Influence of Basalt Aggregate Crushing Technology on Its Geometrical Properties—Preliminary Studies

Abstract

:1. Introduction

2. Materials and Methods

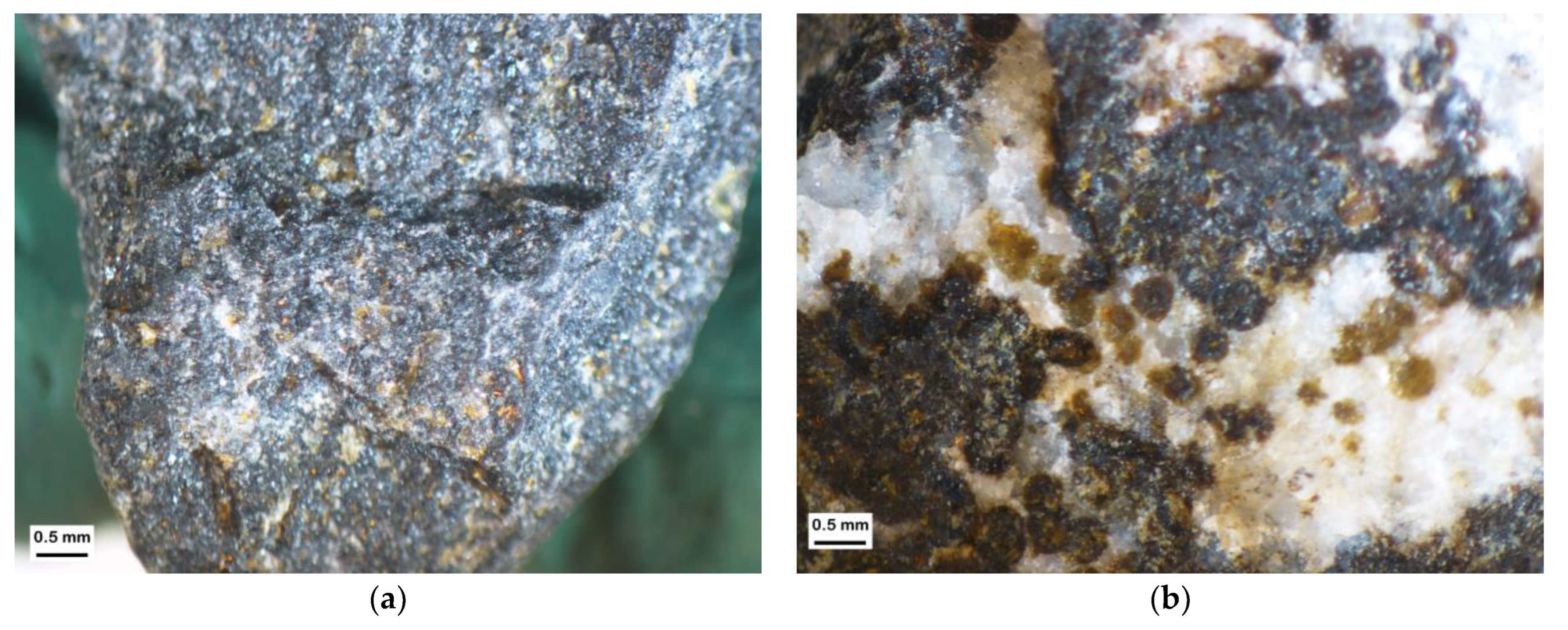

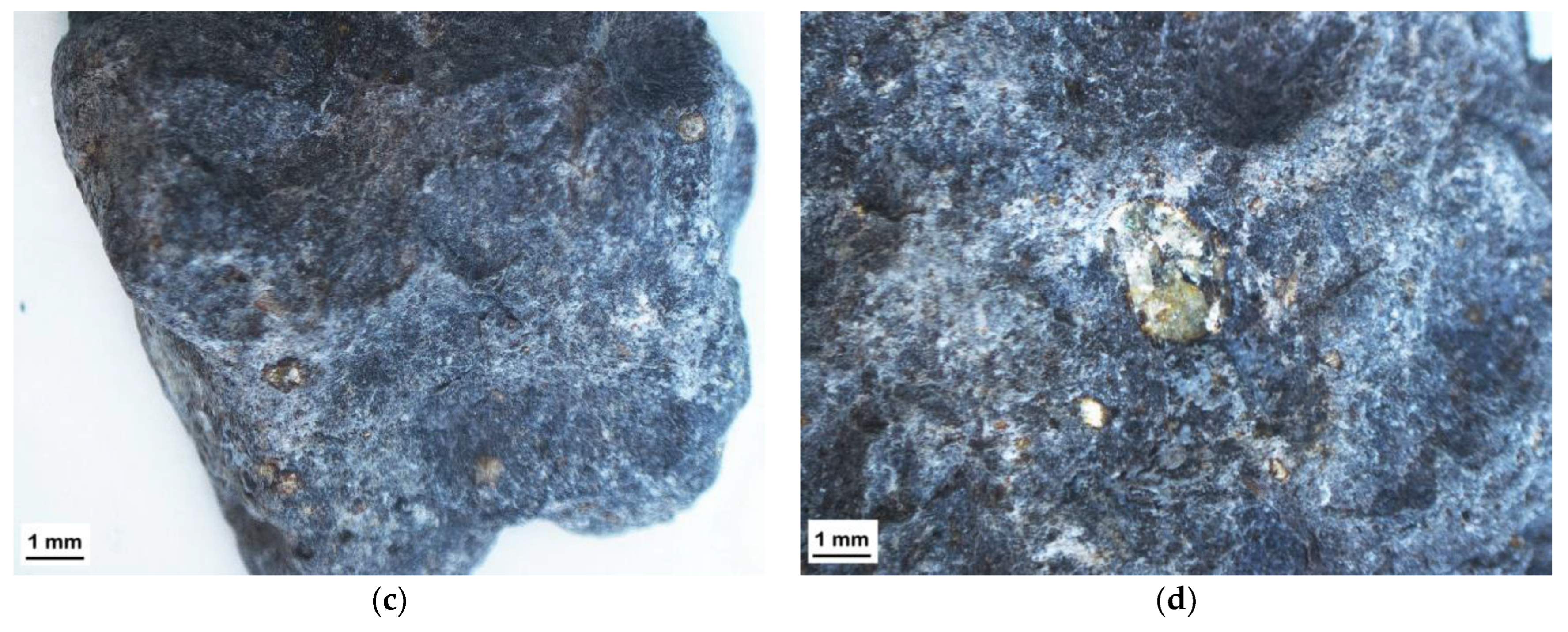

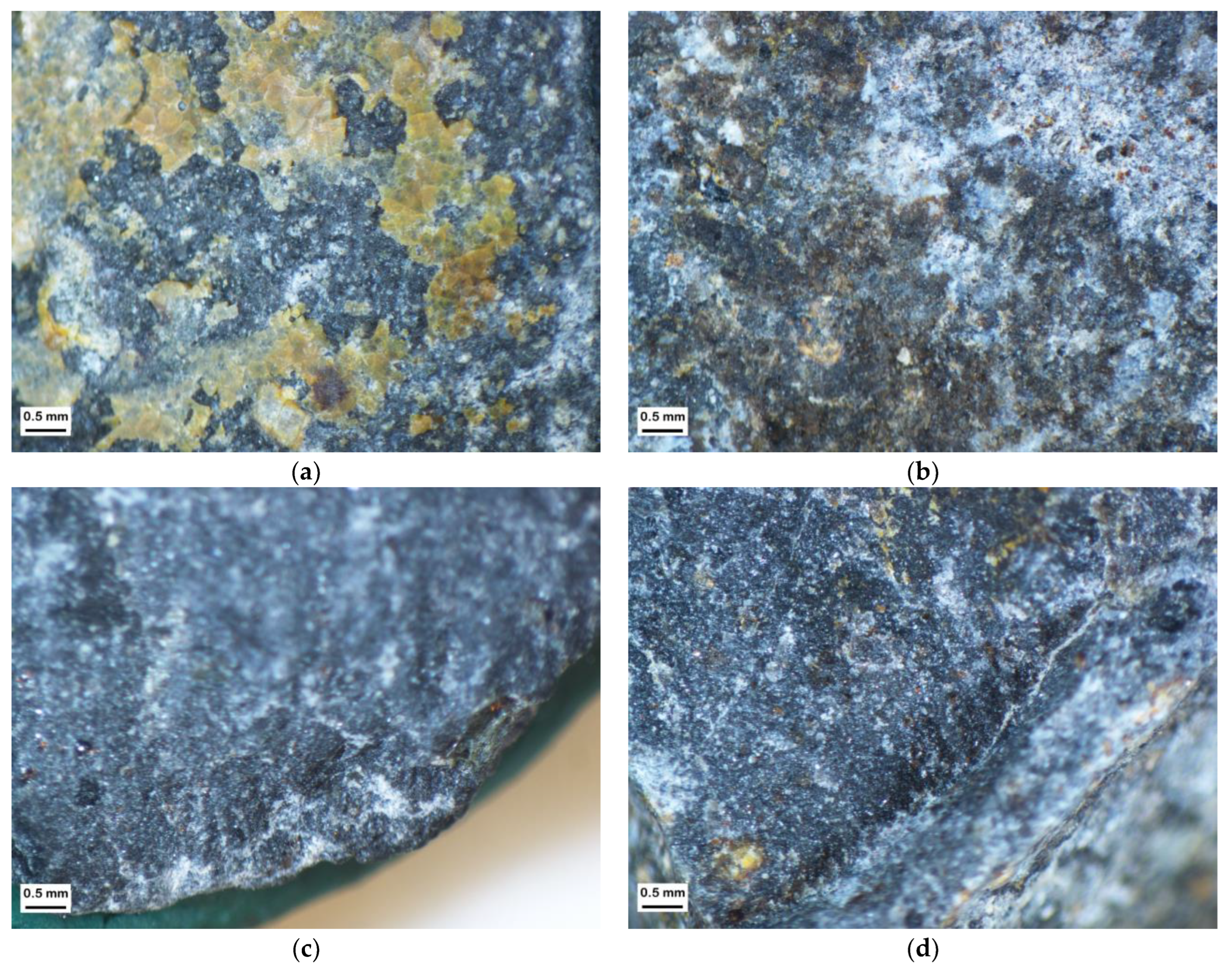

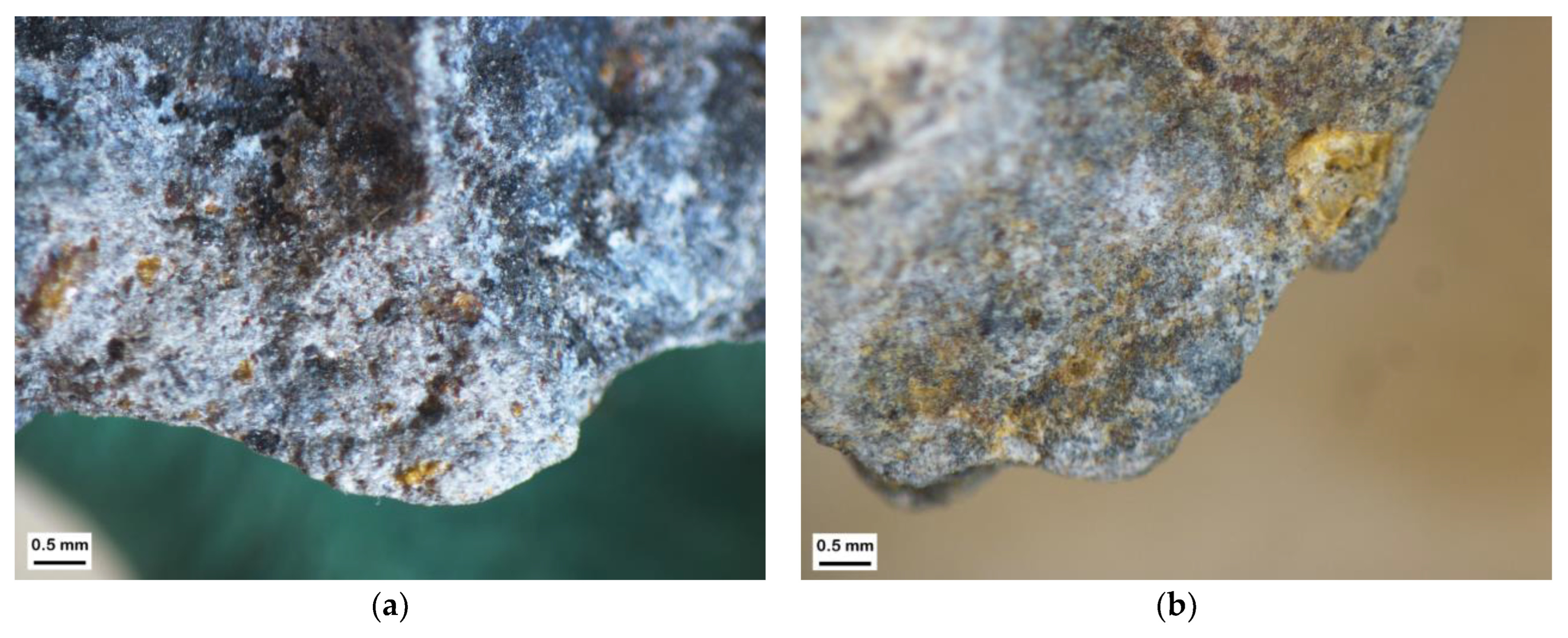

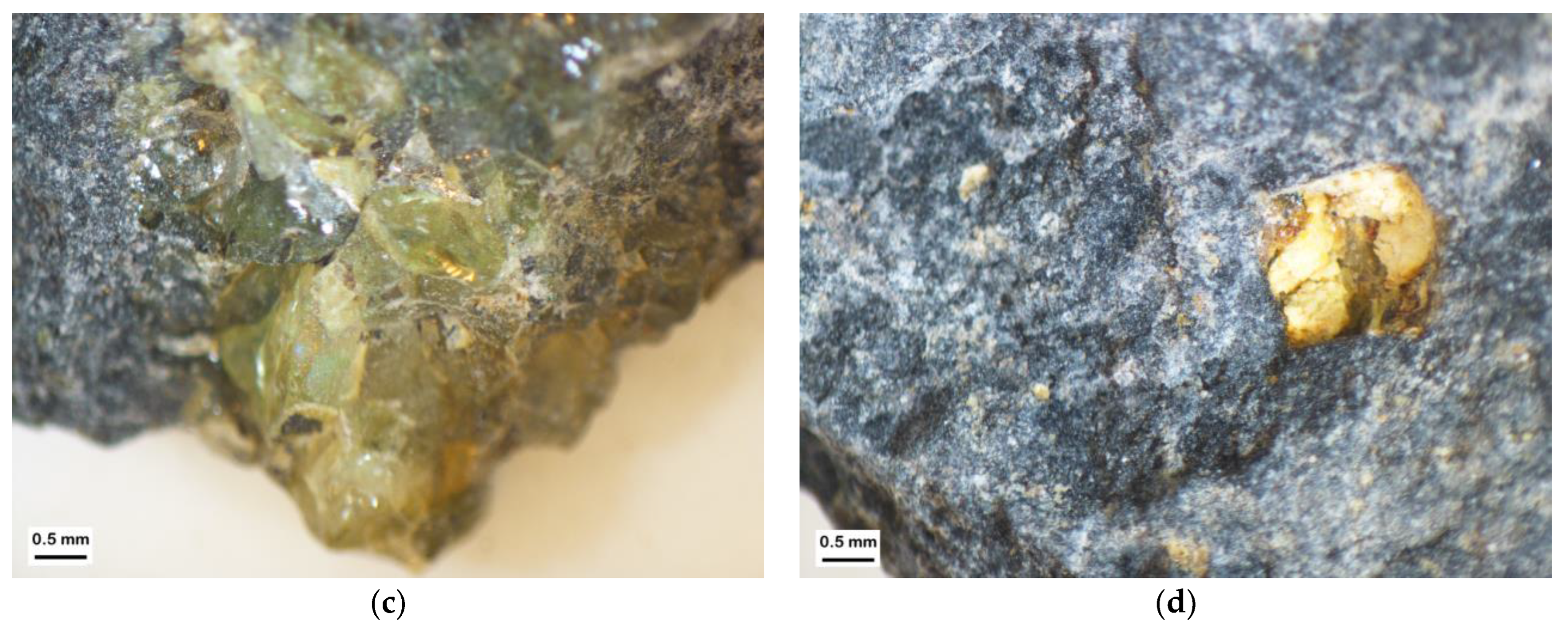

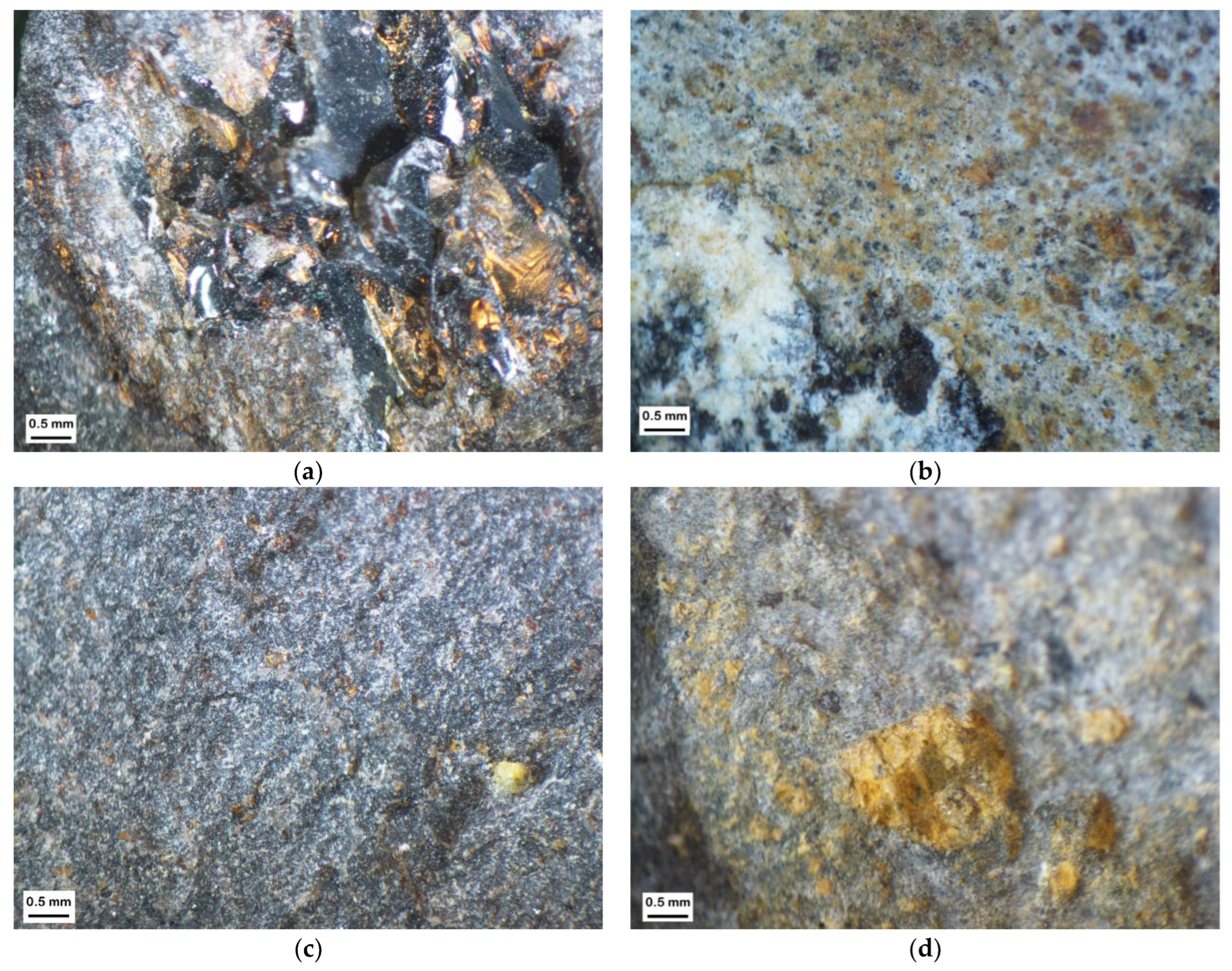

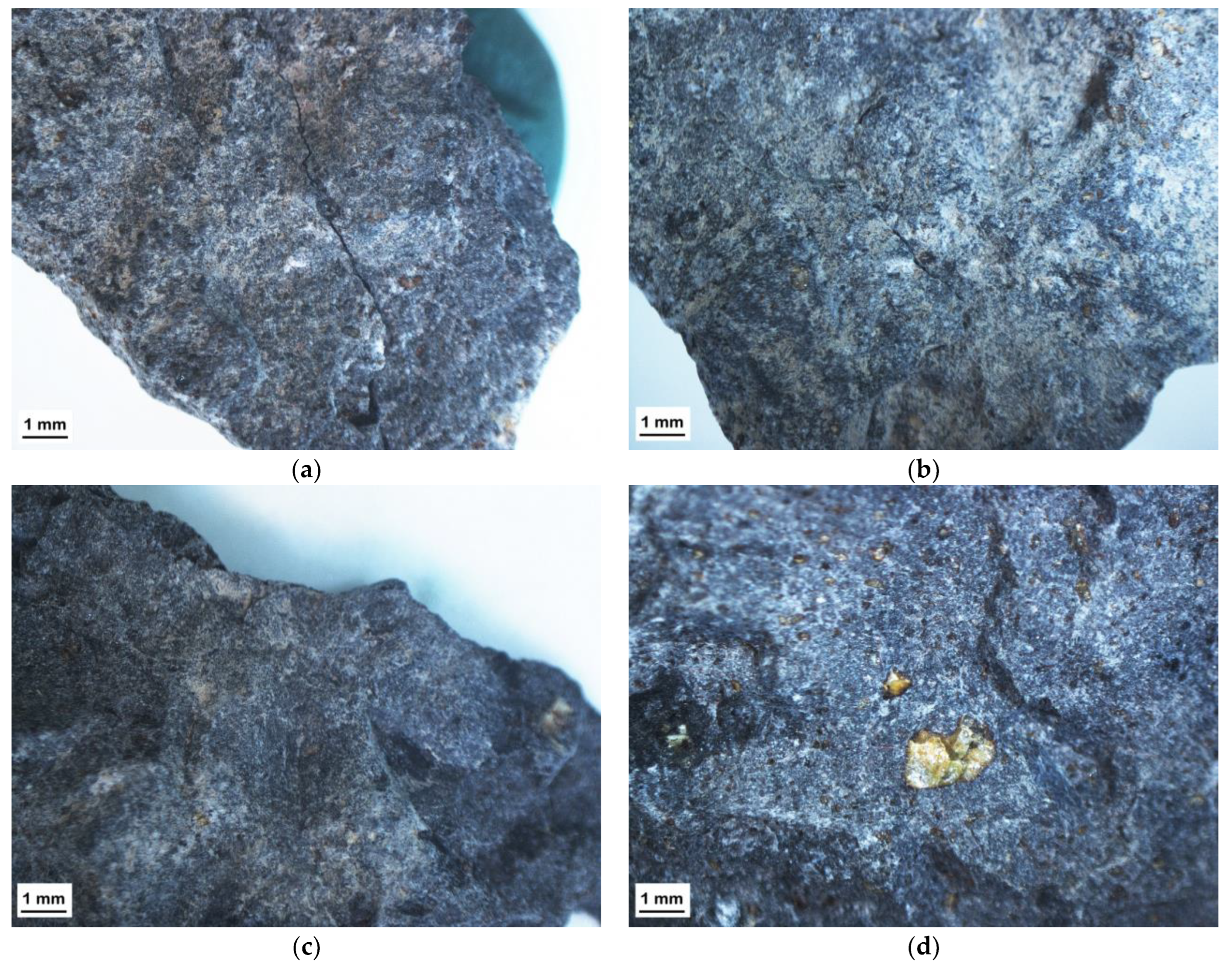

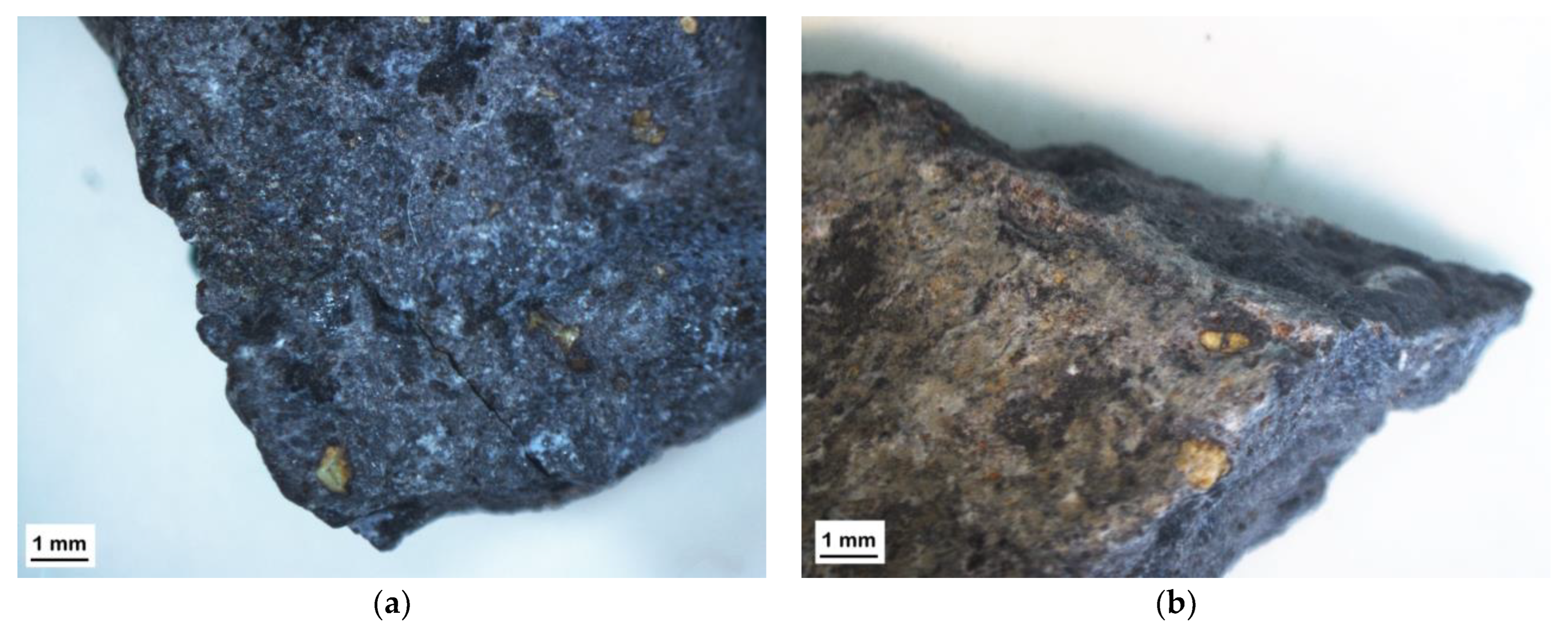

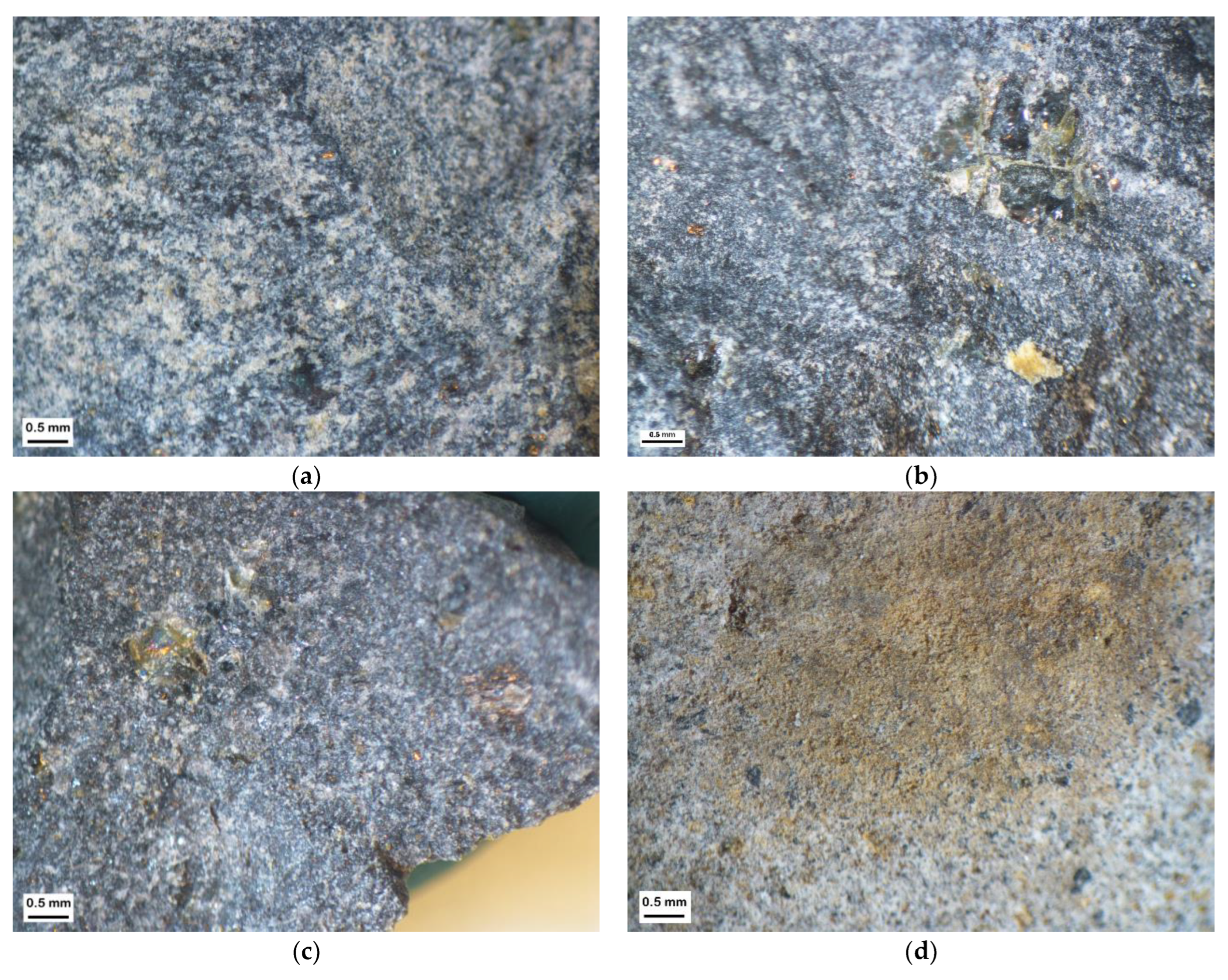

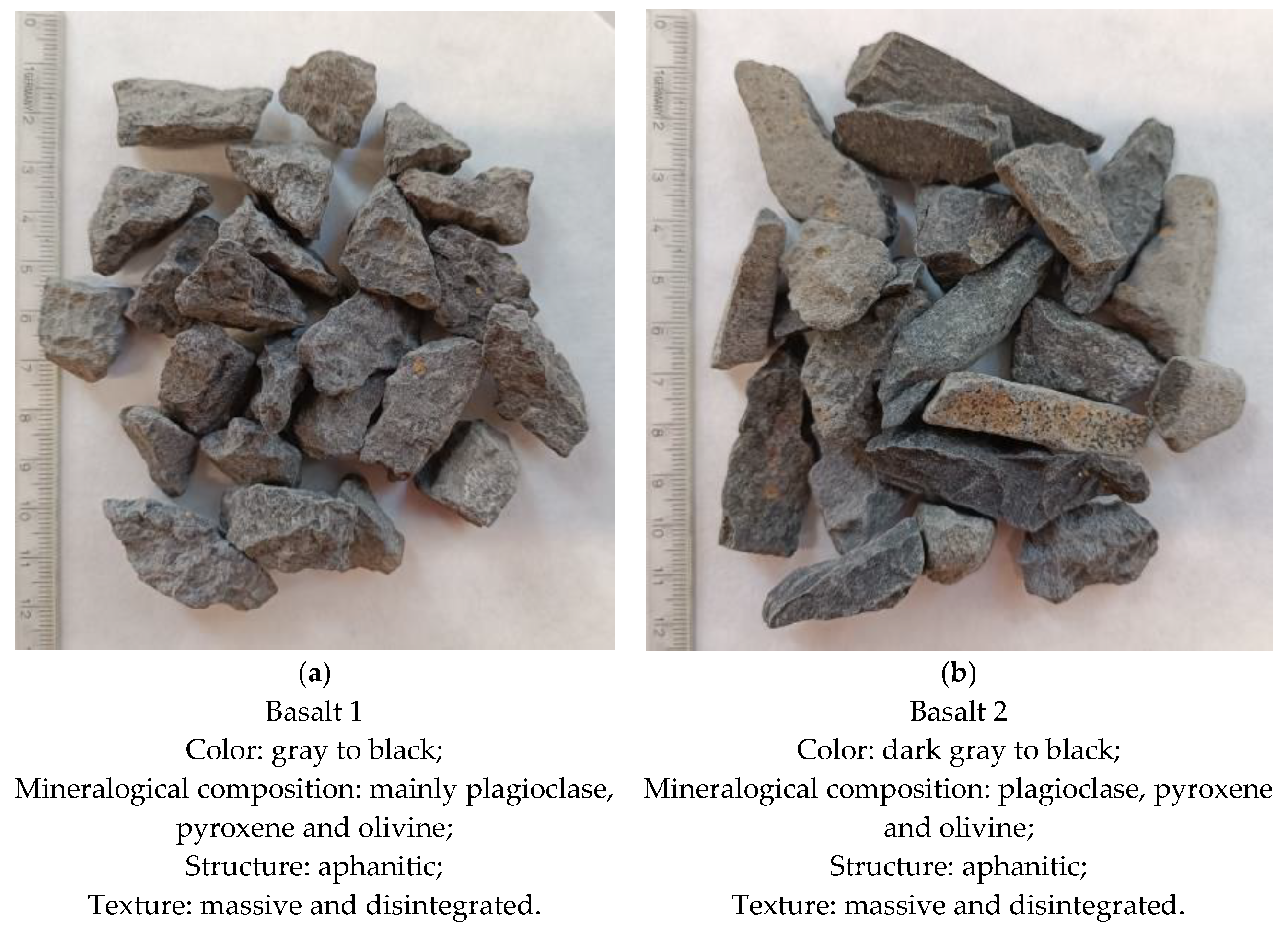

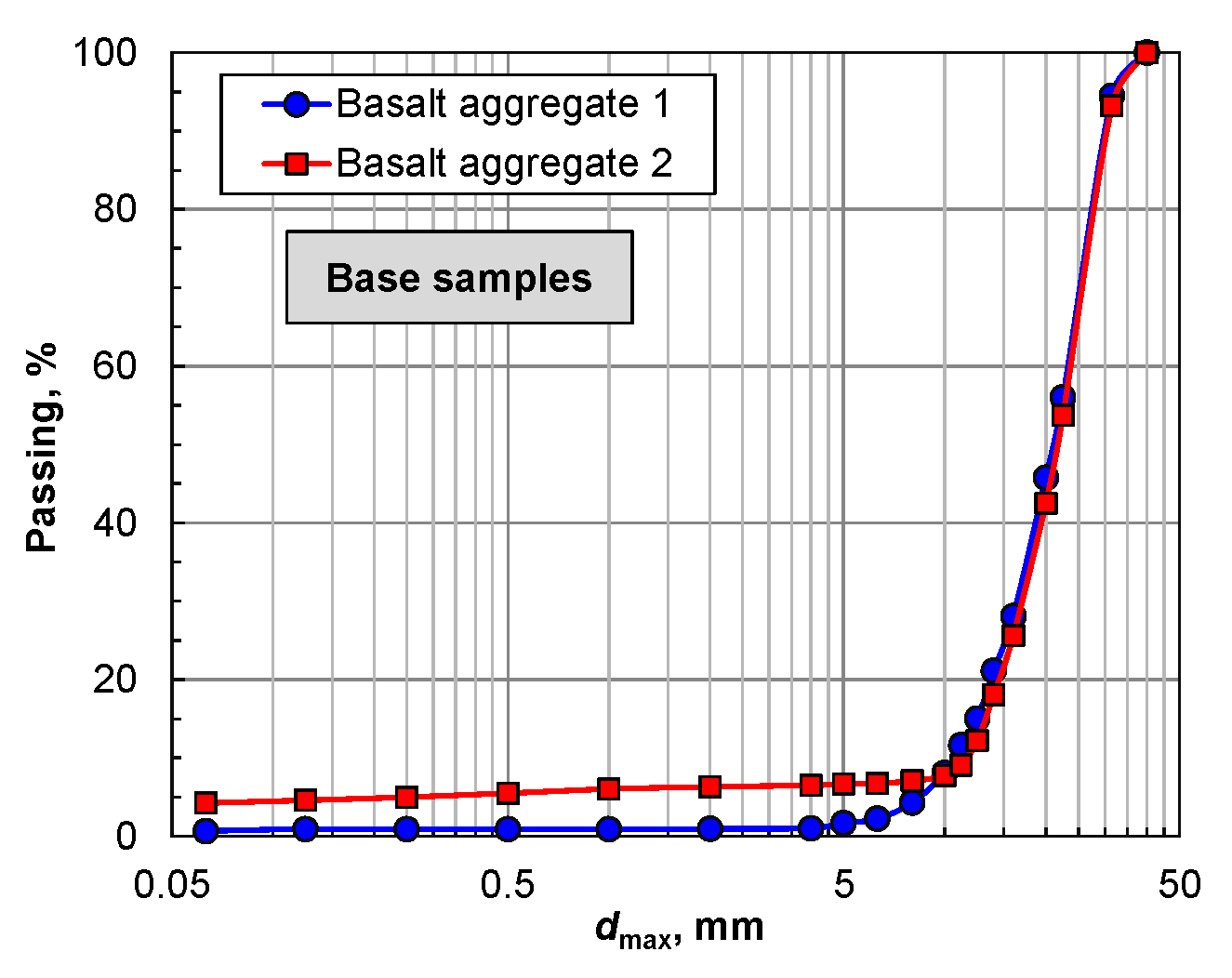

2.1. Materials

2.2. Methods

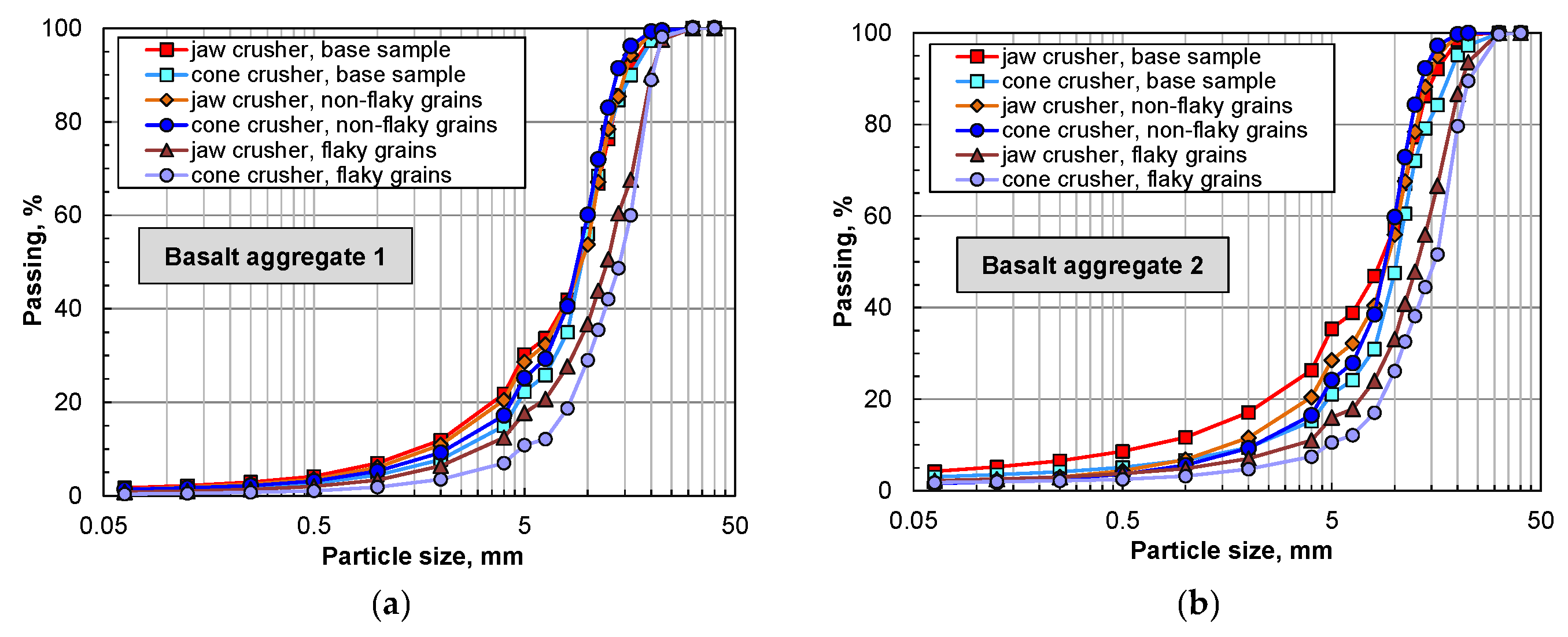

3. Results and Discussion

4. Conclusions

- -

- Lower flakiness and shape indexes after the crushing process, both in the feed with the original geometric composition of the grains and in the feed in the form of flaky and non-cubical particles;

- -

- A higher flakiness index after the crushing process for non-cubical particles and a lower one after the crushing of flaky particles;

- -

- Flakiness indexes for grains below 16 mm after the crushing process of less than 10%, which indicates a more favorable result in relation to the feed;

- -

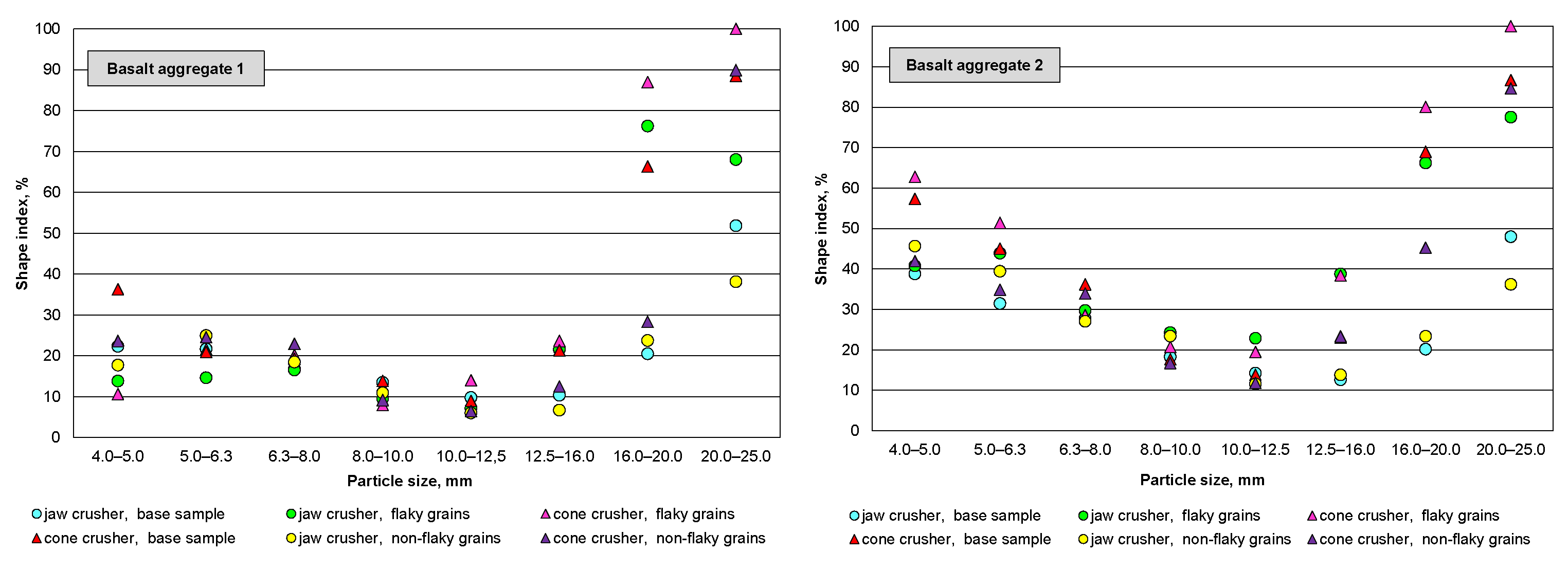

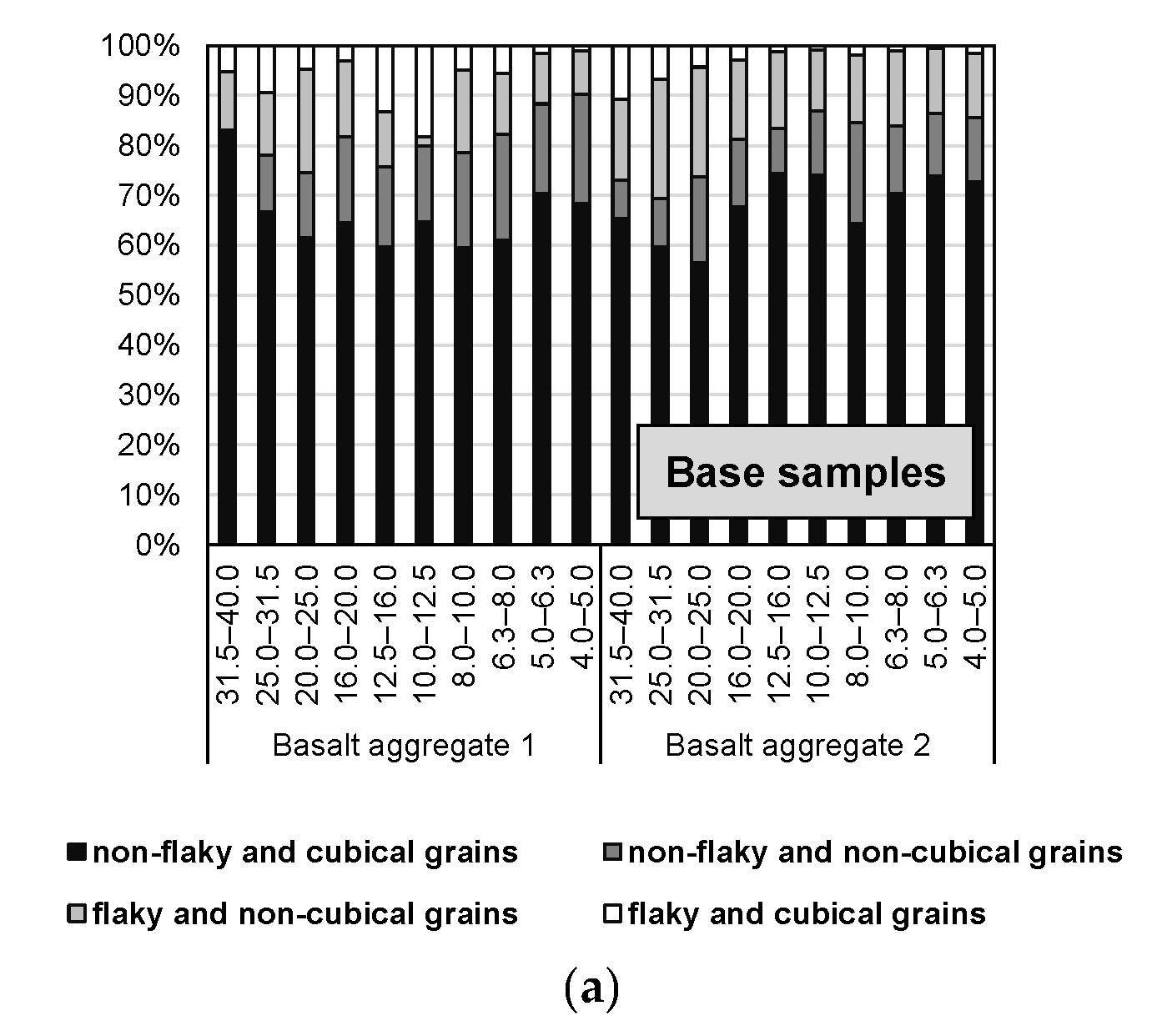

- An accumulation of flaky and non-cubical particles in the finest (below 8 mm) and coarsest (above 20 mm) fractions, with flakiness and shape indexes as high as 80–100%;

- -

- Higher content of flaky and non-cubical particles for grades above 16 mm after crushing in a cone crusher;

- -

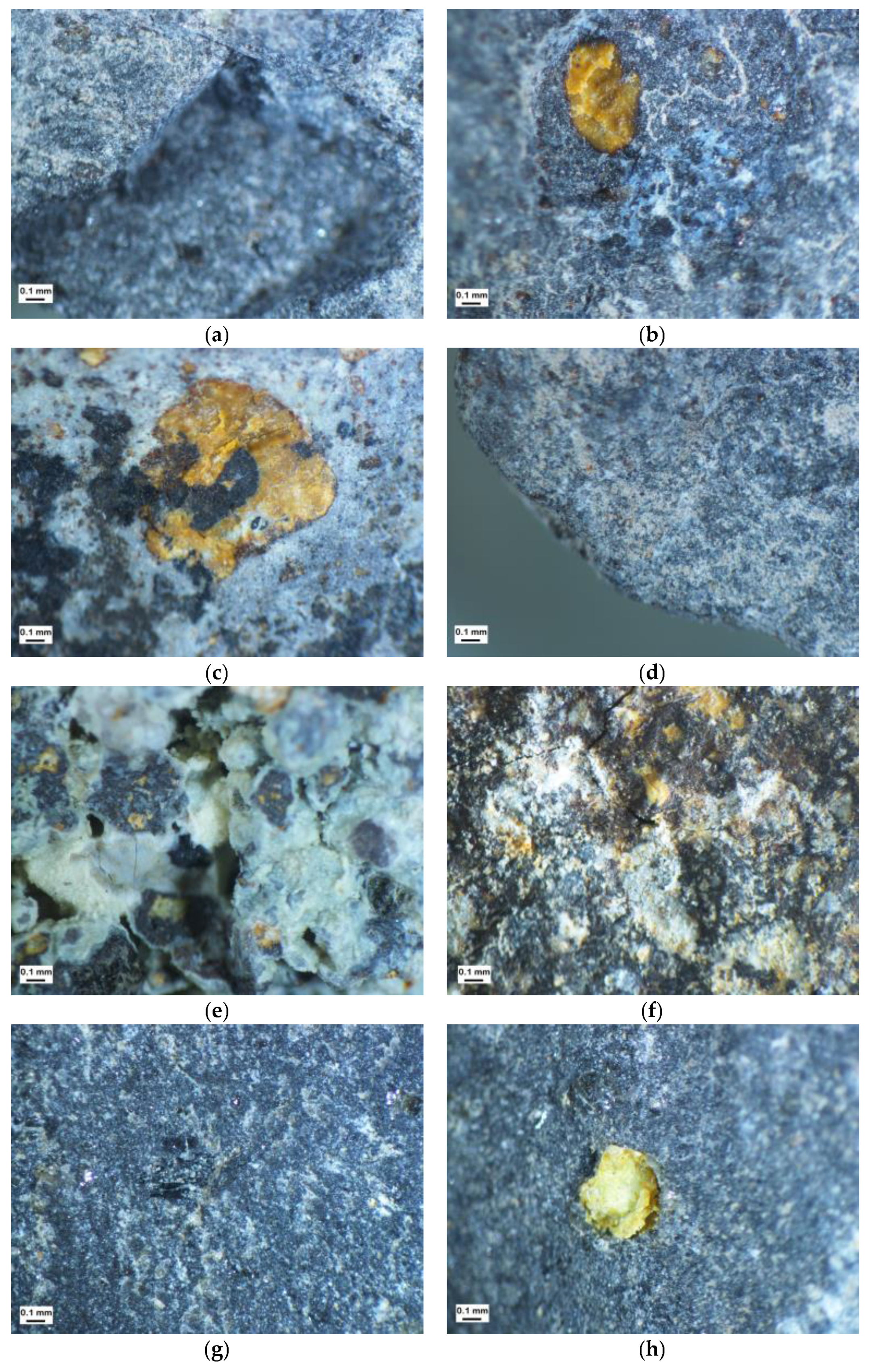

- The presence of turf grains and weathered basalt, mainly in the finest grain classes;

- -

- After crushing, higher contents of flaky and non-cubical particles in samples with higher contents of components other than pure basalt than in pure basalt aggregate;

- -

- Relatively more micro-cracks in post-crushing samples of basalt from a deposit with higher tuff content;

- -

- Reduced quality parameters of the aggregates, resulting in a high content of flaky and non-cubical particles in post-crushing samples due to the increase in tuff content in the sample.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Al-Harthi, A.A. A field index to determine the strength characteristics of crushed aggregate. Bull. Eng. Geol. Environ. 2001, 60, 193–200. [Google Scholar] [CrossRef]

- Gawenda, T. Innowacyjne technologie produkcji kruszyw o ziarnach foremnych. Min. Sci. Miner. Aggreg. 2015, 22, 45–59. (In Polish) [Google Scholar]

- Tikhonov, A.; Velichkin, V. Automation for Crushing and Screening Equipment to Produce Graded Paving Crushed Stone. IOP Conf. Ser. Earth Environ. Sci. 2017, 90, 012194. [Google Scholar] [CrossRef] [Green Version]

- Köken, E.; Özarslan, A. New testing methodology for the quantification of rock crushability: Compressive crushing value (CCV). Int. J. Miner. Metall. Mater. 2018, 25, 1227–1236. [Google Scholar] [CrossRef]

- Galos, K.; Smakowski, T. Development of natural crusched aggregates market in Poland since 2000. Krus. Miner. 2019, 3, 25–38. (In Polish) [Google Scholar]

- Bhadani, K.; Asbjörnsson, G.; Hulthén, E.; Evertsson, M. Development and implementation of key performance indicators for aggregate production using dynamic simulation. Miner. Eng. 2020, 145, 106065. [Google Scholar] [CrossRef]

- Köken, E. Assessment of Los Angeles Abrasion Value (LAAV) and Magnesium Sulphate Soundness (Mwl) of Rock Aggregates Using Gene Expression Programming and Artificial Neural Networks. Arch. Min. Sci. 2022, 67, 401–422. [Google Scholar] [CrossRef]

- Šernas, O.; Vorobjovas, V.; Šneideraitienė, L.; Vaitkus, A. Evaluation of asphalt mix with dolomite aggregates for wearing layer. Transp. Res. Procedia 2016, 14, 732–737. [Google Scholar] [CrossRef] [Green Version]

- Strzałkowski, P.; Kaźmierczak, U. Wear and Fragmentation Resistance of Mineral Aggregates—A Review of Micro-Deval and Los Angeles Tests. Materials 2021, 14, 5456. [Google Scholar] [CrossRef]

- Czinder, B.; Török, Á. Long-term durability tests of andesite aggregates from Hungary. Cent. Eur. Geol. 2017, 60, 333–343. [Google Scholar] [CrossRef] [Green Version]

- Köken, E.; Başpınar Tuncay, E. Assessment of Rock Aggregate Quality Through Fuzzy Inference System. Geotech. Geol. Eng. 2022, 40, 3551–3559. [Google Scholar] [CrossRef]

- Okogbue, C.O.; Aghamelu, O.P. Performance of pyroclastic rocks from Abakaliki Metropolis (southeastern Nigeria) in road construction projects. Bull. Eng. Geol. Environ. 2013, 72, 433–446. [Google Scholar] [CrossRef]

- Ajalloeian, R.; Kamani, M. An investigation of the relationship between Los Angeles abrasion loss and rock texture for carbonate aggregates. Bull. Eng. Geol. Environ. 2019, 78, 1555–1563. [Google Scholar] [CrossRef]

- Adomako, S.; Engelsen, C.J.; Thorstensen, R.T.; Barbieri, D.A. Review of the relationship between aggregates geology and Los Angeles and micro-Deval tests. Bull. Eng. Geol. Environ. 2021, 80, 1963–1980. [Google Scholar] [CrossRef]

- Strzałkowski, P.; Duchnowska, M.; Kaźmierczak, U.; Bakalarz, A.; Wolny, M.; Karwowski, P.; Stępień, T. Evaluation of the Structure and Geometric Properties of Crushed Igneous Rock Aggregates. Materials 2021, 14, 7202. [Google Scholar] [CrossRef]

- EN 1097-6; Tests for Mechanical and Physical properties of Aggregates—Part 6: Determination of Particle Density and water Absorption. European Committee for Standardization: Brussels, Belgium, 2022.

- EN 1367-2; Tests for Thermal and Weathering Properties of Aggregates—Part 2: Magnesium Sulfate Test. European Committee for Standardization: Brussels, Belgium, 2010.

- EN 1097-2; Tests for Mechanical and Physical Properties of Aggregates—Part 2: Methods for the Determination of Resistance to Fragmentation. European Committee for Standardization: Brussels, Belgium, 2020.

- Sim, J.; Park, C. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Ibrahim, A.; Faisal, S.; Jamil, N. Use of basalt in asphalt concrete mixes. Constr. Build. Mater. 2009, 23, 498–506. [Google Scholar] [CrossRef]

- Jalasutram, S.; Sahoo, D.R.; Matsagar, V. Experimental investigation of the mechanical properties of basalt fiber-reinforced concrete. Struct. Concr. 2017, 18, 292–302. [Google Scholar] [CrossRef]

- Karasin, A.; Hadzima-Nyarko, M.; Işık, E.; Doğruyol, M.; Karasin, I.B.; Czarnecki, S. The effect of basalt aggregates and mineral admixtures on the mechanical properties of concrete exposed to sulphate attacks. Materials 2022, 15, 1581. [Google Scholar] [CrossRef]

- Räisänen, M.; Mertamo, M. An evaluation of the procedure and results of laboratory crushing in quality assessment of rock aggregate raw materials. Bull. Eng. Geol. Environ. 2004, 63, 33–39. [Google Scholar] [CrossRef]

- Hofer, V.; Bach, H.; Latal, C.; Neubauer, A.-C. Impact of Geometric and Petrographic Characteristics on the Variability of LA Test Values for Railway Ballast. Math. Geosci. 2013, 45, 727–752. [Google Scholar] [CrossRef]

- Gawenda, T. Wpływ rozdrabniania surowców skalnych w różnych kruszarkach i stadiach kruszenia na jakość kruszyw mineralnych (The influence of rock raw materials comminution in various crushers and crushing stages on the quality of mineral aggregates. Gospod. Surowcami Miner. Miner. 2013, 29, 53–65. (In Polish) [Google Scholar] [CrossRef]

- Rajan, B.; Singh, D. Quantify effects of stage crushing on dimensional distribution of basaltic aggregates using image technique. Int. J. Pavement Res. Technol. 2019, 12, 497–507. [Google Scholar] [CrossRef]

- Rajan, B.; Singh, D. An image-based approach to capture influence of production mechanism on aggregate dimension distribution and breakage potential. Adv. Civ. Eng. Mater. 2020, 9, 152–168. [Google Scholar] [CrossRef]

- Köken, E. Evaluation of size reduction process for rock aggregates in cone crusher. Bull. Eng. Geol. Environ. 2020, 79, 4933–4946. [Google Scholar] [CrossRef]

- Köken, E.; Lawal, A.I. Investigating the effects of feeding properties on rock breakage by jaw crusher using response surface method and gene expression programming. Adv. Powder Technol. 2021, 32, 1521–1531. [Google Scholar] [CrossRef]

- Gawenda, T.; Stempkowska, A.; Saramak, D.; Foszcz, D.; Krawczykowska, A.; Surowiak, A. Assessment of Operational Effectiveness of Innovative Circuit for Production of Crushed Regular Aggregates in Particle Size Fraction 8–16 mm. Minerals 2022, 12, 634. [Google Scholar] [CrossRef]

- Gawenda, T.; Surowiak, A.; Krawczykowska, A.; Stempkowska, A.; Niedoba, T. Analysis of the Aggregate Production Process with Different Geometric Properties in the Light Fraction Separator. Materials 2022, 15, 4046. [Google Scholar] [CrossRef]

- Eloranta, J. Influence of Crushing Process Variables on the Product Quality of Crushed Rock. Ph.D. Thesis, Tampere University of Technology, Tampere, Finland, 1995. [Google Scholar]

- Bengtsson, M.; Evertsson, C.M. An empirical model for predicting flakiness in cone crushing. Int. J. Miner. Process. 2006, 79, 49–60. [Google Scholar] [CrossRef]

- Gang, D.; Xiumin, F.; Dongming, H. Analysis and optimization of cone crusher performance. Miner. Eng. 2009, 22, 1091–1093. [Google Scholar] [CrossRef]

- Cepuritis, R.; Garboczi, E.J.; Jacobsen, S. Three dimensional shape analysis of concrete aggregate fines produced by VSI crushing. Powder Technol. 2017, 308, 410–421. [Google Scholar] [CrossRef] [Green Version]

- Rajan, B.; Singh, D. Investigation on effects of different crushing stages on morphology of coarse and fine aggregates. Int. J. Pavement Eng. 2020, 21, 177–195. [Google Scholar] [CrossRef]

- Rajan, B.; Singh, D. Understanding influence of crushers on shape characteristics of fine aggregates based on digital image and conventional techniques. Constr. Build. Mater. 2017, 150, 833–843. [Google Scholar] [CrossRef]

- Umashankar, O.; Gowreesh, Y.S.; Mamatha, K.H.; Dinesh, S.V. Effect of crushing mechanism on the shape properties of coarse aggregates. Mater. Today Proc. 2022, 60, 534–540. [Google Scholar] [CrossRef]

- Diógenes, L.M.; Bessa, I.S.; Castelo Branco, V.T.F.; Mahmoud, E. The influence of stone crushing processes on aggregate shape properties. Road Mater. Pavement Des. 2019, 20, 877–894. [Google Scholar] [CrossRef]

- Kamani, M.; Rasoul, A. The effect of rock crusher and rock type on the aggregate shape. Constr. Build. Mater. 2020, 230, 117016. [Google Scholar] [CrossRef]

- Bouquety, M.N.; Descantes, Y.; Barcelo, L.; de Larrard, F.; Clavaud, B. Experimental study of crushed aggregate shape. Constr. Build. Mater. 2007, 21, 865–872. [Google Scholar] [CrossRef]

- Al-Rousan, T.; Al Hattamleh, O.; Alfoul, B.A.; Alkuime, H. Investigating the Variations in Crushers’ Daily Production Using Imaging Technique. Int. J. Pavement Res. Technol. 2022, 15, 1195–1208. [Google Scholar] [CrossRef]

- Persson, A.-L. Image analysis of shape and size of fine aggregates. Eng. Geol. 1998, 50, 177–186. [Google Scholar] [CrossRef]

- Michot-Roberto, S.; Garcia-Hernández, A.; Dopazo-Hilario, S.; Dawson, A. The spherical primitive and perlin noise method to recreate realistic aggregate shapes. Granul. Matter 2021, 23, 41. [Google Scholar] [CrossRef]

- EN 933-1; Tests for Geometrical Properties of Aggregates—Part 1: Determination of Particle Size Distribution—Sieving Method. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 933-3; Tests for Geometrical Properties of Aggregates—Part 3: Determination of Particle Shape—Flakiness Index. European Committee for Standardization: Brussels, Belgium, 2012.

- EN 933-4; Tests for Geometrical Properties of Aggregates—Part 4: Determination of Particle Shape—Shape Index. European Committee for Standardization: Brussels, Belgium, 2008.

- Köken, E.; Çimşir, K. Investigation of Rock Aggregate Quality Improvement through Changes in Crushing Circuit: A Case Study on Vertical Shaft Impact Crusher. Konya J. Eng. Sci. 2021, 9, 1040–1050. [Google Scholar] [CrossRef]

- Gawenda, T.; Naziemiec, Z.; Tumidajski, T.; Saramak, D. Sposoby optymalizacji składu ziarnowego i kształtu ziaren kruszyw mineralnych w produktach kruszarek szczękowych (Ways of optimisation of grain composition and shape of grains in aggregates in products of jaw crushers). Górnictwo I Geoinżynieria 2006, 30, 109–124. [Google Scholar]

| Properties of Aggregates | Basalt Aggregate 1 | Basalt Aggregate 2 |

|---|---|---|

| Bulk density (ρ), g/cm3 | 3.10 | 3.03 |

| Absorptivity (WA24), % | 0.45 | 0.70 |

| Micro-Deval index (MDE), % | 8.58 | 8.82 |

| Los Angeles index (LA), % | 9.39 | 9.45 |

| Particle Size, mm | Basalt Aggregate 1 | Basalt Aggregate 2 | ||

|---|---|---|---|---|

| Shape Index | Flakiness Index | Shape Index | Flakiness Index | |

| 31.5–40.0 | 11.77 | 16.87 | 23.94 | 26.84 |

| 25.0–31.5 | 24.06 | 21.96 | 33.59 | 30.56 |

| 20.0–25.0 | 33.84 | 25.51 | 39.15 | 26.26 |

| 16.0–20.0 | 32.21 | 18.27 | 29.56 | 18.82 |

| 12.5–16.0 | 29.33 | 24.32 | 24.37 | 16.60 |

| 10.0–12.5 | 33.53 | 20.03 | 25.10 | 12.97 |

| 8.0–10.0 | 35.62 | 21.36 | 33.68 | 15.86 |

| 6.3–8.0 | 33.42 | 18.04 | 28.51 | 18.34 |

| 5.0–6.3 | 27.98 | 12.01 | 25.62 | 26.72 |

| 4.0–5.0 | 30.58 | 9.33 | 25.69 | 15.05 |

| Particle Size, mm | Crusher Type | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Jaw Crusher | Cone Crusher | Jaw Crusher | Cone Crusher | Jaw Crusher | Cone Crusher | |||||||

| Feed | ||||||||||||

| Base Sample | Flaky Grains | Non-Flaky Grains | ||||||||||

| Shape Index | Flakiness Index | Shape Index | Flakiness Index | Shape Index | Flakiness Index | Shape Index | Flakiness Index | Shape Index | Flakiness Index | Shape Index | Flakiness Index | |

| 20.0–25.0 | 51.83 | 91.72 | 88.53 | 100.00 | 68.02 | 100.00 | 100.00 | 100.00 | 38.13 | 76.26 | 89.89 | 100.00 |

| 16.0–20.0 | 20.48 | 18.20 | 66.30 | 72.01 | 76.20 | 55.13 | 86.96 | 85.69 | 23.72 | 13.60 | 28.31 | 38.11 |

| 12.5–16.0 | 10.35 | 7.58 | 21.34 | 10.50 | 21.56 | 8.05 | 23.63 | 14.63 | 6.69 | 8.54 | 12.48 | 12.35 |

| 10.0–12.5 | 9.80 | 7.39 | 8.97 | 9.62 | 7.21 | 7.68 | 14.02 | 4.15 | 5.99 | 7.18 | 6.48 | 6.54 |

| 8.0–10.0 | 13.48 | 7.92 | 13.87 | 10.37 | 9.51 | 4.87 | 7.97 | 8.20 | 10.94 | 9.31 | 9.18 | 9.35 |

| 6.3–8.0 | 16.84 | 11.43 | 19.26 | 10.63 | 16.52 | 8.45 | 20.16 | 9.36 | 18.48 | 10.74 | 22.95 | 11.17 |

| 5.0–6.3 | 21.69 | 8.70 | 20.90 | 8.04 | 14.63 | 4.87 | 21.59 | 9.05 | 24.96 | 7.40 | 24.53 | 8.62 |

| 4.0–5.0 | 22.33 | 11.15 | 36.29 | 10.62 | 13.81 | 7.23 | 10.64 | 6.45 | 17.72 | 9.17 | 23.62 | 9.96 |

| Particle Size, mm | Crusher Type | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Jaw Crusher | Cone Crusher | Jaw Crusher | Cone Crusher | Jaw Crusher | Cone Crusher | |||||||

| Feed | ||||||||||||

| Base Sample | Flaky Grains | Non-Flaky Grains | ||||||||||

| Shape Index | Flakiness Index | Shape Index | Flakiness Index | Shape Index | Flakiness Index | Shape Index | Flakiness Index | Shape Index | Flakiness Index | Shape Index | Flakiness Index | |

| 20.0–25.0 | 47.97 | 84.10 | 86.69 | 100.00 | 77.53 | 97.31 | 100.00 | 100.00 | 36.19 | 67.43 | 84.60 | 100.00 |

| 16.0–20.0 | 20.18 | 23.82 | 68.96 | 62.66 | 66.20 | 90.13 | 80.05 | 86.51 | 23.36 | 17.02 | 45.31 | 35.71 |

| 12.5–16.0 | 12.62 | 11.23 | 22.98 | 16.31 | 38.80 | 28.30 | 38.39 | 21.54 | 13.83 | 9.44 | 23.33 | 14.21 |

| 10.0–12.5 | 14.26 | 11.84 | 13.84 | 12.02 | 22.88 | 38.52 | 19.49 | 8.30 | 11.57 | 9.00 | 11.81 | 10.76 |

| 8.0–10.0 | 18.29 | 13.98 | 17.68 | 20.68 | 24.28 | 15.26 | 20.75 | 12.94 | 23.41 | 17.23 | 16.73 | 16.91 |

| 6.3–8.0 | 27.72 | 16.87 | 36.20 | 28.52 | 29.75 | 20.27 | 28.57 | 21.77 | 27.07 | 19.52 | 33.99 | 24.50 |

| 5.0–6.3 | 31.44 | 16.80 | 45.02 | 30.48 | 43.90 | 24.07 | 51.43 | 25.44 | 39.43 | 18.74 | 34.84 | 26.44 |

| 4.0–5.0 | 38.80 | 24.81 | 57.34 | 31.74 | 40.77 | 26.72 | 62.79 | 71.87 | 45.66 | 24.12 | 41.93 | 34.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Duchnowska, M.; Strzałkowski, P.; Bakalarz, A.; Kaźmierczak, U.; Köken, E.; Karwowski, P.; Wolny, M.; Stępień, T. Influence of Basalt Aggregate Crushing Technology on Its Geometrical Properties—Preliminary Studies. Materials 2023, 16, 602. https://doi.org/10.3390/ma16020602

Duchnowska M, Strzałkowski P, Bakalarz A, Kaźmierczak U, Köken E, Karwowski P, Wolny M, Stępień T. Influence of Basalt Aggregate Crushing Technology on Its Geometrical Properties—Preliminary Studies. Materials. 2023; 16(2):602. https://doi.org/10.3390/ma16020602

Chicago/Turabian StyleDuchnowska, Magdalena, Paweł Strzałkowski, Alicja Bakalarz, Urszula Kaźmierczak, Ekin Köken, Piotr Karwowski, Michał Wolny, and Tomasz Stępień. 2023. "Influence of Basalt Aggregate Crushing Technology on Its Geometrical Properties—Preliminary Studies" Materials 16, no. 2: 602. https://doi.org/10.3390/ma16020602

APA StyleDuchnowska, M., Strzałkowski, P., Bakalarz, A., Kaźmierczak, U., Köken, E., Karwowski, P., Wolny, M., & Stępień, T. (2023). Influence of Basalt Aggregate Crushing Technology on Its Geometrical Properties—Preliminary Studies. Materials, 16(2), 602. https://doi.org/10.3390/ma16020602