Influence of Basalt/Polypropylene Fiber on Permeability and Uniaxial Compressive Properties of Waste Tire Rubberized Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Mixture Ratio Design and Specimen Preparation

2.3. Test Plan

2.3.1. Slump Test

2.3.2. Water Absorption Test

2.3.3. Uniaxial Compression Test

2.3.4. Permeability Test

3. Test Results and Analysis

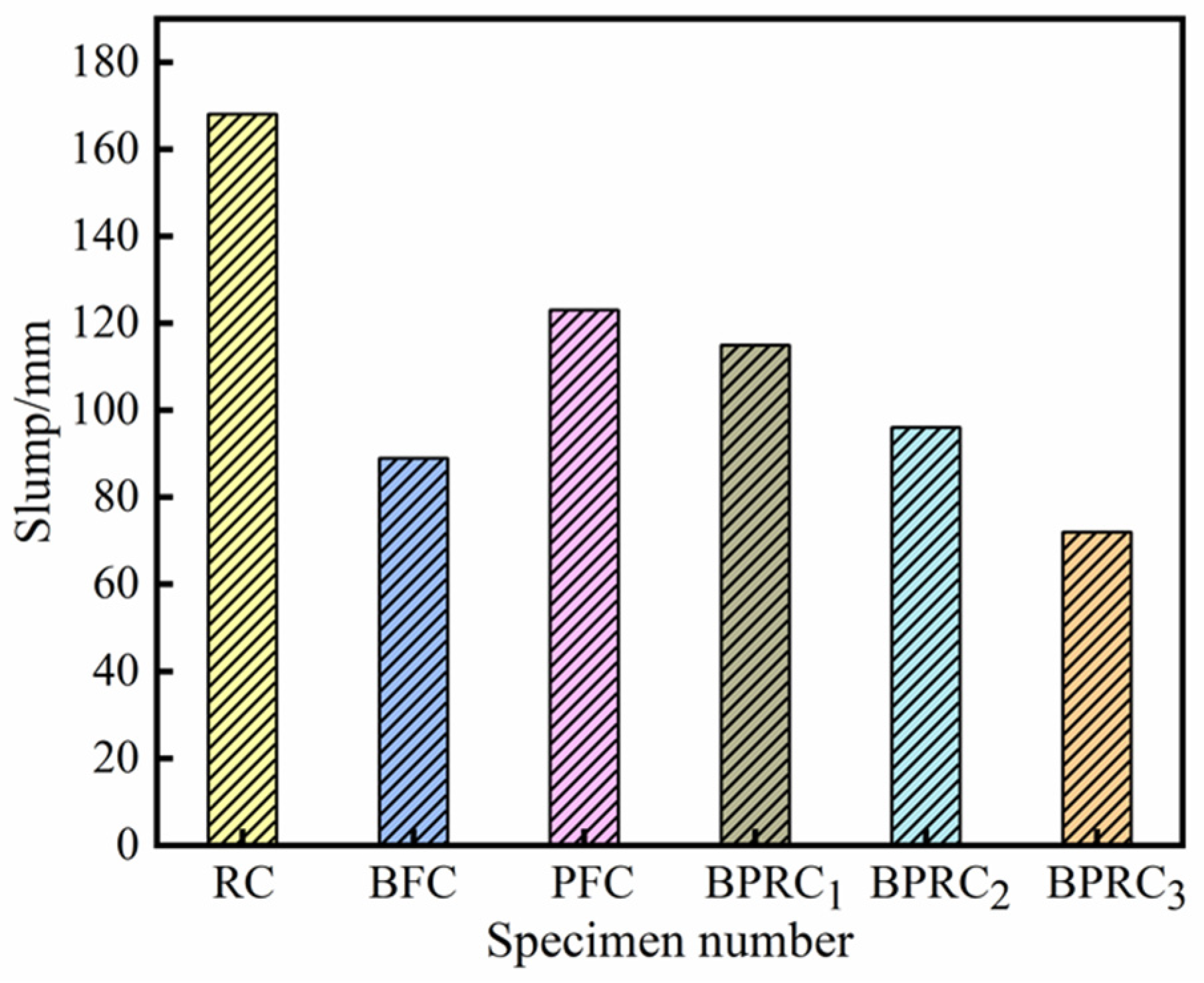

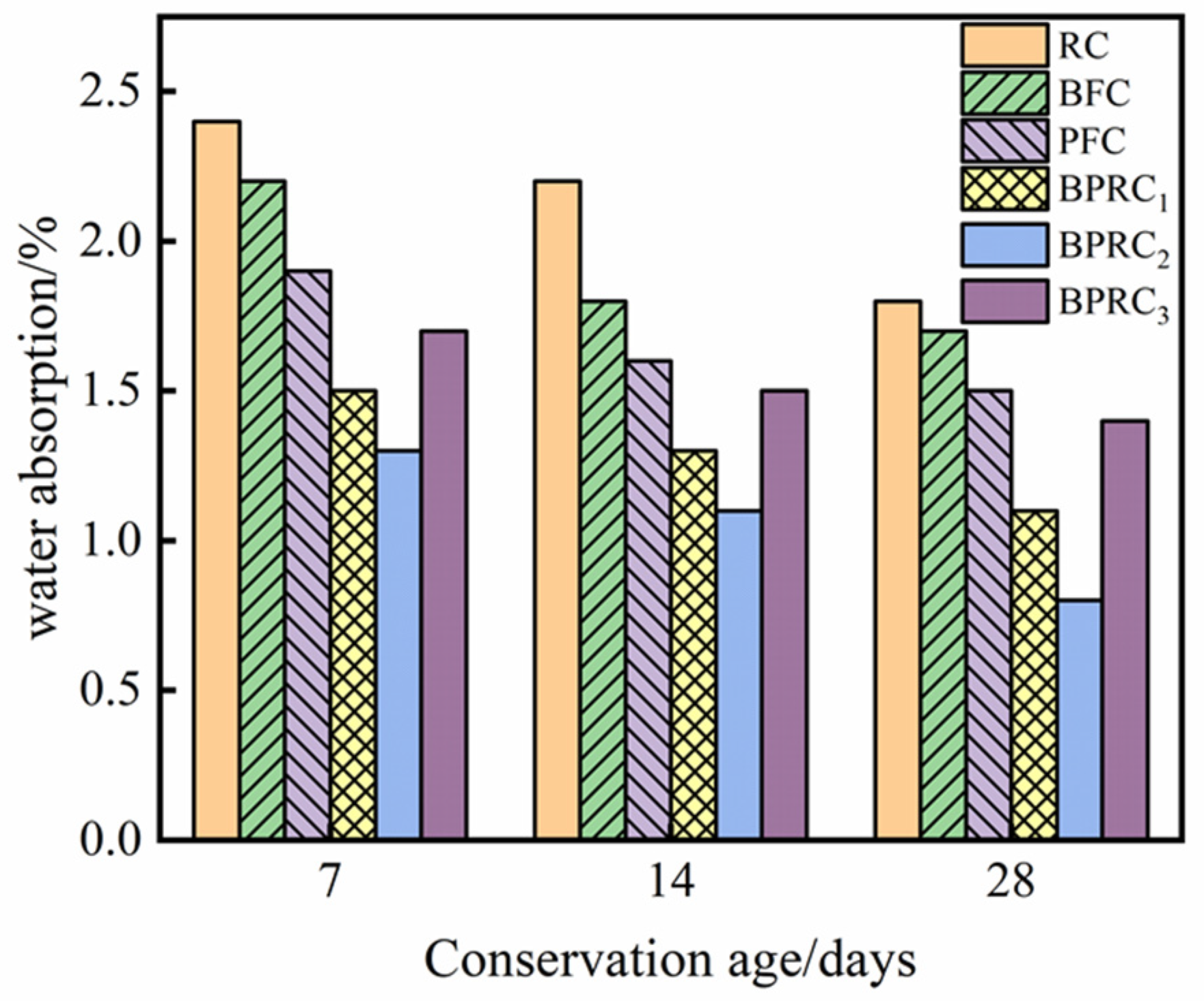

3.1. Slump and Water Absorption

3.2. Uniaxial Compression Test

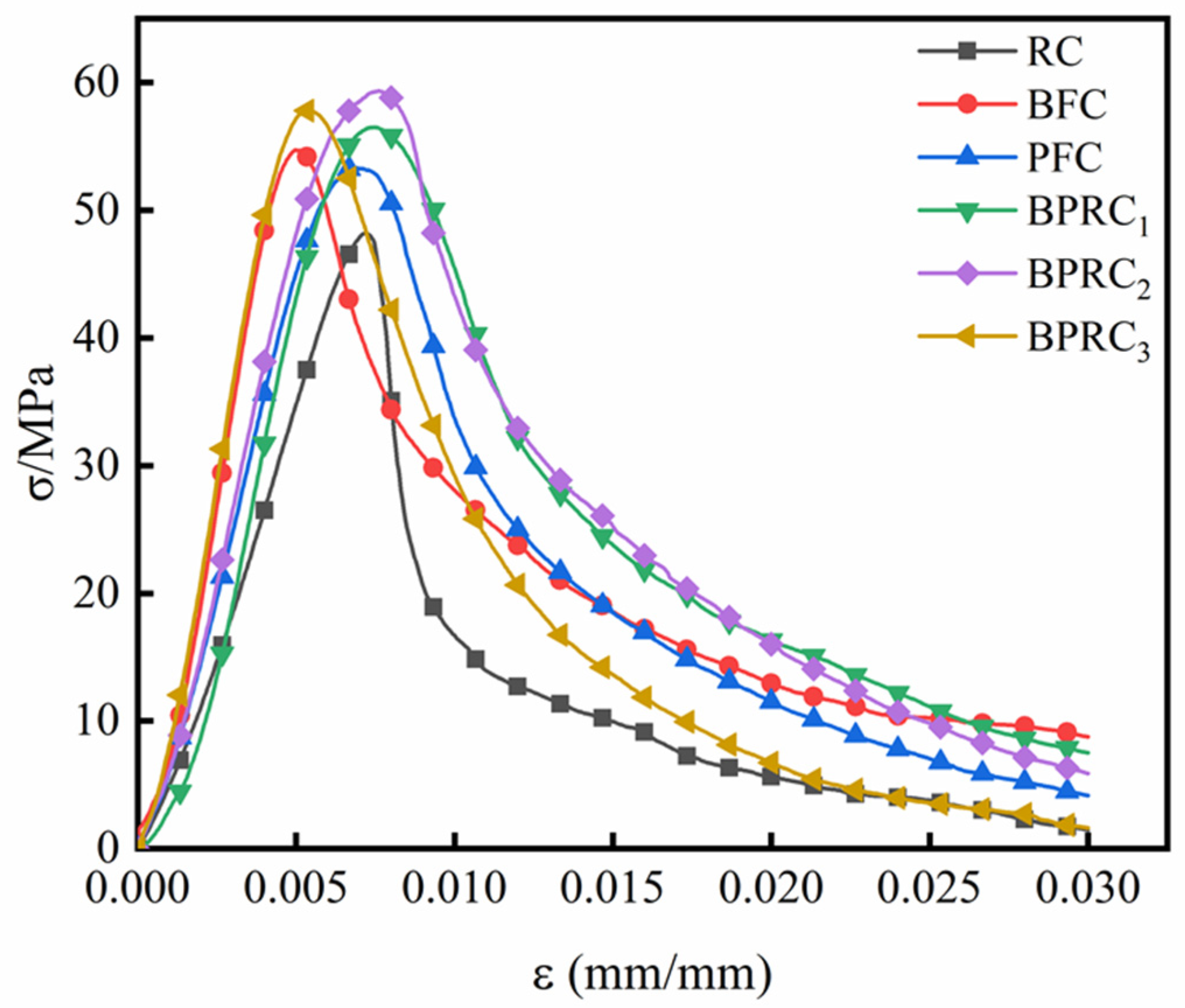

3.2.1. Stress–Strain Curve

- (1)

- On the whole, the stress–strain curve of the fiber–rubber concrete is obviously fuller than that of the rubber concrete. At the initial stage of loading, the stress–strain curve is close to a straight line, and, at this stage, the slope of the fiber–rubber concrete is obviously larger than that of the rubber concrete. This shows that the fiber can effectively increase the stiffness of the rubber concrete and has a good elasticity. Because of the bridging effect of the fiber, the internal defects of the rubber concrete are reduced, and the elastic stage of fiber–rubber concrete is longer than that of the rubber concrete. Intuitively, the BPRC3 group and BFC group revealed similar performances in the elastic stage, the longest elastic time, and the largest slope, which indicated that the basalt fiber in the elastic stage of the rubber concrete lifting effect is more obvious than the polypropylene fiber.

- (2)

- In the stage of rapid stress growth, the stress–strain relationship curve begins to bias from the straight line, with the growth rate of the strain greater than that of the stress at this stage. The slope of the curve decreased gradually, but the decreasing rate was different. The slope of the RC group is the smallest, with those of the BPRC3 group and BFC group being the largest. Compared with the RC group, the top of the fiber–rubber concrete curve is more rounded, while the PFC group is the most rounded, indicating that the polypropylene fiber is more conducive to improving the toughness of the rubberized concrete than the basalt fiber. It can be seen from the whole rising stage of the stress–strain curve that the basalt fiber and polypropylene fiber are both beneficial in improving the compressive capacity and deformation capacity of the rubber concrete.

- (3)

- After the peak stress, the stress drops rapidly to the “inflection point” of the curve. Following the inflection point, the stress decreases slowly, and the stress–strain curve becomes convex toward the strain axis until ultimately reaching stability. After the peak stress, the stress of the RC group decreases rapidly, displaying obvious brittle failure, and the decline rate of the fiber–rubber concrete becomes significantly lower than that of the RC group, indicating that the fiber was beneficial in improving the ductility of the rubberized concrete and improving the brittle failure. Among them, the BPRC2 group declined the most slowly, mainly because the synergistic effect of the basalt fiber and polypropylene fiber improved the internal defects of the rubberized concrete so that it still had a better bearing capacity after compression failure.

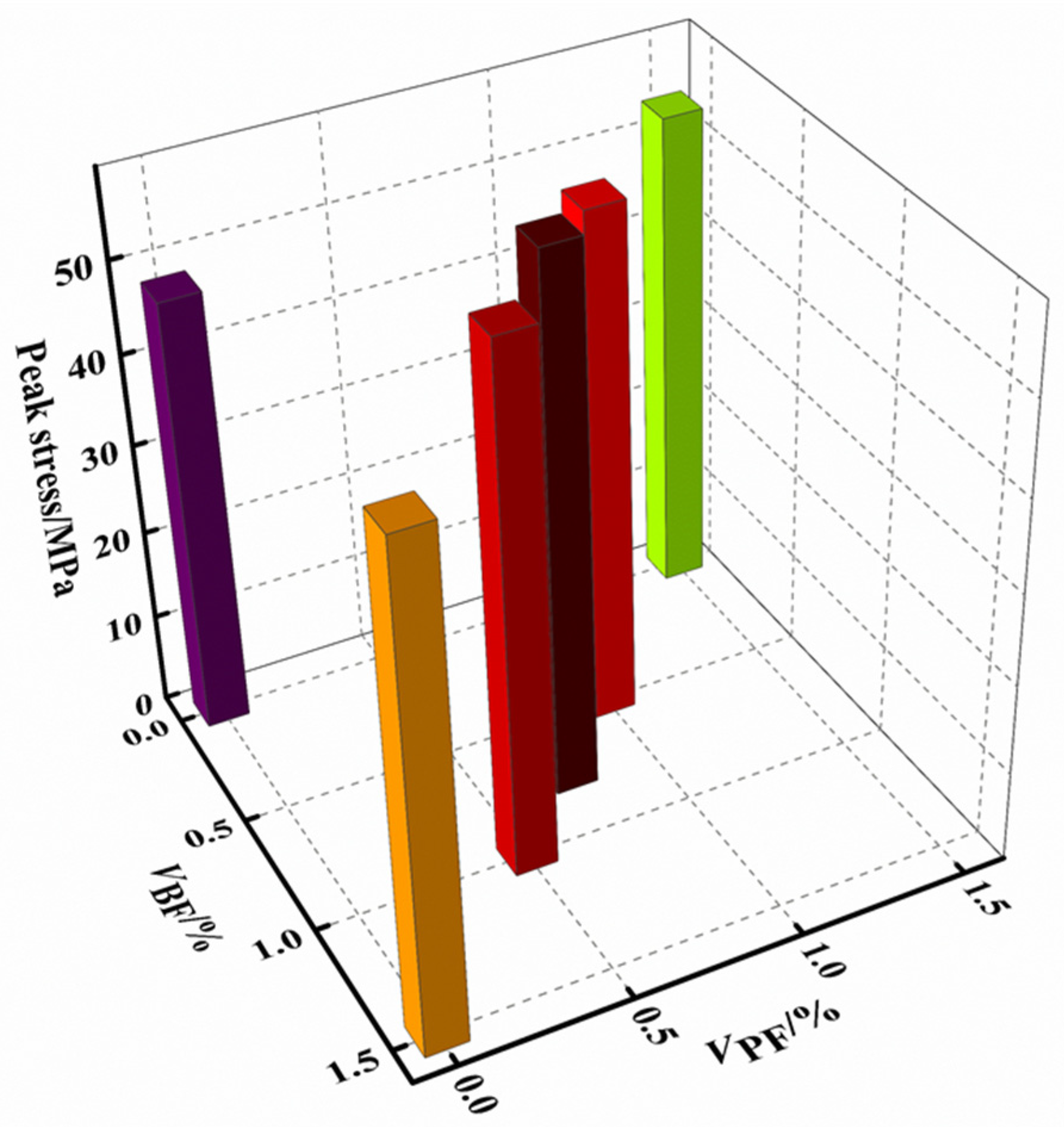

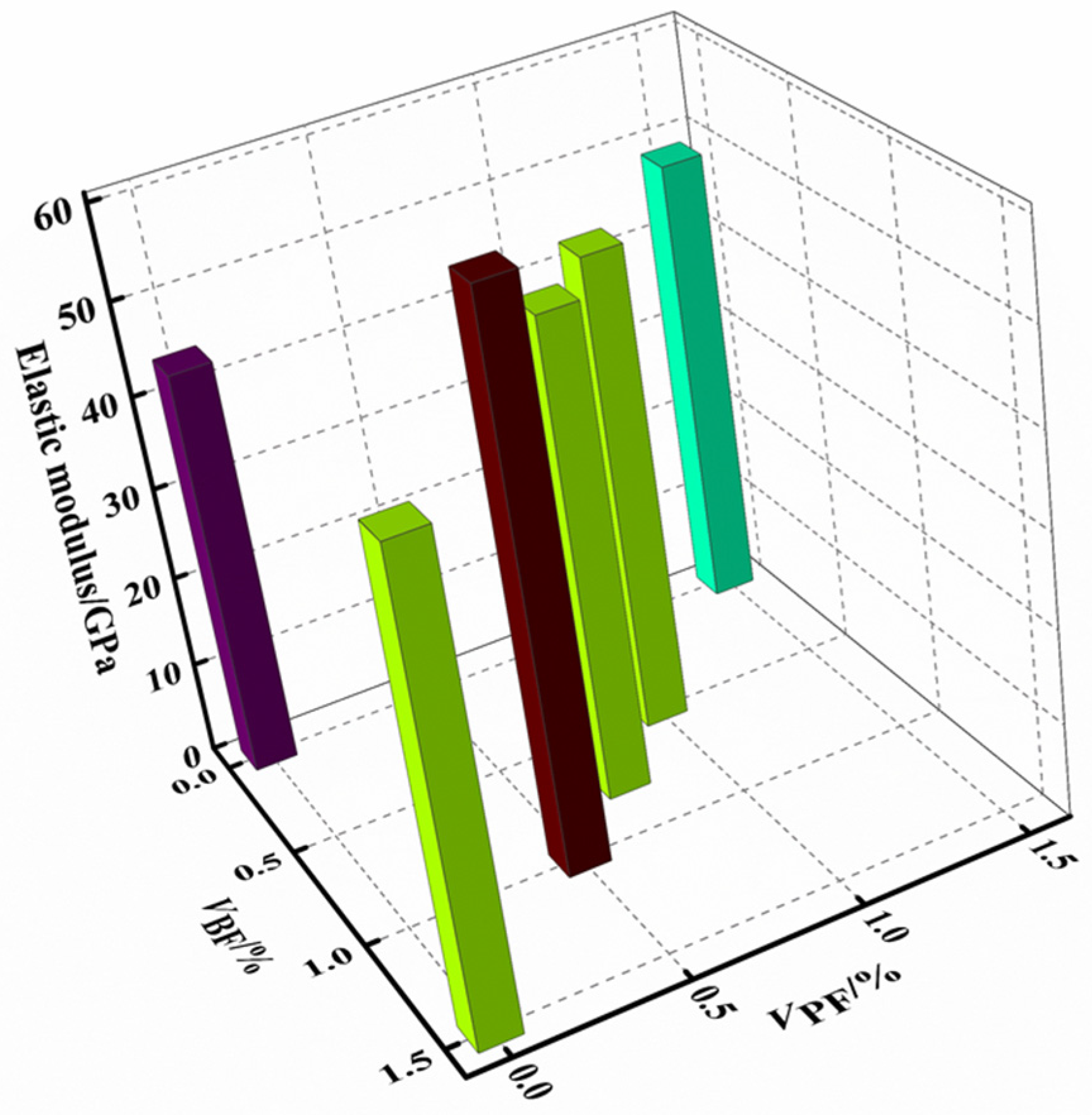

3.2.2. Peak Stress and Elastic Modulus

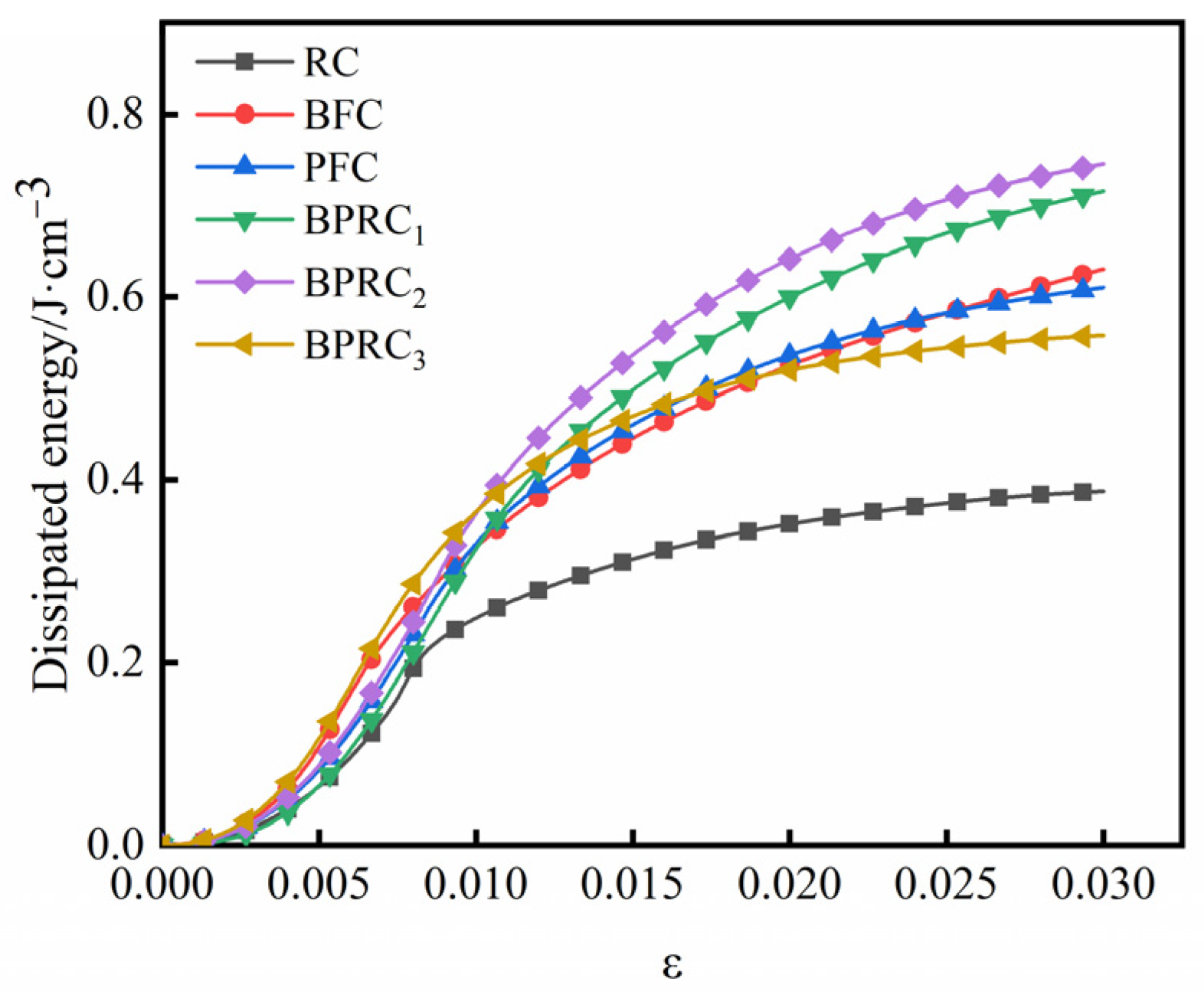

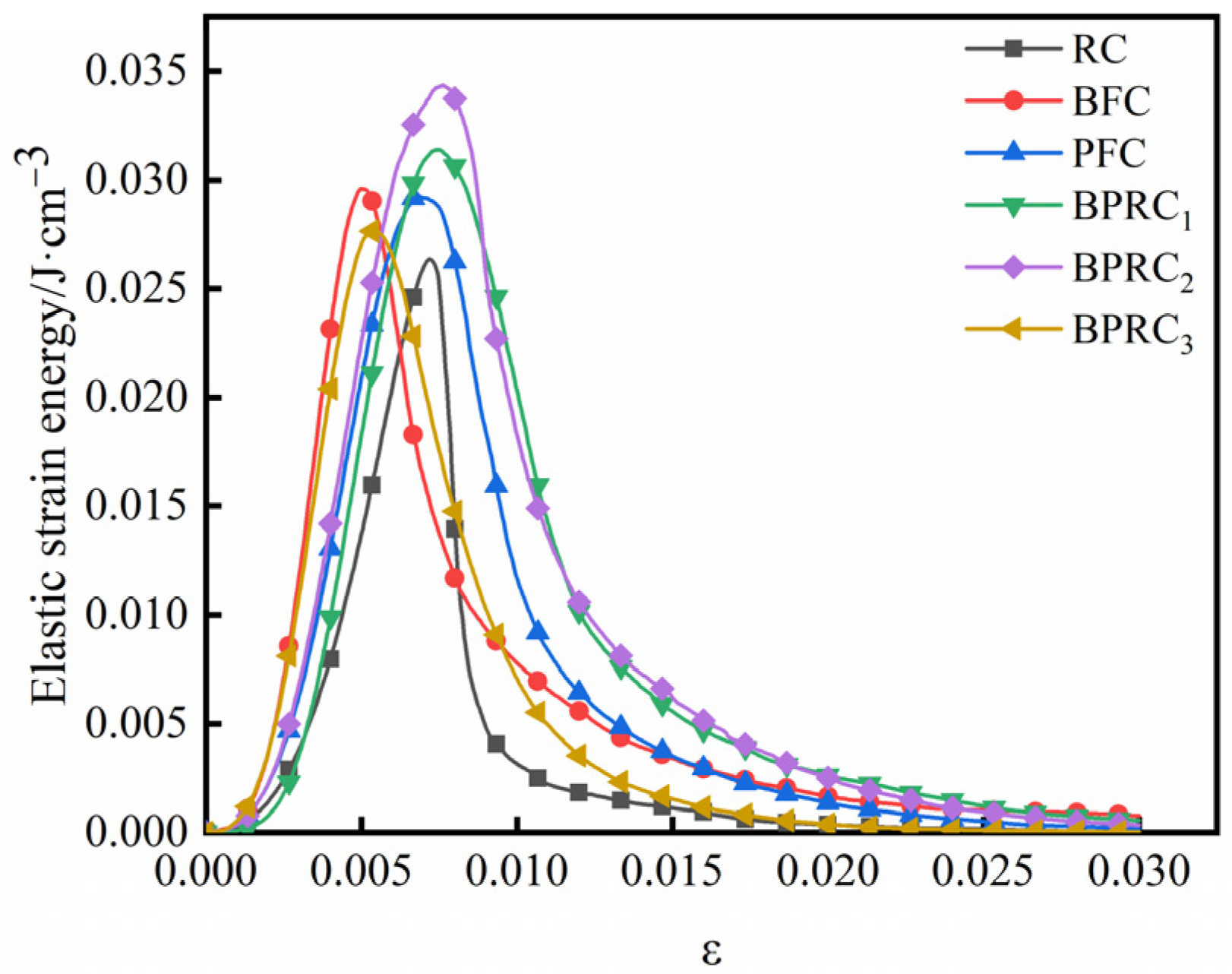

3.2.3. Energy Dissipation Law

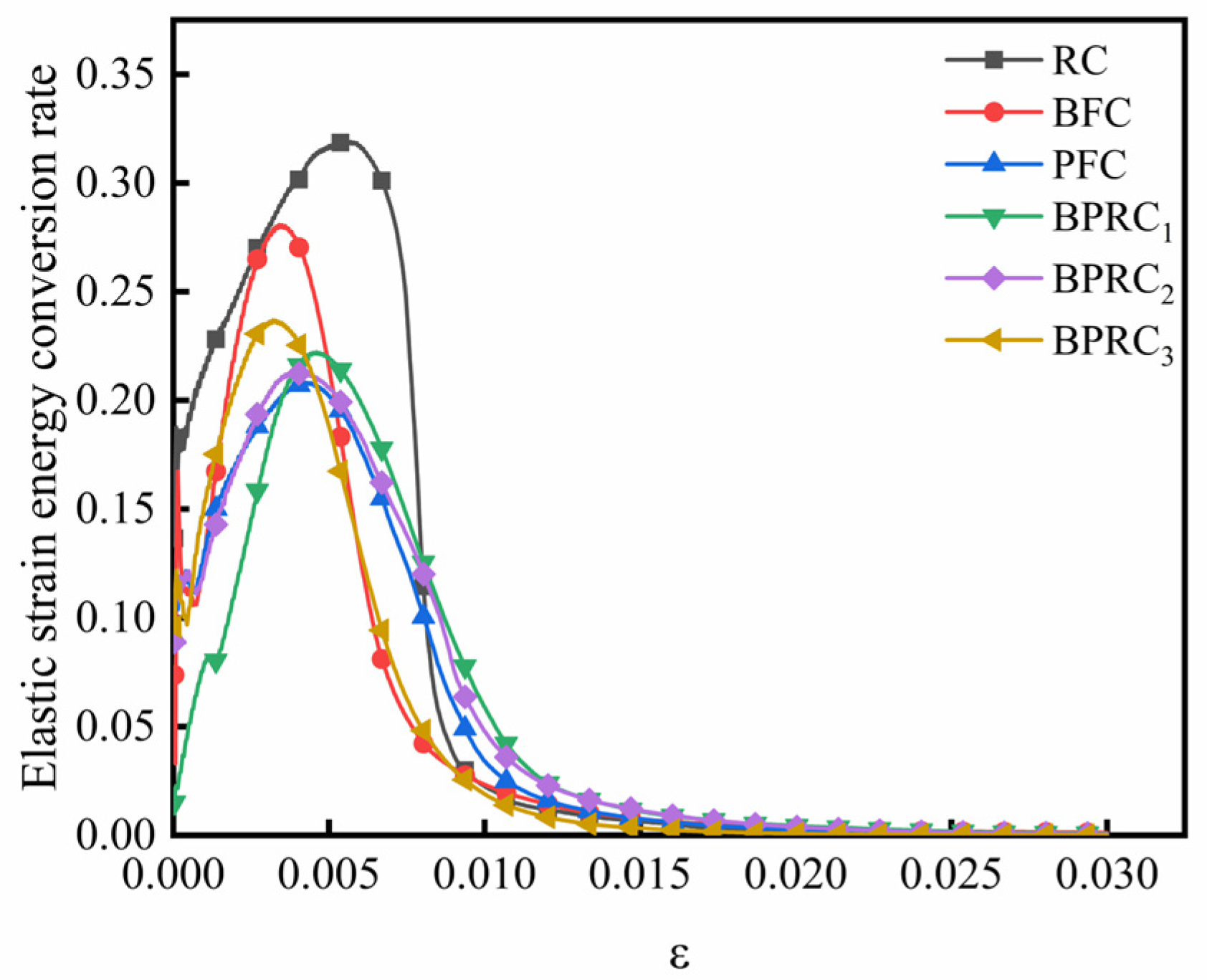

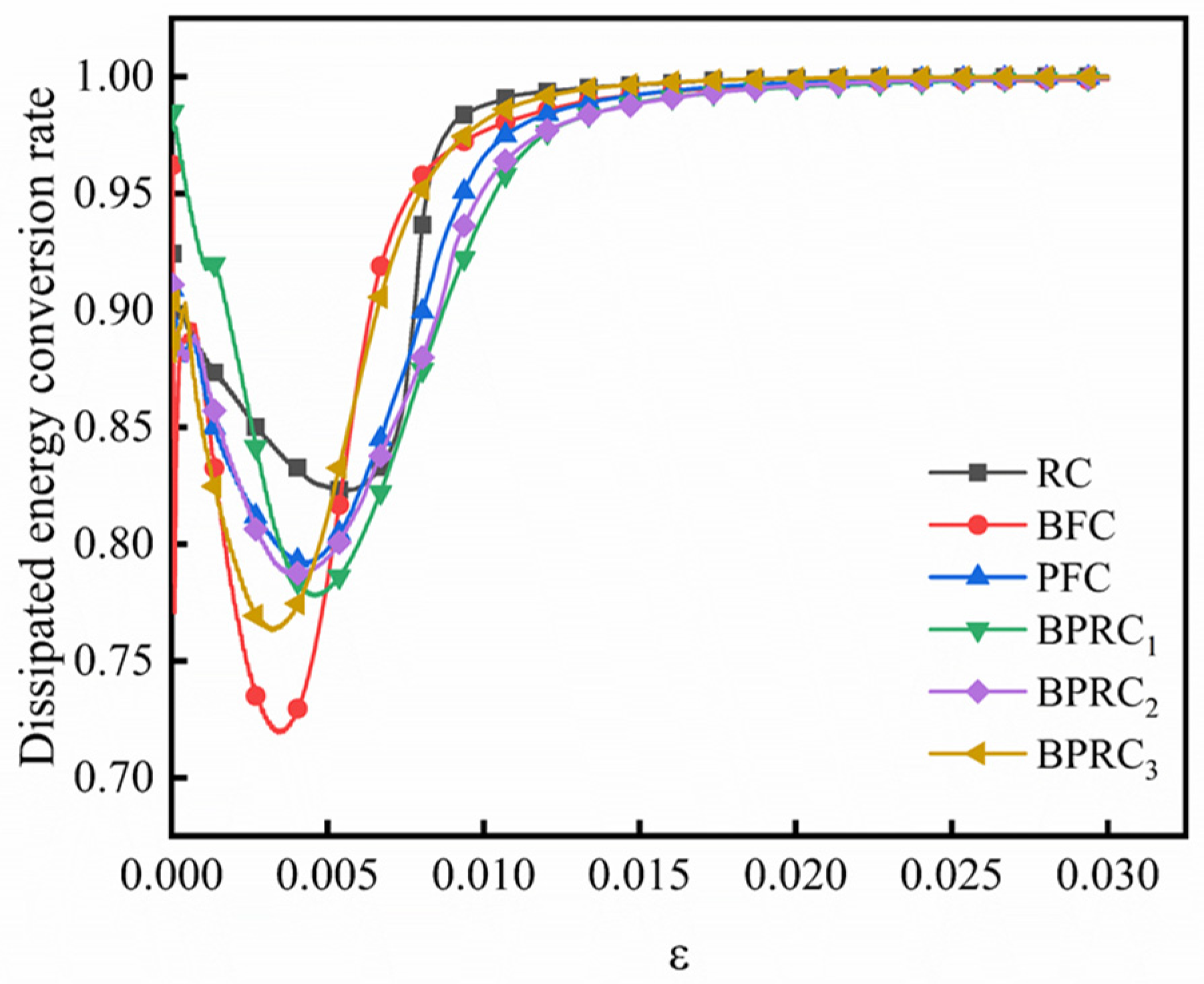

3.2.4. Law of Energy Conversion

3.2.5. Stress–Strain Constitutive Model

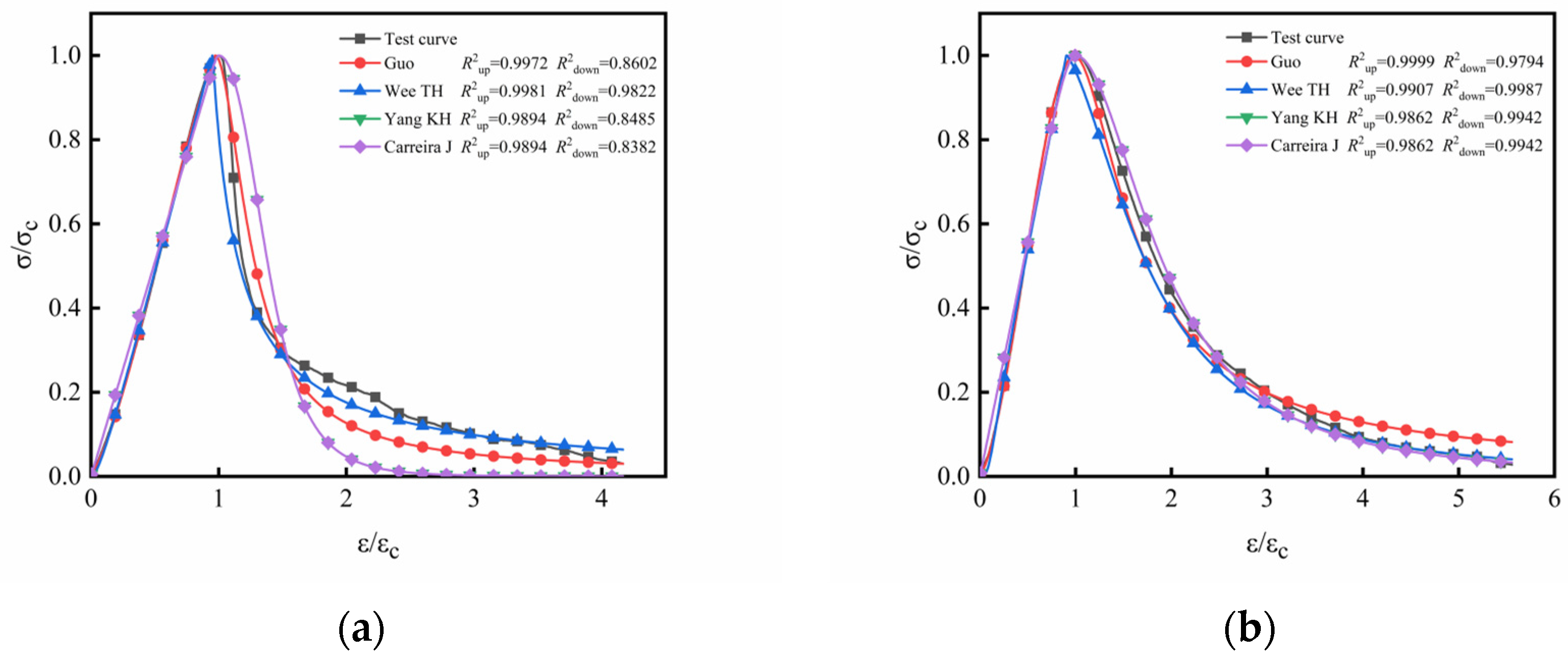

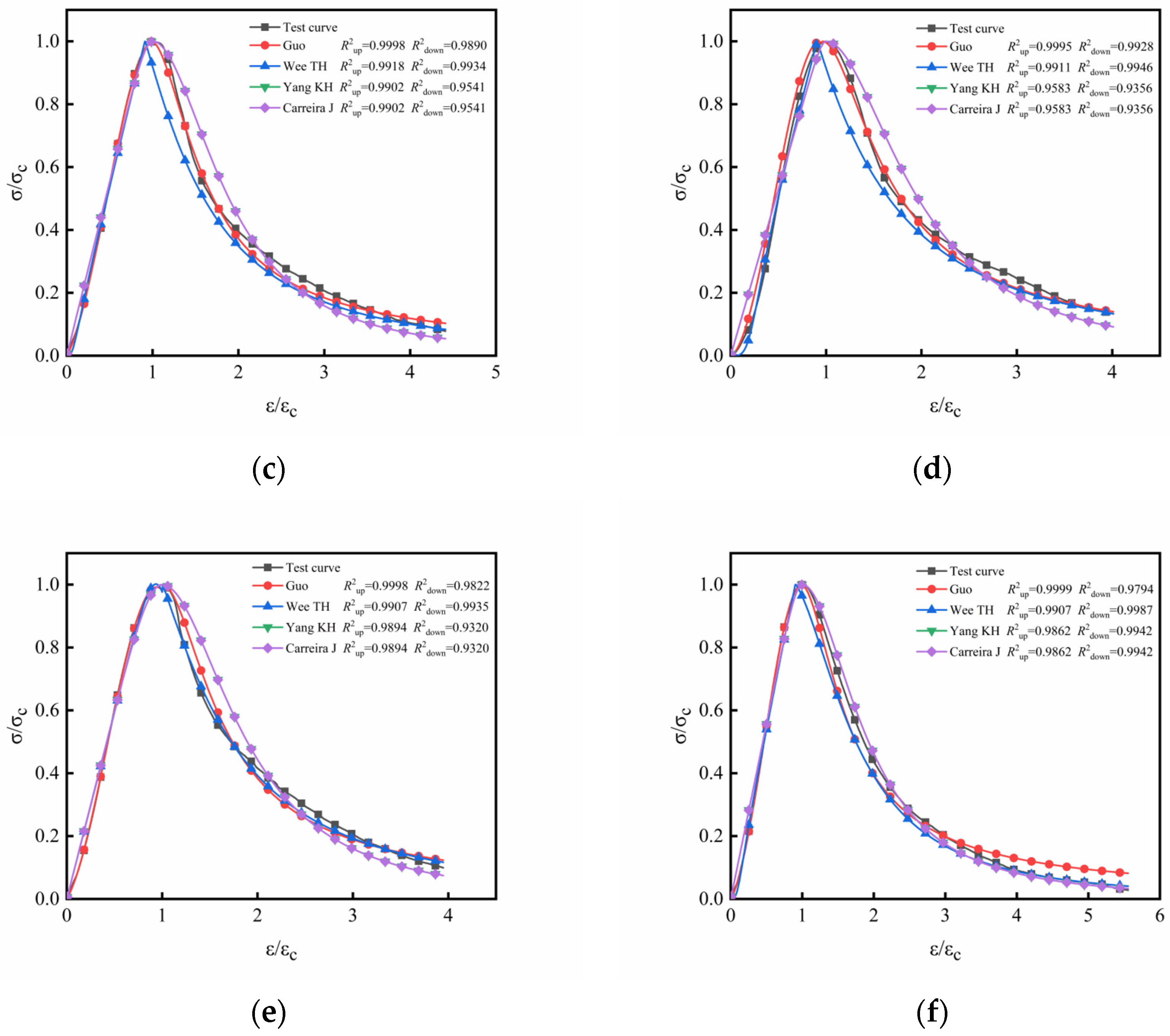

Existing Constitutive Models

Revision of the Constitutive Model

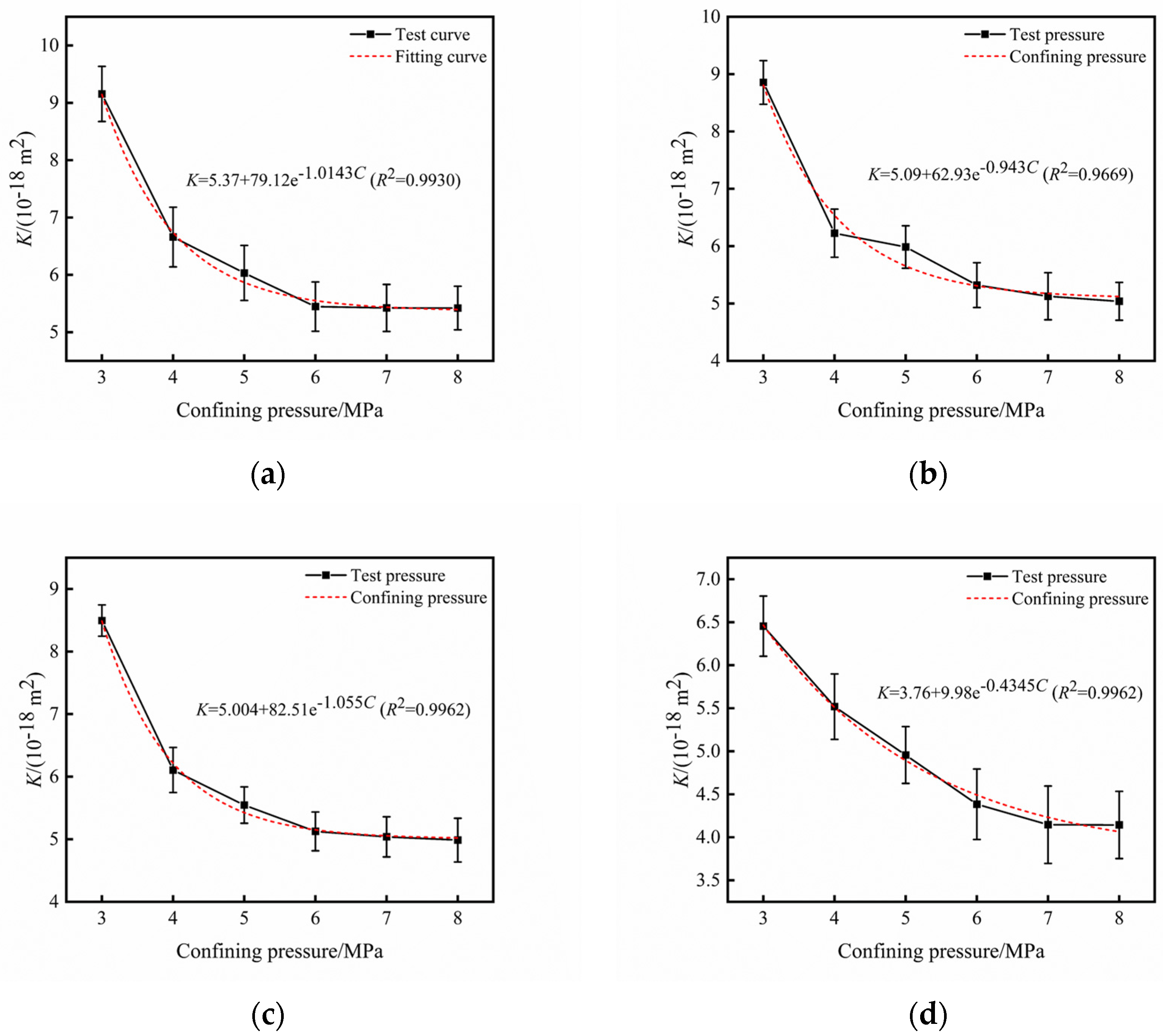

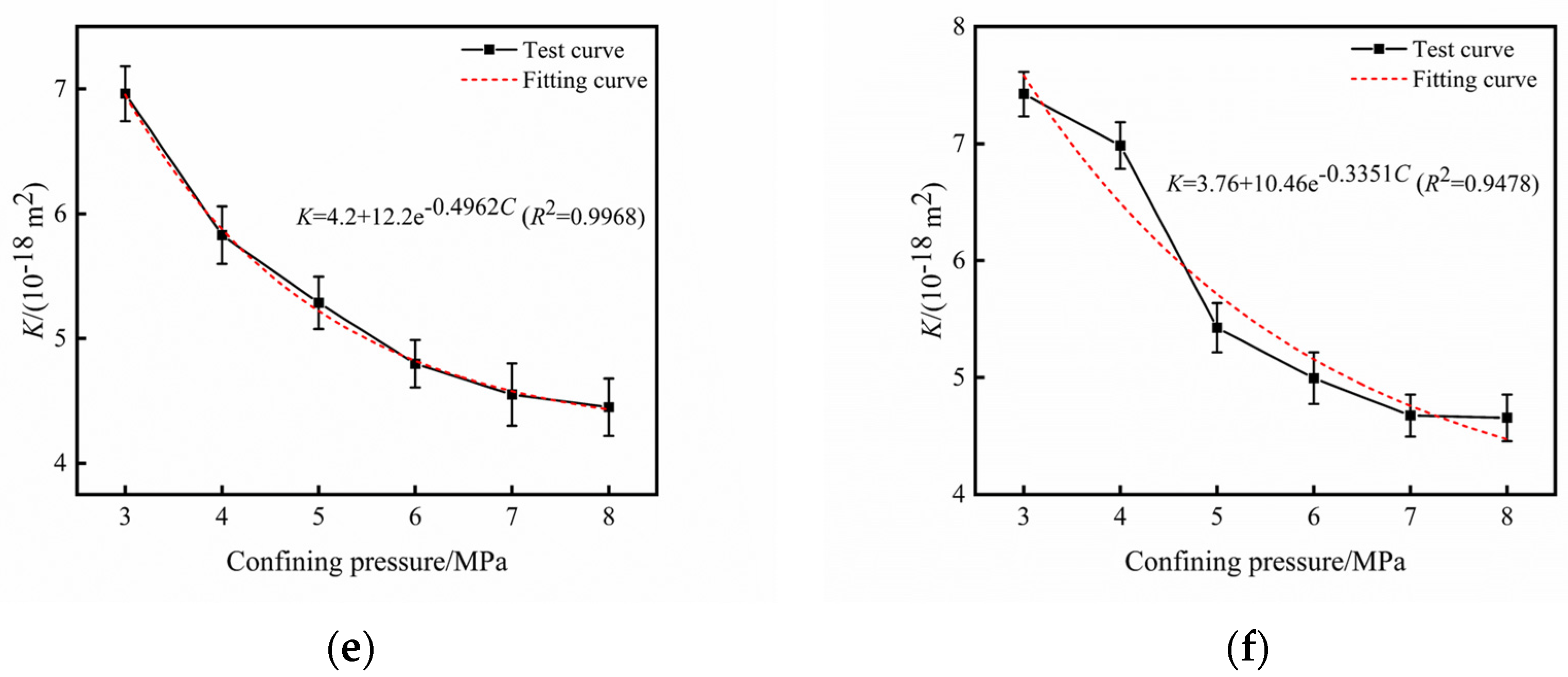

3.3. Penetration

4. Conclusions

- (1)

- Both fibers reduce the slump of rubberized concrete, but the basalt fiber has a greater effect on the slump of the rubberized concrete than the polypropylene fiber. At the same curing time, the water absorption of the fiber–rubber concrete is lower than that of the RC, and the effect of the polypropylene fiber on the water absorption of the rubberized concrete is greater than that of the basalt fiber.

- (2)

- The fiber type/volume ratio has a significant effect on the RC peak stress, and the order of the effect in terms of fiber type is basalt fiber > polypropylene fiber. When the ratio of VBF to VPF is 1:1, the peak stress increases by 23.24% compared to that of the RC. The elastic modulus of the fiber–rubber concrete is larger than that of the RC, and the influence of the polypropylene fiber on the elastic modulus is limited. The elastic modulus of the PFC group is increased by 10.36% compared with the RC group.

- (3)

- The total strain energy and dissipation energy of the fiber–rubber concrete are obviously larger than those of the RC. Before the peak elastic strain energy, the fiber increases the elastic strain energy growth rate of the rubberized concrete, and, after the peak elastic strain energy, the fiber reduces the elastic strain energy reduction rate of the rubberized concrete, leading to obvious ductile failure characteristics.

- (4)

- Along with the characteristics of the fiber–rubber concrete in this paper, two parameters, namely the fiber type and fiber volume ratio, were introduced to establish a modified segmental stress–strain constitutive model. The model calculation results were in good agreement with the experimental results and can effectively reflect the effect of the fiber type/volume ratio on the constitutive behavior of the rubberized concrete.

- (5)

- The effect of the single-mixed basalt fiber on reducing the permeability of the rubber concrete is lower than that of the single-mixed polypropylene fiber, and the effect of the mixed fiber on reducing the permeability of the rubberized concrete is better than that of the single-mixed fiber.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tamanna, N.; Tuladhar, R.; Sivakugan, N. Performance of recycled waste glass sand as partial replacement of sand in concrete. Constr. Build. Mater. 2020, 239, 117804. [Google Scholar]

- Bendixen, M.; Best, J.; Hackney, C.; Iversen, L.L. Time is running out for sand. Nature 2019, 571, 29–31. [Google Scholar] [CrossRef] [PubMed]

- Thomas, B.S.; Gupta, R.C.; Panicker, V.J. Recycling of waste tire rubber as aggregate in concrete: Durability-related performance. J. Clean. Prod. 2016, 112, 504–513. [Google Scholar] [CrossRef]

- Gregory, M.G. Analysis and Testing of Waste Tire Fiber Modified Concrete; Louisiana State University: Baton Rouge, LA, USA, 2005; Volume 3. [Google Scholar]

- Su, H.; Yang, J.; Ling, T.C.; Ghataora, G.S.; Dirar, S. Properties of concrete prepared with waste tyre rubber particles of uniform and varying sizes. J. Clean. Prod. 2015, 91, 288–296. [Google Scholar] [CrossRef]

- Nehdi, M.; Khan, A. Cementitious composites containing recycled tire rubber: An overview of engineering properties and potential applications. Cem. Concr. Aggreg. 2001, 23, 3–10. [Google Scholar]

- Eldin, N.N.; Senouci, A.B. Rubber-tire particles as concrete aggregate. J. Mater. Civ. Eng. 1993, 5, 478–496. [Google Scholar]

- Abdelmonem, A.; El-Feky, M.S.; Nasr, E.S.A.; Kohail, M. Performance of high strength concrete containing recycled rubber. Constr. Build. Mater. 2019, 227, 116660. [Google Scholar] [CrossRef]

- Lv, J.; Zhou, T.; Du, Q.; Wu, H. Effects of rubber particles on mechanical properties of lightweight aggregate concrete. Constr. Build. Mater. 2015, 91, 145–149. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Hansu, O.; İpek, S.; Asaad, D.S. Influence of waste rubber utilization on the fracture and steel–concrete bond strength properties of concrete. Constr. Build. Mater. 2015, 101, 1113–1121. [Google Scholar] [CrossRef]

- Aslani, F.; Ma, G.; Wan, D.L.Y.; Le, V.X.T. Experimental investigation into rubber granules and their effects on the fresh and hardened properties of self-compacting concrete. J. Clean. Prod. 2018, 172, 1835–1847. [Google Scholar]

- Liu, F.; Meng, L.Y.; Ning, G.F.; Li, L.J. Fatigue performance of rubber-modified recycled aggregate concrete (RRAC) for pavement. Constr. Build. Mater. 2015, 95, 207–217. [Google Scholar] [CrossRef]

- Záleská, M.; Pavlík, Z.; Čítek, D.; Jankovský, O.; Pavlíková, M. Eco-friendly concrete with scrap-tyre-rubber-based aggregate–Properties and thermal stability. Constr. Build. Mater. 2019, 225, 709–722. [Google Scholar] [CrossRef]

- Sukontasukkul, P. Use of crumb rubber to improve thermal and sound properties of pre-cast concrete panel. Constr. Build. Mater. 2009, 23, 1084–1092. [Google Scholar] [CrossRef]

- Noaman, A.T.; Abu Bakar, B.H.; Akil, H.M.d. Experimental investigation on compression toughness of rubberized steel fibre concrete. Constr. Build. Mater. 2016, 115, 163–170. [Google Scholar] [CrossRef]

- Li, L.J.; Tu, G.R.; Lan, C.; Liu, F. Mechanical characterization of waste-rubber-modified recycled-aggregate concrete. J. Clean. Prod. 2016, 124, 325–338. [Google Scholar] [CrossRef]

- Xu, J.; Niu, X.; Yao, Z. Mechanical properties and acoustic emission data analyses of crumb rubber concrete under biaxial compression stress states. Constr. Build. Mater. 2021, 298, 123778. [Google Scholar] [CrossRef]

- Feng, W.; Liu, F.; Yang, F.; Li, L.; Jing, L. Experimental study on dynamic split tensile properties of rubber concrete. Constr. Build. Mater. 2018, 165, 675–687. [Google Scholar] [CrossRef]

- Gupta, T.; Chaudhary, S.; Sharma, R.K. Assessment of mechanical and durability properties of concrete containing waste rubber tire as fine aggregate. Constr. Build. Mater. 2014, 73, 562–574. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.; Dave, U.; Pienaar, J. Freeze/thaw performance of concrete using granulated rubber crumb. J. Green Build. 2011, 6, 83–92. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.A.; Ward, G. Freeze/thaw protection of concrete with optimum rubber crumb content. J. Clean. Prod. 2012, 23, 96–103. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.; Edmondson, V.; Dias, E. Crumb rubber used in concrete to provide freeze–thaw protection (optimal particle size). J. Clean. Prod. 2016, 112, 599–606. [Google Scholar] [CrossRef]

- Richardson, A.; Coventry, K.; Pienaar, J. The potential for achieving freeze/thaw protection in concrete through the addition of rubber crumb. Built Nat. Environ. Res. Pap. 2011, 4, 110–126. [Google Scholar]

- Hua, L.; Xiao, F.; Li, Y.; Huang, H.; Zhao, K.; Yu, K.; Hettiarachchi, C. A potential damage mechanism of rubberized cement under freeze-thaw cycle. Constr. Build. Mater. 2020, 252, 119054. [Google Scholar] [CrossRef]

- Su, Q.; Xu, J.M.; Wang, Y.D. Mechanical Properties of Hybrid Fiber Reinforced Rubber Concrete. Materials 2021, 14, 6028. [Google Scholar] [CrossRef] [PubMed]

- Xu, G.; Hannant, D.J. Flexural behaviour of combined polypropylene network and glass fibre reinforced cement. Cem. Concr. Compos. 1992, 14, 51–61. [Google Scholar] [CrossRef]

- Kakemi, M.; Hannant, D.J. Mathematical model for tensile behaviour of hybrid continuous fibre cement composites. Composites 1995, 26, 637–643. [Google Scholar] [CrossRef]

- Yao, W.; Li, J.; Wu, K. Mechanical properties of hybrid fiber-reinforced concrete at low fiber volume fraction. Cem. Concr. Res. 2003, 33, 27–30. [Google Scholar] [CrossRef]

- Song, P.S.; Wu, J.C.; Hwang, S.; Sheu, B.C. Statistical analysis of impact strength and strength reliability of steel–polypropylene hybrid fiber-reinforced concrete. Constr. Build. Mater. 2005, 19, 1–9. [Google Scholar] [CrossRef]

- Hsie, M.; Tu, C.; Song, P.S. Mechanical properties of polypropylene hybrid fiber-reinforced concrete. Mater. Sci. Eng. A 2008, 494, 153–157. [Google Scholar] [CrossRef]

- Li, B.; Chi, Y.; Xu, L.; Shi, Y.; Li, C. Experimental investigation on the flexural behavior of steel-polypropylene hybrid fiber reinforced concrete. Constr. Build. Mater. 2018, 191, 80–94. [Google Scholar] [CrossRef]

- López-Buendía, A.M.; Romero-Sánchez, M.D.; Climent, V.; Guillem, C. Surface treated polypropylene (PP) fibres for reinforced concrete. Cem. Concr. Res. 2013, 54, 29–35. [Google Scholar] [CrossRef]

- Su, N.; Hsu, K.C.; Chai, H.W. A simple mix design method for self-compacting concrete. Cem. Concr. Res. 2001, 31, 1799–1807. [Google Scholar] [CrossRef]

- Xie, H.P.; Ju, Y.; Li, L.Y. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles. Chin. J. Rock Mech. Eng. 2005, 24, 3003–3010. [Google Scholar]

- Guo, Z.; Zhang, X.; Zhang, D.; Wang, R. Experimental investigation of complete stress-strain curve of concrete. J. Build. Struct. 1982, 3, 3–14. [Google Scholar]

- Wee, T.H.; Chin, M.S.; Mansur, M.A. Stress-strain relationship of high-strength concrete in compression. J. Mater. Civ. Eng. 1996, 8, 70–76. [Google Scholar] [CrossRef]

- Yang, K.H.; Mun, J.H.; Cho, M.S.; Kang, T.H. Stress-strain model for various unconfined concretes in compression. ACI Struct. J. 2014, 111, 819. [Google Scholar] [CrossRef]

- Carreira, D.J.; Chu, K.H. Stress-strain relationship for plain concrete in compression. ACI J. 1985, 82, 797–804. [Google Scholar]

| Fiber | Tensile Strength/MPa | Elastic Modulus/GPa | Density/(g/cm3) | Diameter/µm | Length/mm | Elongation at Break/% |

|---|---|---|---|---|---|---|

| BF | 3500 | 90 | 2.8 | 12 | 12 | 3.2 |

| PF | 320 | 0.4 | 0.9 | 8 | 8 | 38 |

| Specimens | Cement | Sand | Stone | Water | Water Reducer | Rubber | BF | PF |

|---|---|---|---|---|---|---|---|---|

| RC | 440 | 665 | 1040 | 180 | 4.6 | 0 | 0 | 0 |

| BFC | 440 | 594.1 | 1040 | 180 | 4.6 | 70.9 | 3.5 | 0 |

| PFC | 440 | 594.1 | 1040 | 180 | 4.6 | 70.9 | 0 | 1.125 |

| BPRC1 | 440 | 594.1 | 1040 | 180 | 4.6 | 70.9 | 1.4 | 0.9 |

| BPRC2 | 440 | 594.1 | 1040 | 180 | 4.6 | 70.9 | 2.1 | 0.675 |

| BPRC3 | 440 | 594.1 | 1040 | 180 | 4.6 | 70.9 | 2.8 | 0.45 |

| Models | Fitting Formula | Key Parameters |

|---|---|---|

| Guo model | Ascent: Descent: | a is the ratio of the initial elastic modulus to the secant elastic modulus; b according to the strength of the concrete grades and constraints determined |

| Wee TH model | If ≤ 50 MPa, ; If 50 MPa ≤ ≤ 120 MPa, , . | |

| Yang KH model | Ascent: Descent: | |

| Carreira J model |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, D.-y.; Pang, J.-y.; Han, C.-y.; Huang, J.-y.; Hu, X.-y.; Shi, W. Influence of Basalt/Polypropylene Fiber on Permeability and Uniaxial Compressive Properties of Waste Tire Rubberized Concrete. Materials 2023, 16, 481. https://doi.org/10.3390/ma16020481

Su D-y, Pang J-y, Han C-y, Huang J-y, Hu X-y, Shi W. Influence of Basalt/Polypropylene Fiber on Permeability and Uniaxial Compressive Properties of Waste Tire Rubberized Concrete. Materials. 2023; 16(2):481. https://doi.org/10.3390/ma16020481

Chicago/Turabian StyleSu, Dan-yang, Jian-yong Pang, Chen-yue Han, Jian-yu Huang, Xiu-yue Hu, and Wei Shi. 2023. "Influence of Basalt/Polypropylene Fiber on Permeability and Uniaxial Compressive Properties of Waste Tire Rubberized Concrete" Materials 16, no. 2: 481. https://doi.org/10.3390/ma16020481

APA StyleSu, D.-y., Pang, J.-y., Han, C.-y., Huang, J.-y., Hu, X.-y., & Shi, W. (2023). Influence of Basalt/Polypropylene Fiber on Permeability and Uniaxial Compressive Properties of Waste Tire Rubberized Concrete. Materials, 16(2), 481. https://doi.org/10.3390/ma16020481