Effect of Process Parameters on Weld Quality in Vortex- Friction Stir Welding of 6061-T6 Aluminum Alloy

Abstract

:1. Introduction

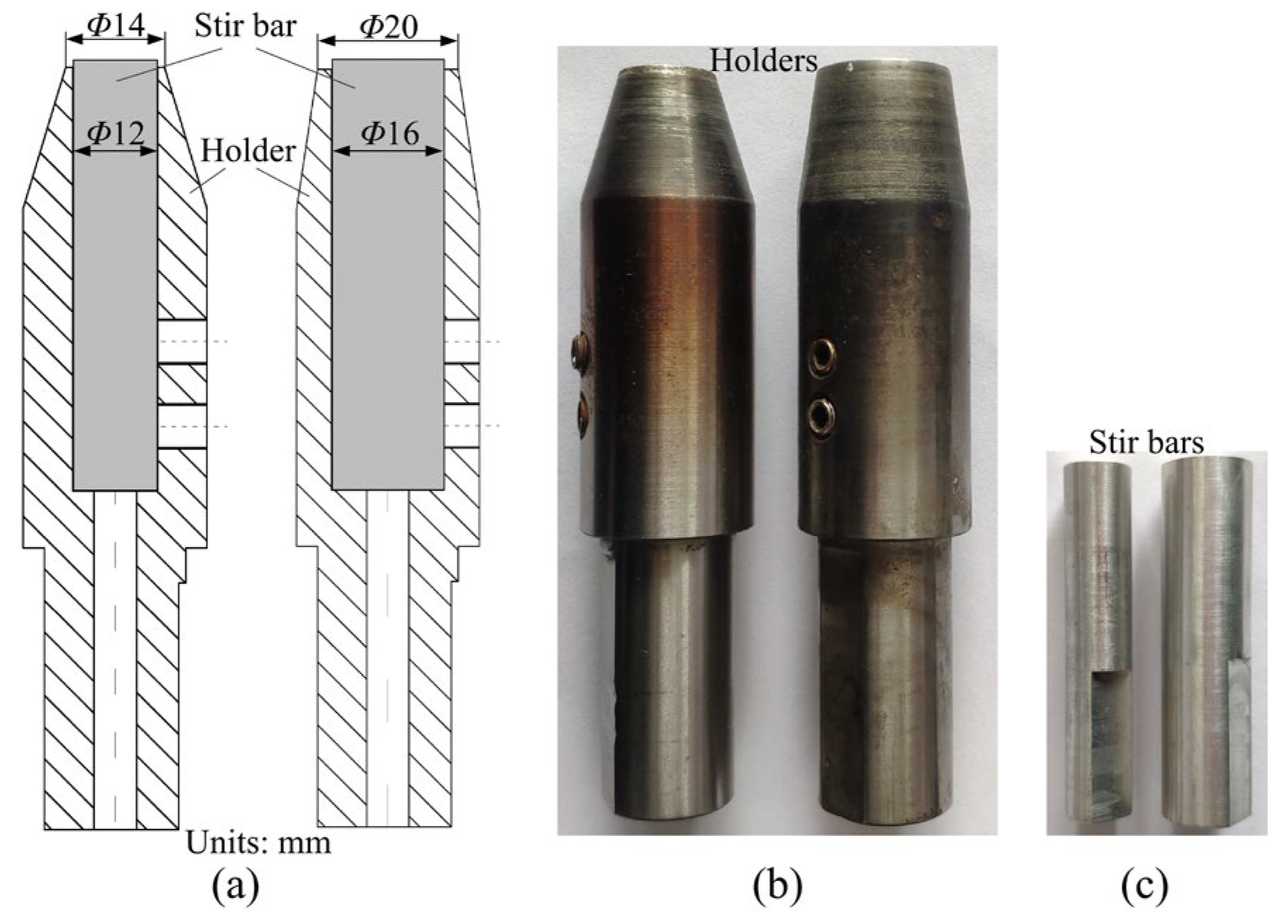

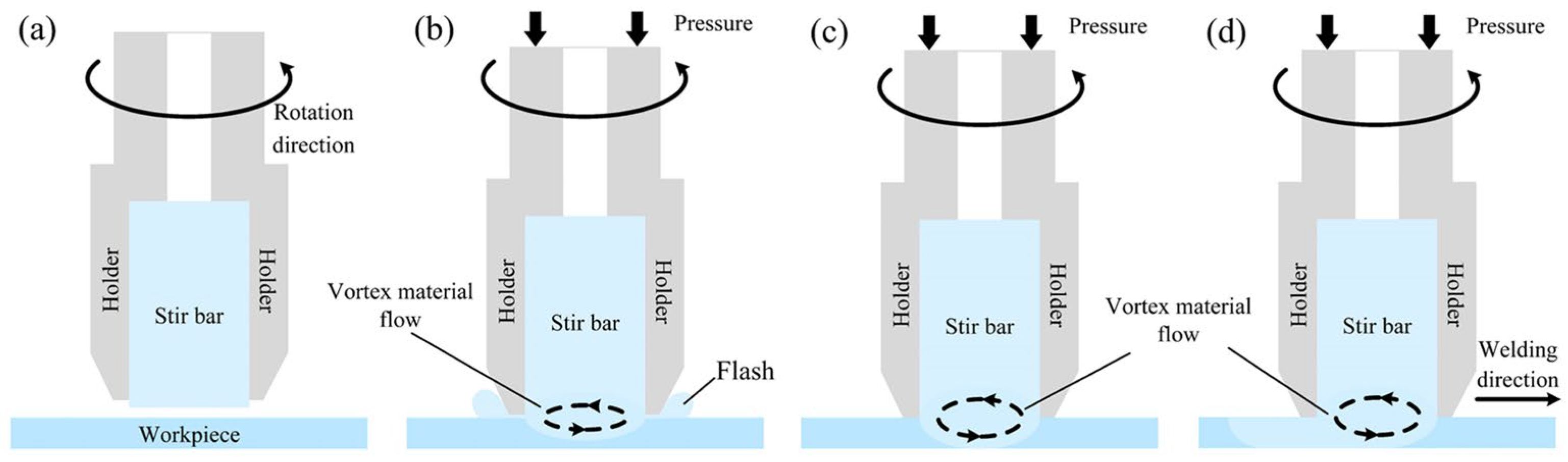

2. Experimental Section

2.1. Materials

2.2. Process Parameters

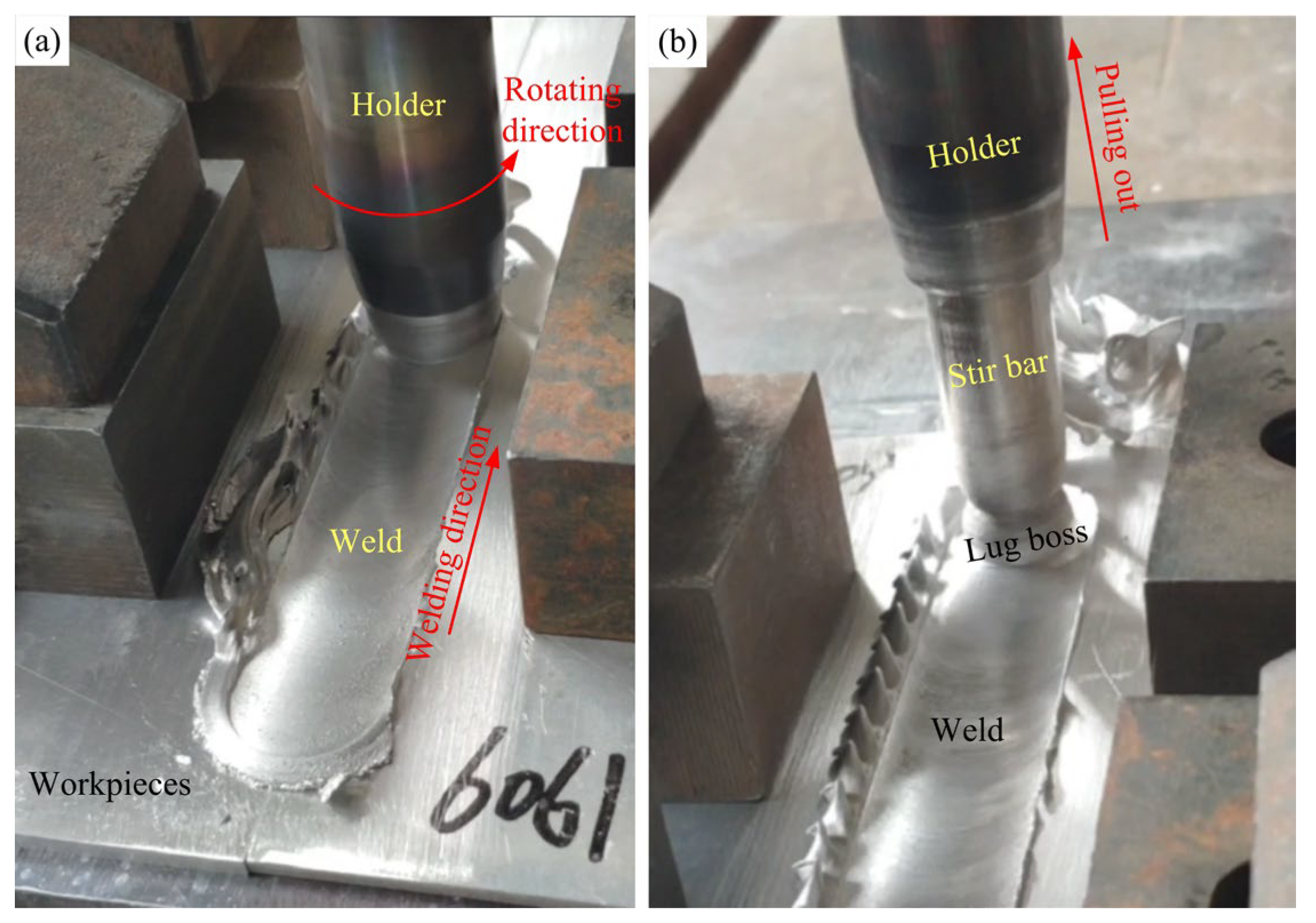

2.3. Welding Procedure

3. Results and Discussion

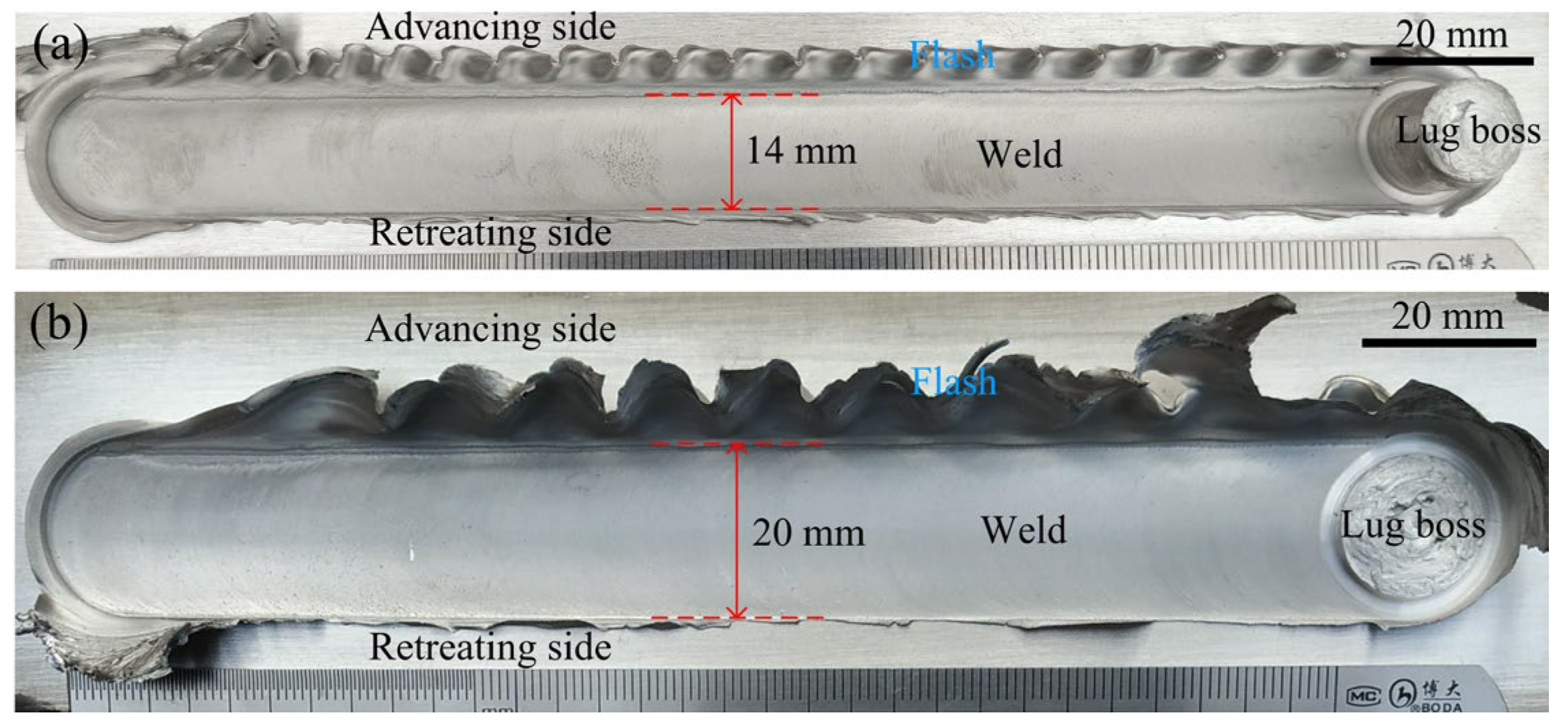

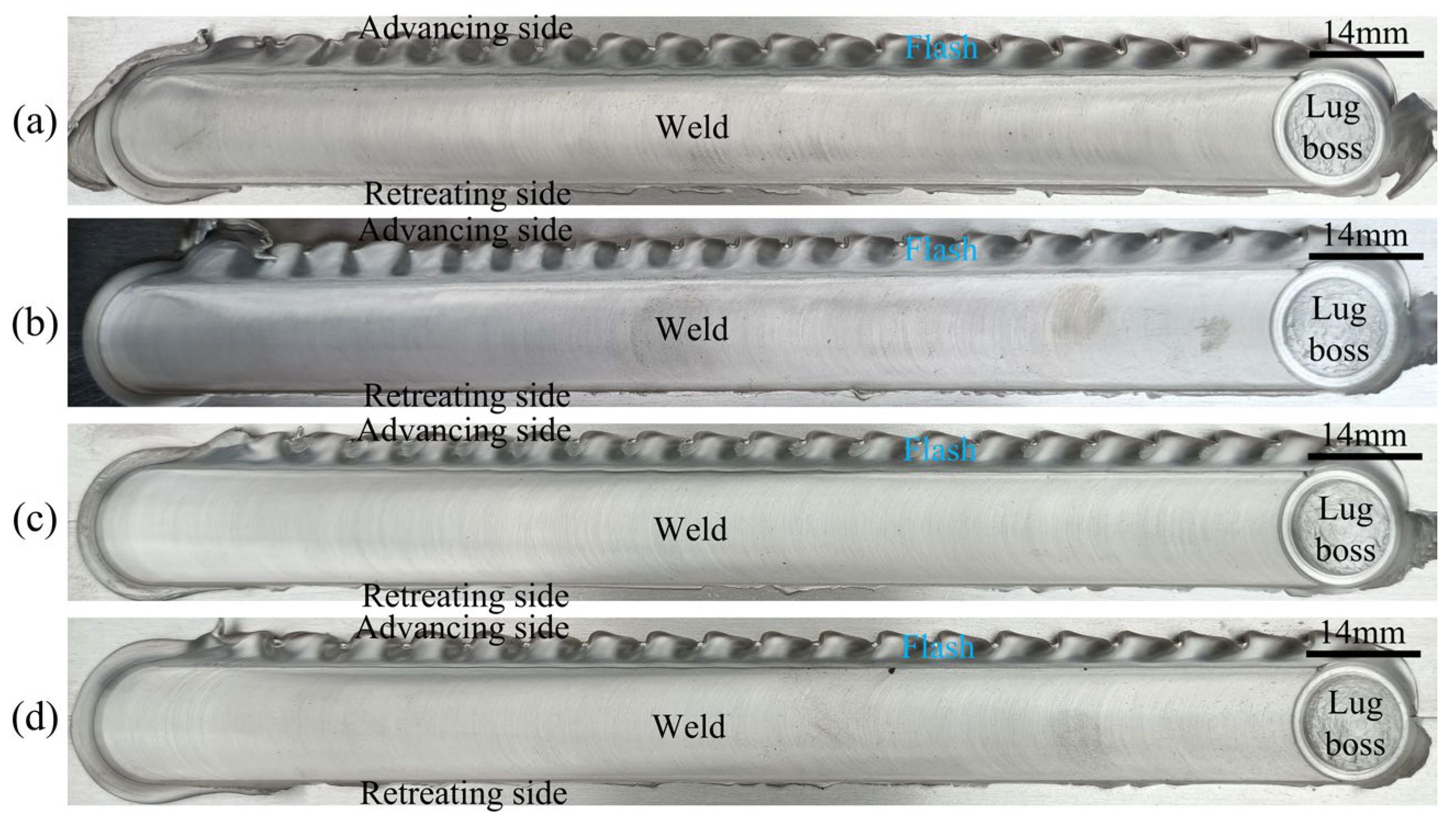

3.1. Weld Morphology

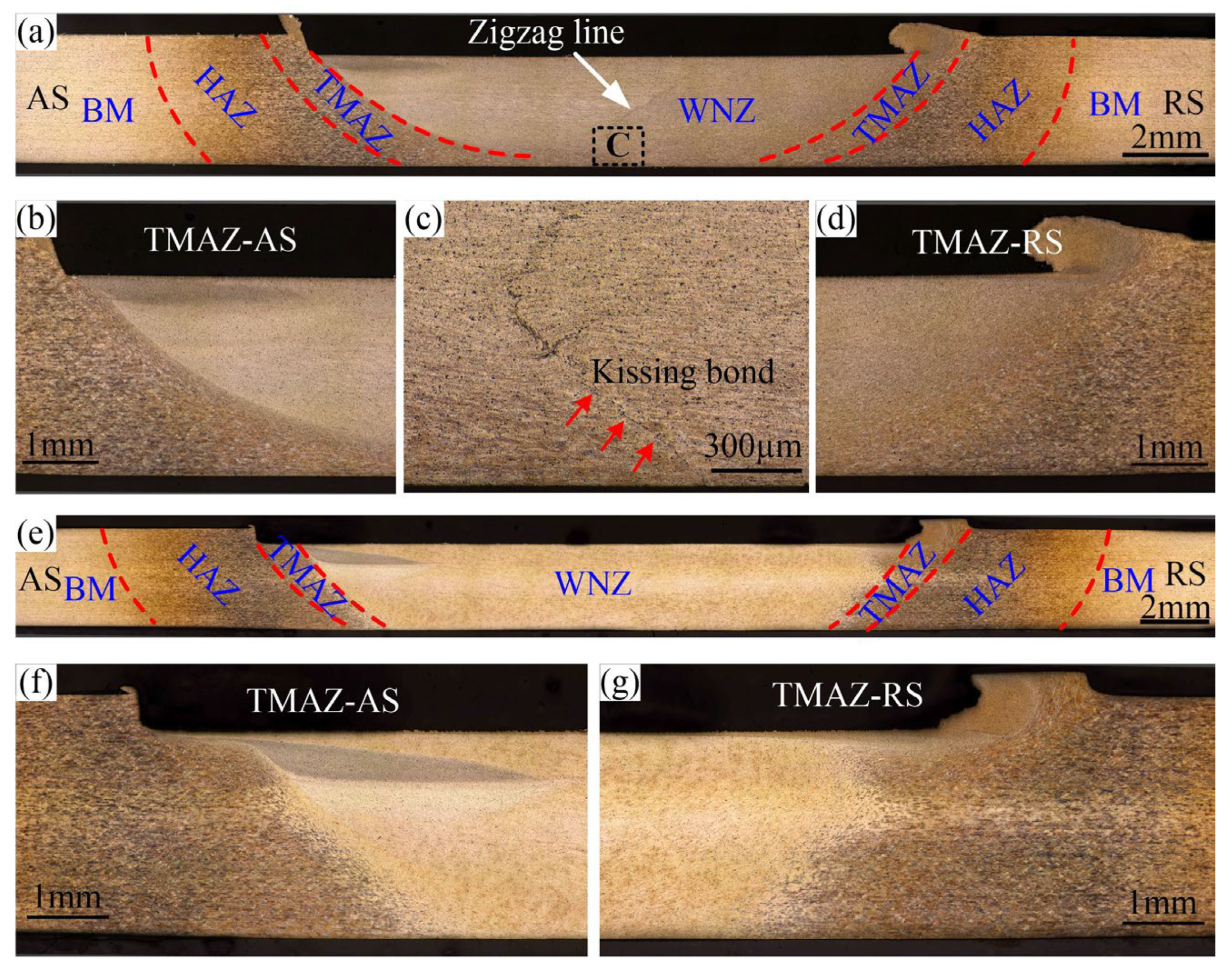

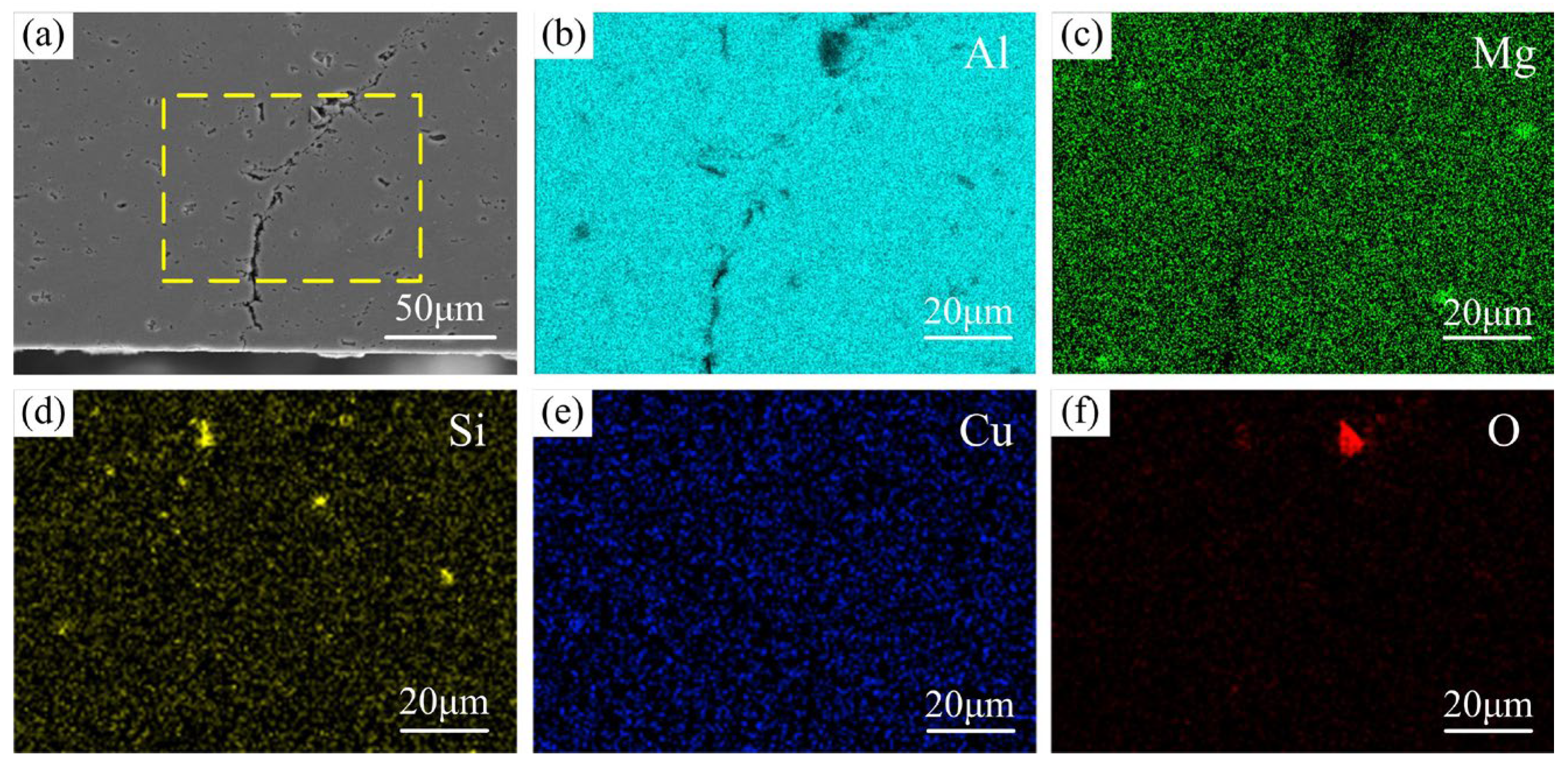

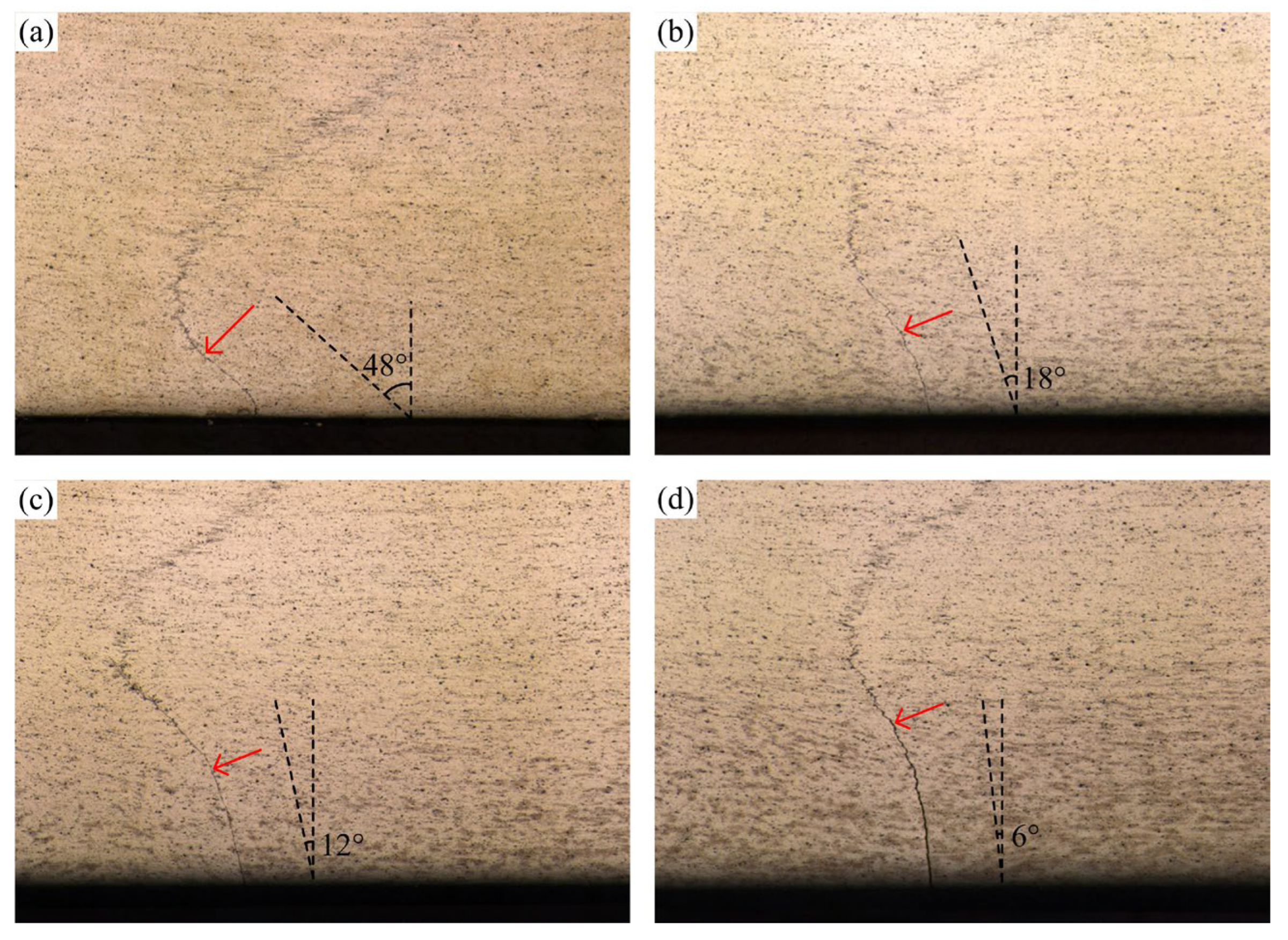

3.2. Weld Macrostructure

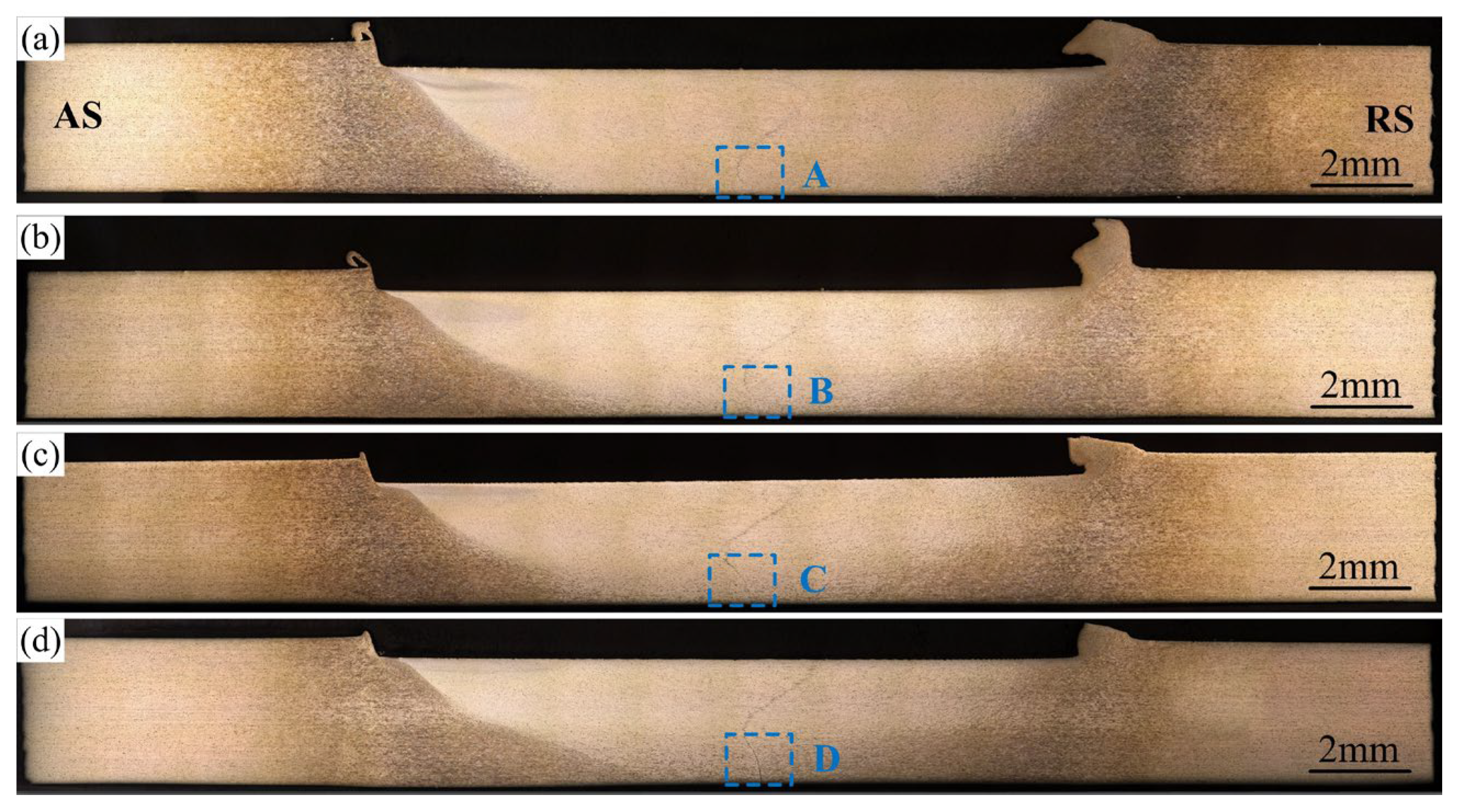

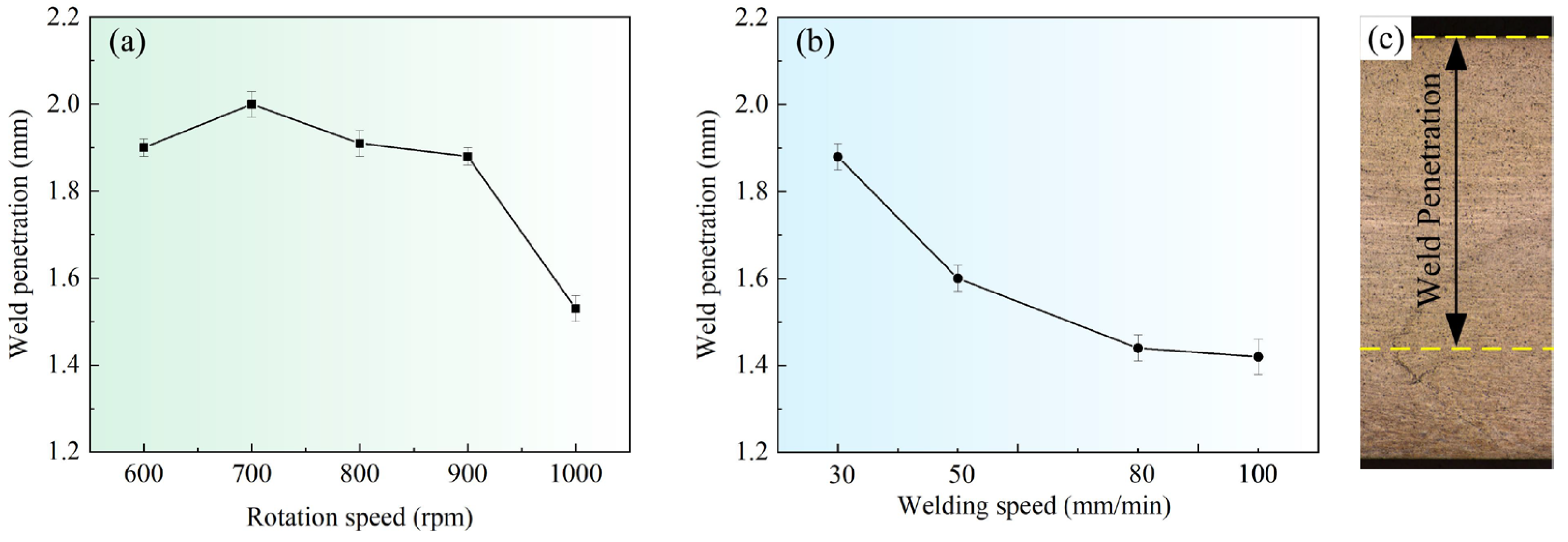

3.3. Weld Penetration

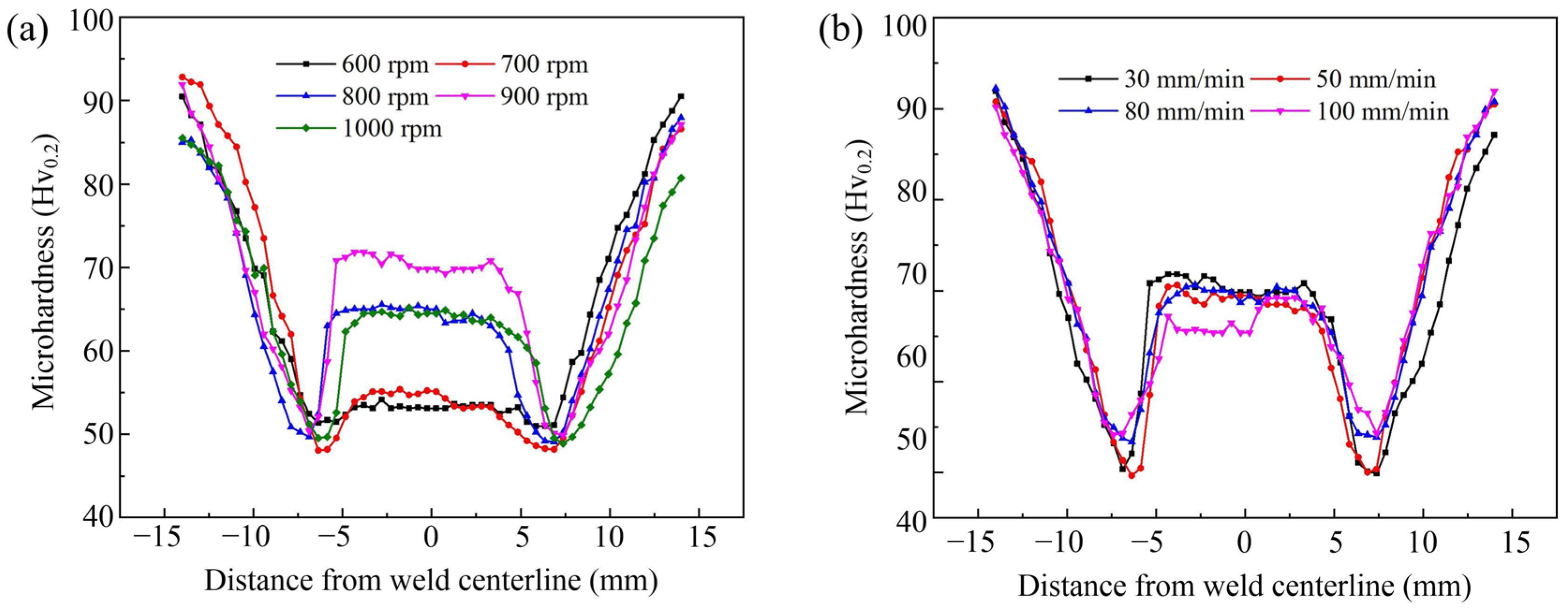

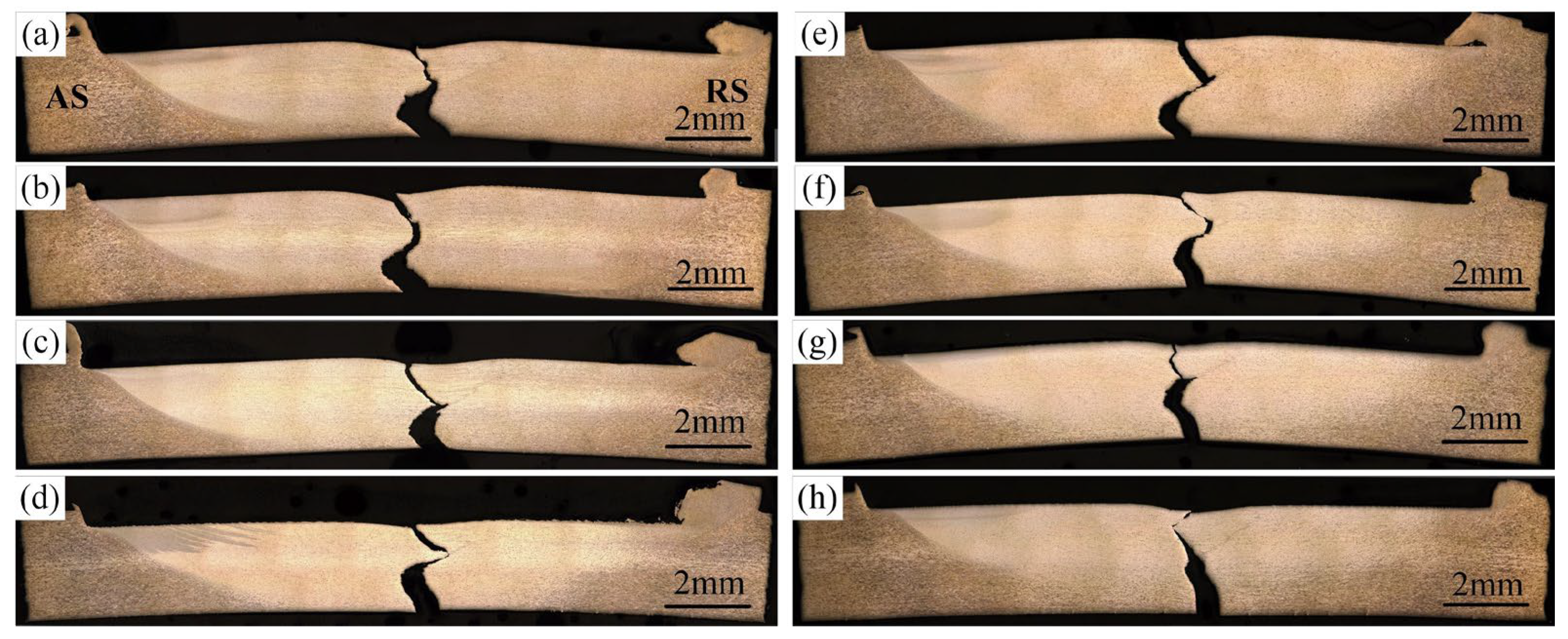

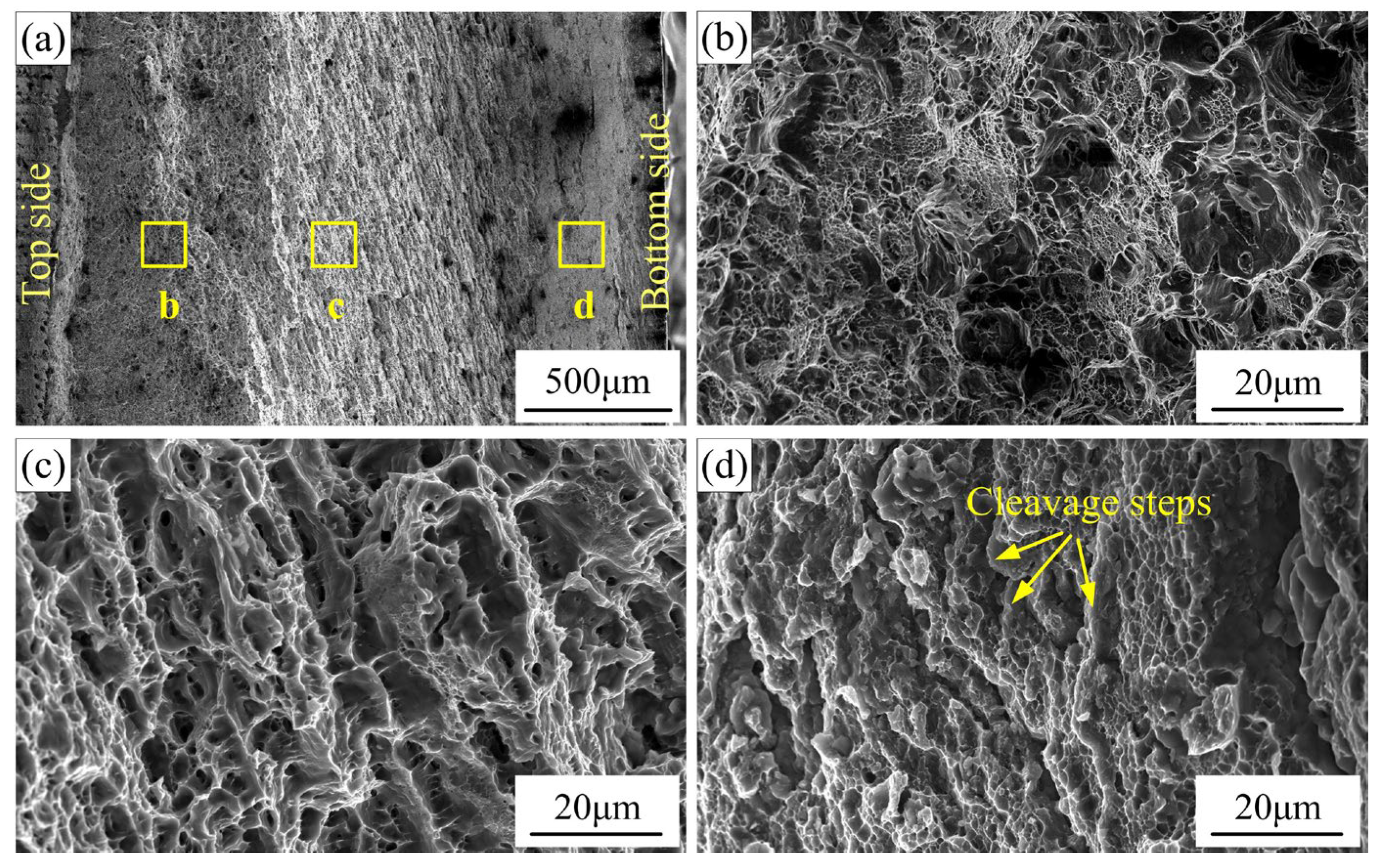

3.4. Mechanical Properties

4. Conclusions

- (1)

- A larger diameter of the stir bar can enhance the vortex material flow in VFSW, increase the heat input, and eliminate the incomplete-penetration defect. For a sheet of 3 mm in thickness, a stir bar of 16 mm in diameter is suitable to obtain a defect-free weld.

- (2)

- Owing to the resulting high temperature and large momentum input, the increase in rotation speed within limits can enhance the weld penetration and the mechanical properties of the WNZ. However, too high a rotation speed reduces the weld penetration and weakens the mechanical properties of the WNZ. With d = 12 mm and v = 30 mm/min, the maximum weld penetration reaches ~2 mm at ω = 700 rpm, and the maximum effective tensile strength reaches ~215 MPa at ω = 900 rpm.

- (3)

- Because of the decrease in the heat input per unit distance, the increase in welding speed reduces the weld penetration invariably but enhances the mechanical properties of the HAZ due to the over-aging becoming weak. However, it nearly does not affect the mechanical properties of the WNZ.

- (4)

- As a crack origin, the incomplete-penetration defect significantly weakens the ductility of the VFSW joint.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, L.; Li, N.; Childs PRN. Light-weighting in aerospace component and system design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Sun, X.; Han, X.; Dong, C.; Li, X. Applications of aluminum alloys in rail transportation. Adv. Alum. Compos. Alloy 2021, 9, 251–268. [Google Scholar]

- Verma, R.P.; Lila, M.K. A short review on aluminium alloys and welding in structural applications. Mater. Today Proc. 2021, 46, 10687–10691. [Google Scholar] [CrossRef]

- Çevik, B. Gas tungsten arc welding of 7075 aluminum alloy: Microstructure properties, impact strength, and weld defects. Mater. Res. Express 2018, 5, 066540. [Google Scholar] [CrossRef]

- Zhao, Q.; Guo, C.; Niu, K.; Zhao, J.; Huang, Y.; Li, X. Long-term corrosion behavior of the 7A85 aluminum alloy in an industrial-marine atmospheric environment. J. Mater. Res. Technol. 2021, 12, 1350–1359. [Google Scholar] [CrossRef]

- Mehdi, H.; Mishra, R.S. Effect of friction stir processing on mechanical properties and wear resistance of tungsten inert gas welded joint of dissimilar aluminum alloys. J. Mater. Eng. Perform. 2021, 30, 1926–1937. [Google Scholar] [CrossRef]

- Zhang, L.; Zhong, H.; Li, S.; Zhao, H.; Chen, J.; Qi, L. Microstructure, mechanical properties and fatigue crack growth behavior of friction stir welded joint of 6061-T6 aluminum alloy. Int. J. Fatigue 2020, 135, 105556. [Google Scholar] [CrossRef]

- Rezaei, A.; Ehsanifar, M.; Wood, D.A. Reducing welding repair requirements in refinery pressure vessel manufacturing: A case study applying six sigma principles. Int. J. Interact. Des. Manuf. 2019, 13, 1089–1102. [Google Scholar] [CrossRef]

- Roeen, G.; Yousefi, S.; Emadi, R.; Shooshtari, M.; Lotfian, S. Remanufacturing the AA5052 GTAW welds using friction stir processing. Metals 2021, 11, 749. [Google Scholar] [CrossRef]

- Bobba, S.; Tecchio, P.; Ardente, F.; Mathieux, F.; dos Santos, F.M.; Pekar, F. Analysing the contribution of automotive remanufacturing to the circularity of materials. Procedia CIRP 2020, 90, 67–72. [Google Scholar] [CrossRef]

- Vishnukumar, M.; Pramod, R.; Kannan, A.R. Wire arc additive manufacturing for repairing aluminium structures in marine applications. Mater. Lett. 2021, 299, 130112. [Google Scholar] [CrossRef]

- Yang, B.; Fu, Z.; Li, T.; Shan, M.; Guo, K.; Chen, B.; Lu, W.; Gou, G.; Gao, W. Microstructure and fracture toughness properties of CMT repairing welded 7075-T651 MIG welding joint. Mater. Res. Express 2020, 6, 1265d6. [Google Scholar] [CrossRef]

- Li, S.; Dong, H.; Wang, X.; Liu, Z.; Tan, Z.; Shangguan, L.; Lu, Q.; Zhong, S. Effect of repair welding on microstructure and mechanical properties of 7N01 aluminum alloy MIG welded joint. J. Manuf. Process. 2020, 54, 80–88. [Google Scholar] [CrossRef]

- Dunkerton, S.B.; Nicholas, D.E.; Sketchley, P.D. Repairing Defective Metal Workpiece–by Friction Welding with a Metal Plug. Great Britain Patent Application No. 9,125,978, 6 December 1991. [Google Scholar]

- Coletta, E.R.; Cantrell, M.A.; McCool, A. Friction plug weld repair geometric innovations. In Proceedings of the AeroMat2000, Seattle, WA, USA, 1 January 2000. [Google Scholar]

- Li, Z.X.; Cantrell, M.A.; Brown, R.J.; McCool, A. Process development and microstructural characterization on friction plug welded 2195 and 2219 Alloys. In Proceedings of the AeroMat2000, Washington, DC, USA, 1 January 2000. [Google Scholar]

- Huang, Y.X.; Han, B.; Tian, Y.; Liu, H.J.; Lv, S.X.; Feng, J.C.; Leng, J.S.; Li, Y. New technique of filling friction stir welding. Sci. Technol. Weld. Join. 2011, 16, 497–501. [Google Scholar] [CrossRef]

- Huang, Y.X.; Han, B.; Lv, S.X.; Feng, J.C.; Liu, H.J.; Leng, J.S.; Li, Y. Interface behaviours and mechanical properties of filling friction stir weld joining AA 2219. Sci. Technol. Weld. Join. 2012, 17, 225–230. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, D.; Nakata, K.; Tsumura, T.; Fujii, H.; Ikeuchi, K.; Michishita, Y.; Fujiya, Y.; Morimoto, M. New technique of self-refilling friction stir welding to repair keyhole. Sci. Technol. Weld. Join. 2012, 17, 649–655. [Google Scholar] [CrossRef]

- Ji, S.; Meng, X.; Huang, R.; Ma, L.; Gao, S. Microstructures and mechanical properties of 7N01-T4 aluminum alloy joints by active-passive filling friction stir repairing. Mater. Sci. Eng. A 2016, 664, 94–102. [Google Scholar] [CrossRef]

- Reimann, M.; Goebel, J.; Gartner, T.M.; dos Santos, J.F. Refilling termination hole in AA 2198–T851 by refill friction stir spot welding. J. Mater. Process. Technol. 2017, 245, 157–166. [Google Scholar] [CrossRef]

- Liu, X.; Zhen, Y.; Shen, Z.; Chen, H.; Li, W.; Guo, W.; Yue, Z. A modified friction stir welding process based on vortex material flow. Chin. J. Mech. Eng. 2020, 33, 90. [Google Scholar] [CrossRef]

- Liu, X.; Zhen, Y.; Chen, H.; Shen, Z. Study on process characteristics of friction stir welding based on vortex material flow using 6061-T6 aluminum alloy. Int. J. Adv. Manuf. Technol. 2022, 119, 5025–5034. [Google Scholar] [CrossRef]

- Liu, X.; Sun, Z. Numerical simulation of vortex- friction stir welding based on internal friction between identical materials. Int. J. Heat Mass Transfer. 2022, 185, 122418. [Google Scholar] [CrossRef]

- Liu, X.; Zhen, Y.; He, X.; Chen, H.; Shen, Z. Vortex- friction stir welding process based on internal friction between identical materials. Acta Aeronaut. Et Astronaut. Sin. 2022, 43, 625012. (In Chinese) [Google Scholar]

- Sato, Y.S.; Takauchi, H.; Park, S.H.C.; Kokawa, H. Characteristics of the kissing-bond in friction stir welded Al alloy 1050. Mater. Sci. Eng. A. 2005, 405, 333–338. [Google Scholar] [CrossRef]

- Ren, S.R.; Ma, Z.Y.; Chen, L.Q. Effect of initial butt surface on tensile properties and fracture behavior of friction stir welded Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A. 2008, 479, 293–299. [Google Scholar] [CrossRef]

- Liu, H.J.; Chen, Y.C.; Feng, J.C. Effect of zigzag line on the mechanical properties of friction stir welded joints of an Al–Cu alloy. Scr. Mater. 2006, 55, 231–234. [Google Scholar] [CrossRef]

- Ogunsemi, B.; Abioye, T.; Ogedengbe, T.; Zuhailawati, H. A review of various improvement strategies for joint quality of AA 6061-T6 friction stir weldments. J. Mater. Res. Technol. 2021, 11, 1061–1089. [Google Scholar] [CrossRef]

- Liu, X.C.; Wang, Q.; Pei, X.J.; Li, Y.Z.; Zhen, Y.Q.; Shen, Z.K.; Chen, H.Y. Effect of vortex- friction stir welding on microstructural evolution of 6061-T6 aluminum alloy. Mater. Charact. 2023, 195, 112544. [Google Scholar] [CrossRef]

- Wang, C.Y. Study on Rapid Solution and Aging Treatment Process and Mechanism of 6061 Aluminum Alloy Sheets. Master’s Thesis, Harbin Institute of Technology, Harbin, China, 2021. (In Chinese). [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Li, W.; Zhen, Y.; Jia, L.; Li, Y.; Pei, X. Effect of Process Parameters on Weld Quality in Vortex- Friction Stir Welding of 6061-T6 Aluminum Alloy. Materials 2023, 16, 873. https://doi.org/10.3390/ma16020873

Liu X, Li W, Zhen Y, Jia L, Li Y, Pei X. Effect of Process Parameters on Weld Quality in Vortex- Friction Stir Welding of 6061-T6 Aluminum Alloy. Materials. 2023; 16(2):873. https://doi.org/10.3390/ma16020873

Chicago/Turabian StyleLiu, Xiaochao, Wentao Li, Yunqian Zhen, Luanluan Jia, Yongzhe Li, and Xianjun Pei. 2023. "Effect of Process Parameters on Weld Quality in Vortex- Friction Stir Welding of 6061-T6 Aluminum Alloy" Materials 16, no. 2: 873. https://doi.org/10.3390/ma16020873

APA StyleLiu, X., Li, W., Zhen, Y., Jia, L., Li, Y., & Pei, X. (2023). Effect of Process Parameters on Weld Quality in Vortex- Friction Stir Welding of 6061-T6 Aluminum Alloy. Materials, 16(2), 873. https://doi.org/10.3390/ma16020873