Evaluation of Flexural Toughness of Concrete Reinforced with High-Performance Steel Fiber

Abstract

:1. Introduction

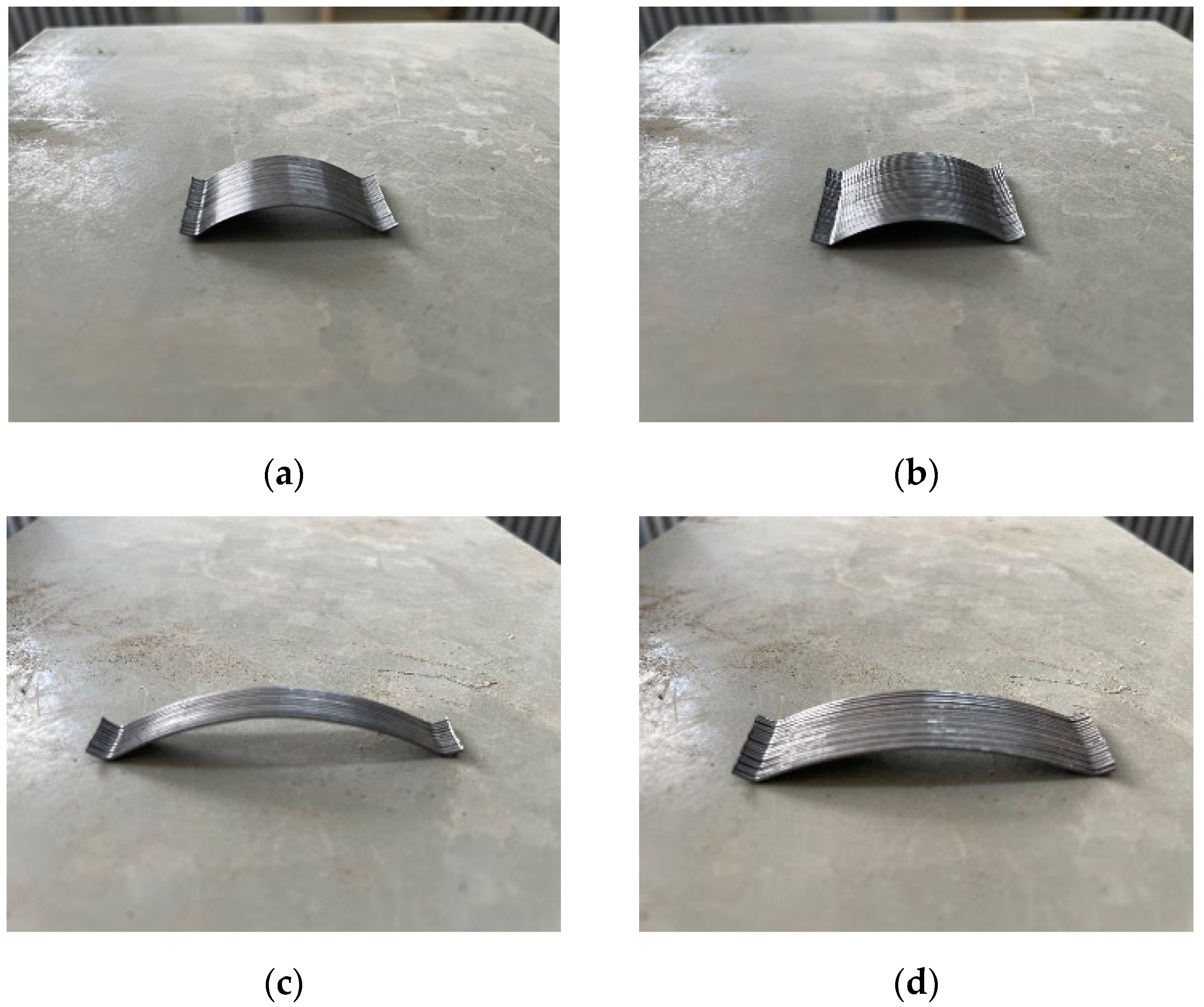

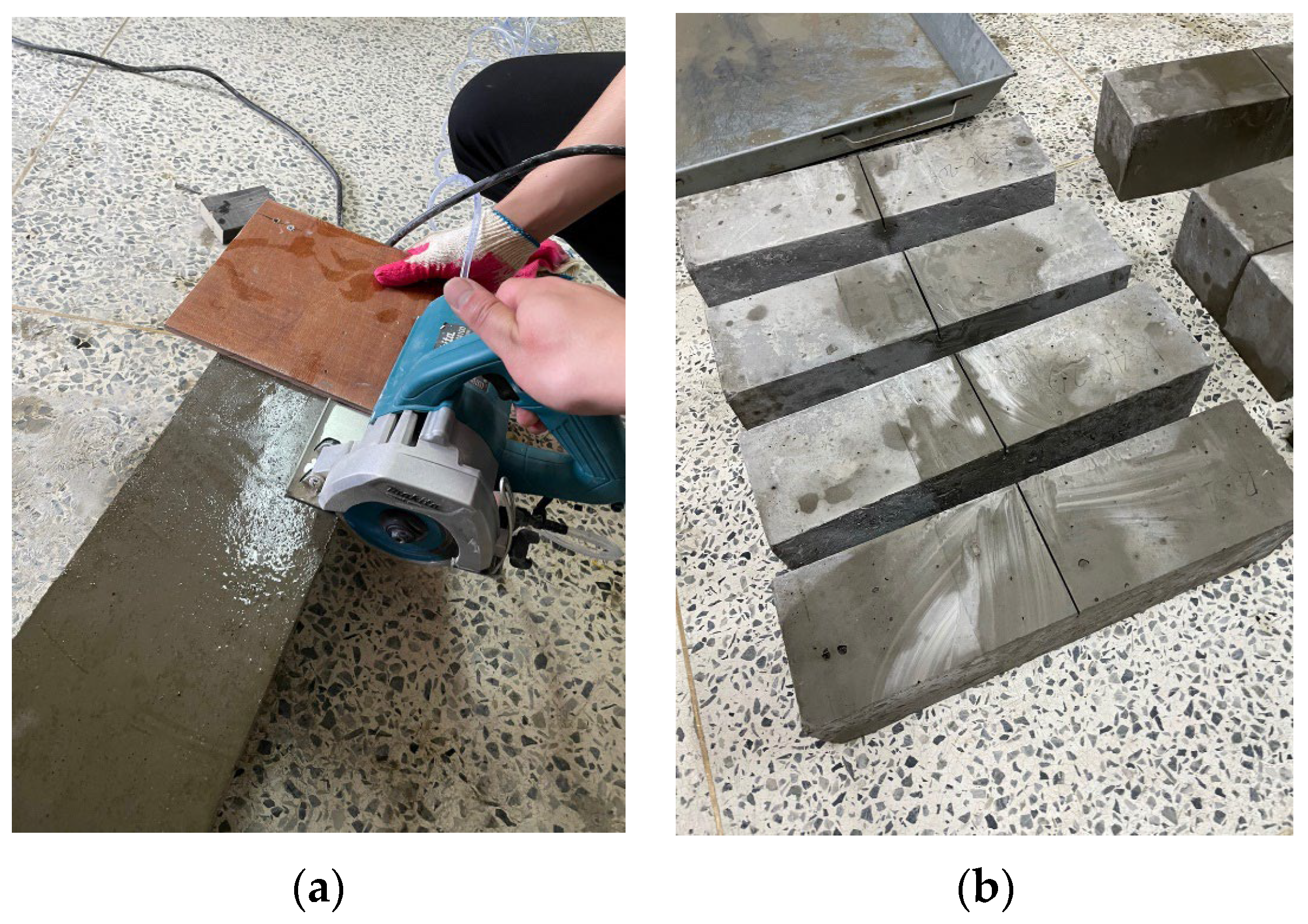

2. Flexural Test on Arched SFRC

2.1. Overview

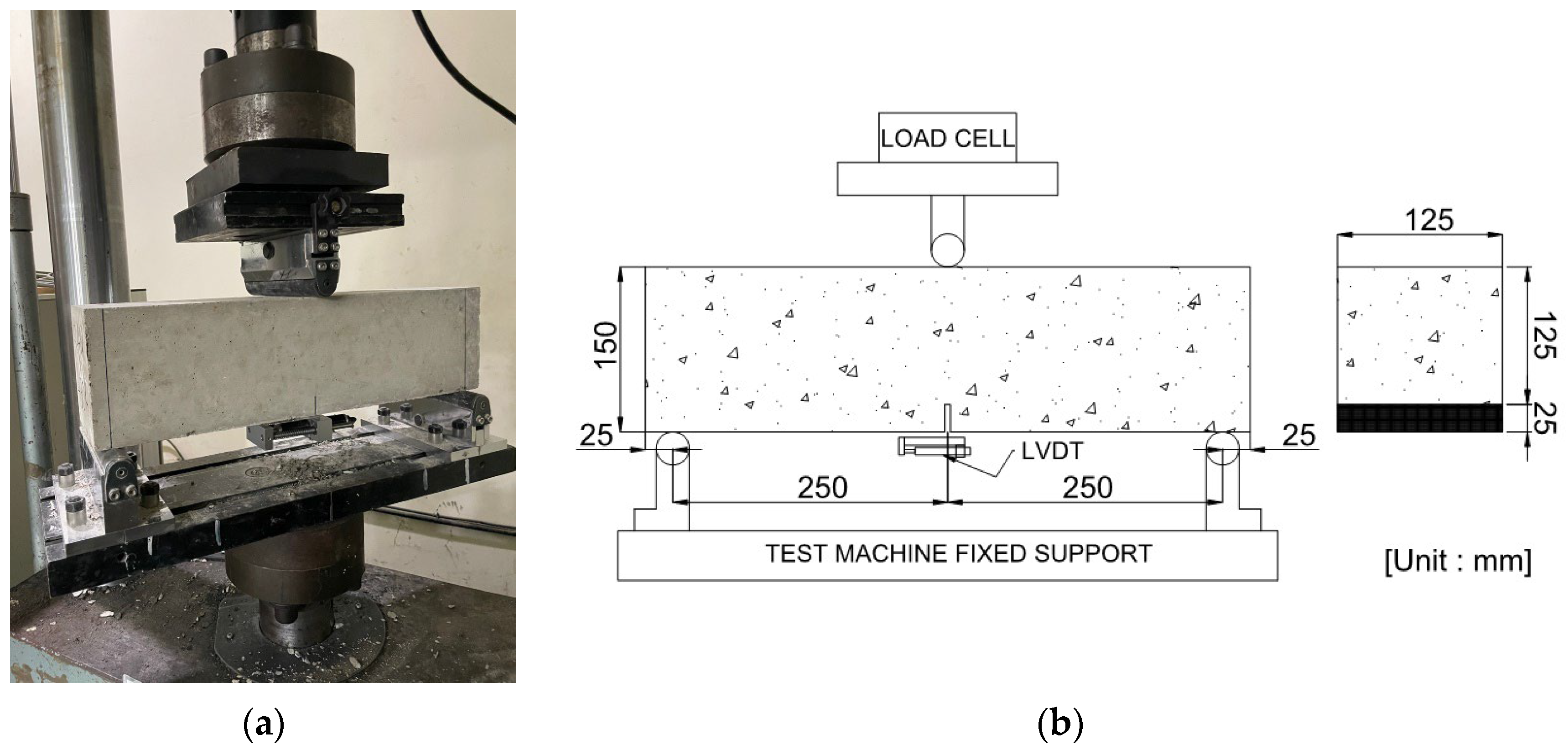

2.2. Experimental Method

2.3. Residual Flexural Strength and Energy Absorption Capacity

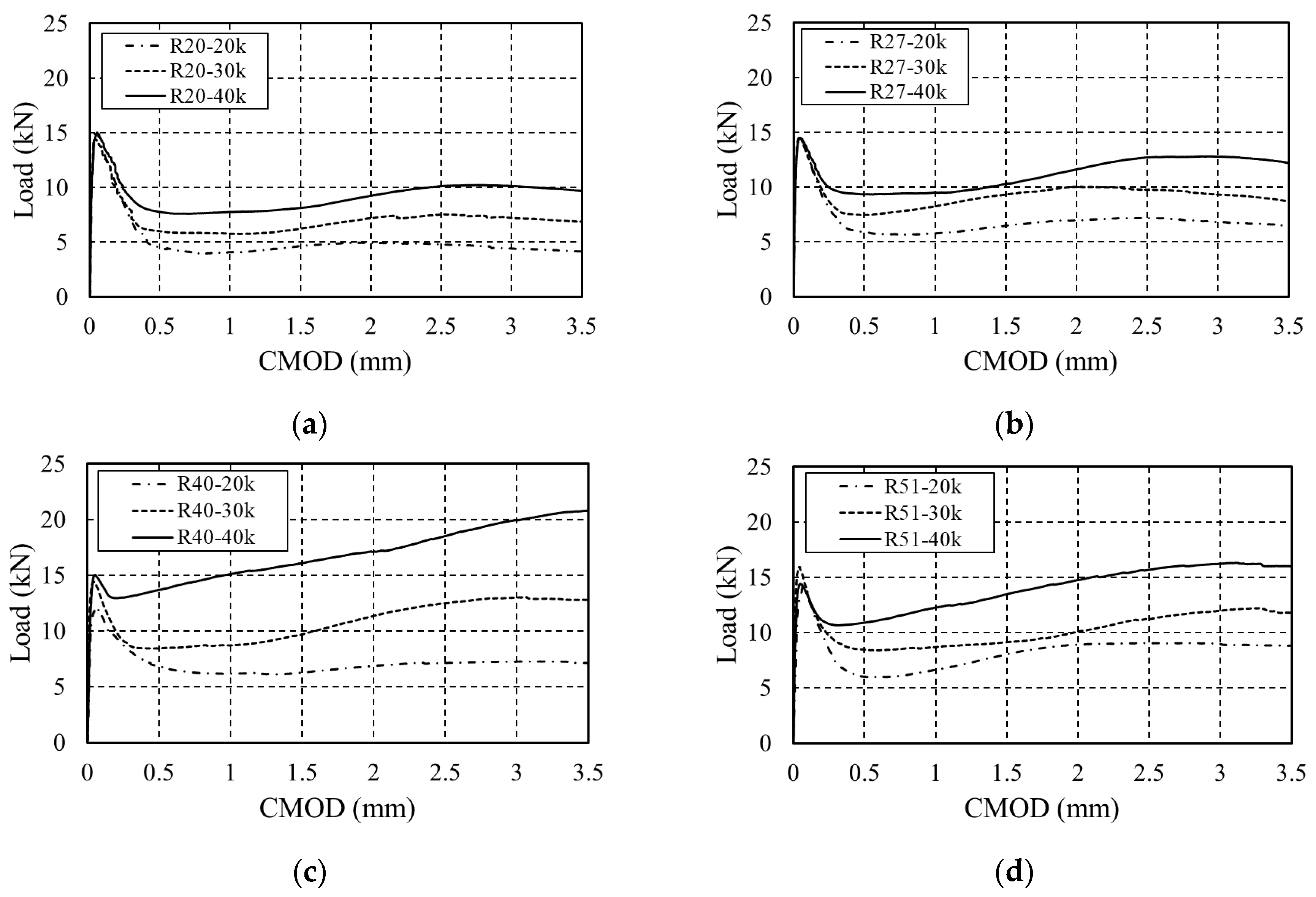

3. Flexural Behavior Measurement Results and Analysis for Arched SFRC

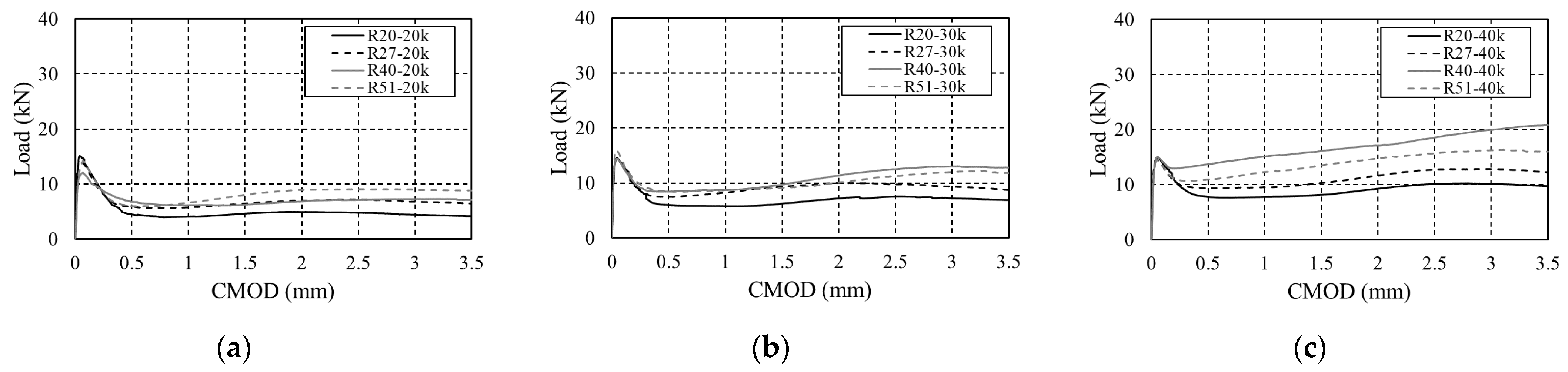

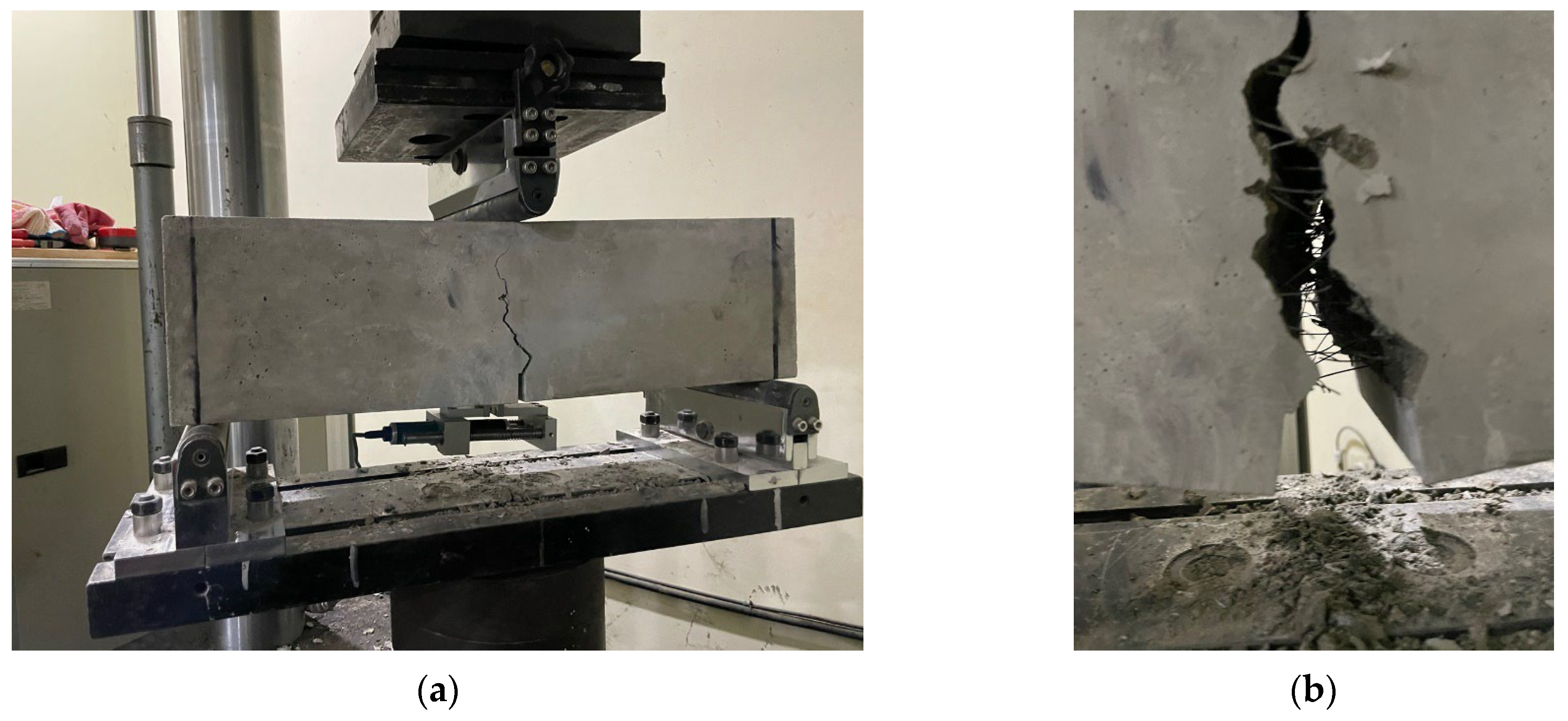

3.1. Results of Flexural Test

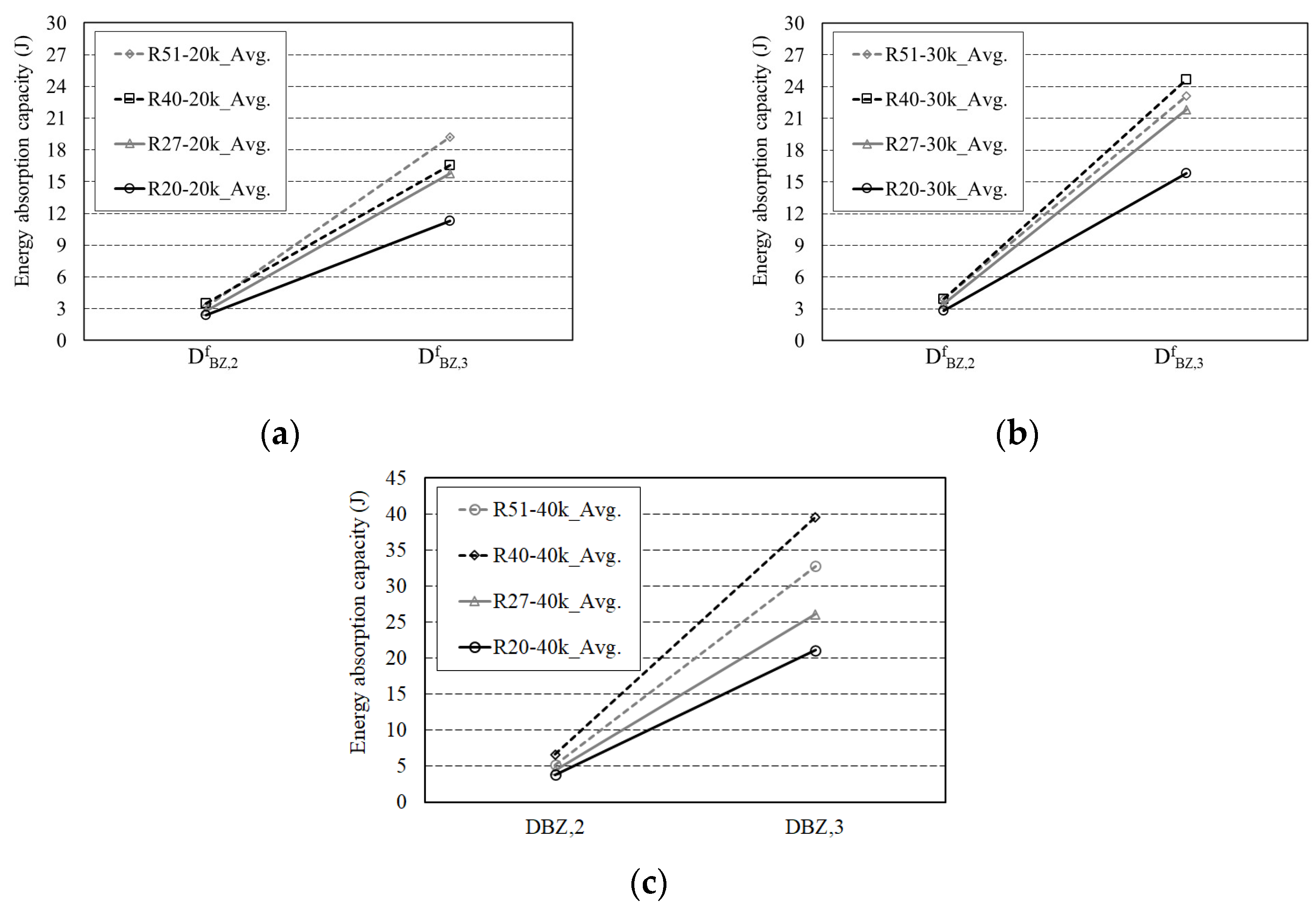

3.2. Energy Absorption Capacity

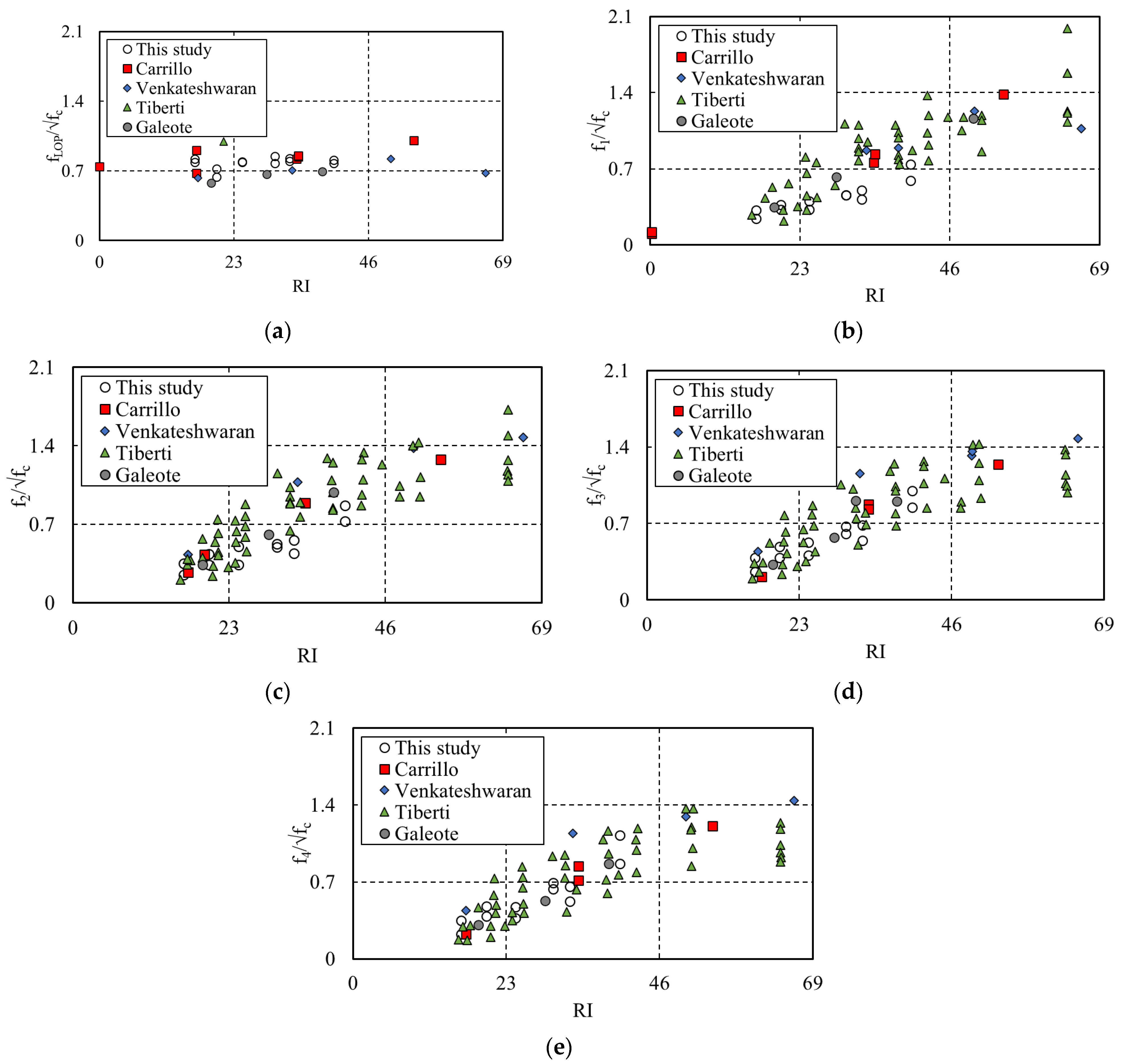

4. Results of Residual Stress Measurement and Analysis for Arched SFRC

5. Conclusions

- Arched SFRC showed no difference in the residual flexural stress of the LOP section depending on the fiber geometry and content. The residual flexural stress after cracking increased by approximately 34.14–73.83% in the serviceability limit state and 57.38–111.06% in the ultimate limit state as the fiber content increased. In addition, the residual flexural stress increased by approximately 30–114.5% depending on the fiber geometry. The specimen mixed with the R40 fiber exhibited the highest residual stress.

- When classifying the SFRC specimens according to the Model Code 2010, R20-20k and R40-20k were found to belong to class C. Class D included R20-30k and 40k and R27-20k, while class E included R27-30k and 40k, R40-30k and 40k, and R51-20k, 30k, and 40k. The specimens with high fiber curvatures and fiber content tended to belong to high classes.

- The energy absorption capacity of arched SFRC increased with increasing curvature and fiber content of fibers. The R40-40k specimen showed the highest energy absorption capacity. The capacity increased by approximately 48.87–138.88% as the content of the R40 fiber increased.

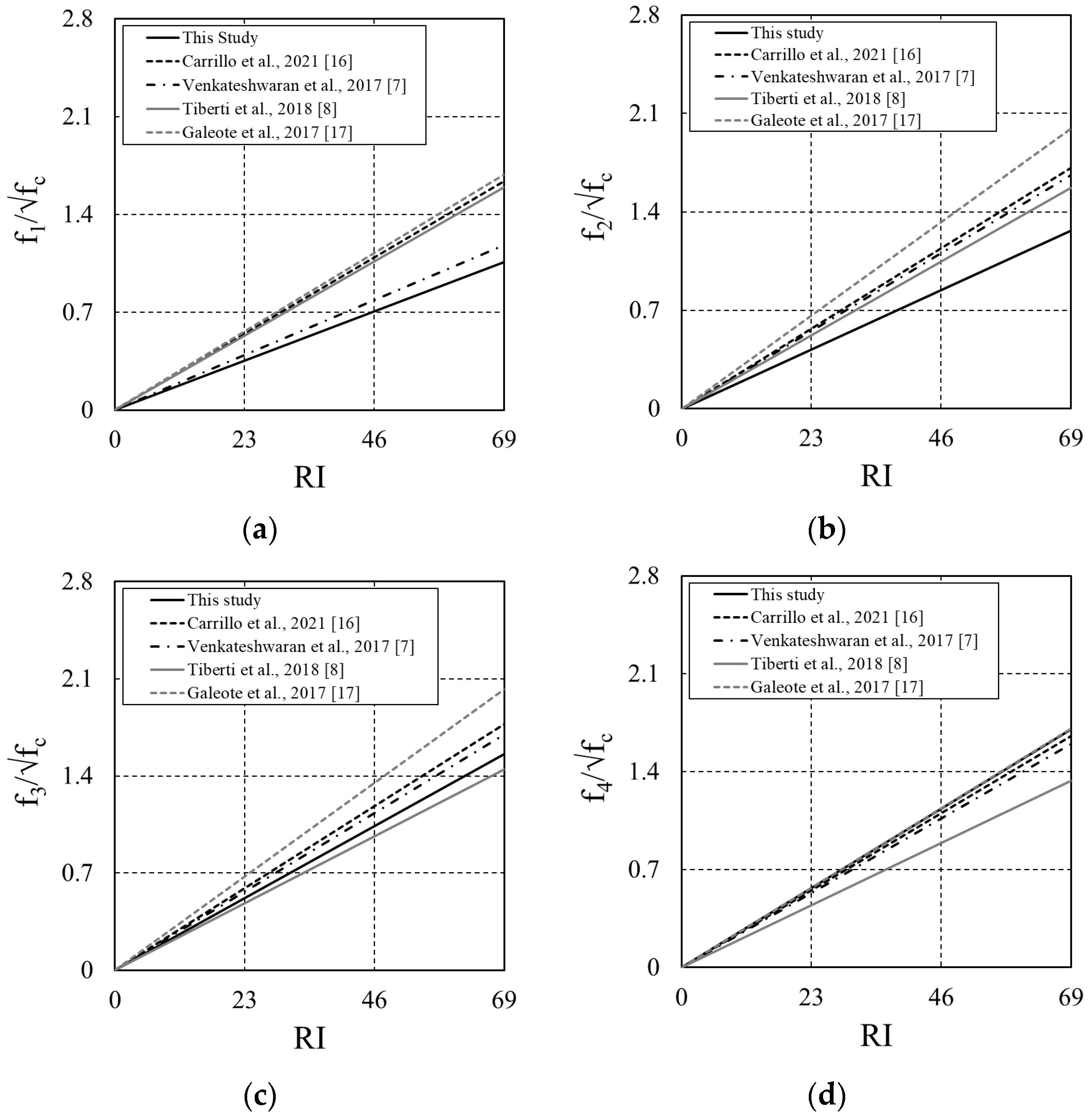

- The comparison of the experimental results of this study to those of previous studies that implemented hooked steel fiber, i.e., Carrillo et al., Venkateshwaran et al., Tiberti et al., Galeote et al. [7,8,16,17] confirmed that the arched steel fibers used exhibited comparable performance to the hooked steel fibers. In the proportional linearity section, the difference between hooked and arched steel fibers was approximately 3.75%. In addition, the R2 value of the trend lines confirmed the reliability of the experimental results; the R2 value, ranged from 0.78–0.86.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bentur, A.; Mindess, S. Fibre Reinforced Cementitious Composites, 2nd ed.; Taylor & Francis Group: London, UK; New York, NY, USA, 2006. [Google Scholar]

- Aci Commitee. 360R-06: Design of Slabs-on-Ground; American Concrete Institute: Farmington Hills, MI, USA, 2006. [Google Scholar]

- Aci Commitee. 544.4R-18: Guide to Design with Fiber-Reinforced Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2018. [Google Scholar]

- Choi, W.C.; Jung, K.Y.; Jang, S.J.; Yun, H.D. The Influence of Steel Fiber Tensile Strengths and Aspect Ratios on the Fracture Properties of High-Strength Concrete. Materials 2019, 12, 2105. [Google Scholar] [CrossRef] [PubMed]

- Jin, A.H.; Kim, D.H.; Yun, H.D.; Kim, S.W.; Park, W.S. Residual Flexural Tensile Strength of 60 MPa Concrete Reinforced with 2000 MPa High-Strength Hooked-End Steel Fibers. J. Korea Concr. Inst. 2023, 35, 79–90. [Google Scholar] [CrossRef]

- Kim, D.H.; Jang, S.J.; Kim, S.W.; Park, W.S.; Yun, H.D. Effect of hooked-end steel fiber volume fraction and aspect ratio on flexural and compressive properties of concrete. J. Korea Inst. Struct. Maint. Insp. 2021, 25, 40–47. [Google Scholar]

- Venkateshwaran, A.; Tan, K.H.; Li, Y. Residual Flexural Strengths of Steel Fiber Reinforced Concrete with Multiple Hooked-End Fibers. Struct. Concr. 2017, 19, 352–365. [Google Scholar] [CrossRef]

- Tiberti, G.; Germano, F.; Mudadu, A.; Plizzari, G.A. An Overview of the Flexural Post-Cracking Behavior of Steel Fiber Reinforced Concrete. Struct. Concr. 2018, 19, 695–718. [Google Scholar] [CrossRef]

- Sakthivel, P.B.; Aravind, S.V. Flexural Strength and Toughness of Steel Fiber Reinforced Concrete Beams. Asian J. Civ. Eng. 2020, 21, 1309–1330. [Google Scholar] [CrossRef]

- Chen, G.; Gao, D.; Zhu, H.; Yuan, J.S.; Xiao, X.; Wang, W. Effects of Novel Multiple Hooked-end Steel Fibers on Flexural Tensile Behaviour of Notched Concrete Beams with Various Strength Grades. Structures 2021, 33, 3644–3654. [Google Scholar] [CrossRef]

- Wang, S.; Zhu, H.; Liu, F.; Cheng, S.; Wang, B.; Yang, L. Effects of Steel Fibers and Concrete Strength on Flexural Toughness of Ultra-High Performance Concrete with Coarse Aggregate. Case Stud. Constr. Mater. 2022, 17, e01170. [Google Scholar] [CrossRef]

- ACI 318; Building Code Requirements for Structural Concrete. American Concrete Institute: Farmington Hills, MI, USA, 2014.

- EN 14651; Test Method for Metallic Fibered Concrete-Measuring the Flexural Tensile Strength (Limit of Proportionality (LOP), Residual. European Committee for Standardization: Brussels, Belgium, 2005.

- RILEM TC 162-TDF; Test and Design Methods for Steel Fibre Reinforced Concrete. RILEM Technical Committees: Brussels, Belgium, 2002.

- CEB CEP-FIP Model Code. Lausanne, Switzerland, International Federation for Structural Concrete (Fib); Committee Euro-International du Beton (CEB): Lausanne, Switzerland, 2010. [Google Scholar]

- Carrillo, J.; Vargas, J.D.; Arroyo, O. Correlation Between Flexural-Tensile Performance of Concrete Reinforced with Hooked-End Steel Fibers Using American and European Standards. J. Mater. Civ. Eng. 2021, 33, 04021211. [Google Scholar] [CrossRef]

- Galeote, E.; Blanco, A.; Cavalaro, S.H.P.; Fuente, A. Correlation Between the Barcelona Test and the Bending Test in Fibre Reinforced Concrete. Constr. Build. Mater. 2017, 152, 529–538. [Google Scholar] [CrossRef]

| W/B (%) | S/a (%) | Unit Weight (kg/m3) | AD, B *% | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| W | C | FA | BS | S | CS | G | S. F | |||

| 36.4 | 55.1 | 160 | 286 | 66 | 88 | 662 | 283 | 770 | 20 | 1.4 |

| 30 | ||||||||||

| 40 | ||||||||||

| Steel Fiber Type | Length | Content (kg/m3) | Tensile Strength of Steel Fibers (MPa) | Compressive Strength of Concrete (MPa) | Number of Specimens |

|---|---|---|---|---|---|

| Steel fiber 65 | R20 | 20 | 1250 | 35 | 4 |

| 30 | 4 | ||||

| 40 | 4 | ||||

| R27 | 20 | 4 | |||

| 30 | 4 | ||||

| 40 | 4 | ||||

| Steel fiber 80 | R40 | 20 | 1100 | 4 | |

| 30 | 4 | ||||

| 40 | 4 | ||||

| R51 | 20 | 4 | |||

| 30 | 4 | ||||

| 40 | 4 |

| Fiber Geometry | Fiber Content (kg/m3) | FLOP (MPa) | F1 (MPa) | F2 (MPa) | F3 (MPa) | F4 (MPa) |

|---|---|---|---|---|---|---|

| R20 | 20 | 4.84 | 1.43 | 1.48 | 1.53 | 1.33 |

| 30 | 4.64 | 1.92 | 1.99 | 2.41 | 2.20 | |

| 40 | 4.88 | 2.49 | 2.60 | 3.23 | 3.10 | |

| R27 | 20 | 4.66 | 1.89 | 2.08 | 2.30 | 2.07 |

| 30 | 4.68 | 2.39 | 2.99 | 3.12 | 2.79 | |

| 40 | 4.71 | 2.99 | 3.29 | 4.07 | 3.91 | |

| R40 | 20 | 3.79 | 2.17 | 2.01 | 2.28 | 2.29 |

| 30 | 4.59 | 2.70 | 3.10 | 3.99 | 4.09 | |

| 40 | 4.79 | 4.38 | 5.15 | 5.93 | 6.66 | |

| R51 | 20 | 4.28 | 1.92 | 2.57 | 2.90 | 2.82 |

| 30 | 5.02 | 2.71 | 2.92 | 3.59 | 3.77 | |

| 40 | 4.61 | 3.49 | 4.31 | 5.02 | 5.12 |

| Description | F1/FLOP | F3/F1 | Class |

|---|---|---|---|

| R20-20k | 0.30 | 1.07 | C |

| R20-30k | 0.41 | 1.25 | D |

| R20-40k | 0.51 | 1.22 | D |

| R27-20k | 0.41 | 1.22 | D |

| R27-30k | 0.51 | 1.31 | E |

| R27-40k | 0.64 | 1.36 | E |

| R40-20k | 0.57 | 1.05 | C |

| R40-30k | 0.59 | 1.48 | E |

| R40-40k | 0.91 | 1.35 | E |

| R51-20k | 0.45 | 1.51 | E |

| R51-30k | 0.54 | 1.33 | E |

| R51-40k | 0.76 | 1.44 | E |

| Description | DfBZ,2 | DfBZ,3 |

|---|---|---|

| R20-20k_Avg. | 2.41 | 11.31 |

| R20-30k_Avg. | 2.80 | 15.81 |

| R20-40k_Avg. | 3.83 | 21.14 |

| R27-20k_Avg. | 2.81 | 15.78 |

| R27-30k_Avg. | 3.48 | 21.85 |

| R27-40k_Avg. | 4.43 | 26.10 |

| R40-20k_Avg. | 3.49 | 16.57 |

| R40-30k_Avg. | 3.92 | 24.69 |

| R40-40k_Avg. | 6.61 | 39.59 |

| R51-20k_Avg. | 3.19 | 19.22 |

| R51-30k_Avg. | 3.91 | 23.10 |

| R51-40k_Avg. | 5.17 | 32.80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Koo, D.-H.; Kim, J.-S.; Kim, S.-H.; Suh, S.-W. Evaluation of Flexural Toughness of Concrete Reinforced with High-Performance Steel Fiber. Materials 2023, 16, 6623. https://doi.org/10.3390/ma16206623

Koo D-H, Kim J-S, Kim S-H, Suh S-W. Evaluation of Flexural Toughness of Concrete Reinforced with High-Performance Steel Fiber. Materials. 2023; 16(20):6623. https://doi.org/10.3390/ma16206623

Chicago/Turabian StyleKoo, Do-Hyuck, Jong-Sun Kim, Sun-Hee Kim, and Sang-Wook Suh. 2023. "Evaluation of Flexural Toughness of Concrete Reinforced with High-Performance Steel Fiber" Materials 16, no. 20: 6623. https://doi.org/10.3390/ma16206623