Effects of Normalizing Temperature on Microstructure and Impact Toughness of V-N Micro-Alloyed P460NL1 Steel

Abstract

:1. Introduction

2. Experiment

2.1. Materials

2.2. Method

2.2.1. Heat Treatment

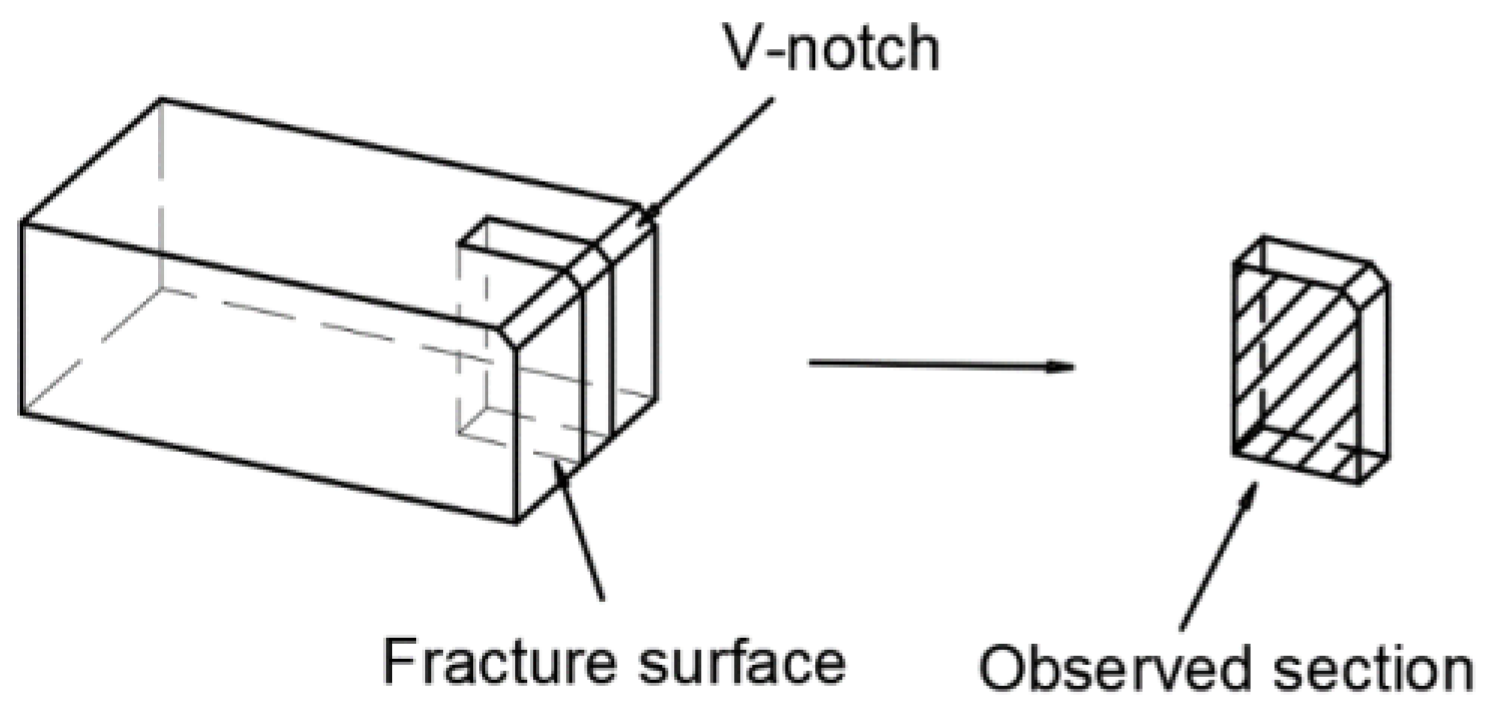

2.2.2. Characterization of Mechanical Properties and Fracture Morphology

2.2.3. Microstructure

3. Results

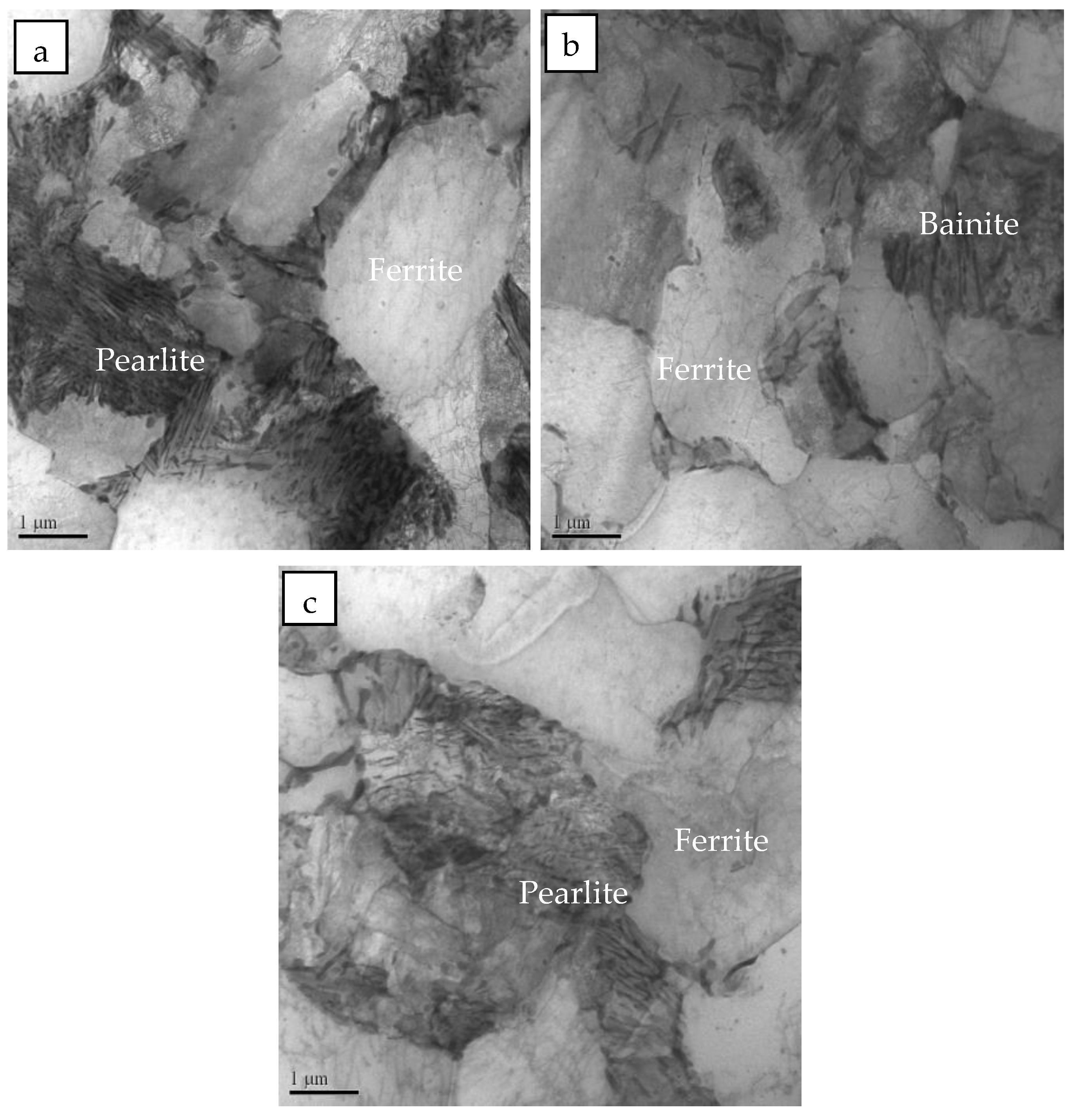

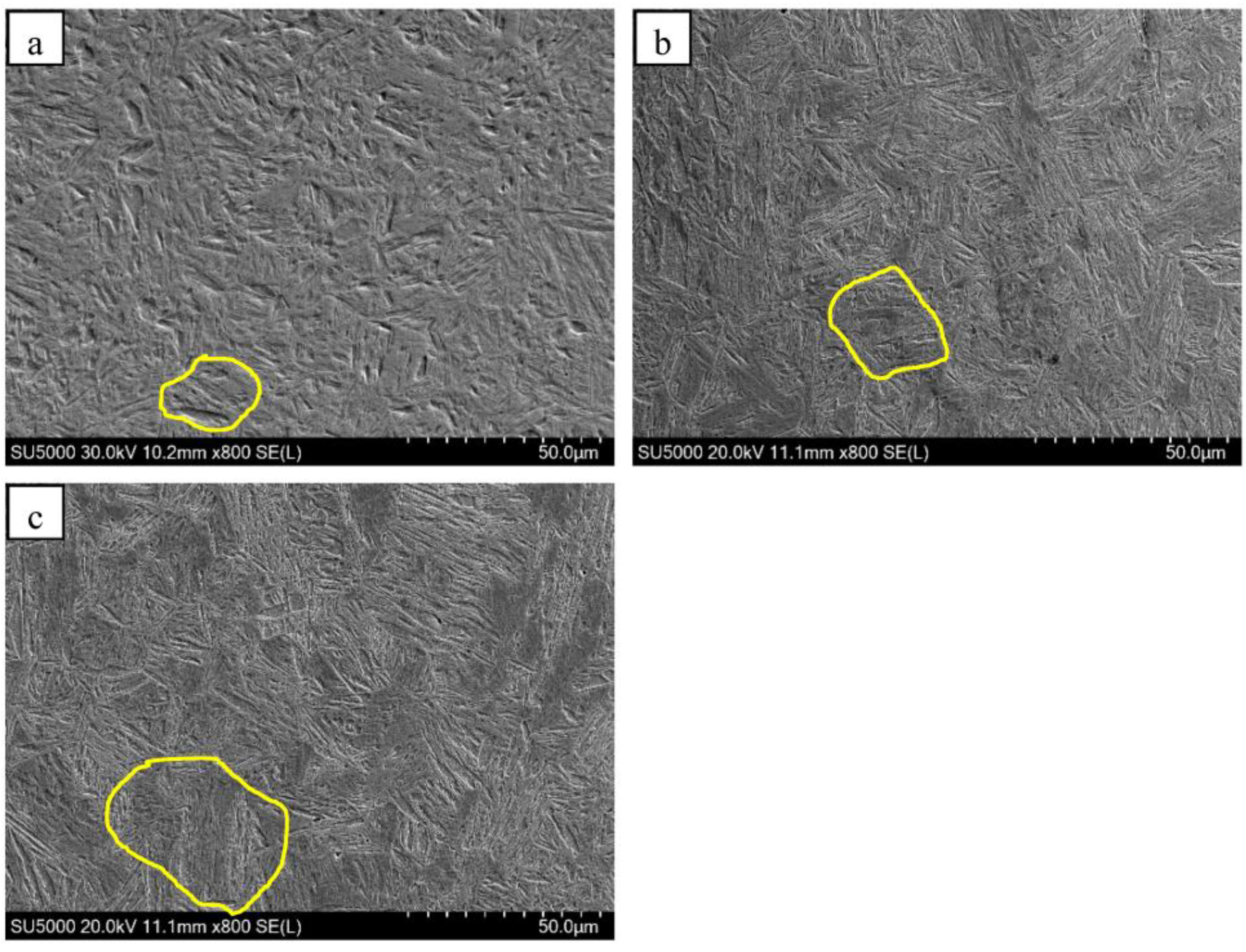

3.1. Effects of Normalizing Temperature on the Microstructure

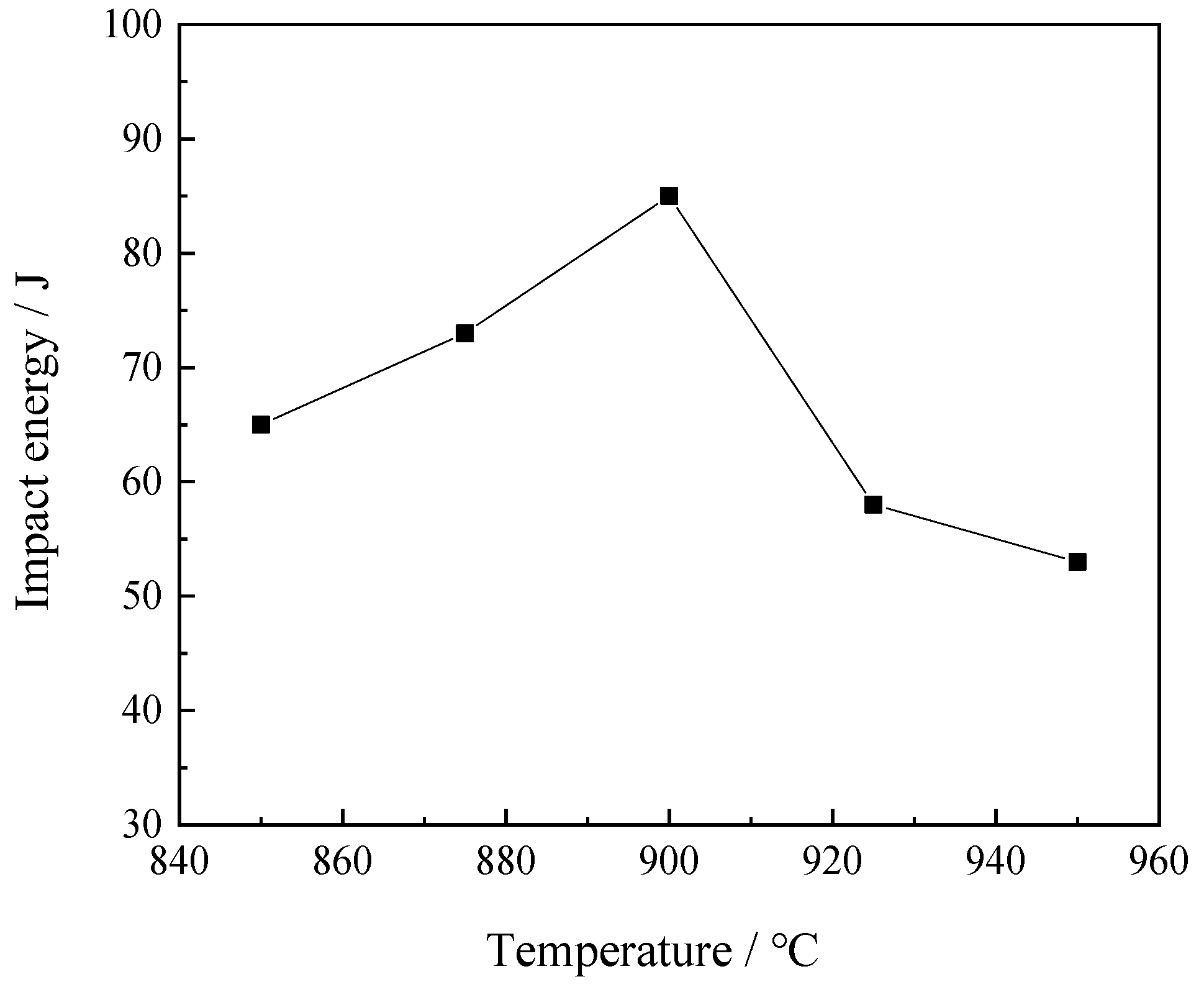

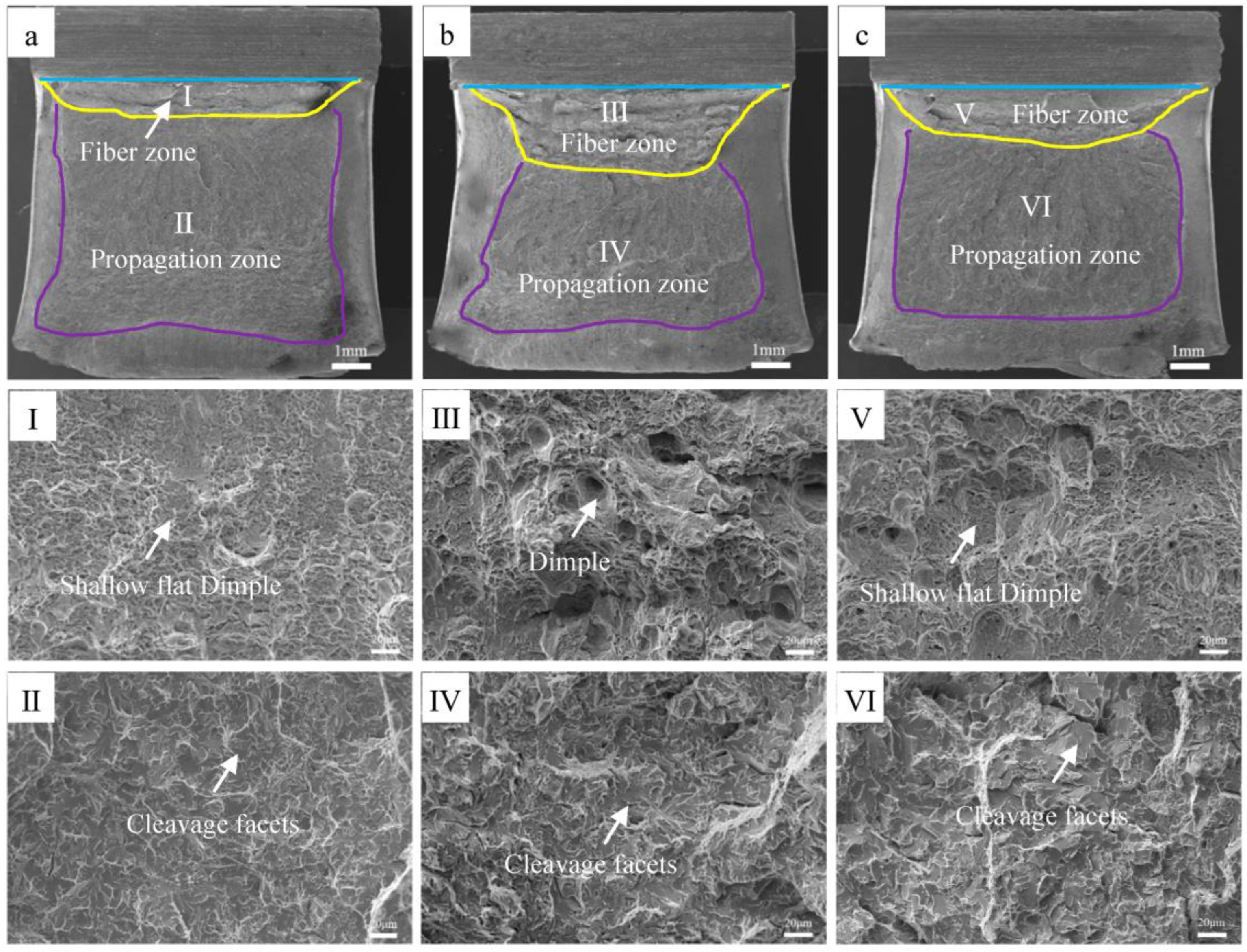

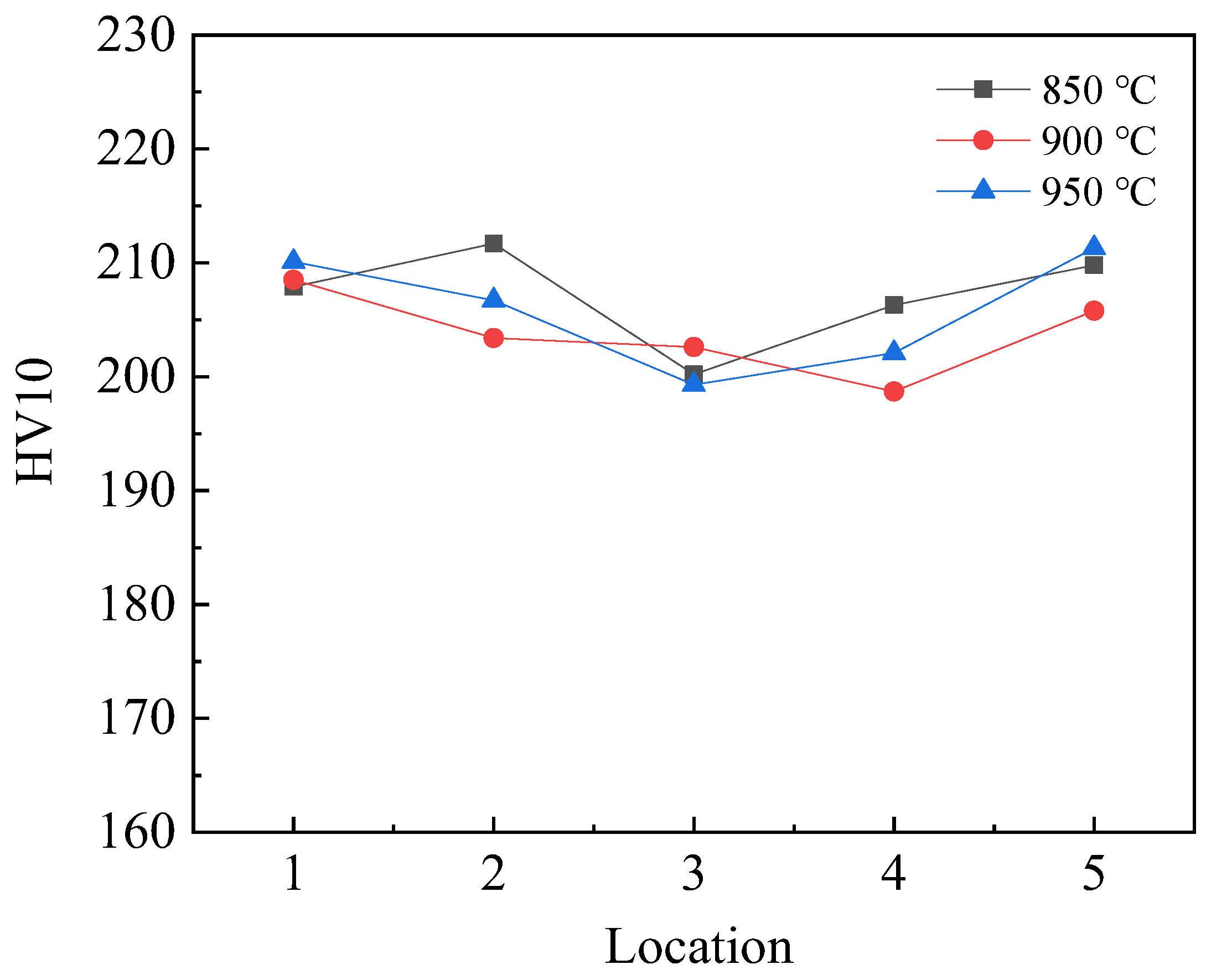

3.2. Effects of Normalizing Temperature on Mechanical Property

4. Discussion

4.1. Effects of Normalizing Temperature on Microstructure

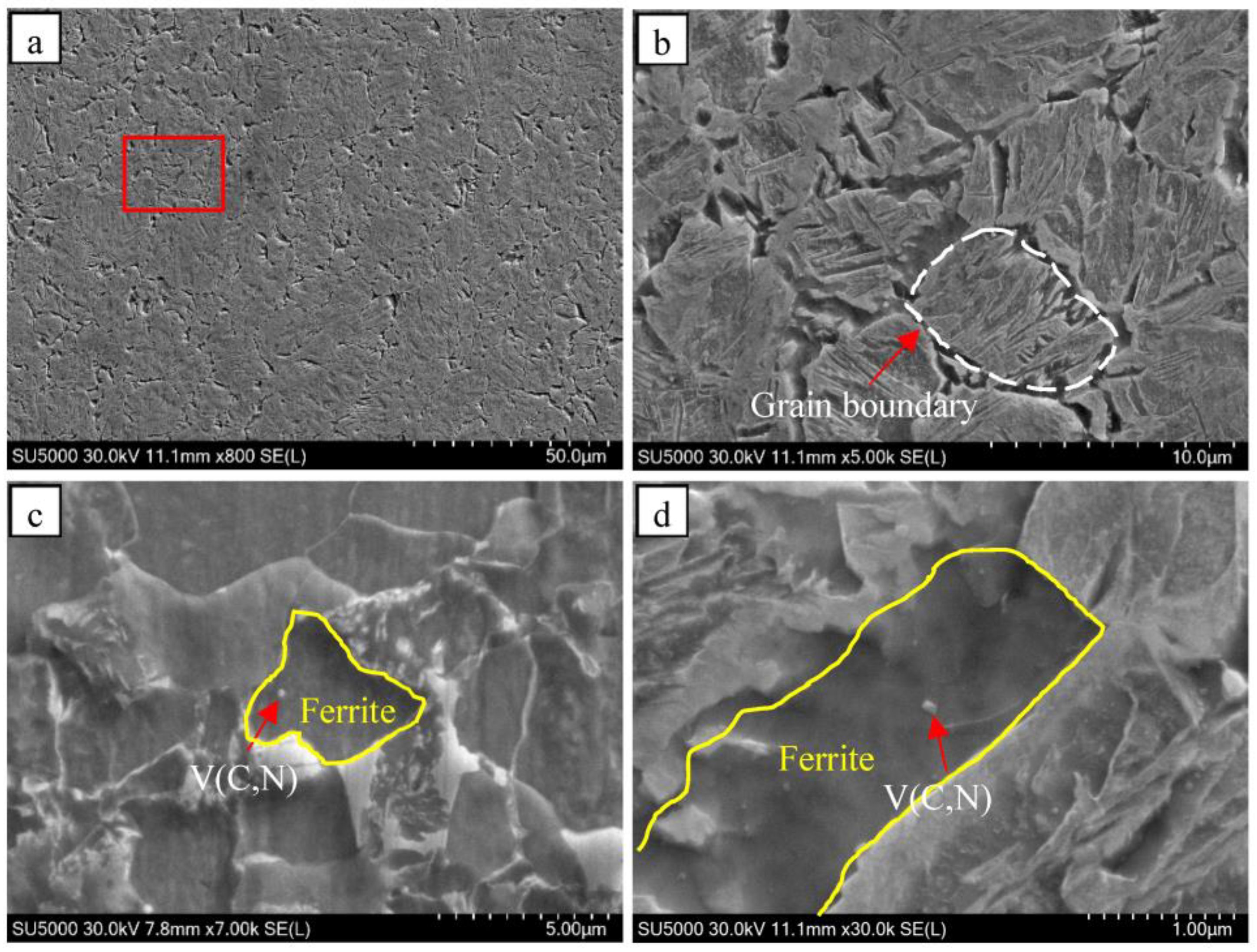

4.1.1. Effects of the Normalizing Temperature on Precipitated Particles

4.1.2. Effects of Normalizing Temperature on Primitive Austenite Grains

4.1.3. Relationship of Primitive Austenite Grain Size with Precipitated Particles and Microstructure

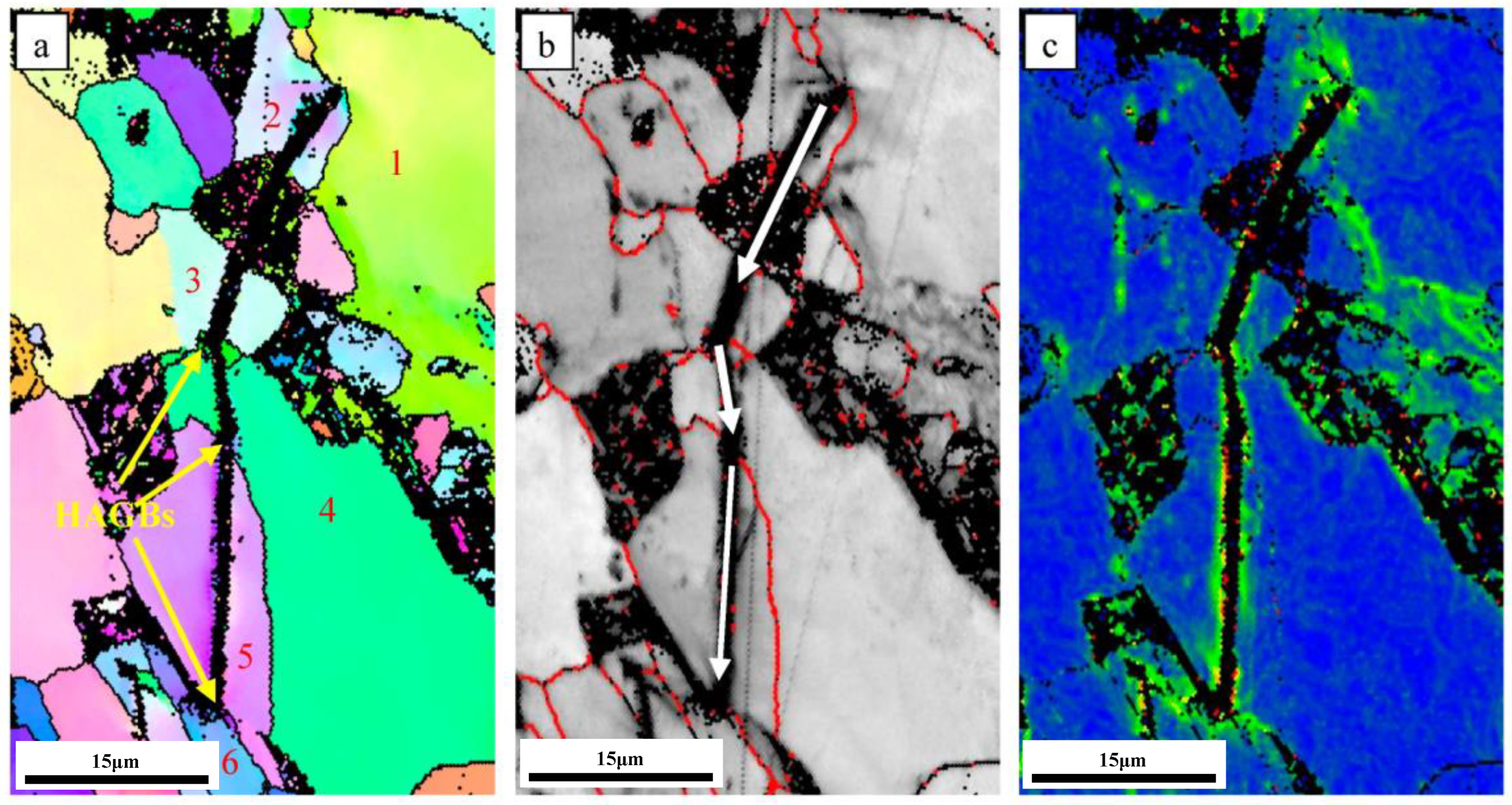

4.2. Effects of Normalizing Temperature on Impact Toughness

5. Conclusions

- (1)

- The precipitated V(C,N) particles dissolved as the temperature was increased, resulting in the coarsening of primitive austenite grains and leading to a reduction in the content of ferrite nucleation particles. As a result, the ferrite grain sizes were coarsened.

- (2)

- With the increase in normalizing temperature, the impact energy of the test steel first increases and then decreases, and the impact toughness of the test steel is at its best when the normalizing temperature is 900 °C.

- (3)

- The severe banded structure of 850 °C normalizing steel results in poor impact toughness. The band structure of 900 °C normalized steel is improved, and the ferrite is not coarsened obviously, so the toughness of the test steel is the best. Although the banded structure of the 950 °C normalizing sample basically disappeared, the microstructure was obviously coarsened, which resulted in poor toughness of the test steel.

- (4)

- Compared with ordinary micro-alloyed normalized steel, V-N micro-alloyed normalized steel has a finer grain size and better impact toughness.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ouchi, C. Advances in Physical Metallurgy and Processing of Steels. Development of Steel Plates by Intensive Use of TMCP and Direct Quenching Processes. Isij Int. 2001, 41, 542–553. [Google Scholar] [CrossRef]

- Li, H.; Feng, Y.; Song, M.; Liang, J.; Cang, D. Effect of Normalizing Cooling Process on Microstructure and Precipitates in Low-Temperature Silicon Steel. Trans. Nonferrous Met. Soc. China 2014, 24, 770–776. [Google Scholar] [CrossRef]

- Pandey, C.; Giri, A.; Mahapatra, M.M. Effect of Normalizing Temperature on Microstructural Stability and Mechanical Properties of Creep Strength Enhanced Ferritic P91 Steel. Mater. Sci. Eng. A 2016, 657, 173–184. [Google Scholar] [CrossRef]

- EN 10028-3:2017; Flat Products Made of Steels for Pressure Purposes—Part 3: Weldable Fine Grain Steels, Normalized. European Committee for Standardization: Brussels, Belgium, 2017.

- Tong, M.W.; Yuan, Z.X.; Zhang, K.G. Influence of Vanadium on Microstructures and Mechanical Properties of High Strength Normalized Steel. Adv. Mater. Res. 2012, 535–537, 628–632. [Google Scholar] [CrossRef]

- Pan, T.; Chai, X.; Wang, J.; Su, H.; Yang, C. Precipitation Behavior of V-N Microalloyed Steels during Normalizing. J. Iron Steel Res. Int. 2015, 22, 1037–1042. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, K.; Chen, H.; Xiao, X.; Wang, Q. Effect of Increased N Content on Microstructure and Tensile Properties of Low-C V-Microalloyed Steels. Mater. Sci. Eng. A 2016, 651, 951–960. [Google Scholar] [CrossRef]

- Hong, H.; Chunming, L.; Hanqian, Z. Effect of N Content on Microstructure and Properties of Normalized Steel for Mobile Containers. Press. Vessel. 2019. [Google Scholar] [CrossRef]

- Sun, L.; Zhang, S.; Song, R.; Ren, S.; Zhang, Y.; Sun, X.; Dai, G.; Hao, Y.; Huo, W.; Zhao, S.; et al. Effect of V, Nb, and Ti Microalloying on Low–Temperature Impact Fracture Behavior of Non–Quenched and Tempered Forged Steel. Mater. Sci. Eng. A 2023, 879, 145299. [Google Scholar] [CrossRef]

- Fang, F.; Qi-Long, Y.; Cai-Fu, Y.; Hang, S.U. Microstructure and Precipitation Behavior in Heat Affected Zone of Nitrogen-Enhanced Microalloyed Steel Containing V and Ti. J. Iron Steel Res. Int. 2007, 14, 249–253. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Liu, Y.; Zhou, Y.N.; Dong, X.M.; Zhang, C.X.; Cao, G.H.; Schneider, R.; Gerthsen, D. Effect of Precipitation of (Ti,V)N and V(C,N) Secondary Phases on Mechanical Properties of V and N Microalloyed 1Cr Steels. Mater. Sci. Eng. A. Struct. Mater. Prop. Misrostruct. Process. 2018, 738, 203–212. [Google Scholar] [CrossRef]

- Medina, S.F.; Chapa, M.; Valles, P. Influence of Ti and N Contents on Austenite Grain Control and Precipitate Size in Structural Steels. ISIJ Int. 1999, 39, 930–936. [Google Scholar] [CrossRef]

- Fan, H.; Shi, G.; Peng, T.; Wang, Q.; Wang, L.; Wang, Q.; Zhang, F. N-Induced Microstructure Refinement and Toughness Improvement in the Coarse Grain Heat-Affected Zone of a Low Carbon Mo–V–Ti–B Steel Subjected to a High Heat Input Welding Thermal Cycle. Mater. Sci. Eng. A 2021, 824, 141799. [Google Scholar] [CrossRef]

- Medina, S.F.; Gómez, M.; Rancel, L. Grain Refinement by Intragranular Nucleation of Ferrite in a High Nitrogen Content Vanadium Microalloyed Steel. Scr. Mater. 2008, 58, 1110–1113. [Google Scholar] [CrossRef]

- Garcia-Mateo, C.; Capdevila, C.; Caballero, F.G.; Andres, C.G.D. Influence of V Precipitates on Acicular Ferrite Transformation Part 1: The Role of Nitrogen. Isij Int. 2008, 48, 1270–1275. [Google Scholar] [CrossRef]

- Xia, Z.X.; Zhang, C.; Yang, Z.G. Control of Precipitation Behavior in Reduced Activation Steels by Intermediate Heat Treatment. Mater. Sci. Eng. A 2011, 528, 6764–6768. [Google Scholar] [CrossRef]

- Zhang, L.; Kannengiesser, T. Austenite Grain Growth and Microstructure Control in Simulated Heat Affected Zones of Microalloyed HSLA Steel. Mater. Sci. Eng. A 2014, 613, 326–335. [Google Scholar] [CrossRef]

- Staśko, R.; Adrian, H.; Adrian, A. Effect of Nitrogen and Vanadium on Austenite Grain Growth Kinetics of a Low Alloy Steel. Mater. Charact. 2006, 56, 340–347. [Google Scholar] [CrossRef]

- Wen, X.; Mei, Z.; Zhang, L.; Liu, Y.; Liu, G. Effect of Normalizing Temperature on Microstructure and Toughness of Nb-V-Ti Microalloyed Large Section Q345E Steel Forging. Mater. Sci. Eng. A 2016, 671, 233–243. [Google Scholar] [CrossRef]

- Dong, F.; Wang, R.; Yang, C.; Liu, X.; Liu, J.; Yang, F. Effects of Heat Treatment Process on Microstructure and Mechanical Properties of XG630DR Steel Plate. Hot Work. Technol. 2019, 48, 133–134. [Google Scholar]

- Rolinska, M.; Gustavsson, F.; Hedstrom, P. Revisiting the Applications of the Extractiona Replica Sample Preparation Technique for Analysis of Precipitates in Engineering Alloys. Mater. Charact. 2022, 189, 111978. [Google Scholar] [CrossRef]

- Wu, D.Y. Quantitative Research on the Role of Large Precipitates in V-Ti Micro-Alloyed Steel during Dynamic Transformation. Acta Metall. Sin. 2015, 28, 77–82. [Google Scholar] [CrossRef]

- Yang, Y.; Zhan, D.; Lei, H.; Li, Y.; Qiu, G.; Wang, R.; Jiang, Z.; Zhang, H. Coupling Effect of Prior Austenite Grain Size and Inclusion Characteristics on Acicular Ferrite Formation in Ti-Zr Deoxidized Low Carbon Steel. Metall. Mater. Trans. B 2020, 51, 480–491. [Google Scholar] [CrossRef]

- Effect of Heat-Input on Austenite Grain Size in the Heat-Affected Zone of HSLA-100 Steel. Available online: https://xueshu.baidu.com/usercenter/paper/show?paperid=519261d22832e48ca51e8c88c594901b&site=xueshu_se&hitarticle=1 (accessed on 27 September 2023).

- Shi, Z.; Wang, R.; Su, H.; Chai, F.; Wang, Q.; Yang, C. Effect of Nitrogen Content on the Second Phase Particles in V–Ti Microalloyed Shipbuilding Steel during Weld Thermal Cycling. Mater. Des. 2016, 96, 241–250. [Google Scholar] [CrossRef]

- Wei, L.; Nelson, T.W. Influence of Heat Input on Post Weld Microstructure and Mechanical Properties of Friction Stir Welded HSLA-65 Steel. Mater. Sci. Eng. A 2012, 556, 51–59. [Google Scholar] [CrossRef]

- Bramfitt, B.L. The Effect of Carbide and Nitride Additions on the Heterogeneous Nucleation Behavior of Liquid Iron. Metall. Trans. 1970, 1, 1987–1995. [Google Scholar] [CrossRef]

- Contribution of Grain Size to Resistance against Cleavage Crack Propagation in Ferritic Steel-ScienceDirect. Available online: http://www-sciencedirect-com-s.vpn.ysu.edu.cn:8118/science/article/pii/S1359645419304112 (accessed on 10 September 2023).

- Mohseni, P.; Solberg, J.K.; Karlsen, M.; Akselsen, O.M.; Østby, E. Investigation of Mechanism of Cleavage Fracture Initiation in Intercritically Coarse Grained Heat Affected Zone of HSLA Steel. Mater. Sci. Technol. 2012, 28, 1261–1268. [Google Scholar] [CrossRef]

- Zhang, S.; Romo, S.; Giorjao, R.A.; Leão, P. EBSD Analysis of Strain Distribution and Evolution in Ferritic-Pearlitic Steel under Cyclic Deformation at Intermediate Temperature. Mater. Charact. 2022, 193, 112293. [Google Scholar] [CrossRef]

- Rodriguez-Ibabe, J.M. The Role of Microstructure in Toughness Behaviour of Microalloyed Steels. Mater. Ence Forum 1998, 284, 51–62. [Google Scholar] [CrossRef]

| Steel | C | Si | Mn | P | S | Ni | V | N | Alt |

|---|---|---|---|---|---|---|---|---|---|

| 165 N | 0.183 | 0.26 | 1.70 | 0.009 | 0.002 | 0.51 | 0.162 | 0.0165 | 0.008 |

| Normalizing Temperature (°C) | 850 | 875 | 900 | 925 | 950 |

|---|---|---|---|---|---|

| Impact energy (J) | 75 64 55/65 | 76 81 61/73 | 92 82 89/88 | 55 60 60/58 | 57 48 54/53 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, X.; Fan, H.; Wang, Q.; Wang, Q. Effects of Normalizing Temperature on Microstructure and Impact Toughness of V-N Micro-Alloyed P460NL1 Steel. Materials 2023, 16, 6921. https://doi.org/10.3390/ma16216921

Li X, Fan H, Wang Q, Wang Q. Effects of Normalizing Temperature on Microstructure and Impact Toughness of V-N Micro-Alloyed P460NL1 Steel. Materials. 2023; 16(21):6921. https://doi.org/10.3390/ma16216921

Chicago/Turabian StyleLi, Xinliang, Huibing Fan, Qiuming Wang, and Qingfeng Wang. 2023. "Effects of Normalizing Temperature on Microstructure and Impact Toughness of V-N Micro-Alloyed P460NL1 Steel" Materials 16, no. 21: 6921. https://doi.org/10.3390/ma16216921

APA StyleLi, X., Fan, H., Wang, Q., & Wang, Q. (2023). Effects of Normalizing Temperature on Microstructure and Impact Toughness of V-N Micro-Alloyed P460NL1 Steel. Materials, 16(21), 6921. https://doi.org/10.3390/ma16216921