Seismic Behavior of Concrete Columns Reinforced with Weakly Bonded Ultra-High Strength Rebars and Confined by Steel Tubes

Abstract

:1. Introduction

2. Experimental Program

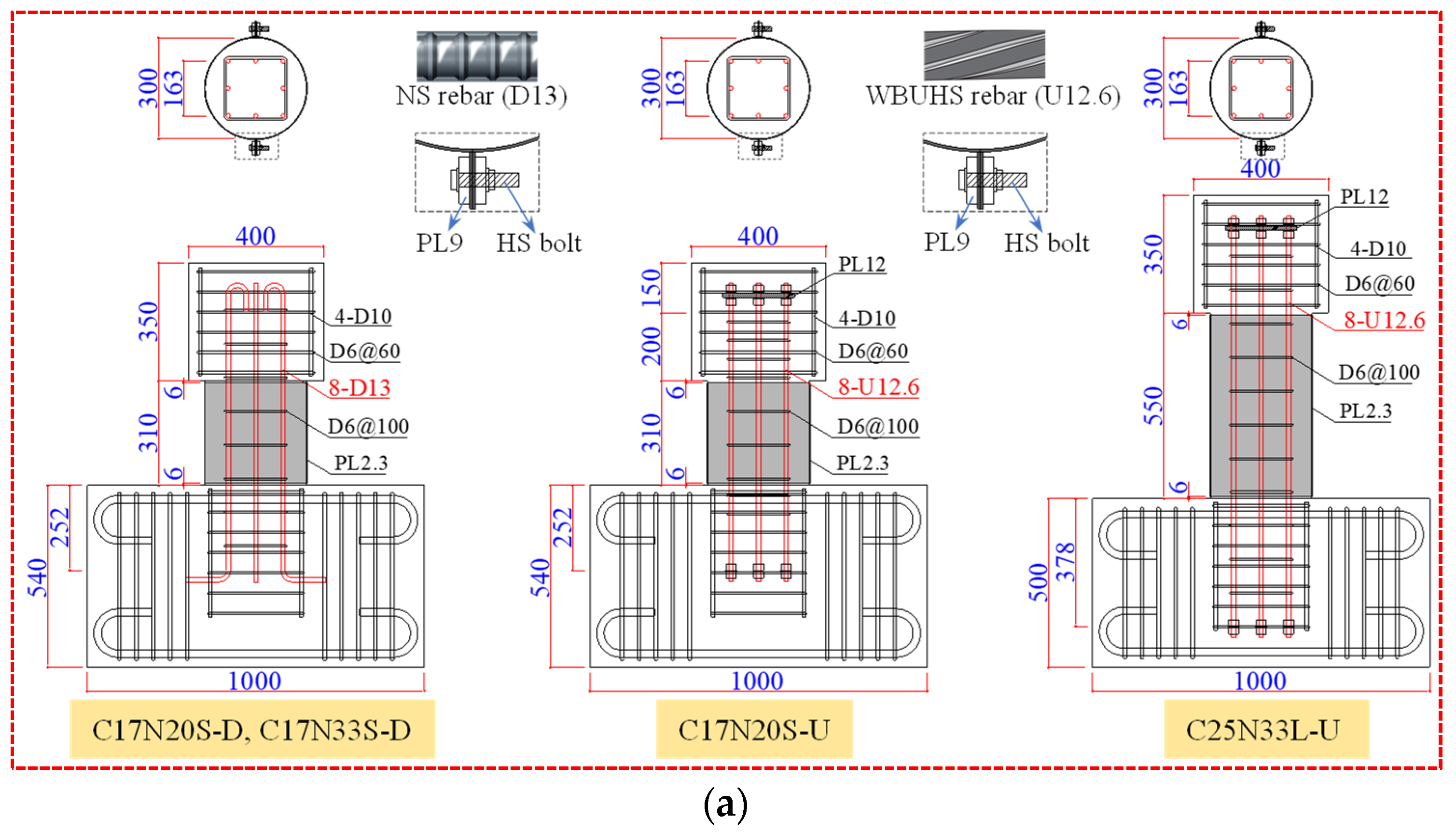

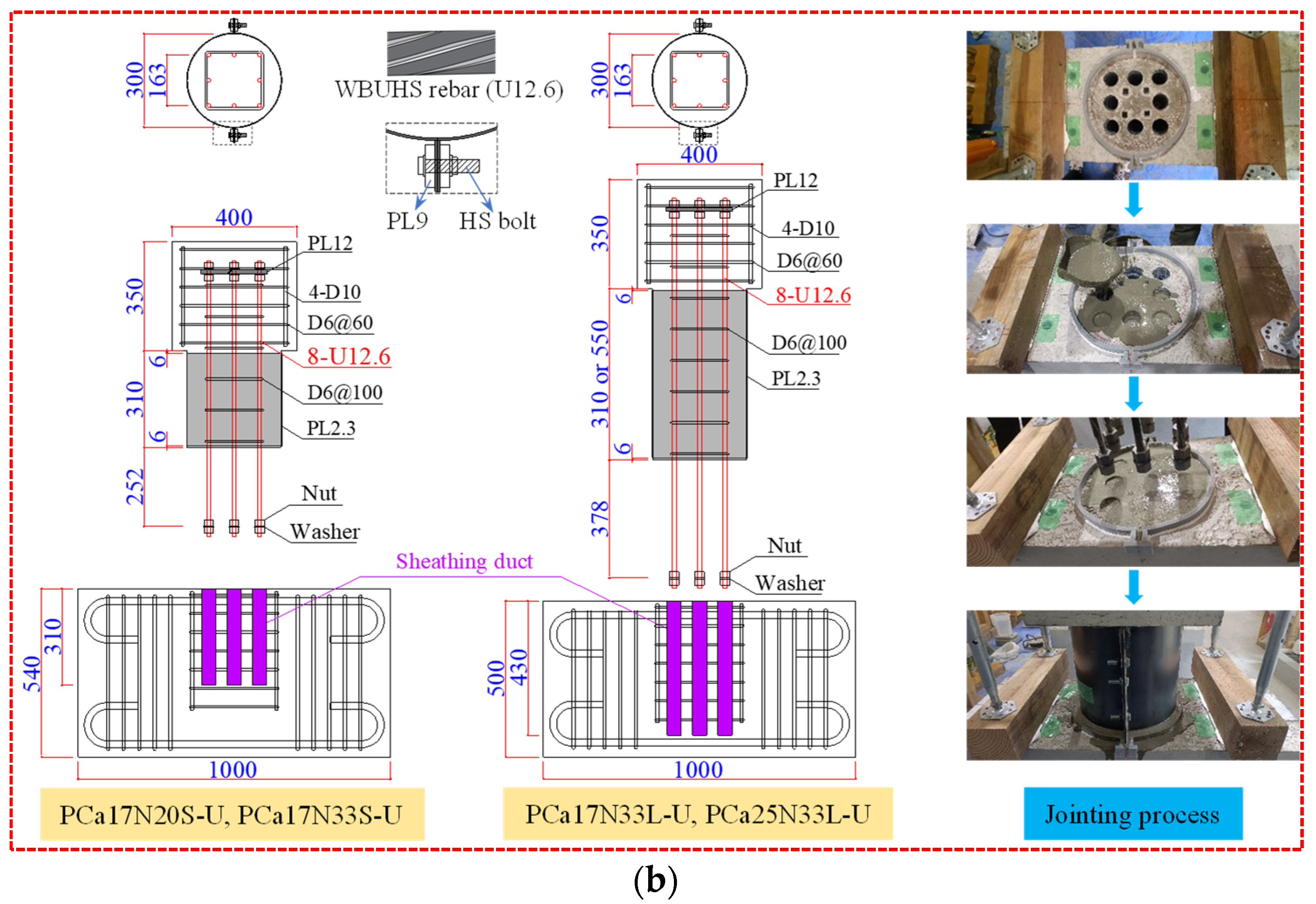

2.1. Details of Test Columns

2.2. Mechanical Properties of Materials

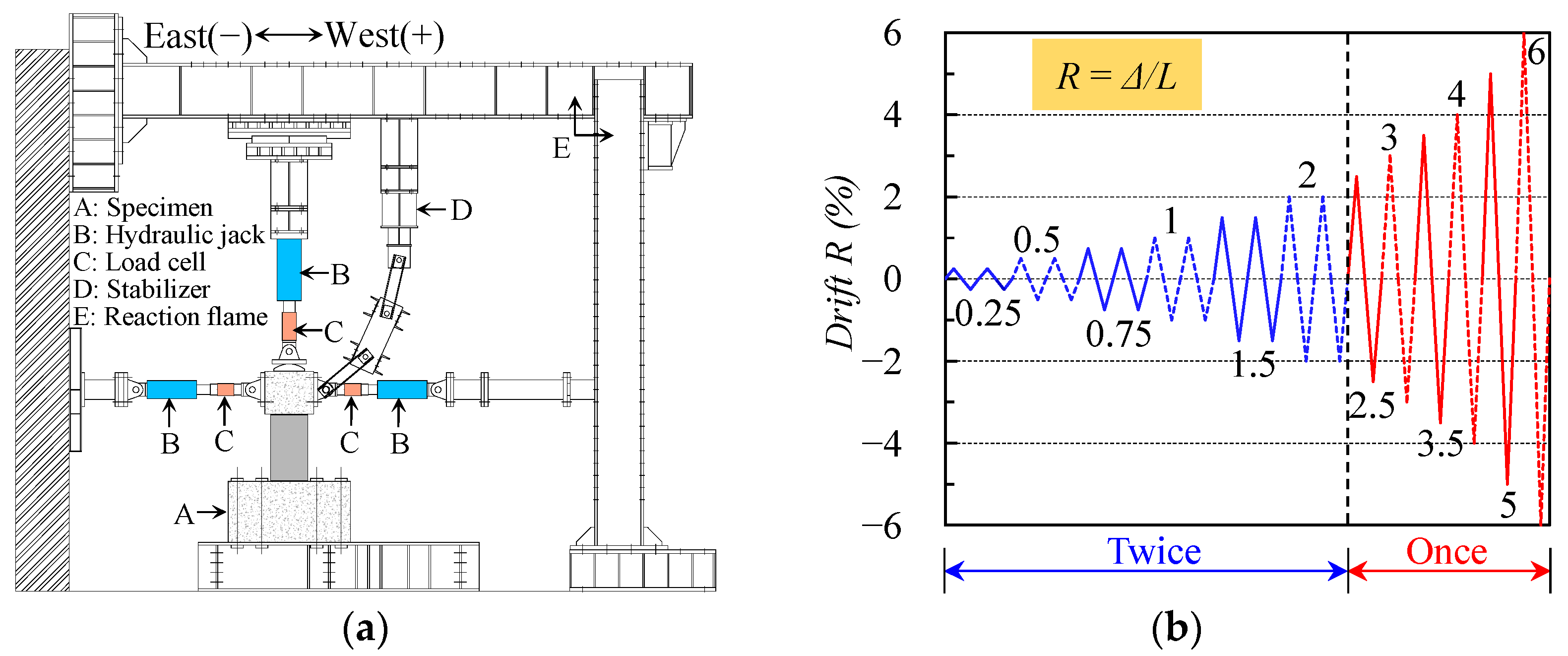

2.3. Test Apparatus and Loading Program

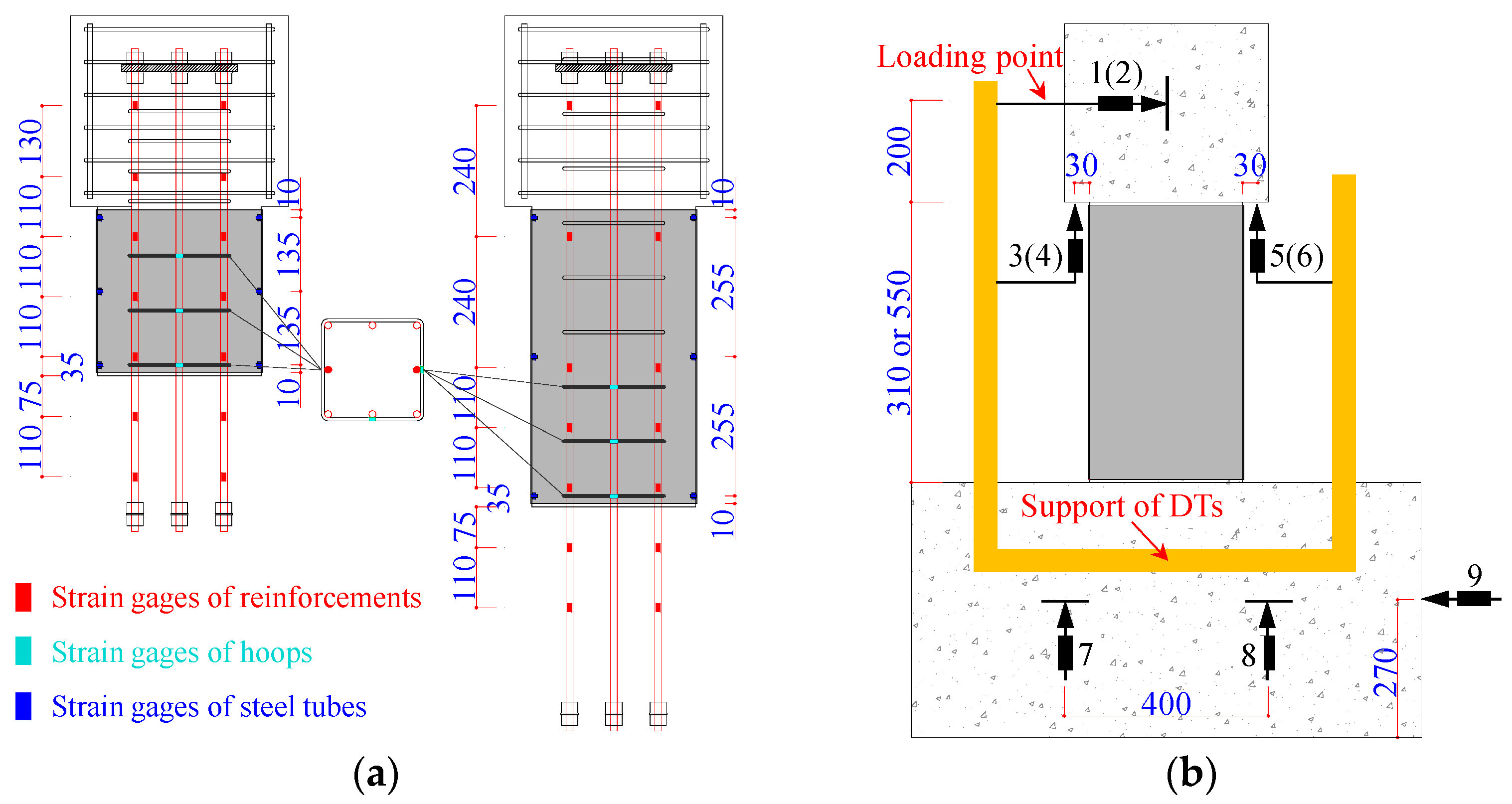

2.4. Instrumentation

3. Experimental Results and Discussion

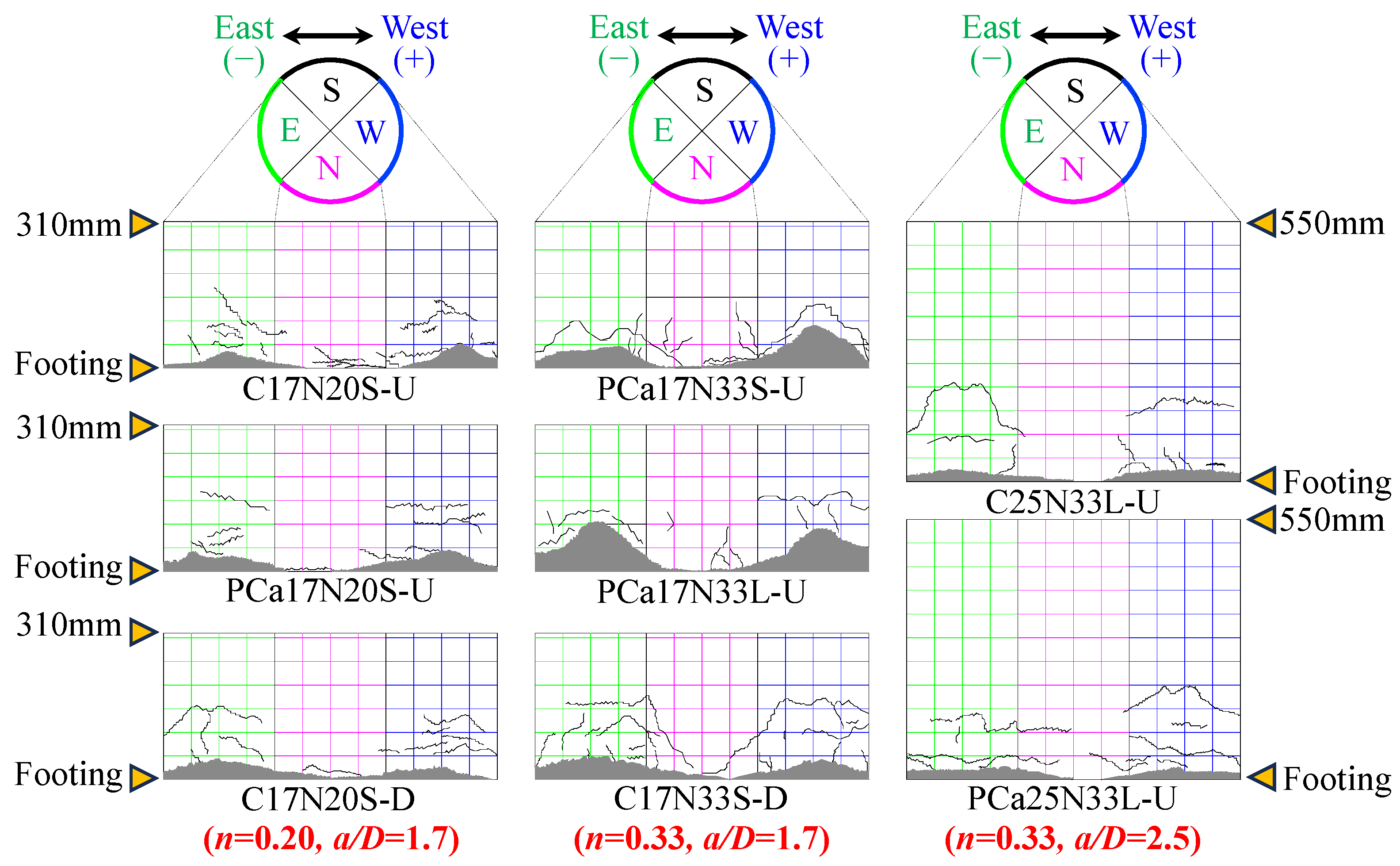

3.1. Failure Mode

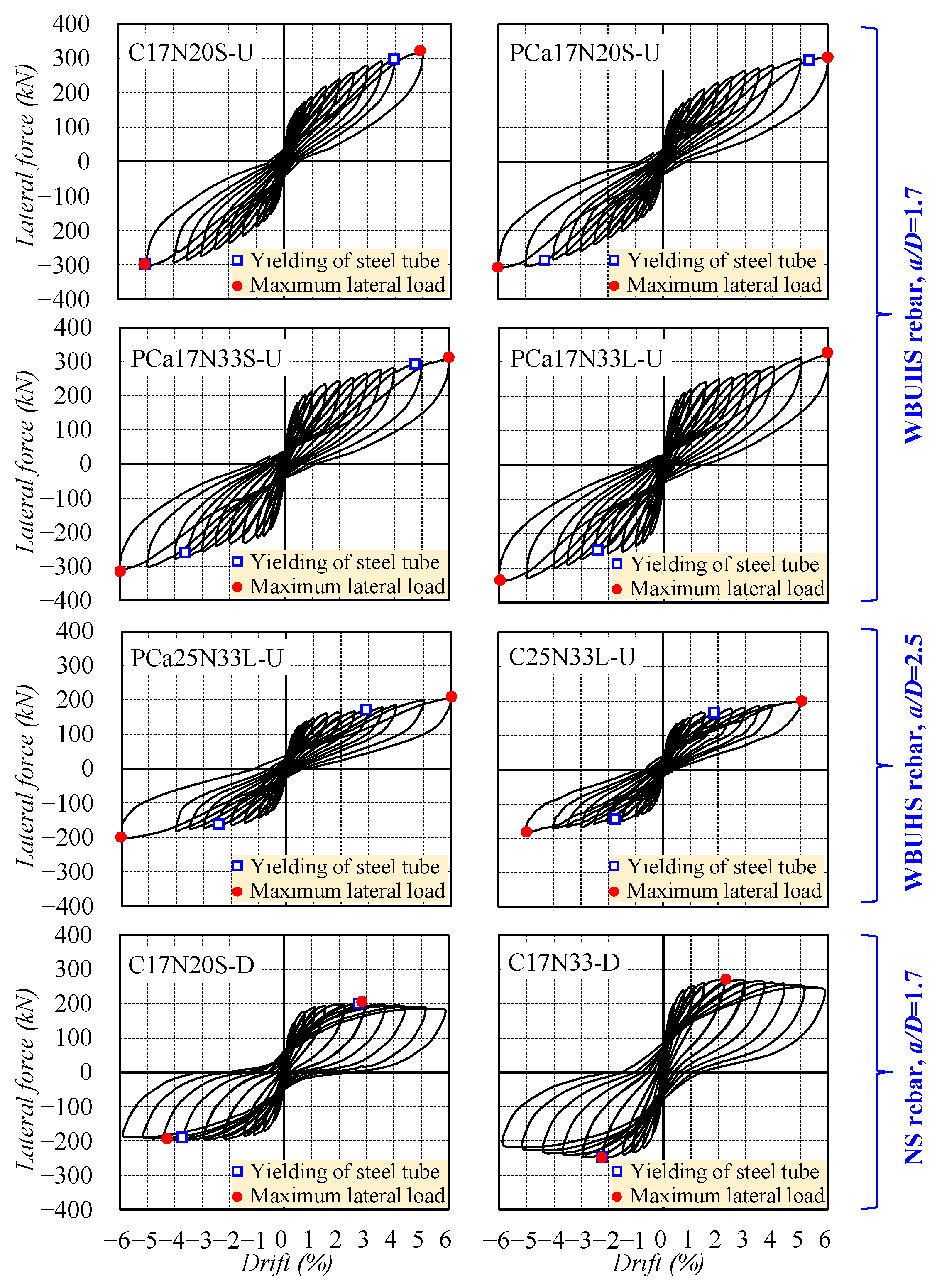

3.2. Lateral Force Versus Drift Relationship

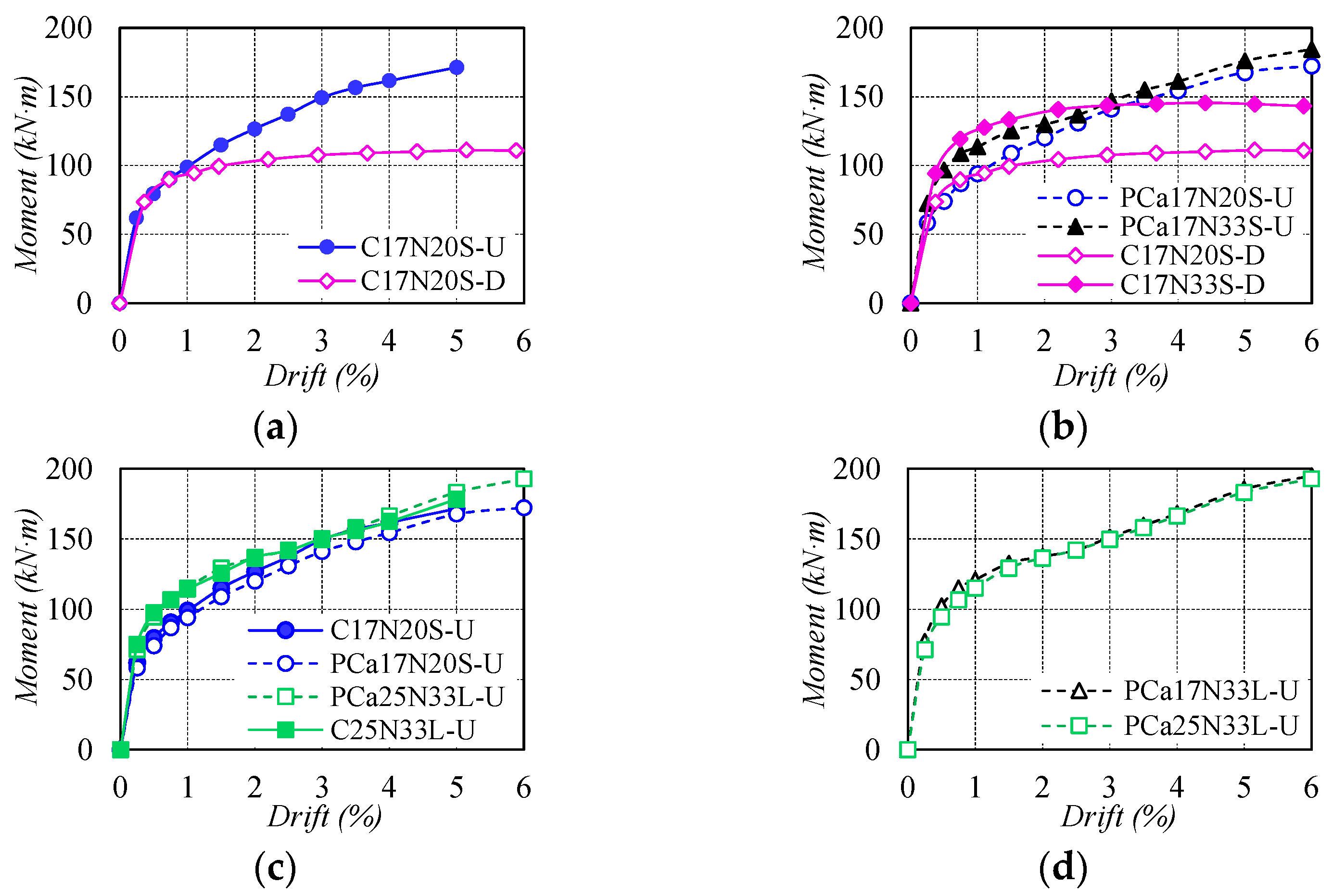

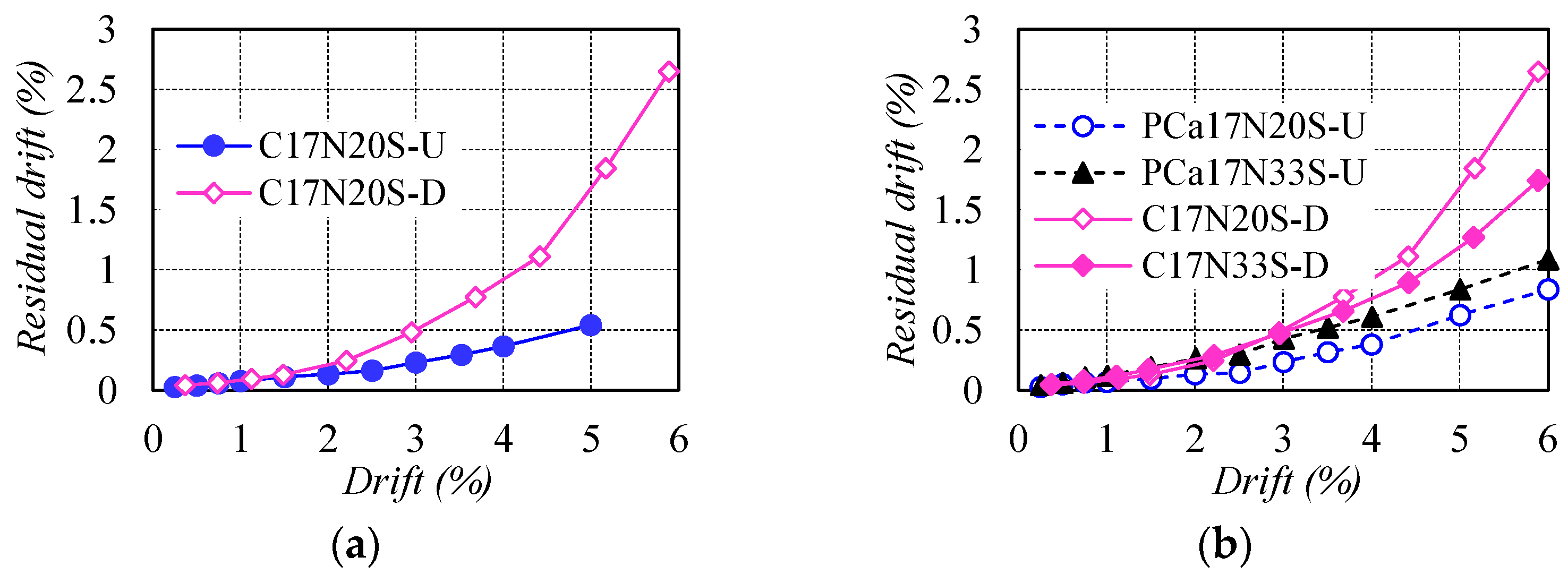

3.3. Self-Centering Capacity

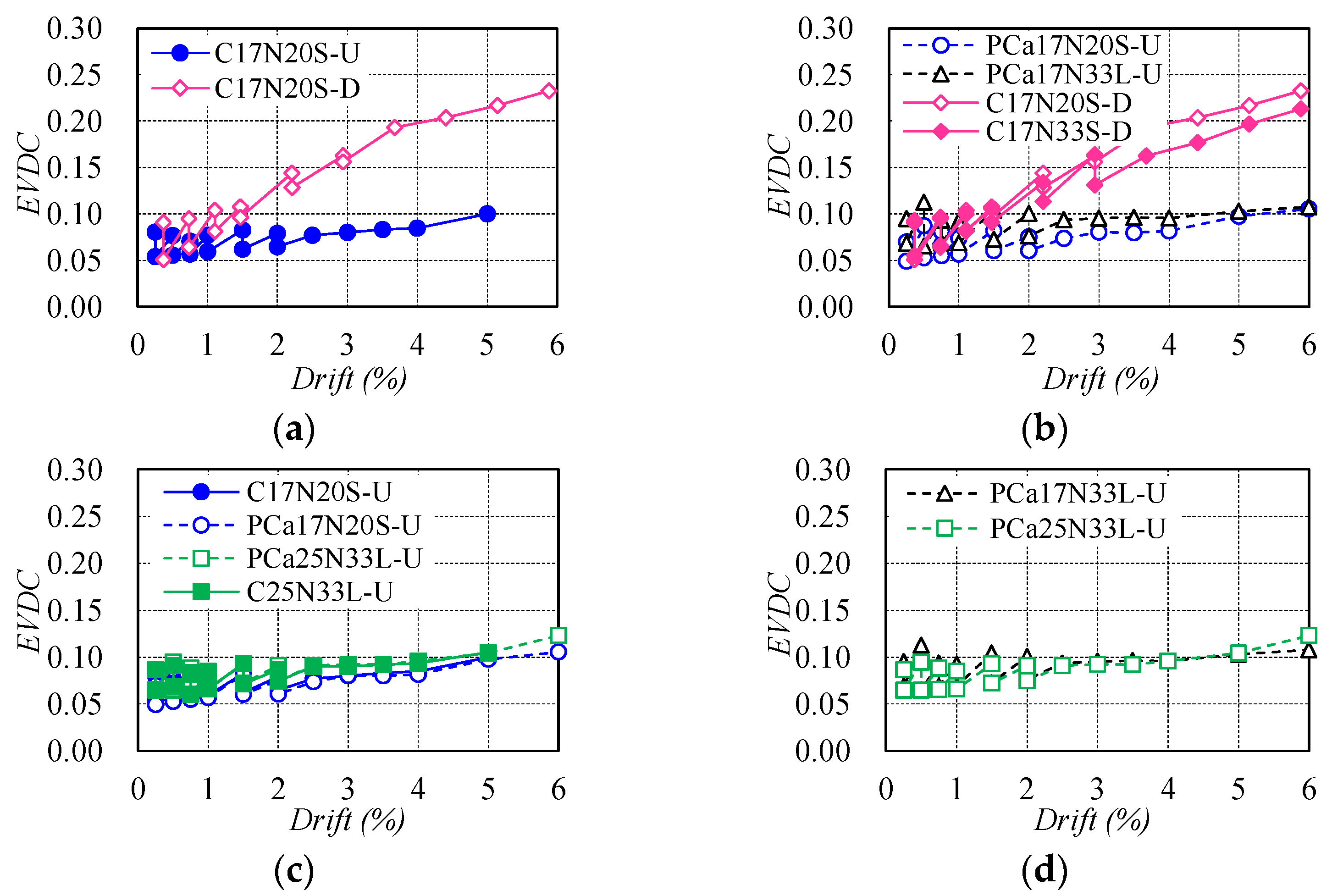

3.4. Energy Dissipation Capacity

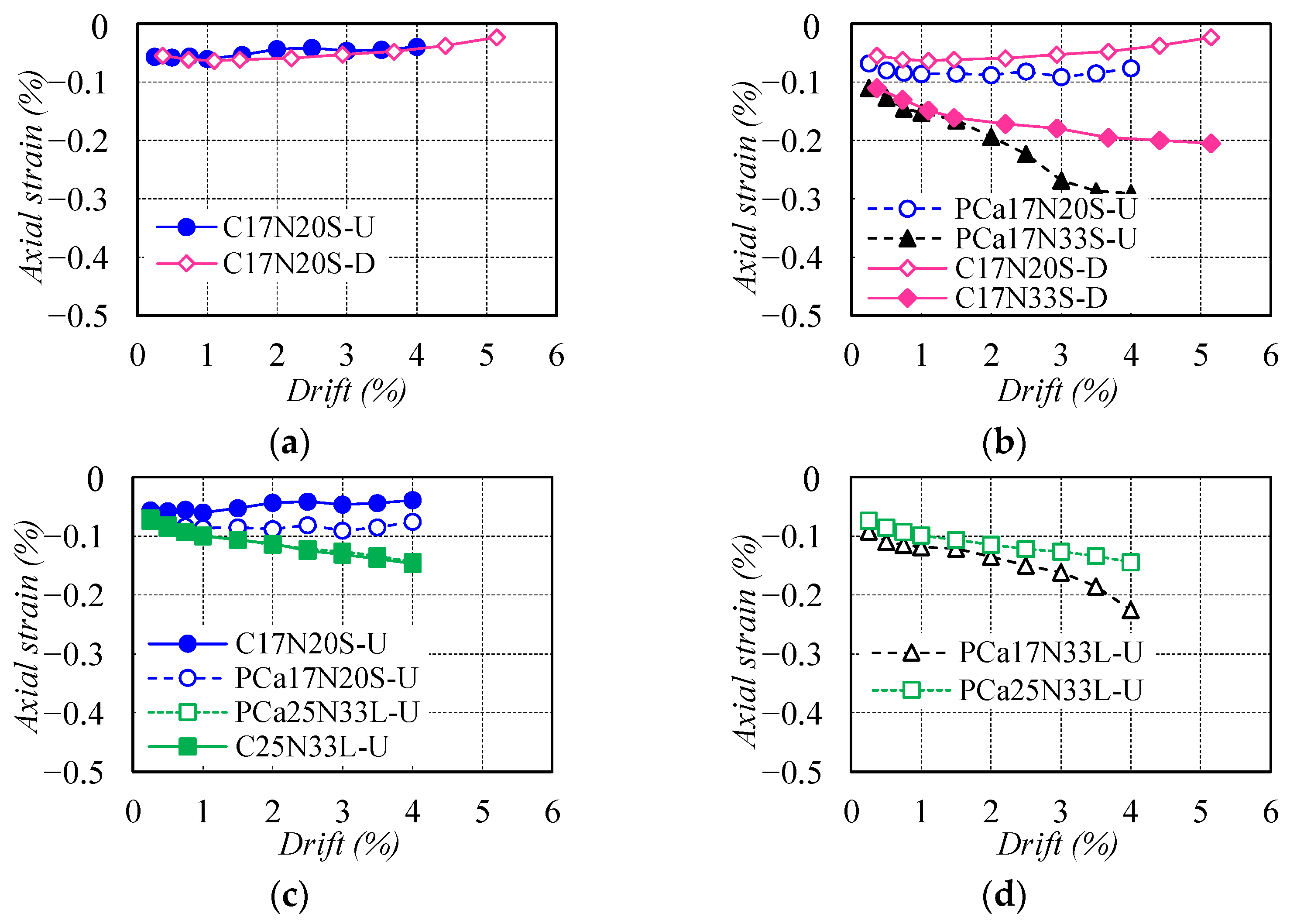

3.5. Axial Strain

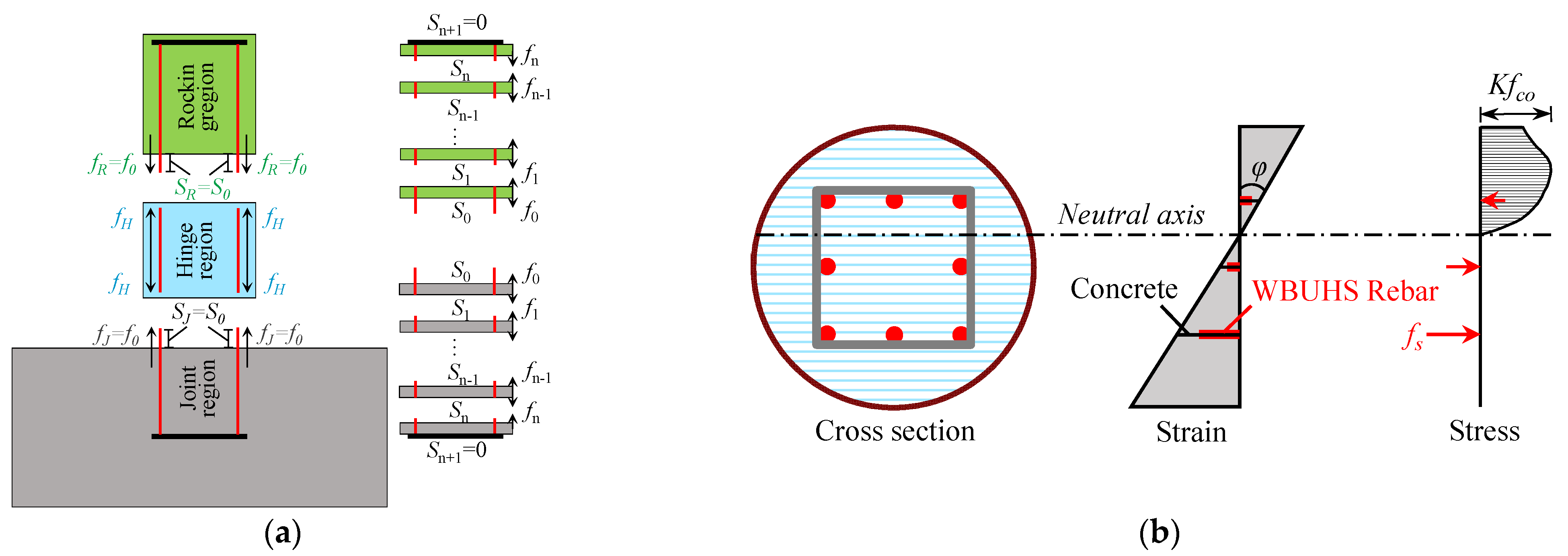

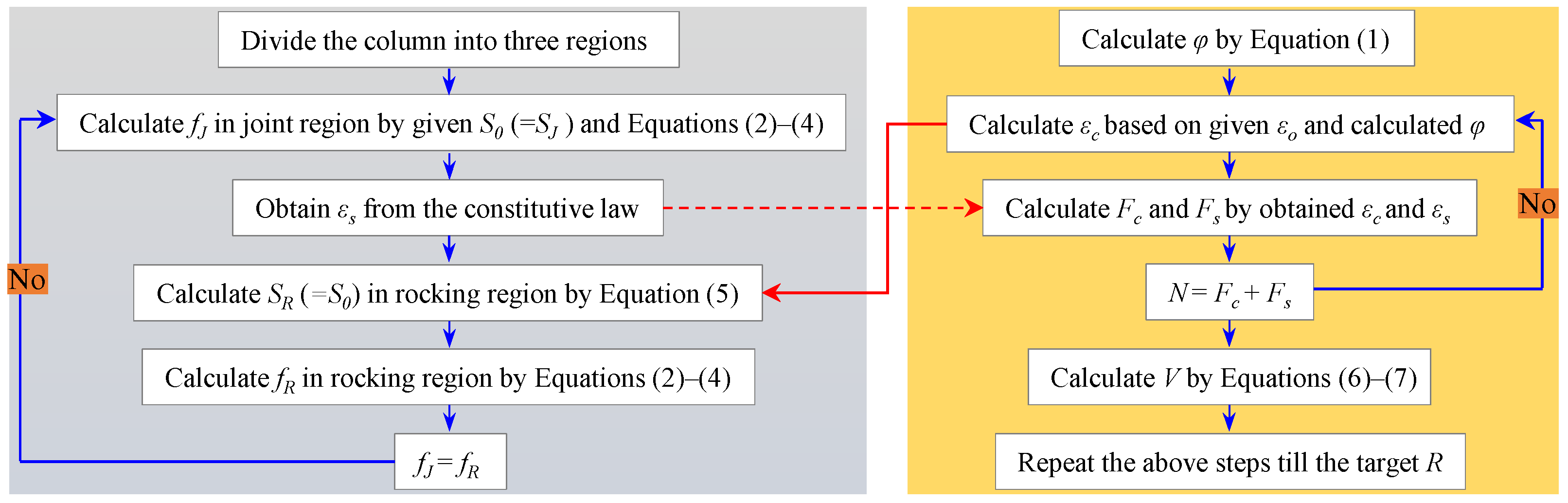

4. Numerical Analysis of Hysteresis Performance

4.1. Procedures of Numerical Analysis

- 1.

- Divide the column into three regions and discretize the joint and rocking region equally into tiny segments (see Figure 12a).

- 2.

- Give an initial concrete strain εo at the center of section, and obtain the strain distribution of concrete εc along the depth of section (see Figure 12b) based on Equation (1).

- 3.

- Give an initial stress f0 (=fJ) and slip S0 (=SJ) of the WBUHS rebar in the first segment of the joint region. According to the relationships between the stress (fk+1) and slip (Sk+1) listed by Equations (2) and (3), it is necessary to judge whether the boundary condition (see Equation (4)) is satisfied, if not, regive a f0 and S0 and repeat this process until Sn+1 = 0 is satisfied. Then the strain of WBUHS rebar εs can be obtained from the constitutive law.

- 4.

- Calculate the slip S0 (=SR) of the WBUHS rebar in the first segment of the rocking region based on Equation (5). The stress f0 (=fR) of the rebar in the first segment of the rocking region can be computed by the same procedure shown in step (3).

- 5.

- Obtain the target value of strain and stress of the WBUHS rebar assumed in step (3) by repeating steps (3)–(4) until fJ = fR was satisfied.

- 6.

- Calculate the force Fc and Fs borne by concrete and WBUHS rebars.

- 7.

- Verify whether N = Fc + Fs was satisfied. If not, reassign a new center strain εo and repeat the process from step (2).

- 8.

- Calculate lateral force V based on Equations (6) and (7).

- 9.

- Repeat the above steps until the target R.

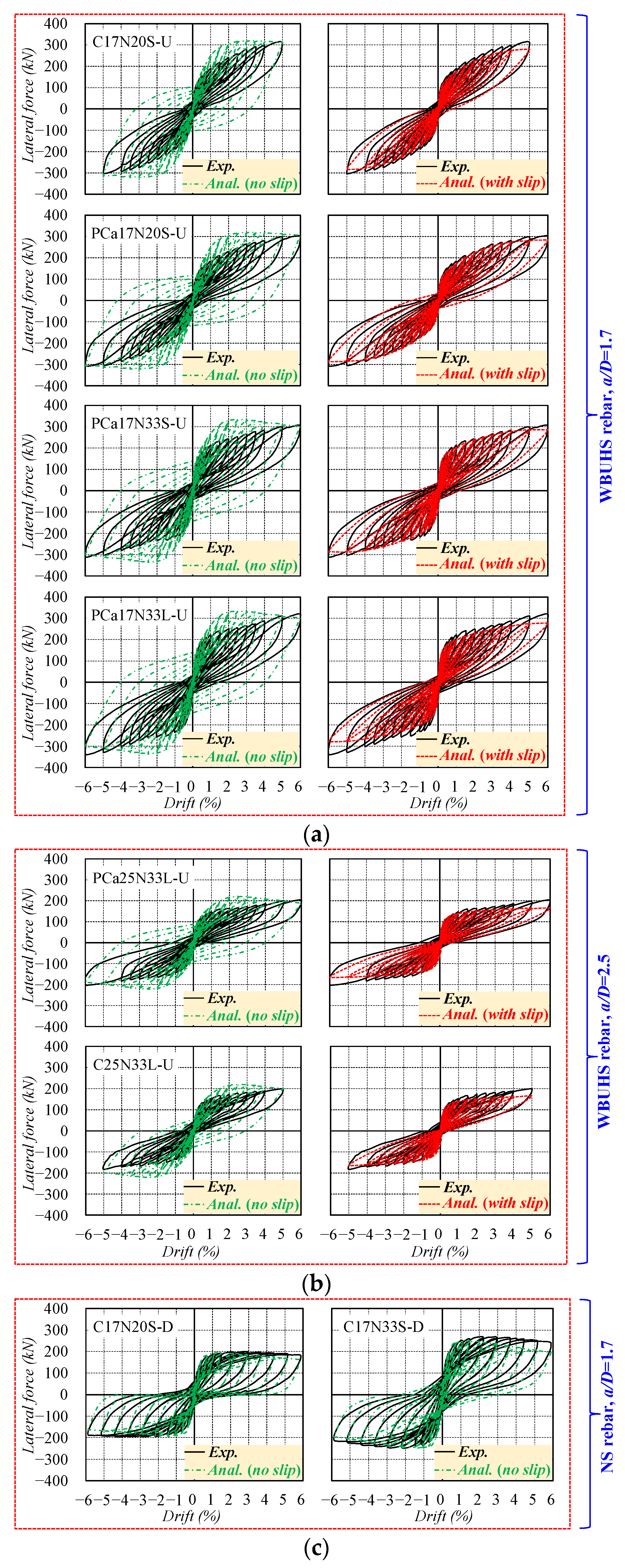

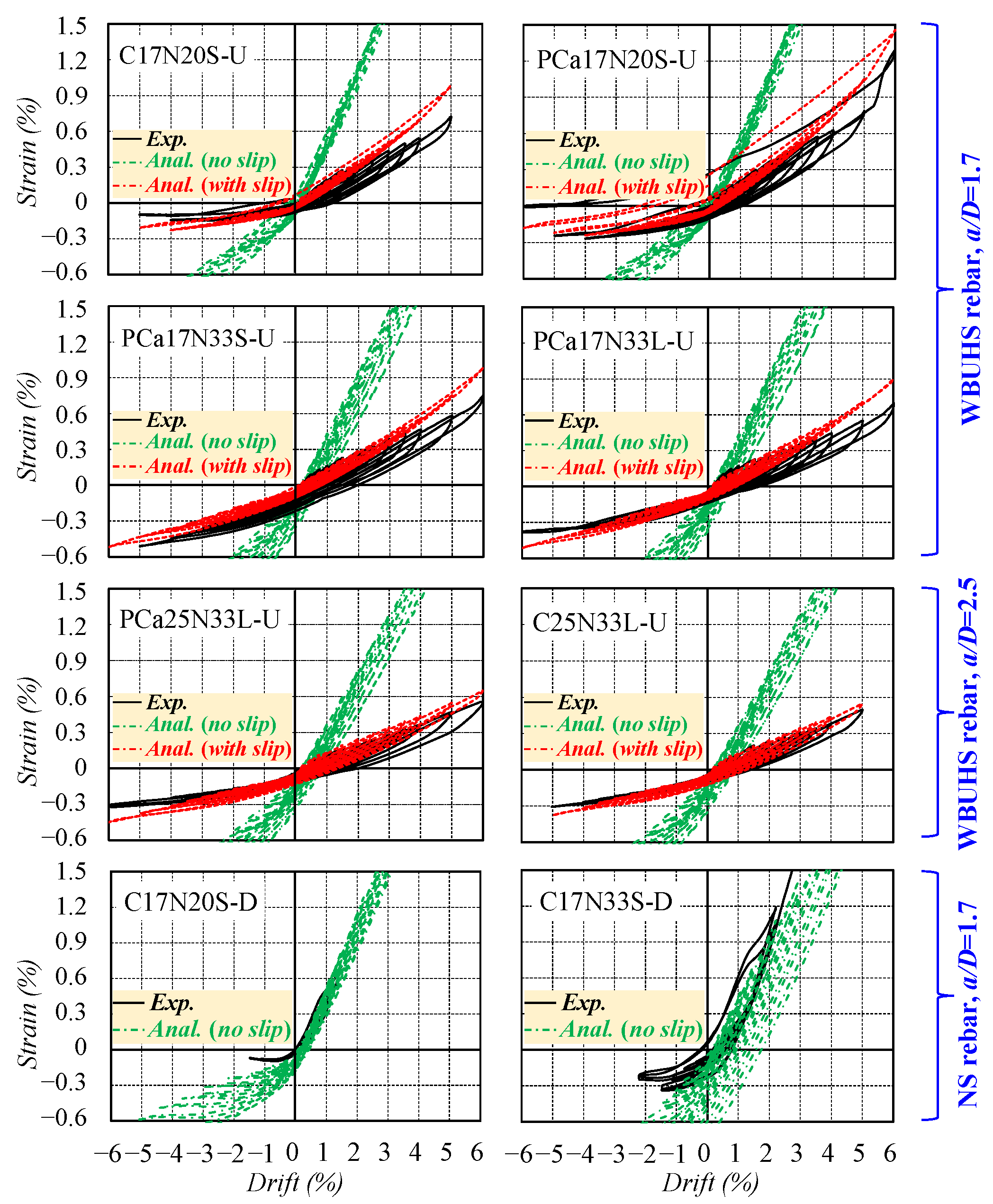

4.2. Discussion of Analytical Results

5. Conclusions

- As compared with traditional ductile concrete columns, the concrete columns reinforced with WBUHS rebars exhibited significant drift-hardening capacity as well as self-centering capacity up to the drift of at least 5%.

- If the embedment length of the WBUHS rebar was 20 times its diameter, the precast concrete columns could exert almost the same excellent seismic performance as cast-in-place columns.

- The test columns under higher axial compression showed comparatively serious concrete damage, but larger moment resistance.

- The analytical results, considering the slippage of reinforcements, effectively predicted the strain development trend of WBUHS rebars, and demonstrated good agreement with the hysteretic performance of test columns reinforced with WBUHS rebars.

- In light of the significant drift-hardening capacity and good self-centering capacity exhibited by the concrete columns reinforced with WBUHS rebars and confined by steel tubes. The use of resilient concrete columns developed in this paper is applicable to the ground floors of mid- and high-rise buildings to reduce the need for maintenance and repairs, particularly for structures in high seismic-intensity areas.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, Z. A preliminary report on the Great Wenchuan Earthquake. Earthq. Eng. Eng. Vib. 2008, 7, 225–234. [Google Scholar] [CrossRef]

- Mimura, N.; Yasuhara, K.; Kawagoe, S.; Yokoki, H.; Kazama, S. Damage from the Great East Japan Earthquake and Tsunami-a quick report. Mitig. Adapt. Strateg. Glob. Chang. 2011, 16, 803–818. [Google Scholar] [CrossRef]

- D’Ayala, D. Commentary: Reflections on the Turkey–Syria earthquakes of 6 February 2023. Proc. Inst. Civ. Eng. Struct. Build. 2023, 176, 478–481. [Google Scholar] [CrossRef]

- Godschalk, D.R. Urban hazard mitigation: Creating resilient cities. Nat. Hazards Rev. 2003, 4, 136–143. [Google Scholar] [CrossRef]

- Patel, R.; Nosal, L. Defining the Resilient City; United Nations University Centre for Policy Research: New York, NY, USA, 2016. [Google Scholar]

- Priestley, M.J.N.; Tao, J.R. Seismic response of precast prestressed concrete frames with partially debonded tendons. PCI J. 1993, 38, 58–69. [Google Scholar] [CrossRef]

- Priestley, M.J.N.; Sritharan, S.; Conley, J.R.; Pampanin, S. Preliminary results and conclusions from the PRESSS five-story precast concrete test building. PCI J. 1999, 44, 42–67. [Google Scholar] [CrossRef]

- Zatar, W.A.; Mutsuyoshi, H. Residual displacements of concrete bridge piers subjected to near field earthquakes. ACI Struct. J. 2002, 99, 740–749. [Google Scholar]

- Marriott, D.; Pampanin, S.; Palermo, A. Quasi-static and pseudo-dynamic testing of unbonded post-tensioned rocking bridge piers with external replaceable dissipaters. Earthq. Eng. Struct. Dyn. 2009, 38, 331–354. [Google Scholar] [CrossRef]

- Ou, Y.C.; Joju, J.; Liu, Y.C. Cyclic Behavior of Reinforced Concrete Columns with Unstressed Steel Strands as Longitudinal Reinforcement. J. Struct. Eng. 2022, 148, 04022125. [Google Scholar] [CrossRef]

- Wang, J.; Zhao, H.; He, J. Seismic behaviors and resilient capacity of CFRP-confined concrete columns with partially debonded high-strength steel rebars. Compos. Struct. 2019, 222, 110912. [Google Scholar] [CrossRef]

- Nikoukalam, M.T.; Sideris, P. Experimental performance assessment of nearly full-scale reinforced concrete columns with partially debonded longitudinal reinforcement. J. Struct. Eng. 2017, 143, 04016218. [Google Scholar] [CrossRef]

- Ibrahim, A.I.; Wu, G.; Sun, Z.; Cui, H. Cyclic behavior of concrete columns reinforced with partially unbonded hybrid. Eng. Struct. 2017, 131, 311–323. [Google Scholar] [CrossRef]

- Mechtcherine, V. Novel cement-based composites for the strengthening and repair of concrete structures. Constr. Build. Mater. 2013, 41, 365–373. [Google Scholar] [CrossRef]

- Franchi, A.; Napoli, P.; Crespi, P.; Giordano, N.; Zucca, M. Unloading and reloading process for the earthquake damage repair of ancient Masonry columns: The case of the Basilica di Collemaggio. Int. J. Archit. Herit. 2022, 16, 1683–1698. [Google Scholar] [CrossRef]

- Liu, J.; Sheikh, S.A. Fiber-Reinforced Polymer-Confined Circular Columns under Simulated Seismic Loads. ACI Struct. J. 2013, 110, 941–952. [Google Scholar]

- Ercan, E.; Arisoy, B.; Ertem, O.B. Experimental assessment of RC beam-column connections with internal and external strengthening techniques. Adv. Civ. Eng. 2019, 2019, 2828353. [Google Scholar] [CrossRef]

- Tobbi, H.; Farghaly, A.S.; Benmokrane, B. Concrete Columns Reinforced Longitudinally and Transversally with Glass Fiber-Reinforced Polymer Bars. ACI Struct. J. 2012, 109, 551–558. [Google Scholar]

- Choo, C.C.; Harik, I.E.; Gesund, H. Strength of rectangular concrete columns reinforced with fiber-reinforced polymer bars. ACI Mater. J. 2006, 103, 452. [Google Scholar]

- Mohamed, N.; Farghaly, A.S.; Benmokrane, B.; Neale, K.W. Flexure and shear deformation of GFRP-reinforced shear walls. J. Compos. Constr. 2014, 18, 04013044. [Google Scholar] [CrossRef]

- Mohamed, N.; Farghaly, A.S.; Benmokrane, B.; Neale, K.W. Experimental investigation of concrete shear walls reinforced with glass fiber–reinforced bars under lateral cyclic loading. J. Compos. Constr. 2014, 18, A4014001. [Google Scholar] [CrossRef]

- Billah, A.M.; Alam, M.S. Seismic performance of concrete columns reinforced with hybrid shape memory alloy (SMA) and fiber reinforced polymer (FRP) bars. Constr. Build. Mater. 2012, 28, 730–742. [Google Scholar] [CrossRef]

- Cai, Z.K.; Wang, D.; Wang, Z. Full-scale seismic testing of concrete building columns reinforced with both steel and CFRP bars. Compos. Struct. 2017, 178, 195–209. [Google Scholar] [CrossRef]

- Wang, Z.; Cai, Z. Analysis of post-tensioned precast segmental bridge piers reinforced with steel and FRP bars. In Proceedings of the Eighth International Conference on Fibre-Reinforced Polymer (FRP) Composites in Civil Engineering, Hong Kong, China, 14–16 December 2016; pp. 754–759. [Google Scholar]

- Funato, Y.; Sun, Y.P. Modeling and application of bond behavior of ultra-high strength bars with spiraled grooves on the surface. Proc. Jpn. Concr. Inst. 2012, 34, 157–162. (In Japanese) [Google Scholar]

- Zhang, J.; Liu, X.; Liu, J.; Zhang, M.; Cao, W. Seismic performance and reparability assessment of recycled aggregate concrete columns with ultra-high-strength steel bars. Eng. Struct. 2023, 277, 115426. [Google Scholar] [CrossRef]

- Cai, R.; Zhang, J.; Liu, Y.; Tao, X. Seismic behavior of recycled concrete columns reinforced with ultra-high-strength steel bars. Eng. Struct. 2023, 279, 115633. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, J.; Liu, J.; Zhang, M.; Cao, W. Seismic performance and damage assessment of earthquake-damaged HSRAC columns with UHSS repaired by CFRP jackets. Structures 2023, 48, 241–257. [Google Scholar] [CrossRef]

- Wang, J.H.; Sun, Y.P.; Takeuchi, T. Seismic fragility and post-earthquake reparability of circular reinforced concrete bridge columns with low-bond high-strength reinforcements. Structures 2021, 34, 840–855. [Google Scholar] [CrossRef]

- Sun, Y.P.; Cai, G.C. Seismic Behavior of Circular Concrete Columns Reinforced by Low Bond Ultrahigh Strength Rebars. J. Struct. Eng. 2023, 149, 04023126. [Google Scholar] [CrossRef]

- Wang, J.H.; Cai, G.C.; Si Larbi, A. Lateral behavior of rectangular concrete columns reinforced by partially debonded high-strength reinforcements based on a proposed equivalent stress block. Bull. Earthq. Eng. 2021, 19, 1901–1930. [Google Scholar] [CrossRef]

- Ou, Y.C.; Yin, S.Y.; Liu, Y.Q.; Wang, J.C. Cyclic behavior of a reinforced concrete column with unstressed seven-wire steel strands as longitudinal reinforcement. ACI 2020, 341, 97–104. [Google Scholar]

- Ou, Y.C.; Wu, J.W.; Pratiwi, A.Y. Effect of the concrete cover thickness ratio on the post-yield stiffness of bridge columns with partially unbonded unstressed steel strands. Adv. Bridge Eng. 2022, 3, 13. [Google Scholar] [CrossRef]

- Architectural Institute of Japan (AIJ). Standard for Structural Calculation of Reinforced Concrete Structures; Maruzen Co., Ltd.: Tokyo, Japan, 2010. [Google Scholar]

- Abdallah, A.E.; El-Salakawy, E.F. Seismic performance of GFRP-RC circular columns with different aspect ratios and concrete strengths. Eng. Struct. 2022, 257, 114092. [Google Scholar] [CrossRef]

- Abdallah, A.E.; El-Salakawy, E.F. Seismic behavior of high-strength concrete circular columns reinforced with glass fiber-reinforced polymer bars. ACI Struct. J. 2021, 118, 221–234. [Google Scholar]

- GB 50011-2010; Code for Seismic Design of Buildings. China Architecture Building Press: Beijing, China, 2016. (In Chinese)

- ACI318-14; Building Code Requirements for Structural Concrete (ACI318-14). American Concrete Institute (ACI): Farmington Hills, MI, USA, 2014.

- Chopra, A.K. Dynamics of Structure: Theory and Applications to Earthquake Engineering; Prentice-Hall: Upper Saddle River, NJ, USA, 1995. [Google Scholar]

- Sun, Y.P.; Fukuhara, T.; Kitajima, H. Analytical study of cyclic response of concrete members made of high-strength materials. In Proceedings of the 8th U.S. National Conference on Earthquake Engineering, San Francisco, CA, USA, 18–22 April 2006; Earthquake Engineering Research Institute: Oakland, CA, USA, 2006. [Google Scholar]

- Menegotto, M.; Pinto, P.E. Method of Analysis for Cyclic Loaded R. C. Plane Frame Including Changes in Geometry and Non-Elastic Behaviour of Elements under Combined Normal Force and Bending. In IABSE Symposium on Resistance and Ultimate Deform Ability of Structures Acted on by Well Defined Repeated Loads; Ein Dienst der ETH-Bibliothek: Zürich, Switzerland, 1973; Volume 11, pp. 15–22. [Google Scholar]

- Sun, Y.P.; Sakino, K. Simplified design method for ultimate capacities of circularly confined high-strength concrete columns. ACI Spec. Publ. 2000, 193, 571–585. [Google Scholar]

- Luo, J.; Takeuchi, T.; Zhao, J.; Sun, Y.P. Experimental study on axial behavior of confined concrete columns with SBPDN rebars. Proc. Jpn. Concr. Inst. 2022, 44, 397–402. [Google Scholar]

| Specimen | Longitudinal Rebar | a/D | Construction Method | le | n | Lateral Confinement | fc′ (MPa) | Qexp (kN) | Rexp (%) |

|---|---|---|---|---|---|---|---|---|---|

| C17N20S-U | 8-U12.6 | 1.7 | Cast-in-place | 20d | 0.20 | D6@100 + PL2.3 | 38.1 | 309.7 | 5.0 |

| PCa17N20S-U | 8-U12.6 | 1.7 | Prefabrication | 20d | 0.20 | D6@100 + PL2.3 | 38.5 | 306.0 | 6.0 |

| PCa17N33S-U | 8-U12.6 | 1.7 | Prefabrication | 20d | 0.33 | D6@100 + PL2.3 | 38.4 | 309.8 | 6.0 |

| PCa17N33L-U | 8-U12.6 | 1.7 | Prefabrication | 30d | 0.33 | D6@100 + PL2.3 | 38.0 | 330.1 | 6.0 |

| PCa25N33L-U | 8-U12.6 | 2.5 | Prefabrication | 30d | 0.33 | D6@100 + PL2.3 | 41.3 | 190.1 | 6.0 |

| C25N33L-U | 8-U12.6 | 2.5 | Cast-in-place | 30d | 0.33 | D6@100 + PL2.3 | 40.6 | 199.1 | 5.0 |

| C17N20S-D | 8-D13 | 1.7 | Cast-in-place | 20d | 0.20 | D6@100 + PL2.3 | 41.7 | 193.6 | 3.6 |

| C17N33S-D | 8-D13 | 1.7 | Cast-in-place | 20d | 0.33 | D6@100 + PL2.3 | 42.8 | 254.5 | 2.2 |

| Name | Diameter or Thickness (mm) | Yield Strength (N/mm2) | Yield Strain (%) | Tensile Strength (N/mm2) | Elasticity Modulus (kN/mm2) |

|---|---|---|---|---|---|

| WBUHS rebar (U12.6) | 12.6 | 1401 | 0.86 | 1478 | 212 |

| NS rebar (D13) | 12.7 | 403 | 0.22 | 600 | 200 |

| Hoop (D6) | 6.35 | 400 | 0.22 | 525 | 197 |

| Steel tube (PL2.3) | 2.3 | 391 | 0.20 | 465 | 201 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, J.; Yuan, S.; Zhao, J.; Sun, Y. Seismic Behavior of Concrete Columns Reinforced with Weakly Bonded Ultra-High Strength Rebars and Confined by Steel Tubes. Materials 2023, 16, 6868. https://doi.org/10.3390/ma16216868

Luo J, Yuan S, Zhao J, Sun Y. Seismic Behavior of Concrete Columns Reinforced with Weakly Bonded Ultra-High Strength Rebars and Confined by Steel Tubes. Materials. 2023; 16(21):6868. https://doi.org/10.3390/ma16216868

Chicago/Turabian StyleLuo, Jing, Shiyu Yuan, Jun Zhao, and Yuping Sun. 2023. "Seismic Behavior of Concrete Columns Reinforced with Weakly Bonded Ultra-High Strength Rebars and Confined by Steel Tubes" Materials 16, no. 21: 6868. https://doi.org/10.3390/ma16216868

APA StyleLuo, J., Yuan, S., Zhao, J., & Sun, Y. (2023). Seismic Behavior of Concrete Columns Reinforced with Weakly Bonded Ultra-High Strength Rebars and Confined by Steel Tubes. Materials, 16(21), 6868. https://doi.org/10.3390/ma16216868