Reinforcement of Silty Soil via Regenerated Fiber Polymer: A Study on Microscopic Mechanisms

Abstract

:1. Introduction

2. Materials

2.1. Experimental Materials

2.1.1. Silty Soil

2.1.2. Recycled Polyester Fiber Properties

2.1.3. Lime, Fly Ash, Gypsum

2.2. Experimental Approach

2.3. Experimental Methodology

2.3.1. Consistency Limit Test

2.3.2. Shrinkage Test

2.3.3. Compaction Evaluation

2.3.4. California Bearing Ratio (CBR) Test

2.3.5. Unconfined Compressive Strength Assessment

2.3.6. Resilience Modulus Testing

3. Experimental Results and Analysis

3.1. Basic Physical Properties

3.1.1. Limiting Moisture Content

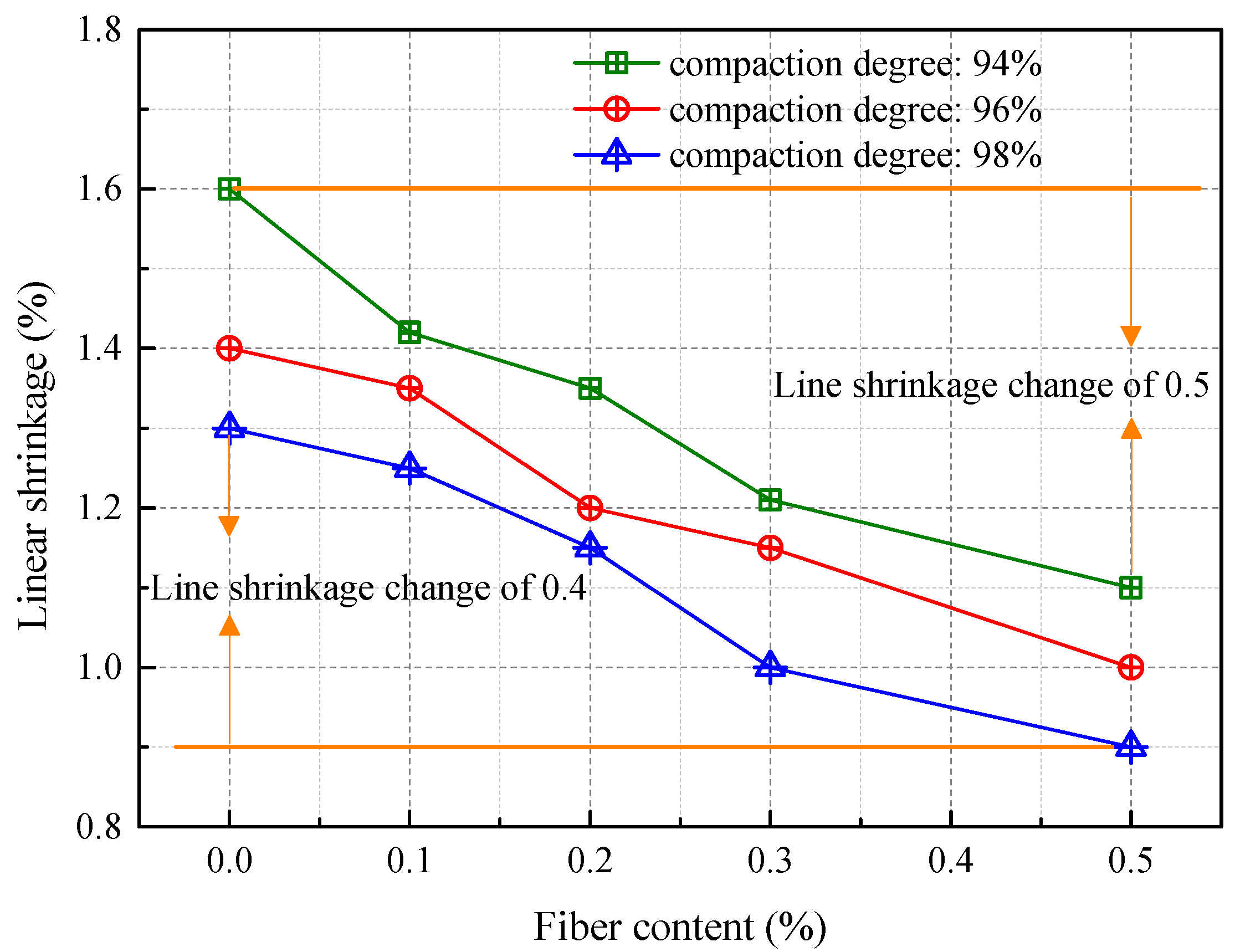

3.1.2. Shrinkage Characteristics

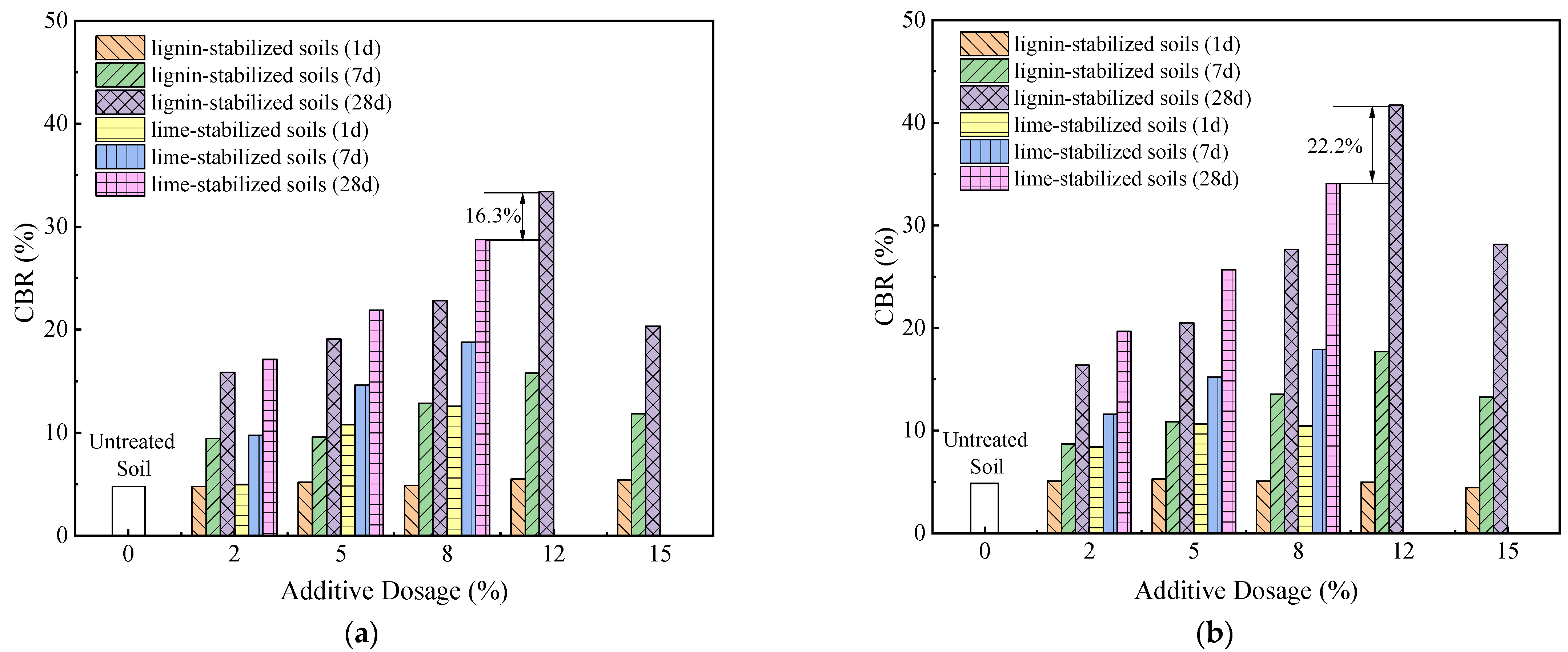

3.2. Mechanical Properties

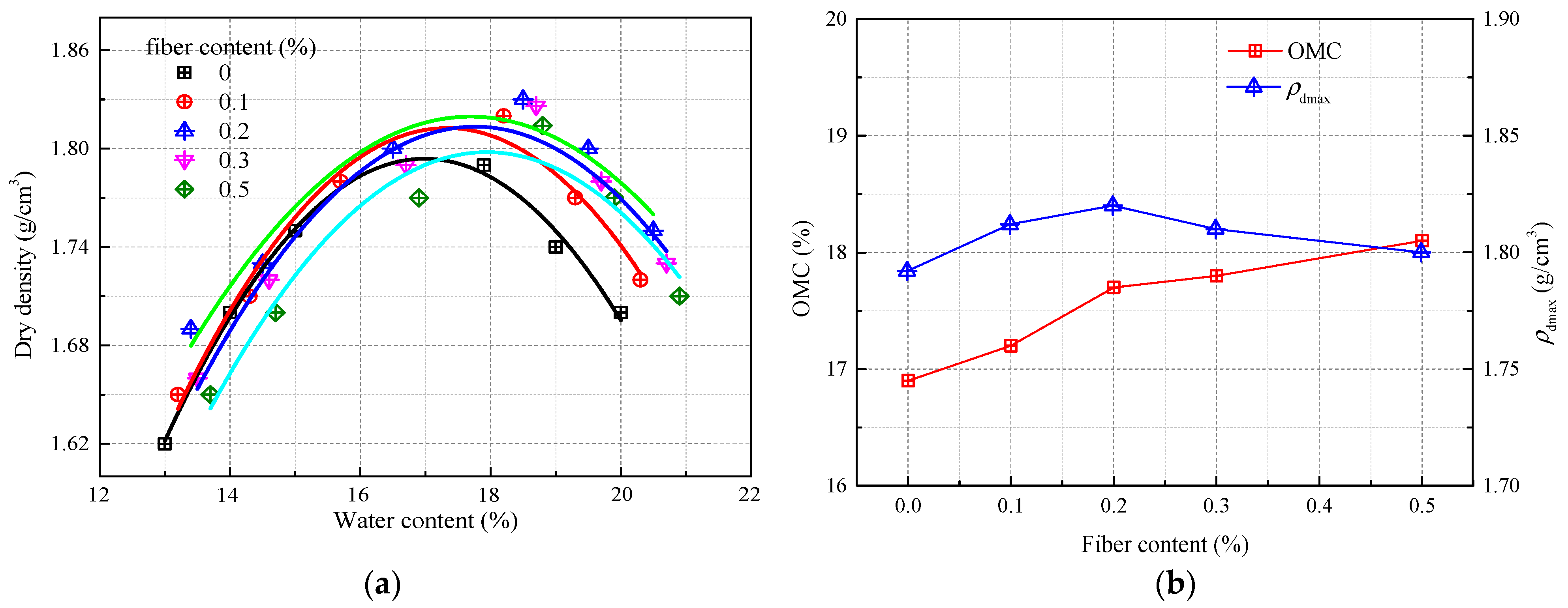

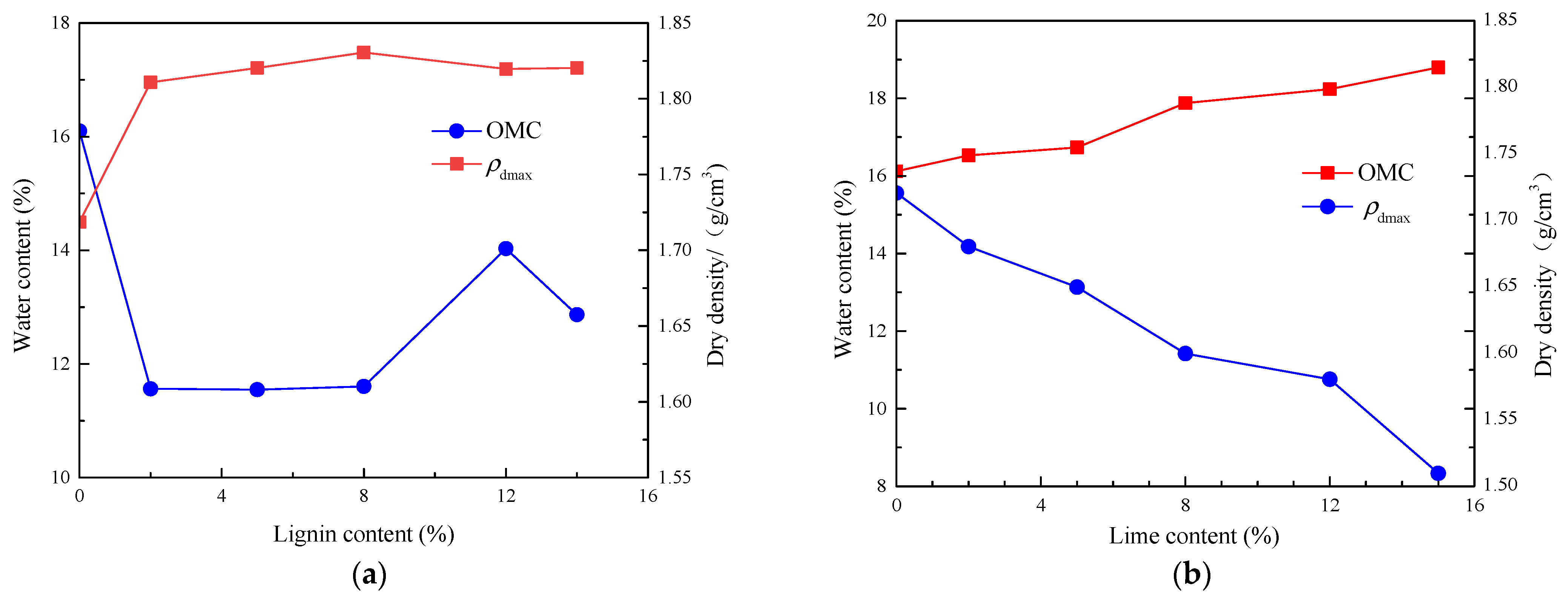

3.2.1. Compaction Characteristics

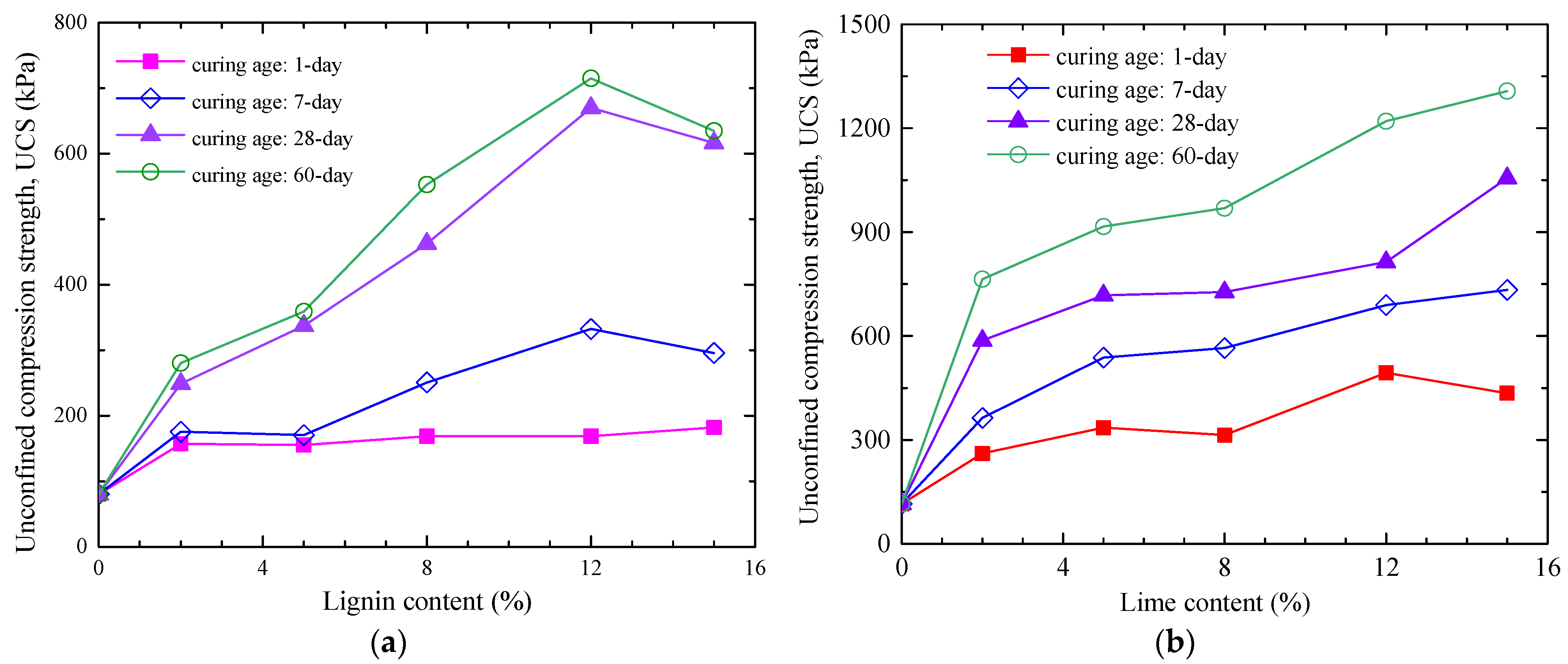

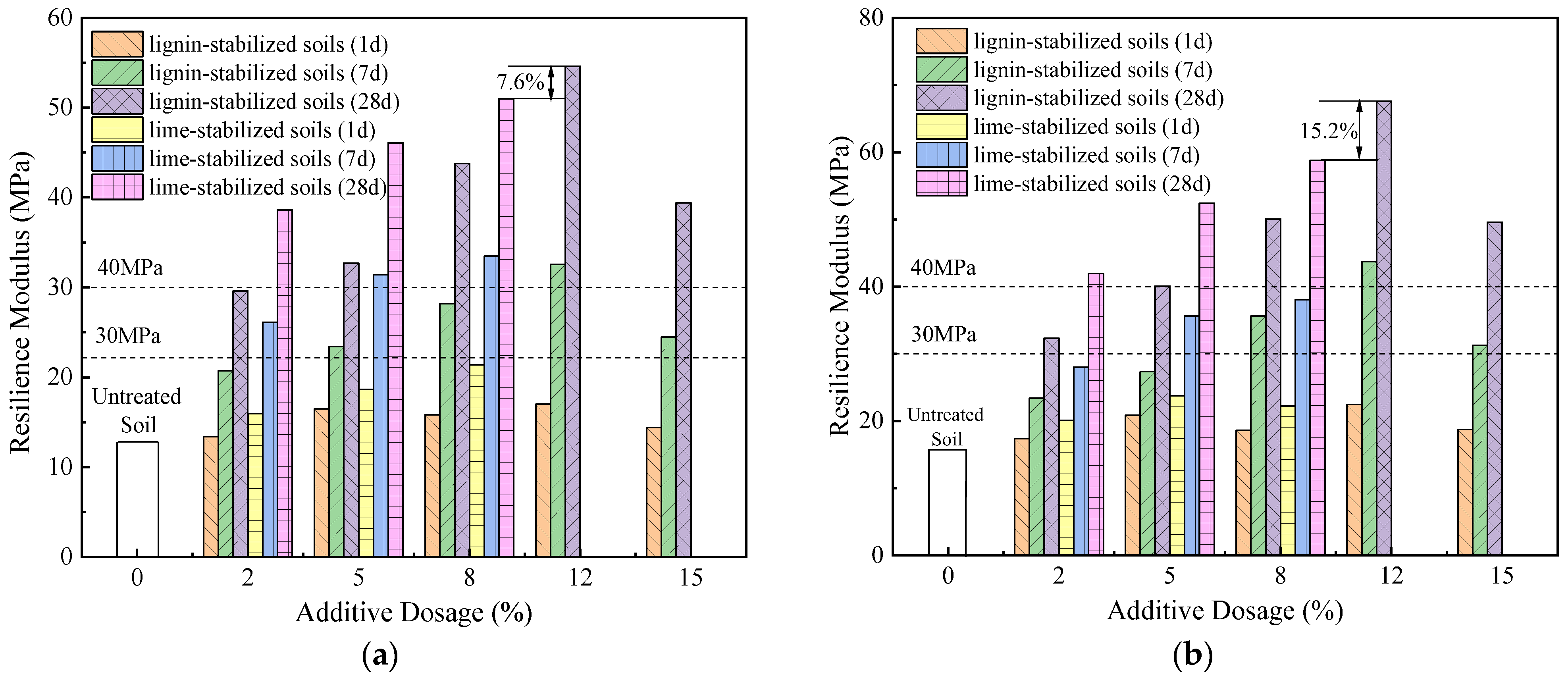

3.2.2. Unconfined Compressive Strength

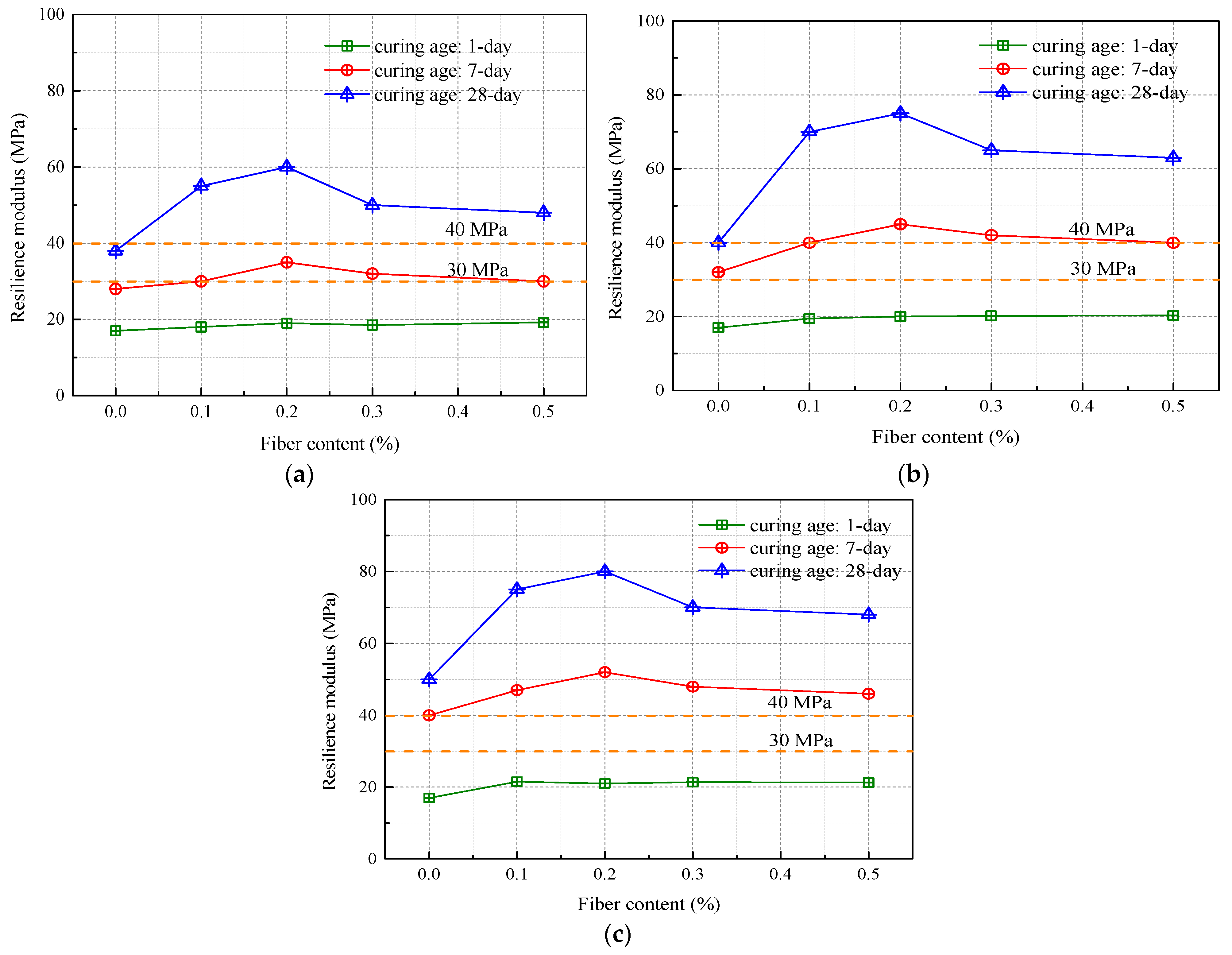

3.2.3. Resilient Modulus

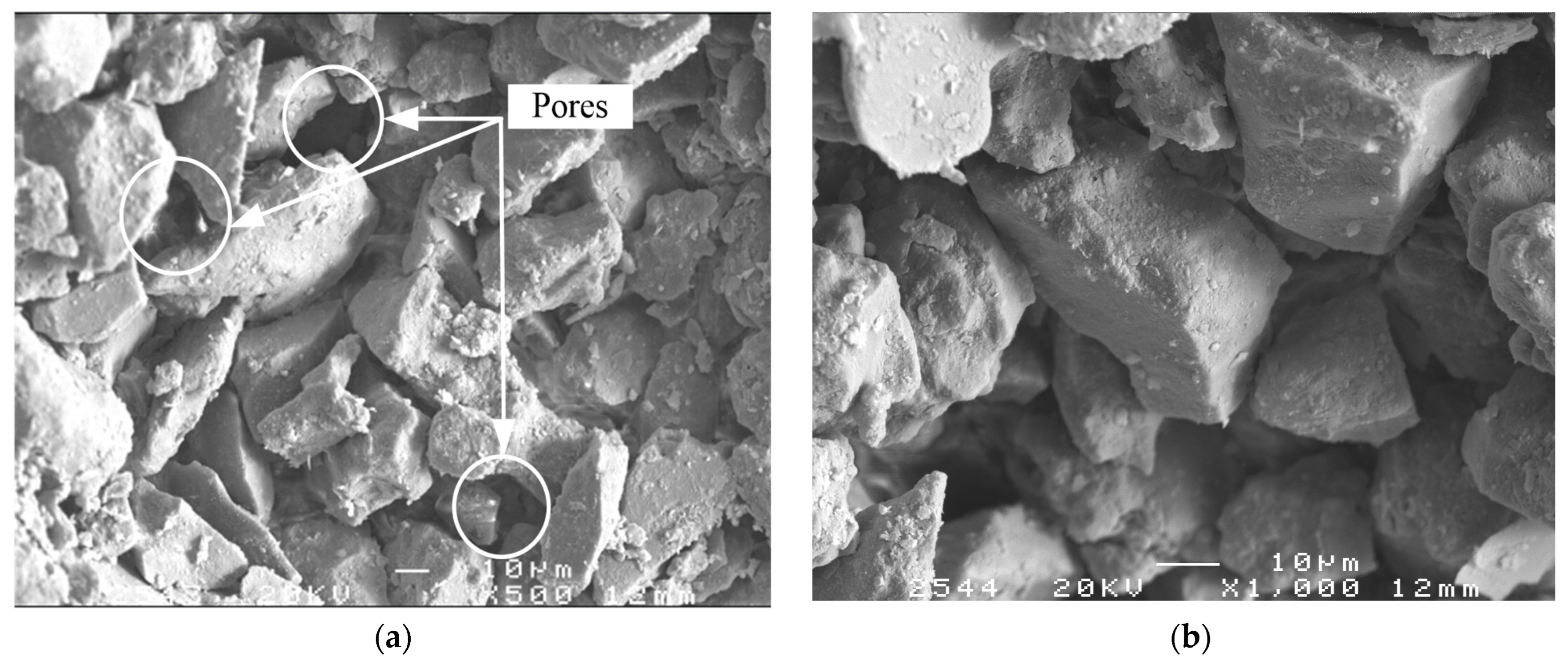

4. Analysis of Reinforcement Mechanisms

5. Conclusions

- (1)

- Fiber-augmented soil exhibits superior liquid and plastic limit values compared to its non-fiber counterpart, increasing incrementally within a range of 2.58% to 3.12% as fiber content rises. The plasticity index remains relatively stable, fluctuating modestly between 2.5 and 3.1. The role of curing age in these metrics is found to be minimal, while the plasticity index shows a marginally declining trend over time. Remarkably, fibers have a notable dampening effect on soil shrinkage, reducing it by a factor of approximately 1.04 to 1.45.

- (2)

- The incorporation of fibers elevates the OMC and initiates an initial uptick in the maximum dry density (ρdmax), which subsequently declines. The peak ρdmax achieves a value of 1.82 g/cm3. However, the variance in ρdmax across different fiber concentrations is negligible, with a maximal deviation of around 1.56%. In the fiber concentration window of 0–0.2%, the OMC experiences a slight rise of about 0.8%, while ρdmax marginally escalates. Beyond this range, OMC experiences a slight ascent, whereas ρdmax shows a nominal descent.

- (3)

- Recycled polyester fibers are highly effective in bolstering the roadway applicability of silty subgrade soil. After a curing period of 28 days, the soil surpasses highway subgrade design benchmarks for both the CBR and resilient modulus. Specifically, a CBR value of 45% is attained with a 98% compaction and a 0.2% fiber concentration.

- (4)

- The unconfined compressive strength of the soil improves synergistically with increasing fiber dosage and curing period. However, a decline in strength is observed when the fiber dosage surpasses 0.2%, with the peak strength value approximating 900 kPa. For silty soils native to Jiangsu, an optimal fiber dosage of around 0.2% is recommended.

- (5)

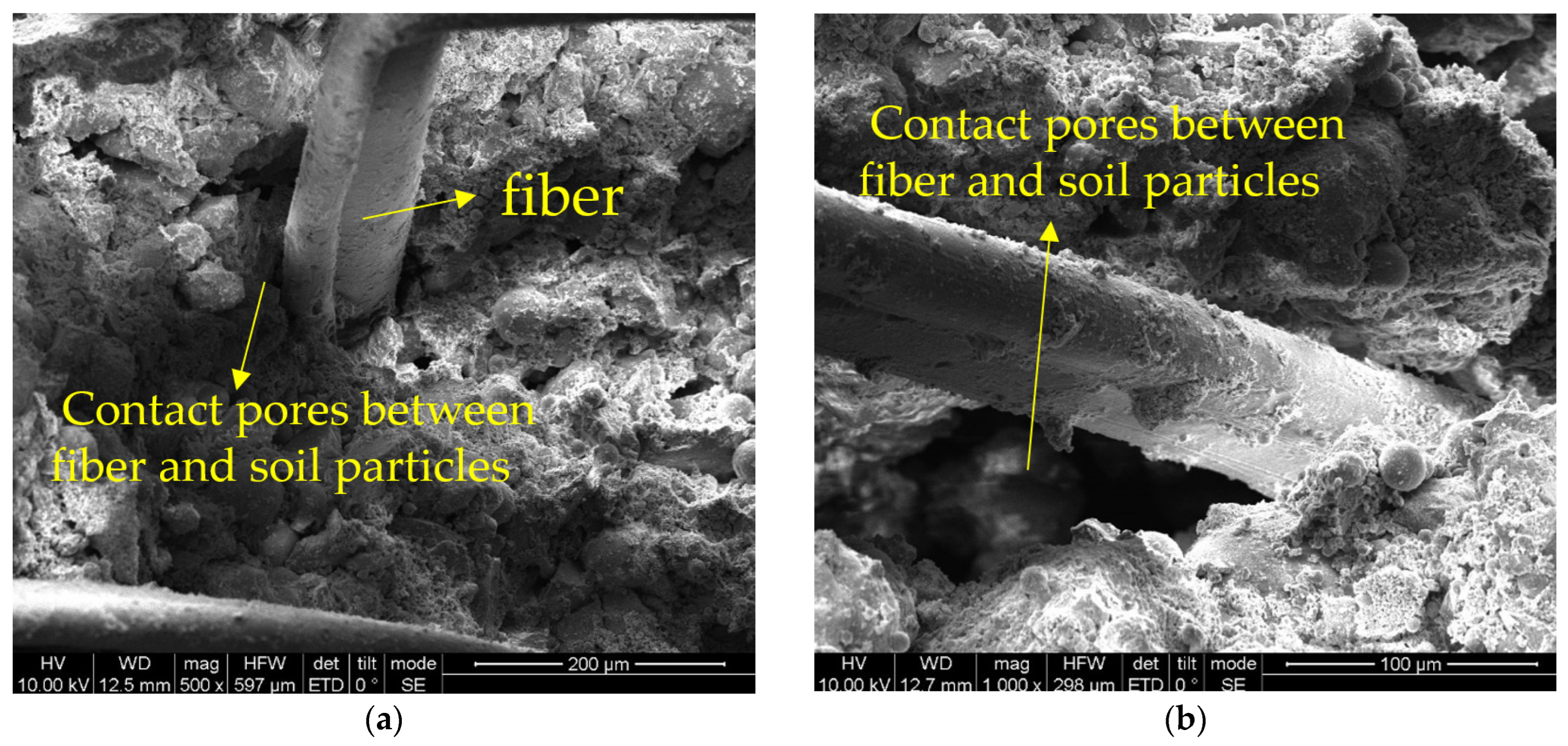

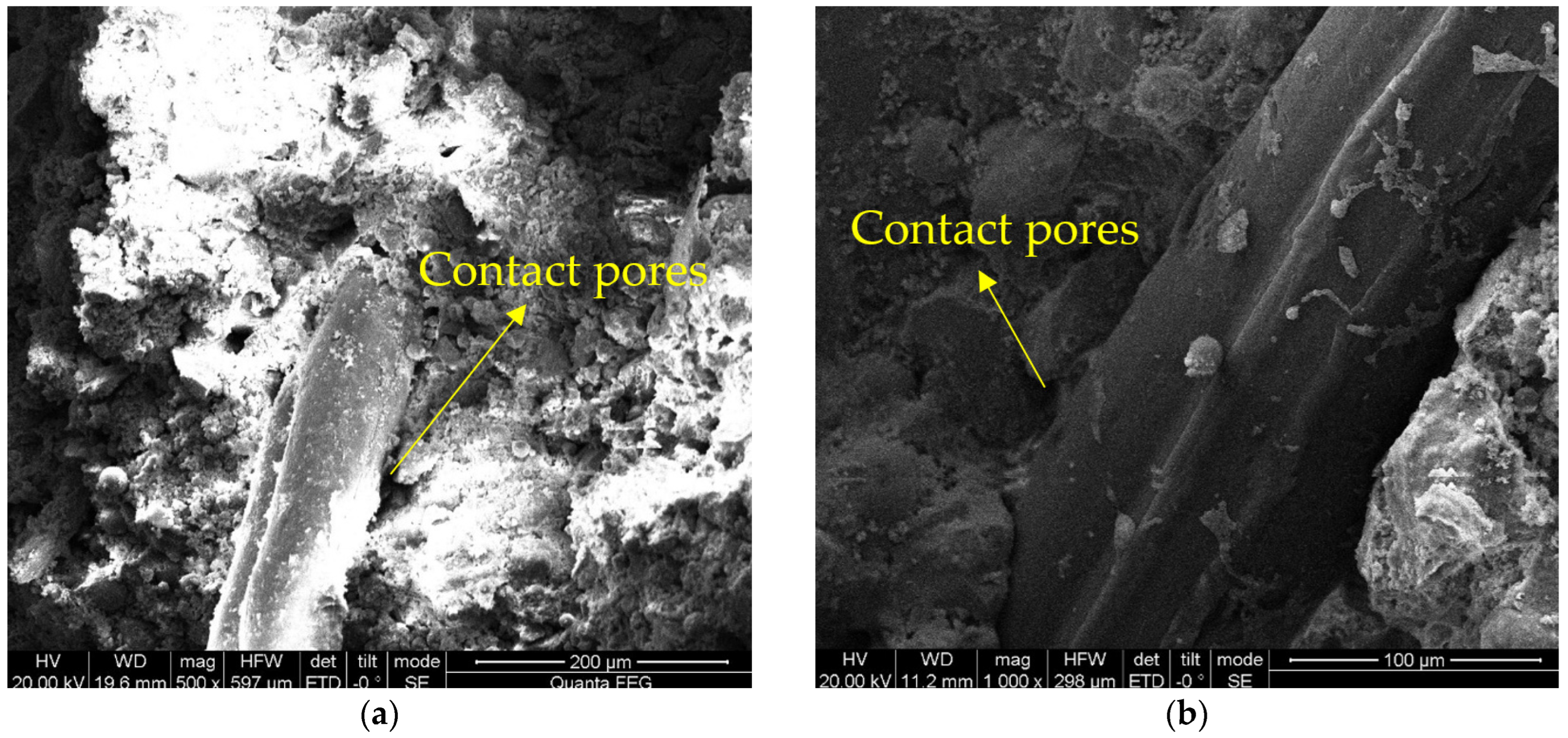

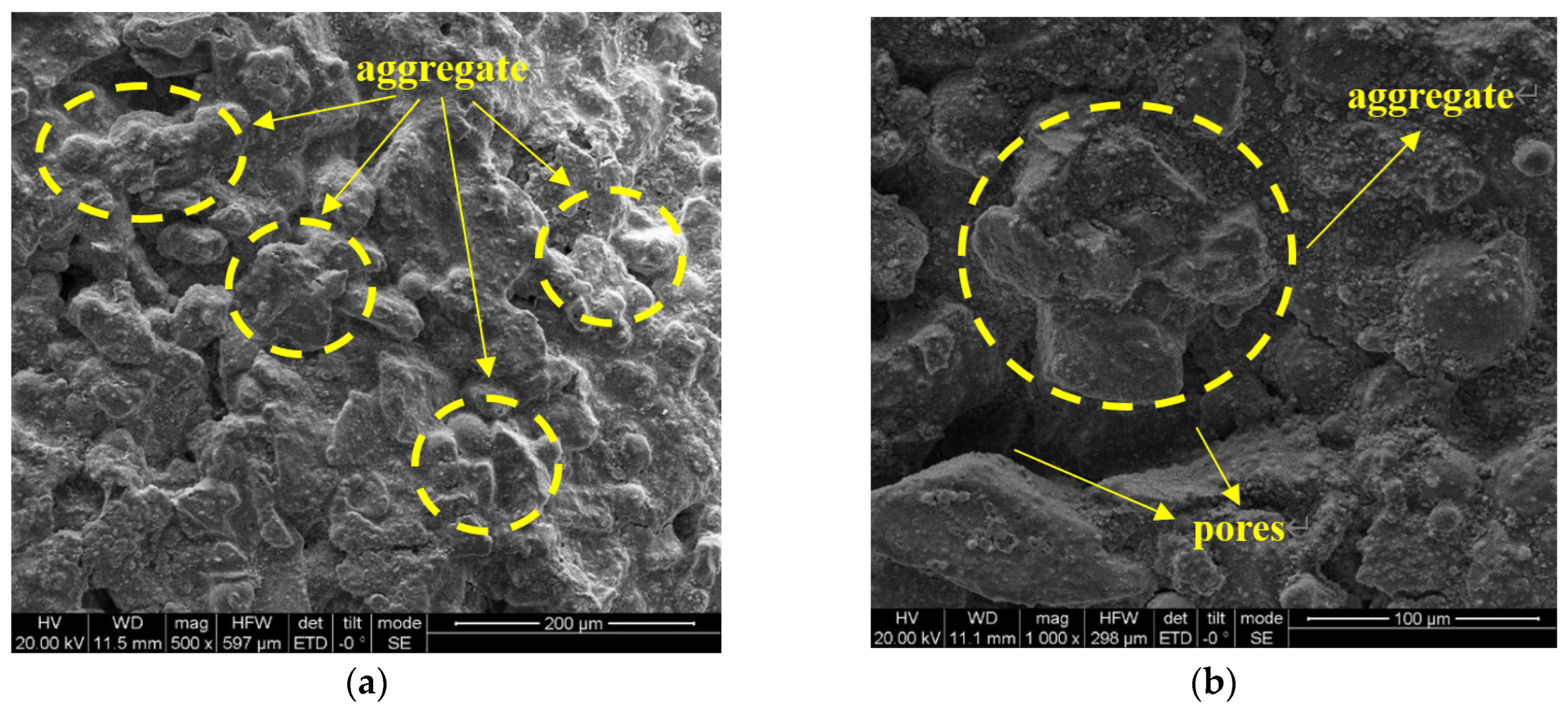

- A microstructural examination discloses the presence of binding substances enveloping soil particles in the treated soil. These substances facilitate the agglomeration of smaller particles into larger clusters while simultaneously filling the interstitial voids to varying degrees, rendering the soil structure more compact and robust compared to untreated soil.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, T.L.; Liu, Y.J.; Yan, H.; Xu, L. An experimental study on the mechanical properties of silty soils under repeated freeze–thaw cycles. Cold Reg. Sci. Technol. 2015, 112, 51–65. [Google Scholar] [CrossRef]

- Barbieri, D.M.; Lou, B.; Dyke, R.J.; Wang, X.; Chen, H.; Shu, B.; Gazder, U.; Horpibulsuk, S.; Tingle, J.S.; Hoff, I. Design and sustainability analyses of road base layers stabilized with traditional and nontraditional additives. J. Clean. Prod. 2022, 372, 133752. [Google Scholar] [CrossRef]

- Khodaparast, M.; Rajabi, A.M.; Mohammadi, M. Mechanical properties of silty clay soil treated with a mixture of lime and zinc oxide nanoparticles. Constr. Build. Mater. 2021, 281, 122548. [Google Scholar] [CrossRef]

- Zhang, T.; Cai, G.J.; Liu, S.Y. Assessment of mechanical properties in recycled lignin-stabilized silty soil as base fill material. J. Clean. Prod. 2018, 172, 1788–1799. [Google Scholar] [CrossRef]

- Aziz, M.; Hamza, M.; Rasool, A.M.; Ali, U.; Ahmed, T.; Kharal, Z.N.; Khan, A.H.; Rehman, Z.U. Use of graphene oxide nanomaterial to improve mechanical properties of cement-treated silty soil. Arab. J. Sci. Eng. 2023, 48, 5603–5618. [Google Scholar] [CrossRef]

- Tang, C.S.; Zhu, C.; Cheng, Q.; Zeng, H.; Xu, J.J.; Tian, B.G.; Shi, B. Desiccation cracking of soils: A review of investigation approaches, underlying mechanisms, and influencing factors. Earth Sci. Rev. 2021, 216, 103586. [Google Scholar] [CrossRef]

- Zhou, S.; Xie, L.; Jia, Y.; Wang, C. Review of cementitious composites containing polyethylene fibers as repairing materials. Polymers 2020, 12, 2624. [Google Scholar] [CrossRef]

- Mariri, M.; Ziaie Moayed, R.; Kordnaeij, A. Stress–strain behavior of loess soil stabilized with cement, zeolite, and recycled polyester fiber. J. Mater. Civ. Eng. 2019, 31, 04019291. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Gao, W.; Chen, F.; Cai, Y. Strength and mechanical behavior of short polypropylene fiber reinforced and cement stabilized clayey soil. Geotext. Geomembr. 2007, 25, 194–202. [Google Scholar] [CrossRef]

- Ahmed, A.; Gariepy, Y.; Raghavan, V. Influence of wood-derived biochar on the compactibility and strength of silt loam soil. Int. Agrophy. 2017, 31, 149–155. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Geetha, A.R.; Jananee, R.; Karunya, S.R. Strength and mechanical behaviour of coir reinforced lime stabilized soil. Geomech. Eng. 2018, 16, 627. [Google Scholar]

- Sujatha, E.R.; Lakshmi Priya, E.; Sangavi, A.R.; Poonkuzhali, K.V. Influence of random inclusion of treated sisal fibres on the unconfined compressive strength of highly compressible clay. Sci. Iran. 2018, 25, 2517–2524. [Google Scholar]

- Ma, Z.; Ryberg, M.W.; Wang, P.; Tang, L.; Chen, W.-Q. China’s import of waste PET bottles benefited global plastic circularity and environmental performance. ACS Sustain. Chem. Eng. 2020, 8, 16861–16868. [Google Scholar] [CrossRef]

- Sun, X.; Wang, X.; Sun, F.; Tian, M.; Qu, L.; Perry, P.; Owens, H.; Liu, X. Textile waste fiber regeneration via a green chemistry approach: A molecular strategy for sustainable fashion. Adv. Mater. 2021, 33, 2105174. [Google Scholar] [CrossRef]

- Akbulut, S.; Arasan, S.; Kalkan, E. Modification of clayey soils using scrap tire rubber and synthetic fibers. Appl. Clay Sci. 2007, 38, 23–32. [Google Scholar] [CrossRef]

- Miller, C.J.; Rifai, S. Fiber reinforcement for waste containment soil liners. J. Environ. Eng. 2004, 130, 891–895. [Google Scholar] [CrossRef]

- Chegenizadeh, A.; Nikraz, H. Effect of fibre content on compressive strength of reinforced soil. In Proceedings of the International Conference on Advances in Geotechnical Engineering, Perth, WA, Australia, 7–9 November 2011; pp. 489–495. [Google Scholar]

- Shao, W.; Cetin, B.; Li, Y.; Li, J.; Li, L. Experimental investigation of mechanical properties of sands reinforced with discrete randomly distributed fiber. Geotech. Geol. Eng. 2014, 32, 901–910. [Google Scholar] [CrossRef]

- Tang, C.S.; Shi, B.; Gao, W.; Cai, Y.; Liu, J. Study on effects of sand content on strength of polypropylene fiber reinforced clay soil. Chin. J. Rock Mech. Eng. 2007, 26, 2968. [Google Scholar]

- Balakrishnan, S.; Viswanadham, B.V.S. Evaluation of tensile load-strain characteristics of geogrids through in-soil tensile tests. Geotext. Geomembr. 2017, 45, 35–44. [Google Scholar] [CrossRef]

- Wang, D.Y.; Tang, C.S.; Li, J.I.; Liu, B.S.; Tang, W.; Zhu, K. Shear strength characteristics of fiber-reinforced unsaturated cohesive soils. Chin. J. Geotech. Eng. 2013, 35, 1933–1940. [Google Scholar]

- Anagnostopoulos, C.A.; Papaliangas, T.T.; Konstantinidis, D.; Patronis, C. Shear strength of sands reinforced with polypropylene fibers. Geotech. Geol. Eng. 2013, 31, 401–423. [Google Scholar] [CrossRef]

- Zhang, Y.; Johnson, A.E.; White, D.J. Freeze-thaw performance of cement and fly ash stabilized loess. Transp. Geotech. 2019, 21, 100279. [Google Scholar] [CrossRef]

- Chaduvula, U.; Viswanadham, B.V.S.; Kodikara, J. A study on desiccation cracking behavior of polyester fiber-reinforced expansive clay. Appl. Clay Sci. 2017, 142, 163–172. [Google Scholar] [CrossRef]

- JTG E40-2007; Test Methods of Soils for Highway Engineering. Ministry of Construction of People’s Republic of China: Beijing, China, 2007.

- Zhang, T.; Yang, Y.-L.; Liu, S.-Y. Application of biomass by-product lignin stabilized soils as sustainable Geomaterials: A review. Sci. Total Environ. 2020, 728, 138830. [Google Scholar] [CrossRef]

- Pan, C.; Rui, X.; Xiaoqi, W.E.I.; Changfu, W.E.I.; Jili, W. Equation for Soil Shrinkage Curve of Clay Considering Soil-Water Adsorption Effect. J. Shanghai Jiaotong Univ. 2020, 54, 866. [Google Scholar]

- Gallipoli, D.; Gens, A.; Sharma, R.; Vaunat, J. An elasto-plastic model for unsaturated soil incorporating the effects of suction and degree of saturation on mechanical behaviour. Géotechnique 2003, 53, 123–135. [Google Scholar] [CrossRef]

- Cheng, Y.; Shi, M.L.; Zhou, Z.M. Aggregation effect of slaked lime on treated expansive soils. Rock Soil Mech. 2008, 29, 2209–2214. [Google Scholar]

- Najmaddin, D.Y.; Canakci, H. Compaction properties of sand mixed with modified waste EPS. Geotech. Geol. Eng. 2013, 31, 315–318. [Google Scholar] [CrossRef]

- Zhang, T. Study on Technology and Engineering Application of Silt Solidified by Lignin. Ph.D. Thesis, Institute of Geotechnical Engineering, Southeast University, Nanjing, China, 2015. [Google Scholar]

- JTG D30-2015; Specifications for Design of Highway Subgrades. Ministry of Transport of the People’s Republic of China: Beijing, China, 2015.

- JTG D50-2006; Standard Methods of Bituminous Pavement Design for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2006.

- Mishra, S.; Mohanty, A.K.; Drzal, L.T.; Misra, M.; Hinrichsen, G. A review on pineapple leaf fibers, sisal fibers and their biocomposites. Macromol. Mater. Eng. 2004, 289, 955–974. [Google Scholar] [CrossRef]

- Prabakar, J.; Sridhar, R.S. Effect of random inclusion of sisal fibre on strength behaviour of soil. Constr. Build. Mater. 2002, 16, 123–131. [Google Scholar] [CrossRef]

- Mattone, R. Sisal fibre reinforced soil with cement or cactus pulp in bahareque technique. Cem. Concr. Compos. 2005, 27, 611–616. [Google Scholar] [CrossRef]

- Dai, S.; Zollars, J. Resilient modulus of Minnesota road research project subgrade soil. Transp. Res. Rec. 2002, 1786, 20–28. [Google Scholar] [CrossRef]

- Arulrajah, A.; Yaghoubi, E.; Wong, Y.C.; Horpibulsuk, S. Recycled plastic granules and demolition wastes as construction materials: Resilient moduli and strength characteristics. Constr. Build. Mater. 2017, 147, 639–647. [Google Scholar] [CrossRef]

- Liu, X.; Congress, S.S.C.; Cai, G.; Liu, L.; Puppala, A.J. Evaluating the thermal performance of unsaturated bentonite–sand–graphite as buffer material for waste repository using an improved prediction model. Can. Geotech. J. 2022, 60, 301–320. [Google Scholar] [CrossRef]

- Liu, L.; Cai, G.; Zhang, J.; Liu, X.; Liu, K. Evaluation of engineering properties and environmental effect of recycled waste tire-sand/soil in geotechnical engineering: A compressive review. Renew. Sustain. Energy Rev. 2020, 126, 109831. [Google Scholar] [CrossRef]

- Liu, X.; Congress, S.S.C.; Cai, G.; Liu, L.; Liu, S.; Puppala, A.J.; Zhang, W. Development and validation of a method to predict the soil thermal conductivity using thermal piezocone penetration testing (T-CPTU). Can. Geotech. J. 2022, 59, 510–525. [Google Scholar] [CrossRef]

- McCarthy, M.J.; Csetenyi, L.J.; Sachdeva, A.; Dhir, R.K. Engineering and durability properties of fly ash treated lime-stabilised sulphate-bearing soils. Eng. Geol. 2014, 174, 139–148. [Google Scholar] [CrossRef]

- Cai, G.H.; Liu, S.Y.; Zheng, X.; Zou, H.; Shao, G.H.; Li, J.S. Freezing-thawing performance of reactive MgO-admixed silty clay subjected to forced carbonation. Cold Reg. Sci. Technol. 2021, 189, 103330. [Google Scholar] [CrossRef]

- Cai, G.H.; Du, Y.J.; Liu, S.Y.; Singh, D.N. Physical properties, electrical resistivity, and strength characteristics of carbonated silty soil admixed with reactive magnesia. Can. Geotech. J. 2015, 52, 1699–1713. [Google Scholar] [CrossRef]

| Soil Properties | Content |

|---|---|

| Plastic limit (%) | 22.8 |

| Liquid limit (%) | 31.6 |

| Plasticity index | 8.8 |

| Maximum dry density (g/cm3) | 1.81 |

| Optimum moisture content (%) | 16.45 |

| Specific gravity | 2.71 |

| pH | 8.21 |

| Chemical Composition | SiO2 | Al2O3 | CaO | Fe2O3 | K2O | MgO | Na2O | SO3 | P2O5 |

| Content/% | 61.32 | 13.24 | 6.68 | 3.41 | 2.61 | 2.47 | 2.17 | 0.23 | 0.18 |

| Specific Gravity | pH | Clay Particle Content/% (<2 μm) | Silt Particle Content/% (2–75 μm) | Coarse Grain Content/% (>75 μm) |

|---|---|---|---|---|

| 3.31 | 12.4 | 5.4 | 42.7 | 51.9 |

| Chemical Composition | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | Na2O | K2O | TiO2 |

| Content/% | 65.23 | 2.62 | 1.16 | 0.74 | 0.46 | 0.13 | 0.20 | 0.18 | 0.053 |

| Specific Gravity | Optimum Moisture Content (%) | Maximum Dry Density (g/cm3) |

|---|---|---|

| 2.15 | 23.2 | 1.34 |

| Chemical Composition | CaO | Fe2O3 | Al2O3 | SiO2 |

| Content/% | 2.8 | 7.9 | 28.4 | 46.2 |

| Test Project | Fiber Content (%) | Fiber Length (mm) | Curing Age (Day) | Other Description |

|---|---|---|---|---|

| limit water content | 0, 0.1, 0.3, 0.5, 0.7, 1.0 | 6, 9, 12, 15, 17 | 1, 7, 28 | --- |

| shrinkage test | 0, 0.1, 0.3, 0.5, 0.7, 1.0 | 6, 9, 12, 15, 17 | 7, 28 | compaction degree: 94%, 96% |

| compaction test | 0, 0.1, 0.3, 0.5, 0.7, 1.0 | 6, 9, 12, 15, 17 | 1 | heavy compaction |

| CBR | 0, 0.1, 0.3, 0.5, 0.7, 1.0 | 6, 9, 12, 15, 17 | 1, 7, 28 | compaction degree: 94%, 96%, 98% |

| unconfined compression strength | 0, 0.1, 0.3, 0.5, 0.7, 1.0 | 6, 9, 12, 15, 17 | 1, 7, 28 | compaction degree: 94%, 96%, 98% |

| resilience modulus | 0, 0.1, 0.3, 0.5, 0.7, 1.0 | 6, 9, 12, 15, 17 | 1, 7, 28 | compaction degree: 94%, 96%, 98% |

| dynamic stress and dynamic modulus | 0, 0.1, 0.3, 0.5, 0.7, 1.0 | 6, 9, 12, 15, 17 | 1, 7, 28 | compaction degree: 94%, 96% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Yan, S.; Liu, L. Reinforcement of Silty Soil via Regenerated Fiber Polymer: A Study on Microscopic Mechanisms. Materials 2023, 16, 6741. https://doi.org/10.3390/ma16206741

Liu X, Yan S, Liu L. Reinforcement of Silty Soil via Regenerated Fiber Polymer: A Study on Microscopic Mechanisms. Materials. 2023; 16(20):6741. https://doi.org/10.3390/ma16206741

Chicago/Turabian StyleLiu, Xiaoyan, Shihao Yan, and Lulu Liu. 2023. "Reinforcement of Silty Soil via Regenerated Fiber Polymer: A Study on Microscopic Mechanisms" Materials 16, no. 20: 6741. https://doi.org/10.3390/ma16206741

APA StyleLiu, X., Yan, S., & Liu, L. (2023). Reinforcement of Silty Soil via Regenerated Fiber Polymer: A Study on Microscopic Mechanisms. Materials, 16(20), 6741. https://doi.org/10.3390/ma16206741