Hard and Highly Adhesive AlMgB14 Coatings RF Sputtered on Tungsten Carbide and High-Speed Steel

Abstract

1. Introduction

2. Materials and Methods

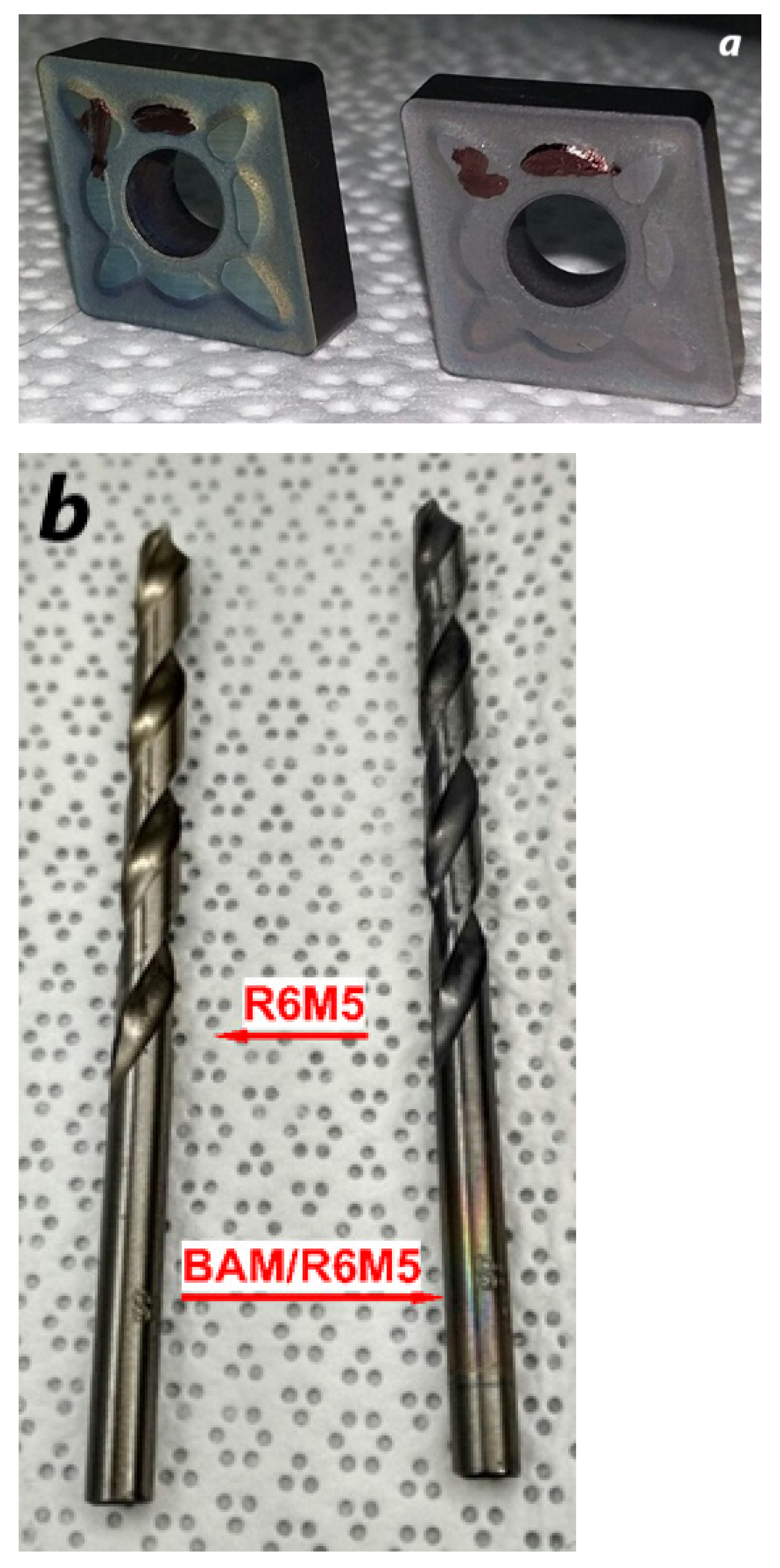

3. BAM-Coated WC-Co Inserts

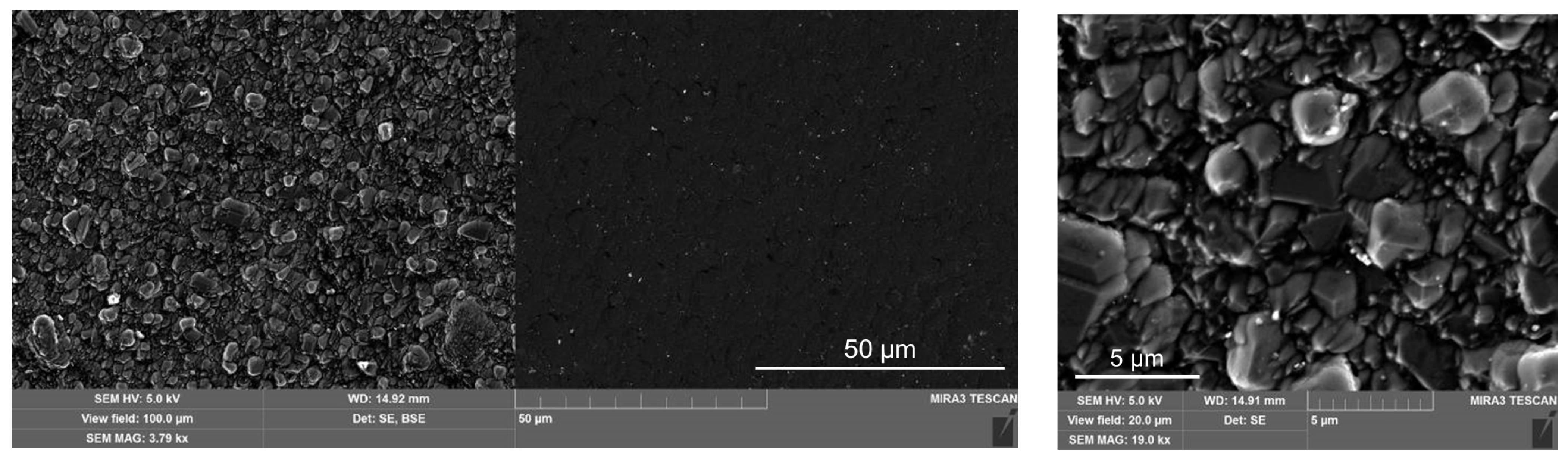

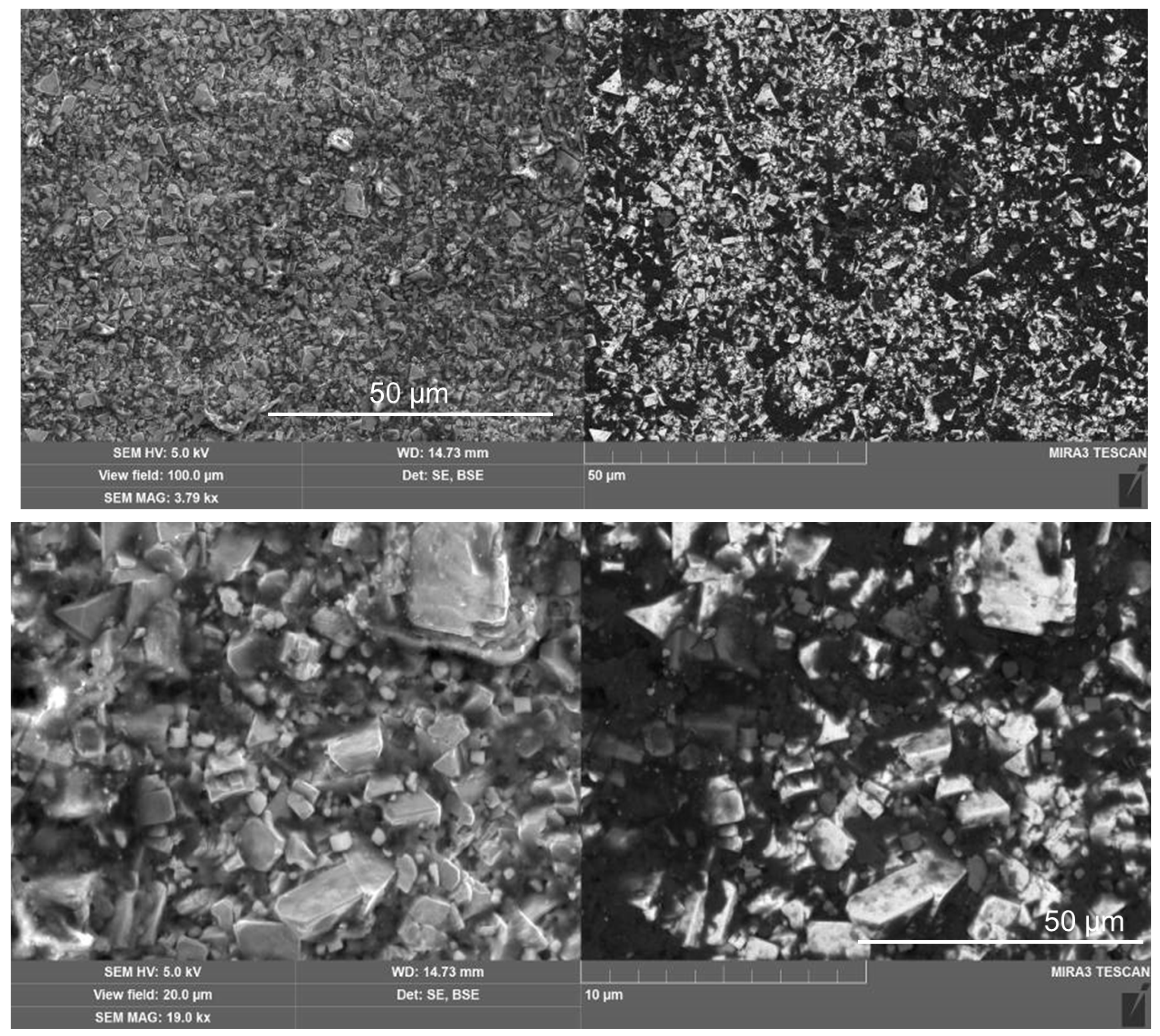

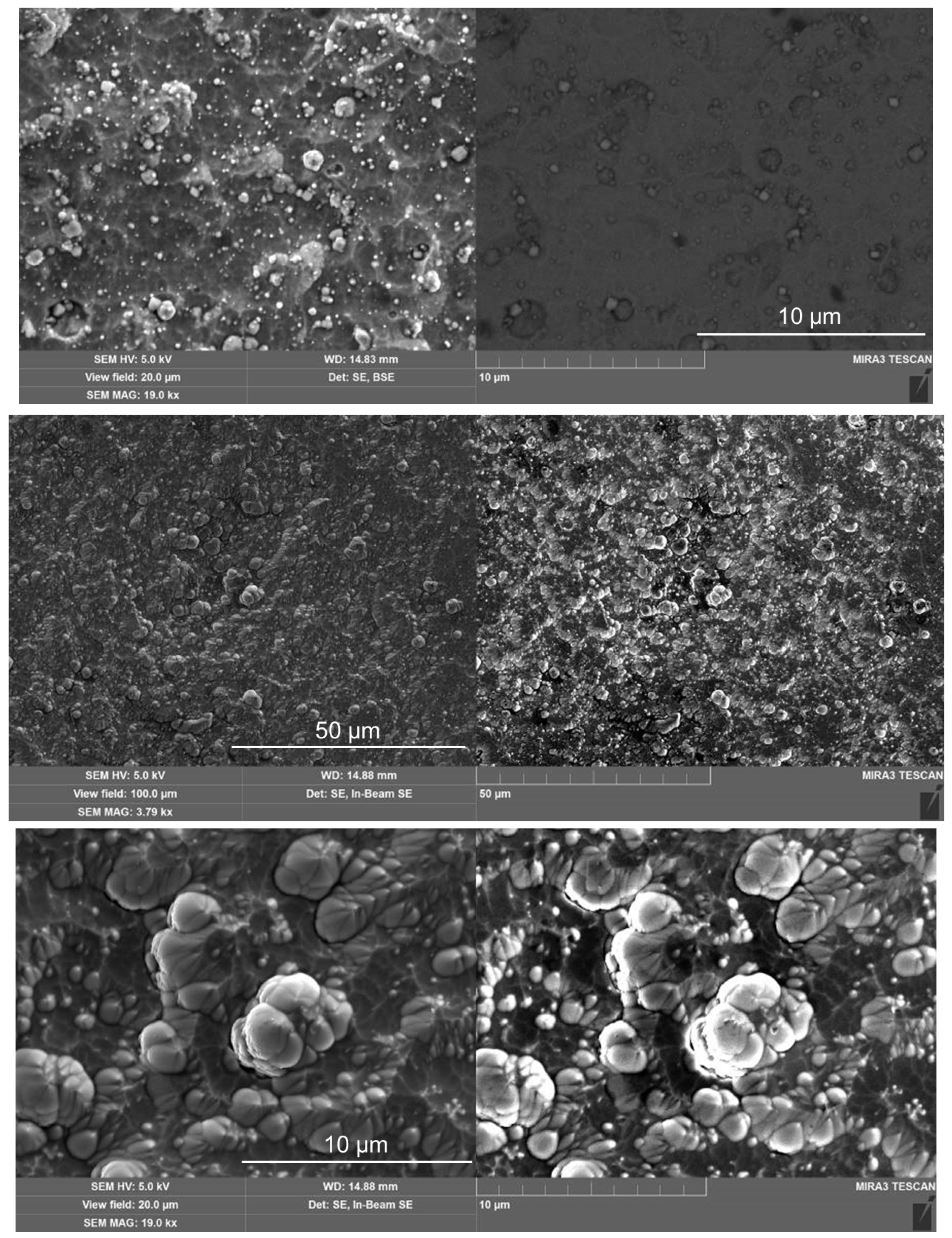

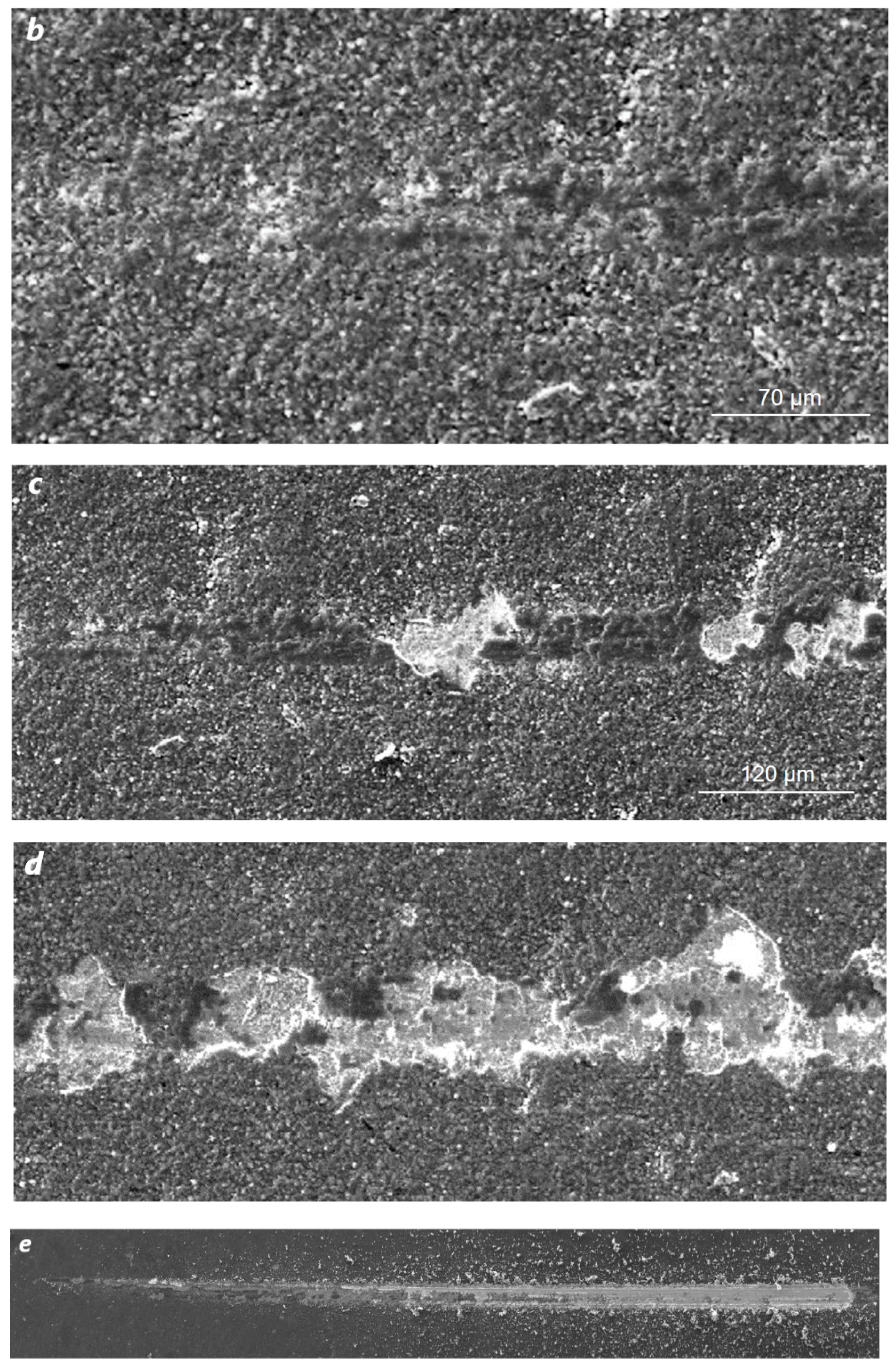

3.1. Microstructure

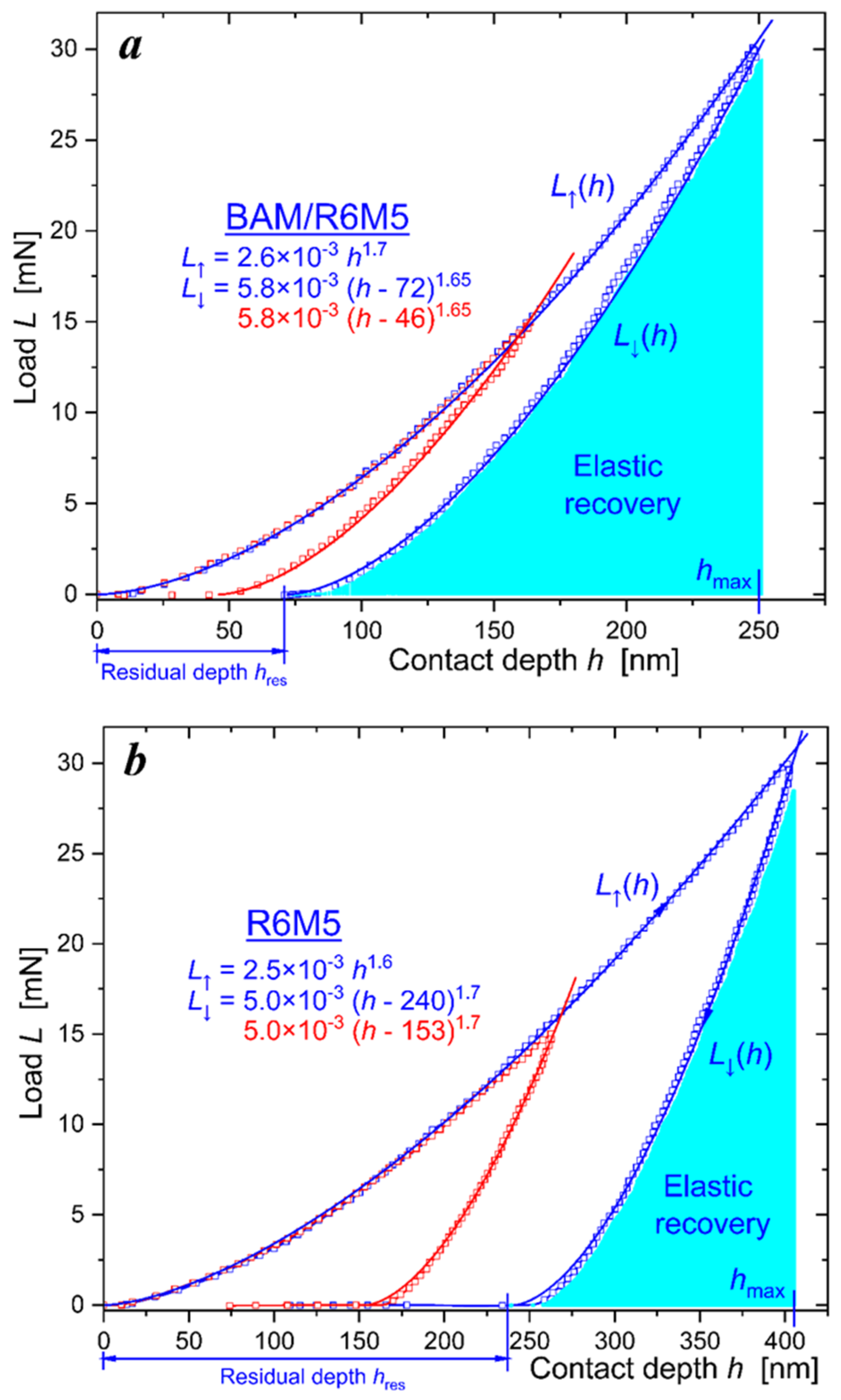

3.2. Nanoindentation, Vickers Hardness

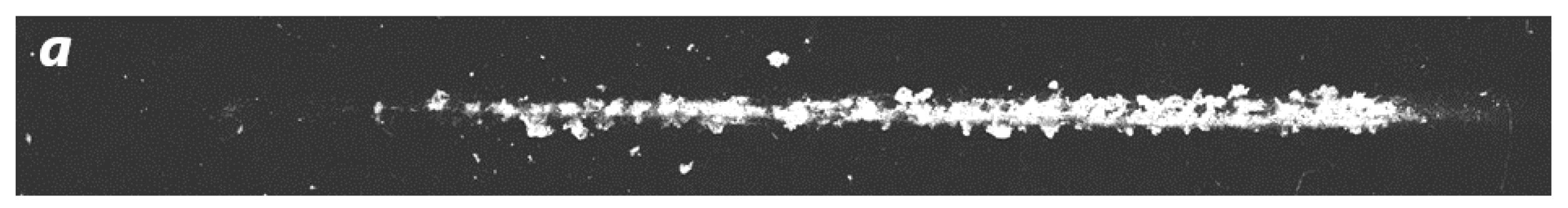

3.3. Adhesive Wear

4. BAM-Coated R6M5 Steel Drill Bits

4.1. Hardness and Young’s Modulus

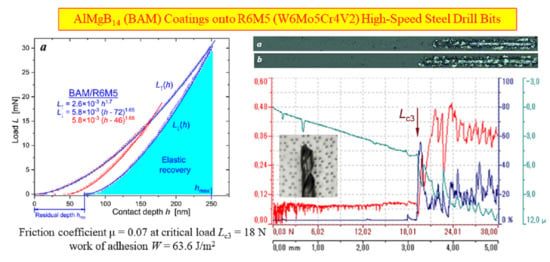

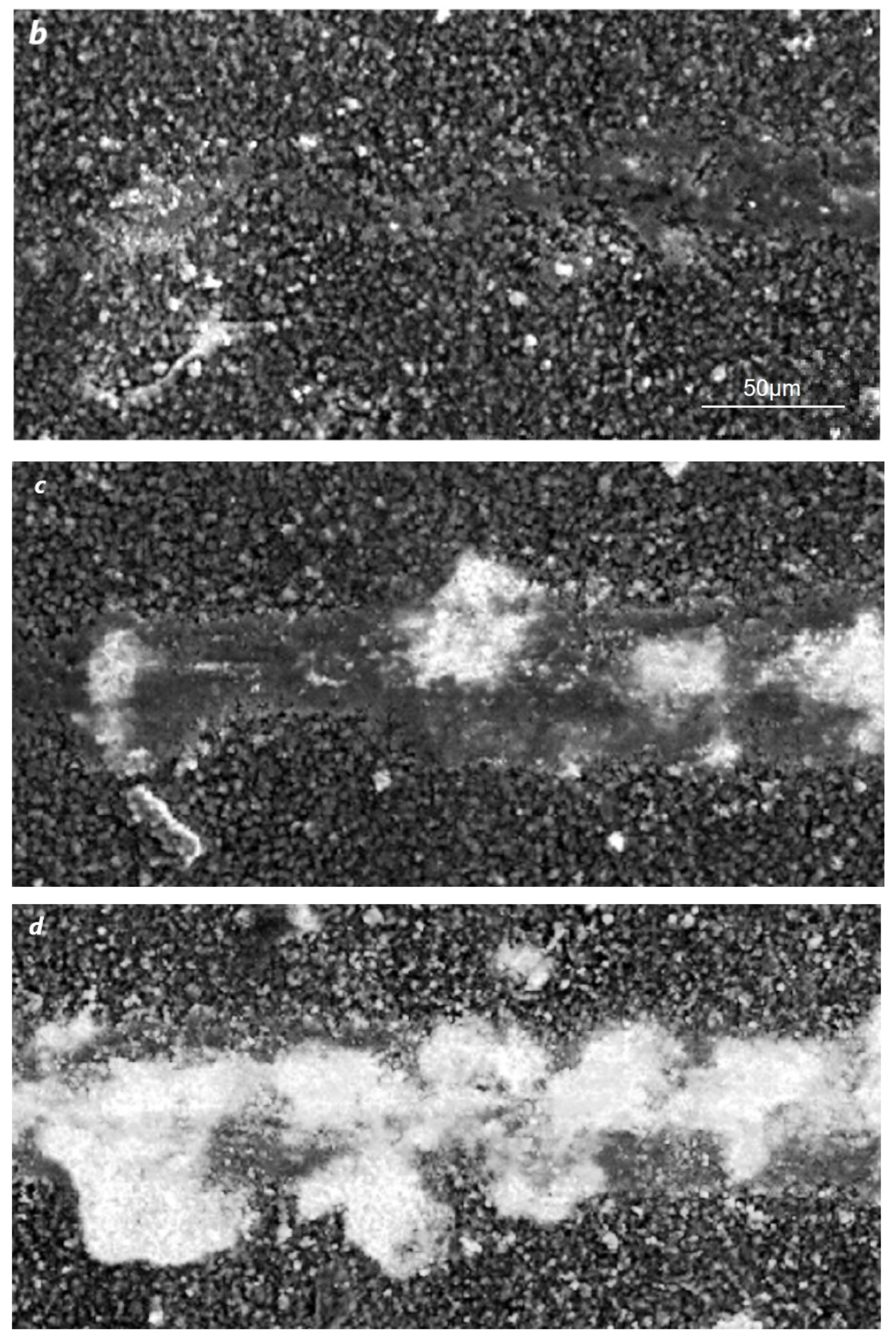

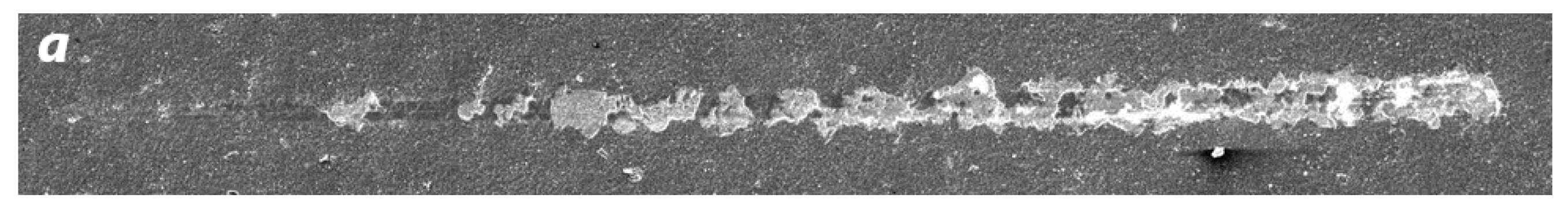

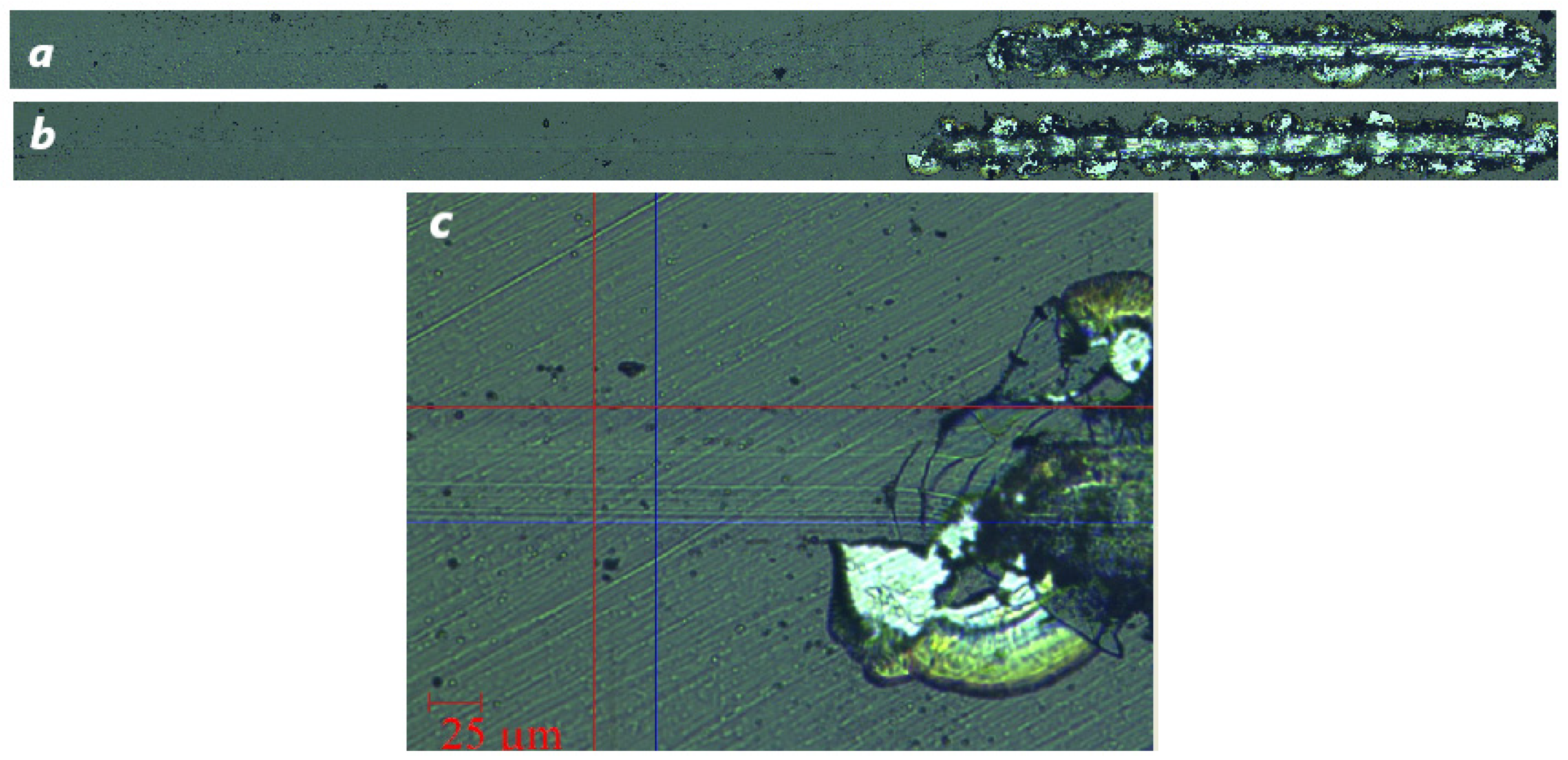

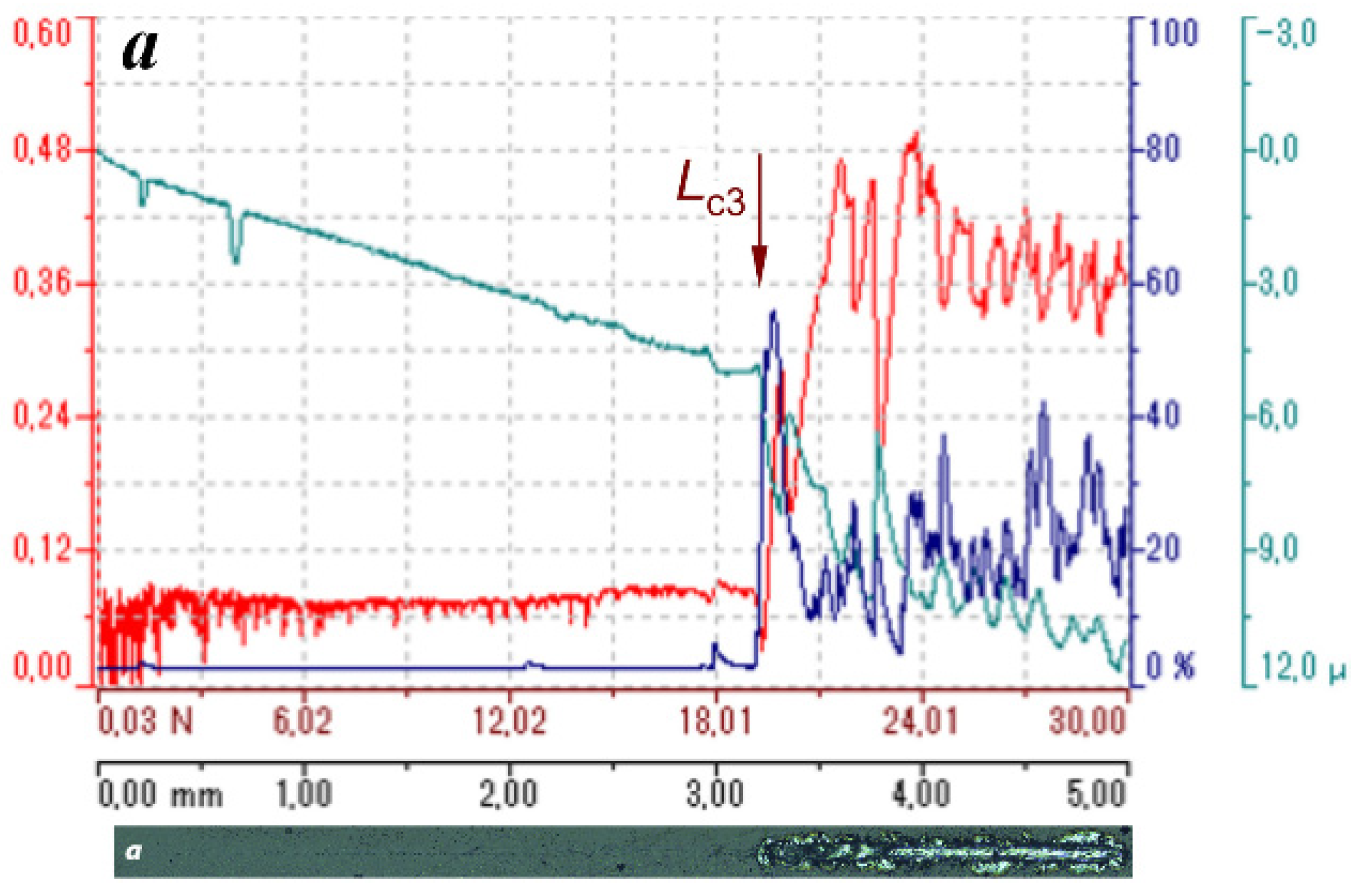

4.2. Adhesive Strength

5. Work of BAM-Coating Adhesion onto R6M5 Steel

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tian, Y.; Bastawros, A.F.; Lo, C.C.H.; Constant, A.P.; Russell, A.M.; Cook, B.A. Superhard self-lubricating AlMgB14 films for microelectromechanical devices. Appl. Phys. Lett. 2003, 83, 2781–2783. [Google Scholar] [CrossRef]

- Cook, B.A.; Tian, Y.; Harringa, J.L.; Constant, A.P.; Russell, A.M.; Molian, P.A. An Ultra-Hard, Low Friction Coating Based on AlMgB14 for Reduced Wear of MEMS and Other Tribological Components and Systems. U.S. Patent 7,238,429 B2, 3 July 2007. [Google Scholar]

- Cook, B.A.; Peters, J.S.; Harringa, J.L.; Russell, A.M. Enhanced wear resistance in AlMgB14-TiB2 composites. Wear 2011, 271, 640–646. [Google Scholar] [CrossRef]

- Higdon, C.; Cook, B.; Harringa, J.; Russell, A.; Goldsmith, J.; Qu, J.; Blau, P. Friction and wear mechanisms in AlMgB14-TiB2 nanocoatings. Wear 2011, 271, 2111–2115. [Google Scholar]

- Cherukuri, R.; Womack, M.; Molian, P.; Russell, A.; Tian, Y. Pulsed laser deposition of AlMgB14 on carbide inserts for metal cutting. Surf. Coat. Technol. 2002, 155, 112–120. [Google Scholar] [CrossRef]

- Tian, Y.; Womack, M.; Molian, P.; Lo, C.C.H.; Anderegg, J.W.; Russell, A.M. Microstructure and nanomechanical properties of Al-Mg-B-Ti films synthesized by pulsed laser deposition. Thin Solid Films 2002, 418, 129–135. [Google Scholar] [CrossRef]

- Tian, Y.; Constant, A.; Lo, C.C.H.; Anderegg, J.W.; Russell, A.M.; Snyder, J.E.; Molian, P. Microstructure evolution of Al-Mg-B thin films by thermal annealing. J. Vac. Sci. Technol. A 2003, 21, 1055–1063. [Google Scholar]

- Tian, Y.; Li, G.; Shinar, J.; Wang, N.L.; Cook, B.A.; Anderegg, J.W.; Constant, A.P.; Russell, A.M.; Snyder, J.E. Electrical transport in amorphous semiconducting AlMgB14 films. Appl. Phys. Lett. 2004, 85, 1181–1183. [Google Scholar] [CrossRef][Green Version]

- Stock, M.; Molian, P. Femtosecond pulsed laser deposition of amorphous, ultrahard boride thin films. J. Vac. Sci. Technol. A 2004, 22, 670–675. [Google Scholar]

- Britson, J.C. Pulsed Laser Deposition of AlMgB14 Thin Films. Master’s Thesis, Iowa State University, Ames, IA, USA, 2008. [Google Scholar]

- Blau, P.J.; Jun Qu, J.; Higdon, C. Nanocoatings for High-Efficiency Industrial and Tooling Systems Eaton Corporation. 2010. Available online: www.osti.gov/scitech/servlets/purl/1005178 (accessed on 25 October 2023).

- Blau, P.J.; Jun Qu, J.; Higdon, C. ULTRACOATINGS—Enabling Energy and Power Solutions in High Contact Stress Environments through Next Generation Nanocoatings Eaton Corporation. 2011. Available online: www.osti.gov/scitech/servlets/purl/1027860 (accessed on 25 October 2023).

- Grishin, A.M.; Khartsev, S.I.; Böhlmark, J.; Ahlgren, M. 2014 Ultra-hard AlMgB14 coatings fabricated by RF magnetron sputtering from a stoichiometric target. JETP Lett. 2014, 100, 680–687. [Google Scholar]

- Grishin, A.M. Abrasion resistant low friction and ultra-hard magnetron sputtered AlMgB14 coatings. Mater. Res. Express 2016, 3, 046402. [Google Scholar] [CrossRef]

- Grishin, A.M.; Putrolaynen, V.V.; Yuzvyuk, M.H. Ultra-hard amorphous AlMgB14 films RF sputtered onto curved substrates. Mater. Res. Express 2017, 4, 036406. [Google Scholar] [CrossRef]

- Noroozi, M.; Petruhins, A.; Greczynski, G.; Rosen, J.; Eklund, P. Structural and mechanical properties of amorphous AlMgB14 thin films deposited by DC magnetron sputtering on Si, Al2O3 and MgO substrates. Appl. Phys. A 2020, 126, 133. [Google Scholar] [CrossRef]

- Tkachev, D.; Zhukov, I.; Nikitin, P.; Sachkov, V.; Vorozhtsov, A. Structure and frictional properties of ultrahard AlMgB14 thin coatings. Nanomaterials 2023, 13, 1589. [Google Scholar] [CrossRef]

- Song, X.G.; Lei, Y.; Fu, W.; Luo, Z.K.; Li, H.L.; Long, W.M.; Hu, S.P. Brazing of super-hard AlMgB14–TiB2 ceramic to 304 stainless steel with AgCuTi filler alloy. Vacuum 2022, 197, 110810. [Google Scholar] [CrossRef]

- Bin Abdullah, M.S.; Kim, D.; Kwon, P.; Kim, T.-G. Effect of cutting edge geometry change due to tool wear on hole quality in drilling of carbon fiber reinforced plastics using advanced ceramic coated tools. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 302–317. [Google Scholar] [CrossRef]

- Duff, R.R.; Parker, J.S.; Ju, Y.; Wang, X. Razor Blades with Aluminum Magnesium Boride (AlMgB14)-Based Coatings. U.S. Patent 11,691,308 B2, 4 July 2023. [Google Scholar]

- Sears, J.W.; Ghanime, G.H.; Fisher, K.L. Bearing Having Components Fabricated from a AlMgB14 Containing Ceramic Matrix Composite. Patent CA 2930555 C, 5 April 2022. [Google Scholar]

- Hernandez-Renjifo, E.; Christian Ortíz, C.; Caicedo, J.C.; Rodríguez, L.A.; Magén, C. Tribomechanical analysis and machining development for TiSiCN material deposited on industrial steel. Int. J. Adv. Manuf. Technol. 2023, 128, 5437–5461. [Google Scholar] [CrossRef]

- Feng, L.; Hu, J.; Yan, S.; He, Z.; Shi, J.; Li, J. Effect of high-speed steel surface nitriding treatment on adhesion and wear resistance properties of nitrogen-doped diamond-like carbon coatings. Diam. Relat. Mater. 2023, 136, 110006. [Google Scholar] [CrossRef]

- W6Mo5Cr4V2 High Speed Steel. Available online: https://www.wixsteel.com/products/alloy-steel-bar/high-speed-steel-bar/w6mo5cr4v2 (accessed on 25 October 2023).

- Grishin, A.M. Hardness, Young’s modulus and elastic recovery in magnetron sputtered amorphous AlMgB14 films. Crystals 2020, 10, 823. [Google Scholar] [CrossRef]

- Wilke, M.; Teichert, G.; Gemma, R.; Pundt, A.; Kirchheim, R.; Romanus, H.; Schaaf, P. Glow discharge optical emission spectroscopy for accurate and well resolved analysis of coatings and thin films. Thin Solid Films 2011, 520, 1660–1667. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Musil, J.; Jílek, R.; Čerstvý, R. Flexible Ti-Ni-N thin films prepared by magnetron sputtering. J. Mater. Sci. Eng. 2014, 4, 27–33. [Google Scholar]

- Musil, J. Hard nanocomposite coatings: Thermal stability, oxidation resistance and toughness. Surf. Coat. Technol. 2012, 207, 50–65. [Google Scholar] [CrossRef]

- Musil, J.; Kunc, F.; Zeman, H.; Polakova, H. Relationships between hardness, Young’s modulus and elastic recovery in hard nanocomposite coatings. Surf. Coat. Technol. 2002, 154, 304–313. [Google Scholar] [CrossRef]

- Macknojia, A.Z.; Ayyagari, A.; Shevchenko, E.; Berman, D. MXene/graphene oxide nanocomposites for friction and wear reduction of rough steel surfaces. Sci. Rep. 2023, 13, 11057. [Google Scholar] [CrossRef] [PubMed]

- Laugier, M.T. An energy approach to the adhesion of coatings using the scratch test. Thin Solid Films 1984, 117, 243–249. [Google Scholar] [CrossRef]

- Park, H.-S.; Kwon, D. An energy approach to quantification of adhesion strength from critical loads in scratch tests. Thin Solid Films 1997, 307, 156–162. [Google Scholar] [CrossRef]

- Hamilton, G.M.; Goodman, L.E. The stress field created by a circular sliding contact. J. Appl. Mech. 1966, 33, 371–376. [Google Scholar] [CrossRef]

- Hamilton, G.M. Explicit equations for the stresses beneath a sliding spherical contact. Proc. Inst. Mech. Eng. C 1983, 197, 53–59. [Google Scholar] [CrossRef]

- Hamilton, G.M. Correction. Proc. Inst. Mech. Eng. C 1983, 197, 282. [Google Scholar] [CrossRef][Green Version]

- Alfredsson, B.; Cadario, A. Correction of the σx stress equation. Proc. Inst. Mech. Eng. C 1983, 217, 281. [Google Scholar]

- Hertz, H. Über die Berührung Fester Elastischer Körper Gesammelte Werke; Lenard, P., Ed.; JA Barth: Leipzig, Germany, 1895; pp. 155–173. [Google Scholar]

- Hertz, H. Über die Berührung Fester Elastischer Körper and über Die Härte Gesammelte Werke; Lenard, P., Ed.; JA Barth: Leipzig, Germany, 1895; pp. 174–196. [Google Scholar]

| Characteristics | BAM/WC-Co | WC-Co | ||

|---|---|---|---|---|

| Loading force L (mN) | 15 | 30 | 15 | 30 |

| Maximum contact depth h (μm) | 0.22 | 0.33 | 0.25 | 0.41 |

| Hardness H (GPa) | 23 ± 4 | 22 ± 4 | 15 ± 3 | 12 ± 3 |

| Elastic modulus E (GPa) | 320 ± 50 | 330 ± 60 | 600 ± 60 | 530 ± 80 |

| Effective Young’s modulus E* (GPa) | 340 ± 60 | 360 ± 70 | 620 ± 70 | 550 ± 90 |

| Elastic recovery ratio Re (%) | 59 ± 5 | 53 ± 3 | 24 ± 6 | 26 ± 3 |

| Elastic strain index H/E* | 0.072 | 0.067 | 0.025 | 0.023 |

| Resistance to plastic deformation ratio H3/E*2 (MPa) | 119 | 98 | 9 | 6 |

| Characteristics | BAM/AlTiN/WC-Co | AlTiN/WC-Co | ||

|---|---|---|---|---|

| Loading force L (mN) | 15 | 30 | 15 | 30 |

| Maximum contact depth h (μm) | 0.21 | 0.32 | 0.25 | 0.40 |

| Hardness H (GPa) | 23 ± 3 | 21 ± 3 | 14 ± 3 | 14 ± 3 |

| Elastic modulus E (GPa) | 370 ± 60 | 380 ± 60 | 310 ± 80 | 300 ± 80 |

| Effective Young’s modulus E* (GPa) | 390 ± 60 | 400 ± 70 | 340 ± 80 | 320 ± 80 |

| Elastic recovery ratio Re (%) | 55 ± 5 | 52 ± 6 | 41 ± 5 | 40 ± 3 |

| Elastic strain index H/E* | 0.062 | 0.055 | 0.045 | 0.047 |

| Resistance to plastic deformation ratio H3/E*2 (MPa) | 89 | 64 | 29 | 30 |

| Sample | Microhardness HV0.2 | |

|---|---|---|

| (kgf/mm2) | (GPa) | |

| Uncoated WC-Co | 1531.74 | 15.02 |

| BAM-coated WC-Co | 3496.50 | 34.29 |

| Uncoated AlTiN/WC-Co | 2515.24 | 24.67 |

| BAM-coated AlTiN/WC-Co | 4589.24 | 45.01 |

| Characteristics | BAM/R6M5 | R6M5 | ||

|---|---|---|---|---|

| Loading force L (mN) | 15 | 30 | 15 | 30 |

| Maximum contact depth h (μm) | 0.17 | 0.27 | 0.28 | 0.44 |

| Hardness H (GPa) | 37 ± 3 | 40 ± 3 | 12.9 ± 0.7 | 12.3 ± 1.0 |

| Elastic modulus E (GPa) | 302 ± 17 | 305 ± 17 | 184 ± 12 | 170 ± 17 |

| Effective Young’s modulus E* (GPa) | 322 ± 18 | 325 ± 18 | 199 ± 13 | 184 ± 18 |

| Elastic recovery ratio Re (%) | 75 ± 5 | 73 ± 4 | 38.2 ± 2.5 | 37.3 ± 1.9 |

| Elastic strain index H/E* | 0.123 | 0.131 | 0.070 | 0.072 |

| Resistance to plastic deformation ratio H3/E*2 (MPa) | 555 | 688 | 63 | 64 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Grishin, A.M.; Putrolaynen, V.V. Hard and Highly Adhesive AlMgB14 Coatings RF Sputtered on Tungsten Carbide and High-Speed Steel. Materials 2023, 16, 6930. https://doi.org/10.3390/ma16216930

Grishin AM, Putrolaynen VV. Hard and Highly Adhesive AlMgB14 Coatings RF Sputtered on Tungsten Carbide and High-Speed Steel. Materials. 2023; 16(21):6930. https://doi.org/10.3390/ma16216930

Chicago/Turabian StyleGrishin, Alexander M., and Vadim V. Putrolaynen. 2023. "Hard and Highly Adhesive AlMgB14 Coatings RF Sputtered on Tungsten Carbide and High-Speed Steel" Materials 16, no. 21: 6930. https://doi.org/10.3390/ma16216930

APA StyleGrishin, A. M., & Putrolaynen, V. V. (2023). Hard and Highly Adhesive AlMgB14 Coatings RF Sputtered on Tungsten Carbide and High-Speed Steel. Materials, 16(21), 6930. https://doi.org/10.3390/ma16216930