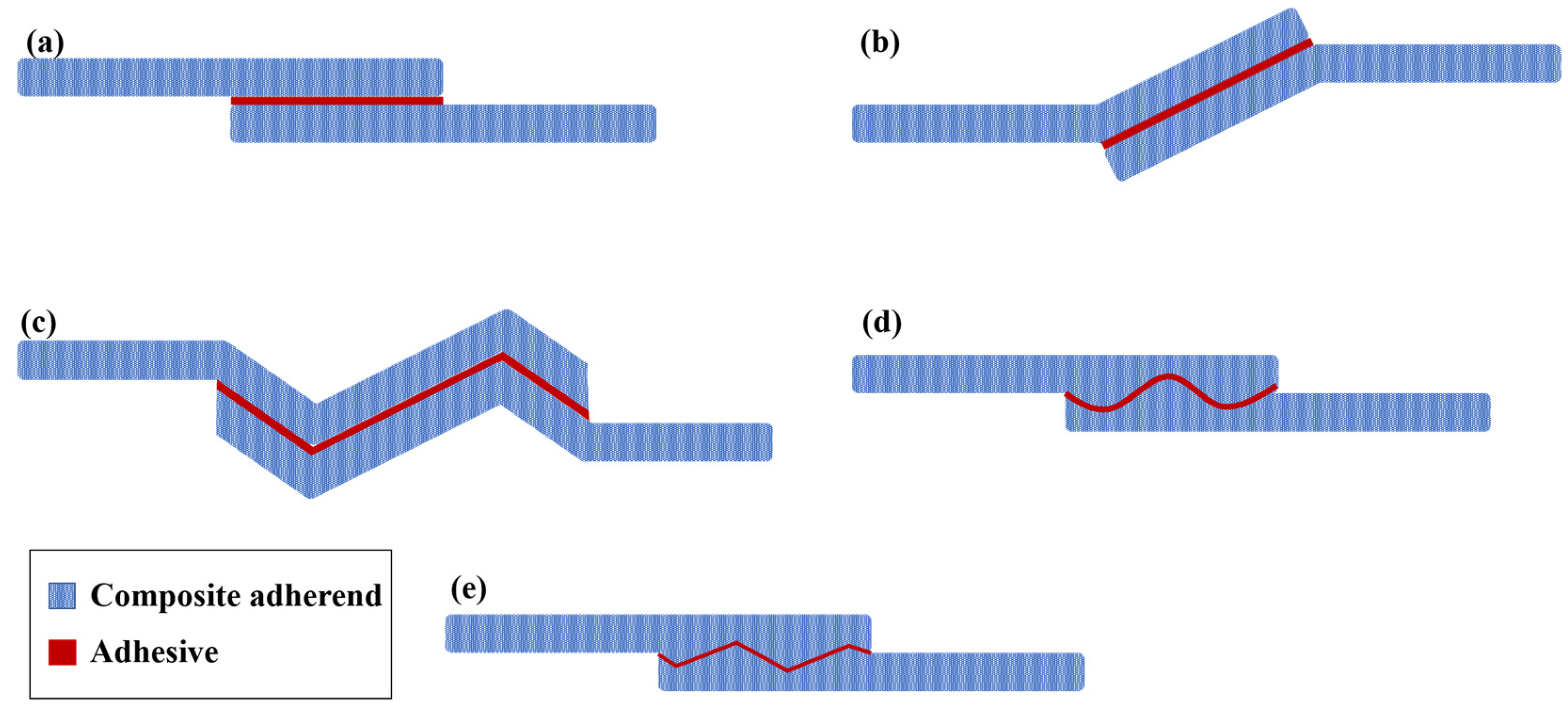

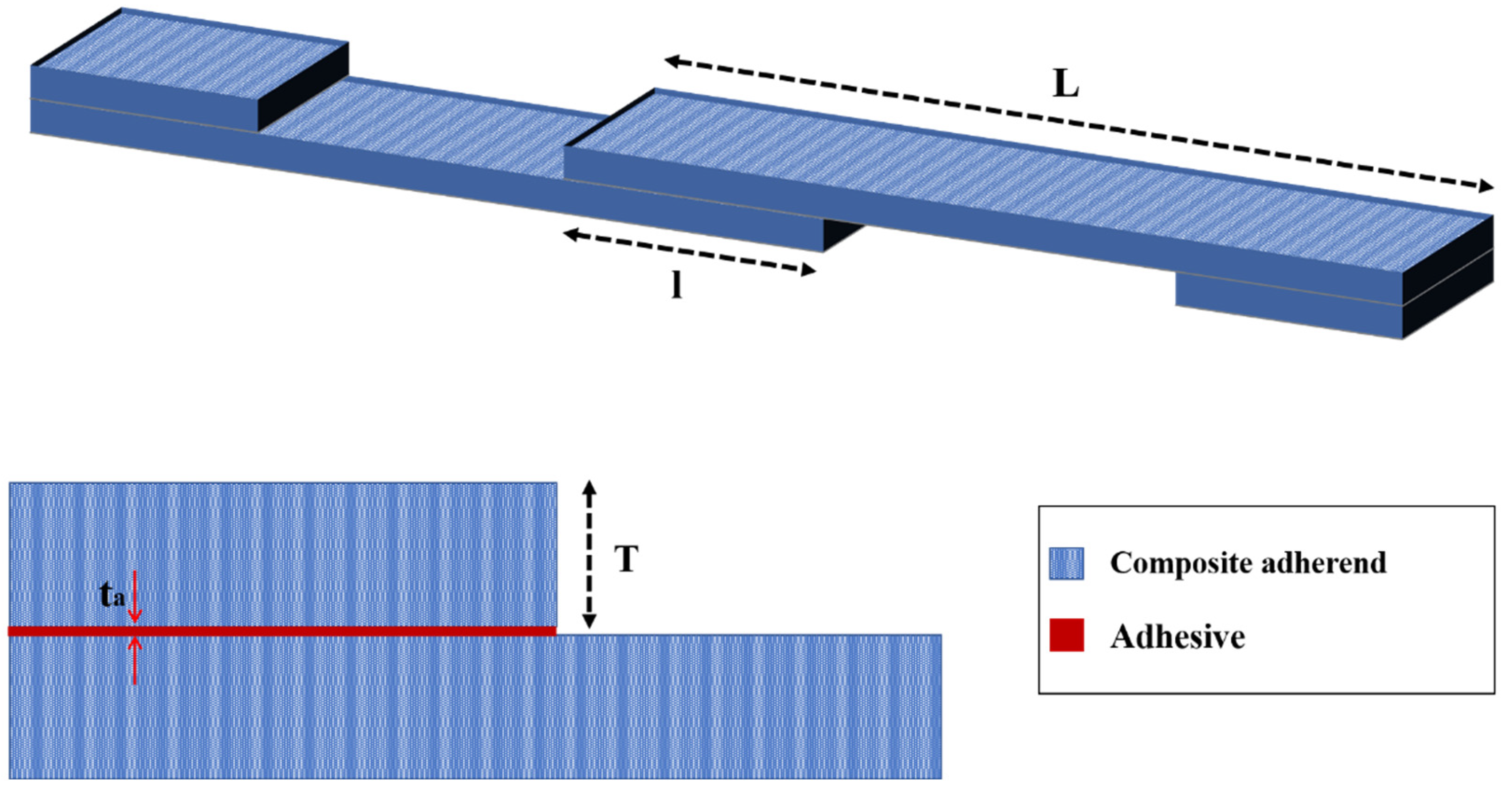

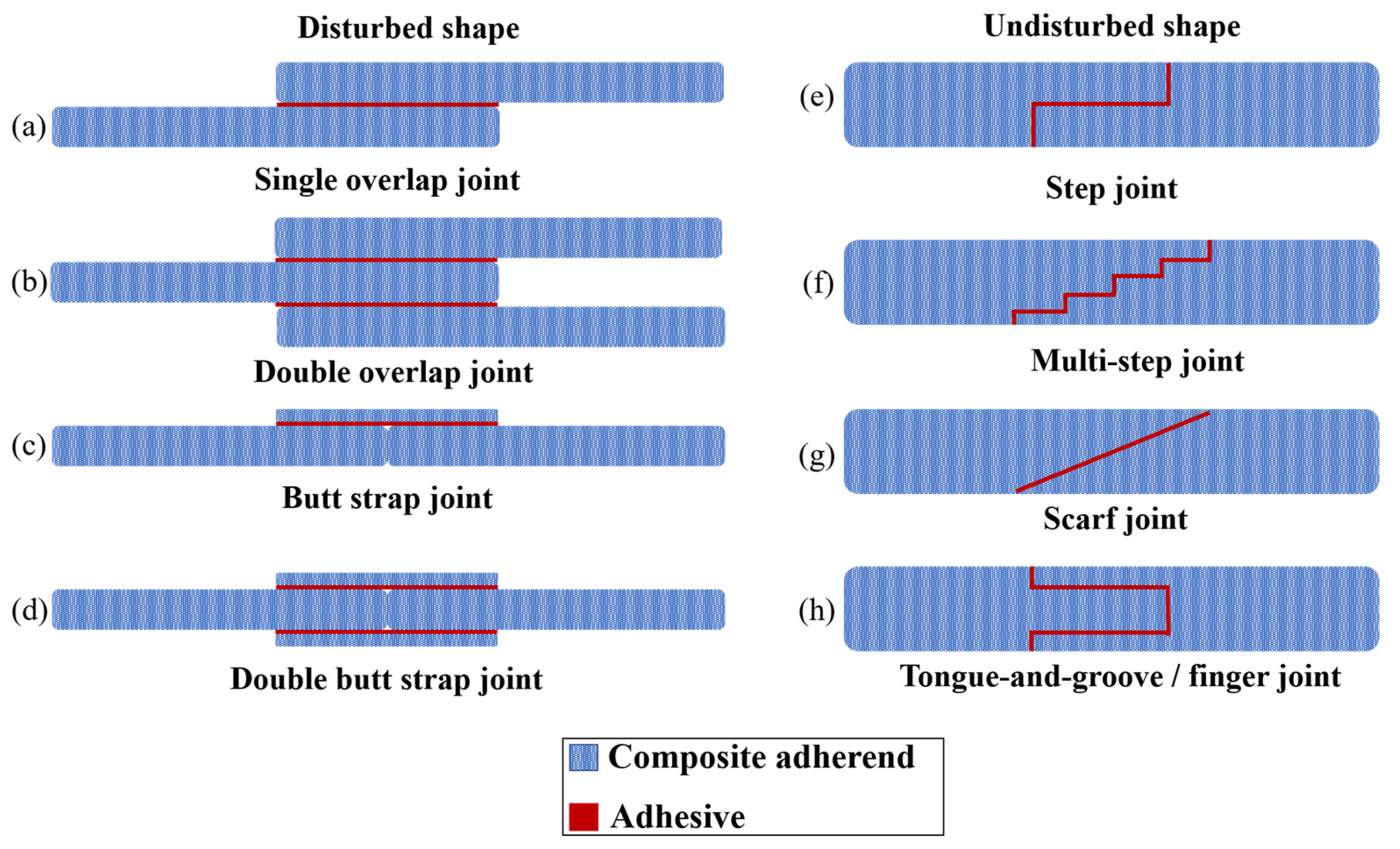

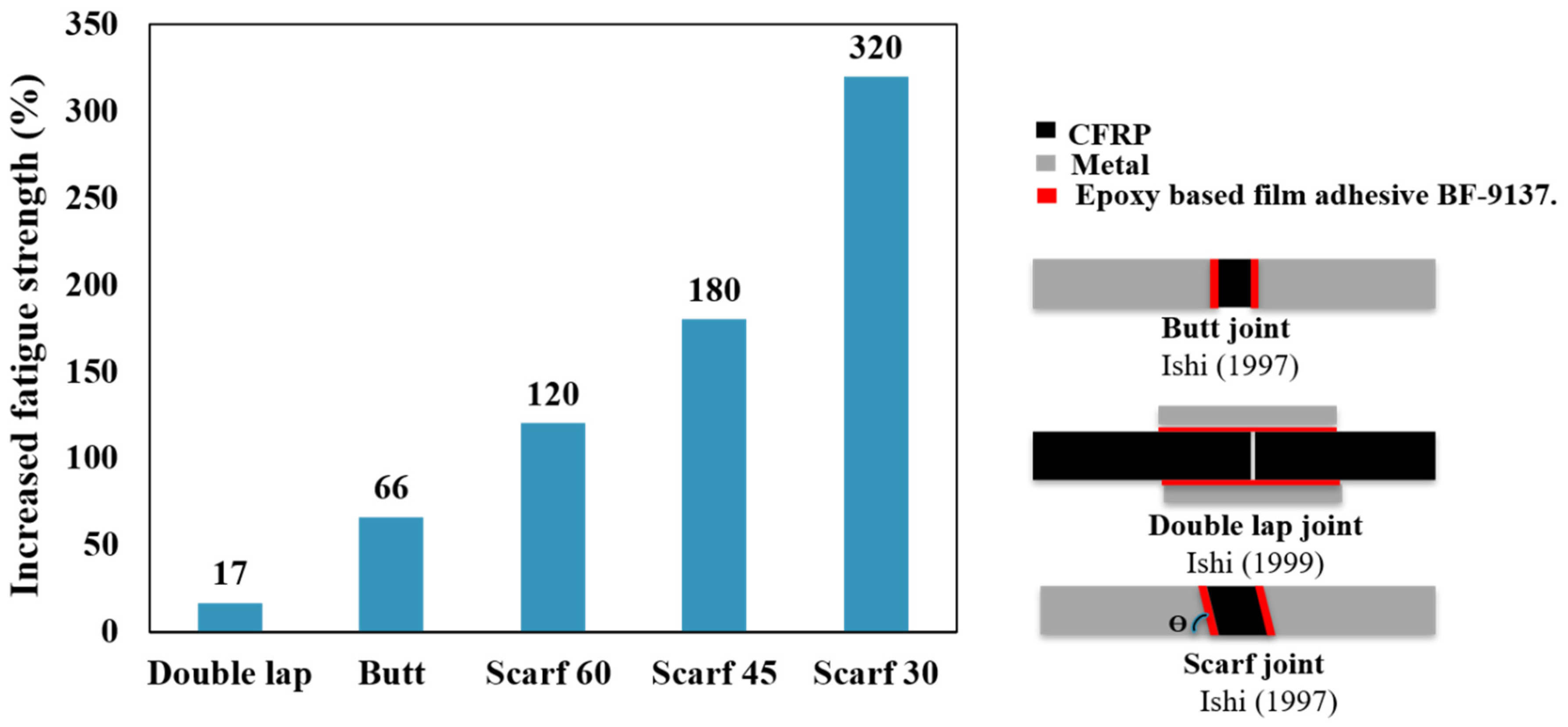

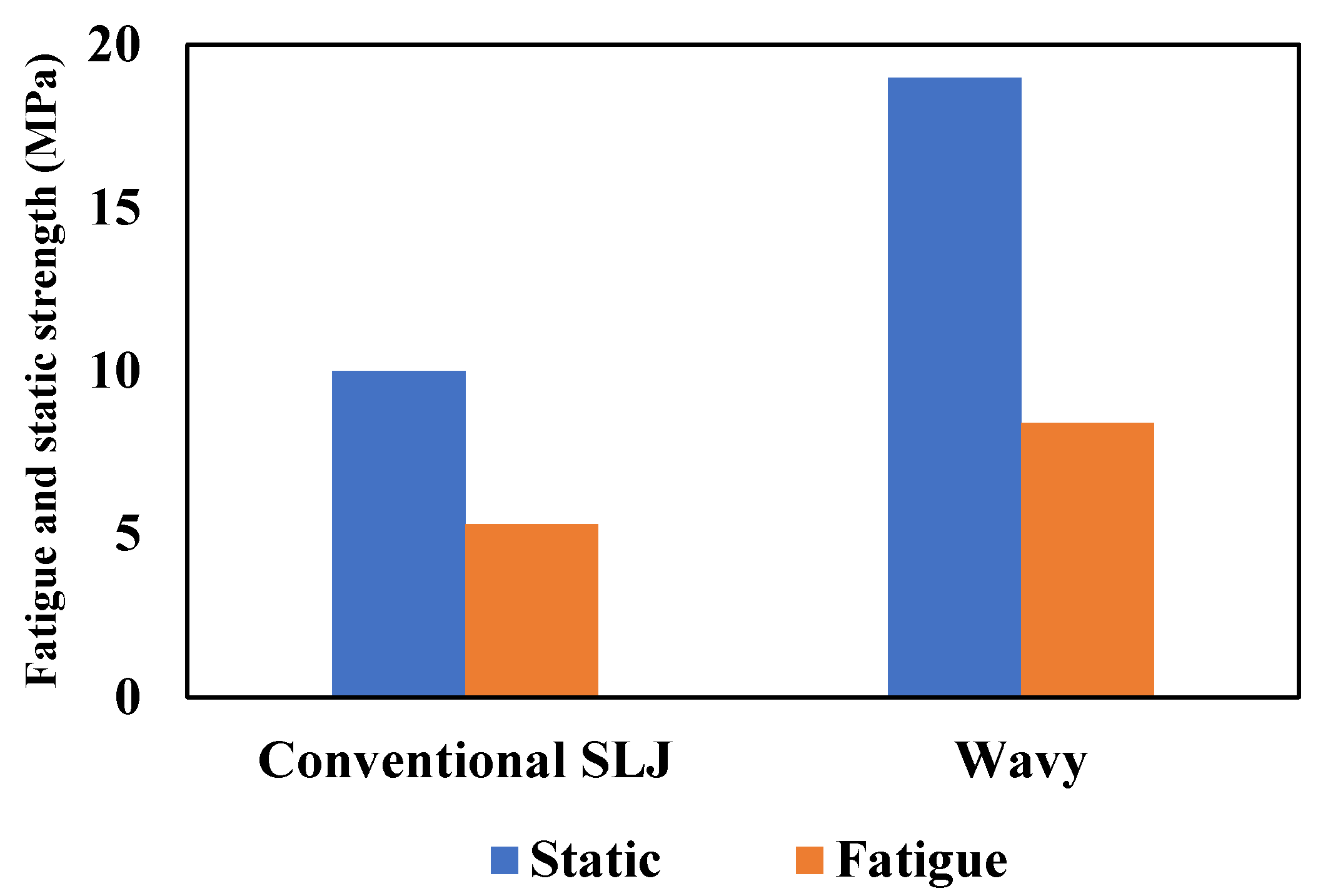

3.1. Overlap Shape

3.2. Overlap Length

3.3. Corner Geometry

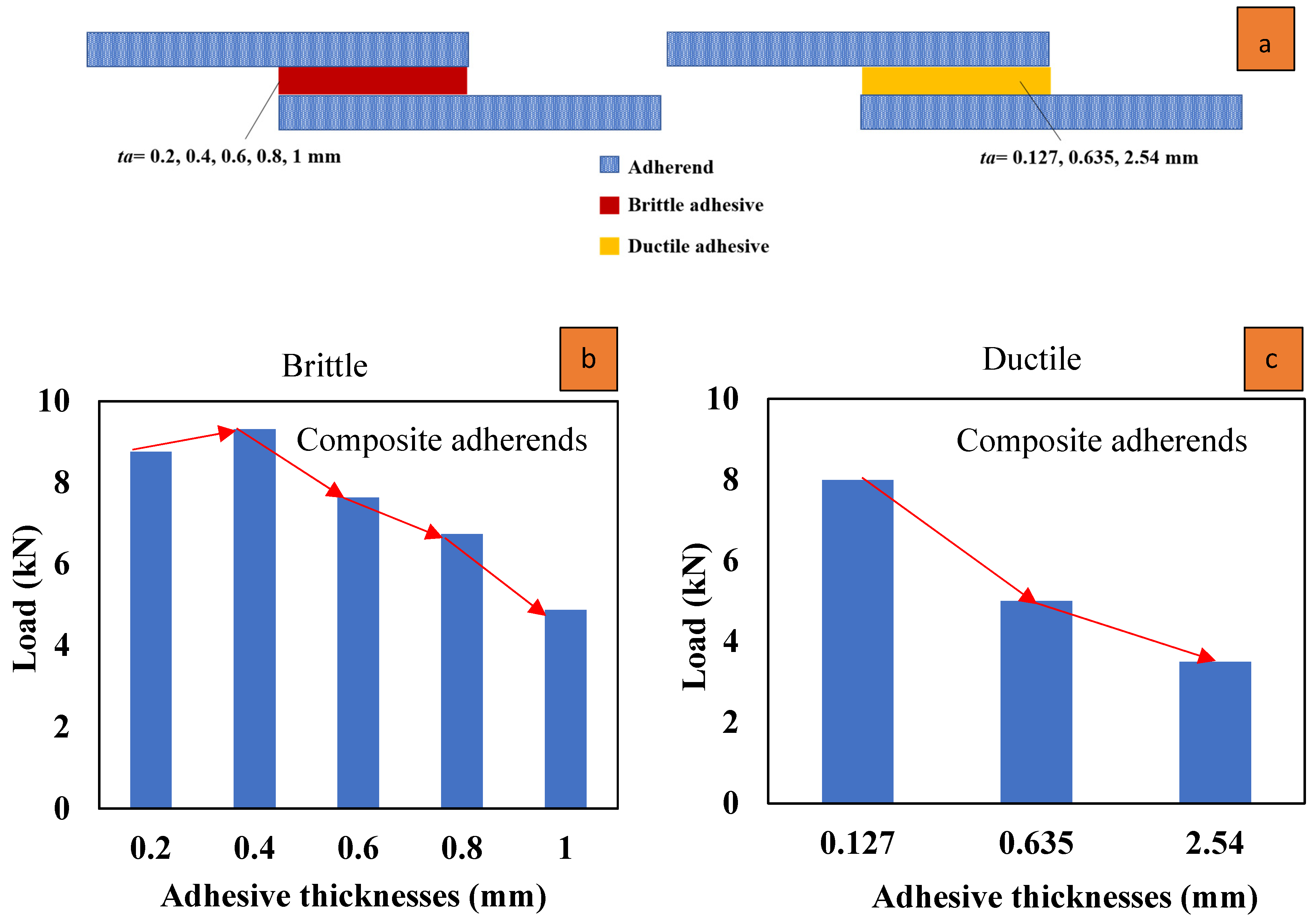

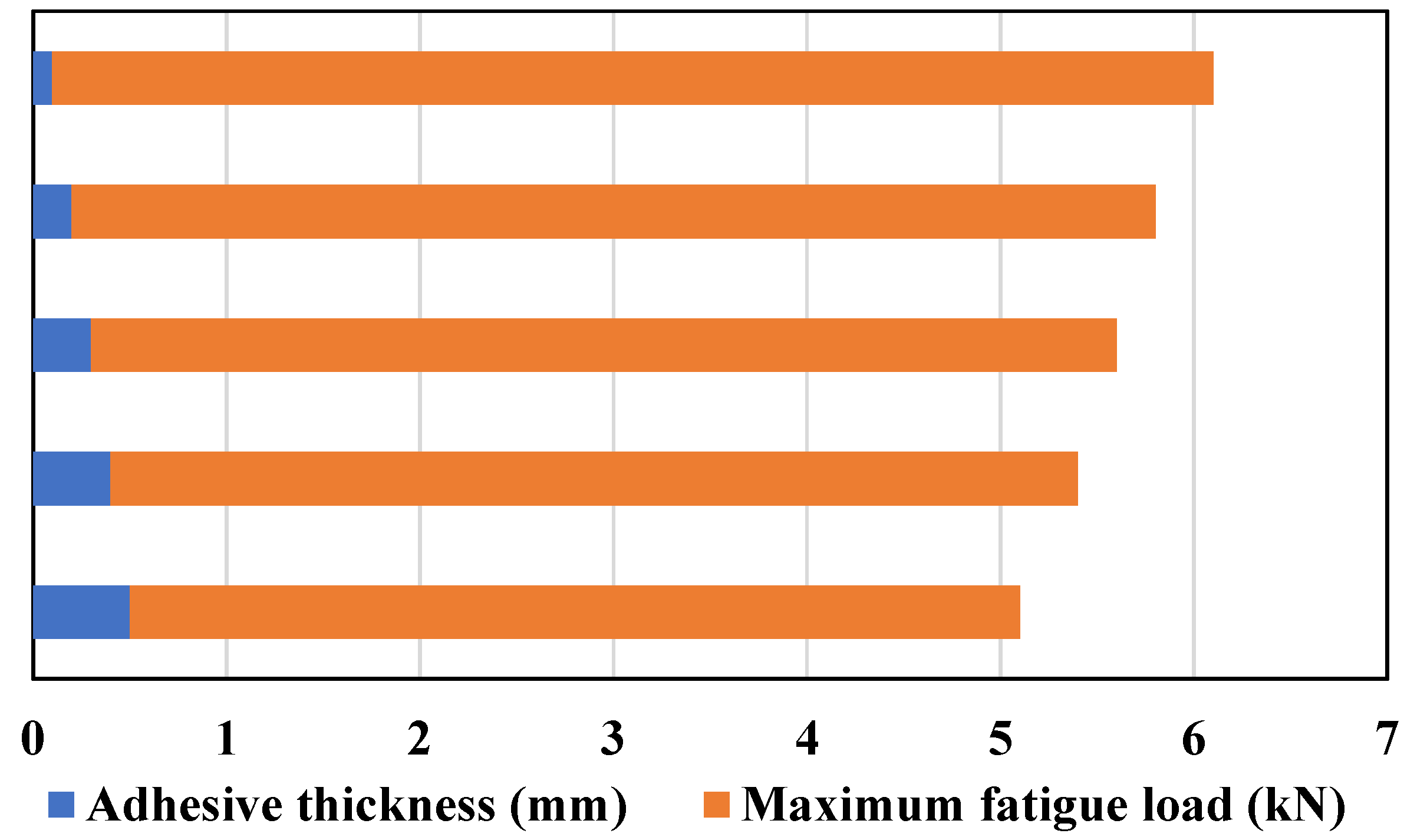

3.4. Adhesive Thickness

4. Adherend Modification

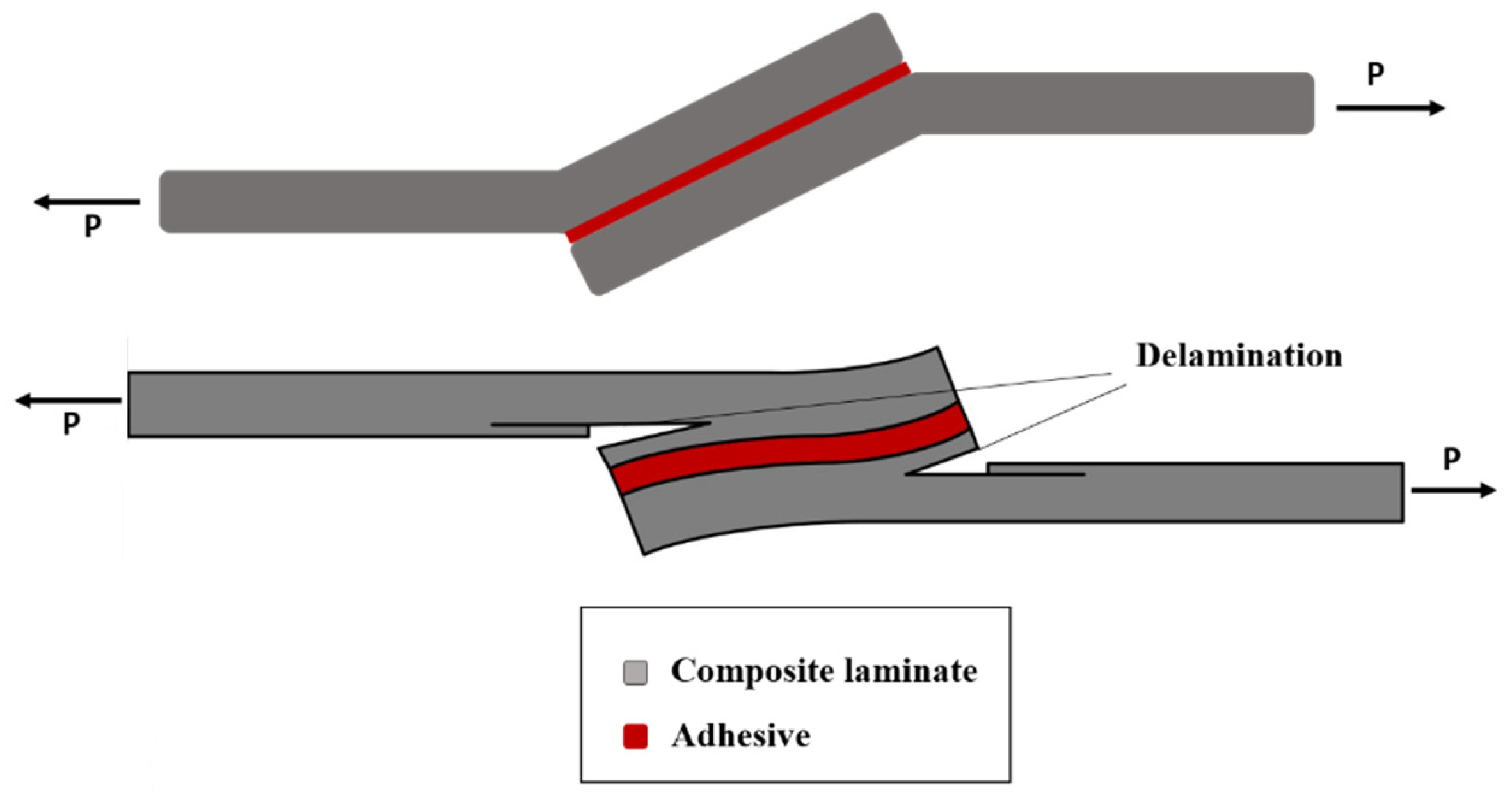

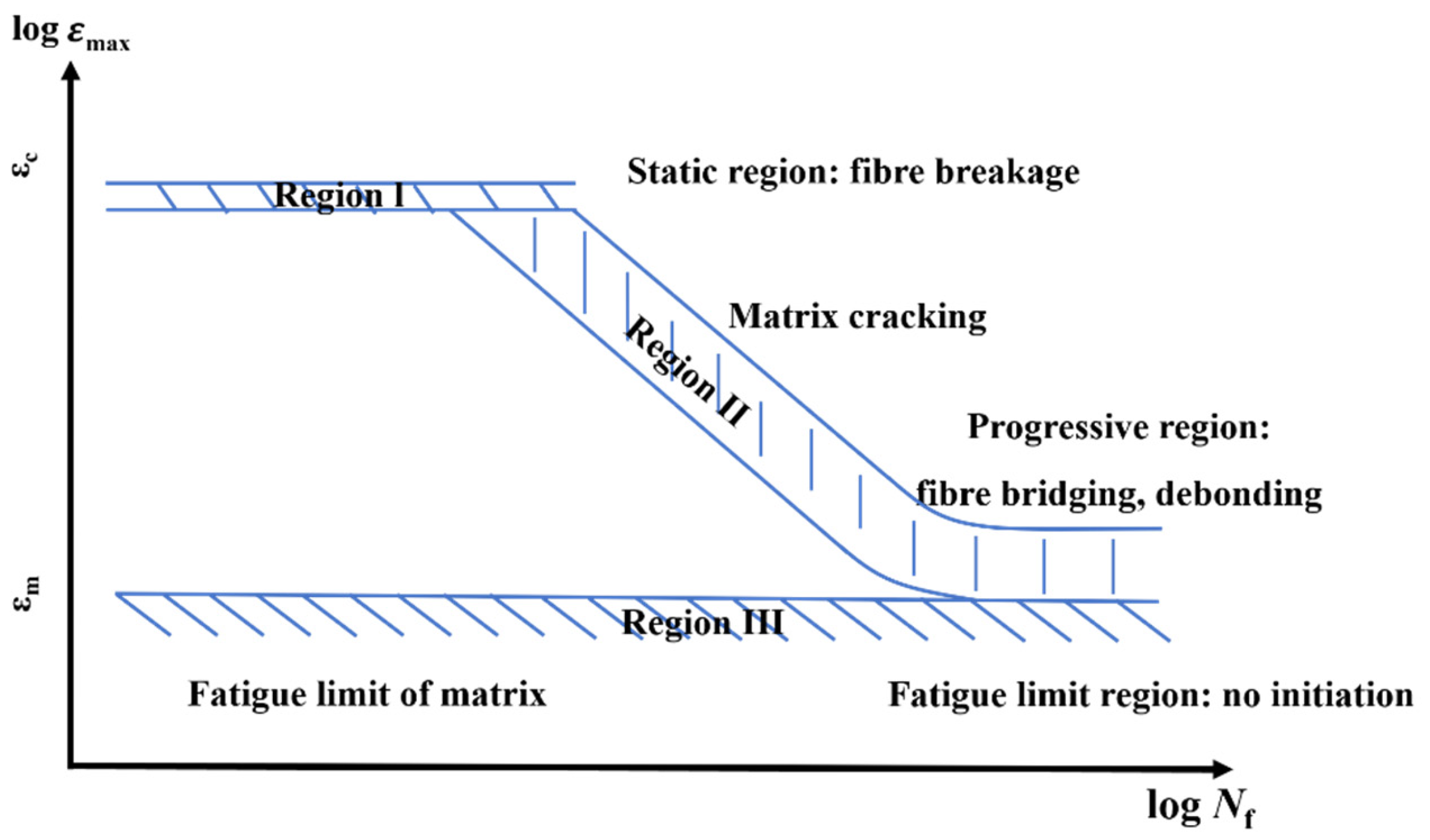

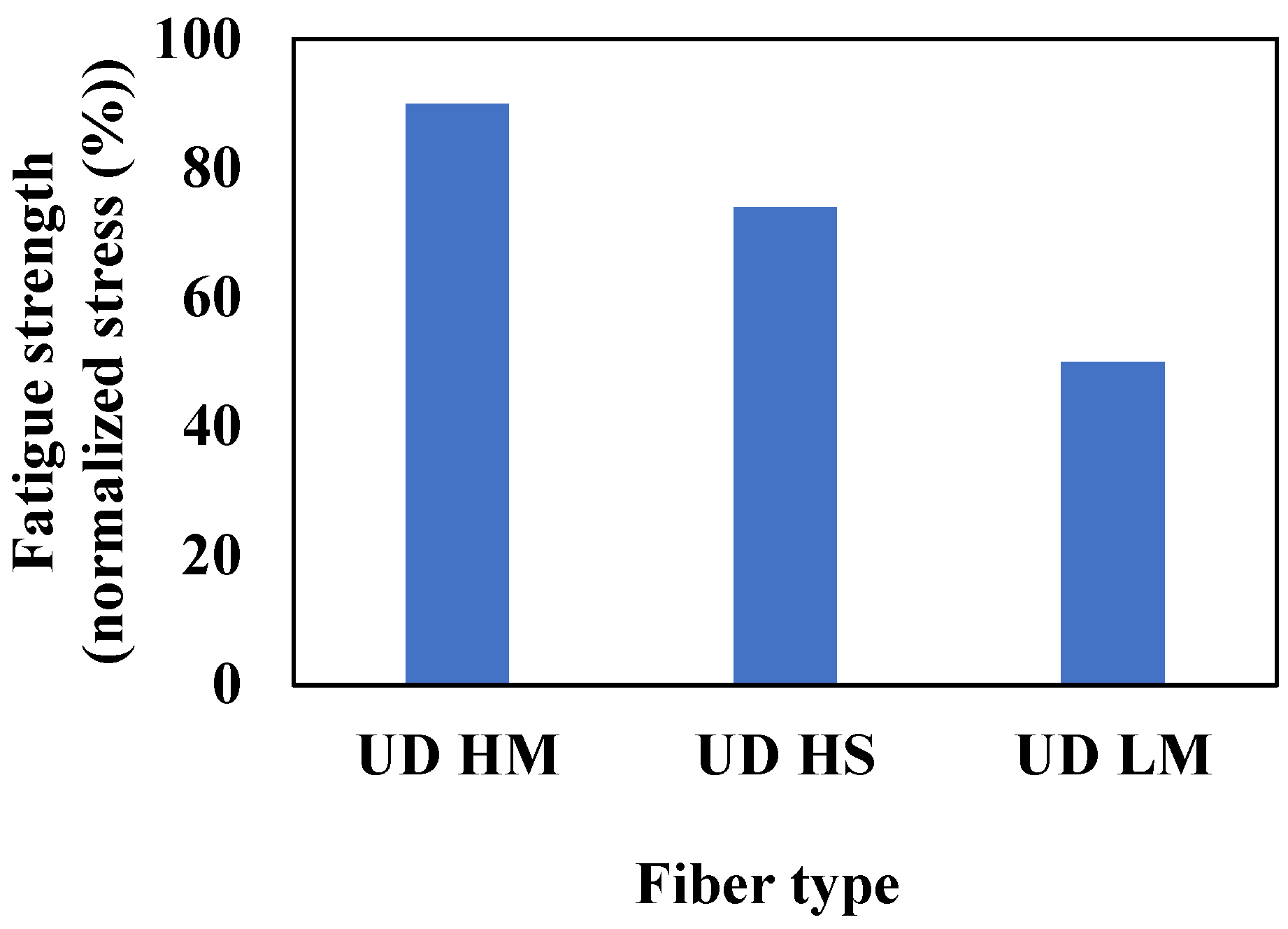

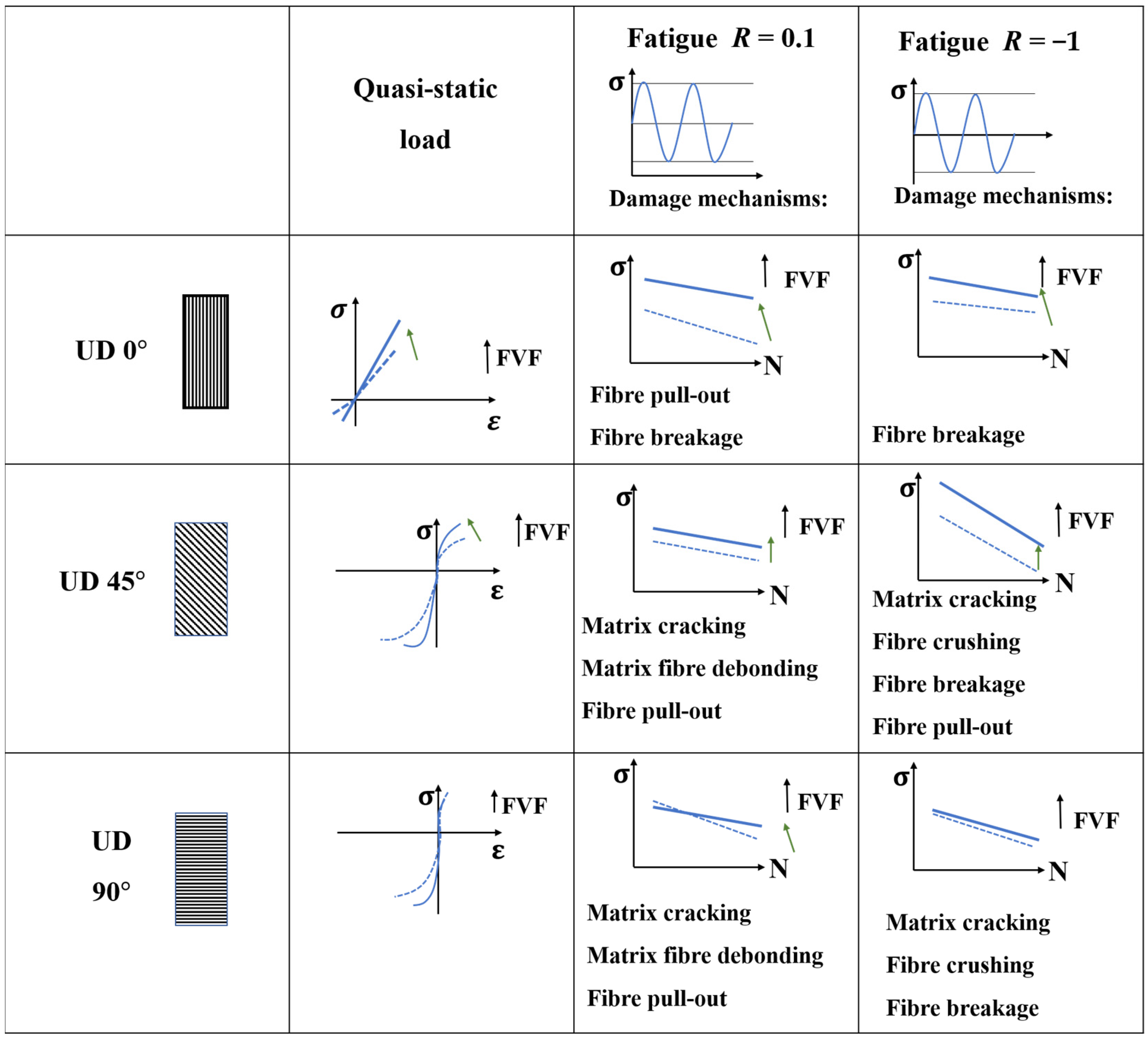

4.1. Composite Materials under Fatigue Loading

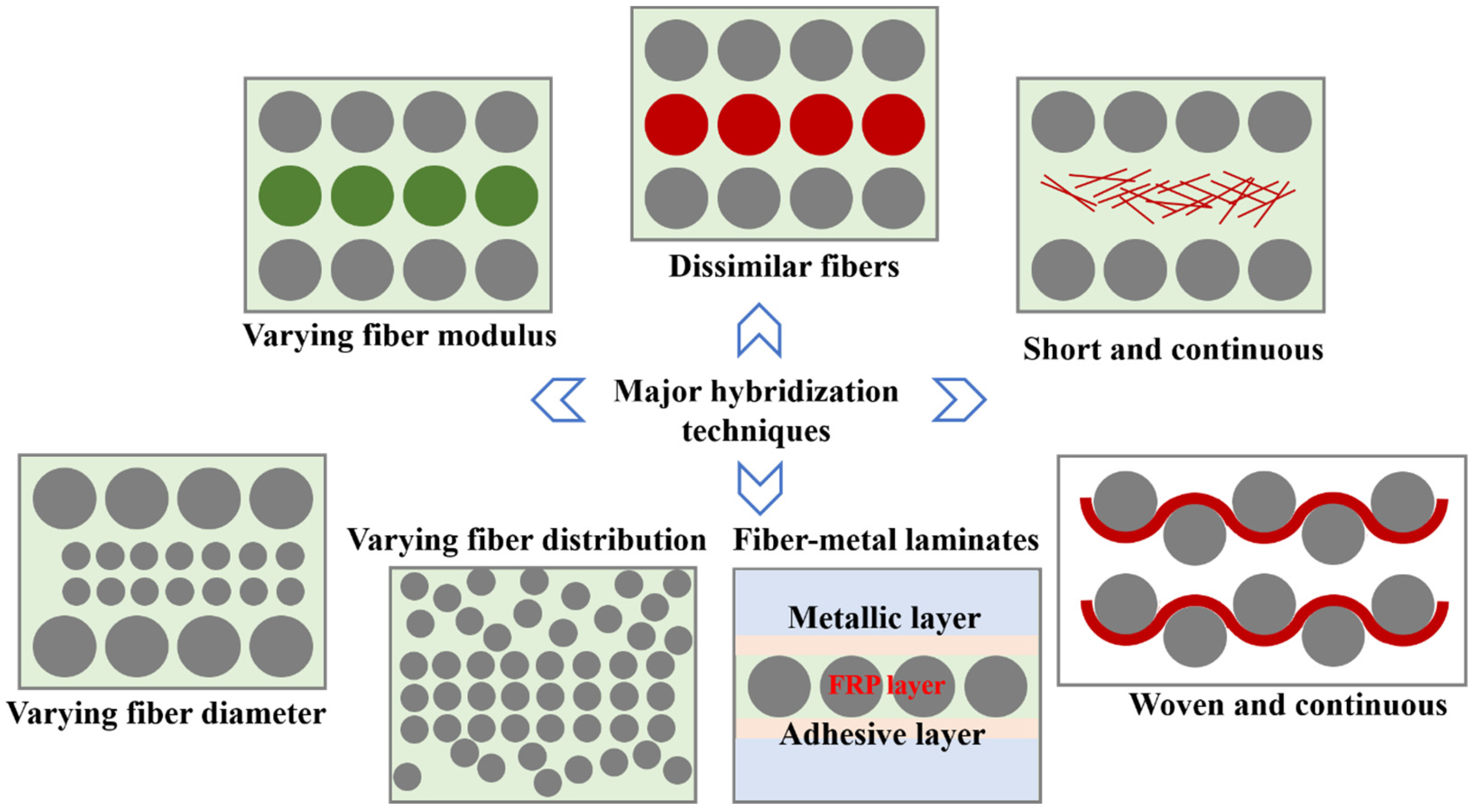

4.2. Hybrid Composite Laminate

4.3. Stacking Sequence and Interface Ply Orientation of Adherends

4.4. Surface Treatment

5. Adhesive Modification

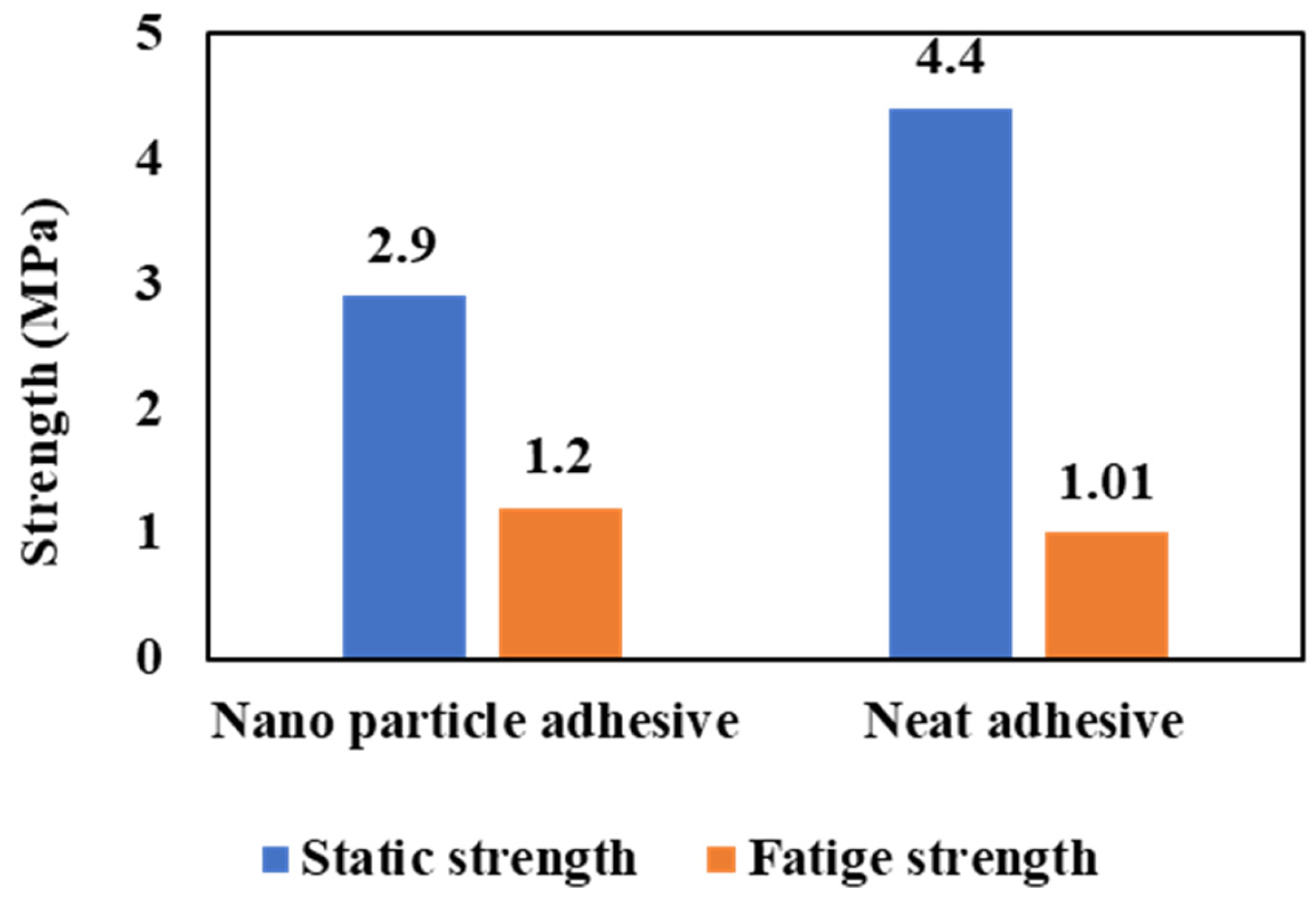

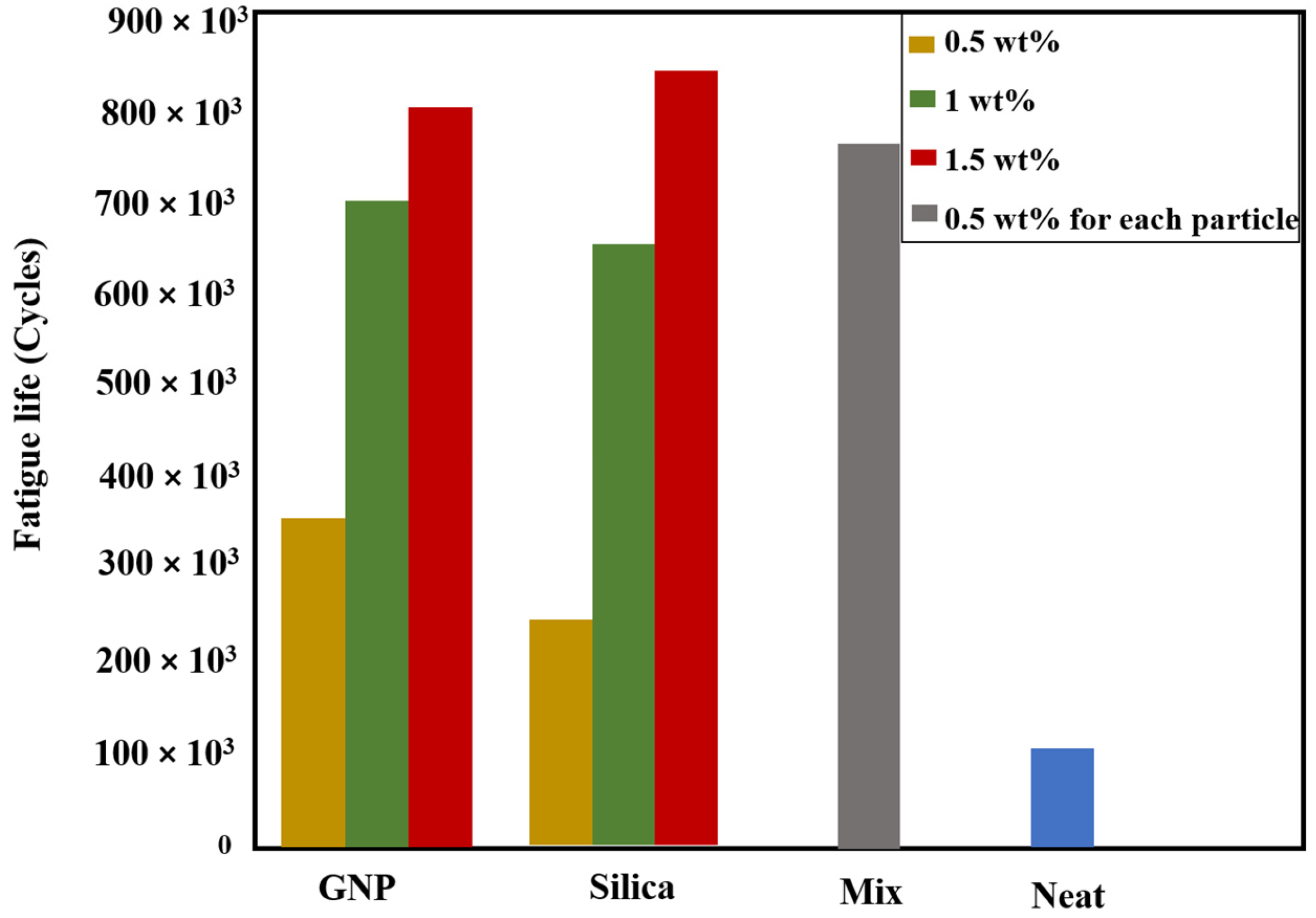

5.1. Nano-Reinforced Adhesive Layers

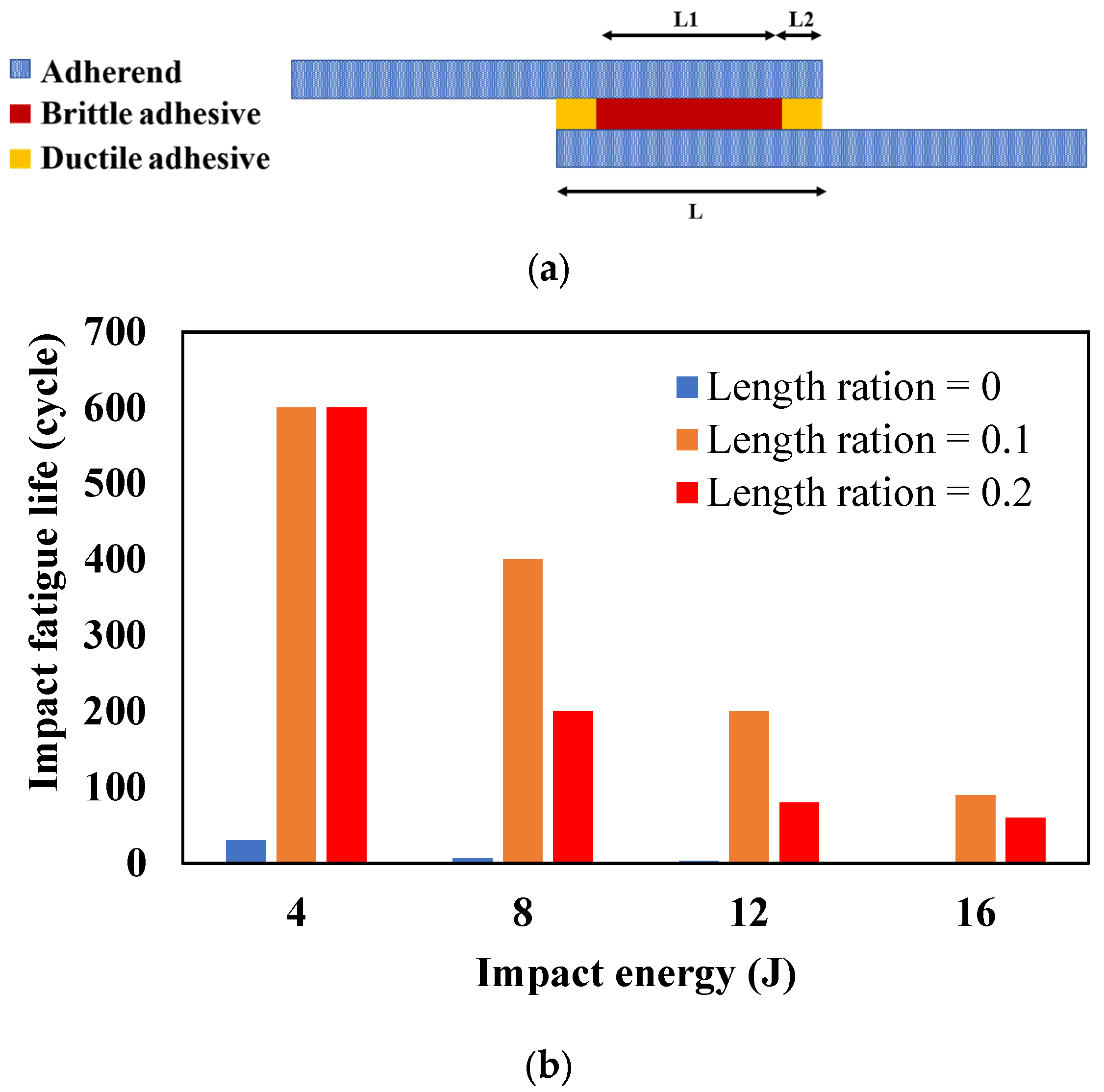

5.2. Mixed Adhesive Layers

5.3. Other Modification Methods

6. Design Guidelines

- -

- -

- The implementation of reverse bent joints has led to a substantial improvement of up to 190% in static strength compared to flat interface geometry. Additionally, in terms of fatigue performance, the increase in strength can be greater than what is observed in static conditions [64]. Nonetheless, achieving precise control over the geometry and manufacturing of curved composite adherends remains a significant challenge.

- -

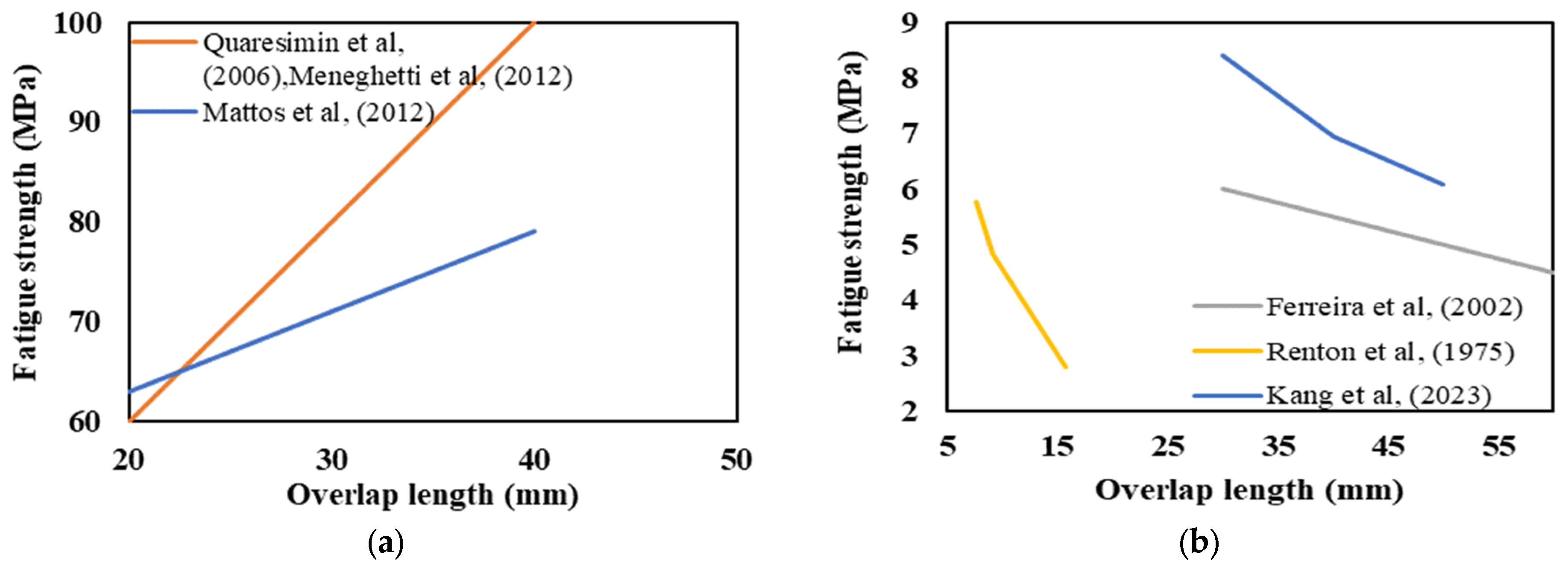

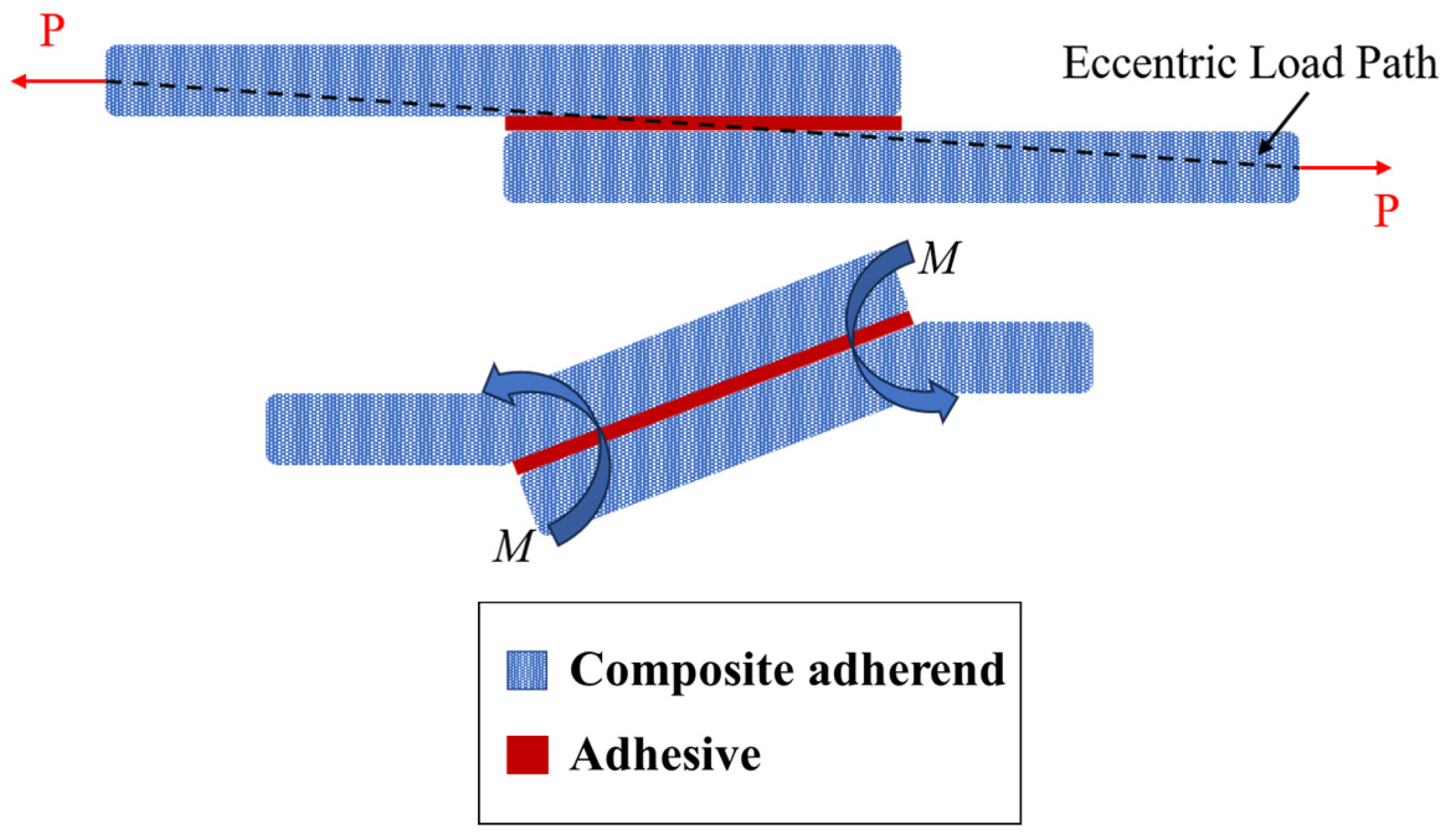

- Increases in overlap length have been shown to correspondingly increase the static failure load of the joint until the adherends reach a critical point [23,75]. However, this effect becomes negligible when utilizing a brittle and stiff adhesive [23]. To achieve optimal fatigue life and strength, it is advisable to determine a minimum overlap length [27]. In general, extending the overlap length tends to enhance the fatigue load [35,44,85]. Nevertheless, conflicting trends for the effect of the overlap length on fatigue strength have been reported in some references. These inconsistencies can be attributed to variations in the adhesive (Brittle or ductile) and composite adherend properties as well as the initiation failure mode.

- -

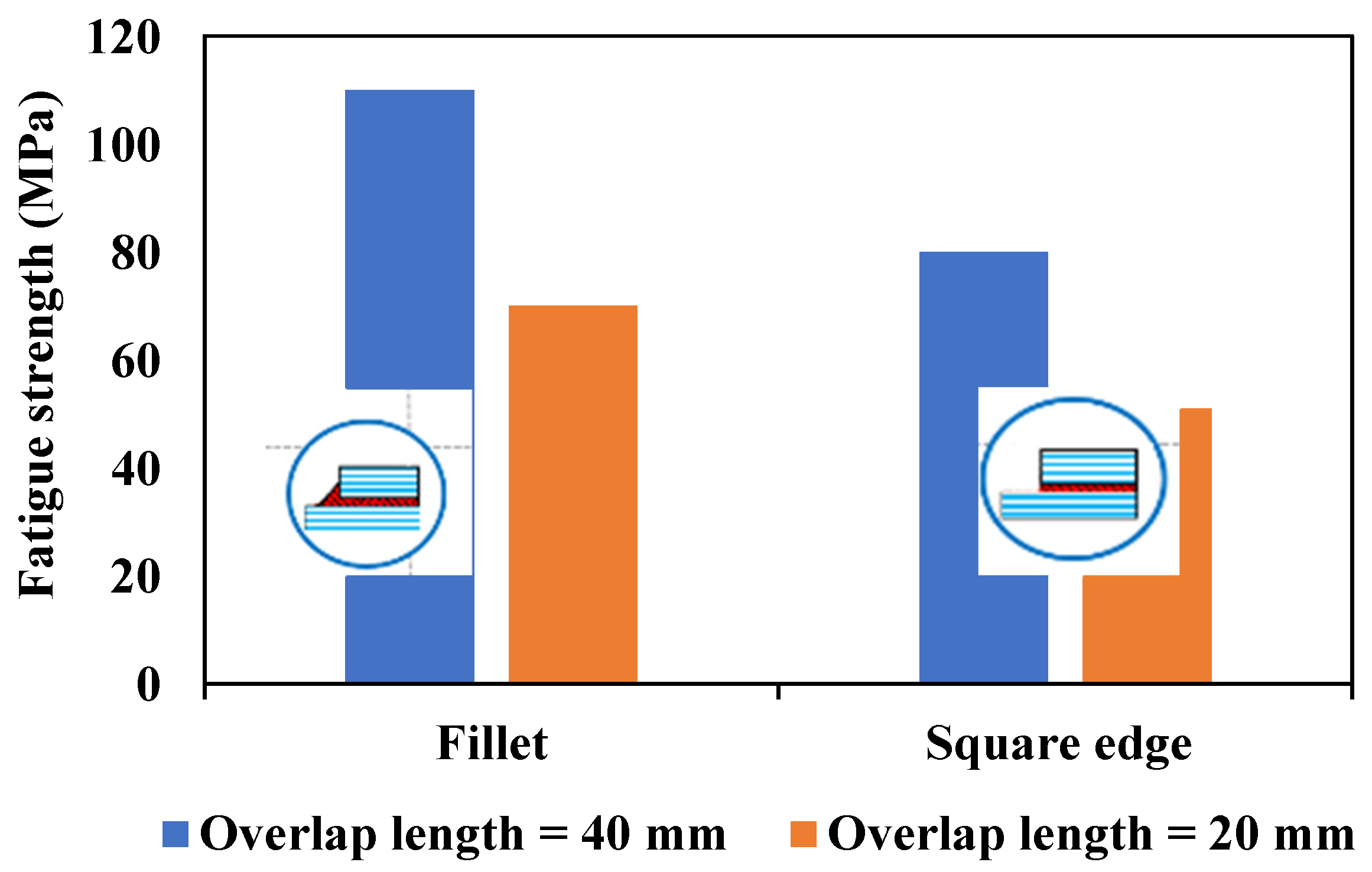

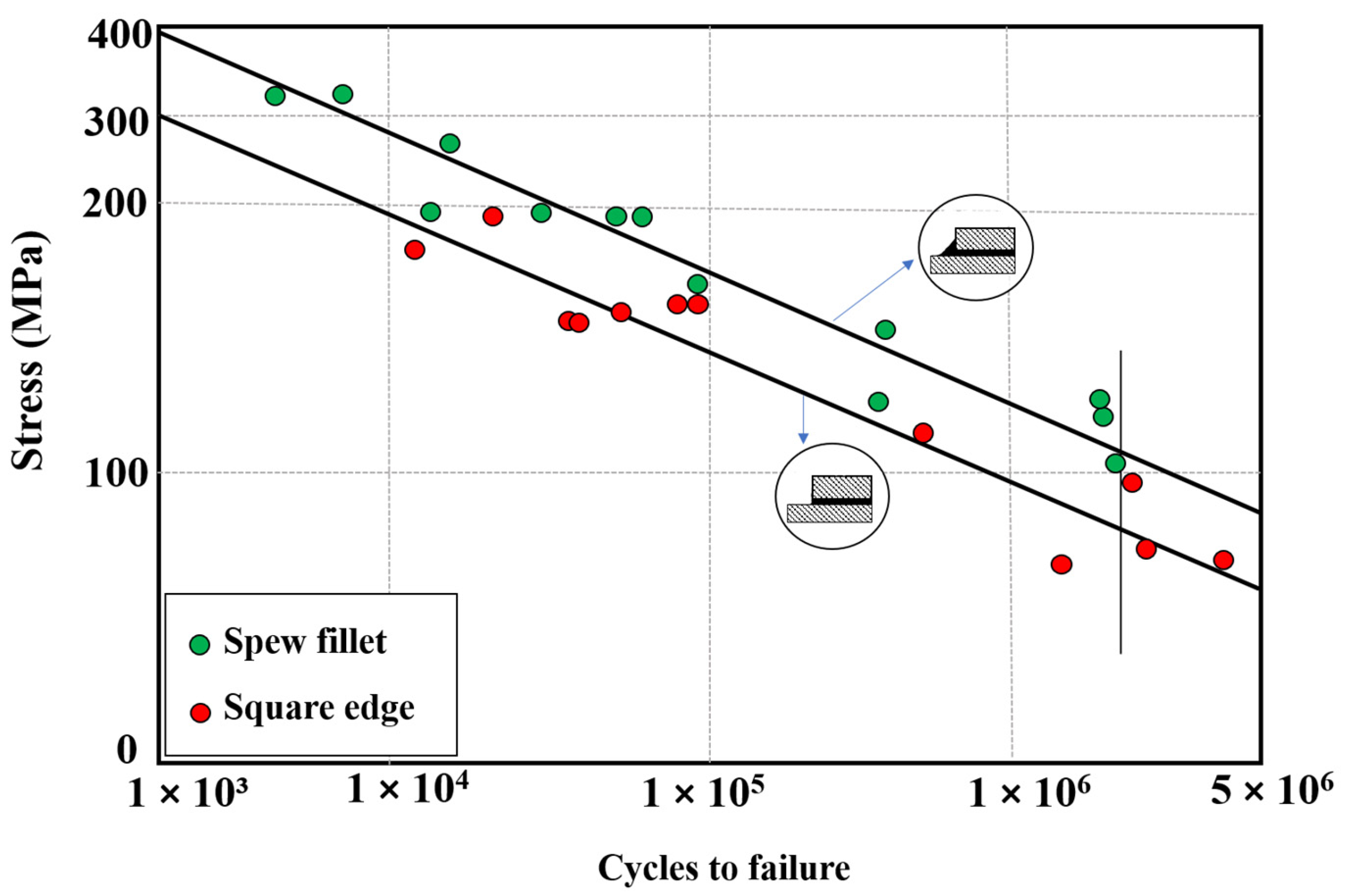

- Applying a fillet to the adherend corner eliminates the singularity in that particular region [44,85]. Utilizing a fillet geometry has been shown to enhance both the static and fatigue strength of adhesively bonded composite joints [93]. This improvement can be attributed to the reduced intensity and degree of singularity associated with the fillet corner geometry compared to a sharp square edge [90]. Nevertheless, the extent of the fatigue strength increase achieved through the use of fillets may be influenced by other factors, including the overlap length and other geometric parameters of the joint. Consequently, it is essential to carefully assess and optimize these parameters in order to attain the desired fatigue performance.

- -

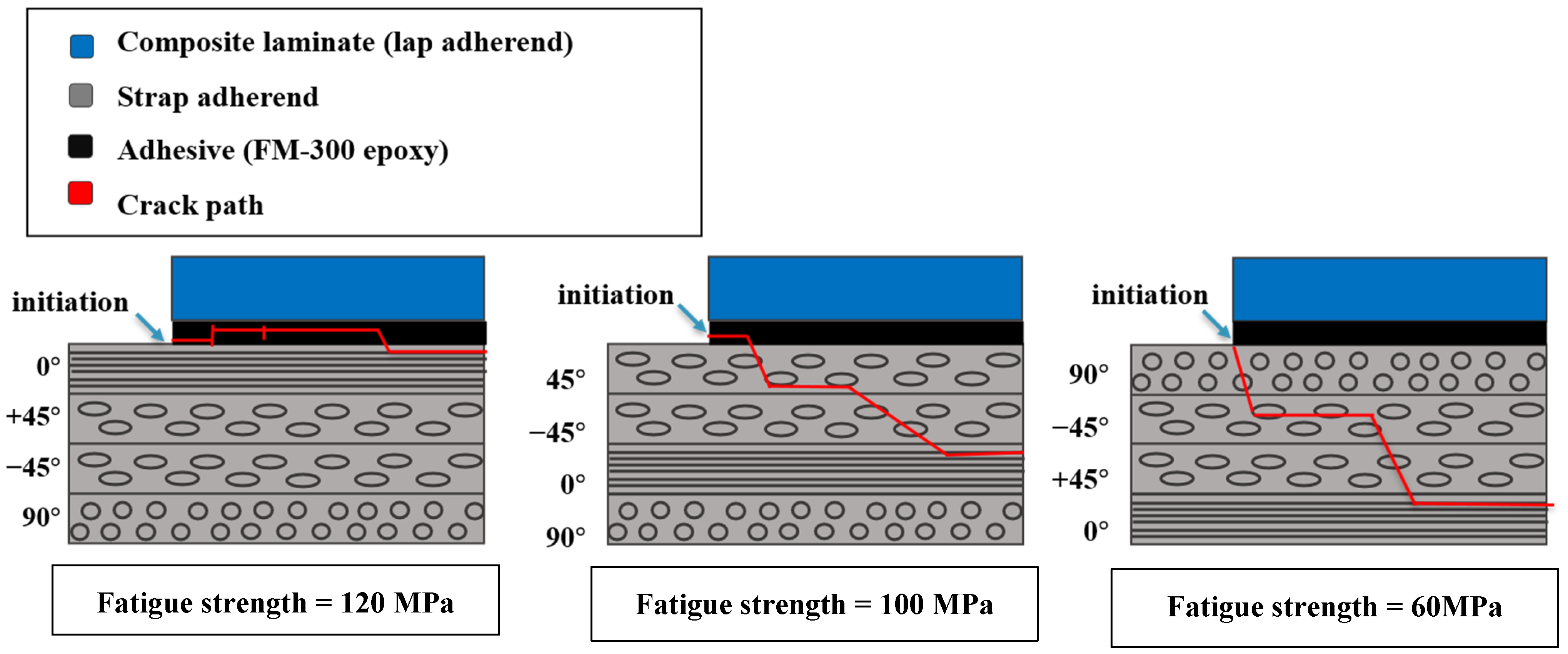

- Considering the adhesive/adherend interface layer orientation, it is important to note that it can have an impact on both the static strength and fatigue behavior of the joint. In terms of static strength, there is a possibility of a slight increase when specific orientations are employed [27,50,52,99,155]. The failure mode also varies depending on the interface orientation. In the case of a 0° interface, failure typically initiates due to adhesive/adherend interface debonding. However, when a 90° interface is present, failure tends to happen inside the composite adherends [130]. Furthermore, the orientation of the adhesive adjacent layers plays a role in fatigue crack propagation. With a 0° orientation, cracks predominantly propagate within the adhesive. However, at 45 and 90°, the crack growth becomes more complex. Using a 90° layer as the interface between adherends and adhesive represents the worst case in terms of fatigue strength, while the 0° orientation is expected to deliver the best performance [27,155,158].

- -

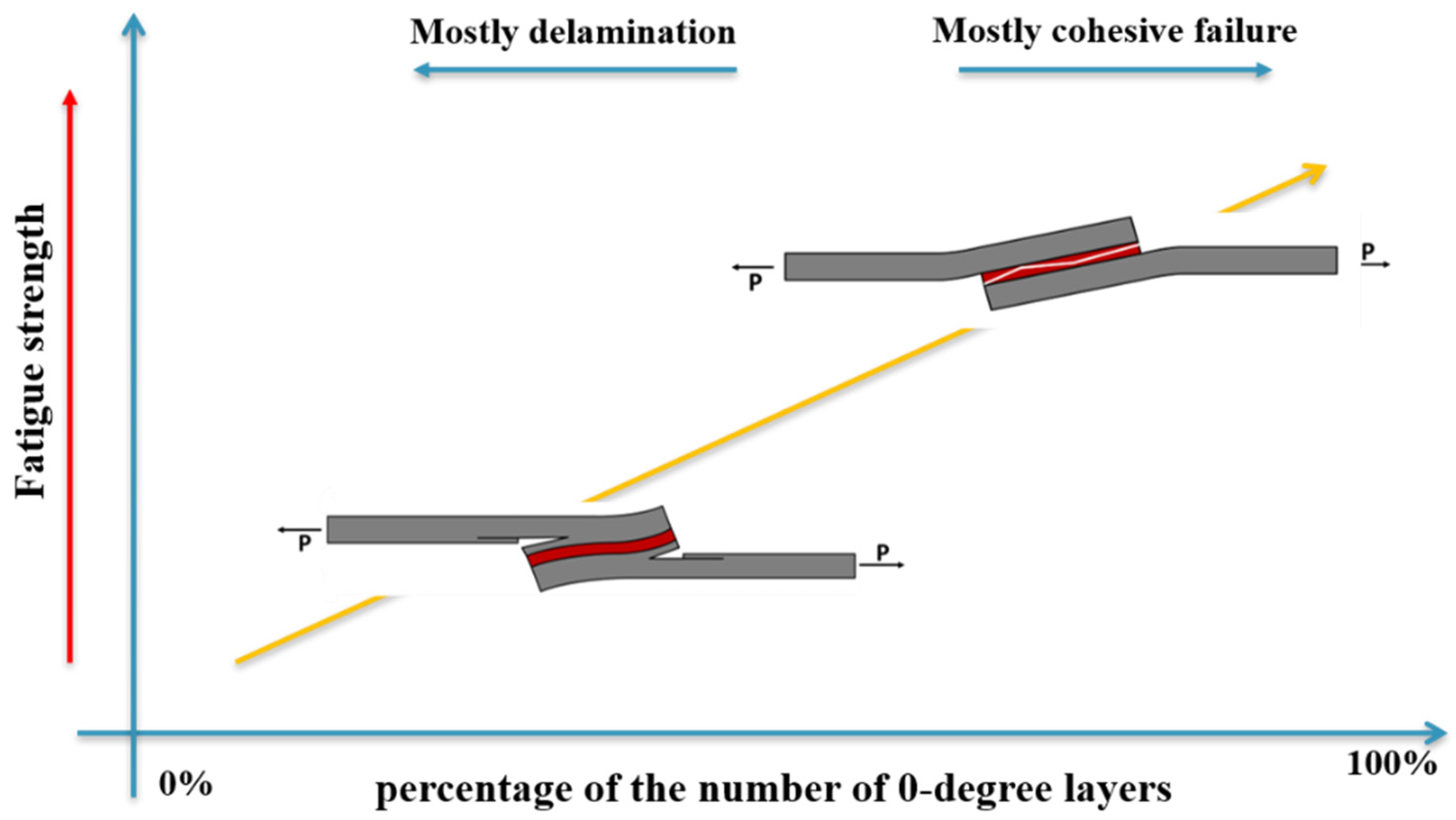

- The stacking sequence has a significant impact on the static failure load simply by modifying the layup configuration. Notably, the majority of [0]16 plies demonstrated higher failure loads, except for the [0/45/−45/90]4 configuration, which exhibited 48% greater strength compared to the stacking sequence consisting entirely of 0° plies [23]. In terms of fatigue strength, the proportion of adherends’ layers oriented at 0° plays a crucial role in determining the joint’s resistance to fatigue [79,156]. It should be noted that the impact of these factors on fatigue strength varies significantly based on the joint configuration.

- -

- The strength of the joint can be enhanced by using adherends with higher stiffness specifically for bending and peel resistance [152,153]. This can be achieved by either increasing the number of layers oriented at 0° or positioning them closer to the outer surfaces of the adherends [130]. Similar to the static failure behavior, the fracture characteristics under cyclic loading are influenced by the stress distribution along the bondline, which, in turn, is affected by the rigidity of the adherends [27]. In general, utilizing a stiffer laminate as adherends tends to improve the fatigue strength of the joint [79].

- -

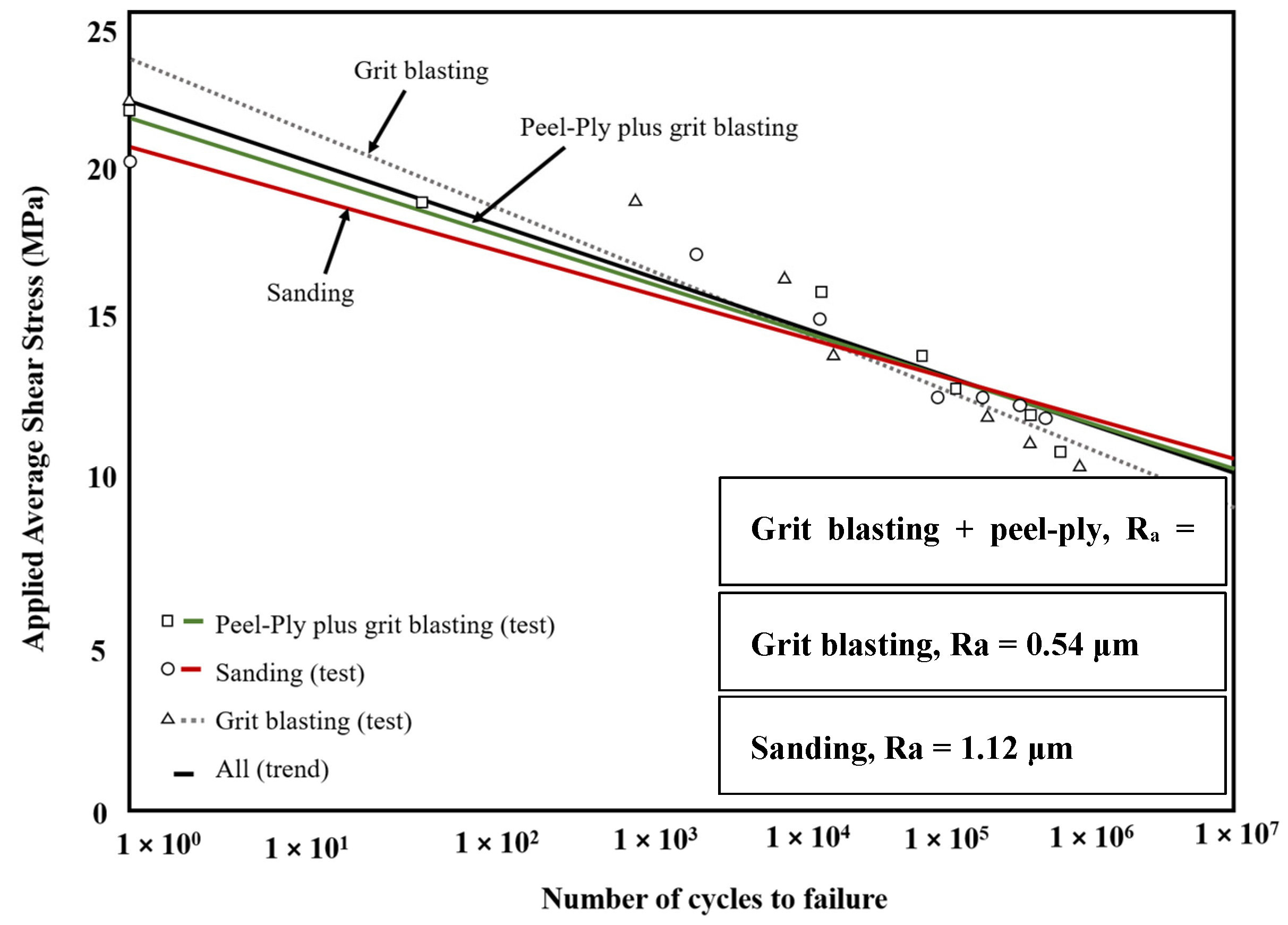

- In the context of surface treatment, the ultimate static strength of an adhesive-bonded joint is lower when the failure occurs at the adhesive layer as compared to a cohesive failure. The effectiveness of pretreatments has a notable impact on this aspect [43]. Furthermore, while failure is attributed to the adhesive, there is a considerable reduction in the fatigue resistance of the bonded joint. Consequently, employing an effective surface treatment can shift the failure mode toward cohesive failure, leading to an increase in fatigue strength [43].

- -

- -

- When it comes to the mixed adhesive layer, the improvement in static strength is not guaranteed and largely depends on the specific adhesive materials used, as well as the length ratio of the layers [199,207]. However, the effect of mixed adhesive layers on the fatigue strength of adhesively bonded composite joints is still relatively unexplored and should be addressed in future research.

- -

- The impact of adhesive thickness on joint strength is contingent upon the ductility of the adhesive. In the case of brittle adhesives, there is a critical thickness beyond which strength begins to decline as the adhesive thickness increases. Conversely, for ductile adhesives, an increase in thickness can result in a reduction in static strength [95,96,106]. Regarding fatigue strength, studies have shown a decrease in fatigue resistance as the bondline thickness increases [50,98]. However, there exists a specific thickness at which the maximum fatigue resistance is observed [27].

7. Conclusions

- It has been shown that changing the geometry of joints can increase the fatigue strength. These changes can take place in adhesive thickness, overlap length, and shape. The influence of these parameters on fatigue life is interconnected, meaning that to investigate the effect of them on fatigue behavior, they should be assessed simultaneously.

- The primary factor that significantly influences joint strength is the configuration of the joints. While wavy, step, butt, and double lap joints have demonstrated superior fatigue strength compared to traditional single lap joints, it is worth noting that the scarf joint has exhibited the most significant enhancement in this regard.

- Increasing the overlap length had a more significant impact on improving the fatigue strength of adhesively bonded composite joints compared to the use of corner fillets.

- In the context of composite adherends and their stacking sequence, the proportion of 0° layers directly affects the rise in fatigue strength and also alters the mode of failure by affecting the adherends’ stiffness.

- Applying an effective surface treatment can shift the failure mode toward cohesive failure, leading to an increase in fatigue strength.

- Modification of the adhesive layer can be achieved through the utilization of either a mixed adhesive layer or an adhesive layer reinforced with nanomaterials. It has been demonstrated that adhesive modification can enhance the fatigue behavior of adhesively bonded composite joints, depending on the type of adhesive and nanoparticles used.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Maiti, S.; Islam, M.R.; Uddin, M.A.; Afroj, S.; Eichhorn, S.J.; Karim, N. Sustainable Fiber-Reinforced Composites: A Review. Adv. Sustain. Syst. 2022, 6, 2200258. [Google Scholar] [CrossRef]

- Bahabadi, H.M.; Farrokhabadi, A.; Rahimi, G.H. Investigation of debonding growth between composite skins and corrugated foam-composite core in sandwich panels under bending loading. Eng. Fract. Mech. 2020, 230, 106987. [Google Scholar] [CrossRef]

- Compton, B.G.; Post, B.K.; Duty, C.E.; Love, L.; Kunc, V. Thermal analysis of additive manufacturing of large-scale thermoplastic polymer composites. Addit. Manuf. 2017, 17, 77–86. [Google Scholar] [CrossRef]

- Mohan, V.R.; Tamma, K.K.; Shires, D.R.; Mark, A. Advanced manufacturing of large-scale composite structures: Process modeling, manufacturing simulations and massively parallel computing platforms. Adv. Eng. Softw. 1998, 29, 249–263. [Google Scholar] [CrossRef]

- Wang, C.; Huang, Y.D.; Xv, H.Y.; Liu, W.B. The durability of adhesive/carbon–carbon composites joints in salt water. Int. J. Adhes. Adhes. 2004, 24, 471–477. [Google Scholar] [CrossRef]

- Borges, C.S.P.; Akhavan-Safar, A.; Tsokanas, P.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. From fundamental concepts to recent developments in the adhesive bonding technology: A general view. Discov. Mech. Eng. 2023, 2, 8. [Google Scholar] [CrossRef]

- Budzik, M.K.; Wolfahrt, M.; Reis, P.; Kozłowski, M.; Sena-Cruz, J.; Papadakis, L.; Nasr Saleh, M.; Machalicka, K.V.; Teixeira de Freitas, S.; Vassilopoulos, A.P. Testing mechanical performance of adhesively bonded composite joints in engineering applications: An overview. J. Adhes. 2022, 98, 2133–2209. [Google Scholar] [CrossRef]

- Higgins, A. Adhesive bonding of aircraft structures. Int. J. Adhes. Adhes. 2000, 20, 367–376. [Google Scholar] [CrossRef]

- Qin, Z.; Yang, K.; Wang, J.; Zhang, L.; Huang, J.; Peng, H.; Xu, J. The effects of geometrical dimensions on the failure of composite-to-composite adhesively bonded joints. J. Adhes. 2021, 97, 1024–1051. [Google Scholar] [CrossRef]

- Dilthey, U.; Stein, L. Multimaterial car body design: Challenge for welding and joining. Sci. Technol. Weld. Join. 2006, 11, 135–142. [Google Scholar] [CrossRef]

- Di Bella, G.; Galtieri, G.; Pollicino, E.; Borsellino, C. Mechanical characterization of adhesive joints with dissimilar substrates for marine applications. Int. J. Adhes. Adhes. 2013, 41, 33–40. [Google Scholar] [CrossRef]

- Delzendehrooy, F.; Akhavan-Safar, A.; Barbosa, A.Q.; Beygi, R.; Cardoso, D.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. A comprehensive review on structural joining techniques in the marine industry. Compos. Struct. 2022, 289, 115490. [Google Scholar] [CrossRef]

- Hizam, R.M.; Manalo, A.C.; Karunasena, W. A review of FRP composite truss systems and its connections. In From Materials to Structures: Advancement through Innovation—Proceedings of the 22nd Australasian Conference on the Mechanics of Structures and Materials, ACMSM 22, Sydney, Australia, 11–14 December 2012; CRC Press: Boca Raton, FL, USA, 2013; pp. 85–90. [Google Scholar]

- Budhe, S.; Banea, M.D.; de Barros, S. Bonded repair of composite structures in aerospace application: A review on environmental issues. Appl. Adhes. Sci. 2018, 6, 3. [Google Scholar] [CrossRef]

- Katnam, K.B.; Da Silva, L.F.M.; Young, T.M. Bonded repair of composite aircraft structures: A review of scientific challenges and opportunities. Prog. Aerosp. Sci. 2013, 61, 26–42. [Google Scholar] [CrossRef]

- Chester, R.J.; Walker, K.F.; Chalkley, P.D. Adhesively bonded repairs to primary aircraft structure. Int. J. Adhes. Adhes. 1999, 19, 1–8. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Öchsner, A.A.R. Handbook of Adhesion Technology: Second Edition; Springer: Cham, Switzerland, 2018; Volume 2, ISBN 9783319554112. [Google Scholar]

- Kim, C.-H.; Choi, J.-H.; Kweon, J.-H. Defect detection in adhesive joints using the impedance method. Compos. Struct. 2015, 120, 183–188. [Google Scholar] [CrossRef]

- Ariaee, S.; Tutunchi, A.; Kianvash, A.; Entezami, A.A. Modeling and optimization of mechanical behavior of bonded composite–steel single lap joints by response surface methodology. Int. J. Adhes. Adhes. 2014, 54, 30–39. [Google Scholar] [CrossRef]

- de Castro Lopes, F.V.B.; Akhavan-Safar, A.; Carbas, R.J.C.; Marque, E.A.S.; Goyal, R.; Jennings, J.; da Silva, L.F.M. The role of loading mode on the property degradation of adhesives at high temperatures. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 1848–1863. [Google Scholar] [CrossRef]

- Shang, X.; Marques, E.A.S.; Machado, J.J.M.; Carbas, R.J.C.; Jiang, D.; da Silva, L.F.M. Review on techniques to improve the strength of adhesive joints with composite adherends. Compos. Part B Eng. 2019, 177, 107363. [Google Scholar] [CrossRef]

- Ramalho, L.D.C.; Campilho, R.D.S.G.; Belinha, J.; da Silva, L.F.M. Static strength prediction of adhesive joints: A review. Int. J. Adhes. Adhes. 2020, 96, 102451. [Google Scholar] [CrossRef]

- Ramezani, F.; Simões, B.D.; Carbas, R.J.C.; Marques, E.A.S.; da Silva, L.F.M. Developments in Laminate Modification of Adhesively Bonded Composite Joints. Materials 2023, 16, 568. [Google Scholar] [CrossRef] [PubMed]

- ASTM D5573-99; Standard Practice for Classifying Failure Modes in Fiber-Reinforced Plastic (FRP). ASTM: West Conshohocken, PA, USA, 1999.

- Khalili, S.M.R.; Shokuhfar, A.; Hoseini, S.D.; Bidkhori, M.; Khalili, S.; Mittal, R.K. Experimental study of the influence of adhesive reinforcement in lap joints for composite structures subjected to mechanical loads. Int. J. Adhes. Adhes. 2008, 28, 436–444. [Google Scholar] [CrossRef]

- Sharba, M.J.; Leman, Z.; Sultan, M.T.H.; Ishak, M.R.; Hanim, M.A.A. Monotonic and fatigue properties of kenaf/glass hybrid composites under fully reversed cyclic loading. IOP Conf. Ser. Mater. Sci. Eng. 2015, 100, 12055. [Google Scholar] [CrossRef]

- De Goeij, W.C.; Van Tooren, M.J.L.; Beukers, A. Composite adhesive joints under cyclic loading. Mater. Des. 1999, 20, 213–221. [Google Scholar] [CrossRef]

- Zamani, P.; Jaamialahmadi, A.; da Silva, L.F.M. Fatigue life evaluation of Al-GFRP bonded lap joints under four-point bending using strain-life criteria. Int. J. Adhes. Adhes. 2023, 122, 103338. [Google Scholar] [CrossRef]

- Beber, V.C.; Schneider, B.; Brede, M. Influence of Temperature on the Fatigue Behaviour of a Toughened Epoxy Adhesive. J. Adhes. 2016, 92, 778–794. [Google Scholar] [CrossRef]

- de Castro Lopes, F.V.B.; Akhavan-Safar, A.; Carbas, R.J.C.; Marques, E.A.S.; Goyal, R.; Jennings, J.; da Silva, L.F.M. The interaction of loading mode and humidity on the properties degradation of an epoxy adhesive subjected to strength, fracture, and fatigue tests. J. Appl. Polym. Sci. 2023, 140, e53490. [Google Scholar] [CrossRef]

- de Barros, S.; Kenedi, P.P.; Ferreira, S.M.; Budhe, S.; Bernardino, A.J.; Souza, L.F.G. Influence of mechanical surface treatment on fatigue life of bonded joints. J. Adhes. 2017, 93, 599–612. [Google Scholar] [CrossRef]

- Javaid, U.; Ling, C.; Cardiff, P. Mechanical performance of carbon-glass hybrid composite joints in quasi-static tension and tension-tension fatigue. Eng. Fail. Anal. 2020, 116, 104730. [Google Scholar] [CrossRef]

- Ramírez, F.M.G.; Garpelli, F.P.; de Sales, R.C.M.; Cândido, G.M.; Arbelo, M.A.; Shiino, M.Y.; Donadon, M.V. Hygrothermal effects on the fatigue delamination growth onset in interlayer toughened CFRP joints. Int. J. Fatigue 2020, 138, 105729. [Google Scholar] [CrossRef]

- Zamani, P.; Alaei, M.H.; da Silva, L.F.M.; Ghahremani-Moghadam, D. On the static and fatigue life of nano-reinforced Al-GFRP bonded joints under different dispersion treatments. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 1088–1110. [Google Scholar] [CrossRef]

- Ishii, K.; Imanaka, M.; Nakayama, H.; Kodama, H. Fatigue failure criterion of adhesively bonded CFRP/metal joints under multiaxial stress conditions. Compos. Part A Appl. Sci. Manuf. 1998, 29, 415–422. [Google Scholar] [CrossRef]

- Khashaba, U.A.; Najjar, I.M.R.; Almitani, K.H. Failure analysis of scarf adhesive joints modified with SiC-nanoparticles under fatigue loading at room temperature. Compos. Sci. Technol. 2022, 221, 109301. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications Surjya Kumar Maiti. MRS Bull. 2016, 41, 635–636. [Google Scholar] [CrossRef]

- Pedro, P.; Camanho, S.R.H. Fatigue and Fracture of Adhesively-Bonded Composite Joints: Behaviour, Simulation and Modelling; Vassilopoulos, A.P., Ed.; Woodhead Publishing: Sawston, UK, 2015; ISBN 978-0-85709-812-2. [Google Scholar]

- Olajide, S.O.; Arhatari, B.D. Recent progress on damage mechanisms in polymeric adhesively bonded high-performance composite joints under fatigue. Int. J. Fatigue 2017, 95, 45–63. [Google Scholar] [CrossRef]

- Augustin, T.; Karsten, J.; Kötter, B.; Fiedler, B. Health monitoring of scarfed CFRP joints under cyclic loading via electrical resistance measurements using carbon nanotube modified adhesive films. Compos. Part A Appl. Sci. Manuf. 2018, 105, 150–155. [Google Scholar] [CrossRef]

- Palanisamy, R.P.; Banerjee, P.; Mukherjee, S.; Haq, M.; Deng, Y. Fatigue damage prognosis in adhesive bonded composite lap-joints using guided waves. In Proceedings of the 2020 IEEE International Conference on Prognostics and Health Management (ICPHM), Detroit, MI, USA, 8–10 June 2020. [Google Scholar] [CrossRef]

- Carboni, M.; Bernasconi, A. Acoustic Emission Based Monitoring of Fatigue Damage in CFRP-CFRP Adhesive Bonded Joints; Springer International Publishing: Berlin/Heidelberg, Germany, 2021; Volume 127, ISBN 9783030645939. [Google Scholar]

- Ourahmoune, R.; Salvia, M.; Mathia, T.G. Fatigue life analysis of adhesively bonded CFR-PEEK composites using acoustic emission monitoring. Rev. Compos. Mater. Av. 2016, 26, 45–62. [Google Scholar] [CrossRef]

- Quaresimin, M.; Ricotta, M. Fatigue behaviour and damage evolution of single lap bonded joints in composite material. Compos. Sci. Technol. 2006, 66, 176–187. [Google Scholar] [CrossRef]

- Ishii, K.; Imanaka, M.; Nakayama, H.; Kodama, H. Evaluation of the fatigue strength of adhesively bonded CFRP/metal single and single-step double-lap joints. Compos. Sci. Technol. 1999, 59, 1675–1683. [Google Scholar] [CrossRef]

- Zeng, Q.; Sun, C.T. Fatigue performance of a bonded wavy composite lap joint. Fatigue Fract. Eng. Mater. Struct. 2004, 27, 413–422. [Google Scholar] [CrossRef]

- Cheuk, P.T.; Tong, L.; Wang, C.H.; Baker, A.; Chalkley, P. Fatigue crack growth in adhesively bonded composite-metal double-lap joints. Compos. Struct. 2002, 57, 109–115. [Google Scholar] [CrossRef]

- Crocombe, A.D.; Ong, C.Y.; Chan, C.M.; Wahab, M.M.A.; Ashcroft, I.A. Investigating Fatigue Damage Evolution In Adhesively Bonded Structures Using Backface Strain Measurement. J. Adhes. 2002, 78, 745–776. [Google Scholar] [CrossRef]

- Graner Solana, A.; Crocombe, A.D.; Ashcroft, I.A. Fatigue life and backface strain predictions in adhesively bonded joints. Int. J. Adhes. Adhes. 2010, 30, 36–42. [Google Scholar] [CrossRef]

- Tang, J.H.; Sridhar, I.; Srikanth, N. Static and fatigue failure analysis of adhesively bonded thick composite single lap joints. Compos. Sci. Technol. 2013, 86, 18–25. [Google Scholar] [CrossRef]

- Rocha, A.V.M.; Akhavan-Safar, A.; Carbas, R.; Marques, E.A.S.; Goyal, R.; El-zein, M.; da Silva, L.F.M. Fatigue crack growth analysis of different adhesive systems: Effects of mode mixity and load level. Fatigue Fract. Eng. Mater. Struct. 2020, 43, 330–341. [Google Scholar] [CrossRef]

- Renton, W.J.; Vinson, J.R. Fatigue behavior of bonded joints in composite material structures. J. Aircr. 1975, 12, 442–447. [Google Scholar] [CrossRef]

- Moreira, R.D.F.; de Moura, M.F.S.F.; Silva, F.G.A.; Reis, J.P. High-cycle fatigue analysis of adhesively bonded composite scarf repairs. Compos. Part B Eng. 2020, 190, 107900. [Google Scholar] [CrossRef]

- Olajide, S.O.; Kandare, E.; Khatibi, A.A. Fatigue life uncertainty of adhesively bonded composite scarf joints–an airworthiness perspective. J. Adhes. 2017, 93, 515–530. [Google Scholar] [CrossRef]

- Yoo, J.S.; Truong, V.H.; Park, M.Y.; Choi, J.H.; Kweon, J.H. Parametric study on static and fatigue strength recovery of scarf-patch-repaired composite laminates. Compos. Struct. 2016, 140, 417–432. [Google Scholar] [CrossRef]

- Kim, J.H.; Park, B.J.; Han, Y.W. Evaluation of fatigue characteristics for adhesively-bonded composite stepped lap joint. Compos. Struct. 2004, 66, 69–75. [Google Scholar] [CrossRef]

- Matthews, F.L.; Kilty, P.F.; Godwin, E.W. A review of the strength of joints in fibre-reinforced plastics. Part 2. Adhesively bonded joints. Composites 1982, 13, 29–37. [Google Scholar] [CrossRef]

- Boss, J.N.; Ganesh, V.K.; Lim, C.T. Modulus grading versus geometrical grading of composite adherends in single-lap bonded joints. Compos. Struct. 2003, 62, 113–121. [Google Scholar] [CrossRef]

- Her, S.-C. Stress analysis of adhesively-bonded lap joints. Compos. Struct. 1999, 47, 673–678. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Ayatollahi, M.R.; Samari, M.; da Silva, L.F.M. Effect of interface non-flatness on the fatigue behavior of adhesively bonded single lap joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1277–1286. [Google Scholar] [CrossRef]

- Akrami, R.; Anjum, S.; Fotouhi, S.; Boaretto, J.; de Camargo, F.V.; Fotouhi, M. Investigating the effect of interface morphology in adhesively bonded composite wavy-lap joints. J. Compos. Sci. 2021, 5, 32. [Google Scholar] [CrossRef]

- Daniel, V.; Pires, C. Department of Mechanical Engineering Study of a Novel Curved Single Lap Joint Concept with Non-Uniform Adhesive Thickness. Master’s Thesis, Porto University, Porto, Portugal, 2023. [Google Scholar]

- McLaren, A.S.; MacInnes, I. The influence on the stress distribution in an adhesive lap joint of bending of the adhering sheets. Br. J. Appl. Phys. 1958, 9, 72. [Google Scholar] [CrossRef]

- Fessel, G.; Broughton, J.; Fellows, N.; Durodola, J.; Hutchinson, A. A numerical and experimental study on reverse-bent joints for composite substrates. In Proceedings of the 48th AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Honolulu, HI, USA, 23–26 April 2007; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2007. [Google Scholar]

- Campilho, R.D.S.G.; Pinto, A.M.G.; Banea, M.D.; Silva, R.F.; da Silva, L.F.M. Strength Improvement of Adhesively-Bonded Joints Using a Reverse-Bent Geometry. J. Adhes. Sci. Technol. 2011, 25, 2351–2368. [Google Scholar] [CrossRef]

- Bodepudi, R.; Hughes, D.J.; Pradhan, A.K. Evaluation of optimum configuration of adhesively bonded reverse bent joints. Int. J. Adhes. Adhes. 2017, 77, 78–84. [Google Scholar] [CrossRef]

- Fessel, G.; Broughton, J.G.; Fellows, N.A.; Durodola, J.F.; Hutchinson, A.R. Evaluation of different lap-shear joint geometries for automotive applications. Int. J. Adhes. Adhes. 2007, 27, 574–583. [Google Scholar] [CrossRef]

- Ávila, A.F.; de Bueno, P.O. Stress analysis on a wavy-lap bonded joint for composites. Int. J. Adhes. Adhes. 2004, 24, 407–414. [Google Scholar] [CrossRef]

- Ashrafi, M.; Ajdari, A.; Rahbar, N.; Papadopoulos, J.; Nayeb-Hashemi, H.; Vaziri, A. Adhesively bonded single lap joints with non-flat interfaces. Int. J. Adhes. Adhes. 2012, 32, 46–52. [Google Scholar] [CrossRef]

- Ayatollahi, M.R.; Samari, M.; Razavi, S.M.J.; da Silva, L.F.M. Fatigue performance of adhesively bonded single lap joints with non-flat sinusoid interfaces. Fatigue Fract. Eng. Mater. Struct. 2017, 40, 1355–1363. [Google Scholar] [CrossRef]

- Zeng, Q.; Sun, C.T. Fatigue performance of a bonded wavy composite lap joint. In Proceedings of the 19th AIAA Applied Aerodynamics Conference, Anaheim, CA, USA, 11–14 June 2001; pp. 413–422. [Google Scholar] [CrossRef]

- Zeng, Q.; Sun, C. A new bonded composite wavy lap joint. In 41st Structures, Structural Dynamics, and Materials Conference and Exhibit, Atalanta, GA, USA, 3–6 April 2000; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2000. [Google Scholar]

- Zeng, Q.-G.; Sun, C.T. Novel Design of a Bonded Lap Joint. AIAA J. 2001, 39, 1991–1996. [Google Scholar] [CrossRef]

- Sharma, R.; Gupta, A. A critical review on influencing parameters for adhesively bonded joints in composite laminates for structural applications. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Li, J.; Yan, Y.; Zhang, T.; Liang, Z. Experimental study of adhesively bonded CFRP joints subjected to tensile loads. Int. J. Adhes. Adhes. 2015, 57, 95–104. [Google Scholar] [CrossRef]

- Canyurt, O.E.; Meran, C.; Uslu, M. Strength estimation of adhesively bonded tongue and groove joint of thick composite sandwich structures using genetic algorithm approach. Int. J. Adhes. Adhes. 2010, 30, 281–287. [Google Scholar] [CrossRef]

- Canyurt, O.E.; Meran, C. Fatigue strength estimation of adhesively bonded tongue and groove joint of thick woven composite sandwich structures using genetic algorithm approach. Int. J. Adhes. Adhes. 2012, 33, 80–88. [Google Scholar] [CrossRef]

- Kupski, J.; Teixeira de Freitas, S. Design of adhesively bonded lap joints with laminated CFRP adherends: Review, challenges and new opportunities for aerospace structures. Compos. Struct. 2021, 268, 113923. [Google Scholar] [CrossRef]

- Ferreira, J.A.M.; Reis, P.N.; Costa, J.D.M.; Richardson, M.O.W. Fatigue behaviour of composite adhesive lap joints. Compos. Sci. Technol. 2002, 62, 1373–1379. [Google Scholar] [CrossRef]

- Kang, T.Y.; Aan, H.S.; Chun, H.J.; Park, J.C. Fatigue and Tensile Behaviors of High Stiffness Adhesive Bonded and Hybrid Joints with Composite-Steel Dissimilar Materials. Int. J. Precis. Eng. Manuf. 2023, 24, 645–656. [Google Scholar] [CrossRef]

- Osiyemi, S.O. The Fatigue Performance of Adhesively Bonded Fibre-Composite Joints. Ph.D. Thesis, University of London, London, UK, 1992. [Google Scholar]

- Kara, E.; KurŞun, A.; Haboğlu, M.R.; Enginsoy, H.M.; Aykul, H. Fatigue behavior of adhesively bonded glass fiber reinforced plastic composites with different overlap lengths. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2015, 229, 1292–1299. [Google Scholar] [CrossRef]

- Meneghetti, G.; Quaresimin, M.; Ricotta, M. Damage mechanisms in composite bonded joints under fatigue loading. Compos. Part B Eng. 2012, 43, 210–220. [Google Scholar] [CrossRef]

- Da Costa Mattos, H.S.; Monteiro, A.H.; Palazzetti, R. Failure analysis of adhesively bonded joints in composite materials. Mater. Des. 2012, 33, 242–247. [Google Scholar] [CrossRef]

- Quaresimin, M.; Ricotta, M. Life prediction of bonded joints in composite materials. Int. J. Fatigue 2006, 28, 1166–1176. [Google Scholar] [CrossRef]

- Mall, S.; Ramamurthy, G. Effect of bond thickness on fracture and fatigue strength of adhesively bonded composite joints. Int. J. Adhes. Adhes. 1989, 9, 11. [Google Scholar] [CrossRef]

- Lang, T.P.; Mallick, P.K. Effect of spew geometry on stresses in single lap adhesive joints. Int. J. Adhes. Adhes. 1998, 18, 167–177. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Adams, R.D. Joint strength predictions for adhesive joints to be used over a wide temperature range. Int. J. Adhes. Adhes. 2007, 27, 362–379. [Google Scholar] [CrossRef]

- da Silva, L.F.M.; Marques, E.A.S.; Campilho, R.D.S.G. Design Rules and Methods to Improve Joint Strength BT—Handbook of Adhesion Technology; da Silva, L.F.M., Öchsner, A., Adams, R.D., Eds.; Springer International Publishing: Cham, Switzerland, 2018; pp. 773–810. ISBN 978-3-319-55411-2. [Google Scholar]

- Quaresimin, M.; Ricotta, M. Stress intensity factors and strain energy release rates in single lap bonded joints in composite materials. Compos. Sci. Technol. 2006, 66, 647–656. [Google Scholar] [CrossRef]

- Crocombe, A.D. Global yielding as a failure criterion for bonded joints. Int. J. Adhes. Adhes. 1989, 9, 145–153. [Google Scholar] [CrossRef]

- Hart-Smith, L.J. Designing to Minimize Peel Stresses in Adhesive-Bonded Joints; Douglas Aircraft Co., McDonnell Douglas Corp.: Long Beach, CA, USA, 1985. [Google Scholar]

- Niranjan, V. Bonded Joints: A Review for Engineers; UTIAS Review; Institute for Aerospace Studies, University of Toronto: Toronto, ON, Canada, 1970. [Google Scholar]

- da Silva, L.F.M.; Rodrigues, T.N.S.S.; Figueiredo, M.A.V.; de Moura, M.F.S.F.; Chousal, J.A.G. Effect of Adhesive Type and Thickness on the Lap Shear Strength. J. Adhes. 2006, 82, 1091–1115. [Google Scholar] [CrossRef]

- Taib, A.A.; Boukhili, R.; Achiou, S.; Gordon, S.; Boukehili, H. Bonded joints with composite adherends. Part I. Effect of specimen configuration, adhesive thickness, spew fillet and adherend stiffness on fracture. Int. J. Adhes. Adhes. 2006, 26, 226–236. [Google Scholar] [CrossRef]

- Diharjo, K.; Anwar, M.; Tarigan, R.A.P.; Rivai, A. Effect of adhesive thickness and surface treatment on shear strength on single lap joint Al/CFRP using adhesive of epoxy/Al fine powder. AIP Conf. Proc. 2016, 1710, 30030. [Google Scholar] [CrossRef]

- Mazumdar, S.K.; Mallick, P.K. Static and fatigue behavior of adhesive joints in SMC-SMC composites. Polym. Compos. 1998, 19, 139–146. [Google Scholar] [CrossRef]

- Sekiguchi, Y.; Sato, C. Effect of bond-line thickness on fatigue crack growth of structural acrylic adhesive joints. Materials 2021, 14, 1723. [Google Scholar] [CrossRef] [PubMed]

- Renton, W.J.; Vinson, J.R. The Efficient Design of Adhesive Bonded Joints. J. Adhes. 1975, 7, 175–193. [Google Scholar] [CrossRef]

- Ebadi-Rajoli, J.; Akhavan-Safar, A.; Hosseini-Toudeshky, H.; da Silva, L.F.M. Progressive damage modeling of composite materials subjected to mixed mode cyclic loading using cohesive zone model. Mech. Mater. 2020, 143, 103322. [Google Scholar] [CrossRef]

- Crocombe, A.D.; Moult, A.C. The Effect of the Adhesive Thickness on the Strength of a Bonded Joint BT—Adhesion 12; Allen, K.W., Ed.; Springer: Dordrecht, The Netherlands, 1988; pp. 174–192. ISBN 978-94-009-1349-3. [Google Scholar]

- Findley, W.N.; Worley, W.J. Mechanical Properties of Five Laminated Plastics; NASA: Washington, DC, USA, 1948.

- Boller, K.H. Fatigue Tests of Glass-Fabric-Base Laminates Subjected to Axial Loading; Forest Products Laboratory: Madison, WI, USA, 1952; Volume 1823. [Google Scholar]

- Boller, K.H. Fatigue properties of fibrous glass-reinforced plastics laminates subjected to various conditions. Mod. Plast. 1957, 34, 145–188. [Google Scholar]

- Hashim, N.; Majid, D.L.A.; Mahdi, E.-S.; Zahari, R.; Yidris, N. Effect of fiber loading directions on the low cycle fatigue of intraply carbon-Kevlar reinforced epoxy hybrid composites. Compos. Struct. 2019, 212, 476–483. [Google Scholar] [CrossRef]

- Dai, G.; Mishnaevsky, L. Fatigue of hybrid glass/carbon composites: 3D computational studies. Compos. Sci. Technol. 2014, 94, 71–79. [Google Scholar] [CrossRef]

- Shahzad, A. Impact and fatigue properties of hemp–glass fiber hybrid biocomposites. J. Reinf. Plast. Compos. 2011, 30, 1389–1398. [Google Scholar] [CrossRef]

- Salkind, M.J. Fatigue of composites. In Composite Materials, Testing and Design, Proceedings of the 2nd Conference; ASTM STP 497; ASTM: West Conshohocken, PA, USA, 1972; pp. 143–169. [Google Scholar]

- Malekinejadbahabadi, H.; Farrokhabadi, A.; Rahimi, G.H.; Nazerigivi, A. Effect of core shape on debonding failure of composite sandwich panels with foam-filled corrugated core. Steel Compos. Struct. 2022, 45, 467–482. [Google Scholar] [CrossRef]

- Berthelot, J.-M. Transverse cracking and delamination in cross-ply glass-fiber and carbon-fiber reinforced plastic laminates: Static and fatigue loading. Appl. Mech. Rev. 2003, 56, 111–147. [Google Scholar] [CrossRef]

- Vassilopoulos, A.P. The history of fiber-reinforced polymer composite laminate fatigue. Int. J. Fatigue 2020, 134, 105512. [Google Scholar] [CrossRef]

- Amraei, J.; Katunin, A. Recent Advances in Limiting Fatigue Damage Accumulation Induced by Self-Heating in Polymer–Matrix Composites. Polymers 2022, 14, 5384. [Google Scholar] [CrossRef]

- Talreja, R. Fatigue of composite materials: Damage mechanisms and fatigue-life diagrams. Proc. R. Soc. Lond. A. Math. Phys. Sci. 1981, 378, 461–475. [Google Scholar] [CrossRef]

- Alam, P.; Mamalis, D.; Robert, C.; Floreani, C.; Brádaigh, C.M.Ó. The fatigue of carbon fi bre reinforced plastics—A review. Compos. Part B 2019, 166, 555–579. [Google Scholar] [CrossRef]

- Jones, C.J.; Dickson, R.F.; Adam, T.; Reiter, H.; Harris, B. The environmental fatigue behaviour of reinforced plastics. Proc. Math. Phys. Eng. Sci. 1984, 396, 315–338. [Google Scholar]

- Konur, O.; Matthews, F.L. Effect of the properties of the constituents on the fatigue performance of composites: A review. Composites 1989, 20, 317–328. [Google Scholar] [CrossRef]

- Curtis, P.T.; Moore, B.B. A Comparison of Plain and Double Waisted Coupons for Static and Fatigue Tensile Testing of Unidirectional GRP and CFRP BT—Composite Structures 2; Marshall, I.H., Ed.; Springer: Dordrecht, The Netherlands, 1983; pp. 383–398. ISBN 978-94-009-6640-6. [Google Scholar]

- Hull, D.C.T. An Introduction to Composite Materials, 2nd, ed.; Cambridge University Press: Cambridge, UK, 1998. [Google Scholar]

- Sabiston, T.; Li, B.; Muhammad, W.; Kang, J.; Engler-Pinto, C. The Role of Fibre Length on the Fatigue Failure of Injection-Moulded Composites at Elevated Temperatures under a Range of Axial Loading Conditions. J. Compos. Sci. 2022, 6, 38. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Friedrich, K. Fatigue crack propagation in short and long fibre-reinforced injection-moulded PA 6.6 composites. Composites 1988, 19, 105–114. [Google Scholar] [CrossRef]

- Meneghetti, G.; Ricotta, M.; Lucchetta, G.; Carmignato, S. An hysteresis energy-based synthesis of fully reversed axial fatigue behaviour of different polypropylene composites. Compos. Part B Eng. 2014, 65, 17–25. [Google Scholar] [CrossRef]

- Naik, P.S.; Orangalu, S.A.; Londhe, N. V Effect of fiber weight fraction on mechanical properties of carbon–carbon composites. Polym. Compos. 2012, 33, 1329–1334. [Google Scholar] [CrossRef]

- Brunbauer, J.; Pinter, G. Effects of mean stress and fibre volume content on the fatigue-induced damage mechanisms in CFRP. Int. J. Fatigue 2015, 75, 28–38. [Google Scholar] [CrossRef]

- Hiremath, C.; Senthilnathan, K.; Guha, A.; Tewari, A. Effect of Volume Fraction on Damage Accumulation for a Lattice Arrangement of Fibers in CFRP. Mater. Today Proc. 2015, 2, 2671–2678. [Google Scholar] [CrossRef]

- Brunbauer, J.; Stadler, H.; Pinter, G. Mechanical properties, fatigue damage and microstructure of carbon/epoxy laminates depending on fibre volume content. Int. J. Fatigue 2015, 70, 85–92. [Google Scholar] [CrossRef]

- Roundi, W.; El Mahi, A.; El Gharad, A.; Rebière, J.-L. Experimental and numerical investigation of the effects of stacking sequence and stress ratio on fatigue damage of glass/epoxy composites. Compos. Part B Eng. 2017, 109, 64–71. [Google Scholar] [CrossRef]

- Mandell, J.F.; Damborsky, D.D. SNL/MSU/DOE Composite Materials Fatigue Database V22.0; Assistant Secretary for Energy Efficiency and Renewable Energy: Washington, DC, USA, 1997. [Google Scholar] [CrossRef]

- Sharma, N.; Singh, K.K. Transverse fatigue behavior analysis of symmetric and asymmetric glass fiber-reinforced laminates. Polym. Compos. 2023, 44, 2871–2886. [Google Scholar] [CrossRef]

- Şen, I.; Alderliesten, R.C.; Benedictus, R. Lay-up optimisation of fibre metal laminates based on fatigue crack propagation and residual strength. Compos. Struct. 2015, 124, 77–87. [Google Scholar] [CrossRef]

- Kupski, J.; Teixeira de Freitas, S.; Zarouchas, D.; Camanho, P.P.; Benedictus, R. Composite layup effect on the failure mechanism of single lap bonded joints. Compos. Struct. 2019, 217, 14–26. [Google Scholar] [CrossRef]

- Maa, R.-H.; Cheng, J.-H. A CDM-based failure model for predicting strength of notched composite laminates. Compos. Part B Eng. 2002, 33, 479–489. [Google Scholar] [CrossRef]

- Zhao, X.; Wang, X.; Wu, Z.; Keller, T.; Vassilopoulos, A.P. Temperature effect on fatigue behavior of basalt fiber-reinforced polymer composites. Polym. Compos. 2019, 40, 2273–2283. [Google Scholar] [CrossRef]

- Movahedi-Rad, A.V.; Keller, T.; Vassilopoulos, A.P. Fatigue damage in angle-ply GFRP laminates under tension-tension fatigue. Int. J. Fatigue 2018, 109, 60–69. [Google Scholar] [CrossRef]

- Turon, A.; Costa, J.; Camanho, P.P.; Dávila, C.G. Simulation of delamination in composites under high-cycle fatigue. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2270–2282. [Google Scholar] [CrossRef]

- Ribeiro, F.; Sena-Cruz, J.; Vassilopoulos, A.P. Tension-tension fatigue behavior of hybrid glass/carbon and carbon/carbon composites. Int. J. Fatigue 2021, 146, 106143. [Google Scholar] [CrossRef]

- Zuo, P.; Srinivasan, D.V.; Vassilopoulos, A.P. Review of hybrid composites fatigue. Compos. Struct. 2021, 274, 114358. [Google Scholar] [CrossRef]

- Tabrizi, I.E.; Kefal, A.; Zanjani, J.S.M.; Akalin, C.; Yildiz, M. Experimental and numerical investigation on fracture behavior of glass/carbon fiber hybrid composites using acoustic emission method and refined zigzag theory. Compos. Struct. 2019, 223, 110971. [Google Scholar] [CrossRef]

- Wan, Y.Z.; Huang, Y.; He, F.; Li, Q.Y.; Lian, J.J. Tribological properties of three-dimensional braided carbon/Kevlar/epoxy hybrid composites under dry and lubricated conditions. Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process. 2007, 452–453, 202–209. [Google Scholar] [CrossRef]

- Chinnasamy, V.; Pavayee Subramani, S.; Palaniappan, S.K.; Mylsamy, B.; Aruchamy, K. Characterization on thermal properties of glass fiber and kevlar fiber with modified epoxy hybrid composites. J. Mater. Res. Technol. 2020, 9, 3158–3167. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; Elayaperumal, A.; Sathiya, G.K. Prediction of tensile properties of hybrid-natural fiber composites. Compos. Part B Eng. 2012, 43, 793–796. [Google Scholar] [CrossRef]

- Dickson, R.F.; Fernando, G.; Adam, T.; Reiter, H.; Harris, B. Fatigue behaviour of hybrid composites—Part 2 Carbon-glass hybrids. J. Mater. Sci. 1989, 24, 227–233. [Google Scholar] [CrossRef]

- Hofer, K.E.; Stander, M.; Bennett, L.C. Degradation and enhancement of the fatigue behavior of glass/graphite/epoxy hybrid composites after accelerated aging. Polym. Eng. Sci. 1978, 18, 120–127. [Google Scholar] [CrossRef]

- Shan, Y.; Liao, K. Environmental fatigue behavior and life prediction of unidirectional glass–carbon/epoxy hybrid composites. Int. J. Fatigue 2002, 24, 847–859. [Google Scholar] [CrossRef]

- Yu, H.; Longana, M.L.; Jalalvand, M.; Wisnom, M.R.; Potter, K.D. Pseudo-ductility in intermingled carbon/glass hybrid composites with highly aligned discontinuous fibres. Compos. Part A Appl. Sci. Manuf. 2015, 73, 35–44. [Google Scholar] [CrossRef]

- París, F.; Velasco, M.L.; Correa, E. 9—Modelling fibre–matrix interface debonding and matrix cracking in composite laminates. In Multi-Scale Continuum Mechanics Modelling of Fibre-Reinforced Polymer Composites; Woodhead Publishing Series in Composites Science and Engineering; Van Paepegem, W., Ed.; Woodhead Publishing: Sawston, UK, 2021; pp. 243–274. ISBN 978-0-12-818984-9. [Google Scholar]

- Parvizi, A.; Garrett, K.W.; Bailey, J.E. Constrained cracking in glass fibre-reinforced epoxy cross-ply laminates. J. Mater. Sci. 1978, 13, 195–201. [Google Scholar] [CrossRef]

- Flaggs, D.L.; Kural, M.H. Experimental Determination of the In Situ Transverse Lamina Strength in Graphite/Epoxy Laminates. J. Compos. Mater. 1982, 16, 103–116. [Google Scholar] [CrossRef]

- Sánchez, S. Damage and Failure Mechanisms under Fatigue in Long Fibre Composites with Ultra-Thin Plies, 2023. Ph.D. Thesis, University of Seville, Seville, Spain, 2023. [Google Scholar]

- Sánchez-Carmona, S.; Correa, E.; Barroso, A.; París, F. Fatigue life of unidirectional 90° carbon/epoxy laminates made of conventional and ultra-thin plies varying manufacturing and testing conditions. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 1837–1847. [Google Scholar] [CrossRef]

- París, F.; Velasco, M.L.; Correa, E. The scale effect in composites: An explanation physically based on the different mechanisms of damage involved in failure. Compos. Struct. 2021, 257, 113089. [Google Scholar] [CrossRef]

- Fuller, J.D.; Wisnom, M.R. Exploration of the potential for pseudo-ductility in thin ply CFRP angle-ply laminates via an analytical method. Compos. Sci. Technol. 2015, 112, 8–15. [Google Scholar] [CrossRef]

- Matthews, F.L.; Tester, T.T. The influence of stacking sequence on the strength of bonded CFRP single lap joints. Int. J. Adhes. Adhes. 1985, 5, 13–18. [Google Scholar] [CrossRef]

- Kairouz, K.C.; Matthews, F.L. Strength and failure modes of bonded single lap joints between cross-ply adherends. Composites 1993, 24, 475–484. [Google Scholar] [CrossRef]

- Renton, J.; Vinson, R. The Analysis and Design of Composite Material Bonded Joints under Static and Fatigue Loadings; Defense Technical Information Center: Fort Belvoir, VA, USA, 1973. [CrossRef]

- Purimpat, S.; Jérôme, R.; Shahram, A. Effect of fiber angle orientation on a laminated composite single-lap adhesive joint. Adv. Compos. Mater. 2013, 22, 139–149. [Google Scholar] [CrossRef]

- Apalak, Z.G.; Apalak, M.K.; Genc, M.S. Progressive damage modeling of an adhesively bonded unidirectional composite single-lap joint in tension at the mesoscale level. J. Thermoplast. Compos. Mater. 2006, 19, 671–702. [Google Scholar] [CrossRef]

- Shin, K.C.; Lee, J.J. Fatigue characteristics of a co-cured single lap joint subjected to cyclic tensile loads. J. Adhes. Sci. Technol. 2002, 16, 347–359. [Google Scholar] [CrossRef]

- Johnson, W.S.; Mall, S. Influence of interface ply orientation on fatigue damage of adhesively bonded composite joints. J. Compos. Technol. Res. 1986, 8, 82–93. [Google Scholar]

- Mall, S.; Johnson, W.S.; Everett, R.A. Cyclic Debonding of Adhesively Bonded Composites BT—Adhesive Joints: Formation, Characteristics, and Testing; Mittal, K.L., Ed.; Springer: Boston, MA, USA, 1984; pp. 639–658. ISBN 978-1-4613-2749-3. [Google Scholar]

- Casas-Rodriguez, J.P.; Ashcroft, I.A.; Silberschmidt, V.V. Damage in adhesively bonded CFRP joints: Sinusoidal and impact-fatigue. Compos. Sci. Technol. 2008, 68, 2663–2670. [Google Scholar] [CrossRef]

- Köckritz, T.; Schiefer, T.; Jansen, I.; Beyer, E. Improving the bond strength at hybrid-yarn textile thermoplastic composites for high-technology applications by laser radiation. Int. J. Adhes. Adhes. 2013, 46, 85–94. [Google Scholar] [CrossRef]

- Mittal, K.L. Polymer Surface Modification: Relevance to Adhesion; Mittal, K.L., Ed.; Taylor & Francis: Abingdon, UK, 2004. [Google Scholar]

- Rhee, K.Y.; Yang, J.-H. A study on the peel and shear strength of aluminum/CFRP composites surface-treated by plasma and ion assisted reaction method. Compos. Sci. Technol. 2003, 63, 33–40. [Google Scholar] [CrossRef]

- Schmutzler, H.; Popp, J.; Büchter, E.; Wittich, H.; Schulte, K.; Fiedler, B. Improvement of bonding strength of scarf-bonded carbon fibre/epoxy laminates by Nd:YAG laser surface activation. Compos. Part A Appl. Sci. Manuf. 2014, 67, 123–130. [Google Scholar] [CrossRef]

- Wingfield, J.R.J. Treatment of composite surfaces for adhesive bonding. Int. J. Adhes. Adhes. 1993, 13, 151–156. [Google Scholar] [CrossRef]

- Bernardi, C.; Toury, B.; Salvia, M.; Contraires, E.; Dubreuil, F.; Virelizier, F.; Ourahmoune, R.; Surowiec, B.; Benayoun, S. Effects of flaming on polypropylene long glass fiber composites for automotive bonding applications with polyurethane. Int. J. Adhes. Adhes. 2022, 113, 103033. [Google Scholar] [CrossRef]

- Pijpers, A.P.; Meier, R.J. Adhesion behaviour of polypropylenes after flame treatment determined by XPS(ESCA) spectral analysis. J. Electron Spectros. Relat. Phenomena 2001, 121, 299–313. [Google Scholar] [CrossRef]

- Baldan, A. Adhesion phenomena in bonded joints. Int. J. Adhes. Adhes. 2012, 38, 95–116. [Google Scholar] [CrossRef]

- Islam, M.S.; Tong, L.; Falzon, P.J. Influence of metal surface preparation on its surface profile, contact angle, surface energy and adhesion with glass fibre prepreg. Int. J. Adhes. Adhes. 2014, 51, 32–41. [Google Scholar] [CrossRef]

- Kanerva, M.; Saarela, O. The Peel Ply Surface Treatment for Adhesive Bonding of Composites: A Review. Int. J. Adhes. Adhes. 2013, 43, 60–69. [Google Scholar] [CrossRef]

- Prolongo, S.G.; Gude, M.R.; Del Rosario, G.; Ureña, A. Surface Pretreatments for Composite Joints: Study of Surface Profile by SEM Image Analysis. J. Adhes. Sci. Technol. 2010, 24, 1855–1867. [Google Scholar] [CrossRef]

- Ramaswamy, K.; O’Higgins, R.M.; Kadiyala, A.K.; McCarthy, M.A.; McCarthy, C.T. Evaluation of grit-blasting as a pre-treatment for carbon-fibre thermoplastic composite to aluminium bonded joints tested at static and dynamic loading rates. Compos. Part B Eng. 2020, 185, 107765. [Google Scholar] [CrossRef]

- Thull, D.; Zimmer, F.; Hofmann, T.; Holtmannspoetter, J.; Koerwien, T.; Hoffmann, M. Investigation of fluorine-based release agents for structural adhesive bonding of carbon fibre reinforced plastics. Appl. Adhes. Sci. 2019, 7, 2. [Google Scholar] [CrossRef]

- Park, S.M.; Roy, R.; Kweon, J.H.; Nam, Y. Strength and failure modes of surface treated CFRP secondary bonded single-lap joints in static and fatigue tensile loading regimes. Compos. Part A Appl. Sci. Manuf. 2020, 134, 105897. [Google Scholar] [CrossRef]

- Sancaktar, E.; Gomatam, R. A Study on the Effects of Surface Roughness on the Strength of Single Lap Joints; ASME: New York, NY, USA, 1998; pp. 91–111. [Google Scholar] [CrossRef]

- Banea, M.D.; Da Silva, L.F.M. Adhesively bonded joints in composite materials: An overview. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2009, 223, 1–18. [Google Scholar] [CrossRef]

- Johnson, R.T.; Blohowiak, K.; Osborne, J.; Wilson, R.; Flinn, B.D. Improving Adhesive Bonding of Composites through Surface Characterization Using Inverse Gas Chromatography (IGC) Methods; Joint Advanced Materials and Structures Center of Excellence: Wichita, KS, USA, 2017; pp. 665–683. [Google Scholar]

- Yang, G.; Yang, T.; Yuan, W.; Du, Y. The influence of surface treatment on the tensile properties of carbon fiber-reinforced epoxy composites-bonded joints. Compos. Part B Eng. 2019, 160, 446–456. [Google Scholar] [CrossRef]

- Thäsler, T.; Holtmannspötter, J.; Gudladt, H.J. Surface topography influences on the fatigue behavior of composite joints. Key Eng. Mater. 2019, 809, 341–346. [Google Scholar] [CrossRef]

- Liu, X.; Zheng, G.; Luo, Q.; Li, Q.; Sun, G. Fatigue behavior of carbon fibre reinforced plastic and aluminum single-lap adhesive joints after the transverse pre-impact. Int. J. Fatigue 2021, 144, 105973. [Google Scholar] [CrossRef]

- Naat, N.; Boutar, Y.; Naïmi, S.; Mezlini, S.; Da Silva, L.F.M. Effect of surface texture on the mechanical performance of bonded joints: A review. J. Adhes. 2023, 99, 166–258. [Google Scholar] [CrossRef]

- Zecchini, M. Finite Element Stress Analysis on Non-Flat Adhesively Bonded Single Lap Joints with Sinusoid Interfaces. Master’s Thesis, University of Padua, Padua, Italy, 2018. [Google Scholar]

- Monteiro, J.; Salgado, R.M.; Da Rocha, T.; Pereira, G.; Marques, E.A.S.; Carbas, R.J.C.; Da Silva, L.F.M. Effect of adhesive type and overlap length on the mechanical resistance of a simple overlap adhesive joint. U. Porto J. Eng. 2021, 7, 1–12. [Google Scholar] [CrossRef]

- Davis, M.; Bond, D. Principles and practices of adhesive bonded structural joints and repairs. Int. J. Adhes. Adhes. 1999, 19, 91–105. [Google Scholar] [CrossRef]

- Marques, D.; Ribeiro, M.L.; Tita, V. Comparative study of adhesive fatigue in aeronautical bonded joints: A numerical approach in the frequency domain. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 236, 1400–1407. [Google Scholar] [CrossRef]

- Lou, S.; Cheng, B.; Ren, G.; Li, Y.; Bai, X.; Chen, P. Effect of adhesive modification and surface treatment of laminates on the single lap bonding joint properties of carbon fibre composites. J. Adhes. 2023, 99, 1916–1932. [Google Scholar] [CrossRef]

- Akpinar, I.A.; Gültekin, K.; Akpinar, S.; Akbulut, H.; Ozel, A. Experimental analysis on the single-lap joints bonded by a nanocomposite adhesives which obtained by adding nanostructures. Compos. Part B Eng. 2017, 110, 420–428. [Google Scholar] [CrossRef]

- Gude, M.R.; Prolongo, S.G.; Gómez-del Río, T.; Ureña, A. Mode-I adhesive fracture energy of carbon fibre composite joints with nanoreinforced epoxy adhesives. Int. J. Adhes. Adhes. 2011, 31, 695–703. [Google Scholar] [CrossRef]

- Tutunchi, A.; Kamali, R.; Kianvash, A. Adhesive strength of steel–epoxy composite joints bonded with structural acrylic adhesives filled with silica nanoparticles. J. Adhes. Sci. Technol. 2015, 29, 195–206. [Google Scholar] [CrossRef]

- Kang, M.-H.; Choi, J.-H.; Kweon, J.-H. Fatigue life evaluation and crack detection of the adhesive joint with carbon nanotubes. Compos. Struct. 2014, 108, 417–422. [Google Scholar] [CrossRef]

- Budhe, S.; Banea, M.D.; de Barros, S.; da Silva, L.F.M. An updated review of adhesively bonded joints in composite materials. Int. J. Adhes. Adhes. 2017, 72, 30–42. [Google Scholar] [CrossRef]

- Park, S.W.; Kim, B.C.; Lee, D.G. Tensile Strength of Joints Bonded With a Nano-particle-Reinforced Adhesive. J. Adhes. Sci. Technol. 2009, 23, 95–113. [Google Scholar] [CrossRef]

- Omairey, S.; Jayasree, N.; Kazilas, M. Defects and uncertainties of adhesively bonded composite joints. SN Appl. Sci. 2021, 3, 769. [Google Scholar] [CrossRef]

- Zamani, P.; Jaamialahmadi, A.; da Silva, L.F.M. The influence of GNP and nano-silica additives on fatigue life and crack initiation phase of Al-GFRP bonded lap joints subjected to four-point bending. Compos. Part B Eng. 2021, 207, 108589. [Google Scholar] [CrossRef]

- Bali, G.; Topkaya, T. Effect of graphene nano-particle reinforcement on the fatigue behavior of adhesively bonded single lap joints. Int. J. Adhes. Adhes. 2023, 120, 103279. [Google Scholar] [CrossRef]

- Koricho, E.G.; Khomenko, A.; Haq, M. Fatigue Behavior of Glass-Bubbles Modified Adhesively Bonded Composite Joints BT—Fracture, Fatigue, Failure, and Damage Evolution; Carroll, J., Daly, S., Eds.; Springer International Publishing: Cham, Switzerland, 2015; Volume 5, pp. 181–187. [Google Scholar]

- Khashaba, U.A.; Aljinaidi, A.A.; Hamed, M.A. Fatigue and reliability analysis of nano-modified scarf adhesive joints in carbon fiber composites. Compos. Part B 2017, 1201, 3–117. [Google Scholar] [CrossRef]

- Gültekin, K.; Akpinar, S.; Gürses, A.; Eroglu, Z.; Cam, S.; Akbulut, H.; Keskin, Z.; Ozel, A. The effects of graphene nanostructure reinforcement on the adhesive method and the graphene reinforcement ratio on the failure load in adhesively bonded joints. Compos. Part B Eng. 2016, 98, 362–369. [Google Scholar] [CrossRef]

- Machado, J.J.M.; Gamarra, P.-R.; Marques, E.A.S.; da Silva, L.F.M. Numerical study of the behaviour of composite mixed adhesive joints under impact strength for the automotive industry. Compos. Struct. 2018, 185, 373–380. [Google Scholar] [CrossRef]

- Abdel Wahab, M.M. Fatigue in Adhesively Bonded Joints: A Review. ISRN Mater. Sci. 2012, 2012, 746308. [Google Scholar] [CrossRef]

- Jairaja, R.; Naik, G.N. Single and dual adhesive bond strength analysis of single lap joint between dissimilar adherends. Int. J. Adhes. Adhes. 2019, 92, 142–153. [Google Scholar] [CrossRef]

- Jalali, S.; Ayatollahi, M.R.; Akhavan-Safar, A.; da Silva, L.F.M. Effects of impact fatigue on residual static strength of adhesively bonded joints. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2021, 235, 1519–1531. [Google Scholar] [CrossRef]

- Akhavan-Safar, A.; Eisaabadi Bozchaloei, G.; Jalali, S.; Beygi, R.; Ayatollahi, M.R.; da Silva, L.F.M. Impact Fatigue Life of Adhesively Bonded Composite-Steel Joints Enhanced with the Bi-Adhesive Technique. Materials 2023, 16, 419. [Google Scholar] [CrossRef]

- Akhavan-Safar, A.; Eisaabadi, B.G.; Jalali, S.; Beygi, R.; da Silva, L.F.M. Impact fatigue life improvement of bonded structures using the bi-adhesive technique. Fatigue Fract. Eng. Mater. Struct. 2022, 45, 1379–1390. [Google Scholar] [CrossRef]

- Potter, K.D.; Guild, F.J.; Harvey, H.J.; Wisnom, M.R.; Adams, R.D. Understanding and control of adhesive crack propagation in bonded joints between carbon fibre composite adherends I. Experimental. Int. J. Adhes. Adhes. 2001, 21, 435–443. [Google Scholar] [CrossRef]

- Guild, F.J.; Potter, K.D.; Heinrich, J.; Adams, R.D.; Winsom, M.R. Understanding and control of adhesive crack propagation in bonded joints between carbon fibre composite adherends II. Finite element analysis. Int. J. Adhes. Adhes. 2001, 21, 445–453. [Google Scholar] [CrossRef]

- Machado, J.J.M.; Gamarra, P.M.-R.; Marques, E.A.S.; da Silva, L.F.M. Improvement in impact strength of composite joints for the automotive industry. Compos. Part B Eng. 2018, 138, 243–255. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malekinejad, H.; Carbas, R.J.C.; Akhavan-Safar, A.; Marques, E.A.S.; Castro Sousa, F.; da Silva, L.F.M. Enhancing Fatigue Life and Strength of Adhesively Bonded Composite Joints: A Comprehensive Review. Materials 2023, 16, 6468. https://doi.org/10.3390/ma16196468

Malekinejad H, Carbas RJC, Akhavan-Safar A, Marques EAS, Castro Sousa F, da Silva LFM. Enhancing Fatigue Life and Strength of Adhesively Bonded Composite Joints: A Comprehensive Review. Materials. 2023; 16(19):6468. https://doi.org/10.3390/ma16196468

Chicago/Turabian StyleMalekinejad, Hossein, Ricardo J. C. Carbas, Alireza Akhavan-Safar, Eduardo A. S. Marques, Fernando Castro Sousa, and Lucas F. M. da Silva. 2023. "Enhancing Fatigue Life and Strength of Adhesively Bonded Composite Joints: A Comprehensive Review" Materials 16, no. 19: 6468. https://doi.org/10.3390/ma16196468

APA StyleMalekinejad, H., Carbas, R. J. C., Akhavan-Safar, A., Marques, E. A. S., Castro Sousa, F., & da Silva, L. F. M. (2023). Enhancing Fatigue Life and Strength of Adhesively Bonded Composite Joints: A Comprehensive Review. Materials, 16(19), 6468. https://doi.org/10.3390/ma16196468