Assessment of Properties and Microstructure of Concrete with Cotton Textile Waste and Crushed Bricks

Abstract

:1. Introduction

1.1. Textile Wastes in Concrete

1.2. Crushed Brick Waste in Concrete

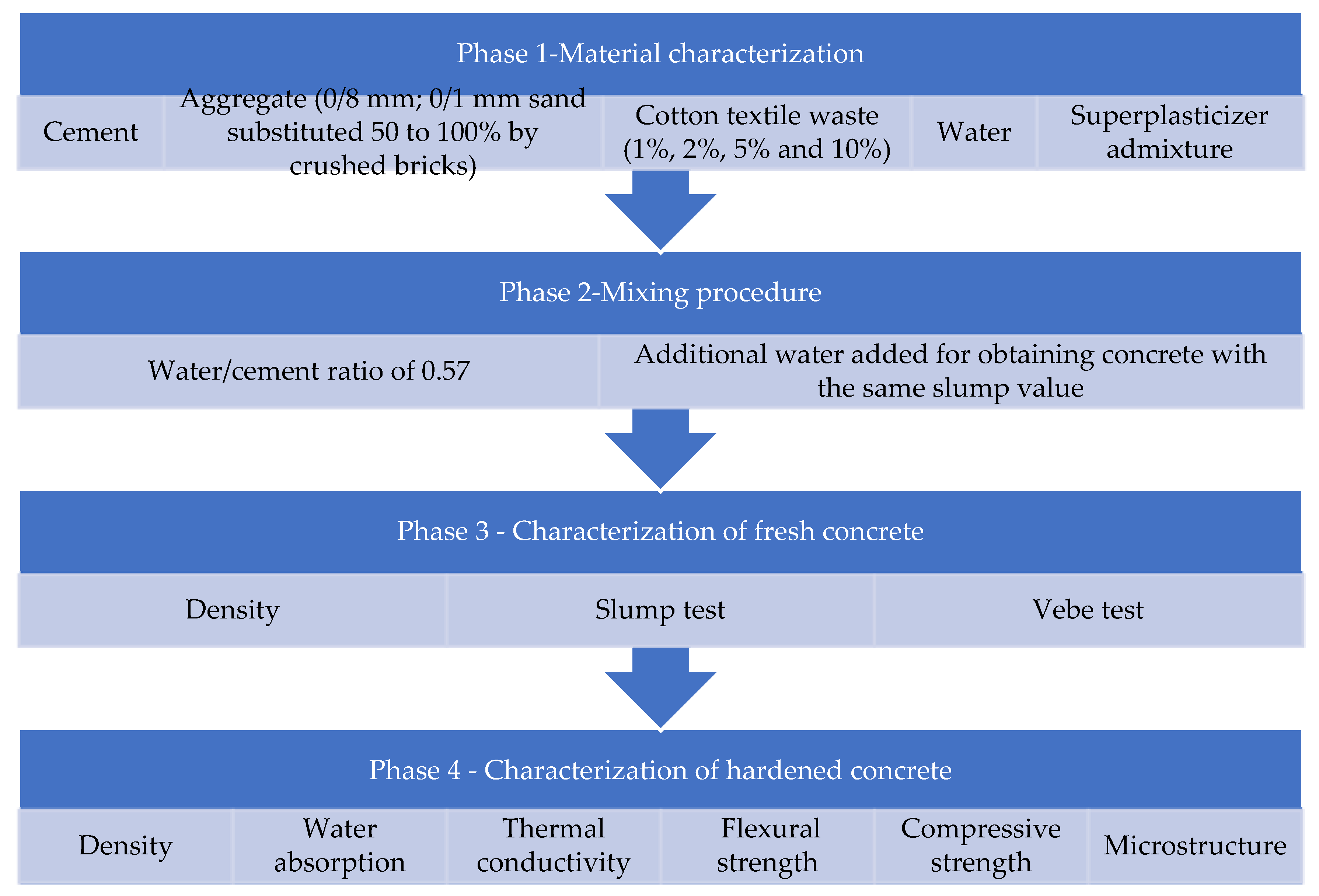

2. Materials and Methods

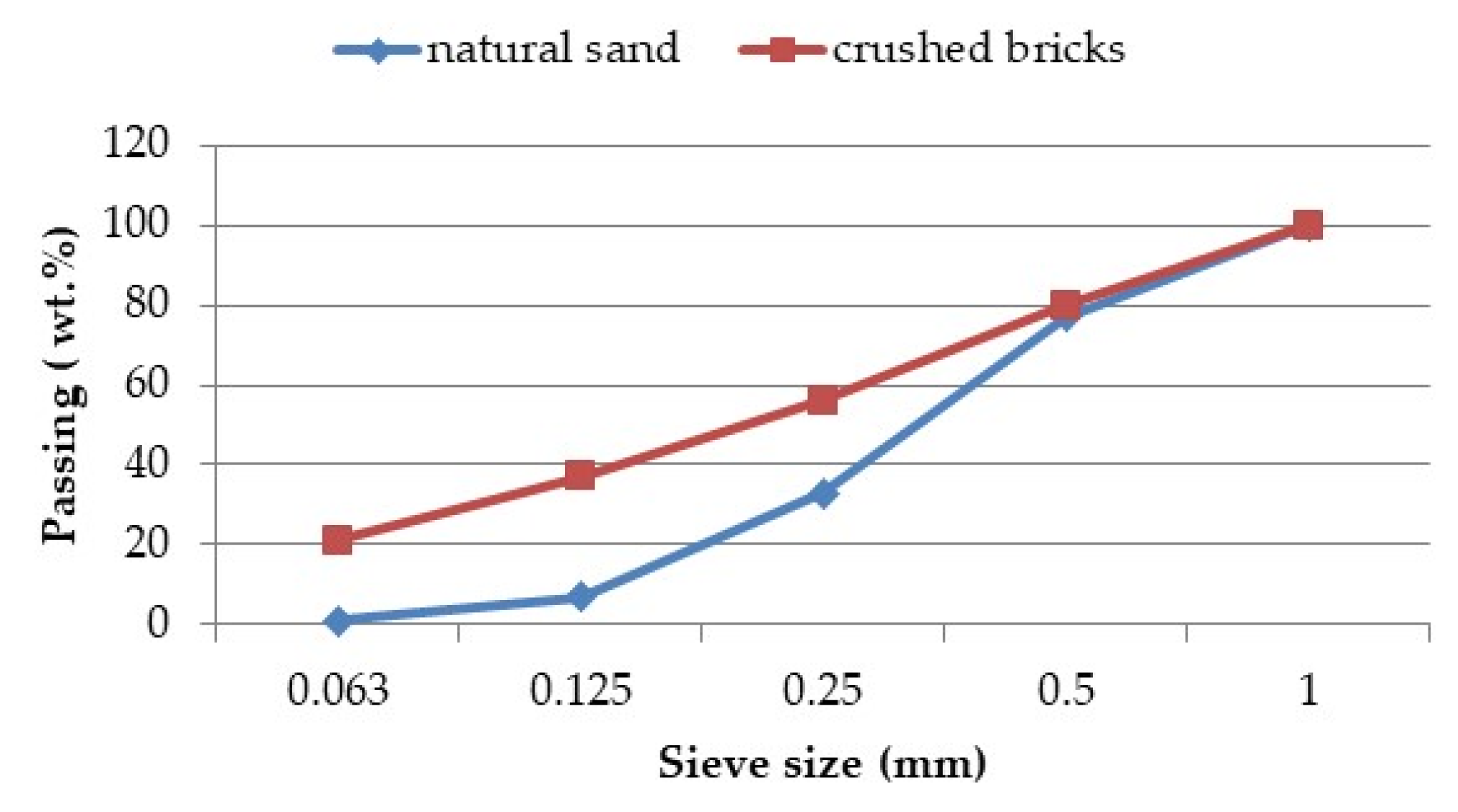

2.1. Materials

2.2. Concrete Mix Design

2.3. Mixing Procedure

2.4. Testing Methods

2.4.1. Concrete in Fresh State

2.4.2. Density of Hardened Concrete

2.4.3. Water Absorption Due to Capillary Action

2.4.4. Mechanical Strengths

2.4.5. Thermal Conductivity

2.4.6. Structure of Concrete

3. Results and Discussion

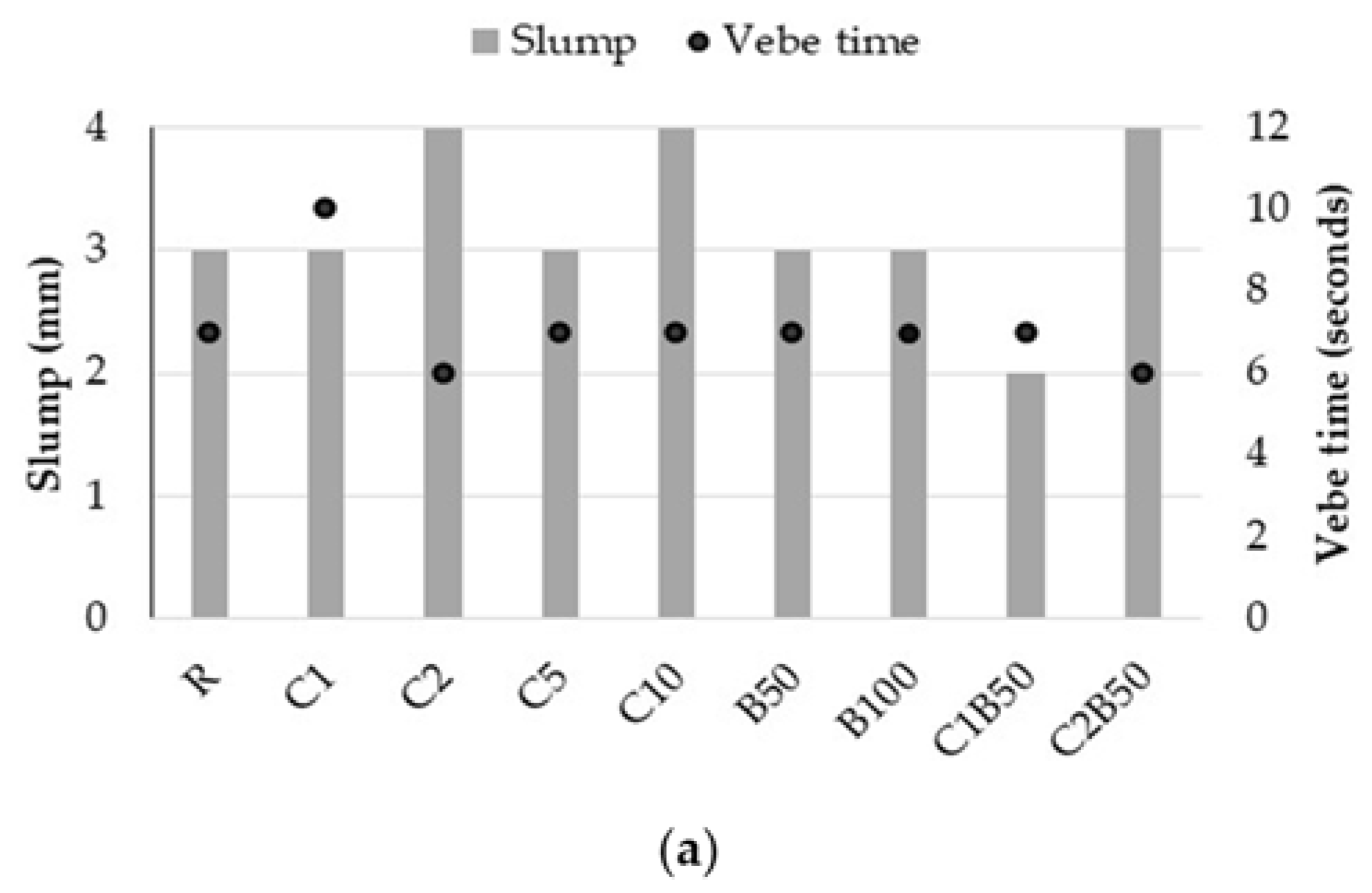

3.1. Workability of Concrete

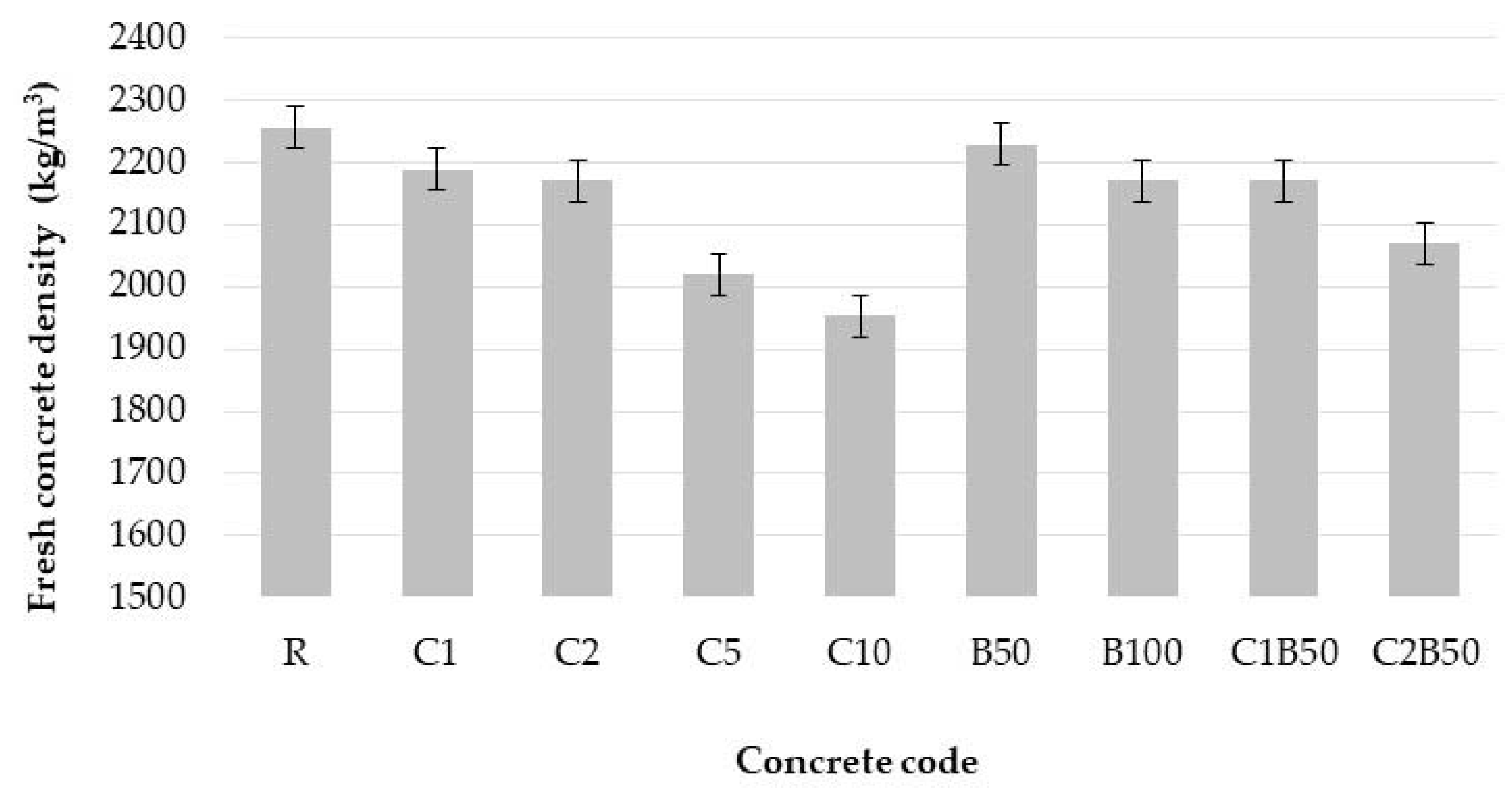

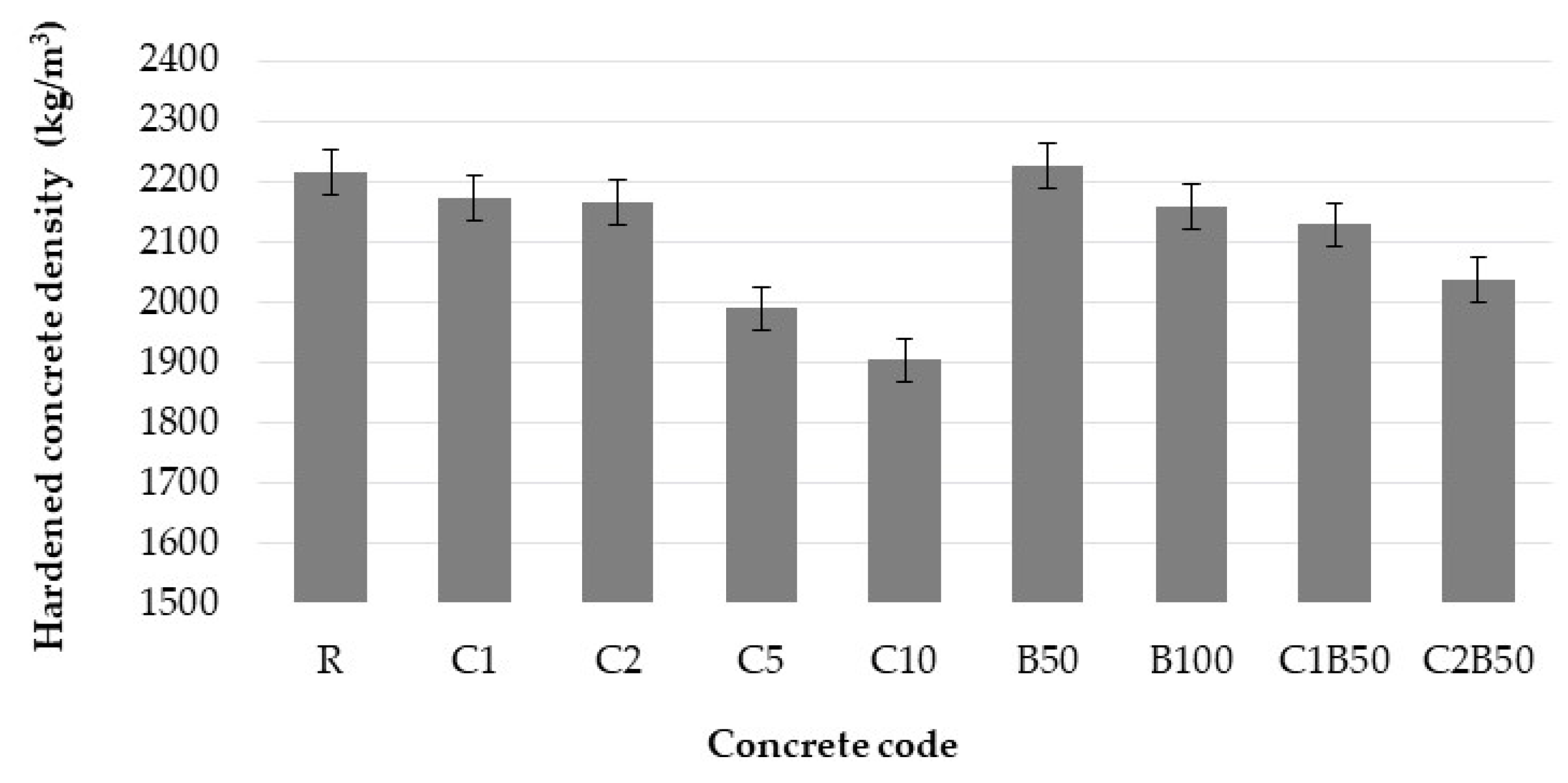

3.2. Density of Fresh and Hardened Concrete

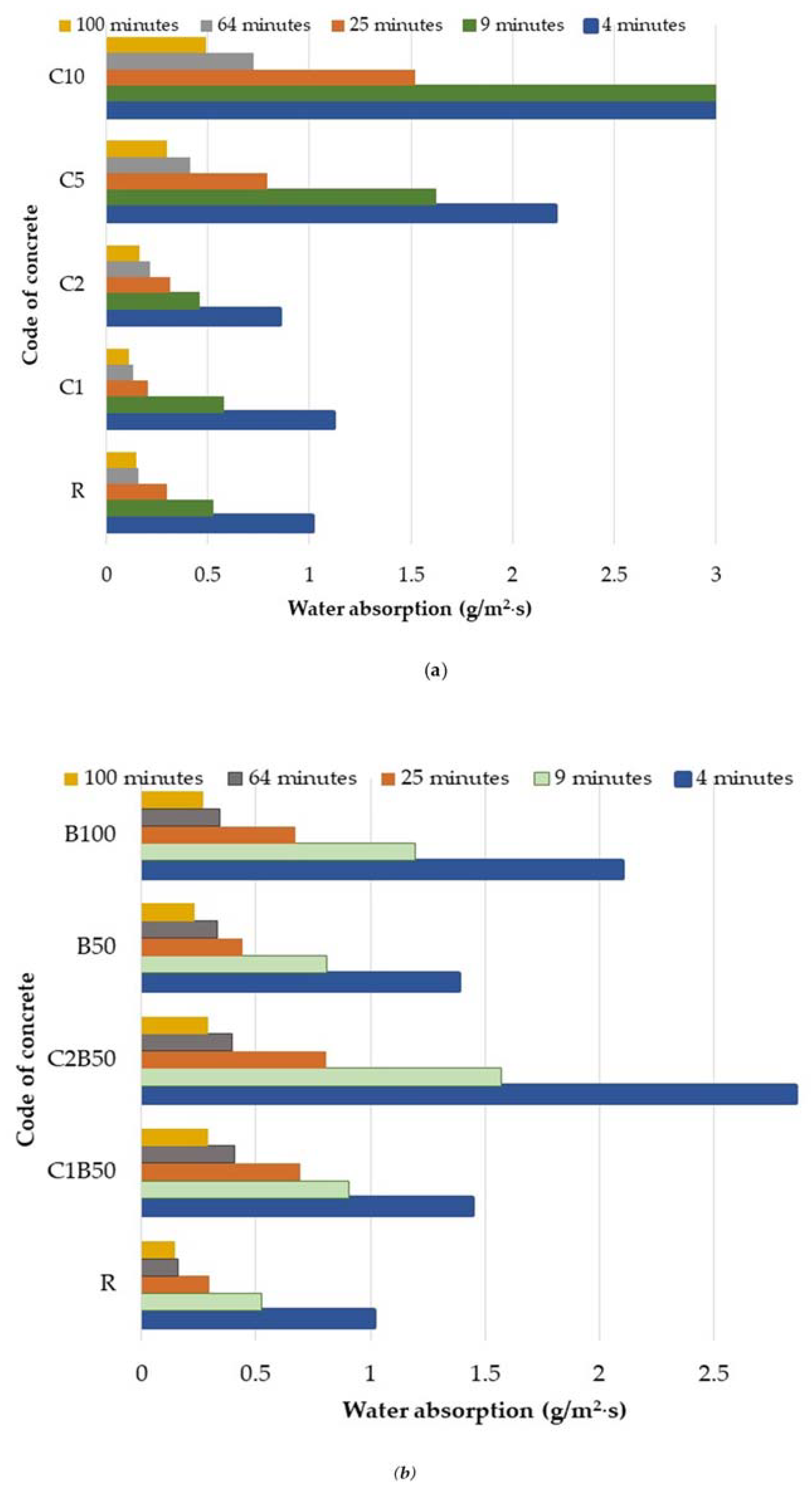

3.3. Water Absorption Due to Capillary Action

3.4. Thermal Conductivity

3.5. Mechanical Strengths

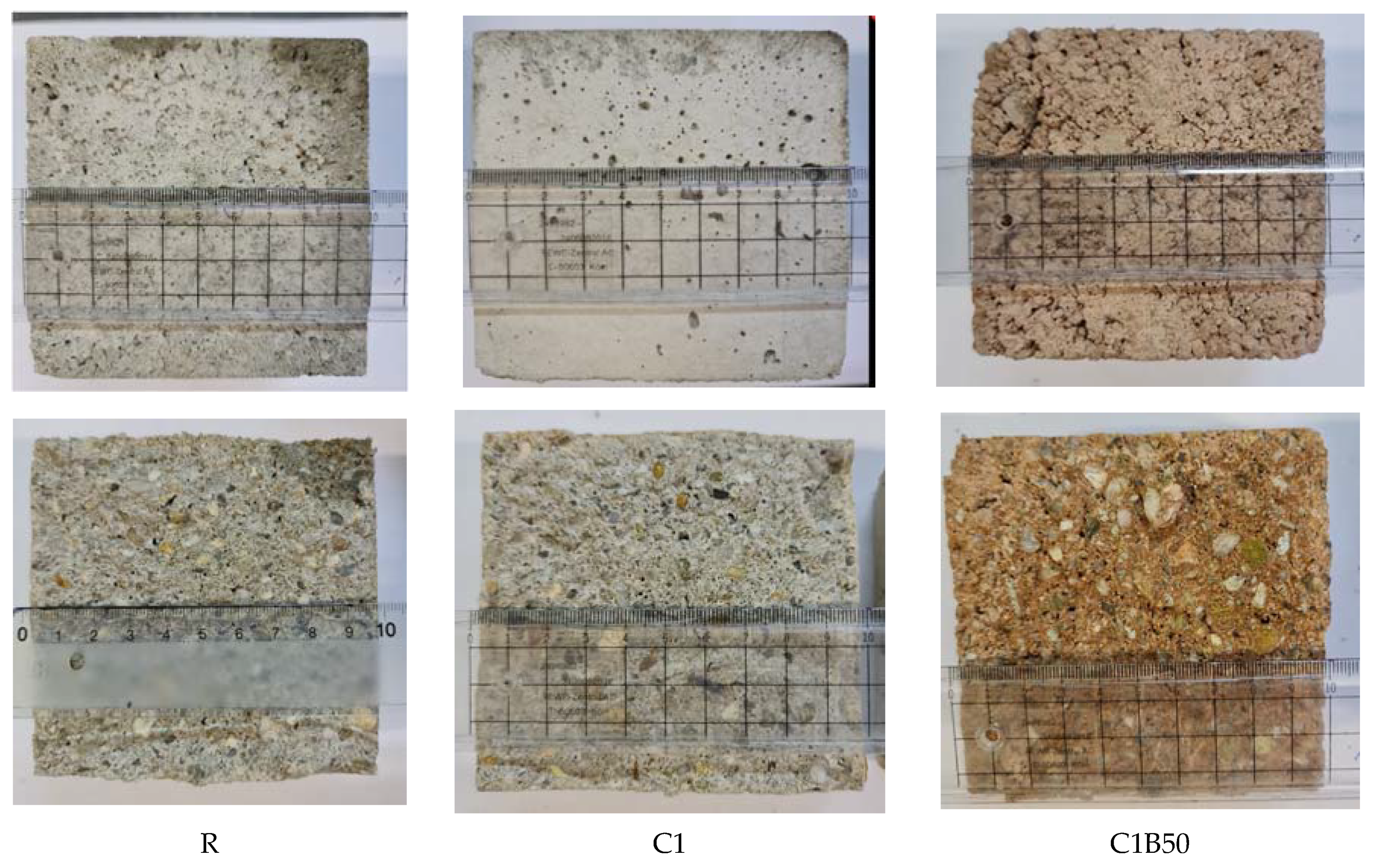

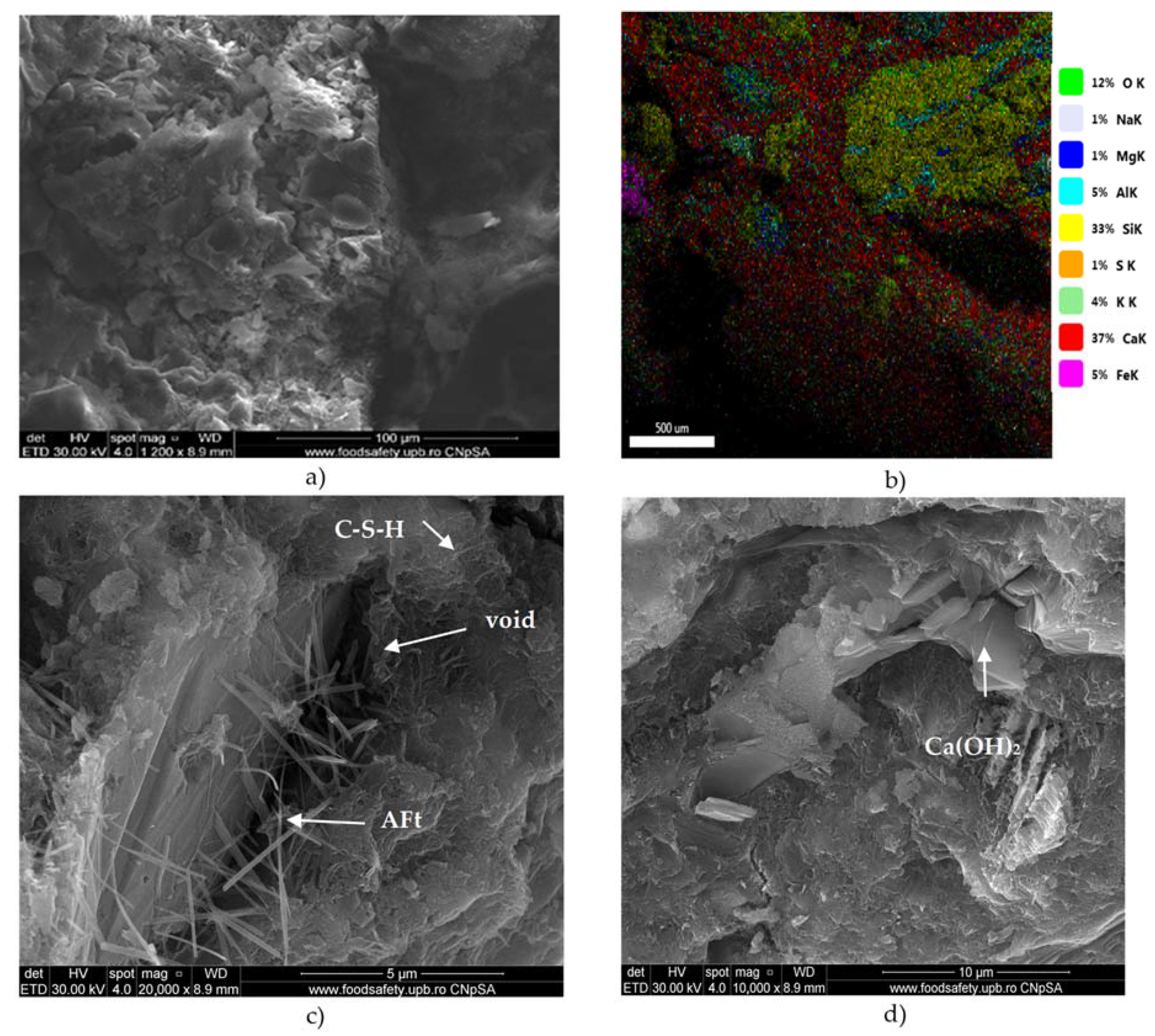

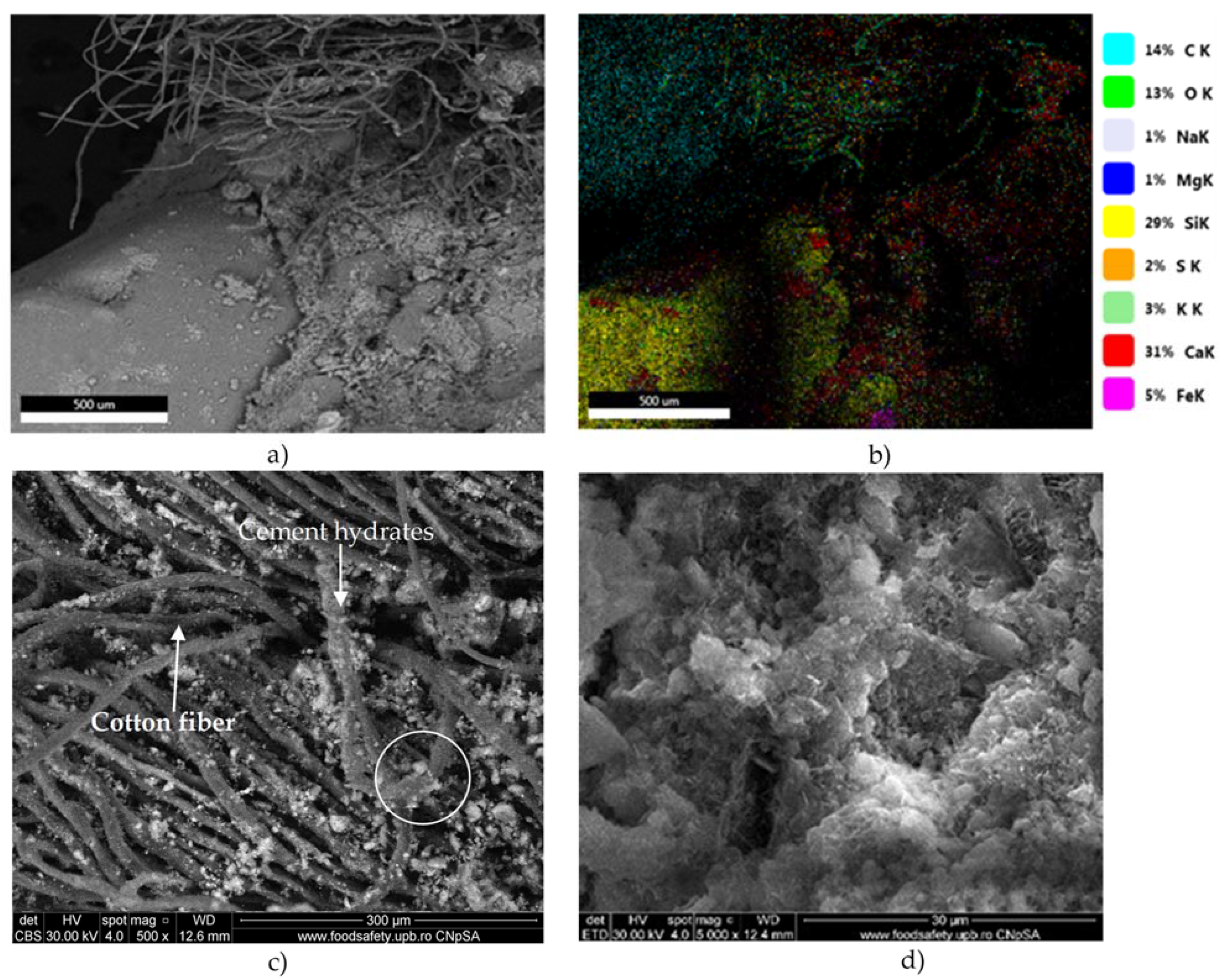

3.6. Microstructure

4. Conclusions

- The addition of cotton textile waste in concrete (1, 2, 5, and 10 wt.%) has led to increased water quantities required for obtaining concrete with the same slump value as reference, due to the absorption capacity of waste. The same trend was observed for concrete with CB (50 to 100% CB substituted the natural sand under 1 mm) and concrete with both wastes. The additional water-influenced properties were tested. The density of fresh and hardened concrete decreased compared to the reference;

- The water absorption via capillarity increased for mixes with wastes because of the increased water/cement ratio, which led to a more porous cement matrix;

- The 28-day compressive strength of concrete with 1 and 2 wt.% CW was between 26.7 and 26.9 MPa, representing a decrease of 19.2% and 19.8%, respectively, compared to the reference. The compressive strength of concrete with 10 wt.% significantly decreased to 8.8 MPa, compared to 33.3 MPa for reference. The same observation is also valid for flexural strength. Concretes with 1 and 2 wt.% CW had higher splitting strength than reference due to their reinforcement effect;

- The partial substitution of natural sand under 1 mm with crushed bricks (50 vol.%) led to the 28 days’ mechanical strengths comparable to reference (compressive strength of 33.7 MPa compared to 33.3 MPa). The increase in CB concrete compressive strength over time was significant over time compared to other mixes, which suggests a pozzolanic reaction. When CB content increased to 100 vol.%, the mechanical strengths decreased;

- The incorporation of both CW and CB in concrete resulted in a decreased compressive and flexural strength, except for the splitting strength;

- From a statistical point of view, the conclusion stated above regarding the diminishing of mechanical strength with the increase in the addition of textile waste is supported by correlation coefficients lower than zero;

- The SEM and EDX analyses showed an improved microcrystalline aspect of concrete with crushed brick and the presence of hydrates on the CW;

- The addition of cotton textile waste in concrete leads to a decrease in the thermal conductivity to 0.32 W/(m·K) compared to 0.37 W/(m·K) for reference, improving the insulation properties, which are directly related to the buildings’ energy efficiency.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Velenturf, A.P.M.; Purnell, P. Resource recovery from waste: Restoring the balance between resource scarcity and waste overload. Sustainability 2017, 9, 1603. [Google Scholar] [CrossRef]

- World Economic Forum. Shaping the Future of Construction: A Breakthrough in Mindset and Technology; World Economic Forum: Cologny, Switzerland, 2016. [Google Scholar]

- Romania’s Sustainable Development Strategy 2030. Available online: http://dezvoltaredurabila.gov.ro/web/wp-content/uploads/2019/03/Romanias-Sustaina ble-Development-Strategy-2030.pdf (accessed on 12 September 2023).

- Dahlbo, H.; Aalto, K.; Eskelinen, H.; Salmenperä, H. Increasing textile circulation—Consequences and requirements. Sustain. Prod. Consum. 2017, 9, 44. [Google Scholar] [CrossRef]

- EEA. Reducing Loss of Resources from Waste Management Is Key to Strengthening the Circular Economy in Europe; European Environment Agency: Copenhagen, Denmark, 2021.

- Wang, Y. Fibre and textile waste utilization. Waste Biomass Valorization 2010, 1, 135–143. [Google Scholar] [CrossRef]

- Dissanayake, D.G.K.; Weerasinghe, D.U.; Thebuwanage, L.M.; Bandara, U.A.A.N. An environmentally friendly sound insulation material from post-industrial textile waste and natural rubber. J. Build. Eng. 2021, 33, 101606. [Google Scholar] [CrossRef]

- Du, W.; Zheng, J.; Li, W.; Liu, Z.; Wang, H.; Han, X. Efficient Recognition and Automatic Sorting Technology of Waste Textiles Based on Online Near Infrared Spectroscopy and Convolutional Neural Network. Resour. Conserv. Recycl. 2022, 180, 106157. [Google Scholar] [CrossRef]

- Kamble, Z.; Behera, B.K. Sustainable hybrid composites reinforced with textile waste for construction and building applications. Constr. Build. Mater. 2021, 284, 122800. [Google Scholar] [CrossRef]

- Sadrolodabaee, P.; Claramunt, J.; Ardanuy, M.; de la Fuente, A. Mechanical and durability characterization of a new textile waste micro-fiber reinforced cement composite for building applications. Case Stud. Constr. Mater. 2021, 14, e00492. [Google Scholar] [CrossRef]

- Selvaraj, R.; Priyanka, R. Study on recycled waste cloth in concrete. Int. J. Eng. Res. Technol. 2015, 4, 891–895. [Google Scholar] [CrossRef]

- Anglade, J.; Benavente, E.; Rodríguez, J.; Hinostroza, A. Use of Textile Waste as an Addition in the elaboration of an Ecological Concrete Block. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1054, 012005. [Google Scholar] [CrossRef]

- Patnaik, A.; Myubu, M.; Muniyasamy, S.; Botha, A.; Anandjiwal, R.D. Thermal and sound insulation materials from waste wool and recycled polyester fibres and their biodegradation studies. Energy Build. 2015, 92, 161–169. [Google Scholar] [CrossRef]

- Briga-Sá, A.; Gaibor, N.; Magalhães, L.; Pinto, T.; Leitão, D. Thermal performance characterization of cement-based lightweight blocks incorporating textile waste. Constr. Build. Mater. 2022, 321, 126330. [Google Scholar] [CrossRef]

- Available online: https://ec.europa.eu/eurostat/statistics-explained/index.php?title=Waste_statistics#Total_waste_generation (accessed on 18 October 2023).

- Lu, G.; Fan, Z.; Sun, Z.; Liu, P.; Leng, Z.; Wang, D.; Oeser, M. Improving the polishing resistance of cement mortar by using recycled ceramic. Resour. Conserv. Recycl. 2020, 158, 104796. [Google Scholar] [CrossRef]

- González, S.J.; Gayarre, F.L.; Pérez, C.L.C.; Ros, P.S.; López, M.A.S. Influence of recycled brick aggregates on properties of structural concrete for manufacturing precast prestressed beams. Constr. Build. Mater. 2017, 149, 507–514. [Google Scholar] [CrossRef]

- Rashid, K.; Razzaq, A.; Ahmad, M.; Rashid, T.; Tariq, S. Experimental and analytical selection of sustainable recycled concrete with ceramic waste aggregate. Constr. Build. Mater. 2017, 154, 829–840. [Google Scholar] [CrossRef]

- Subaşı, S.; Öztürk, H.; Emiroğlu, M. Utilizing of waste ceramic powders as filler material in self-consolidating concrete. Constr. Build. Mater. 2017, 149, 567–574. [Google Scholar] [CrossRef]

- Lam, M.N.T.; Nguyen, D.T.; Nguyen, D.L. Potential use of clay Rick waste powder and ceramic waste aggregate in mortar. Constr. Build. Mater. 2021, 313, 125516. [Google Scholar] [CrossRef]

- Duan, Z.; Hou, S.; Xiao, J.; Singh, A. Rheological properties of mortar containing recycled powder from construction and demolition wastes. Constr. Build. Mater. 2020, 237, 117662. [Google Scholar] [CrossRef]

- Ma, Z.; Shen, J.; Wu, H.; Zhang, P. Properties, and activation modification of eco-friendly cementitious materials incorporating high-volume hydrated cement powder from construction waste. Constr. Build. Mater. 2022, 216, 125788. [Google Scholar] [CrossRef]

- Sai Rahul, D.; Reddy, S.V.; Tarun, N.; Basutkar, S.M.; Wali, R.S.; Renukadevi, M.V. Influence of brick waste and brick waste fines as fine aggregate on the properties of paver blocks—Preliminary investigation. Mater. Today Proc. 2021, 43, 1496–1502. [Google Scholar] [CrossRef]

- Dang, J.; Zhao, J. Influence of waste clay bricks as fine aggregate on the mechanical and microstructural properties of concrete. Constr. Build. Mater. 2019, 228, 116757. [Google Scholar] [CrossRef]

- Vieira, T.; Alves, A.; de Brito, J.; Correia, J.R.; Silva, R.V. Durability-related performance of concrete containing fine recycled aggregates from crushed bricks and sanitary ware. Mater. Des. 2016, 90, 767–776. [Google Scholar] [CrossRef]

- Siddique, S.; Shrivastava, S.; Chaudhary, S.; Gupta, T. Strength, and impact resistance properties of concrete containing fine bone china ceramic aggregate. Constr. Build. Mater. 2018, 169, 289–298. [Google Scholar] [CrossRef]

- Cachim, P.B. Mechanical properties of Rick aggregate concrete. Constr. Build Mater. 2009, 23, 1292–1297. [Google Scholar] [CrossRef]

- Vera, R.; Suarez, A.; Zambrano, F.; Marquez, R.; Bedard, J.; Vivas, K.E.; Pifano, A.; Farrel, M.; Ankeny, M.; Jameel, H.; et al. Upcycling cotton textile waste into biobased blocks through an environmentally and high-yield conversion process. Res. Conserv. Recycl. 2023, 189, 106715. [Google Scholar] [CrossRef]

- SR EN 197-1; Cement Part 1: Composition, Specifications and Conformity Criteria for Common Cements. Romanian Standard Association: Bucharest, Romania, 2011.

- SR EN 1097-6; Test for Mechanical and Physical Properties of Aggregates-Part 6. Determination of Particle Density and Water Absorption. Romanian Standard Association: Bucharest, Romania, 2013.

- Asim, A.; Abdan, H.; Jawaid, M.; Nasir, M.; Dashtizadeh, M.; Ishak, M.R.; Hogue, M. A Review on Pineapple Leaves Fibre and Its Composites. Int. J. Polymer Sci. 2015, 2015, 950567. [Google Scholar] [CrossRef]

- Chokshi, S.; Gohil, P.; Lalakiya, A.; Patel, P.; Parmar, A. Tensile strength prediction of natural fiber and natural fiber yarn: Strain rate variation upshot. Mater. Today Proc. 2020, 27, 1218–1223. [Google Scholar] [CrossRef]

- SR EN 206+A2; Concrete—Specification, Performance, Production and Conformit. Romanian Standard Association: Bucharest, Romania, 2021.

- NE 012; Regulations for the Production and Execution of Concrete, Reinforced Concrete and Prestressed Concrete Works—Part 1: Concrete Production. Romanian Standard Association: Bucharest, Romania, 2007.

- SR EN 12350-2; Testing Fresh Concrete. Part 2: Slump Test. Romanian Standard Association: Bucharest, Romania, 2019.

- SR EN 12350-3; Testing Fresh Concrete. Part 3: Vebe Test. Romanian Standard Association: Bucharest, Romania, 2019.

- SR EN 12350-6; Testing Fresh Concrete. Part 6: Density. Romanian Standard Association: Bucharest, Romania, 2019.

- SR EN 12390-7; Testing Hardened Concrete. Part 7: Density of Hardened Concrete. Romanian Standard Association: Bucharest, Romania, 2019.

- SR EN 772-11; Methods of Test for Masonry Units Part 11: Determination of Water Absorption of Aggregate Concrete, Autoclaved Aerated Concrete, Manufactured Stone, and Natural Stone Masonry Units Due to Capillary Action and the initial Rate of Water Absorption of Clay Masonry Unit. Romanian Standard Association: Bucharest, Romania, 2011.

- SR EN 12390; Testing of Hardened Concrete. Romanian Standard Association: Bucharest, Romania, 2021.

- EN 12664; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Dry and Moist Products of Medium and Low Thermal Resistance. Romanian Standard Association: Bucharest, Romania, 2002.

- ACI 116R-90; Cement and Concrete Terminology. Romanian Standard Association: Bucharest, Romania, 1990.

- Olofinnade, O.; Ogara, J. Workability, strength, and microstructure of high strength sustainable concrete incorporating recycled clay brick aggregate and calcined clay. Clean. Eng. Technol. 2021, 2, 100123. [Google Scholar] [CrossRef]

- Yang, Y. Thermal Conductivity. In Physical Properties of Polymers Handbook; Mark, J.E., Ed.; Springer: New York, NY, USA, 2007. [Google Scholar] [CrossRef]

- Raznjević, K. Thermodynamic Diagrams and Tables; “Tehnica” Publishing House: Bucharest, Rumania, 1978. [Google Scholar]

| Concrete Code | w/c Ratio | Cement (kg) | Coarse Aggregate (kg) | Sand Aggregate (kg) | Crushed Bricks (kg) | Textile Waste (kg) | wa */Cement |

|---|---|---|---|---|---|---|---|

| R | 0.57 | 262 | 629 | 1336 | 0 | 0 | 0 |

| C1 | 0.57 | 262 | 629 | 1336 | 0 | 2.62 | 0.011 |

| C2 | 0.57 | 262 | 629 | 1336 | 0 | 5.24 | 0.011 |

| C5 | 0.57 | 262 | 629 | 1336 | 0 | 13.1 | 0.130 |

| C10 | 0.57 | 262 | 629 | 1336 | 0 | 26.2 | 0.149 |

| B50 | 0.57 | 262 | 629 | 992 | 344 | 0 | 0.160 |

| B100 | 0.57 | 262 | 629 | 649 | 687 | 0 | 0.449 |

| C1B50 | 0.57 | 262 | 629 | 992 | 344 | 2.62 | 0.171 |

| C2B50 | 0.57 | 262 | 629 | 992 | 344 | 5.24 | 0.172 |

| Code of Concrete | Compressive Strength (MPa) | Flexural Strength (MPa) | Splitting Strength (MPa) | |

|---|---|---|---|---|

| 2 Days | 28 Days | 28 Days | 28 Days | |

| R | 19.9 | 33.3 | 7.09 | 2.25 |

| C1 | 18 | 26.7 | 6.02 | 2.71 |

| C2 | 20.5 | 26.9 | 6.13 | 2.95 |

| C5 | 10.4 | 17.5 | 2.55 | 1.62 |

| C10 | 5.9 | 8.9 | 1.92 | 1.23 |

| B50 | 8 | 33.7 | 8.67 | 3.11 |

| B100 | 8 | 26 | 6.05 | 2.99 |

| C1B50 | 13.2 | 21.9 | 5.95 | 2.36 |

| C2B50 | 10.2 | 17.9 | 5.74 | 2.29 |

| Percent Cotton (%) | |

|---|---|

| Compressive strength | 0.980 |

| Flexural strength | 0.931 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Saca, N.; Radu, L.; Truşcă, R.; Calotă, R.; Dobre, D.; Năstase, I. Assessment of Properties and Microstructure of Concrete with Cotton Textile Waste and Crushed Bricks. Materials 2023, 16, 6807. https://doi.org/10.3390/ma16206807

Saca N, Radu L, Truşcă R, Calotă R, Dobre D, Năstase I. Assessment of Properties and Microstructure of Concrete with Cotton Textile Waste and Crushed Bricks. Materials. 2023; 16(20):6807. https://doi.org/10.3390/ma16206807

Chicago/Turabian StyleSaca, Nastasia, Lidia Radu, Roxana Truşcă, Răzvan Calotă, Daniela Dobre, and Ilinca Năstase. 2023. "Assessment of Properties and Microstructure of Concrete with Cotton Textile Waste and Crushed Bricks" Materials 16, no. 20: 6807. https://doi.org/10.3390/ma16206807

APA StyleSaca, N., Radu, L., Truşcă, R., Calotă, R., Dobre, D., & Năstase, I. (2023). Assessment of Properties and Microstructure of Concrete with Cotton Textile Waste and Crushed Bricks. Materials, 16(20), 6807. https://doi.org/10.3390/ma16206807