Additive Manufacturing of SS316L/IN718 Bimetallic Structure via Laser Powder Bed Fusion

Abstract

:1. Introduction

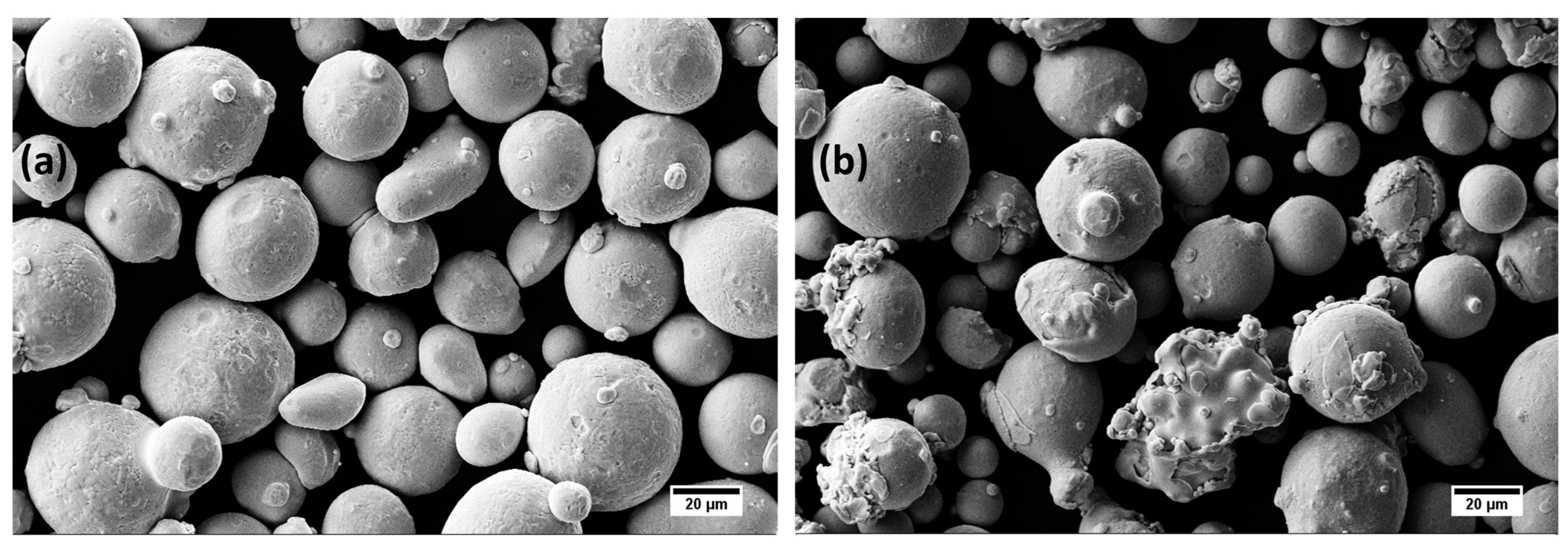

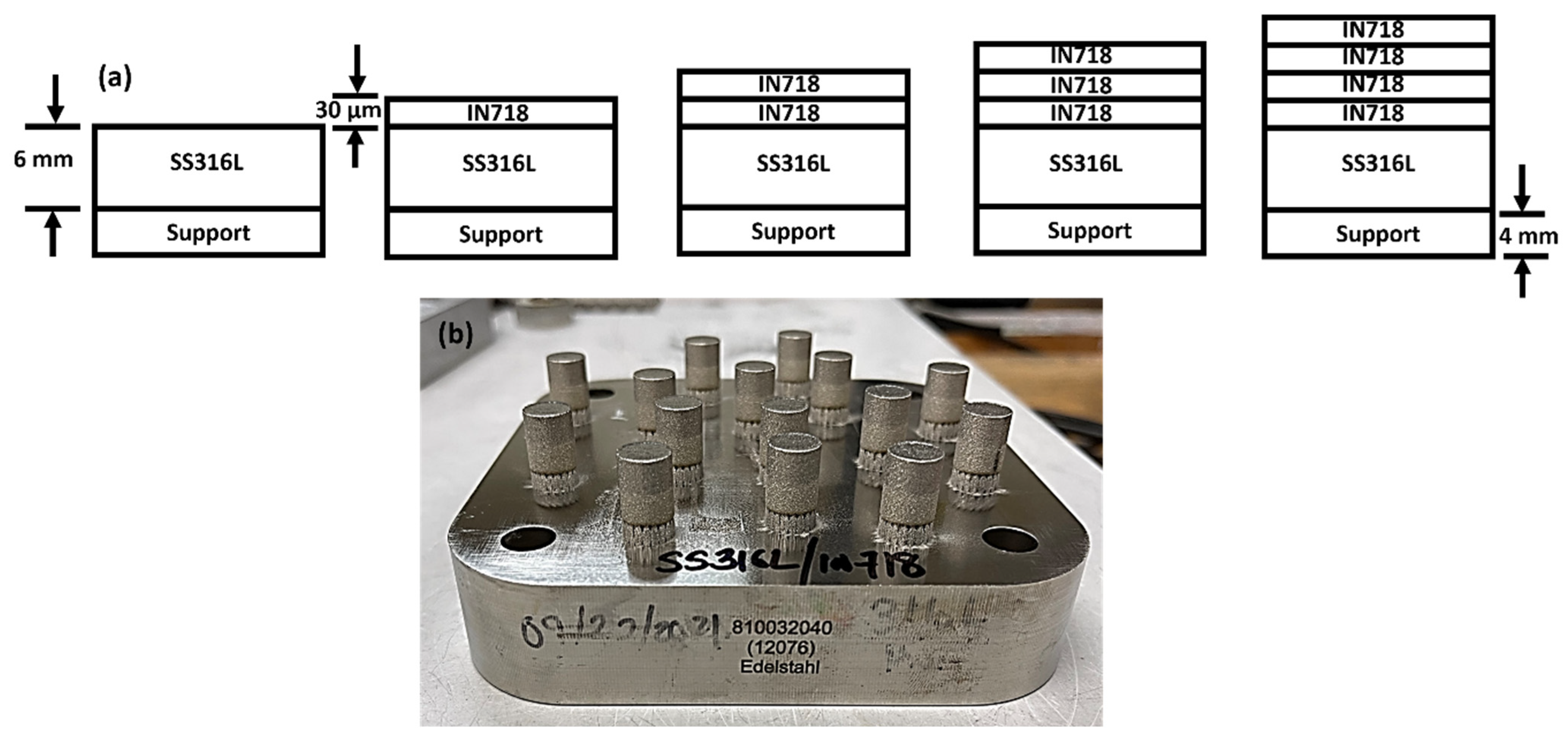

2. Materials and Methods

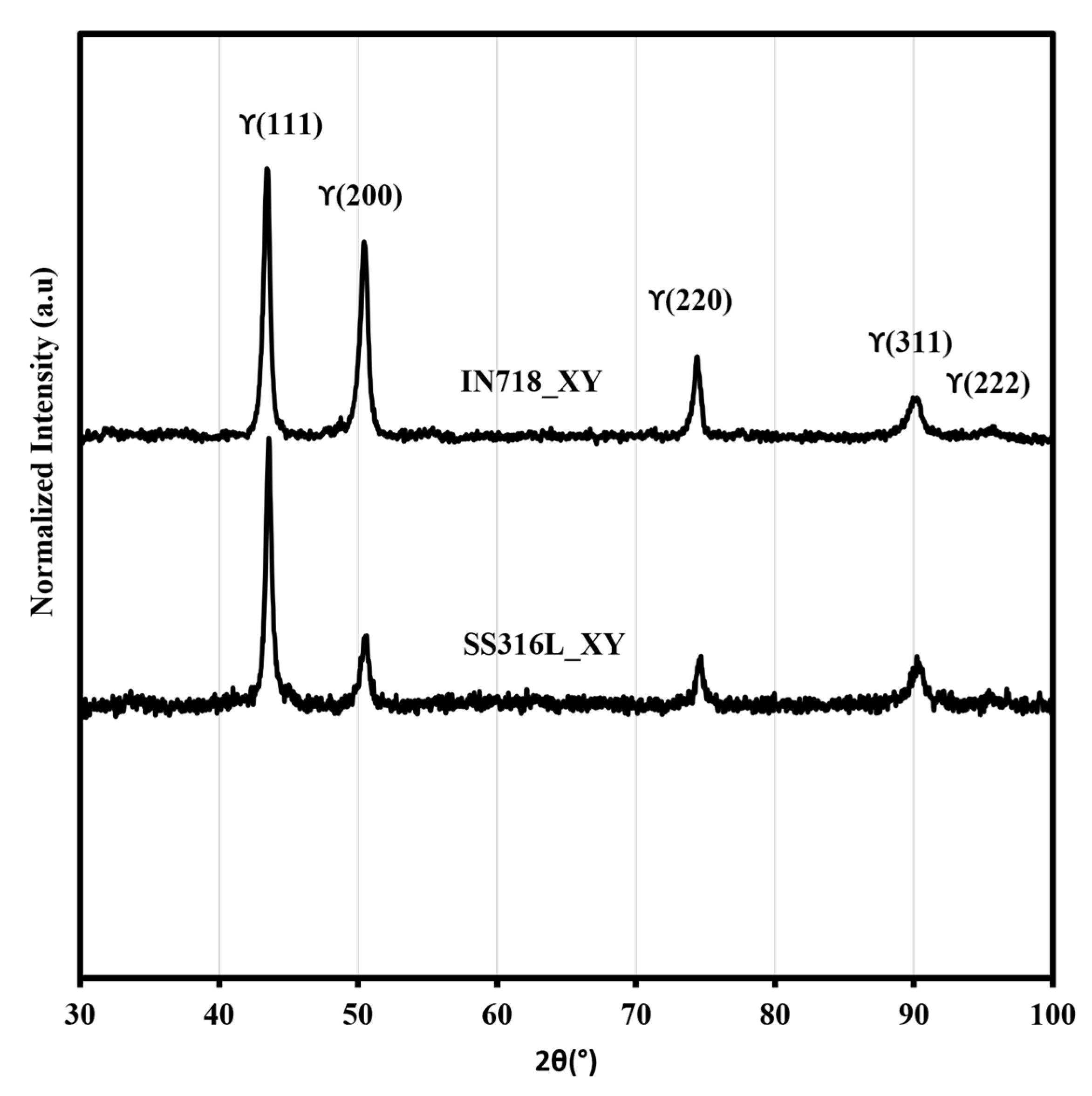

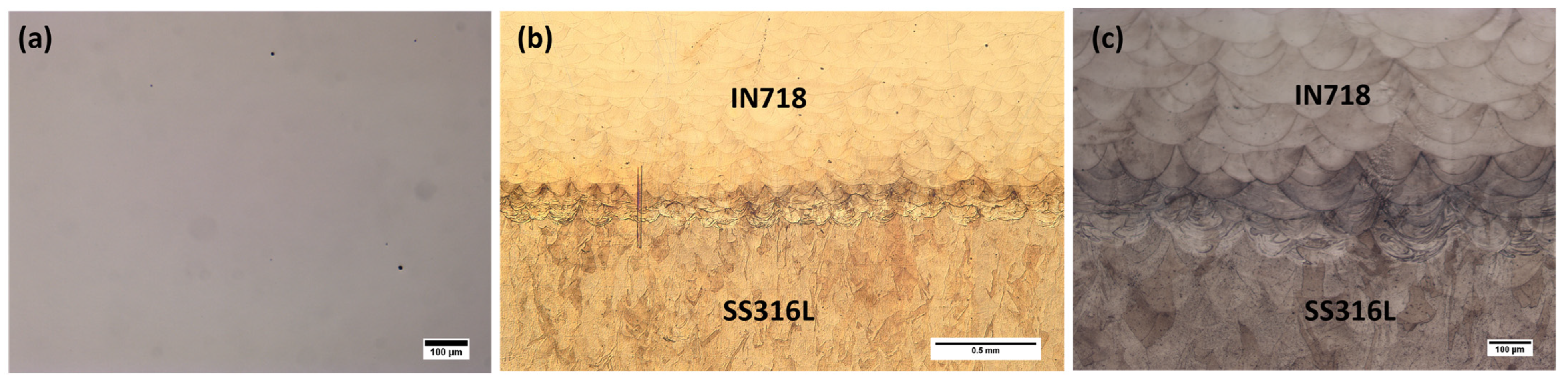

3. Results and Discussion

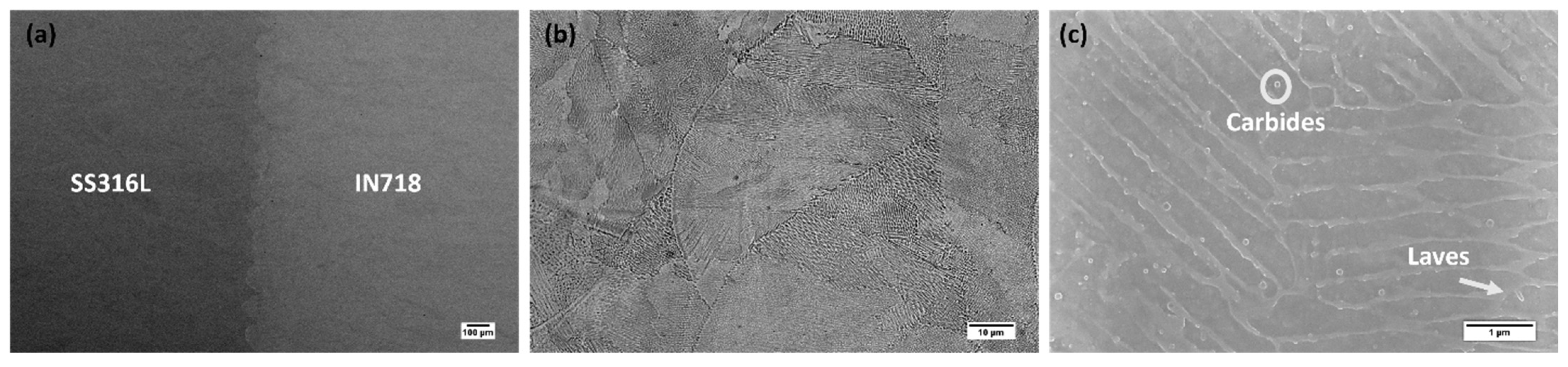

3.1. Phase Constituents and Microstructure

3.2. Constituents Intermixing and Nanohardness

| Fabrication Technique | Terminal Composition (wt.%) | Temperature (°C) | Time (Days) | of Ni (m2/s) | Ref. |

|---|---|---|---|---|---|

| Diffusion Couple | Fe5Ni-Fe10Ni | 910 | ~1 | 2.7 | [33] |

| Fe5Ni-Fe10Ni | 850 | 1.75 | 4.4 | [33] | |

| Fe10Ni-Fe15Ni | 802 | 3 | 3.6 | [34] | |

| Fe10Ni-Fe15Ni | 757 | 24 | 2.3 | [34] | |

| Fe15Ni-Fe20Ni | 705 | 40 | 1.6 | [33] | |

| Fe20Ni-Fe25Ni | 650 | 121 | 1.2 | [33] | |

| Fe25Ni-Fe30Ni | 610 | 62 | 4.0 | [33] | |

| LPBF | SS316L/IN718 Bimetallic | Varying | 10 ms | 6.5 | This study |

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Frazier, W.E. Metal Additive Manufacturing: A Review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive Manufacturing of Metallic Components–Process, Structure and Properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Zhou, L.; Mehta, A.; McWilliams, B.; Cho, K.; Sohn, Y. Microstructure, Precipitates and Mechanical Properties of Powder Bed Fused Inconel 718 before and after Heat Treatment. J Mater Sci Technol. 2019, 35, 1153–1164. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive Manufacturing of Metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Yap, C.Y.; Chua, C.K.; Dong, Z.L.; Liu, Z.H.; Zhang, D.Q.; Loh, L.E.; Sing, S.L. Review of Selective Laser Melting: Materials and Applications. Appl. Phys. Rev. 2015, 2, 041101. [Google Scholar] [CrossRef]

- King, W.E.; Anderson, A.T.; Ferencz, R.M.; Hodge, N.E.; Kamath, C.; Khairallah, S.A.; Rubenchik, A.M. Laser Powder Bed Fusion Additive Manufacturing of Metals; Physics, Computational, and Materials Challenges. Appl. Phys. Rev. 2015, 2, 041304. [Google Scholar] [CrossRef]

- Joo, H.; Woo, J.; Sohn, Y.; Lee, K.-A. Effect of Process Stopping and Restarting on the Microstructure and Local Property of 316L Stainless Steel Manufactured by Selective Laser Melting Process. J. Korean Powder Metall. Inst. 2022, 29, 1–7. [Google Scholar] [CrossRef]

- Hinojos, A.; Mireles, J.; Reichardt, A.; Frigola, P.; Hosemann, P.; Murr, L.E.; Wicker, R.B. Joining of Inconel 718 and 316 Stainless Steel Using Electron Beam Melting Additive Manufacturing Technology. Mater. Des. 2016, 94, 17–27. [Google Scholar] [CrossRef]

- Carroll, B.E.; Otis, R.A.; Borgonia, J.P.; Suh, J.O.; Dillon, R.P.; Shapiro, A.A.; Hofmann, D.C.; Liu, Z.K.; Beese, A.M. Functionally Graded Material of 304L Stainless Steel and Inconel 625 Fabricated by Directed Energy Deposition: Characterization and Thermodynamic Modeling. Acta Mater. 2016, 108, 46–54. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Zhang, Y.; Onuike, B. Additive Manufacturing of Bimetallic Structures. Virtual Phys. Prototyp. 2022, 17, 256–294. [Google Scholar] [CrossRef]

- Singh, S.P.; Aggarwal, A.; Upadhyay, R.K.; Kumar, A. Processing of IN718-SS316L Bimetallic-Structure Using Laser Powder Bed Fusion Technique. Mater. Manuf. Process. 2021, 36, 1028–1039. [Google Scholar] [CrossRef]

- Chen, N.; Khan, H.A.; Wan, Z.; Lippert, J.; Sun, H.; Shang, S.L.; Liu, Z.K.; Li, J. Microstructural Characteristics and Crack Formation in Additively Manufactured Bimetal Material of 316L Stainless Steel and Inconel 625. Addit. Manuf. 2020, 32, 101037. [Google Scholar] [CrossRef]

- Locci, I.E.; Bowman, C.L.; Gabbs, T.P. Development of High Temperature Dissimilar Joint Technology for Fission Surface Power Systems. In Proceedings of the 4th International Brazing and Soldering Conference, Orlando, FL, USA, 26–29 April 2009. [Google Scholar]

- Ribeiro, M.; Sousa Carneiro, O.; Ferreira da Silva, A. Interface Geometries in 3D Multi-Material Prints by Fused Filament Fabrication. Rapid Prototyp. J. 2019, 25, 38–46. [Google Scholar] [CrossRef]

- Stano, G.; Ovy, S.M.A.I.; Percoco, G.; Zhang, R.; Lu, H.; Tadesse, Y. Additive Manufacturing for Bioinspired Structures: Experimental Study to Improve the Multimaterial Adhesion Between Soft and Stiff Materials. 3D Print Addit. Manuf. 2023. [Google Scholar] [CrossRef]

- Ghanavati, R.; Naffakh-Moosavy, H.; Moradi, M. Additive Manufacturing of Thin-Walled SS316L-IN718 Functionally Graded Materials by Direct Laser Metal Deposition. J. Mater. Res. Technol. 2021, 15, 2673–2685. [Google Scholar] [CrossRef]

- Mei, X.; Wang, X.; Peng, Y.; Gu, H.; Zhong, G.; Yang, S. Interfacial Characterization and Mechanical Properties of 316L Stainless Steel/Inconel 718 Manufactured by Selective Laser Melting. Mater. Sci. Eng. A 2019, 758, 185–191. [Google Scholar] [CrossRef]

- Hyer, H.; Zhou, L.; Park, S.; Gottsfritz, G.; Benson, G.; Tolentino, B.; McWilliams, B.; Cho, K.; Sohn, Y. Understanding the Laser Powder Bed Fusion of AlSi10Mg Alloy. Metallogr. Microstruct. Anal. 2020, 9, 484–502. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Yusuf, S.M.; Mazlan, N.; Musa, N.H.; Zhao, X.; Chen, Y.; Yang, S.; Nordin, N.A.; Mazlan, S.A.; Gao, N. Interfa-cial Microstructures and Strengthening Mechanisms of 2 Multi-Material 316L Stainless Steel / Inconel 718 Fabricated by 3 Selective Laser Melting. Metals 2023, 13, 400. [Google Scholar] [CrossRef]

- Tucho, W.M.; Cuvillier, P.; Sjolyst-Kverneland, A.; Hansen, V. Microstructure and Hardness Studies of Inconel 718 Manufactured by Selective Laser Melting before and after Solution Heat Treatment. Mater. Sci. Eng. A 2017, 689, 220–232. [Google Scholar] [CrossRef]

- Zhang, D.; Niu, W.; Cao, X.; Liu, Z. Effect of Standard Heat Treatment on the Microstructure and Mechanical Properties of Selective Laser Melting Manufactured Inconel 718 Superalloy. Mater. Sci. Eng. A 2015, 644, 32–40. [Google Scholar] [CrossRef]

- Feenstra, D.R.; Molotnikov, A.; Birbilis, N. Effect of Energy Density on the Interface Evolution of Stainless Steel 316L Deposited upon INC 625 via Directed Energy Deposition. J. Mater. Sci. 2020, 55, 13314–13328. [Google Scholar] [CrossRef]

- Boltzmann, L. Zur Integration Der Diffusionsgleichung Bei Variabeln Diffusionscoefficienten. Ann. Phys. 1894, 289, 959–964. [Google Scholar] [CrossRef]

- Kammerer, C.C.; Kulkarni, N.S.; Warmack, R.J.; Sohn, Y.H. Interdiffusion and Impurity Diffusion in Polycrystalline Mg Solid Solution with Al or Zn. J. Alloys Compd. 2014, 617, 968–974. [Google Scholar] [CrossRef]

- Perez, E.; Patterson, T.; Sohn, Y. Interdiffusion Analysis for NiAl versus Superalloys Diffusion Couples. J. Phase Equilibria Diffus. 2006, 27, 659–664. [Google Scholar] [CrossRef]

- Pantawane, M.V.; Ho, Y.H.; Joshi, S.S.; Dahotre, N.B. Computational Assessment of Thermokinetics and Associated Microstructural Evolution in Laser Powder Bed Fusion Manufacturing of Ti6Al4V Alloy. Sci. Rep. 2020, 10, 7579. [Google Scholar] [CrossRef]

- Huynh, T.; Mehta, A.; Graydon, K.; Woo, J.; Park, S.; Hyer, H.; Zhou, L.; Imholte, D.D.; Woolstenhulme, N.E.; Wachs, D.M.; et al. Microstructural Development in Inconel 718 Nickel-Based Superalloy Additively Manufactured by Laser Powder Bed Fusion. Metallogr. Microstruct. Anal. 2022, 11, 88–107. [Google Scholar] [CrossRef]

- Dayananda, M.A.; Sohn, Y.H. Average Effective Interdiffusion Coefficients and Their Applications for Isothermal Multicomponent Diffusion Couples. Scr. Mater. 1996, 35, 683–688. [Google Scholar] [CrossRef]

- England, J.; Uddin, M.J.; Ramirez-Cedillo, E.; Karunarathne, D.; Nasrazadani, S.; Golden, T.D.; Siller, H.R. Nanoindentation Hardness and Corrosion Studies of Additively Manufactured 316L Stainless Steel. J. Mater. Eng. Perform. 2022, 31, 6795–6805. [Google Scholar] [CrossRef]

- Ghanavati, R.; Lannunziata, E.; Norouzi, E.; Bagherifard, S.; Iuliano, L.; Saboori, A. Design and Development of SS316L-IN718 Functionally Graded Materials via Laser Powder Bed Fusion. Mater. Lett. 2023, 349, 134793. [Google Scholar] [CrossRef]

- Dean, D.C.; Goldstein, J.I. Determination of the Interdiffusion Coefficients in the Fe-Ni and Fe-Ni-P Systems Below 900 °C. Metall. Trans. A 1986, 17, 1131–1138. [Google Scholar] [CrossRef]

- Narayan, C.; Goldstein, J.I. Low Temperature Diffusivity Measurements in the FeNi System Using STEM Techniques. Metall. Mater. Trans. A 1983, 14, 2437–2439. [Google Scholar]

| Fe | Cr | Ni | Mo | Mn | Si | |

|---|---|---|---|---|---|---|

| Supplier | Bal. | 16–18 | 10–14 | 2.0–3.0 | 2.0 | 1.0 |

| XEDS | 64.93 ± 0.33 | 18.86 ± 0.10 | 11.98 ± 0.15 | 2.21 ± 0.09 | 1.11 ± 0.22 | 0.91 ± 0.03 |

| Fe | Cr | Ni | Nb | Mo | Co | Al | Mn | Ti | Si | |

|---|---|---|---|---|---|---|---|---|---|---|

| Supplier | Bal. | 17–21 | 50–55 | 4.75–5.50 | 2.8–3.30 | 1.0 | 0.20–0.80 | 0.35 | 0.65–1.15 | 0.35 |

| XEDS | 18.9 ± 0.59 | 20.4 ± 0.18 | 51.3 ± 0.59 | 4.6 ± 0.59 | 2.5 ± 0.21 | 0.1 ± 0.17 | 1.0 ± 0.2 | 0.1 ± 0.09 | 1.0 ± 0.16 | 0.2 ± 0.09 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmud, A.; Ayers, N.; Huynh, T.; Sohn, Y. Additive Manufacturing of SS316L/IN718 Bimetallic Structure via Laser Powder Bed Fusion. Materials 2023, 16, 6527. https://doi.org/10.3390/ma16196527

Mahmud A, Ayers N, Huynh T, Sohn Y. Additive Manufacturing of SS316L/IN718 Bimetallic Structure via Laser Powder Bed Fusion. Materials. 2023; 16(19):6527. https://doi.org/10.3390/ma16196527

Chicago/Turabian StyleMahmud, Asif, Nicolas Ayers, Thinh Huynh, and Yongho Sohn. 2023. "Additive Manufacturing of SS316L/IN718 Bimetallic Structure via Laser Powder Bed Fusion" Materials 16, no. 19: 6527. https://doi.org/10.3390/ma16196527

APA StyleMahmud, A., Ayers, N., Huynh, T., & Sohn, Y. (2023). Additive Manufacturing of SS316L/IN718 Bimetallic Structure via Laser Powder Bed Fusion. Materials, 16(19), 6527. https://doi.org/10.3390/ma16196527