Environmental Impact of Concrete Slab Made of Recycled Aggregate Concrete Based on Limit States of Load-Bearing Capacity and Serviceability—LCA Case Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Fine Recycled Aggregate

2.2. Recycled Aggregate Concrete

2.3. Recycled Aggregate Concrete Properties

2.4. Environmental Assessment

2.4.1. Goal and Scope Definition, Functional Unit, and System Boundaries

2.4.2. Life Cycle Inventory (LCI)

2.4.3. Life Cycle Impact Assessment, Normalization, and Weighing

2.5. Design of Structural Elements

3. Results and Discussion

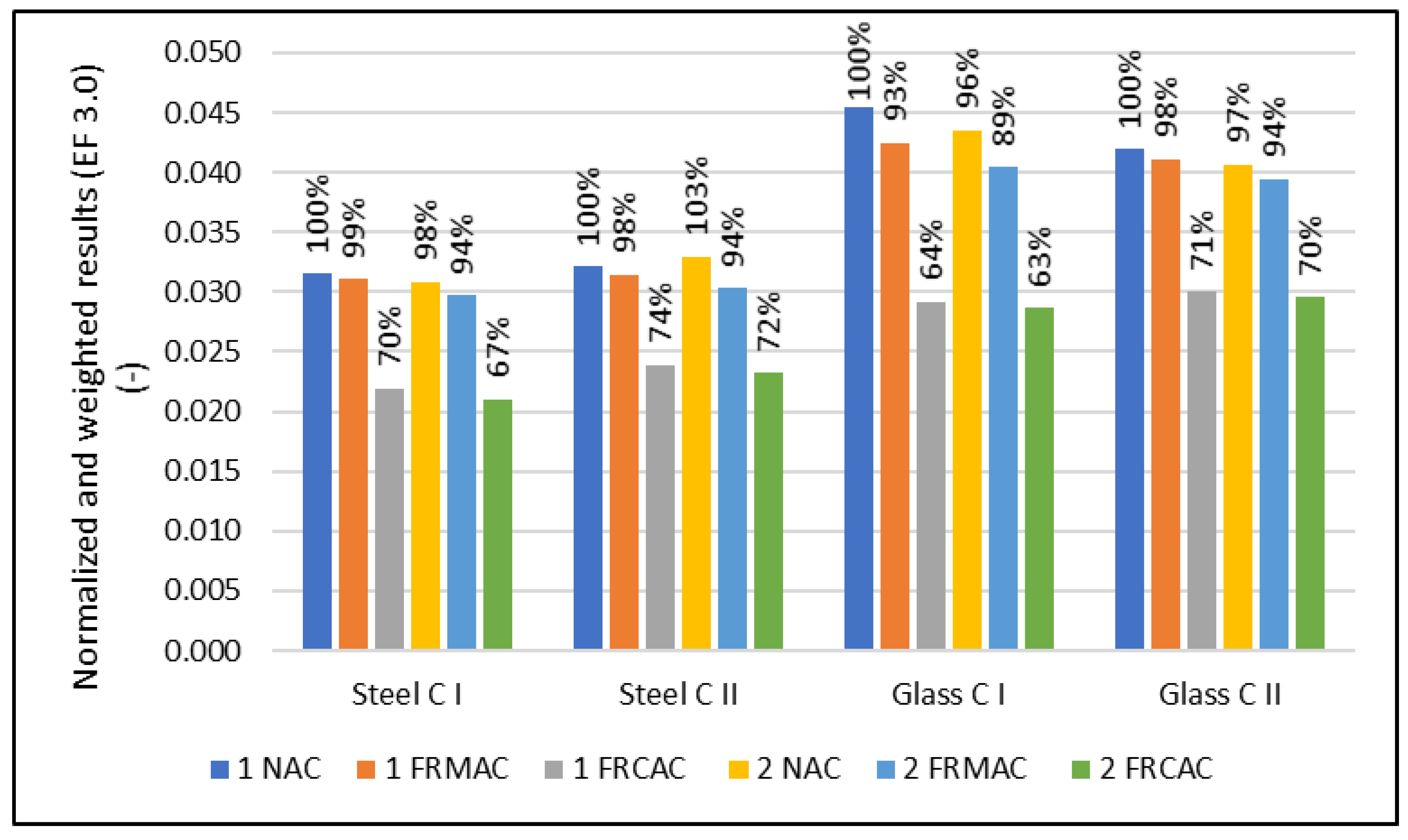

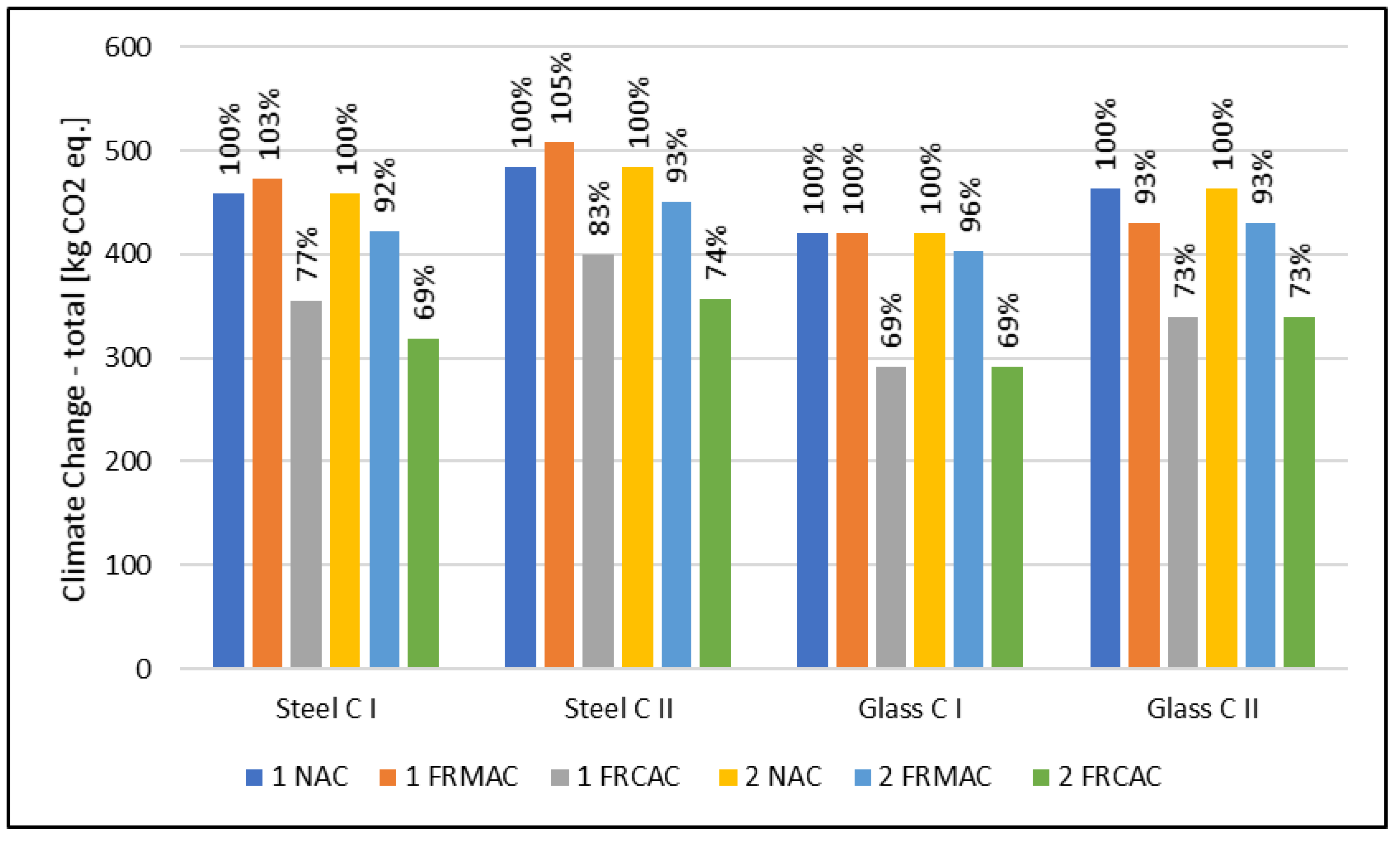

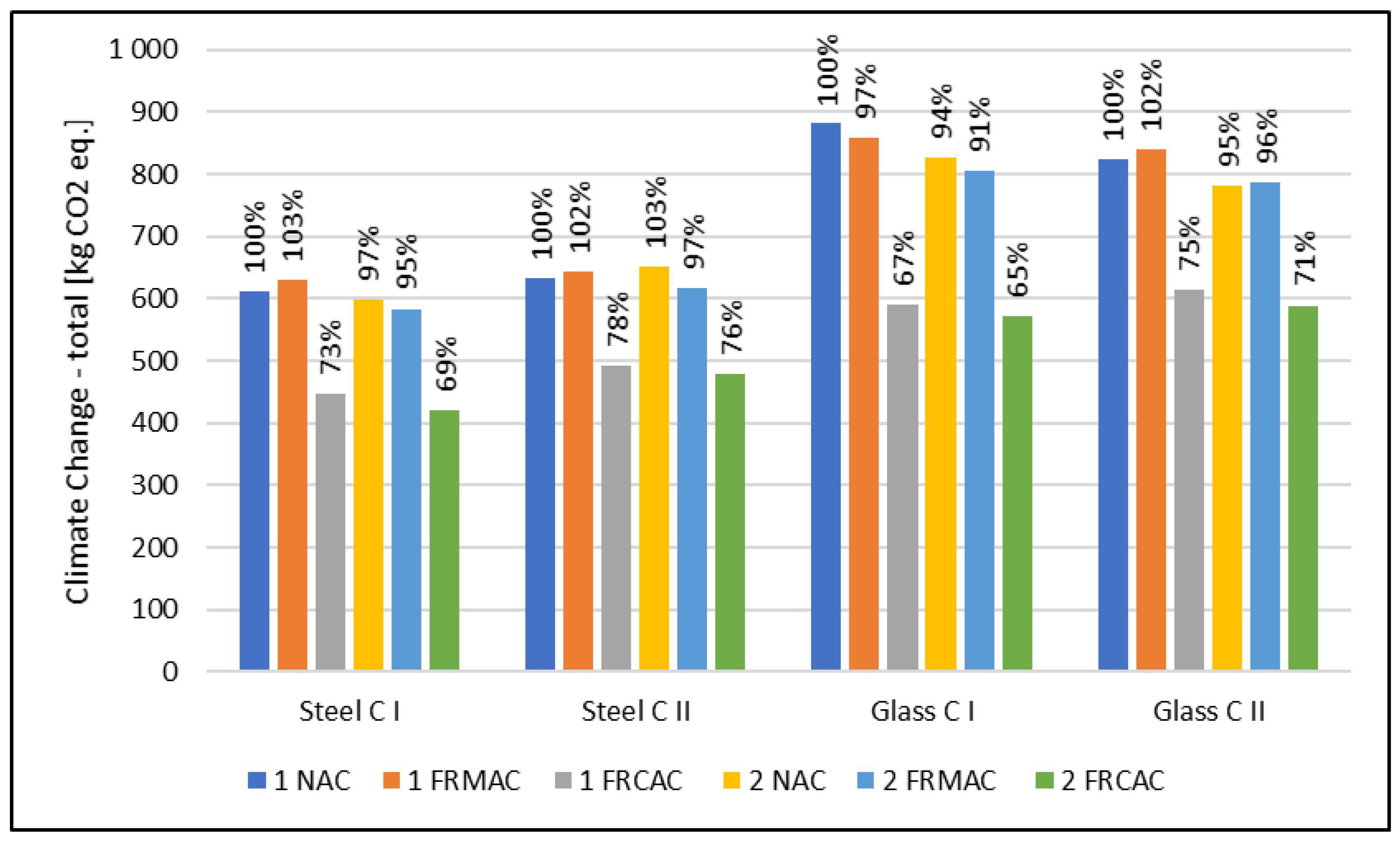

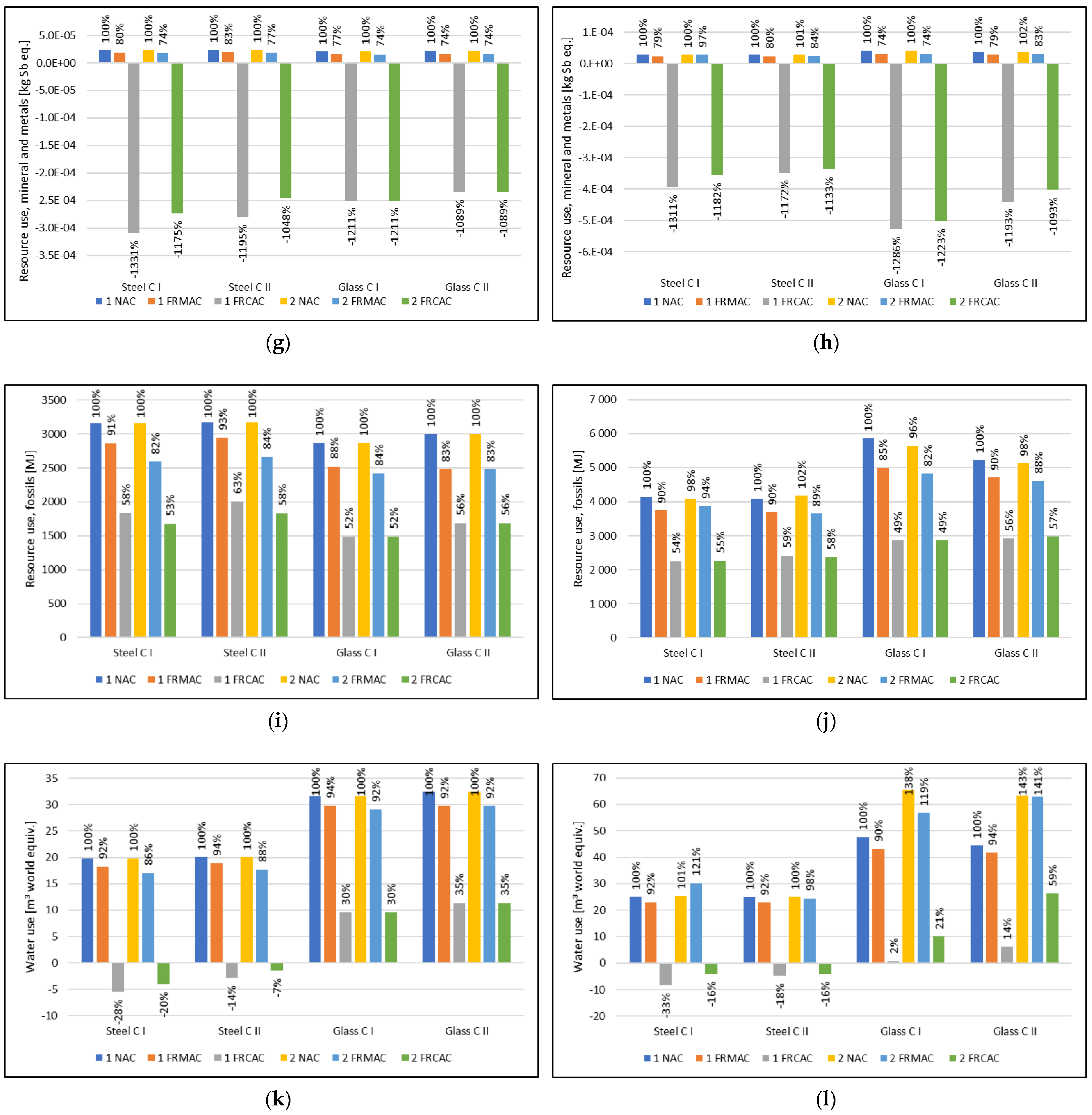

3.1. Results

3.2. Discussion

4. Conclusions

- Generally, the results show a strong positive influence on the environmental impacts for the mixtures containing a fine recycled concrete aggregate. The decrease in the result of the climate change indicator was essential. However, the replacement of natural sand by fine recycled concrete aggregate has either no impact, or an insignificant impact, on the mechanical properties of concrete, which is the probable reason for very positive results in the LCA analysis.

- In the case of compensation for the decline of mechanical properties, the results show a lower environmental impact for a higher reinforcement level in comparison with increasing the slab thickness.

- The design of the slab was based on the limit states of load-bearing capacity (LBC) and serviceability (SA), where the LBC is based on the compressive strength and SA on the modulus of elasticity. The results of the LCA case study show the differences between these two approaches. Generally, the concrete slab was significantly larger in the SA design approach. In addition, the results of the environmental assessment differ in the case of reinforcement type, where the results for these two design approaches were exactly the opposite. The use of steel reinforcement is more advantageous for the SA limit state and, on the contrary, the glass fibers are better in the LBC approach, which is caused by the increase of slab thickness due to the minimal reinforcement level.

- The results of the climate change indicator show similar or slightly higher values for mixtures containing a fine recycled masonry aggregate than reference mixtures with natural sand. On the contrary, the normalized and weighted results show a slightly positive impact of replacing the natural sand, which shows a positive effect in the other impact categories.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Estanqueiro, B.; Dinis Silvestre, J.; de Brito, J.; Duarte Pinheiro, M. Environmental Life Cycle Assessment of Coarse Natural and Recycled Aggregates for Concrete. Eur. J. Environ. Civ. Eng. 2018, 22, 429–449. [Google Scholar] [CrossRef]

- Flower, D.J.M.; Sanjayan, J.G. Green House Gas Emissions Due to Concrete Manufacture. Int. J. Life Cycle Assess. 2007, 12, 282–288. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Toxicity and Environmental and Economic Performance of Fly Ash and Recycled Concrete Aggregates Use in Concrete: A Review. Heliyon 2018, 4, e00611. [Google Scholar] [CrossRef]

- Braunschweig, A.; Kytzia, S.; Bischof, S. Recycled Concrete: Environmentally Beneficial over Virgin Concrete? LCM 2011-Towards Life Cycle Sustainability Management; Spring: Berlin, Germany, 2011. [Google Scholar]

- Marinković, S.; Dragaš, J.; Ignjatović, I.; Tošić, N. Environmental Assessment of Green Concretes for Structural Use. J. Clean. Prod. 2017, 154, 633–649. [Google Scholar] [CrossRef] [Green Version]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative Environmental Assessment of Natural and Recycled Aggregate Concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- Tošić, N.; Marinković, S.; Dašić, T.; Stanić, M. Multicriteria Optimization of Natural and Recycled Aggregate Concrete for Structural Use. J. Clean. Prod. 2015, 87, 766–776. [Google Scholar] [CrossRef]

- Xing, W.; Tam, V.W.; Le, K.N.; Hao, J.L.; Wang, J. Life Cycle Assessment of Recycled Aggregate Concrete on Its Environmental Impacts: A Critical Review. Constr. Build. Mater. 2022, 317, 125950. [Google Scholar] [CrossRef]

- Kleijer, A.L.; Lasvaux, S.; Citherlet, S.; Viviani, M. Product-Specific Life Cycle Assessment of Ready Mix Concrete: Comparison between a Recycled and an Ordinary Concrete. Resour. Conserv. Recycl. 2017, 122, 210–218. [Google Scholar] [CrossRef]

- Turk, J.; Cotič, Z.; Mladenovič, A.; Šajna, A. Environmental Evaluation of Green Concretes versus Conventional Concrete by Means of LCA. Waste Manag. 2015, 45, 194–205. [Google Scholar] [CrossRef]

- Knoeri, C.; Sanyé-Mengual, E.; Althaus, H.-J. Comparative LCA of Recycled and Conventional Concrete for Structural Applications. Int. J. Life Cycle Assess. 2013, 18, 909–918. [Google Scholar] [CrossRef]

- Braga, A.M.; Silvestre, J.D.; de Brito, J. Compared Environmental and Economic Impact from Cradle to Gate of Concrete with Natural and Recycled Coarse Aggregates. J. Clean. Prod. 2017, 162, 529–543. [Google Scholar] [CrossRef]

- Van den Heede, P.; De Belie, N. Environmental Impact and Life Cycle Assessment (LCA) of Traditional and ‘Green’ Concretes: Literature Review and Theoretical Calculations. Cem. Concr. Compos. 2012, 34, 431–442. [Google Scholar] [CrossRef]

- Vieira, D.R.; Calmon, J.L.; Coelho, F.Z. Life Cycle Assessment (LCA) Applied to the Manufacturing of Common and Ecological Concrete: A Review. Constr. Build. Mater. 2016, 124, 656–666. [Google Scholar] [CrossRef]

- De Schepper, M.; Van den Heede, P.; Van Driessche, I.; De Belie, N. Life Cycle Assessment of Completely Recyclable Concrete. Materials 2014, 7, 6010–6027. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Taranu, N.; Maxineasa, S.G.; Mihai, P.; Entuc, I.-S.; Oprisan, G. The environmental impact of different concrete mixes. Int. Multidiscip. Sci. GeoConference SGEM 2016, 1, 707–714. [Google Scholar]

- Evangelista, L.; De Brito, J. Environmental Life Cycle Assessment of Concrete Made with Fine Recycled Concrete Aggregates. Port. Sb07-Sustain. Constr. Mater. Pract. Chall. Ind. New Millenn. Pts 2007, 1, 789–794. [Google Scholar]

- Nedeljković, M.; Visser, J.; Šavija, B.; Valcke, S.; Schlangen, E. Use of Fine Recycled Concrete Aggregates in Concrete: A Critical Review. J. Build. Eng. 2021, 38, 102196. [Google Scholar] [CrossRef]

- Sosa, M.E.; Villagrán Zaccardi, Y.A.; Zega, C.J. A Critical Review of the Resulting Effective Water-to-Cement Ratio of Fine Recycled Aggregate Concrete. Constr. Build. Mater. 2021, 313, 125536. [Google Scholar] [CrossRef]

- Xiao, J.; Wang, C.; Ding, T.; Akbarnezhad, A. A Recycled Aggregate Concrete High-Rise Building: Structural Performance and Embodied Carbon Footprint. J. Clean. Prod. 2018, 199, 868–881. [Google Scholar] [CrossRef]

- Malešev, M.; Radonjanin, V.; Marinković, S. Recycled Concrete as Aggregate for Structural Concrete Production. Sustainability 2010, 2, 1204–1225. [Google Scholar] [CrossRef] [Green Version]

- Marinković, S.B.; Ignjatović, I.; Radonjanin, V. 23—Life-Cycle Assessment (LCA) of Concrete with Recycled Aggregates (RAs). In Handbook of Recycled Concrete and Demolition Waste; Pacheco-Torgal, F., Tam, V.W.Y., Labrincha, J.A., Ding, Y., de Brito, J., Eds.; Woodhead Publishing Series in Civil and Structural Engineering; Woodhead Publishing: Sawston, UK, 2013; pp. 569–604. ISBN 978-0-85709-682-1. [Google Scholar]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of Incorporation of High Volume of Recycled Concrete Aggregates and Fly Ash on the Strength and Global Warming Potential of Concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Serres, N.; Braymand, S.; Feugeas, F. Environmental Evaluation of Concrete Made from Recycled Concrete Aggregate Implementing Life Cycle Assessment. J. Build. Eng. 2016, 5, 24–33. [Google Scholar] [CrossRef]

- Colangelo, F.; Forcina, A.; Farina, I.; Petrillo, A. Life Cycle Assessment (LCA) of Different Kinds of Concrete Containing Waste for Sustainable Construction. Buildings 2018, 8, 70. [Google Scholar] [CrossRef] [Green Version]

- Faleschini, F.; De Marzi, P.; Pellegrino, C. Recycled Concrete Containing EAF Slag: Environmental Assessment through LCA. Eur. J. Environ. Civ. Eng. 2014, 18, 1009–1024. [Google Scholar] [CrossRef]

- Pavlů, T.; Kočí, V.; Hájek, P. Environmental Assessment of Two Use Cycles of Recycled Aggregate Concrete. Sustainability 2019, 11, 6185. [Google Scholar] [CrossRef] [Green Version]

- Pešta, J.; Pavlů, T.; Fořtová, K.; Kočí, V. Sustainable Masonry Made from Recycled Aggregates: LCA Case Study. Sustainability 2020, 12, 1581. [Google Scholar] [CrossRef] [Green Version]

- Tošić, N.; Marinković, S.; Pecić, N.; Ignjatović, I.; Dragaš, J. Long-Term Behaviour of Reinforced Beams Made with Natural or Recycled Aggregate Concrete and High-Volume Fly Ash Concrete. Constr. Build. Mater. 2018, 176, 344–358. [Google Scholar] [CrossRef]

- Marinković, S.; Carević, V.; Dragaš, J. The Role of Service Life in Life Cycle Assessment of Concrete Structures. J. Clean. Prod. 2021, 290, 125610. [Google Scholar] [CrossRef]

- García-Segura, T.; Yepes, V.; Alcalá, J. Life Cycle Greenhouse Gas Emissions of Blended Cement Concrete Including Carbonation and Durability. Int. J. Life Cycle Assess. 2014, 19, 3–12. [Google Scholar] [CrossRef]

- Vieira, D.R.; Calmon, J.L.; Zulcão, R.; Coelho, F.Z. Consideration of Strength and Service Life in Cradle-to-Gate Life Cycle Assessment of Self-Compacting Concrete in a Maritime Area: A Study in the Brazilian Context. Environ. Dev. Sustain. 2018, 20, 1849–1871. [Google Scholar] [CrossRef]

- Silva, M.G.; Saade, M.R.M.; Gomes, V. Influence of Service Life, Strength and Cement Type on Life Cycle Environmental Performance of Concrete. Rev. IBRACON Estrut. E Mater. 2013, 6, 844–853. [Google Scholar] [CrossRef] [Green Version]

- Pedro, D.; de Brito, J.; Evangelista, L. Influence of the Use of Recycled Concrete Aggregates from Different Sources on Structural Concrete. Constr. Build. Mater. 2014, 71, 141–151. [Google Scholar] [CrossRef]

- Ossa, A.; García, J.L.; Botero, E. Use of Recycled Construction and Demolition Waste (CDW) Aggregates: A Sustainable Alternative for the Pavement Construction Industry. J. Clean. Prod. 2016, 135, 379–386. [Google Scholar] [CrossRef]

- Rao, A.; Jha, K.N.; Misra, S. Use of Aggregates from Recycled Construction and Demolition Waste in Concrete. Resour. Conserv. Recycl. 2007, 50, 71–81. [Google Scholar] [CrossRef]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled Aggregate from C&D Waste & Its Use in Concrete—A Breakthrough towards Sustainability in Construction Sector: A Review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar] [CrossRef]

- Debieb, F.; Kenai, S. The Use of Coarse and Fine Crushed Bricks as Aggregate in Concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Ge, Z.; Feng, Y.; Zhang, H.; Xiao, J.; Sun, R.; Liu, X. Use of Recycled Fine Clay Brick Aggregate as Internal Curing Agent for Low Water to Cement Ratio Mortar. Constr. Build. Mater. 2020, 264, 120280. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J.; Pang, S.D.; Zhao, S. Durability and Microstructural Properties of Concrete with Recycled Brick as Fine Aggregates. Constr. Build. Mater. 2020, 262, 120032. [Google Scholar] [CrossRef]

- Vieira, T.; Alves, A.; de Brito, J.; Correia, J.R.; Silva, R.V. Durability-Related Performance of Concrete Containing Fine Recycled Aggregates from Crushed Bricks and Sanitary Ware. Mater. Des. 2016, 90, 767–776. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Tam, C.M. Assessment of Durability of Recycled Aggregate Concrete Produced by Two-Stage Mixing Approach. J. Mater. Sci. 2007, 42, 3592–3602. [Google Scholar] [CrossRef] [Green Version]

- ISO 14040:2006; CEN Environmental Management—Life Cycle Assessment—Principles and Framework. ISO: Geneve, Switzerland, 2006.

- Guinee, J. Handbook on Life Cycle Assessment—Operational Guide to the ISO Standards. Int. J. Life Cycle Assess. 2001, 6, 255. [Google Scholar] [CrossRef]

- GaBi Professional. Available online: https://sphera.com/product-sustainability-gabi-data-search/ (accessed on 5 December 2022).

- Zhao, Z.; Courard, L.; Groslambert, S.; Jehin, T.; Léonard, A.; Xiao, J. Use of Recycled Concrete Aggregates from Precast Block for the Production of New Building Blocks: An Industrial Scale Study. Resour. Conserv. Recycl. 2020, 157, 104786. [Google Scholar] [CrossRef]

- Roh, S.; Kim, R.; Park, W.-J.; Ban, H. Environmental Evaluation of Concrete Containing Recycled and By-Product Aggregates Based on Life Cycle Assessment. Appl. Sci. 2020, 10, 7503. [Google Scholar] [CrossRef]

- Dezhampanah, S.; Nikbin, I.; Charkhtab, S.; Fakhimi, F.; Bazkiaei, S.M.; Mohebbi, R. Environmental Performance and Durability of Concrete Incorporating Waste Tire Rubber and Steel Fiber Subjected to Acid Attack. J. Clean. Prod. 2020, 268, 122216. [Google Scholar] [CrossRef]

- Bostanci, S.C.; Limbachiya, M.; Kew, H. Use of Recycled Aggregates for Low Carbon and Cost Effective Concrete Construction. J. Clean. Prod. 2018, 189, 176–196. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, M.F.; Rizwan, S.H.; Ahmed, M.H.; Batikha, M. Using Recycled Waste Material from UAE in Concrete. In Proceedings of the 2020 Advances in Science and Engineering Technology International Conferences (ASET), Dubai, United Arab Emirates, 4 February–9 April 2020; pp. 1–6. [Google Scholar]

- Kurda, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Optimizing Recycled Concrete Containing High Volume of Fly Ash in Terms of the Embodied Energy and Chloride Ion Resistance. J. Clean. Prod. 2018, 194, 735–750. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. A Comparative Study of the Mechanical and Life Cycle Assessment of High-Content Fly Ash and Recycled Aggregates Concrete. J. Build. Eng. 2020, 29, 101173. [Google Scholar] [CrossRef]

- Yang, R.; Yu, R.; Shui, Z.; Gao, X.; Xiao, X.; Fan, D.; Chen, Z.; Cai, J.; Li, X.; He, Y. Feasibility Analysis of Treating Recycled Rock Dust as an Environmentally Friendly Alternative Material in Ultra-High Performance Concrete (UHPC). J. Clean. Prod. 2020, 258, 120673. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J. Life Cycle Assessment of Concrete Made with High Volume of Recycled Concrete Aggregates and Fly Ash. Resour. Conserv. Recycl. 2018, 139, 407–417. [Google Scholar] [CrossRef]

| RA Types | Grading (mm) | Finest Particles Content | Oven-Dried Particle Density | Water Absorption Capacity | ||

|---|---|---|---|---|---|---|

| f (%) | ρRD (kg/m3) | σ | WA24 (%) | σ | ||

| Natural aggregate (NA1) | 0–4 | 0.3 | 2570 | 81 | 1.0 | 0.0 |

| 4–8 | 0.3 | 2530 | 12 | 1.7 | 0.3 | |

| 8–16 | 0.4 | 2540 | 12 | 1.9 | 0.2 | |

| Fine recycled masonry aggregate (fRMA) | 0–4 | 1.0 | 2320 | 130 | 6.6 | 0.8 |

| Fine recycled concrete aggregate (fRCA) | 0–4 | 0.6 | 2430 | 60 | 3.6 | 0.8 |

| Concrete Mixture | Cement | Mixing Water + Additional Water | w/c Ratio | Natural Aggregate | Recycled Aggregate | |

|---|---|---|---|---|---|---|

| Fine | Coarse | Fine | ||||

| (kg/m3) | (kg/m3) | (-) | (kg/m3) | (kg/m3) | (kg/m3) | |

| NAC I | 260 | 169 + 0 | 0.65 | 709 | 1130 | 0 |

| fRMAC I | 260 | 169 + 18 | 0.72 | 0 | 766 | 971 |

| fRCAC1 I | 260 | 169 + 17 | 0.71 | 0 | 949 | 843 |

| NAC II | 300 | 165 + 0 | 0.55 | 671 | 1167 | 0 |

| fRMAC II | 300 | 165 + 17 | 0.61 | 0 | 822 | 920 |

| fRCAC1 II | 300 | 165 +16 | 0.60 | 0 | 994 | 800 |

| Recycled Concrete Mixture | Dry Density | Compressive Strength | Target Concrete Strength Class | Flexural Strength | Static Modulus of Elasticity | ||||

|---|---|---|---|---|---|---|---|---|---|

| Designation | (kg/m3) | (kg/m3) | (MPa) | σ | (-) | (MPa) | σ | (GPa) | σ |

| NAC IA | 2301 | 2301 | 33.2 | 2.5 | C20/25 | 6.2 | 0.2 | 36.7 | 1.4 |

| fRMAC IA | 2181 | 2181 | 30.0 | 2.2 | C20/25 | 5.5 | 0.4 | 22.4 | 1.0 |

| fRCAC1 IA | 2276 | 2276 | 34.4 | 1.7 | C25/30 | 5.8 | 0.3 | 29.6 | 0.4 |

| NAC IIA | 2324 | 2324 | 44.9 | 0.9 | C30/37 | 7.6 | 0.9 | 35.9 | 0.5 |

| fRMAC IIA | 2191 | 2191 | 38.0 | 0.9 | C25/30 | 6.8 | 0.6 | 25.3 | 0.2 |

| fRCAC1 IIA | 2278 | 2278 | 42.9 | 0.8 | C30/37 | 6.5 | 0.4 | 31.4 | 1.0 |

| Recycled Concrete Mixture | Flexural Strength + Standard Deviation | Frost Resistance Coefficient | Freeze–Thaw Resistance | Carbonation Depth | |||

|---|---|---|---|---|---|---|---|

| Designation | 0 Cycles | 100 Cycles | (-) | Cycles | (mm) | ||

| NAC IA | 6.15 | ±0.22 | 6.87 | ±0.20 | 1.12 | 100 | 2.78 |

| fRMAC IA | 5.53 | ±0.39 | 5.85 | ±0.40 | 1.06 | 100 | 7.10 |

| fRCAC1 IA | 5.78 | ±0.30 | 6.57 | ±0.26 | 1.14 | 100 | 4.51 |

| NAC IIA | 7.55 | ±0.87 | 7.80 | ±0.12 | 1.03 | 100 | 0.77 |

| fRMAC IIA | 6.84 | ±0.60 | 6.78 | ±0.00 | 0.99 | 100 | 1.71 |

| fRCAC1 IIA | 6.54 | ±0.44 | 6.73 | ±0.10 | 1.03 | 100 | 0.57 |

| Design | Mixture | t | ds | a | c | MEd | MRd | Vconc. | Wreinf. |

|---|---|---|---|---|---|---|---|---|---|

| Designation | (mm) | (mm) | (mm) | (mm) | (kNm) | (kNm) | (m3) | (kg) | |

| Steel reinfor., thickness modification | NAC IA | 230 | 10 | 100 | 20 | 65.593 | 66.532 | 1.380 | 36.992 |

| fRMAC IA | 260 | 10 | 100 | 35 | 70.149 | 71.149 | 1.560 | 36.992 | |

| fRCAC1 IA | 260 | 10 | 100 | 35 | 70.149 | 71.812 | 1.560 | 36.992 | |

| NAC IIA | 220 | 10 | 100 | 20 | 64.074 | 64.218 | 1.320 | 36.992 | |

| fRMAC IIA | 250 | 10 | 100 | 35 | 68.63 | 68.795 | 1.500 | 36.992 | |

| fRCAC1 IIA | 250 | 10 | 100 | 35 | 68.63 | 69.204 | 1.500 | 36.992 | |

| GFRP reinf., thickness modification | NAC IA | 210 | 6 | 75 | 15 | 62.555 | 62.562 | 1.260 | 4.750 |

| fRMAC IA | 230 | 6 | 75 | 15 | 65.593 | 68.933 | 1.380 | 4.750 | |

| fRCAC1 IA | 210 | 6 | 75 | 15 | 62.555 | 62.722 | 1.260 | 4.750 | |

| NAC IIA | 210 | 6 | 75 | 15 | 62.555 | 63.68 | 1.260 | 4.750 | |

| fRMAC IIA | 210 | 6 | 75 | 15 | 62.555 | 63.126 | 1.260 | 4.750 | |

| fRCAC1 IIA | 210 | 6 | 75 | 15 | 62.555 | 63.542 | 1.260 | 4.750 | |

| Steel reinfor., reinforcem. Modification | NAC IA | 230 | 10 | 100 | 20 | 65.593 | 66.532 | 1.380 | 36.992 |

| fRMAC IA | 230 | 10 | 92 | 35 | 65.593 | 65.826 | 1.380 | 40.209 | |

| fRCAC1 IA | 230 | 10 | 93 | 35 | 65.593 | 65.934 | 1.380 | 39.776 | |

| NAC IIA | 220 | 10 | 100 | 20 | 64.074 | 64.218 | 1.320 | 36.992 | |

| fRMAC IIA | 220 | 10 | 90 | 35 | 64.074 | 64.696 | 1.320 | 41.102 | |

| fRCAC1 IIA | 220 | 10 | 91 | 35 | 64.074 | 64.519 | 1.320 | 40.651 | |

| GFRP reinf., reinforcem. modification | NAC IA | 210 | 6 | 75 | 15 | 62.555 | 62.562 | 1.260 | 4.750 |

| fRMAC IA | 220 | 6 | 76 | 15 | 64.074 | 64.682 | 1.320 | 4.688 | |

| fRCAC1 IA | 210 | 6 | 75 | 15 | 62.555 | 62.722 | 1.260 | 4.750 | |

| NAC IIA | 210 | 6 | 75 | 15 | 62.555 | 63.68 | 1.260 | 4.750 | |

| fRMAC IIA | 210 | 6 | 75 | 15 | 62.555 | 63.126 | 1.260 | 4.750 | |

| fRCAC1 IIA | 210 | 6 | 76 | 15 | 62.555 | 62.739 | 1.260 | 4.688 |

| Design | Mixture | t | ds | a | c | MEd | MRd | Vconc. | Wreinf. | s |

|---|---|---|---|---|---|---|---|---|---|---|

| Designation | (mm) | (mm) | (mm) | (mm) | (kNm) | (kNm) | (m3) | (kg) | (mm) | |

| Steel reinfor., thickness modification | NAC IA | 310 | 10 | 100 | 20 | 77.743 | 93.85 | 1.860 | 36.992 | 23.98 |

| fRMAC IA | 350 | 10 | 100 | 35 | 83.818 | 101.882 | 2.100 | 36.992 | 23.29 | |

| fRCAC1 IA | 330 | 10 | 100 | 35 | 80.78 | 95.715 | 1.980 | 36.992 | 22.84 | |

| NAC IIA | 290 | 10 | 100 | 20 | 74.705 | 88.121 | 1.740 | 36.992 | 22.66 | |

| fRMAC IIA | 320 | 10 | 100 | 35 | 79.262 | 92.698 | 1.920 | 36.992 | 23.75 | |

| fRCAC1 IIA | 310 | 10 | 100 | 35 | 77.743 | 89.693 | 1.860 | 36.992 | 22.01 | |

| GFRP reinf., thickness modification | NAC IA | 450 | 6 | 75 | 15 | 99.005 | 145.172 | 2.700 | 4.750 | 21.34 |

| fRMAC IA | 480 | 6 | 75 | 15 | 103.562 | 154.985 | 2.880 | 4.750 | 21.81 | |

| fRCAC1 IA | 440 | 6 | 75 | 15 | 97.487 | 141.89 | 2.640 | 4.750 | 22.23 | |

| NAC IIA | 380 | 6 | 75 | 15 | 88.374 | 122.195 | 2.280 | 4.750 | 20.99 | |

| fRMAC IIA | 420 | 6 | 75 | 15 | 94.449 | 135.41 | 2.520 | 4.750 | 20.4 | |

| fRCAC1 IIA | 390 | 6 | 75 | 15 | 89.893 | 125.499 | 2.340 | 4.750 | 21.15 | |

| Steel reinfor., reinforcem. Modification | NAC IA | 300 | 12 | 120 | 20 | 76.224 | 107.28 | 1.800 | 44.391 | 23.88 |

| fRMAC IA | 300 | 12 | 45 | 35 | 76.224 | 242.309 | 1.800 | 118.375 | 23.98 | |

| fRCAC1 IA | 300 | 12 | 85 | 35 | 76.224 | 140.324 | 1.800 | 62.669 | 23.64 | |

| NAC IIA | 300 | 12 | 170 | 20 | 76.224 | 77.554 | 1.800 | 31.335 | 22.35 | |

| fRMAC IIA | 300 | 12 | 90 | 35 | 76.224 | 134.045 | 1.800 | 59.188 | 23.71 | |

| fRCAC1 IIA | 300 | 12 | 135 | 35 | 76.224 | 91.487 | 1.800 | 39.458 | 23.88 | |

| GFRP reinf., reinforcem. modification | NAC IA | 410 | 10 | 96 | 15 | 92.93 | 274.715 | 2.460 | 10.308 | 21.74 |

| fRMAC IA | 440 | 10 | 110 | 15 | 97.487 | 259.314 | 2.640 | 8.996 | 23.34 | |

| fRCAC1 IA | 420 | 10 | 140 | 15 | 94.449 | 197.432 | 2.520 | 7.069 | 23.42 | |

| NAC IIA | 350 | 10 | 95 | 15 | 83.818 | 237.517 | 2.100 | 10.417 | 23.27 | |

| fRMAC IIA | 380 | 10 | 90 | 15 | 88.374 | 270.969 | 2.280 | 10.996 | 23.16 | |

| fRCAC1 IIA | 360 | 10 | 100 | 15 | 85.337 | 232.763 | 2.160 | 9.896 | 23.67 |

| Scenario | EF 3.0. | −Δ (%) | Scenario | EF 3.0. | −Δ (%) | Scenario | EF 3.0. | −Δ (%) | Scenario | EF 3.0. | −Δ (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1S NAC I | 0.024 | 0.0 | 1S NAC II | 0.025 | 0.0 | 1G NAC I | 0.022 | 0.0 | 1G NAC II | 0.024 | 0.0 |

| 1S fRMAC I | 0.023 | 1.4 | 1S fRMAC II | 0.025 | −0.7 | 1G fRMAC I | 0.021 | 4.2 | 1G fRMAC II | 0.021 | 10.6 |

| 1S fRCAC I | 0.018 | 26.0 | 1S fRCAC II | 0.020 | 21.0 | 1G FRCAC I | 0.015 | 33.2 | 1G fRCAC II | 0.017 | 29.4 |

| 2S NAC I | 0.024 | 0.0 | 2S NAC II | 0.025 | 0.0 | 2G NAC I | 0.022 | 0.0 | 2G NAC II | 0.024 | 0.0 |

| 2S fRMAC I | 0.021 | 11.6 | 2S fRMAC II | 0.022 | 10.2 | 2G fRMAC I | 0.020 | 8.1 | 2G fRMAC II | 0.021 | 10.6 |

| 2S fRCAC I | 0.016 | 33.4 | 2S fRCAC II | 0.017 | 29.3 | 2G fRCAC I | 0.015 | 33.2 | 2G fRCAC II | 0.017 | 29.4 |

| Scenario | EF 3.0. | −Δ (%) | Scenario | EF 3.0. | −Δ (%) | Scenario | EF 3.0. | −Δ (%) | Scenario | EF 3.0. | −Δ (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 1S NAC I | 0.032 | 0.0 | 1S NAC II | 0.032 | 0.0 | 1G NAC I | 0.046 | 0.0 | 1G NAC II | 0.042 | 0.0 |

| 1S fRMAC I | 0.031 | 1.5 | 1S fRMAC II | 0.031 | 2.1 | 1G fRMAC I | 0.042 | 6.8 | 1G fRMAC II | 0.041 | 2.0 |

| 1S fRCAC I | 0.022 | 30.4 | 1S fRCAC II | 0.024 | 25.6 | 1G fRCAC I | 0.029 | 35.9 | 1G fRCAC II | 0.030 | 28.5 |

| 2S NAC I | 0.031 | 2.3 | 2S NAC II | 0.033 | −2.7 | 2G NAC I | 0.044 | 4.4 | 2G NAC II | 0.041 | 3.0 |

| 2S fRMAC I | 0.030 | 5.9 | 2S fRMAC II | 0.030 | 5.5 | 2G fRMAC I | 0.040 | 11.1 | 2G fRMAC II | 0.039 | 5.9 |

| 2S fRCAC I | 0.021 | 33.4 | 2S fRCAC II | 0.023 | 27.6 | 2G fRCAC I | 0.029 | 37.0 | 2G fRCAC II | 0.030 | 29.6 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pavlů, T.; Pešta, J.; Vlach, T.; Fořtová, K. Environmental Impact of Concrete Slab Made of Recycled Aggregate Concrete Based on Limit States of Load-Bearing Capacity and Serviceability—LCA Case Study. Materials 2023, 16, 616. https://doi.org/10.3390/ma16020616

Pavlů T, Pešta J, Vlach T, Fořtová K. Environmental Impact of Concrete Slab Made of Recycled Aggregate Concrete Based on Limit States of Load-Bearing Capacity and Serviceability—LCA Case Study. Materials. 2023; 16(2):616. https://doi.org/10.3390/ma16020616

Chicago/Turabian StylePavlů, Tereza, Jan Pešta, Tomáš Vlach, and Kristina Fořtová. 2023. "Environmental Impact of Concrete Slab Made of Recycled Aggregate Concrete Based on Limit States of Load-Bearing Capacity and Serviceability—LCA Case Study" Materials 16, no. 2: 616. https://doi.org/10.3390/ma16020616

APA StylePavlů, T., Pešta, J., Vlach, T., & Fořtová, K. (2023). Environmental Impact of Concrete Slab Made of Recycled Aggregate Concrete Based on Limit States of Load-Bearing Capacity and Serviceability—LCA Case Study. Materials, 16(2), 616. https://doi.org/10.3390/ma16020616