Application of Plasticizer Glycerol in Lignosulfonate-Filled Rubber Compounds Based on SBR and NBR

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Methods

2.2.1. Preparation and Curing of Rubber Compounds

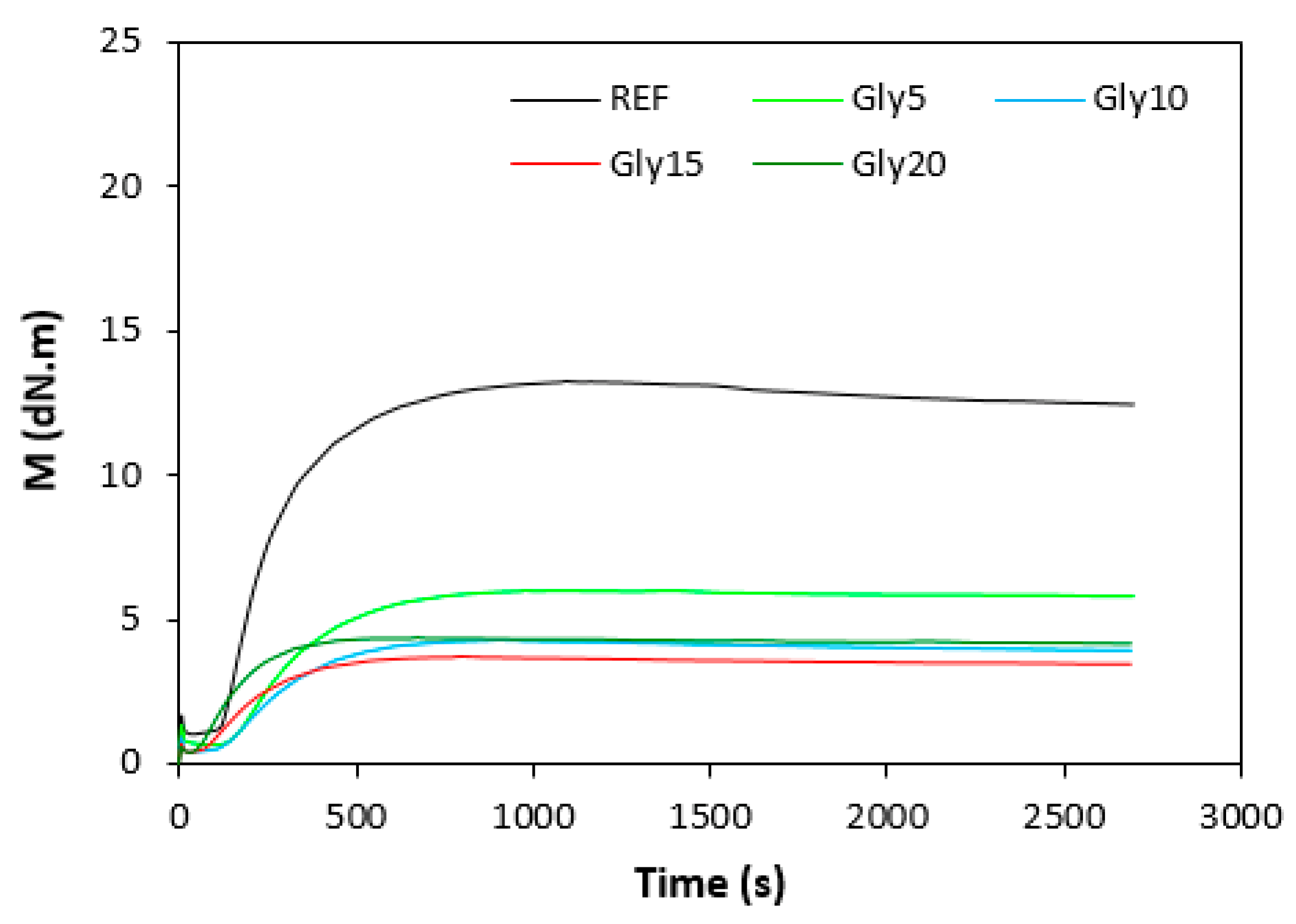

2.2.2. Determination of Curing Characteristics

- ML—minimum torque (dN·m).

- MH—maximum torque (dN·m).

- ∆M—torque difference, the difference between MH and ML (dN·m).

- tc90—optimum curing time (min).

- ts1—scorch time (min).

2.2.3. Determination of Cross-Link Density

2.2.4. Rheological Measurements

2.2.5. Investigation of Physical–Mechanical Characteristics

2.2.6. Microscopic Analysis

2.2.7. Determination of Dynamic Mechanical Properties

3. Results and Discussion

3.1. Curing Process and Cross-Link Density

3.2. Rheological Measurement

3.3. Physical–Mechanical Properties

3.4. Morphology

3.5. Dynamic Mechanical Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Roy, K.; Debnath, S.C.; Potiyaraj, P. A review on recent trends and future prospects of lignin based green rubber composites. J. Polym. Environ. 2020, 28, 367–387. [Google Scholar] [CrossRef]

- Khan, A.; Nair, V.; Colmenares, J.C.; Gläser, R. Lignin-based composite materials for photocatalysis and photovoltaics. Top. Curr. Chem. 2018, 376, 20. [Google Scholar] [CrossRef] [Green Version]

- Wei, X.; Cui, S.; Xie, Y. Synthesis and antibacterial properties of oligomeric dehydrogenation polymer from lignin precursors. Molecules 2022, 27, 1466. [Google Scholar] [CrossRef] [PubMed]

- Hudzik, J.M.; Barekati-Goudarzi, M.; Khachatryan, L.; Bozzelli, J.W.; Ruckenstein, E.; Asatryan, R. OH-initiated reactions of para-coumaryl alcohol relevant to the lignin pyrolysis. Part II. Kinetic analysis. J. Phys. Chem. A 2020, 124, 4875–4904. [Google Scholar] [CrossRef] [PubMed]

- Sadeghifar, H.; Argyropoulos, D.S. Correlations of the antioxidant properties of softwood kraft lignin fractions with the thermal stability of its blends with polyethylene. ACS Sustain. Chem. Eng. 2015, 3, 349–356. [Google Scholar] [CrossRef]

- Lu, Y.; Lu, Y.C.; Hu, H.Q.; Xie, F.J.; Wei, X.Y.; Fan, X. Structural characterization of lignin and its degradation products with spectroscopic methods. J. Spectrosc. 2017, 2017, 8951658. [Google Scholar] [CrossRef] [Green Version]

- Katahira, R.; Elder, T.J.; Beckham, G.T. A Brief Introduction to Lignin Structure. In Lignin Valorization: Emerging Approaches; Royal Society of Chemistry: Cambridge, UK, 2018; pp. 1–20. [Google Scholar] [CrossRef] [Green Version]

- Yu, O.; Kim, K.H. Lignin to materials: A focused review on recent novel lignin applications. Appl. Sci. 2020, 10, 4626. [Google Scholar] [CrossRef]

- Laurichesse, S.; Avérous, L. Chemical modification of lignins: Towards biobased polymers. Prog. Polym. Sci. 2014, 39, 1266–1290. [Google Scholar] [CrossRef]

- Guadix-Montero, S.; Sankar, M. Review on catalytic cleavage of C–C inter-unit linkages in lignin model compounds: Towards lignin depolymerisation. Top. Catal. 2018, 61, 183–198. [Google Scholar] [CrossRef]

- Aro, T.; Fatehi, P. Production and application of lignosulfonates and sulfonated lignin. ChemSusChem 2017, 10, 1861–1877. [Google Scholar] [CrossRef] [Green Version]

- Li, T.; Takkellapati, S. The current and emerging sources of technical lignins and their applications. Biofuels Bioprod. Biorefin. 2018, 12, 756–787. [Google Scholar] [CrossRef]

- Fearon, O.; Kuitunen, S.; Ruuttunen, K.; Alopaeus, V.; Vuorinen, T. Detailed modeling of kraft pulping chemistry. Delignification. Ind. Eng. Chem. Res. 2020, 59, 12977–12985. [Google Scholar] [CrossRef]

- Komisarz, K.; Majka, T.M.; Pielichowski, K. Chemical transformation of lignosulfonates to lignosulfonamides with improved thermal characteristics. Fibers 2022, 10, 20. [Google Scholar] [CrossRef]

- Chen, J.; Kazzaz, A.E.; AlipoorMazandarani, N.; Feizi, Z.H.; Fatehi, P. Production of flocculants, adsorbents, and dispersants from lignin. Molecules 2018, 23, 868. [Google Scholar] [CrossRef] [Green Version]

- Guterman, R.; Molinari, V.; Josef, E. Ionic liquid lignosulfonate: Dispersant and binder for preparation of biocomposite materials. Angew. Chem. Int. Ed. Engl. 2019, 58, 13044–13050. [Google Scholar] [CrossRef]

- Wang, H.M.; Yuan, T.Q.; Song, G.Y.; Sun, R.C. Advanced and versatile lignin-derived biodegradable composite film materials toward a sustainable world. Green. Chem. 2021, 23, 3790–3817. [Google Scholar] [CrossRef]

- Sugiarto, S.; Leow, Y.; Li Tan, C.; Wang, G.; Kai, D. How far is Lignin from being a biomedical material? Bioact. Mater. 2022, 8, 71–94. [Google Scholar] [CrossRef]

- Nan, N.; Hu, W.; Wang, J. Lignin-based porous biomaterials for medical and pharmaceutical applications. Biomedicines 2022, 10, 747. [Google Scholar] [CrossRef]

- Mili, M.; Hashmi, S.A.R.; Ather, M.; Hada, V.; Markandeya, N.; Kamble, S.; Mohapatra, M.; Rathore, S.K.S.; Srivastava, A.K.; Verma, S. Novel lignin as natural-biodegradable binder for various sectors—A review. J. Appl. Polym. Sci. 2022, 139, e51951. [Google Scholar] [CrossRef]

- Madyaratri, E.W.; Ridho, M.R.; Aristri, M.A.; Lubis, M.A.R.; Iswanto, A.H.; Nawawi, D.S.; Antov, P.; Kristak, L.; Majlingová, A.; Fatriasari, W. Recent advances in the development of fire-resistant biocomposites—A review. Polymers 2022, 14, 362. [Google Scholar] [CrossRef]

- de Carvalho, D.M.; Lahtinen, M.H.; Bhattarai, M.; Lawoko, M.; Mikkonen, K.S. Active role of lignin in anchoring wood-based stabilizers to the emulsion interface. Green Chem. 2021, 23, 9084. [Google Scholar] [CrossRef]

- Ridho, M.R.; Agustiany, E.A.; Dn, M.R.; Madyaratri, E.W.; Ghozali, M.; Restu, W.K.; Falah, F.; Lubis, M.A.R.; Syamani, F.A.; Nurhamiyah, Y.; et al. Lignin as green filler in polymer composites: Development methods, characteristics, and potential applications. Adv. Mater. Sci. Eng. 2022, 2022, 1363481. [Google Scholar] [CrossRef]

- Abid, U.; Gill, Y.Q.; Irfan, M.S.; Umer, R.; Saeed, F. Potential applications of polycarbohydrates, lignin, proteins, polyacids, and other renewable materials for the formulation of green elastomers. Int. J. Biol. Macromol. 2021, 181, 1–29. [Google Scholar] [CrossRef] [PubMed]

- Wei, D.; Wu, C.; Jiang, G.; Sheng, X.; Xie, Y. Lignin-assisted construction of well-defined 3D graphene aerogel/PEG form-stable phase change composites towards efficient solar thermal energy storage. Sol. Energy Mater. Sol. Cells 2021, 224, 111013. [Google Scholar] [CrossRef]

- Barana, D.; Orlandi, M.; Zoia, L.; Castellani, L.; Hanel, T.; Bolck, C.; Gosselink, R. Lignin based functional additives for natural rubber. ACS Sustain. Chem. Eng. 2018, 6, 11843–11852. [Google Scholar] [CrossRef]

- Liu, R.; Li, J.; Lu, T.; Han, X.; Yan, Z.; Zhao, S.; Wang, H. Comparative study on the synergistic reinforcement of lignin between carbon black/lignin and silica/lignin hybrid filled natural rubber composites. Ind. Crops Prod. 2022, 187, 115378. [Google Scholar] [CrossRef]

- Ghosh, A. Organosolv lignin improved thermoplastic elastomeric behavior of polyethylene/polyisoprene blend. ACS Omega 2022, 7, 8483–8492. [Google Scholar] [CrossRef]

- Sun, N.; Di, M.; Liu, Y. Lignin-containing polyurethane elastomers with enhanced mechanical properties via hydrogen bond interactions. Int. J. Biol. Macromol. 2021, 184, 1–8. [Google Scholar] [CrossRef]

- Chowdhury, S.G.; Ghosh, S.; Pal, A.; Pal, K.; Chanda, J.; Samui, B.K.; Bhattacharyya, S.K.; Mukhopadhya, R.; Bandyopadhyay, A. Evaluation of lignin as potential green filler in an optimally designed solution grade styrene–butadiene rubber (SSBR) based tyre tread compound. Plast. Rubber Compos. 2021. [Google Scholar] [CrossRef]

- Intapun, J.; Rungruang, T.; Suchat, S.; Cherdchim, B.; Hiziroglu, S. The Characteristics of natural rubber composites with Klason lignin as a green reinforcing filler: Thermal stability, mechanical and dynamical Properties. Polymers 2021, 13, 1109. [Google Scholar] [CrossRef]

- Raju, G.; Khalid, M.; Shaban, M.M.; Azahari, B. Preparation and characterization of eco-friendly spent coffee/ENR50 biocomposite in comparison to carbon black. Polymers 2021, 13, 2796. [Google Scholar] [CrossRef]

- Bahl, K.; Jana, S.C. Surface modification of lignosulfonates for reinforcement of styrene–butadiene rubber compounds. J. Appl. Polym. Sci. 2014, 131, 40123. [Google Scholar] [CrossRef]

- Shorey, R.; Gupta, A.; Mekonnen, T.H. Hydrophobic modification of lignin for rubber composites. Ind. Crops Prod. 2021, 174, 114189. [Google Scholar] [CrossRef]

- Hait, S.; De, D.; Ghosh, P.; Chanda, J.; Mukhopadhyay, R.; Dasgupta, S.; Sallat, A.; Al Aiti, M.; Stöckelhuber, K.W.; Wießner, S.; et al. Understanding the coupling effect between lignin and polybutadiene elastomer. J. Compos. Sci. 2021, 5, 154. [Google Scholar] [CrossRef]

- Frigerio, P.; Zoia, L.; Orlandi, M.; Hanel, T.; Castellani, L. Application of sulphur-free lignins as a filler for elastomers: Effect of hexamethylenetetramine treatment. Bioresources 2014, 9, 1387–1400. [Google Scholar] [CrossRef]

- Mohamad Aini, N.A.; Othman, N.; Hussin, M.H.; Sahakaro, K.; Hayeemasae, N. Hydroxymethylation-modified lignin and its effectiveness as a filler in rubber composites. Processes 2019, 7, 315. [Google Scholar] [CrossRef] [Green Version]

- Kraus, G. Swelling of filler-reinforced vulcanizates. J. Appl. Polym. Sci. 1963, 7, 861–871. [Google Scholar] [CrossRef]

- Alexy, P.; Feranc, J.; Kramárová, Z.; Hajšová, M.; Ďuračka, M.; Mošková, D.; Chodak, I.; Ilish, S. Application of lignins in rubber compounds. Kautsch Gummi Kunstst. 2008, 61, 26–32. [Google Scholar]

- Maciejewska, M.; Krzywania-Kaliszewska, A.; Zaborski, M. Ionic liquids applied to improve the dispersion of calcium oxide nanoparticles in the hydrogenated acrylonitrile-butadiene elastomer. Am. J. Mater. Sci. 2013, 3, 63–69. [Google Scholar]

- Kruželák, J.; Sýkora, R.; Hudec, I. Vulcanization of rubber compounds with peroxide curing systems. Rubber Chem. Technol. 2017, 90, 60–88. [Google Scholar] [CrossRef]

| Glycerol (phr) | G′ (MPa) (0 °C) | G′ (MPa) (20 °C) | G′ (MPa) (60 °C) | G″ (MPa) (0 °C) | G″ (MPa) (20 °C) | G″ (MPa) (60 °C) |

|---|---|---|---|---|---|---|

| 0 | 6.17 | 5.06 | 4.25 | 1.65 | 0.64 | 0.41 |

| 5 | 6.78 | 5.66 | 4.75 | 1.80 | 0.81 | 0.60 |

| 10 | 7.82 | 6.47 | 5.16 | 1.77 | 0.93 | 0.78 |

| 15 | 9.02 | 7.15 | 4.35 | 2.01 | 1.07 | 1.01 |

| 20 | 7.94 | 6.27 | 2.93 | 1.67 | 0.95 | 0.87 |

| Glycerol (phr) | G′ (MPa) (0 °C) | G′ (MPa) (20 °C) | G′ (MPa) (60 °C) | G″ (MPa) (0 °C) | G″ (MPa) (20 °C) | G″ (MPa) (60 °C) |

|---|---|---|---|---|---|---|

| 0 | 21.79 | 8.20 | 6.43 | 24.74 | 1.97 | 0.51 |

| 5 | 28.19 | 9.46 | 6.81 | 35.96 | 2.79 | 0.81 |

| 10 | 26.70 | 10.12 | 7.08 | 29.83 | 2.64 | 0.92 |

| 15 | 25.84 | 9.78 | 6.05 | 27.70 | 2.51 | 1.11 |

| 20 | 24.22 | 8.97 | 3.84 | 24.55 | 2.39 | 1.19 |

| Glycerol (phr) | Tg (°C) | tan δ (0 °C) | tan δ (20 °C) | tan δ (60 °C) |

|---|---|---|---|---|

| 0 | −26.8 | 0.27 | 0.13 | 0.10 |

| 5 | −26.1 | 0.27 | 0.14 | 0.13 |

| 10 | −28.6 | 0.23 | 0.14 | 0.15 |

| 15 | −28.2 | 0.22 | 0.15 | 0.23 |

| 20 | −30.2 | 0.21 | 0.15 | 0.30 |

| Glycerol (phr) | Tg (°C) | tan δ (0 °C) | tan δ (20 °C) | tan δ (60 °C) |

|---|---|---|---|---|

| 0 | −7.4 | 1.14 | 0.24 | 0.08 |

| 5 | −5.1 | 1.28 | 0.30 | 0.12 |

| 10 | −7 | 1.12 | 0.26 | 0.13 |

| 15 | −7.4 | 1.07 | 0.26 | 0.18 |

| 20 | −6.8 | 1.01 | 0.27 | 0.31 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kruželák, J.; Hložeková, K.; Kvasničáková, A.; Džuganová, M.; Chodák, I.; Hudec, I. Application of Plasticizer Glycerol in Lignosulfonate-Filled Rubber Compounds Based on SBR and NBR. Materials 2023, 16, 635. https://doi.org/10.3390/ma16020635

Kruželák J, Hložeková K, Kvasničáková A, Džuganová M, Chodák I, Hudec I. Application of Plasticizer Glycerol in Lignosulfonate-Filled Rubber Compounds Based on SBR and NBR. Materials. 2023; 16(2):635. https://doi.org/10.3390/ma16020635

Chicago/Turabian StyleKruželák, Ján, Klaudia Hložeková, Andrea Kvasničáková, Michaela Džuganová, Ivan Chodák, and Ivan Hudec. 2023. "Application of Plasticizer Glycerol in Lignosulfonate-Filled Rubber Compounds Based on SBR and NBR" Materials 16, no. 2: 635. https://doi.org/10.3390/ma16020635

APA StyleKruželák, J., Hložeková, K., Kvasničáková, A., Džuganová, M., Chodák, I., & Hudec, I. (2023). Application of Plasticizer Glycerol in Lignosulfonate-Filled Rubber Compounds Based on SBR and NBR. Materials, 16(2), 635. https://doi.org/10.3390/ma16020635