1. Introduction

As car numbers rise in China, engine oil usage follows suit. Impurity content in this oil escalates during use, interacting with atmospheric oxygen to generate macromolecular oxides, such as resin and asphaltene, collectively termed ‘waste engine oil’. Developed countries, such as the United States, prioritize waste engine oil regeneration and utilization. Processes, such as centrifugal separation, molecular distillation, flocculation, and membrane treatment, extract light components from waste engine oil, repurposing them for lower-grade engine or lubricating oils. This regenerates and utilizes 75–85% of waste engine oil. However, the remaining 15–25% of heavy components resist effective recycling due to impurity inclusion, forming ‘waste engine oil residue’ (WEOR) [

1].

Given the significant consumption of construction materials in road projects, the field of road construction has emerged as a pivotal domain for the resourceful reuse of waste. For instance, waste plastic [

2,

3], waste rubber [

4,

5], waste glass [

6,

7], waste catalysts [

8,

9], waste cooking oil [

10], and so on. International research demonstrates that WEORs can soften aged asphalt and, with specialized processing, enhance aged asphalt performance [

11,

12,

13]. So, the WEORs can be used for asphalt rejuvenation. Qurashi [

14] reported that adding WEORs improves road performance of aged asphalt. Ren [

15] assessed the rejuvenating effect of waste edible oil and waste engine oil on aged asphalt performance, with results indicating that both waste oils increase adhesion and crack resistance. Moreover, incorporating styrene butadiene rubber can enhance temperature sensitivity. Evaluations by Tabakovic [

16] and Li [

17] showed that a WEOR can reduce allowable strain and low-temperature limit grading of aged asphalt, and modification technologies have been suggested to augment the regenerative effect of WEORs on aged asphalts.

Experiments conducted by John D’Angelo [

18,

19], Wielinski [

20,

21], Kemas [

22], Zamhari [

23], Oliveira [

24], and Deden [

25] have studied the regeneration effect of WEOR on both asphalt and asphalt mixtures. Their results affirm that WEOR plays a significant role in improving the performance of asphalt, particularly in the low-temperature range. Research by Villanueva [

26], Zaumanis [

23], and Li [

27] further extends this understanding, demonstrating various impacts of WEOR, such as an enhanced permeability index, increased creep flexibility and fracture energy, as well as superior low-temperature cracking resistance.

Furthermore, the studies by Xue [

28] and Khan [

29] have introduced additional aspects, including the use of lignin and the integration of WEOR with other materials. They have revealed insights into the alterations of elasticity and stiffness in asphalt binders and demonstrated the feasibility of designing specific asphalt mixes with up to 100% recycled asphalt pavement (RAP) in combination with WEOR and CRM, meeting standard criteria. These findings not only contribute to the ongoing innovation in waste engine oil utilization, but also underscore the potential for significant improvements in road construction and maintenance.

At present, global scholars have focused their research on three principal indicators of WEOR-modified asphalts, assessing the mixed road performances and confirming the feasibility of employing WEOR as an asphalt modifier. Despite these advancements, investigation into WEOR asphalt regenerant products within China is limited, and challenges related to the transformation of WEORs for road use continue to persist. Furthermore, a previous study proved that the inclusion of waste engine oil can lead to a decreased rutting resistance of the asphalt binder [

30]. From this point of view, it is not wise to only use WEOR as an asphalt regenerant. It is necessary to study the introduction of other additives to obtain the asphalt regenerant based upon WEOR.

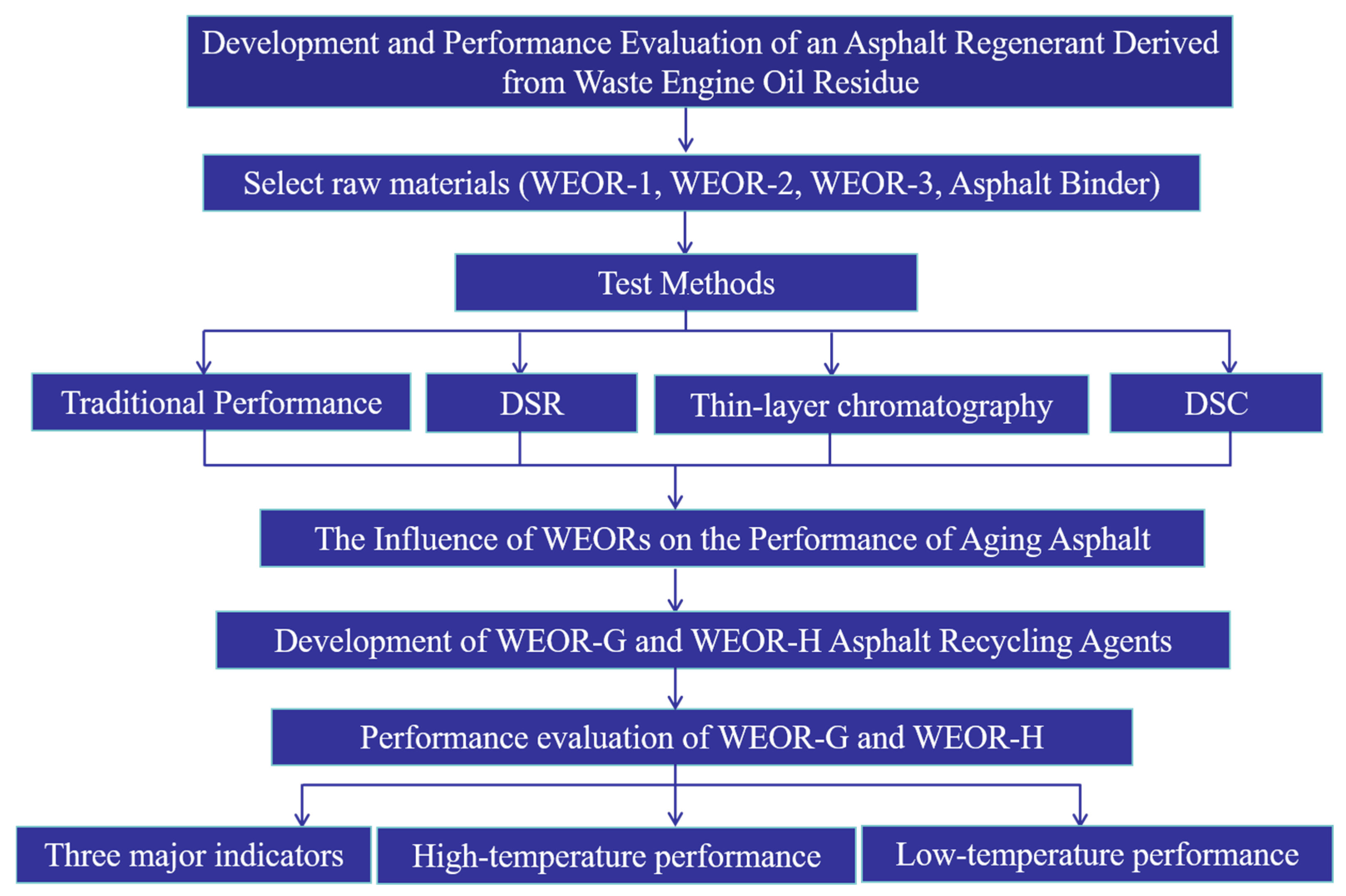

This study embarks on an examination of three distinct WEORs, produced through two separate processes. Initially, the research scrutinizes the impact of the three varying WEORs on the performance of aging asphalt, followed by the preparation of WEOR-G and WEOR-H asphalt regenerants utilizing two technological pathways to augment the regenerative effect of WEORs on aged asphalt. Finally, the study conducts a comparative analysis of the road performances of regenerant J, WEOR-G, and WEOR-H, with the objective of formulating a strategy to recycle WEORs and bolster waste engine oil utilization. The results show that the asphalt binder regenerated by WEOR-G, composed of WEOR-1, liquid rubber, ultraviolet absorber, light shielding agent, and antioxidant, exhibited the best high- and low-temperature performance. This inquiry furnishes vital data support for the practical implementation of high-performance WEOR regenerative RAP.

The flowchart of this work is shown in

Figure 1.

3. Analysis of the Influence of WEOR on the Performance of Aging Asphalt

3.1. Test Results for Three Major Indicators

Penetration can indicate the degree of softness and the relative viscosity of the asphalt binder. The softening point is an important indicator for evaluating the hardness and high-temperature performance of asphalt. Ductility can be used to evaluate the tensile deformation and flexibility of the asphalt binder.

Figure 2 illustrates the three key indicators of aged asphalt subject to varying WEOR dosages (0%, 6%, 8%, 10%, 12%, and 14% aged asphalt qualities).

Recovery impacts of differing WEORs on the three primary indicators of aged asphalt reveal variations. As dosage escalates, the recovery effects on the three indicators augment but fail to revert to their original conditions. At a 14% WEOR-1 concentration, the recovery effect on the three major indicators of aged asphalt is optimal, though the recovery effect on ductility at 10 °C is subpar. Comparable findings apply to WEOR-2 and WEOR-3. Sun’s research [

33] proposes that WEORs are unable to wholly reestablish the low-temperature performance of aged asphalt.

Given identical dosage, WEOR-1’s recovery effect on the three major indicators of aged asphalt surpasses those of WEOR-2 and WEOR-3. Nevertheless, the recovery rate of 10 °C ductility in aged asphalt from the three WEOR types is constrained, with a peak recovery of 36.9% from the original asphalt. Thus, this study advocates for the deployment of WEOR modification technology to offset the deficiencies in recovering aged asphalt performance.

3.2. Analysis of Dynamic Shear Rheometer (DSR) Rheological Performance Test Results

The DSR provided data, such as the phase angle (δ) and rutting factor (G*/sinδ), to assess the high-temperature rheological properties of asphalt mastics.

Figure 3 displays results concerning the complex moduli and phase angles of aged asphalts under various WEOR dosages. Introducing a WEOR escalates the phase angle of aged asphalt while diminishing the complex modulus, suggesting a weakened deformation resistance in aged asphalt post-WEOR addition. It also implies a decline in high-temperature performance and a heightened risk of rutting. At a 14% dosage, WEOR-3 most effectively recovers the complex modulus of an aged asphalt, followed by WEOR-1 and WEOR-2. However, these fail to restore to the original asphalt level, implying the presence of unrecovered or less-recovered aged asphalt.

Figure 4 reveals that the aging asphalt exhibits the highest rutting resistance factor, while the matrix asphalt shows the lowest among all test samples. The asphalt’s high-temperature performance improves after aging. However, the addition of WEOR-1, WEOR-2, and WEOR-3 reduces the rutting resistance factor of aged asphalt, signifying that the high-temperature performance of aged asphalt diminishes with the inclusion of WEORs, thus elevating the risk of rutting. The greater the quantity of WEORs added, the more pronounced the decrease in the anti-rutting factor. When the content of WEOR-1 and WEOR-3 reaches 14%, the anti-rutting factor of WEORs modified asphalt sample approximates that of the original asphalt. Scholars such as Bennett [

34] and Rubab [

35] theorize that an excessive amount of WEOR may accelerate asphalt aging in subsequent stages, leading to a decline in low-temperature performance. In alignment with Ding’s [

36] findings, this study recommends keeping the WEOR content below 14%.

3.3. Analysis of Four-Component Test Results in Thin-Layer Chromatography

A sample comprising 14% WEOR served as the representative for analyzing aged asphalt’s four-component alterations pre- and post-WEOR addition.

Table 3 presents the thin-layer chromatography test results. The experimental data in the table led to the following observations.

The chemical compositions of WEORs, produced through varying treatment processes, display disparities, with WEOR-1 containing a higher percentage of saturate and aromatic components (89.4%)—a value substantially surpassing that of WEOR-2 (75.5%) and WEOR-3 (80.9%). This explains WEOR-1’s superior aged asphalt performance recovery effect relative to WEOR-2 and WEOR-3. Comparatively, the molecular distillation process outperforms the membrane treatment process in reclaiming waste engine oil’s light components. Conversely, post-distillation, WEOR-2 and WEOR-3 encompass significant molecular components such as asphaltene and resin.

WEOR can replenish the missing lightweight components in aged asphalt, thereby enhancing its performance. WEOR addition decreases aged asphalt’s heavy components, such as asphaltene, and augments light components, such as aromatic components. Nevertheless, none of the WEORs can reestablish the component proportions in aged asphalt to the level of original asphalt. For instance, with WEOR-1 addition, asphalt content in aged asphalt diminishes by 3.68%, resin content contracts by 4.29%, while aromatic content and saturate content increase by 6.76% and 1.21%, respectively. WEOR-2 and WEOR-3 follow identical increase and decrease trends.

In conclusion, while all three WEOR types enhance aged asphalt performance, the impact is relatively negligible, especially in terms of low-temperature performance recovery. Therefore, the direct application of WEORs for aged asphalt regeneration and utilization is not advised. This study, thus, amalgamated other modifiers to improve WEORs and develop better performing WEOR regeneration agents.

5. Discussion

According to the results of previous studies, the inclusion of WEOR to aged asphalt can lead to the performance restoration to some extent [

37]. The light components in WEOR contribute to the dissolution of asphaltenes, thus softening the aged binder [

38,

39]. However, adding WEOR to neat asphalt binder lowers the elastic recovery ability and deformation resistance at high temperatures, leading to a decreased rutting resistance of asphalt [

30]. Wang’s results show that there is no decrease in high-temperature performance for the aged asphalt modified by styrene-butadiene-styrene (SBS), after regeneration by WEOR. The reason is that the light components induce the swelling of SBS network, restricting the thermal motion of asphalt molecules. Unfortunately, the viscous property of asphalt has not been restored due to the presence of SBS [

39]. The results of this study also proved that there are both positive and negative effects on the performance of asphalt binder regenerated by WEOR. Excessive additives should be introduced to the WEOR to obtain a high-performance asphalt regenerant. More research needs to be conducted to ascertain the effects of the excessive additives on the performance of WEOR-regenerated asphalt in future.

Most of the chemical compounds in WEOR are light components with molecular weights of less than 200 g/mol, for instance, paraffin oil, polyolefin oil, aromatic solvents, and so on. These are similar to the light components of asphalt binder, allowing WEOR to be compatible with asphalt easily [

40]. However, the light components from WEOR, easily volatile, lead to a decrease in the secondary aging resistance of WEOR-rejuvenated asphalt [

10]. That is to say, the long-term aging resistance property of WEOR-rejuvenated asphalt binder is poor. Furthermore, WEOR has relatively higher levels of heavy metals such as Fe, Cd, Cr, Pb, etc., [

41]. These metals can cause pollution of the groundwater and soil when discharged into land or a water source, so are thereby harmful to human health. As such, it is necessary to perform pre-treatment on WEOR before using it as asphalt regenerant to ensure its purity and avoid environmental pollution.