On Characterization of Shear Viscosity and Wall Slip for Concentrated Suspension Flows in Abrasive Flow Machining

Abstract

:1. Introduction

2. Theoretical Analysis for Determining Shear Viscosity and Wall Slip Behaviors Using Capillary Flow Test

- (1)

- Measuring the flow rate and total pressure drop across capillaries with different length-to-diameter ratios and diameters within a designated flow rate range.

- (2)

- Applying the Bagley correction to these measurements to discern the dependency of on for various diameters.

- (3)

- Utilizing the Mooney method (as per Equation (6)) to establish the correlation between wall slip velocity and wall shear stress.

- (4)

- Employing Equation (7) to derive the relationship between shear viscosity and shear rate.

3. Experimental Materials and Methodology

3.1. Preparation of Abrasive Media

3.2. Capillary Flow Setup

- (1)

- An abrasive cylinder of 50 mm diameter and 220 mm length.

- (2)

- 304 stainless steel tubes of different specifications, detailed in Figure 1b.

- (3)

- A hydraulic system.

- (4)

- Two specialized sensors: a flat-film pressure sensor strategically placed close to the constriction (specifications: CYYZ51X, ranges 0–2.5 MPa and 0–10 MPa; repeatability: 0.1% F.S.; from Star Sensor Manufacturing Co., Ltd., Langfang, China); and a magnetostrictive displacement sensor (specifications: BYDS-OPLC03VM1-A3010G200FO; repeatability: ±0.002% F.S.; from Shanghai Boyi Industrial Co., Ltd., Shanghai, China).

- (5)

- An adapter flange making a converging half angle of 90° to the horizontal, aiming to achieve uniform pressure in the abrasive cylinder.

3.3. Small Amplitude Oscillatory Shear and Controlled Shear Rate Tests

4. Results and Discussion

4.1. Analysis of Capillary Flow Results and Discussion on Wall Slip Models

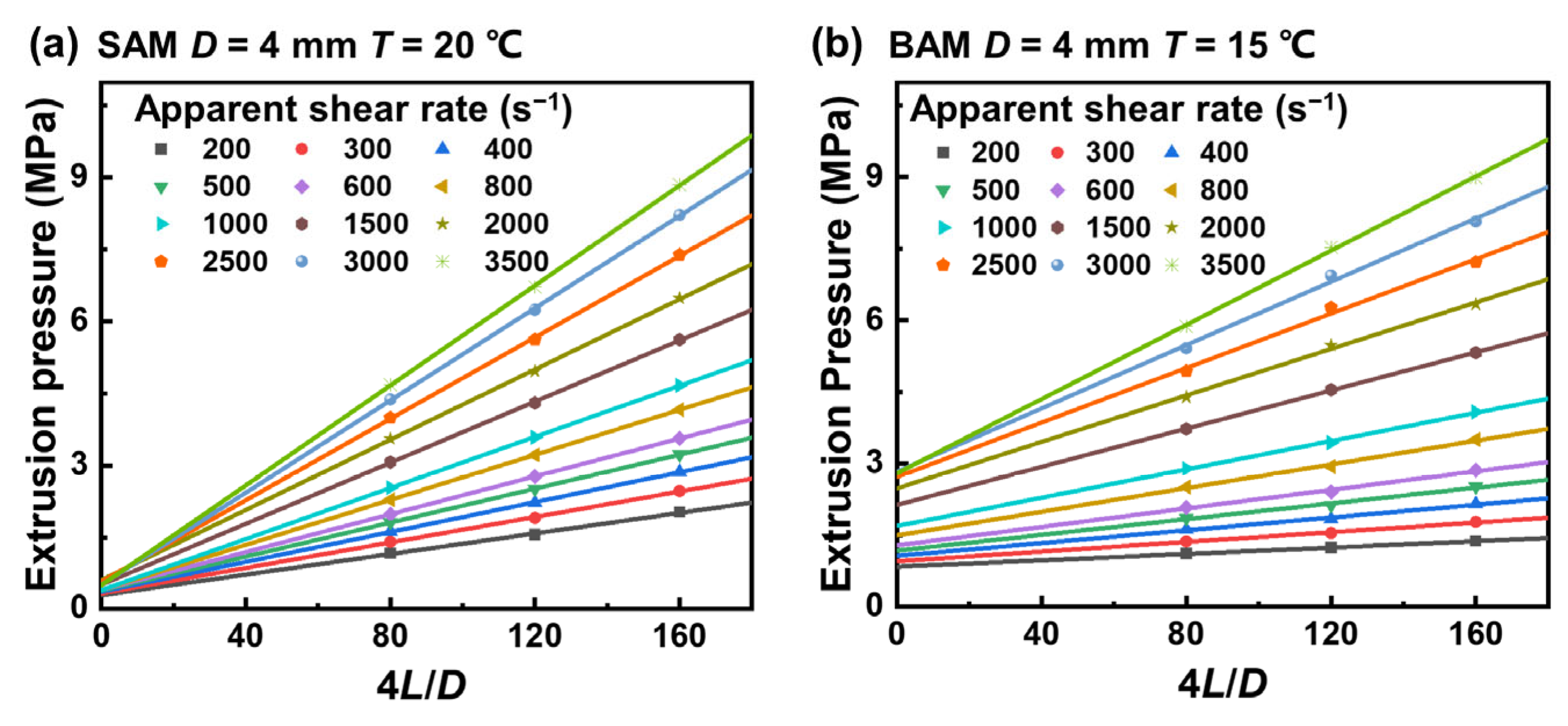

4.1.1. Entrance Pressure Loss Correction

4.1.2. Wall Slip Behavior Analysis of SAM and BAM

4.1.3. Wall Slip Mechanism and Lubricant’s Effects on Slip Behavior

4.2. Rheological Properties and Characterization

4.2.1. Linear Viscoelastic Properties

4.2.2. Examination of the Applicability of the Cox–Merz Rule

4.2.3. Rheological Characterization

5. Validation of the Rheological and Wall Slip Models

6. Conclusions

- (1)

- The abrasive media exhibit Navier nonlinear wall slip, as successfully revealed with the Mooney method. Drawing from the literature, the formation of a lubricant layer, influenced by internal shear forces, might contribute to this slip. The lubricant concentration could be a pivotal factor in this behavior.

- (2)

- CFT analysis uncovers significant wall slip phenomena and entrance pressure loss effects. The findings underscore the importance of our proposed compensation correction strategy for accurate evaluations. Through meticulous analysis of rheological data, the enhanced CFT method proved effective, especially for determining the shear viscosity of the abrasive media not aligned with the Cox–Merz rule. This is especially important at shear rates beyond the critical wall slip inception point, which are typically within 10 s−1.

- (3)

- Two fundamental models, the tailored constitutive model and the slip model, are effectively developed through the comprehensive framework. The first captures the inherent rheological attributes of the abrasive media, while the second details the interaction dynamics between the abrasive media and the solid boundary. This duality of insights culminates in the formulation of analytical prediction models tailored for the fully developed capillary flow of the abrasive media. The MAPE between the experimental data and predicted outcomes, which does not exceed 6.9%, demonstrates the models’ remarkable fidelity under careful scrutiny. Such close congruence demonstrates the comprehensive framework’s robustness, accuracy, and practicality.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature and Abbreviations

| Nomenclature | [−] | Actual observed values from experiments | |

| [m] | Diameter of circular tube | [−] | Predicted values |

| [m] | Diameter of abrasive cylinder | [−] | Shear strain |

| [Pa] | Storage modulus | [−] | Maximum value of oscillating shear strain |

| [Pa] | Loss modulus | [s−1] | Shear rate |

| [] | Slip coefficient | [s−1] | Apparent shear rate |

| [Pa·sn] | Consistency index | [s−1] | Maximum value of oscillating shear rate |

| [m] | Length of circular tube | [s−1] | The shear rate at the wall |

| [−] | Slip index | [Pa·s] | Shear viscosity |

| [−] | Mean absolute percentage error | [Pa·s] | Viscosity at zero shear rate |

| [−] | Power-law index | [Pa·s] | Viscosity at infinite shear rate |

| [−] | Total number of observations | [Pa·s] | Complex viscosity |

| [Pa] | Pressure | [s] | Time constant |

| [Pa] | Extrusion pressure | [Pa] | Shear stress acting in the z-direction on a plane normal to the r-direction |

| [Pa] | Entrance pressure drop | [Pa] | Shear stress on the wall |

| [Pa] | Pressure drop in fully developed region | [rad/s] | Frequency of oscillation |

| [Pa] | Exit pressure drop | Abbreviations | |

| [m3/s] | Volume flow rate | AIC | Akaike information criterion |

| , [m3/s] | Shear flow contribution to volume flow rate | AFM | Abrasive flow machining |

| [m3/s] | Wall slip contribution to volume flow rate | BAM | BSR-based abrasive media |

| [m, rad, m] | Coordinates of a cylindrical coordinate system | BIC | Bayesian information criterion |

| [m] | Radius of circular tube | BSR | Boron-modified silicone rubber |

| [m] | Displacement of piston | CFT | Capillary flow test |

| [s] | Time | CSRT | Controlled shear rate test |

| [−] | Loss factor | SAM | SBR-based abrasive media |

| [°C] | Temperature | SAOS | Small amplitude oscillatory shear |

| [m/s] | Velocity component in the z-direction | SBR | Styrene-butadiene rubber |

| [m/s] | Velocity at wall | W−R | Weissenberg–Rabinowitsch |

Appendix A. Analytical Models for Power-Law and Bird–Carreau Capillary Flows

References

- Rhoades, L. Abrasive Flow Machining: A Case Study. J. Mater. Process. Technol. 1991, 28, 107–116. [Google Scholar] [CrossRef]

- Kum, C.W.; Wu, C.H.; Wan, S.; Kang, C.W. Prediction and Compensation of Material Removal for Abrasive Flow Machining of Additively Manufactured Metal Components. J. Mater. Process. Technol. 2020, 282, 116704. [Google Scholar] [CrossRef]

- Fu, Y.; Gao, H.; Yan, Q.; Wang, X.; Wang, X. An Efficient Approach to Improving the Finishing Properties of Abrasive Flow Machining with the Analyses of Initial Surface Texture of Workpiece. Int. J. Adv. Manuf. Technol. 2020, 107, 2417–2432. [Google Scholar] [CrossRef]

- Dixit, N.; Sharma, V.; Kumar, P. Research Trends in Abrasive Flow Machining: A Systematic Review. J. Manuf. Process. 2021, 64, 1434–1461. [Google Scholar] [CrossRef]

- Zhang, L.; Huang, Y.; Chen, G.; Xu, M.; Xia, W.; Fu, Y. Experimental Study of Coverage Constraint Abrasive Flow Machining of Titanium Alloy Artificial Joint Surface. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2019, 233, 2399–2409. [Google Scholar] [CrossRef]

- Ferchow, J.; Baumgartner, H.; Klahn, C.; Meboldt, M. Model of Surface Roughness and Material Removal Using Abrasive Flow Machining of Selective Laser Melted Channels. Rapid Prototyp. J. 2020, 26, 1165–1176. [Google Scholar] [CrossRef]

- Bouland, C.; Urlea, V.; Beaubier, K.; Samoilenko, M.; Brailovski, V. Abrasive Flow Machining of Laser Powder Bed-Fused Parts: Numerical Modeling and Experimental Validation. J. Mater. Process. Technol. 2019, 273, 116262. [Google Scholar] [CrossRef]

- Fu, Y.; Wang, X.; Gao, H.; Wei, H.; Li, S. Blade Surface Uniformity of Blisk Finished by Abrasive Flow Machining. Int. J. Adv. Manuf. Technol. 2016, 84, 1725–1735. [Google Scholar] [CrossRef]

- Shao, Y.; Adetoro, O.B.; Cheng, K. Development of Multiscale Multiphysics-Based Modelling and Simulations with the Application to Precision Machining of Aerofoil Structures. Eng. Comput. 2021, 38, 1330–1349. [Google Scholar] [CrossRef]

- Peng, C.; Xu, Q.; Ding, L.; Zhou, T.; Gao, H.; Wang, X. Novel Insights into Abrasive Flow Machining Uniformity for SLM Channels. Int. J. Mech. Sci. 2023, 108726. [Google Scholar] [CrossRef]

- Wang, A.-C.; Tsai, L.; Liang, K.-Z.; Liu, C.-H.; Weng, S.-H. Uniform Surface Polished Method of Complex Holes in Abrasive Flow Machining. Trans. Nonferrous Met. Soc. China 2009, 19, s250–s257. [Google Scholar] [CrossRef]

- Chih-Hua, W.; Chun Wai, K.; Stephen Yee Ming, W.; Adri Muhammad, A.B. Numerical and Experimental Investigation of Abrasive Flow Machining of Branching Channels. Int. J. Adv. Manuf. Technol. 2020, 108, 2945–2966. [Google Scholar] [CrossRef]

- Wang, H.; Gao, H. Influence of Wall-Slip on Material Removal in Abrasive Flow Machining. Int. J. Mech. Sci. 2023, 108727. [Google Scholar] [CrossRef]

- Barnes, H.A. A Review of the Slip (Wall Depletion) of Polymer Solutions, Emulsions and Particle Suspensions in Viscometers: Its Cause, Character, and Cure. J. Non-Newton. Fluid Mech. 1995, 56, 221–251. [Google Scholar] [CrossRef]

- Anand, V. Effect of Slip on Heat Transfer and Entropy Generation Characteristics of Simplified Phan-Thien–Tanner Fluids with Viscous Dissipation under Uniform Heat Flux Boundary Conditions: Exponential Formulation. Appl. Therm. Eng. 2016, 98, 455–473. [Google Scholar] [CrossRef]

- Kang, M.; Gu, Y.; Lin, J.; Zhou, X.; Zhang, S.; Zhao, H.; Li, Z.; Yu, B.; Fu, B. Material Removal Mechanism of Non-Resonant Vibration-Assisted Magnetorheological Finishing of Silicon Carbide Ceramics. Int. J. Mech. Sci. 2023, 242, 107986. [Google Scholar] [CrossRef]

- Wei, H.; Peng, C.; Gao, H.; Wang, X.; Wang, X. On Establishment and Validation of a New Predictive Model for Material Removal in Abrasive Flow Machining. Int. J. Mach. Tools Manuf. 2019, 138, 66–79. [Google Scholar] [CrossRef]

- Jain, R.K.; Jain, V.K. Specific Energy and Temperature Determination in Abrasive Flow Machining Process. Int. J. Mach. Tools Manuf. 2001, 41, 1689–1704. [Google Scholar] [CrossRef]

- Shao, Y.; Cheng, K. Integrated Modelling and Analysis of Micro-Cutting Mechanics with the Precision Surface Generation in Abrasive Flow Machining. Int. J. Adv. Manuf. Technol. 2019, 105, 4571–4583. [Google Scholar] [CrossRef]

- Zhang, B.; Qiao, Y.; Khiabani, N.; Wang, X. Study on Rheological Behaviors of Media and Material Removal Mechanism for Abrasive Flow Machining (AFM) Micro Structures and Corresponding Simulations. J. Manuf. Process. 2022, 73, 248–259. [Google Scholar] [CrossRef]

- Wan, S.; Ang, Y.J.; Sato, T.; Lim, G.C. Process Modeling and CFD Simulation of Two-Way Abrasive Flow Machining. Int. J. Adv. Manuf. Technol. 2014, 71, 1077–1086. [Google Scholar] [CrossRef]

- Fan, W.; Sun, Y.; Su, Q.; Zhao, J.; Yang, F. Wall-Slip Characteristics of Viscoelastic Abrasive Medium in Abrasive Flow Machining Process. Int. J. Adv. Manuf. Technol. 2023, 127, 253–261. [Google Scholar] [CrossRef]

- Mooney, M. Explicit Formulas for Slip and Fluidity. J. Rheol. 1931, 2, 210–222. [Google Scholar] [CrossRef]

- Kalyon, D.M.; Aktaş, S. Factors Affecting the Rheology and Processability of Highly Filled Suspensions. Annu. Rev. Chem. Biomol. Eng. 2014, 5, 229–254. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Lee, S.S.; Kalyon, D.M. Shear Viscosity and Wall Slip Behavior of Dense Suspensions of Polydisperse Particles. J. Rheol. 2019, 63, 19–32. [Google Scholar] [CrossRef]

- Lam, Y.C.; Wang, Z.Y.; Chen, X.; Joshi, S.C. Wall Slip of Concentrated Suspension Melts in Capillary Flows. Powder Technol. 2007, 177, 162–169. [Google Scholar] [CrossRef]

- Aktas, S.; Kalyon, D.M.; Marín-Santibáñez, B.M.; Pérez-González, J. Shear Viscosity and Wall Slip Behavior of a Viscoplastic Hydrogel. J. Rheol. 2014, 58, 513–535. [Google Scholar] [CrossRef]

- Kalyon, D.M. Apparent Slip and Viscoplasticity of Concentrated Suspensions. J. Rheol. 2005, 49, 621–640. [Google Scholar] [CrossRef]

- Talmon, A.; Meshkati, E. Rheology, Rheometry and Wall Slip. In Slurry Technology—New Advances [Working Title]; IntechOpen: London, UK, 2022. [Google Scholar]

- Kumar, S.S.; Hiremath, S.S. Temperature-Dependent Rheological Properties of Viscoelastic Polymer Based Flexible Abrasive Media for Finishing Process. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2021, 235, 973–985. [Google Scholar] [CrossRef]

- Cox, W.P.; Merz, E.H. Correlation of Dynamic and Steady Flow Viscosities. J. Polym. Sci. 1958, 28, 619–622. [Google Scholar] [CrossRef]

- Fu, Y.; Gao, H.; Yan, Q.; Wang, X.; Wang, X. Rheological Characterisation of Abrasive Media and Finishing Behaviours in Abrasive Flow Machining. Int. J. Adv. Manuf. Technol. 2020, 107, 3569–3580. [Google Scholar] [CrossRef]

- Fan, W.; Sun, Y.; Liu, C.; Zhao, J.; Yang, F. Modeling and Quantitative Study of Soft Contact between Abrasive Medium and Active Abrasive Particles in Abrasive Flow Machining. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2023, 237, 1844–1854. [Google Scholar] [CrossRef]

- Rabinowitsch, B. Über Die Viskosität Und Elastizität von Solen. Z. Phys. Chem. 1929, 145A, 1–26. [Google Scholar] [CrossRef]

- Bagley, E.B. End Corrections in the Capillary Flow of Polyethylene. J. Appl. Phys. 1957, 28, 624–627. [Google Scholar] [CrossRef]

- Gao, H.; Fu, Y.Z.; Zhu, J.H.; Wu, M.Y.; Sun, Y.W. Study on the Characteristics of New Abrasive Medium for Abrasive Flow Machining. Adv. Mater. Res. 2013, 797, 417–422. [Google Scholar] [CrossRef]

- Ravi Sankar, M.; Jain, V.K.; Ramkumar, J.; Joshi, Y.M. Rheological Characterization of Styrene-Butadiene Based Medium and Its Finishing Performance Using Rotational Abrasive Flow Finishing Process. Int. J. Mach. Tools Manuf. 2011, 51, 947–957. [Google Scholar] [CrossRef]

- Kar, K.K.; Ravikumar, N.L.; Tailor, P.B.; Ramkumar, J.; Sathiyamoorthy, D. Preferential Media for Abrasive Flow Machining. J. Manuf. Sci. Eng. 2009, 131, 011009. [Google Scholar] [CrossRef]

- Schowalter, W.R. The Behavior of Complex Fluids at Solid Boundaries. J. Non-Newton. Fluid Mech. 1988, 29, 25–36. [Google Scholar] [CrossRef]

- Vega-Sánchez, C.; Peppou-Chapman, S.; Zhu, L.; Neto, C. Nanobubbles Explain the Large Slip Observed on Lubricant-Infused Surfaces. Nat. Commun. 2022, 13, 351. [Google Scholar] [CrossRef]

- Hatzikiriakos, S.G. Slip Mechanisms in Complex Fluid Flows. Soft Matter 2015, 11, 7851–7856. [Google Scholar] [CrossRef]

- Kanu, R.C.; Shaw, M.T. Rheology of Polymer Blends: Simultaneous Slippage and Entrance Pressure Loss in the Ethylene-Propylene-Diene (EPDM)/Viton System. Polym. Eng. Sci. 1982, 22, 507–511. [Google Scholar] [CrossRef]

- Wilms, P.; Wieringa, J.; Blijdenstein, T.; Van Malssen, K.; Hinrichs, J.; Kohlus, R. Wall Slip of Highly Concentrated Non-Brownian Suspensions in Pressure Driven Flows: A Geometrical Dependency Put into a Non-Newtonian Perspective. J. Non-Newton. Fluid Mech. 2020, 282, 104336. [Google Scholar] [CrossRef]

- Peppou-Chapman, S.; Hong, J.K.; Waterhouse, A.; Neto, C. Life and Death of Liquid-Infused Surfaces: A Review on the Choice, Analysis and Fate of the Infused Liquid Layer. Chem. Soc. Rev. 2020, 49, 3688–3715. [Google Scholar] [CrossRef] [PubMed]

- Scarratt, L.R.J.; Zhu, L.; Neto, C. Large Effective Slip on Lubricated Surfaces Measured with Colloidal Probe AFM. Langmuir 2020, 36, 6033–6040. [Google Scholar] [CrossRef]

- Dixit, N.; Sharma, V.; Kumar, P. Development and Characterization of Xanthan Gum-Based Abrasive Media and Performance Analysis Using Abrasive Flow Machining. J. Manuf. Process. 2021, 67, 101–115. [Google Scholar] [CrossRef]

- Karapetsas, G.; Mitsoulis, E. Some Experiences with the Slip Boundary Condition in Viscous and Viscoelastic Flows. J. Non-Newton. Fluid Mech. 2013, 198, 96–108. [Google Scholar] [CrossRef]

| Parameters | SAM | BAM |

|---|---|---|

| Matrix | SBR | BSR |

| Abrasive particle | SiC 80# | SiC 80# |

| Volume fraction of abrasive particles | 18.95 vol% | 18.95 vol% |

| Mass fraction of abrasive particles | 45.00 wt% | 43.95 wt% |

| Mass fraction of lubricant | 2.93 wt% | 9.19 wt% |

| Density of abrasive media | 1.35 g/cm3 | 1.38 g/cm3 |

| Parameters | SAM | BAM | ||

|---|---|---|---|---|

| Model 1 | Model 2 | Model 1 | Model 2 | |

| 1.84 × 10−2 | 4.565 × 10−6 | 4.60 × 10−2 | 2.953 × 10−4 | |

| 1 | 1.796 | 1 | 1.493 | |

| R2 | 0.881 | 0.997 | 0.924 | 0.991 |

| AIC | 401.27 | 168.91 | 231.10 | 117.84 |

| BIC | 405.42 | 175.04 | 234.88 | 123.39 |

| Preferred model | Model 2 | Model 2 | ||

| Abrasive Media | Data Source | Power-Law Model | Bird–Carreau Model | |||

|---|---|---|---|---|---|---|

| () | () | () | ||||

| SAM | CSRT & W−R | 3522.739 | 0.333 | - | - | - |

| SAOS | 7948.124 | 0.359 | - | - | - | |

| BAM | CSRT & SAOS | - | - | 4330.660 | 0.029 | 0.144 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Peng, C.; Gao, H.; Wang, X. On Characterization of Shear Viscosity and Wall Slip for Concentrated Suspension Flows in Abrasive Flow Machining. Materials 2023, 16, 6803. https://doi.org/10.3390/ma16206803

Peng C, Gao H, Wang X. On Characterization of Shear Viscosity and Wall Slip for Concentrated Suspension Flows in Abrasive Flow Machining. Materials. 2023; 16(20):6803. https://doi.org/10.3390/ma16206803

Chicago/Turabian StylePeng, Can, Hang Gao, and Xuanping Wang. 2023. "On Characterization of Shear Viscosity and Wall Slip for Concentrated Suspension Flows in Abrasive Flow Machining" Materials 16, no. 20: 6803. https://doi.org/10.3390/ma16206803

APA StylePeng, C., Gao, H., & Wang, X. (2023). On Characterization of Shear Viscosity and Wall Slip for Concentrated Suspension Flows in Abrasive Flow Machining. Materials, 16(20), 6803. https://doi.org/10.3390/ma16206803