The Dissolution Mechanism of Low-Molecular-Weight Organic Acids on the Sillimanite

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Procedure

2.3. Characterization of the Sample

2.4. Characterization of the Sillimanite Dissolution Solutions

3. Results and Discussion

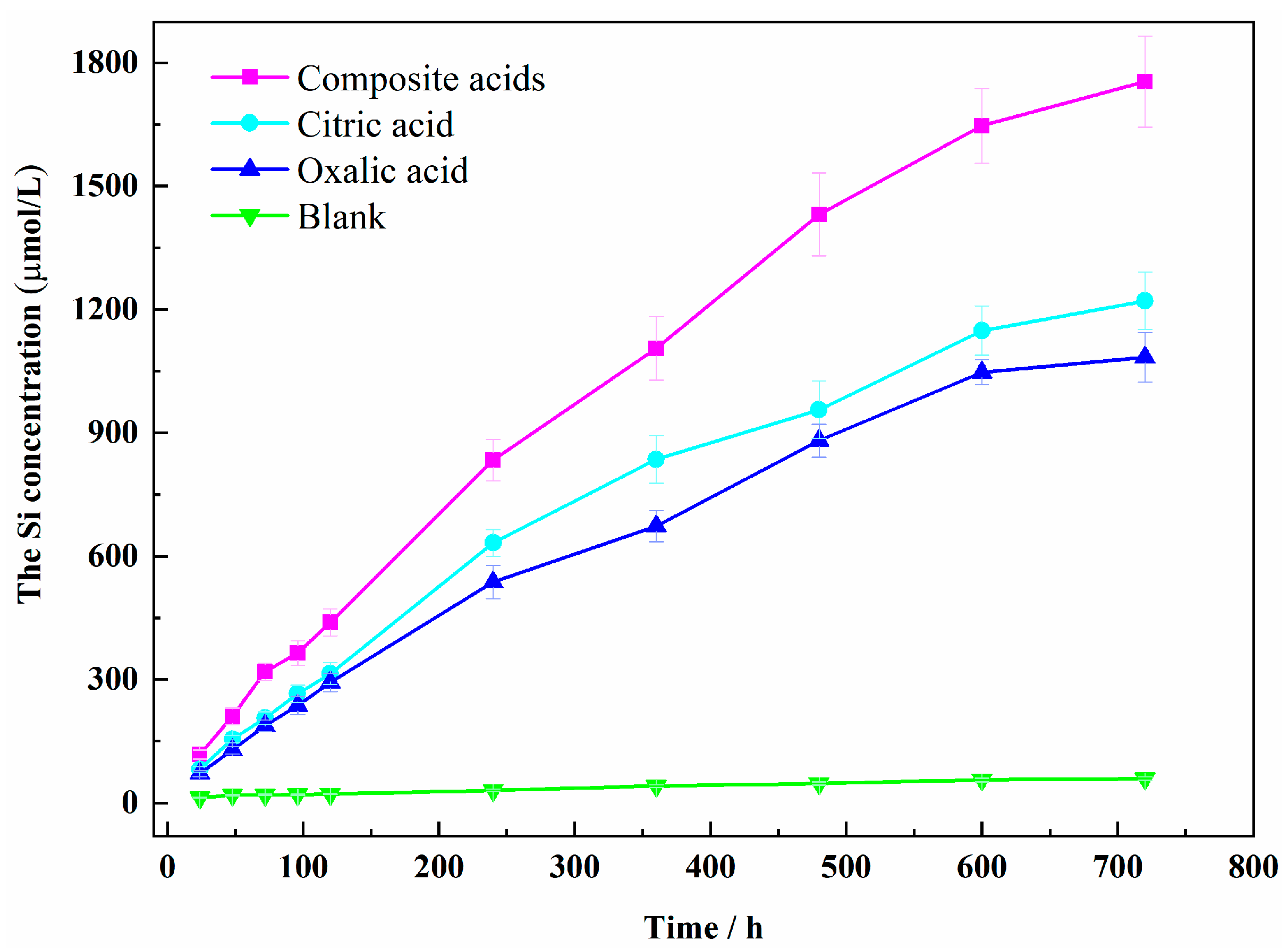

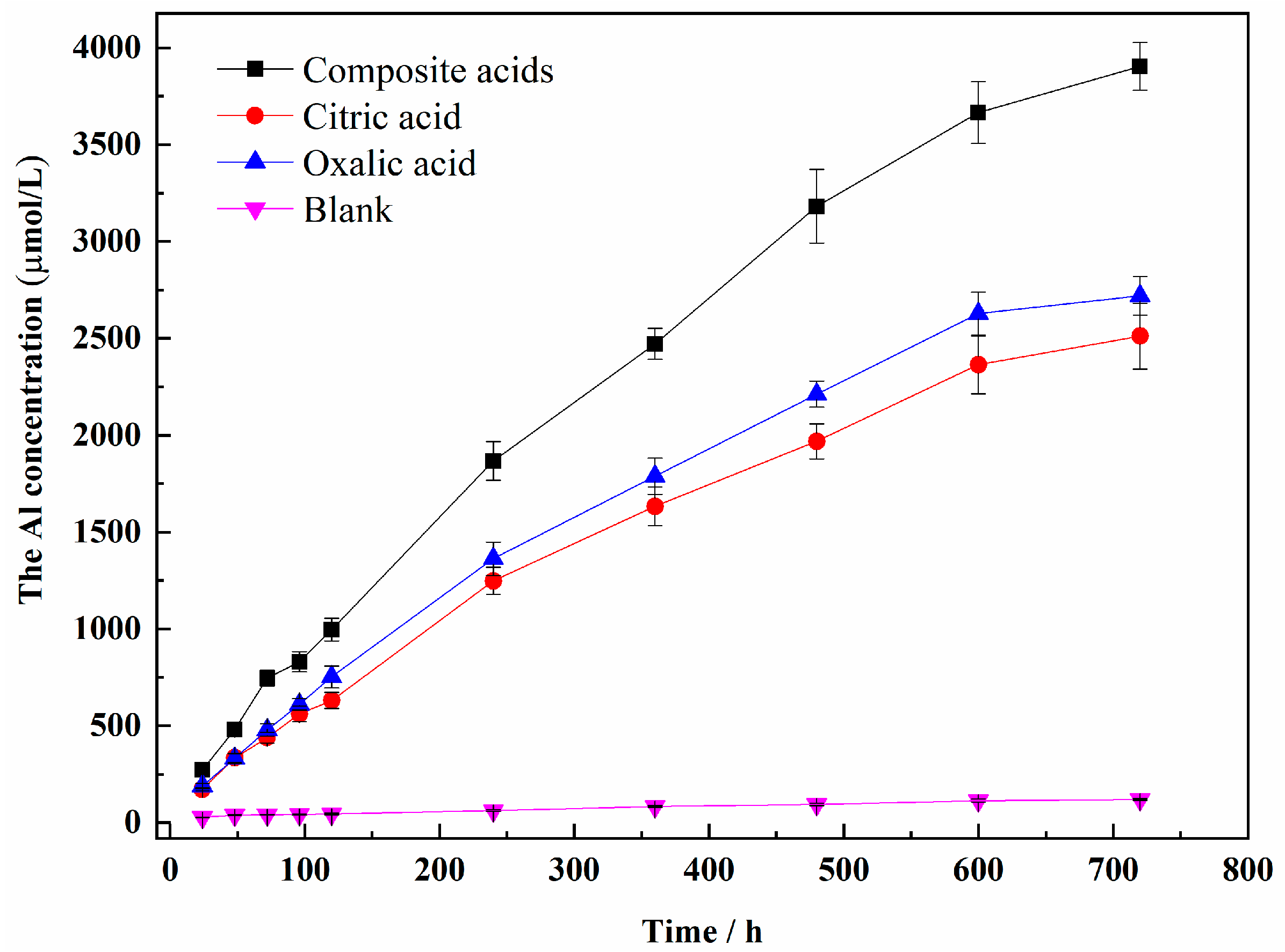

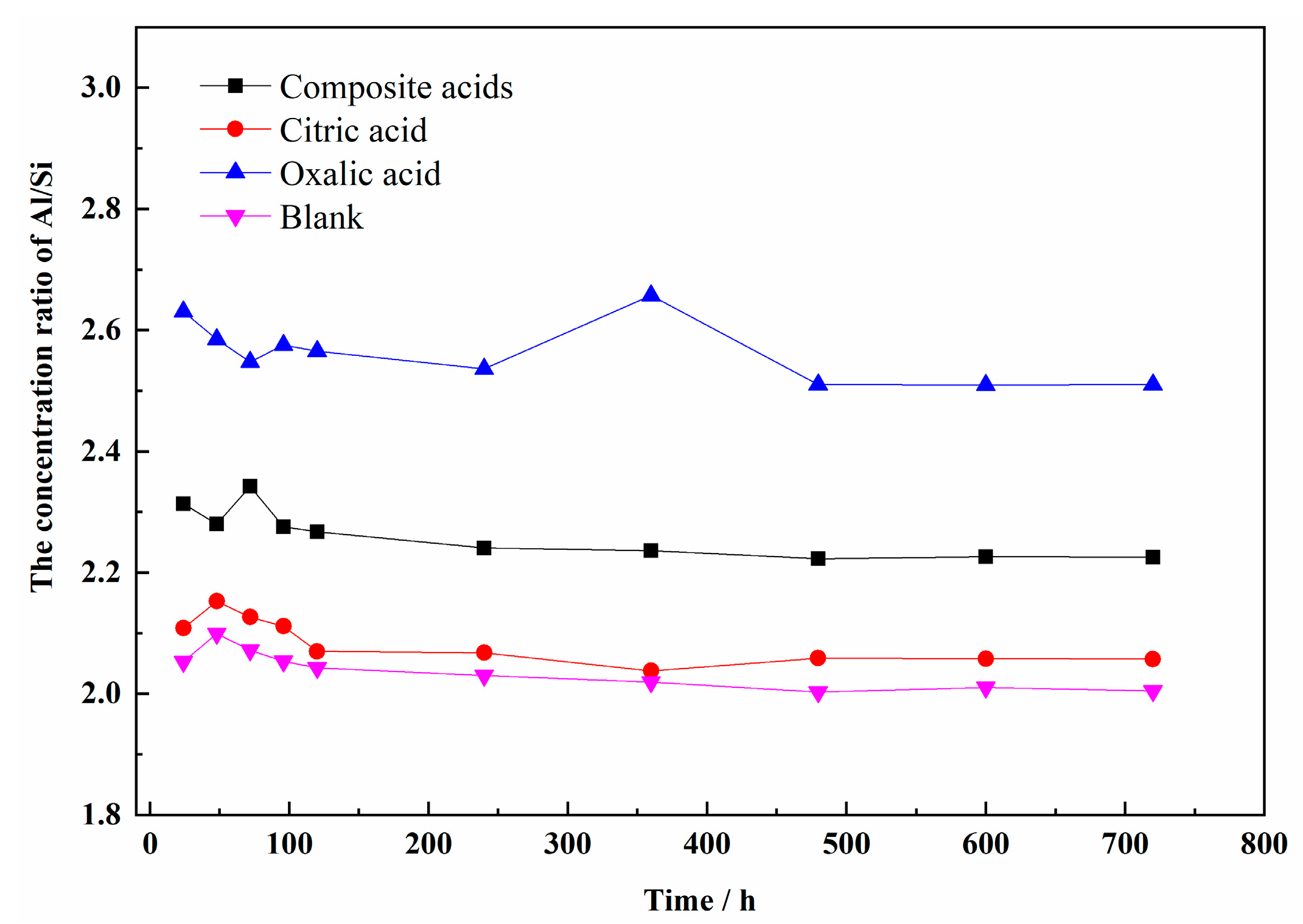

3.1. Dissolution Kinetics of Si and Al in Different Organic Acids

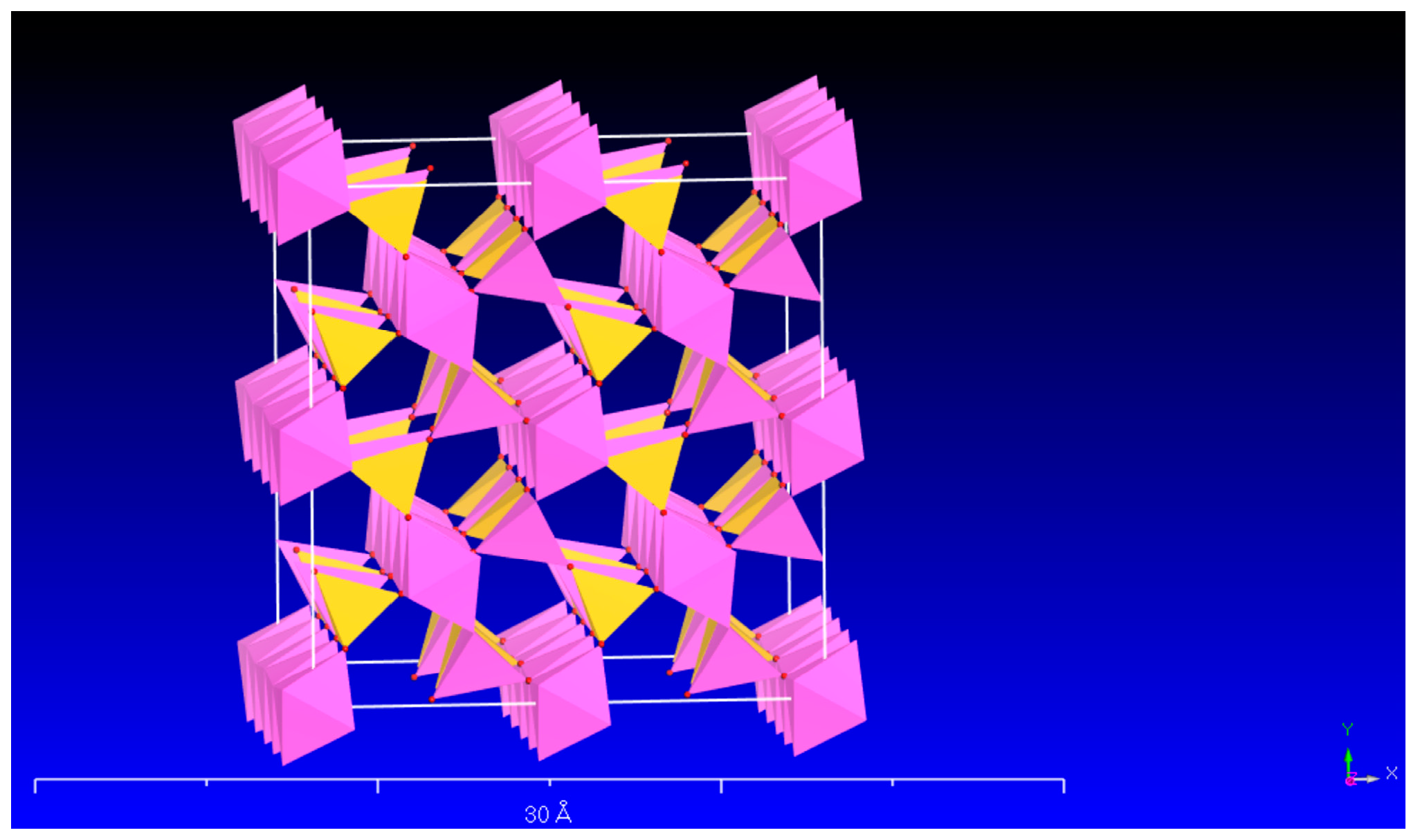

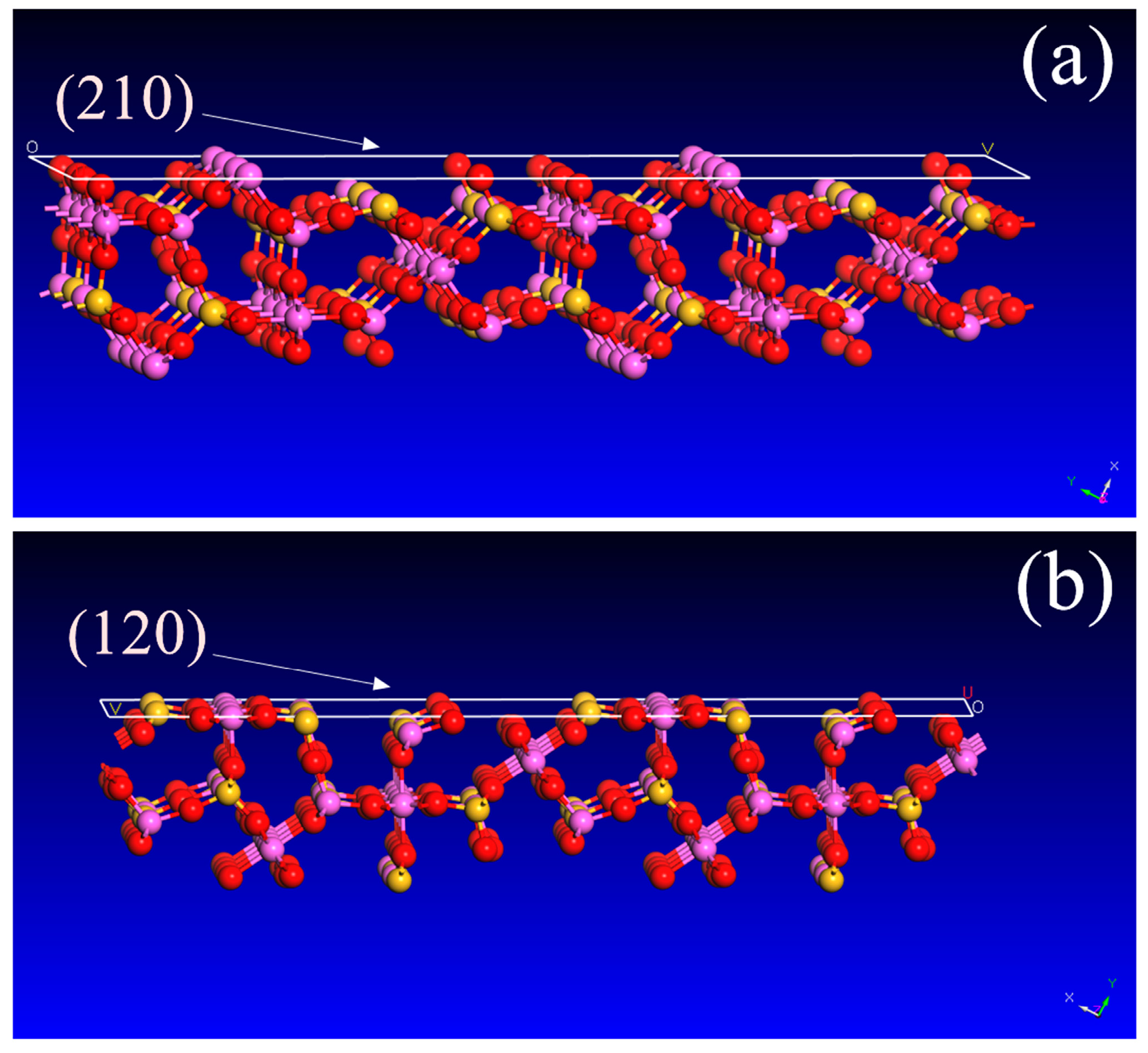

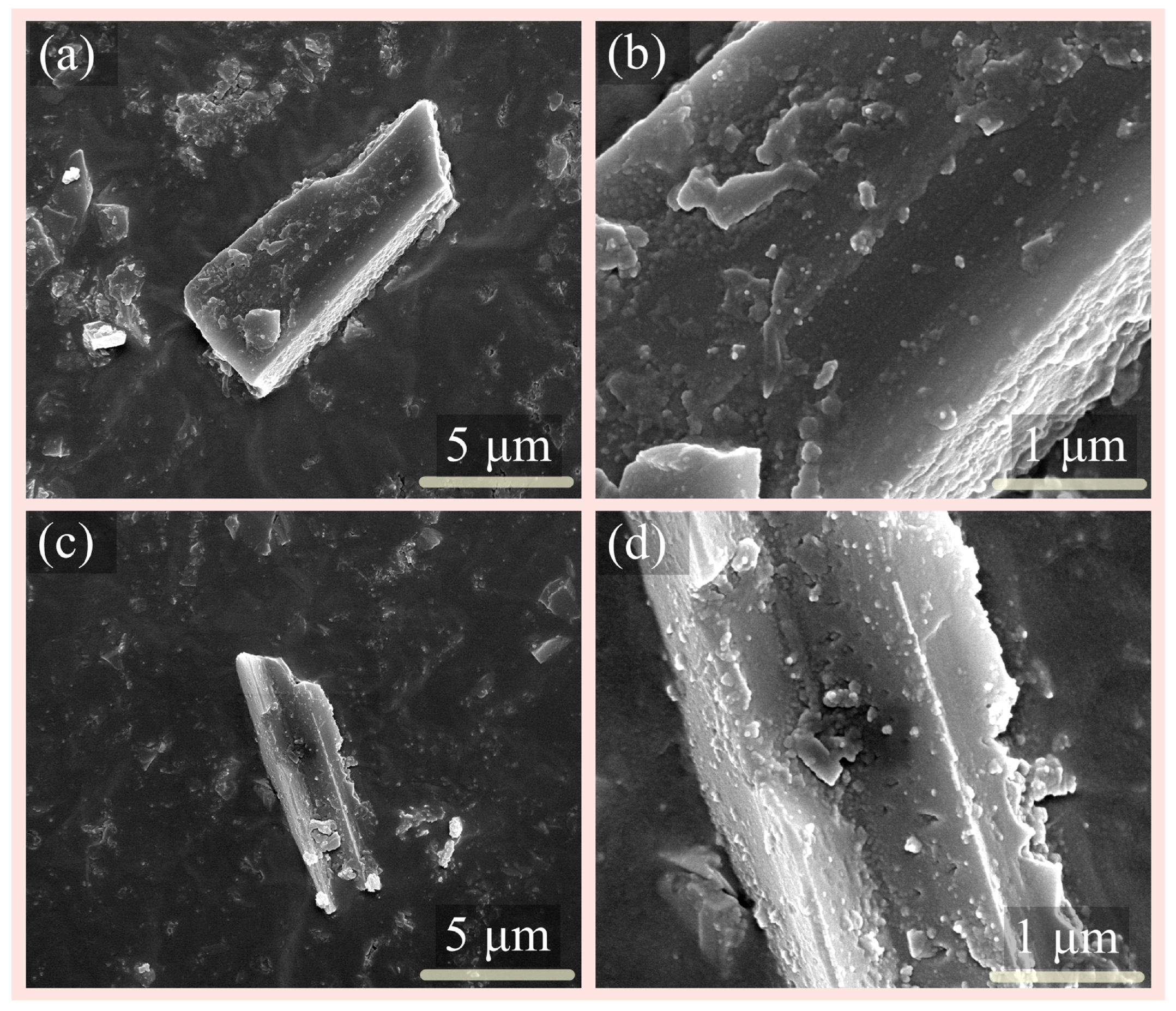

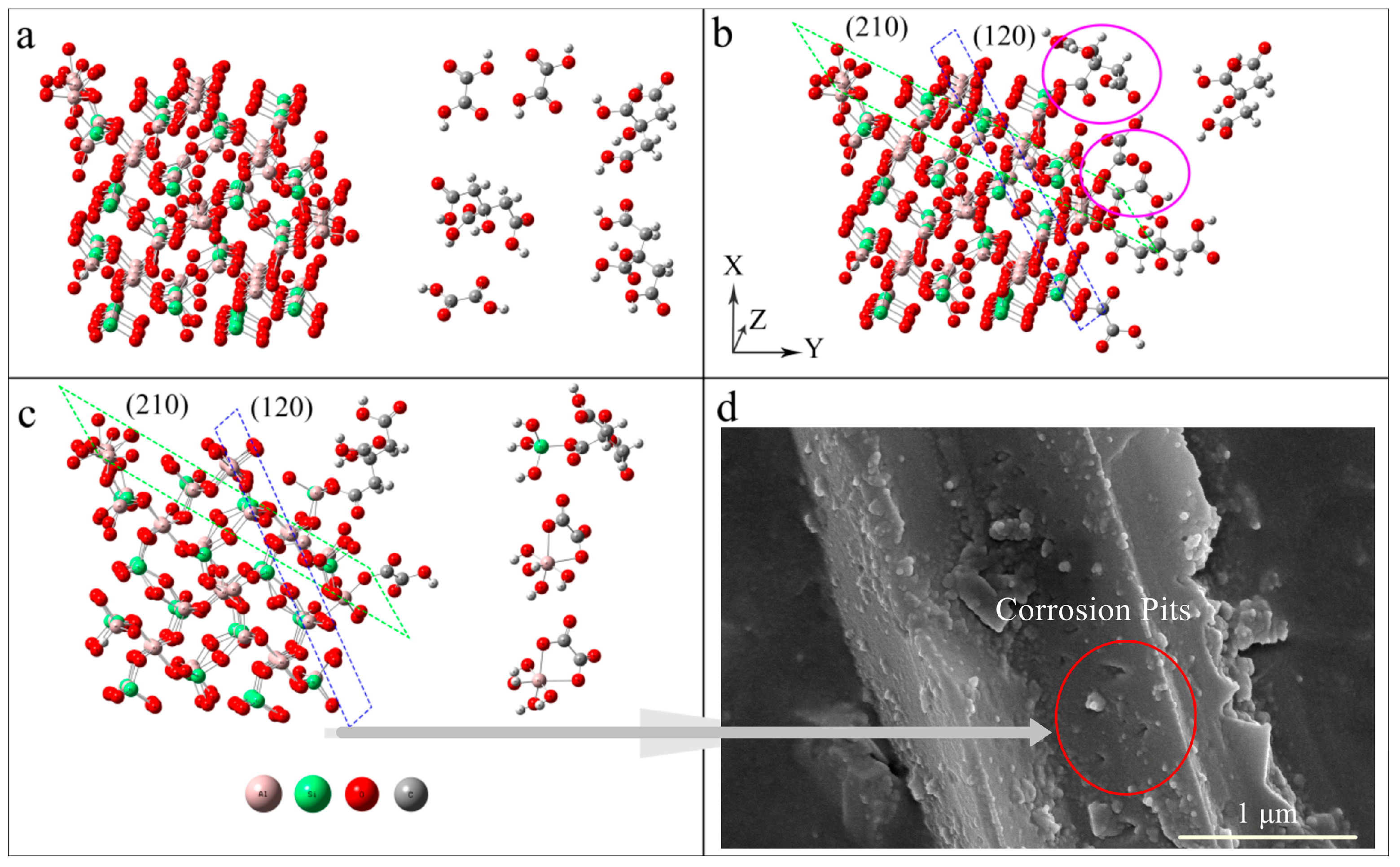

3.2. Changes in the Crystal Structure of Sillimanite after Treatment with Different Organic Acids

3.3. Dissolution Mechanism of Sillimanite in LMWOAs

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cano, N.F.; Watanabe, S. Ab initio study of the electronic and optical properties of sillimanite (Al2SiO5) crystal. Opt. Mater. 2011, 33, 1813–1816. [Google Scholar] [CrossRef]

- Xu, L.; Xi, X.; Shui, A. Synthesis of sillimanite whiskers. Ceram. Int. 2015, 41, 10304–10307. [Google Scholar] [CrossRef]

- Haldar, M.K.; Pal, T.K.; Banerjee, G. Preparation and properties of Y2O3 containing zirconia-mullite composites derived from sillimanite beach sand. Ceram. Int. 2002, 28, 311–318. [Google Scholar] [CrossRef]

- Vijay, M.; Ananthapadmanabhan, P.V.; Ramachandran, K.; Hiremath, G.; Mathai, C.B.; Nalini, B.; Pillai, B.C. Carbothermal reduction of sillimanite in a transferred arc thermal plasma reactor. Int. J. Refract. Met. Hard Mater. 2013, 36, 174–178. [Google Scholar] [CrossRef]

- Maiti, K.N.; Kumar, S. Effect of glass-ceramics and sillimanite sand additions on microstructure and properties of porcelain. Ceram. Int. 1992, 18, 403–412. [Google Scholar] [CrossRef]

- Maity, S.; Mukhopadhyayh, T.K.; Sarkarc, B.K. Strength of Sillimanite Sand Reinforced Porcelain Subjected to Thermal Shock. Eur. Ceram. Soc. 1997, 17, 749–752. [Google Scholar] [CrossRef]

- Sadik, C.; El Amrani, I.-E.; Albizane, A. Recent advances in silica-alumina refractory: A review. J. Asian Ceram. Soc. 2014, 2, 83–96. [Google Scholar] [CrossRef]

- Tripathi, H.S.; Banerjee, G. Synthesis and mechanical properties of mullite from beach sand sillimanite: Effect of TiO2. J. Eur. Ceram. Soc. 1998, 18, 2081–2087. [Google Scholar] [CrossRef]

- Rahman, S.; Feustel, U.; Freimann, S. Structure description of the thermic phase transformation sillimanite-mullite. J. Eur. Ceram. Soc. 2001, 21, 2471–2478. [Google Scholar] [CrossRef]

- Rüscher, C.H. Thermic transformation of sillimanite single crystals to 3:2 mullite plus melt: Investigations by polarized IR-reflection micro spectroscopy. J. Eur. Ceram. Soc. 2001, 21, 2463–2469. [Google Scholar] [CrossRef]

- Tomba, A.; Camerucci, M.A.; Urretavizcaya, G.; Cavalieri, A.L.; Sainz, M.A.; Caballero, A. Elongated mullite crystals obtained from high temperature transformation of sillimanite. Ceram. Int. 1999, 25, 245–252. [Google Scholar] [CrossRef]

- Gupta, R.; Sharma, S.; Nanda, T.; Pandey, O.P. Wear studies of hybrid AMCs reinforced with naturally occurring sillimanite and rutile ceramic particles for brake-rotor applications. Ceram. Int. 2020, 46, 16849–16859. [Google Scholar] [CrossRef]

- Kumar, S.; Das, S.K.; Daspoddar, P.K. Thermo-mechanical behaviour of low cement castables derived from mullite aggregates synthesised from beach sand sillimanite. Ceram. Int. 2003, 29, 139–144. [Google Scholar] [CrossRef]

- Sharma, R.; Pei, J.; Miah, M.J.; Jang, J.G. Effect of sillimanite sand on the mechanical property and thermal resistance of alkali-activated slag mortar. Constr. Build. Mater. 2023, 370, 130654. [Google Scholar] [CrossRef]

- Prabaharan, J.S.; Sophia, M.; Babu, O.G.; Raja, M.A. High temperature effects on the compressive strength and UPV of nano alumina modified concrete containing sillimanite. Mater. Today Proc. 2022, 62, 5613–5619. [Google Scholar] [CrossRef]

- Liu, M.; Peng, Z.; Wang, X.; He, Y.; Huang, S.; Wan, J.; Wang, B.; Zhou, Y.; Yang, H.; Zheng, H. The effect of high energy ball milling on the structure and properties of two greenish mineral pigments. Dyes. Pig. 2021, 193, 109494. [Google Scholar] [CrossRef]

- Shang, W.; Song, J.; Yue, H.; Tang, S.; Liu, C.; Li, C.; Liang, B.; Xie, H. An efficient milling-assisted technology for K-feldspar processing, industrial waste treatment and CO2 mineralization. Chem. Eng. J. 2016, 292, 255–263. [Google Scholar] [CrossRef]

- Tripathi, H.S.; Das, S.K.; Mukherjee, B.; Ghosh, A.; Banerjee, G. Synthesis and thermo-mechanical properties of mullite-alumina composite derived from sillimanite beach sand: Effect of ZrO2. Ceram. Int. 2001, 27, 833–837. [Google Scholar] [CrossRef]

- Haldar, M.K. Effect of magnesia additions on the properties of zirconia-mullite composites derived from sillimanite beach sand. Ceram. Int. 2003, 29, 573–581. [Google Scholar] [CrossRef]

- Xue, H.; Dong, X.; Fan, Y.; Ma, X.; Yao, S. Study of Structural Transformation and Chemical Reactivity of Kaolinite-Based High Ash Slime during Calcination. Minerals 2023, 13, 466. [Google Scholar] [CrossRef]

- Kostova, B.; Petkova, V.; Stoyanov, V.; Uzunov, Z. The effect of high energy milling and high thermal treatment on the structure and thermal decomposition of minerals from natural CaO-SiO2-P2O5 ceramic system. Mater. Today Commun. 2021, 26, 101983. [Google Scholar] [CrossRef]

- Sarier, N.; Güler, C. Thermal investigation of acid-activated clay minerals. Thermochim. Acta 1987, 119, 293–300. [Google Scholar] [CrossRef]

- Hariharan, S.; Werner, M.; Hänchen, M.; Zingaretti, D.; Baciocchi, R.; Mazzotti, M. Dissolution Kinetics of Thermally Activated Serpentine for Mineralization at Flue Gas Conditions. Energy Procedia 2014, 63, 5887–5891. [Google Scholar] [CrossRef][Green Version]

- Murat, M.; Driouche, M. Chemical reactivity of thermally activated clay minerals estimation by dissolution in hydrofluoric acid. Cem. Concr. Res. 1988, 18, 221–228. [Google Scholar] [CrossRef]

- Cappelli, C.; Van Driessche, A.E.S.; Cama, F.J.; Huertas, J. Alteration of trioctahedral micas in the presence of inorganic and organic acids. Appl. Clay Sci. 2023, 238, 106923. [Google Scholar] [CrossRef]

- Sun, C.; Yao, Z.; Wang, Q.; Guo, L.; Shen, X. Theoretical study on the organic acid promoted dissolution mechanism of forsterite mineral. Appl. Surf. Sci. 2023, 614, 156063. [Google Scholar] [CrossRef]

- Lin, S.-M.; Yu, Y.-L.; Zhang, Z.-J.; Zhang, C.-Y.; Zhong, M.-F.; Wang, L.-M.; Lu, S.-X.; Xu, W.; Li, N.; Huang, X. The synergistic mechanisms of citric acid and oxalic acid on the rapid dissolution of kaolinite. Appl. Clay Sci. 2020, 196, 105756. [Google Scholar] [CrossRef]

- Potysz, A.; Bartz, W. Bioweathering of minerals and dissolution assessment by experimental simulations—Implications for sandstone rocks: A review. Constr. Build. Mater. 2022, 316, 125862. [Google Scholar] [CrossRef]

- Yuan, G.; Cao, Y.; Schulz, H.; Hao, F.; Gluyas, J.; Liu, K.; Yang, T.; Wang, Y.; Xi, K.; Li, F. A review of feldspar alteration and its geological significance in sedimentary basins: From shallow aquifers to deep hydrocarbon reservoirs. Earth.-Sci. Rev. 2019, 191, 114–140. [Google Scholar] [CrossRef]

| Sample | SiO2 | Al2O3 | CaO | MgO | Fe2O3 | Na2O | K2O | TiO2 | P2O5 | MnO | LOI 1 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Sillimanite | 41.25 | 55.07 | 0.66 | 0.71 | 0.23 | 0.12 | 0.43 | 0.55 | 0.03 | 0.02 | 0.93 |

| The Solution | ||||||

|---|---|---|---|---|---|---|

| b | R2 | b | R2 | b | R2 | |

| Blank | 2.13 | 0.906 | 13.76 | 0.891 | 4.09 × 10−3 | 0.896 |

| Oxalic acid | 49.43 | 0.991 | 3.21 × 102 | 0.915 | 1.70 × 10−3 | 0.996 |

| Citric acid | 55.29 | 0.993 | 3.61 × 102 | 0.925 | 1.84 × 10−3 | 0.998 |

| Composite acids | 79.51 | 0.991 | 5.15 × 102 | 0.911 | 1.93 × 10−3 | 0.998 |

| The Solution | ||||||

|---|---|---|---|---|---|---|

| b | R2 | b | R2 | b | R2 | |

| Blank | 4.26 | 0.902 | 27.44 | 0.884 | 4.21 × 10−3 | 0.882 |

| Oxalic acid | 1.24 × 102 | 0.993 | 8.09 × 102 | 0.922 | 1.86 × 10−3 | 0.998 |

| Citric acid | 1.22 × 102 | 0.993 | 7.32 × 102 | 0.918 | 1.78 × 10−3 | 0.998 |

| Composite acids | 1.75 × 102 | 0.992 | 1.14 × 103 | 0.913 | 1.97 × 10−3 | 0.998 |

| Samples | Blank | Oxalic Acid | Citric Acid | Composite Acids |

|---|---|---|---|---|

| I(120)/I(210) | 1.07 | 1.43 | 1.19 | 1.28 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, C.; Yu, Y.; Zhong, M.; Zhuang, J.; Yang, H.; Lin, S.; Zhang, Z.; Wu, Y. The Dissolution Mechanism of Low-Molecular-Weight Organic Acids on the Sillimanite. Materials 2023, 16, 6663. https://doi.org/10.3390/ma16206663

Zhang C, Yu Y, Zhong M, Zhuang J, Yang H, Lin S, Zhang Z, Wu Y. The Dissolution Mechanism of Low-Molecular-Weight Organic Acids on the Sillimanite. Materials. 2023; 16(20):6663. https://doi.org/10.3390/ma16206663

Chicago/Turabian StyleZhang, Chenyang, Yaling Yu, Mingfeng Zhong, Jieyi Zhuang, Huan Yang, Shaomin Lin, Zhijie Zhang, and Yunying Wu. 2023. "The Dissolution Mechanism of Low-Molecular-Weight Organic Acids on the Sillimanite" Materials 16, no. 20: 6663. https://doi.org/10.3390/ma16206663

APA StyleZhang, C., Yu, Y., Zhong, M., Zhuang, J., Yang, H., Lin, S., Zhang, Z., & Wu, Y. (2023). The Dissolution Mechanism of Low-Molecular-Weight Organic Acids on the Sillimanite. Materials, 16(20), 6663. https://doi.org/10.3390/ma16206663