Performance Prediction of Hybrid Bamboo-Reinforced Concrete Beams Using Gene Expression Programming for Sustainable Construction

Abstract

:1. Introduction

2. Materials and Methods

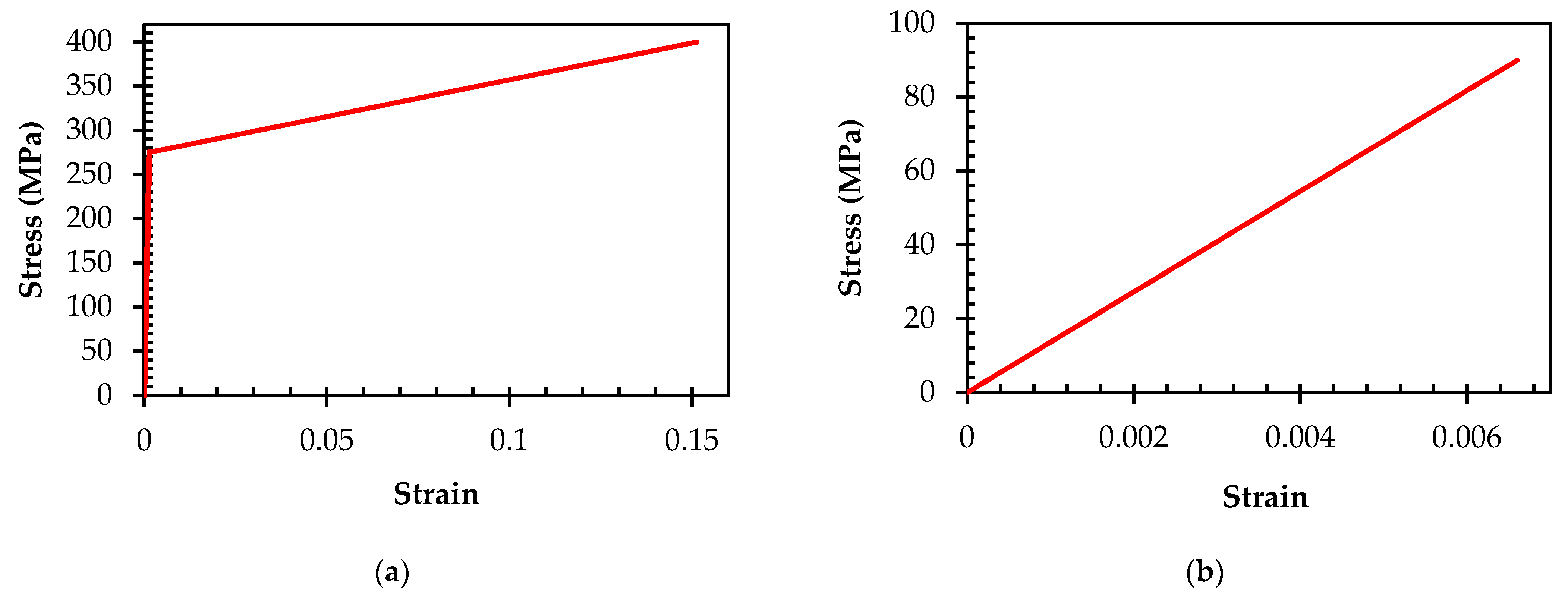

2.1. Constitutive Modeling of Material

- For tensile loading:

- For compressive loading:

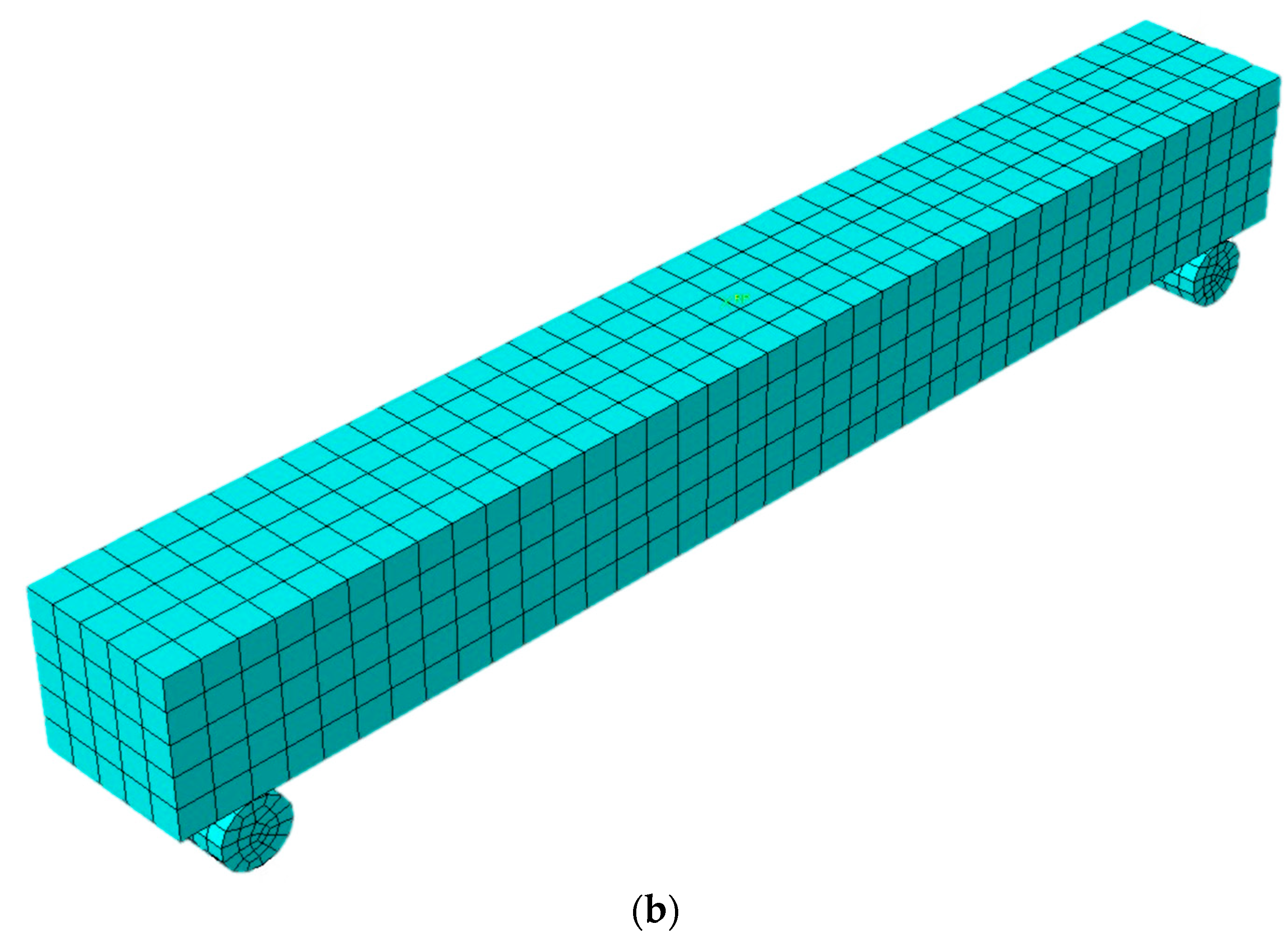

2.2. Description of Model

2.3. Boundary Conditions, Interactions, and Loading

2.4. Meshing

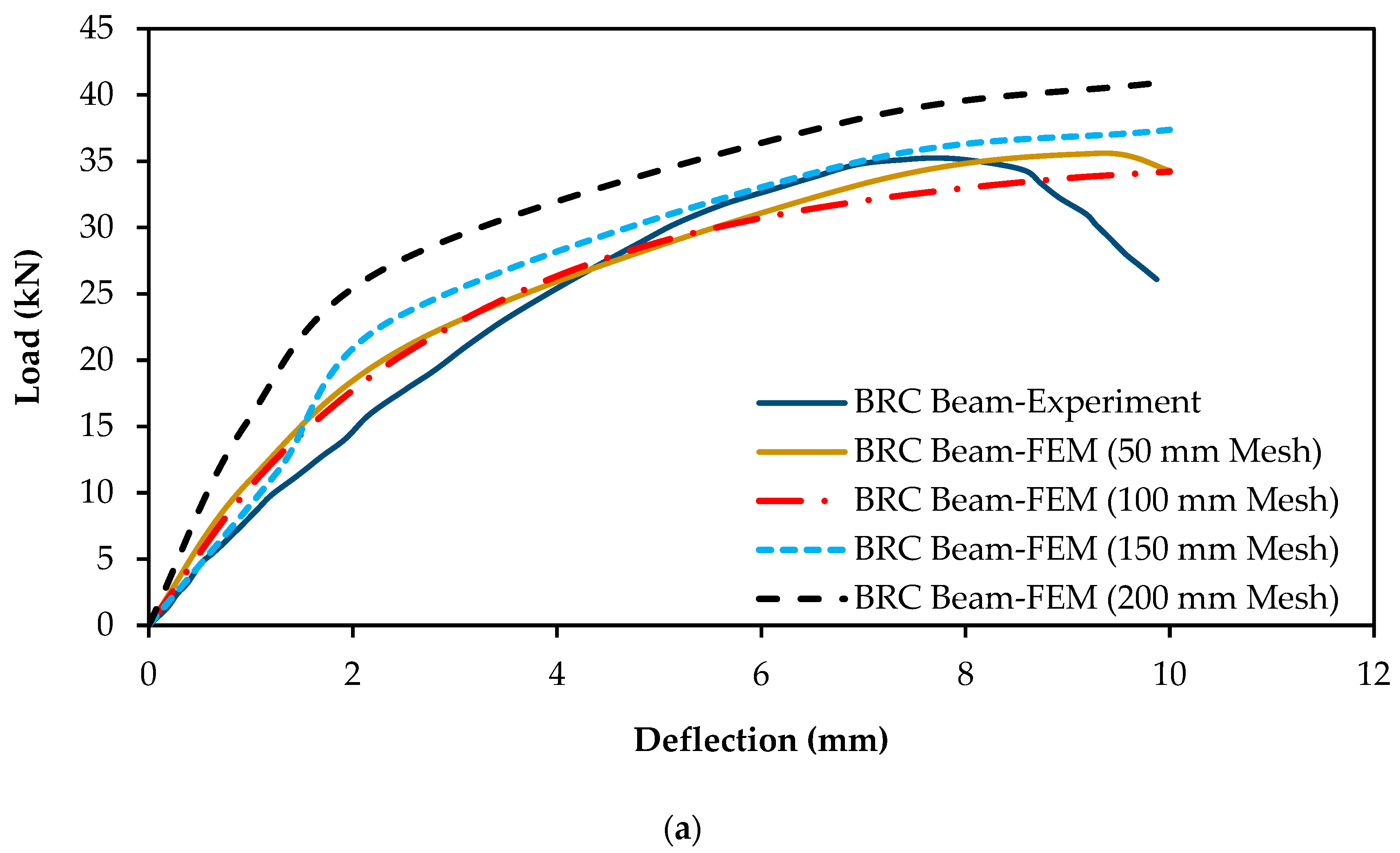

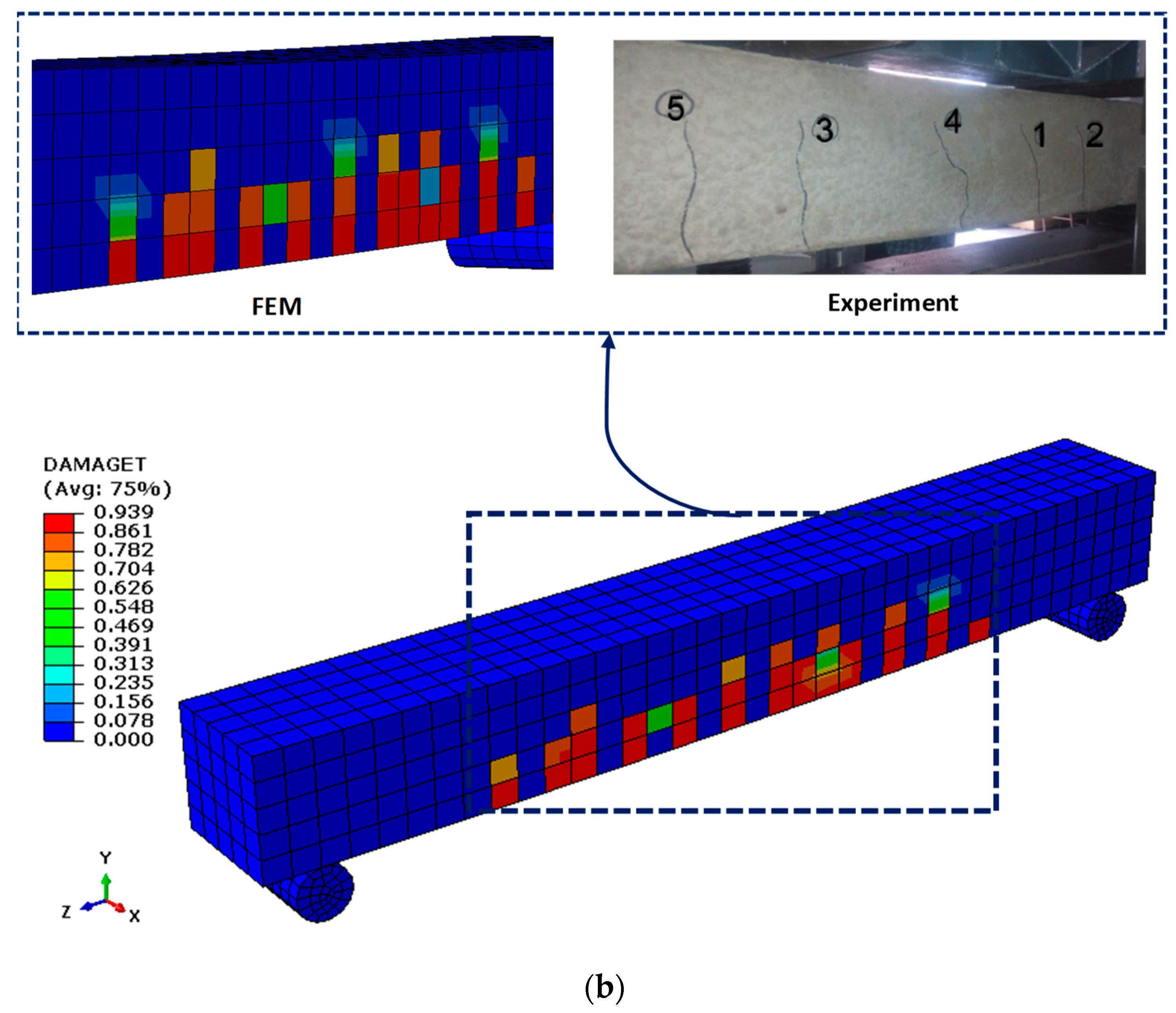

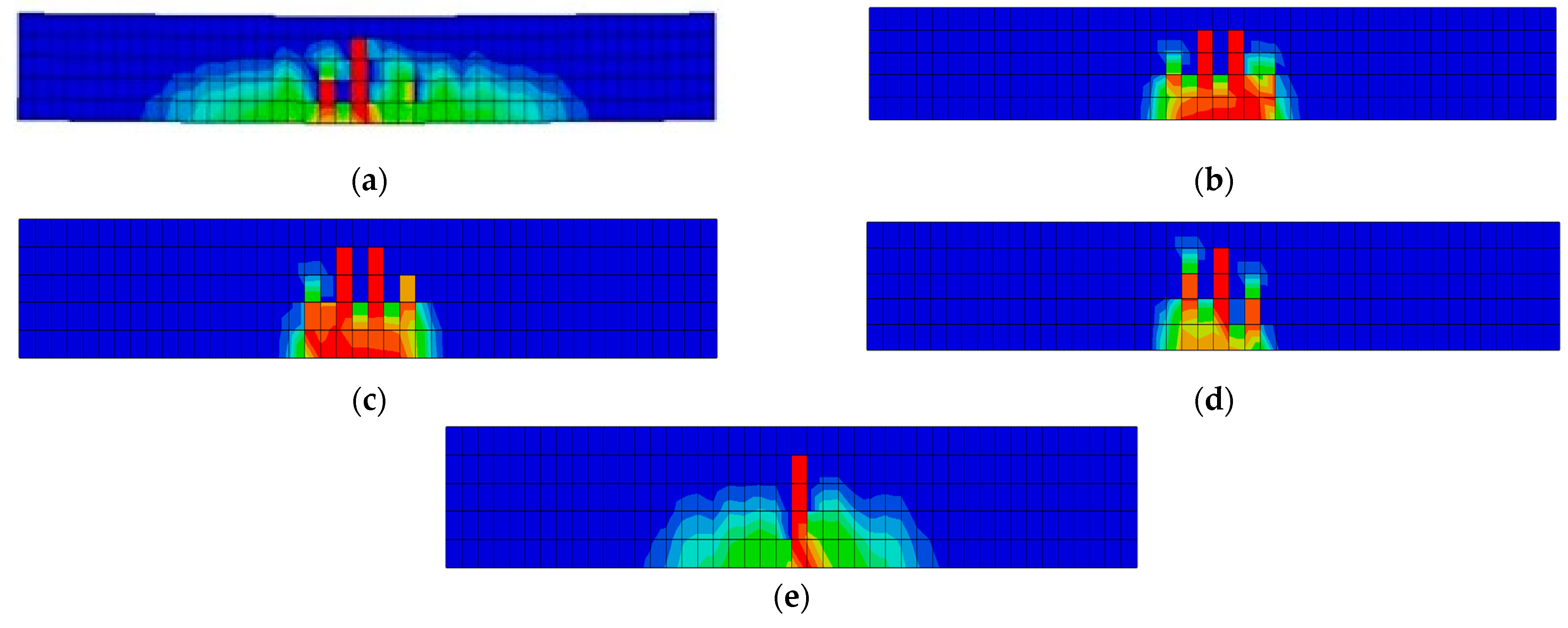

2.5. Validation of Model

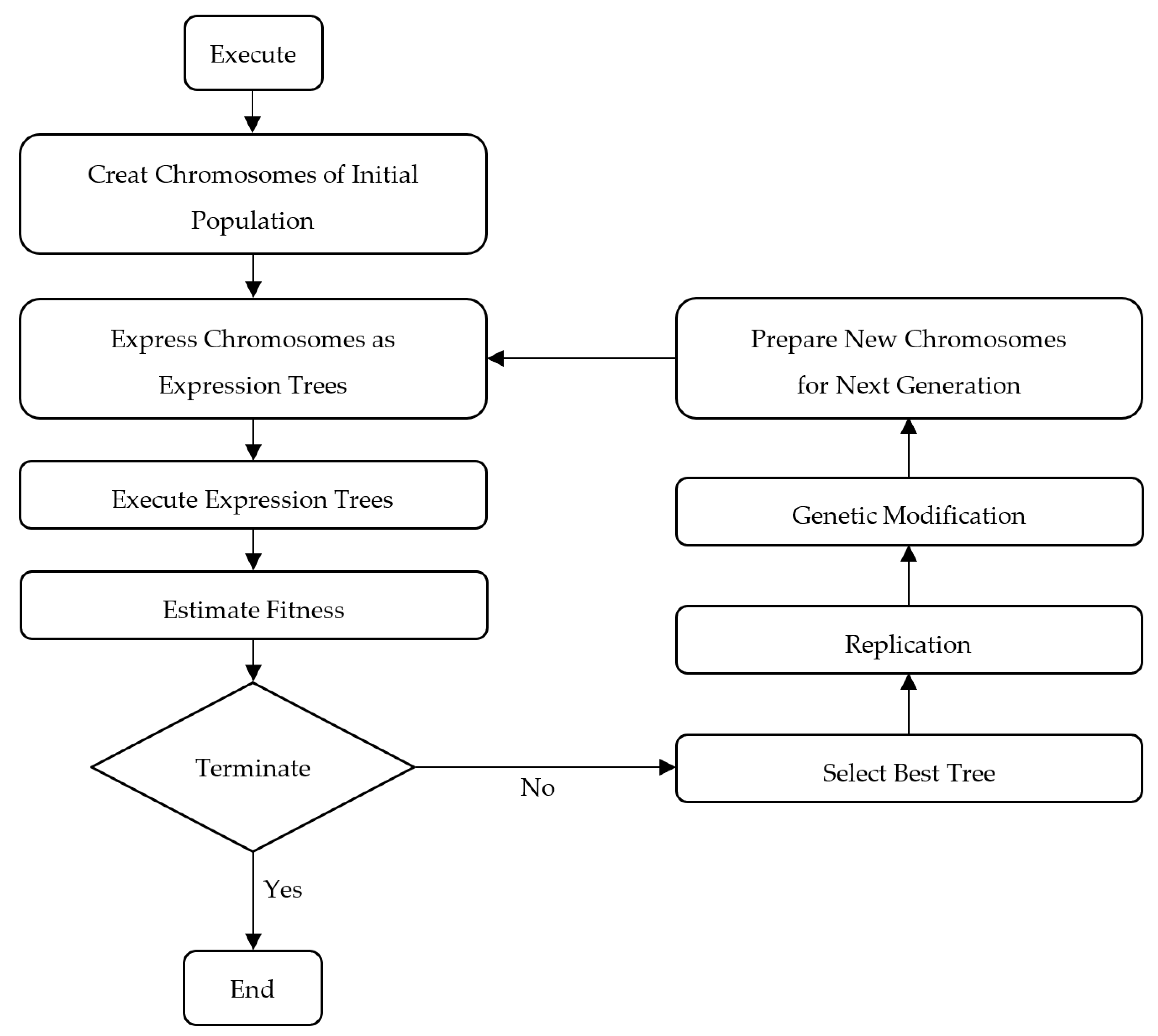

3. GEP Algorithm

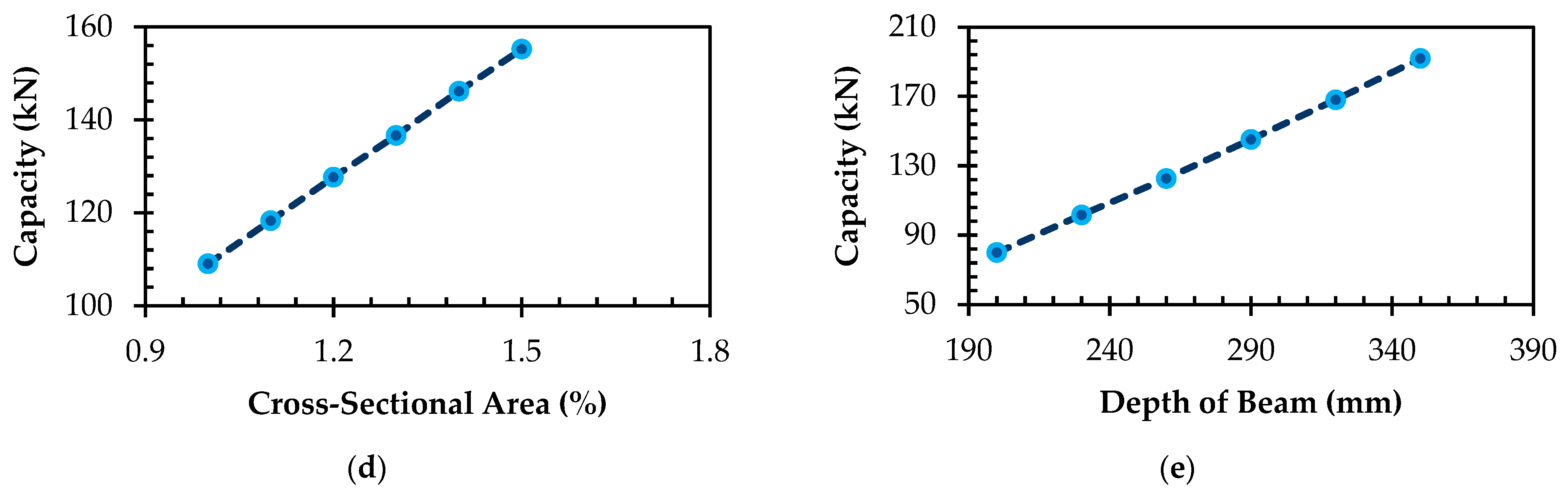

3.1. Parametric Study

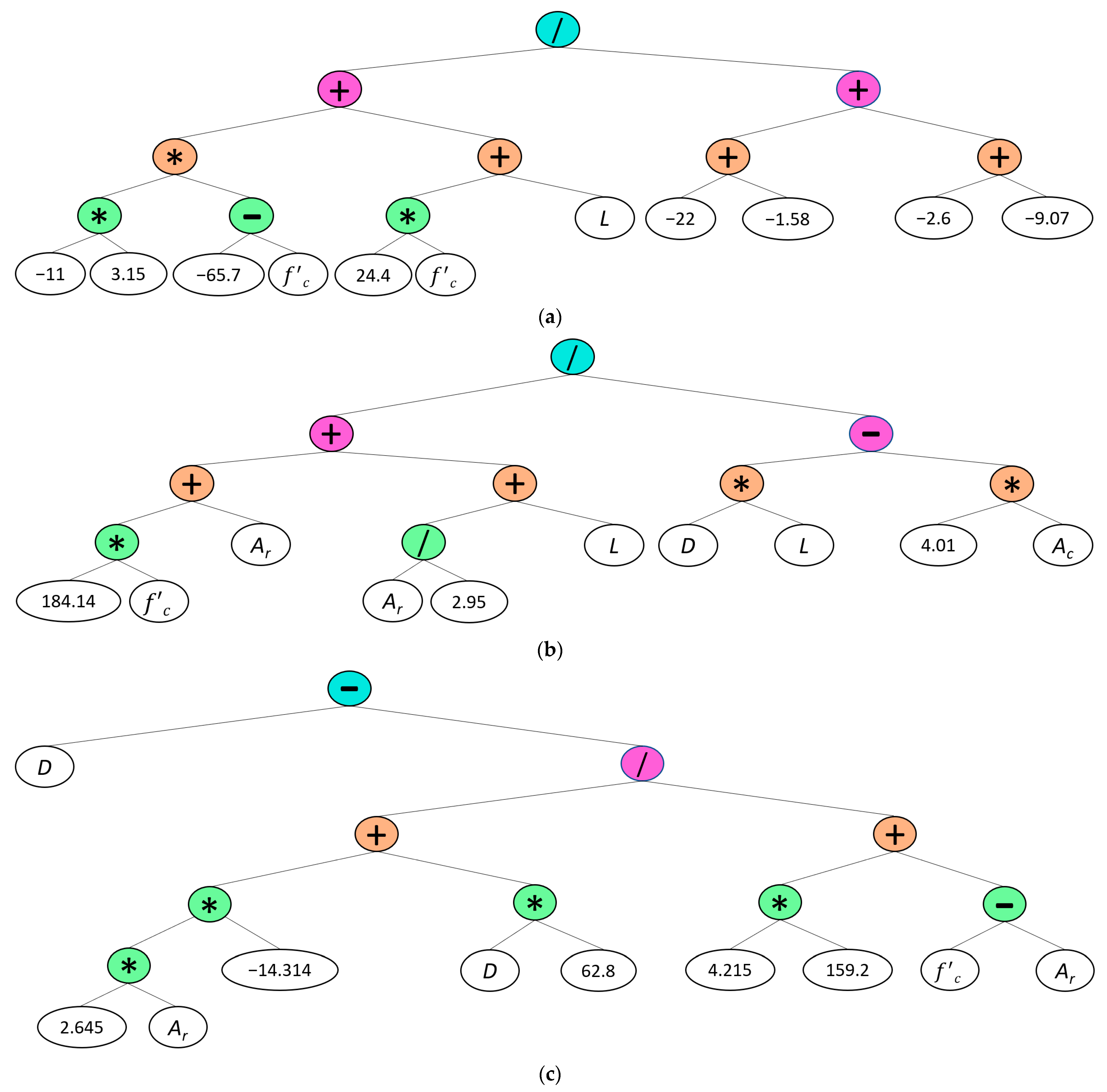

3.2. Proposed GEP Model for Estimating Flexural Strength of Hybrid BRC Beams

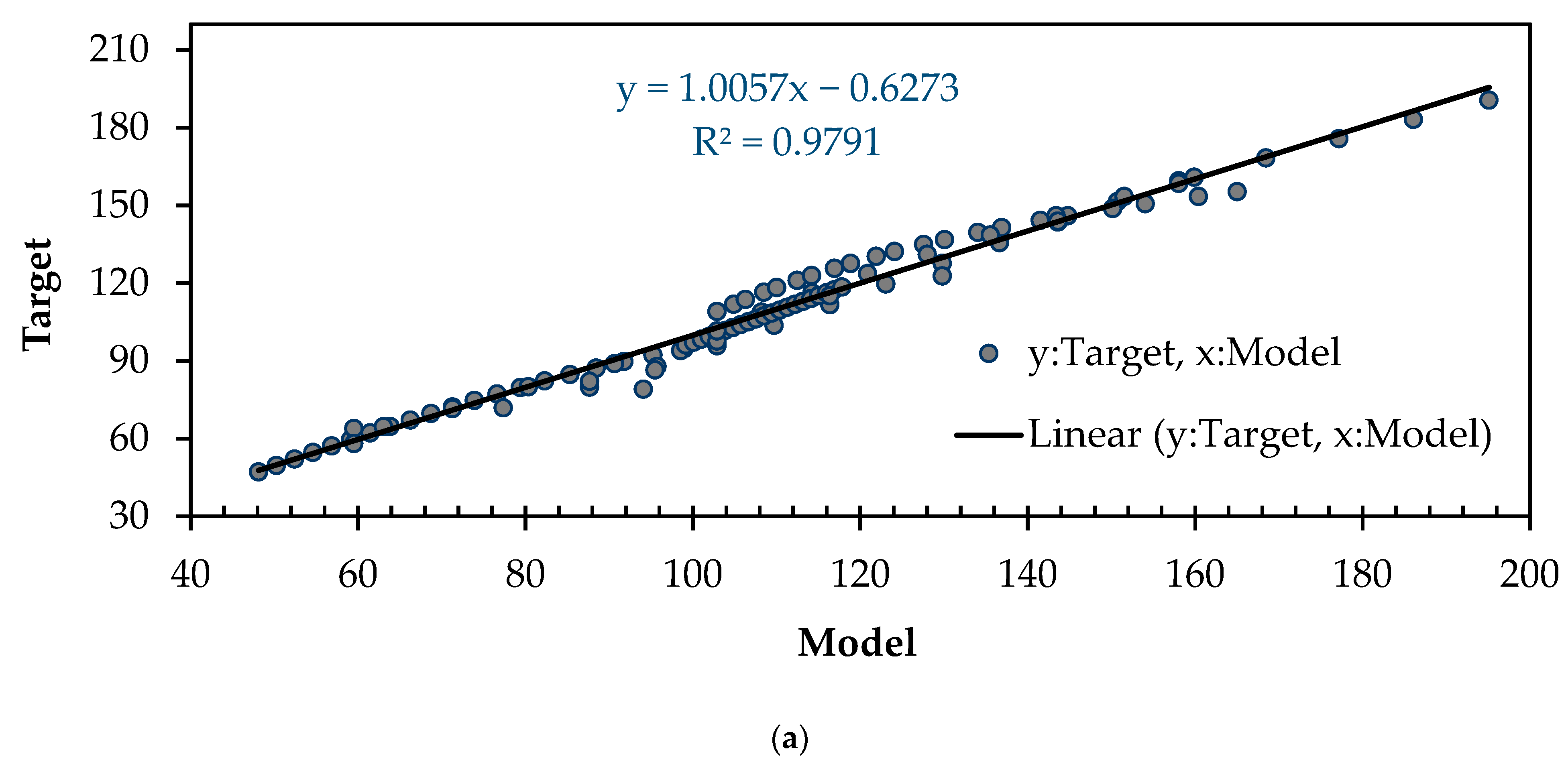

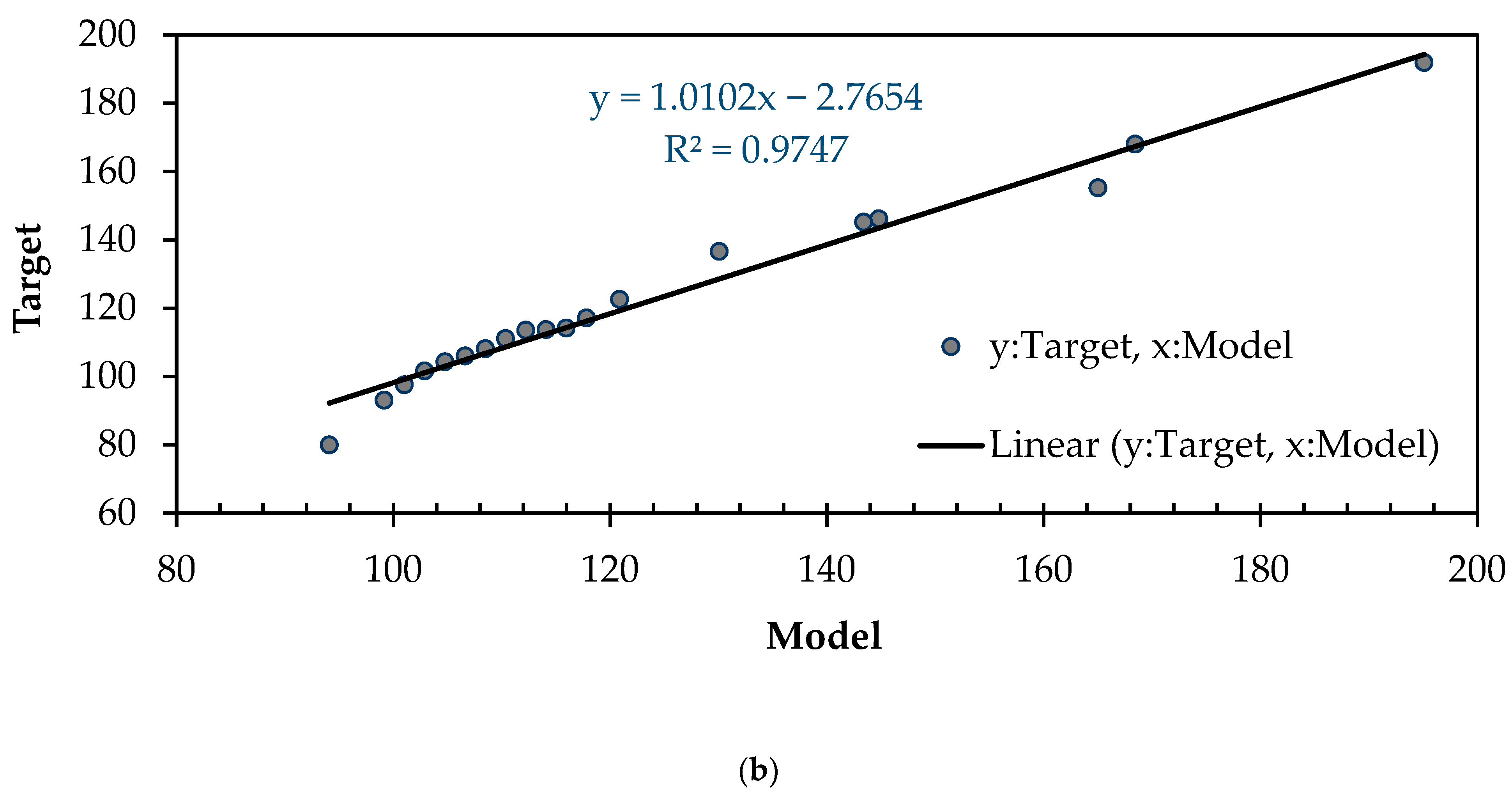

3.3. Accuracy and Validation of Proposed GEP Model

4. Results and Discussion

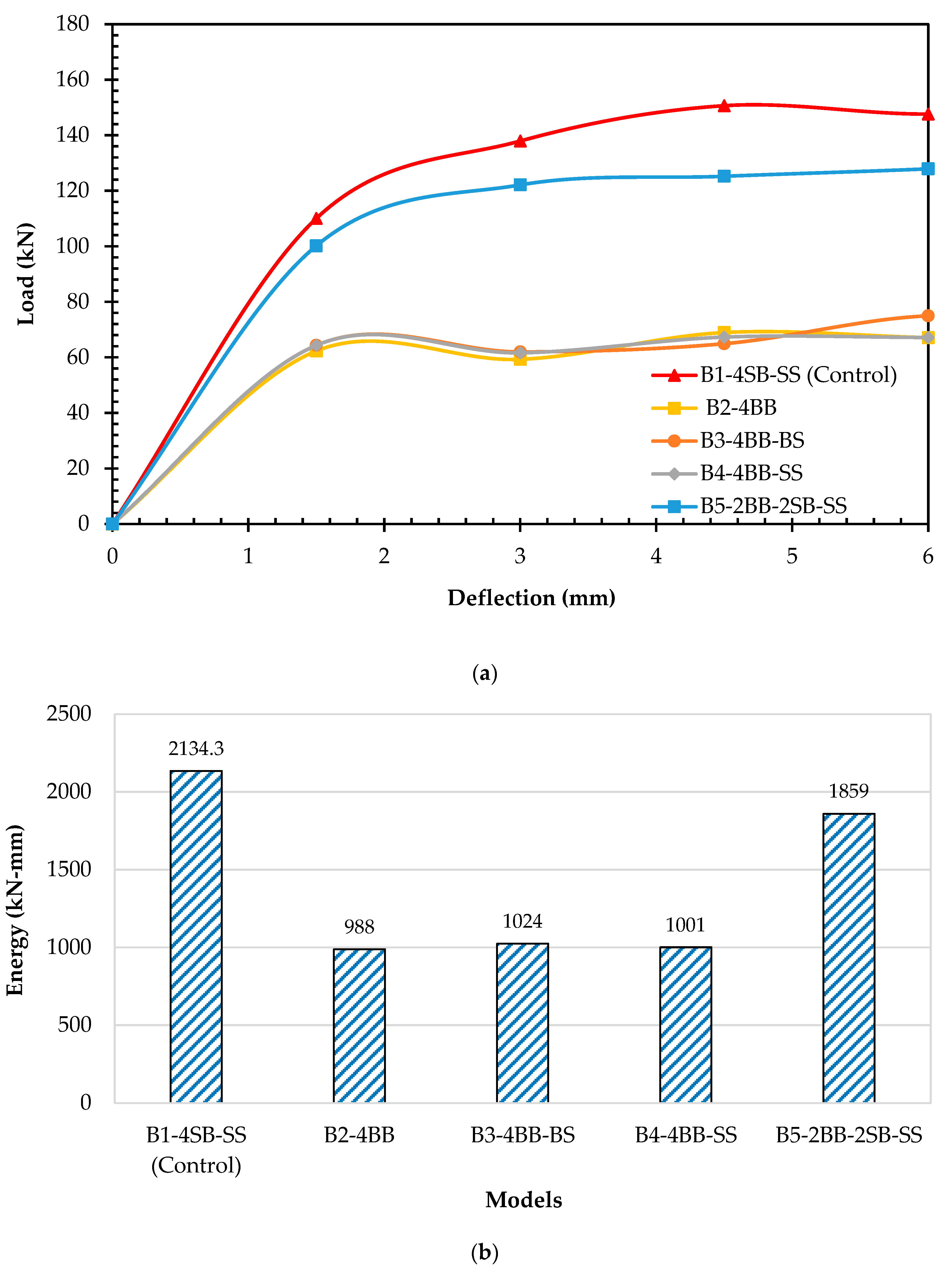

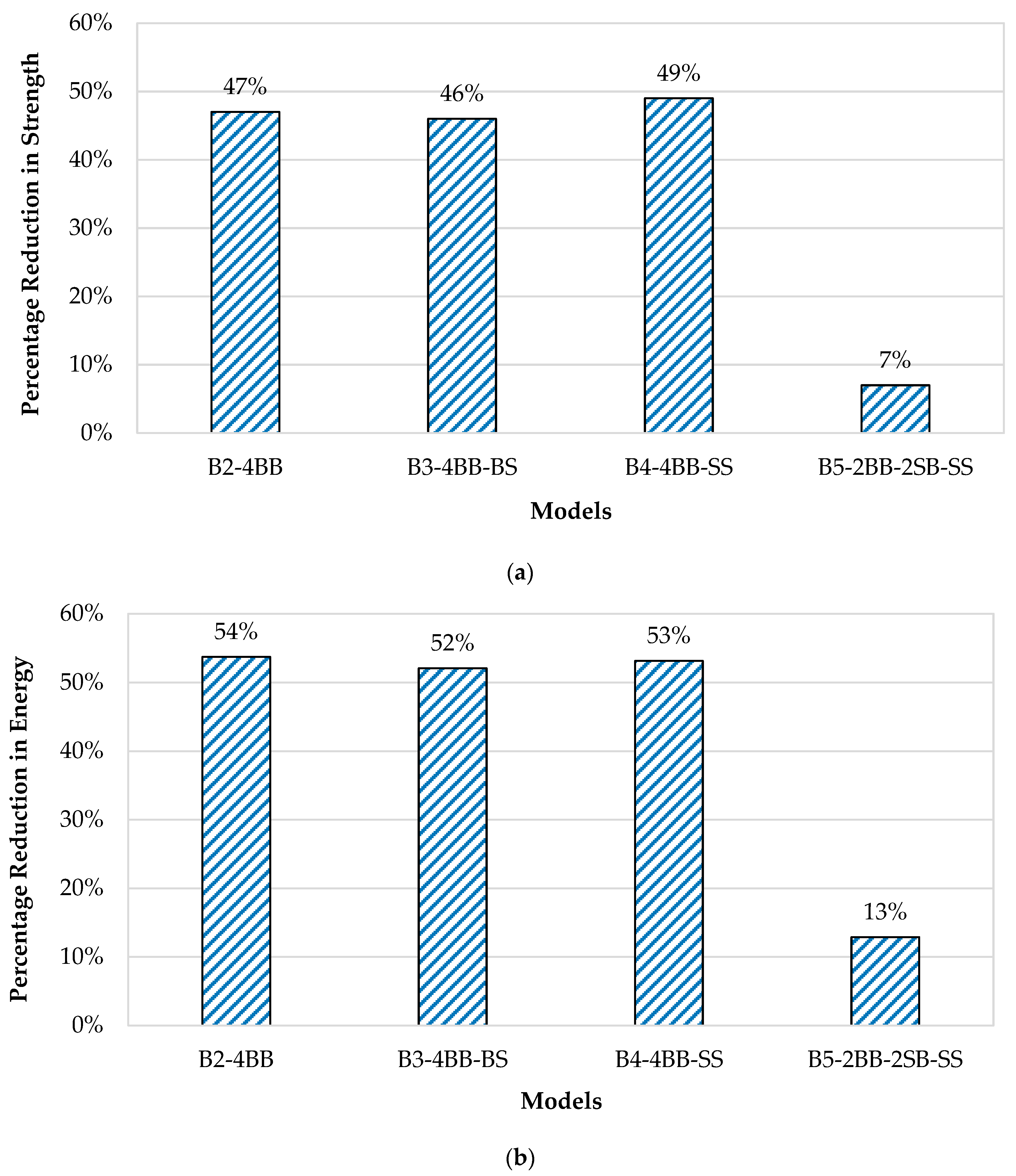

Load–Deflection Curves and Energy Absorption of All Models

5. Conclusions

- A hybrid beam configuration with 50% steel and 50% bamboo reinforcements in the tension region can achieve a competitive ultimate strength, with only the marginal 7% reduction compared to a conventional SRC beam. This proportion of bamboo replacement for steel in beam construction holds great promise for significantly reducing the reliance on steel resources in the building and construction industry.

- The proposed hybrid bamboo–steel beams revealed comparable serviceability performance while requiring less reinforcement. The energy absorption of the BRC and SRC beams proved to be quite similar, with the minimal difference of only 13%. This suggests that the BRC beams can meet the required performance standards while being an environmentally sustainable and cost-effective alternative.

- The developed GEP-based predictive model proved to be a robust tool for estimating the flexural strength of the BRC beams. By incorporating key parameters such as the cross-sectional area of concrete, area of reinforcements, concrete compressive strength, and span and depth of the beams, this model achieved an impressive 97% accuracy. This highlights its potential as a valuable tool for engineers and designers in the building and construction industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barbuta, M.; Bucur, R.D.; Cimpeanu, S.M.; Paraschiv, G.; Bucur, D. Wastes in building materials industry. In Agroecology; In Tech: London, UK, 2015. [Google Scholar] [CrossRef]

- Saingam, P.; Ejaz, A.; Ali, N.; Nawaz, A.; Hussain, Q.; Joyklad, P. Prediction of stress–strain curves for HFRP composite confined brick aggregate concrete under axial load. Polymers 2023, 15, 844. [Google Scholar] [CrossRef]

- Dräger, P.; Letmathe, P. Value losses and environmental impacts in the construction industry—Tradeoffs or correlates? J. Clean. Prod. 2022, 336, 130435. [Google Scholar] [CrossRef]

- Chaturvedi, S.; Ochsendorf, J. Global environmental impacts due to cement and steel. Struct. Eng. Int. 2004, 14, 198–200. [Google Scholar] [CrossRef]

- Suparp, S.; Ejaz, A.; Khan, K.; Hussain, Q.; Joyklad, P.; Saingam, P. Load-bearing performance of non-prismatic RC beams wrapped with carbon FRP composites. Sensors 2023, 23, 5409. [Google Scholar] [CrossRef] [PubMed]

- Yooprasertchai, E.; Ejaz, A.; Saingam, P.; Ng, A.W.M.; Joyklad, P. Development of stress-strain models for concrete columns externally strengthened with steel clamps. Constr. Build. Mater. 2023, 377, 131155. [Google Scholar] [CrossRef]

- Maraveas, C. Production of sustainable construction materials using agro-wastes. Materials 2020, 13, 262. [Google Scholar] [CrossRef]

- Muhtar. The prediction of stiffness reduction non-linear phase in bamboo reinforced concrete beam using the finite element method (FEM) and artificial neural networks (ANNs). Forests 2020, 11, 1313. [Google Scholar] [CrossRef]

- Al-Fasih, M.Y.; Hamzah, S.; Ahmad, Y.; Ibrahim, I.S.; Ariffin, M.A.M. Tensile properties of bamboo strips and flexural behaviour of the bamboo reinforced concrete beams. Eur. J. Environ. Civ. Eng. 2021, 26, 1015–1038. [Google Scholar] [CrossRef]

- Atanda, J. Environmental impacts of bamboo as a substitute constructional material in Nigeria. Case Stud. Constr. Mater. 2015, 3, 33–39. [Google Scholar] [CrossRef]

- Nurdiah, E.A. The potential of bamboo as building material in organic shaped buildings. Procedia—Soc. Behav. Sci. 2016, 216, 30–38. [Google Scholar] [CrossRef]

- Chaowana, P. Bamboo: An Alternative raw material for wood and wood-based composites. J. Mater. Sci. Res. 2013, 2, 90. [Google Scholar] [CrossRef]

- Ghavami, K. Bamboo as reinforcement in structural concrete elements. Cem. Concr. Compos. 2005, 27, 637–649. [Google Scholar] [CrossRef]

- Awalluddin, D.; Azreen, M.; Ariffin, M.; Osman, M.H.; Warid, M. Mechanical properties of different bamboo species. In Proceedings of the 6th International Conference of Euro Asia Civil Engineering Forum (EACEF 2017), Seoul, Republic of Korea, 22–25 August 2017; Volume 138, p. 1024. [Google Scholar] [CrossRef]

- Sabbir, A.; Mamun, S.; Fancy, S.F. Performance evaluation of bamboo twig as a potential reinforcement in concrete considering tensile property. Int. J. Eng. Res. Appl. 2012, 2, 3205–3209. [Google Scholar]

- Takeuchi, C.P.; Estrada, M.; Linero, D.L. The elastic modulus and Poisson’s ratio of laminated bamboo Guadua angustifolia. In Key Engineering Materials; Trans Tech Publications Ltd.: Bäch, Switzerland, 2016; pp. 126–133. [Google Scholar] [CrossRef]

- Archila, H.; Kaminski, S.; Trujillo, D.; Escamilla, E.Z.; Harries, K.A. Bamboo reinforced concrete: A critical review. Mater. Struct. 2018, 51, 102. [Google Scholar] [CrossRef]

- Obataya, E.; Kitin, P.; Yamauchi, H. Bending characteristics of bamboo (Phyllostachys pubescens) with respect to its fiber–foam composite structure. Wood Sci. Technol. 2007, 41, 385–400. [Google Scholar] [CrossRef]

- Dewi, S.M.; Nuralinah, D. The recent research on bamboo reinforced concrete. MATEC Web Conf. 2017, 103, 02001. Available online: https://www.academia.edu/en/34286511/The_Recent_Research_on_Bamboo_Reinforced_Concrete (accessed on 3 March 2023). [CrossRef]

- Tan, K.F.; Chin, S.C.; Doh, S.I.; Gimbun, J.; Mustafa, M.T. Potential use of bamboo reinforced concrete beams towards sustainable construction. In Civil Engineering and Urban Planning; World Scientific: Singapore, 2017; pp. 456–467. [Google Scholar] [CrossRef]

- Ramaswamy, S.N. Performance evaluation of bamboo reinforced concrete beam. Int. J. Civ. Eng. Technol. (IJCIET) 2019, 10, 2512–2523. [Google Scholar]

- Khan, I.K. Performance of bamboo reinforced concrete beam. Int. J. Sci. Environ. Technol. 2014, 3, 836–840. [Google Scholar]

- Qaiser, S.; Hameed, A.; Alyousef, R.; Aslam, F.; Alabduljabbar, H. Flexural strength improvement in bamboo reinforced concrete beams subjected to pure bending. J. Build. Eng. 2020, 31, 2020. [Google Scholar] [CrossRef]

- Javed, M.F.; Amin, M.N.; Shah, M.I.; Khan, K.; Iftikhar, B.; Farooq, F.; Aslam, F.; Alyousef, R.; Alabduljabbar, H. Applications of gene expression programming and regression techniques for estimating compressive strength of bagasse ash based concrete. Crystals 2020, 10, 737. [Google Scholar] [CrossRef]

- Javed, M.F.; Farooq, F.; Memon, S.A.; Akbar, A.; Khan, M.A.; Aslam, F.; Alyousef, R.; Alabduljabbar, H.; Rehman, S.K.U.; Rehman, S.K.U.; et al. New prediction model for the ultimate axial capacity of concrete-filled steel tubes: An evolutionary approach. Crystals 2020, 10, 741. [Google Scholar] [CrossRef]

- Murad, Y. Joint shear strength models for exterior RC beam-column connections exposed to biaxial and uniaxial cyclic loading. J. Build. Eng. 2020, 30, 101225. [Google Scholar] [CrossRef]

- Murad, Y.Z.; Hunifat, R.; Al-Bodour, W. Interior reinforced concrete beam-to-column joints subjected to cyclic loading: Shear strength prediction using gene expression programming. Case Stud. Constr. Mater. 2020, 13, e00432. [Google Scholar] [CrossRef]

- Naderpour, H.; Mirrashid, M. An innovative approach for compressive strength estimation of mortars having calcium inosilicate minerals. J. Build. Eng. 2018, 19, 205–215. [Google Scholar] [CrossRef]

- Tarawneh, A.; Almasabha, G.; Alawadi, R.; Tarawneh, M. Innovative and reliable model for shear strength of steel fibers reinforced concrete beams. Structures 2021, 32, 1015–1025. [Google Scholar] [CrossRef]

- Naderpour, H.; Haji, M.; Mirrashid, M. Shear capacity estimation of FRP-reinforced concrete beams using computational intelligence. Structures 2020, 28, 321–328. [Google Scholar] [CrossRef]

- Ebid, A.M.; Deifalla, A. Prediction of shear strength of FRP reinforced beams with and without stirrups using (GP) technique. Ain Shams Eng. J. 2021, 12, 2493–2510. [Google Scholar] [CrossRef]

- Iqbal, M.F.; Javed, M.F.; Rauf, M.; Azim, I.; Ashraf, M.; Yang, J.; Liu, Q.-F. Sustainable utilization of foundry waste: Forecasting mechanical properties of foundry sand based concrete using multi-expression programming. Sci. Total Environ. 2021, 780, 146524. [Google Scholar] [CrossRef]

- Murad, Y.; Imam, R.; Abu Hajar, H.; Habeh, D.; Hammad, A.; Shawash, Z. Predictive compressive strength models for green concrete. Int. J. Struct. Integr. 2019, 11, 169–184. [Google Scholar] [CrossRef]

- Shahmansouri, A.A.; Bengar, H.A.; Ghanbari, S. Compressive strength prediction of eco-efficient GGBS-based geopolymer concrete using GEP method. J. Build. Eng. 2020, 31, 101326. [Google Scholar] [CrossRef]

- Mansouri, I.; Güneyisi, E.M.; Mosalam, K.M. Improved shear strength model for exterior reinforced concrete beam-column joints using gene expression programming. Eng. Struct. 2020, 228, 111563. [Google Scholar] [CrossRef]

- Wei, Y.; Xue, X. Permeability prediction in tight carbonate rocks using gene expression programming (GEP). Rock Mech. Rock Eng. 2021, 54, 2581–2593. [Google Scholar] [CrossRef]

- Murad, Y.; Ashteyat, A.; Hunaifat, R. Predictive model to the bond strength of FRP-to-concrete under direct pullout using gene expression programming. J. Civ. Eng. Manag. 2019, 25, 773–784. [Google Scholar] [CrossRef]

- Azim, I.; Yang, J.; Iqbal, M.F.; Mahmood, Z.; Javed, M.F.; Wang, F.; Liu, Q.-F. Prediction of catenary action capacity of RC beam-column substructures under a missing column scenario using evolutionary algorithm. KSCE J. Civ. Eng. 2021, 25, 891–905. [Google Scholar] [CrossRef]

- Aval, S.B.; Ketabdari, H.; Gharebaghi, S.A. Estimating shear strength of short rectangular reinforced concrete columns using nonlinear regression and gene expression programming. Structures 2017, 12, 13–23. [Google Scholar] [CrossRef]

- Iqbal, M.F.; Liu, Q.-F.; Azim, I.; Zhu, X.; Yang, J.; Javed, M.F.; Rauf, M. Prediction of mechanical properties of green concrete incorporating waste foundry sand based on gene expression programming. J. Hazard. Mater. 2019, 384, 121322. [Google Scholar] [CrossRef]

- Murad, Y.Z.; Tarawneh, B.K.; Ashteyat, A.M. Prediction model for concrete carbonation depth using gene expression programming. Comput. Concr. 2020, 26, 497–504. [Google Scholar] [CrossRef]

- Azim, I.; Yang, J.; Iqbal, M.F.; Javed, M.F.; Nazar, S.; Wang, F.; Liu, Q.-F. Semi-analytical model for compressive arch action capacity of RC frame structures. Structures 2020, 27, 1231–1245. [Google Scholar] [CrossRef]

- Hamdia, K.M.; Ghasemi, H.; Bazi, Y.; AlHichri, H.; Alajlan, N.; Rabczuk, T. A novel deep learning based method for the computational material design of flexoelectric nanostructures with topology optimization. Finite Elem. Anal. Des. 2019, 165, 21–30. [Google Scholar] [CrossRef]

- Hamdia, K.M.; Ghasemi, H.; Zhuang, X.; Alajlan, N.; Rabczuk, T. Computational machine learning representation for the flexoelectricity effect in truncated pyramid structures. Comput. Mater. Contin. 2019, 59, 79–87. [Google Scholar] [CrossRef]

- Gao, W.; Karbasi, M.; Derakhsh, A.M.; Jalili, A. Development of a novel soft-computing framework for the simulation aims: A case study. Eng. Comput. 2018, 35, 315–322. [Google Scholar] [CrossRef]

- Tariq, M.; Khan, A.; Ullah, A.; Zamin, B.; Kashyzadeh, K.R.; Ahmad, M. Gene expression programming for estimating shear strength of RC squat wall. Buildings 2022, 12, 918. [Google Scholar] [CrossRef]

- Kavitha, S.; Kala, T.F. Fire resistance of bamboo fiber reinforced SCC with GGBS and alccofine partially in place of cement. ACS J. Sci. Eng. 2021, 1, 38–46. [Google Scholar] [CrossRef]

- Hafezolghorani, M.; Hejazi, F.; Vaghei, R.; Jaafar, M.S.B.; Karimzade, K. Simplified damage plasticity model for concrete. Struct. Eng. Int. 2017, 27, 68–78. [Google Scholar] [CrossRef]

- Senthil, K.; Rupali, S.; Satyanarayanan, K.S. Experiments on ductile and non-ductile reinforced concrete frames under static and cyclic loading. J. Coupled Syst. Multiscale Dyn. 2017, 5, 38–50. [Google Scholar] [CrossRef]

- Senthil, K.; Rupali, S.; Kaur, N. The performance of monolithic reinforced concrete structure includes slab, beam and column against blast load. J. Mat. Eng. Struct. 2018, 5(2), 137–151. [Google Scholar]

- Iqbal, M.; Rai, S.; Sadique, M.; Bhargava, P. Numerical simulation of aircraft crash on nuclear containment structure. Nucl. Eng. Des. 2012, 243, 321–335. [Google Scholar] [CrossRef]

- Khan, A.; Ullah, A.; Tariq, M.; Waqas, H.A.; Khan, A.; Khan, J.S. Response of shear critical RC beam under transverse impact using improved linear complementarity. Structures 2023, 54, 1520–1540. [Google Scholar] [CrossRef]

- Zhao, K.; Wei, Y.; Yan, S.; Chen, S.; Dong, F. Experimental and analytical investigations on flexural behavior of bamboo beams strengthened with steel bars. Adv. Struct. Eng. 2021, 24, 3338–3356. [Google Scholar] [CrossRef]

- Xiao, Y.; Chen, Z.; Zhou, J.; Leng, Y.; Xia, R. Concrete plastic-damage factor for finite element analysis: Concept, simulation, and experiment. Adv. Mech. Eng. 2017, 9. [Google Scholar] [CrossRef]

- Shafique, T.; Tariq, Z.; Ahmad, S.; Khan, A.P.; Waqas, H.A. Comparative analysis of flexural capacity of bamboo reinforced and conventional steel reinforced concrete beams through numerical evaluation. Sustain. Struct. Mater. 2023, 6, 101–105. [Google Scholar]

- Simulia. Abaqus/CAE User’s Manual Abaqus 6.11 Abaqus/CAE User’s Manual; Simulia: Johnstone, RI, USA, 2011. [Google Scholar]

- American Concrete Institute. Building Code Requirements for Structural Concrete (ACI 318-19) Commentary on Building Code Requirements for Structural Concrete (ACI 318R-19); American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

- Tariq, M.; Khan, A.; Ullah, A.; Shayanfar, J.; Niaz, M. Improved shear strength prediction model of steel fiber reinforced concrete beams by adopting gene expression programming. Materials 2022, 15, 3758. [Google Scholar] [CrossRef] [PubMed]

- Tariq, M.; Khan, A.; Shayanfar, J.; Hanif, M.U.; Ullah, A. A regression model for predicting the shear strength of RC knee joint subjected to opening and closing moment. J. Build. Eng. 2021, 41, 102727. [Google Scholar] [CrossRef]

- Teodorescu, L.; Sherwood, D. High energy physics event selection with gene expression programming. Comput. Phys. Commun. 2008, 178, 409–419. [Google Scholar] [CrossRef]

- Ilie, I.; Dittrich, P.; Carvalhais, N.; Jung, M.; Heinemeyer, A.; Migliavacca, M.; Morison, J.I.L.; Sippel, S.; Subke, J.-A.; Wilkinson, M.; et al. Reverse engineering model structures for soil and ecosystem respiration: The potential of gene expression programming. Geosci. Model Dev. 2017, 10, 3519–3545. [Google Scholar] [CrossRef]

- Kose, M.M.; Kayadelen, C. Modeling of transfer length of prestressing strands using genetic programming and neuro-fuzzy. Adv. Eng. Softw. 2010, 41, 315–322. [Google Scholar] [CrossRef]

- Pham, T.M.; Hao, H. Prediction of the impact force on reinforced concrete beams from a drop weight. Adv. Struct. Eng. 2016, 19, 1710–1722. [Google Scholar] [CrossRef]

- Tariq, M.; Khan, A.; Ullah, A. Predicting the response of RC beam from a drop-weight using gene expression programming. Materials 2022, 15, 6910. [Google Scholar] [CrossRef]

| Material | Density (kg/m3) | Young’s Modulus (MPa) | Poisson’s Ratio | Compressive Strength (MPa) | Tensile Strength (MPa) |

|---|---|---|---|---|---|

| Bamboo | 700 | 18,475 | 0.20 | 90 | 90 |

| Steel | 7850 | 200,000 | 0.30 | 400 | 400 |

| Concrete | 2300 | 33,600 | 0.15 | 31.31 | 3.13 |

| Plasticity Parameter | Notation | Value |

|---|---|---|

| Dilation angle | ψ | 40 |

| Eccentricity | ϵ | 0.1 |

| Stress ratio | 1.16 | |

| Shape factor | K | 0.66 |

| Viscosity | μ | 0 |

| Designation | Reinforcement Type | Description |

|---|---|---|

| B1-4SB-SS (Control) | Steel | Reference beam with steel bars and steel stirrups |

| B2-4BB | Bamboo | Beam only with bamboo bars |

| B3-4BB-BS | Bamboo | Beam with bamboo bars and bamboo stirrups |

| B4-4BB-SS | Bamboo and steel | Beam with bamboo bars and steel stirrups |

| B5-2BB-2SB-SS | Bamboo and steel | Beam with 50% steel bars, 50% bamboo bars, and steel stirrups |

| Beam | Pu (kN) | ||

|---|---|---|---|

| Experiment | FEM | Experiment/FEM | |

| SRC | 51 | 49.6 | 1.028 |

| BRC | 35 | 34.22 | 1.023 |

| Parameter | Range |

|---|---|

| Concrete compressive strength (f’c) | 10–50 MPa |

| Span length (L) | 100–140% |

| Area of reinforcement (Ar) | 2–8% |

| Area of cross-section (Ac) | 100–150% |

| Depth of beam (D) | 200–350 mm |

| Function Set | +, −, /, x |

|---|---|

| Number of chromosomes | 50 |

| Head size | 10 |

| Number of genes | 3 |

| Linking function | Addition |

| One-point recombination | 0.0027 |

| Two-point recombination | 0.0027 |

| Constants per gene | 10 |

| Gene recombination | 0.0027 |

| Gene transposition | 0.0027 |

| Lower/upper bound of constants | −10/10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Waqas, H.A.; Bahrami, A.; Sahil, M.; Poshad Khan, A.; Ejaz, A.; Shafique, T.; Tariq, Z.; Ahmad, S.; Özkılıç, Y.O. Performance Prediction of Hybrid Bamboo-Reinforced Concrete Beams Using Gene Expression Programming for Sustainable Construction. Materials 2023, 16, 6788. https://doi.org/10.3390/ma16206788

Waqas HA, Bahrami A, Sahil M, Poshad Khan A, Ejaz A, Shafique T, Tariq Z, Ahmad S, Özkılıç YO. Performance Prediction of Hybrid Bamboo-Reinforced Concrete Beams Using Gene Expression Programming for Sustainable Construction. Materials. 2023; 16(20):6788. https://doi.org/10.3390/ma16206788

Chicago/Turabian StyleWaqas, Hafiz Ahmed, Alireza Bahrami, Mehran Sahil, Adil Poshad Khan, Ali Ejaz, Taimoor Shafique, Zain Tariq, Sajeel Ahmad, and Yasin Onuralp Özkılıç. 2023. "Performance Prediction of Hybrid Bamboo-Reinforced Concrete Beams Using Gene Expression Programming for Sustainable Construction" Materials 16, no. 20: 6788. https://doi.org/10.3390/ma16206788