Annual Transmittance Behavior of Light-Transmitting Concrete with Optical Fiber Bundles

Abstract

:1. Introduction

Research Significance

2. Experimental Methodology

2.1. Materials and Properties

2.2. Optical Fibers

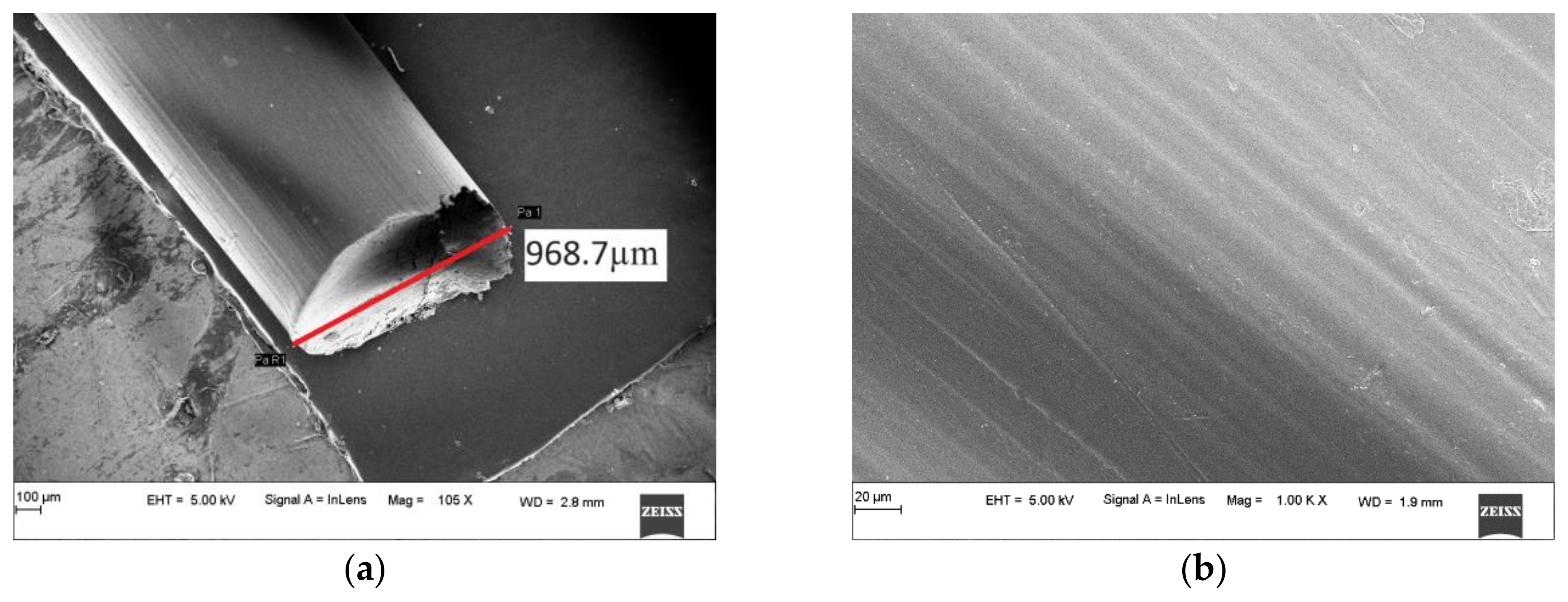

SEM Result Analysis

2.3. Mix Design and Designation

2.4. Mold Preparation, Casting and Specimen Preparation

2.5. Optical Properties under Natural Light

2.6. Statistical Analysis

3. Results and Discussions

3.1. Depending on the Time of Day

3.2. Monthly Variation

3.3. Seasonal Variation

3.4. Applicability of Light-Transmitting Concrete

3.5. Dependence of Illumination on the Irradiance of Sunlight

4. Conclusions

- The correlation between the area of fibers available for transmission and transmittance is evident. As the area of fibers increases, the transmittance also increases. This relationship is independent of the type or nature of the source of illumination. This is further proven when the area and number of fibers are studied, where variants of 1 mm diameter show transmittance up to 85.14% higher than 0.5 mm for the same spacing, just as the variants with a larger number of fibers per bundle exhibited transmittance in the range of 52.33–101.48% for the same spacing.

- The angle of inclination of the sun has an insignificant impact as the scattered light aids in providing enough intensity of light in the directions within the acceptance cone of the fibers, as the acceptance cone of the fibers is as large as 61°.

- Transmittance is highest in the months of April and May, with peak illumination being 360 lux and 372 lux, respectively. The sparse clouds and bright sun cause increased light to be available for transmittance, hence increased transmission occurs.

- The loss of illumination during monsoon is high, and, for most variants, the illuminance is below 300 lux, which indicates the need for artificial illumination during these periods of low light. The transmission ranges for the month of July range between 57 lux and 176 lux, where all the variants have significantly low transmittance in comparison with the other months.

- Most mixes have luminance in the 200–300 lux range, making them suitable for most commercial, public and industrial applications for most months during the year.

- In the present study, considering all the testing parameters and variables, the sample consisting of seven bundled 1 mm fibers with 12 mm spacing is found to have the best performance in light transmission.

5. Patent

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Roy, S. Mechanical Properties of Concrete Using Optical and Glass Fibre. IOSR J. Mech. Civ. Eng. 2018, 15, 56–65. [Google Scholar]

- Palanisamy, C.; Krishnaswami, N.; Velusamy, S.K.; Krishnamurthy, H.; Velmurugan, H.K.; Udhayakumar, H. Transparent concrete by using optical fibre. Mater. Today Proc. 2022, 65, 1774–1778. [Google Scholar] [CrossRef]

- Nikhil, K.; Farook, U.; Ahmed, S.; Juraige, M.K.; Saleem, R.; Omar, S. Experimental Analysis of Translucent Concrete by Using Optical Fibers. SSRG Int. J. Civ. Eng. 2016, 3, 69–74. [Google Scholar]

- Government of India. Central Statistics Office Ministry of Statistics and Programme Implementation. Energy Statistics 2017. 2017. Available online: www.mospi.gov.in2017 (accessed on 10 March 2023).

- Slusky, D.J.G.; Zeckhauser, R.J. Sunlight and Protection Against Influenza. Econ. Hum. Biol. 2021, 40, 100942. [Google Scholar] [CrossRef]

- Wirz-Justice, A.; Skene, D.J.; Münch, M. The relevance of daylight for humans. Biochem. Pharmacol. 2021, 191, 114304. [Google Scholar] [CrossRef]

- Bauer, M.; Glenn, T.; Alda, M.; Andreassen, O.A.; Angelopoulos, E.; Ardau, R.; Baethge, C.; Bauer, R.; Bellivier, F.; Belmaker, R.H.; et al. Relationship between sunlight and the age of onset of bipolar disorder: An international multisite study. J. Affect. Disord. 2014, 167, 104–111. [Google Scholar] [CrossRef] [PubMed]

- Waldie, K.E.; Poulton, R.; Kirk, I.J.; Silva, P.A. The effects of pre- and post-natal sunlight exposure on human growth: Evidence from the Southern Hemisphere. Early Hum. Dev. 2000, 60, 35–42. [Google Scholar] [CrossRef] [PubMed]

- Morales-Bravo, J.; Navarrete-Hernandez, P. Enlightening wellbeing in the home: The impact of natural light design on perceived happiness and sadness in residential spaces. Build. Environ. 2022, 223, 109317. [Google Scholar] [CrossRef]

- Chiew, S.M.; Ibrahim, I.S.; Ariffin, M.A.M.; Lee, H.S.; Singh, J.K. Development and properties of light-transmitting concrete (LTC)—A review. J. Clean. Prod. 2021, 284, 124780. [Google Scholar] [CrossRef]

- Chiew, S.M.; Ibrahim, I.S.; Ariffin, M.A.M.; Lee, H.S.; Singh, J.K. Evaluation of light transmittance performance of light-transmitting concrete with optical fibre. Constr. Build. Mater. 2022, 351, 128949. [Google Scholar] [CrossRef]

- Su, X.; Zhang, L.; Liu, Z.; Luo, Y.; Liang, P.; Lian, J. An optical and thermal analysis of translucent concrete considering its dynamic transmittance. J. Clean. Prod. 2022, 364, 132588. [Google Scholar] [CrossRef]

- Souayfane, F.; Biwole, P.H.; Fardoun, F. Thermal behavior of a translucent superinsulated latent heat energy storage wall in summertime. Appl. Energy 2018, 217, 390–408. [Google Scholar] [CrossRef]

- Su, X.; Zhang, L.; Liu, Z.; Luo, Y.; Lian, J.; Liang, P. Daylighting performance simulation and analysis of translucent concrete building envelopes. Renew. Energy 2020, 154, 754–766. [Google Scholar] [CrossRef]

- Chiatti, C.; Rosso, F.; Fabiani, C.; Pisello, A.L. Integrated energy performance of an innovative translucent photoluminescent building envelope for lighting energy storage. Sustain. Cities Soc. 2021, 75, 103234. [Google Scholar] [CrossRef]

- Mainini, A.G.; Poli, T.; Zinzi, M.; Cangiano, S. Spectral light transmission measure and radiance model validation of an innovative transparent concrete panel for façades. Energy Procedia 2012, 30, 1184–1194. [Google Scholar] [CrossRef]

- Ahuja, A.; Mosalam, K.M. Evaluating energy consumption saving from translucent concrete building envelope. Energy Build. 2017, 153, 448–460. [Google Scholar] [CrossRef]

- Spiesz, P.; Rouvas, S.; Brouwers, H.J.H. Utilization of waste glass in translucent and photocatalytic concrete. Constr. Build. Mater. 2016, 128, 436–448. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Cao, Y.; Hu, Q.; Guo, X. Design and evaluation of light-transmitting concrete (LTC) using waste tempered glass: A novel concrete for future photovoltaic road. Constr. Build. Mater. 2021, 280, 122551. [Google Scholar] [CrossRef]

- Arias-Erazo, J.; Villaquirán-Caicedo, M.A.; Goyes, C.E. Ecological light transmiting concrete made from glass waste and acrylic sheets. Constr. Build. Mater. 2021, 304, 124644. [Google Scholar] [CrossRef]

- Abdulmajeed, N.S.; Said, S.H. Compressive characteristics of resin translucent cement mortar (RTCM) used in the external walls to rationalize the energy spent inside the building. Case Stud. Constr. Mater. 2022, 17, e01687. [Google Scholar] [CrossRef]

- Shenoy, A.; Nayak, G.; Tantri, A.; Shetty, K.K. Thermal transmission characteristics of plastic optical fibre embedded light transmitting concrete. Mater. Today Proc. 2022, 65, 1759–1773. [Google Scholar] [CrossRef]

- IS 8112: 2013; Indian Standard 43 Grade Ordinary Portland Cement-Specification (First Revision). Bureau of Indian Standards: New Delhi, India, 1997.

- IS: 383-1970; Indian Standard Specification for Coarse and Fine Aggregates From Natural Sources For Concrete (Second Revision) (Reaffirmed 1997). Bureau of Indian Standards: New Delhi, India, 1997.

- IS 3812 (Part 1): 2013; Indian Standard Specification for Pulverized Fuel Ash, Part 1: For Use as Pozzolana in Cement, Cement Mortar and Concrete. Bureau of Indian Standards: New Delhi, India, 2013.

- Tantri, A.; Nayak, G.; Shenoy, A.; Shetty, K.K.; Achar, J.; Kamath, M. Implementation assessment of calcined and uncalcined cashew nut-shell ash with total recycled concrete aggregate in self-compacting concrete employing Bailey grading technique. Innov. Infrastruct. Solut. 2022, 7, 305. [Google Scholar] [CrossRef]

- Tantri, A.; Nayak, G.; Shenoy, A.; Shetty, K.K. Development of self-compacting concrete using Bailey aggregate grading technique in comparison with Indian standard code of practice. J. Eng. Des. Technol. 2022, 20, 1664–1697. [Google Scholar] [CrossRef]

- IS 10262: 2019; Indian Standard Concrete Mix Proportioning-Guidelines. Bureau of Indian Standards: New Delhi, India, 2019. Available online: www.standardsbis.in (accessed on 15 February 2023).

- The European Precast Concrete Organization (BIBM); The European Cement Association (CEMBUREAU); The European Ready-mix Concrete Organization (ERMCO); The European Federation of Concrete Admixture Association (EFCA); The European Federation of Specialist Construction Chemicals and Concrete Systems (EFNARC). The European Guidelines for Self-Compacting Concrete- Specification, Production and Use. 2005. Available online: www.efnarc.org (accessed on 12 April 2023).

- Navabi, D.; Javidruzi, M.; Hafezi, M.R.; Mosavi, A. The high-performance light transmitting concrete and experimental analysis of using polymethylmethacrylate optical fibers in it. J. Build. Eng. 2021, 38, 102076. [Google Scholar] [CrossRef]

- Nam, H.P.; Hai, N.M.; Van Huong, N.; Quang, P.D.; Tuan, N.D.; Binh, N.T.; Vy, T.Q. Experimental study on 80 MPa grade light transmitting concrete with high content of optical fibers and eco-friendly raw materials. Case Stud. Constr. Mater. 2023, 18, e01810. [Google Scholar] [CrossRef]

- Henriques, T.D.S.; Dal Molin, D.C.; Masuero, Â.B. Study of the influence of sorted polymeric optical fibers (POFs) in samples of a light-transmitting cement-based material (LTCM). Constr. Build. Mater. 2018, 161, 305–315. [Google Scholar] [CrossRef]

- IS 456: 2000; Indian Standard Plain and Reinforced Concrete-Code of Practice. Bureau of Indian Standards: New Delhi, India, 2000.

- Kankriya, M. Translucent Concrete by Using Optical Fibers and Glass Rods. Int. J. Sci. Res. Publ. 2016, 6, 625. [Google Scholar]

- Tahwia, A.M.; Abdel-Raheem, A.; Abdel-Aziz, N.; Amin, M. Light transmittance performance of sustainable translucent self-compacting concrete. J. Build. Eng. 2021, 38, 102178. [Google Scholar] [CrossRef]

- Su, X.; Zhang, L.; Luo, Y.; Liu, Z. An energy analysis of translucent concrete embedded with inclined optical fibers. Energy Build. 2022, 273, 112409. [Google Scholar] [CrossRef]

- Rosso, F.; Pisello, A.L.; Cotana, F.; Ferrero, M. Cool, Translucent Natural Envelope: Thermal-Optics Characteristics Experimental Assessment and Thermal-Energy and Day Lighting Analysis. Energy Procedia 2017, 111, 578–587. [Google Scholar] [CrossRef]

- Rahai, A.; Dolati, A.; Kamel, M.E.; Babaizadeh, H. Studying the effect of various parameters on mechanical properties of lightweight aggregate concrete using MANOVA. Mater. Struct. Mater. Constr. 2015, 48, 2353–2365. [Google Scholar] [CrossRef]

- IS 3646-1 (1992); Code of Practice for Interior Illumination, Part 1: General Requirements and Recommendations for Working Interiors. Bureau of Indian Standards: New Delhi, India, 1992.

| Fiber Diameter | 0.5 mm | 1 mm | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Fiber Spacing | 12 mm | 15 mm | 12 mm | 15 mm | |||||

| Number of fibers | 1 | M11 |  | M12 |  | M13 |  | M14 |  |

| 2 | M21 |  | M22 |  | M23 |  | M24 |  | |

| 3 | M31 |  | M32 |  | M33 |  | M34 |  | |

| 4 | M41 |  | M42 |  | M43 |  | M44 |  | |

| 5 | M51 |  | M52 |  | M53 |  | M54 |  | |

| 6 | M61 |  | M62 |  | M63 |  | M64 |  | |

| 7 | M71 |  | M72 |  | M73 |  | M74 |  | |

| Ordinary Portland Cement | Fly Ash | Coarse Aggregates | Fine Aggregates | Superplasticizer | Water |

|---|---|---|---|---|---|

| 420 | 180 | 780 | 700 | 2.514 | 180 |

| Reference Factor | Average Annual Illumination | |||||

|---|---|---|---|---|---|---|

| Source | Degree of Freedom | Sequnetial Sums of Squares | Adjusted Sums of Squares | Adjusted Mean Square | F-Statistic Adj. MS/P | Probability |

| Time | 7 | 18,378.6 | 18,378.6 | 2625.5 | 5059.66 | 0.000 |

| Diameter | 1 | 403,755.2 | 403,755.2 | 403,755.2 | 778,083.36 | 0.001 |

| Spacing | 1 | 15,449.2 | 15,449.2 | 15,449.2 | 29,772.47 | 0.000 |

| No. of fibers | 6 | 270,594.6 | 270,594.6 | 45,099.1 | 86,911.22 | 0.002 |

| Time × Diameter | 7 | 808.3 | 808.3 | 115.5 | 222.53 | 0.000 |

| Time × Spacing | 7 | 27.2 | 27.2 | 3.9 | 7.5 | 0.000 |

| Time × No. of fibers | 42 | 573.9 | 573.9 | 13.7 | 26.33 | 0.000 |

| Diameter × Spacing | 1 | 485.7 | 485.7 | 485.7 | 935.98 | 0.003 |

| Diameter × No. of fibers | 6 | 20,932.8 | 20,932.8 | 3488.8 | 6723.34 | 0.000 |

| Spacing × No. of fibers | 6 | 2847.8 | 2847.84 | 74.68 | 914.68 | 0.001 |

| Diameter × Spacing × No. of fibers | 6 | 375.9 | 375.9 | 62.6 | 120.73 | 0.000 |

| Error | 133 | 69.0 | 69.0 | 0.5 | ||

| Total | 233 | 734,298.3 | ||||

| Application | Illumination (lux) | Application | Illumination (lux) | Application | Illumination (lux) |

|---|---|---|---|---|---|

| Commerce | |||||

| Offices | 300 | Filing rooms | 200 | Bank public areas | 200 |

| Deep plan general offices | 500 | Drawing boards | 500 | Computer and data preparation | 300 |

| Computer workstations | 300 | Print rooms | 200 | Bank public areas | 200 |

| Conference rooms | 300 | Bank counters | 300 | ||

| Supermarkets, hypermarkets | |||||

| General, checkout, showrooms for large objects | 300 | Shopping precincts, arcades | 100 | ||

| Public assembly structures | |||||

| Village halls, worship halls | 200 | Projection rooms | 100 | Dressing rooms | 200 |

| Cinema hall lobbies | 150 | Church bodies | 100 | Vestries | 100 |

| Ticket counters | 200 | Altar, communion table, chancel | 100 | Organ room | 200 |

| Auditorium | 50 | ||||

| Hotels | |||||

| Entrance halls | 50 | Cloak rooms | 50 | Bedrooms | 30 |

| Reception, cashier | 200 | Dining rooms, restaurnats, bars etc | 50 | Bathrooms | 50 |

| Education | |||||

| General | 200 | Laboratories | 300 | Needlework Rooms | 300 |

| Lecture and teaching spaces | 200 | Libraries | 200 | Sports Halls | 200 |

| Seminar Rooms | 300 | Music Rooms | 200 | Workshops | 200 |

| Art Rooms | 300 | ||||

| Transport facilities | |||||

| Lounges and waiting areas | 150 | Timetable | 150 | Concourse | 150 |

| Baggage counter | 150 | Covered platforms | 30 | Loading areas | 100 |

| Baggage handling | 50 | Open platforms | 20 | Customs, immigration | 300 |

| General building areas | |||||

| Entrance halls, lobbies, waiting areas, gatehouses | 150 | Staff changing, locker and cleaners rooms, cloakrooms, lavatories | 50 | Resting/waiting areas | 100 |

| Lifts, corridors, passageways, stairs | 50 | Staff restrooms | 100 | Stores | 100 |

| Escalators, travellators | 100 | Canteens, cafeteria, dining and mess halls | 150 | Cooking | 300 |

| Medical aid treatment rooms | 300 | Servery and prep | 200 | Stores and cellars | 150 |

| Car parks-covered | |||||

| Floors | 50 | Control booth | 150 | Entrance and exit | 50 |

| Ramps and corners | 30 | Outdoor parks | 50 | ||

| RF | Average Annual Illumination | ||||

|---|---|---|---|---|---|

| Source | Degree of Freedom | Adjusted Sums of Squares | Adjusted Mean Square | F-Statistic Adj. MS/P | Probability |

| Irradiance (Wh/m2) | 30 | 559,702 | 18,657 | 636.75 | 0.000 |

| No. of Fibers | 6 | 1,094,366 | 182,394 | 6225.09 | 0.000 |

| Spacing | 1 | 62,684 | 62,684 | 2139.40 | 0.000 |

| Diameter | 1 | 1,633,537 | 1,633,537 | 55,752.42 | 0.000 |

| Irradiance × No. of fibers | 180 | 13,296 | 74 | 2.52 | 0.003 |

| Irradiance × Spacing | 30 | 860 | 29 | 0.98 | 0.525 * |

| Irradiance × Diameter | 30 | 19,983 | 666 | 22.73 | 0.000 |

| No. of fibers × Spacing | 6 | 11,431 | 1905 | 65.03 | 0.000 |

| No. of fibers × Diameter | 6 | 84,364 | 14,061 | 479.89 | 0.000 |

| Spacing of fibers × Diameter | 1 | 2011 | 2011 | 68.63 | 0.000 |

| Irradiance × No. of fibers × Spacing of fibers | 180 | 215 | 1 | 0.04 | 1.000 * |

| Irradiance × No. of fibers × Diameter | 180 | 1336 | 7 | 0.25 | 1.000 * |

| Irradiance × Spacing × Diameter | 30 | 36 | 1 | 8.29 | 1.000 * |

| No. of fibers × Spacing × Diameter | 6 | 1458 | 243 | 8.29 | 0.000 |

| Irradiance × No. of fibers × Spacing × Diameter | 180 | 317 | 2 | 0.06 | 1.000 * |

| Error | 28 | 820 | 29 | ||

| Total | 895 | 3,534,472 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Shenoy, A.; Nayak, G.; Tantri, A.; Shetty, K.K.; Shendkar, M.R. Annual Transmittance Behavior of Light-Transmitting Concrete with Optical Fiber Bundles. Materials 2023, 16, 7037. https://doi.org/10.3390/ma16217037

Shenoy A, Nayak G, Tantri A, Shetty KK, Shendkar MR. Annual Transmittance Behavior of Light-Transmitting Concrete with Optical Fiber Bundles. Materials. 2023; 16(21):7037. https://doi.org/10.3390/ma16217037

Chicago/Turabian StyleShenoy, Adithya, Gopinatha Nayak, Adithya Tantri, Kiran Kumar Shetty, and Mangeshkumar R. Shendkar. 2023. "Annual Transmittance Behavior of Light-Transmitting Concrete with Optical Fiber Bundles" Materials 16, no. 21: 7037. https://doi.org/10.3390/ma16217037

APA StyleShenoy, A., Nayak, G., Tantri, A., Shetty, K. K., & Shendkar, M. R. (2023). Annual Transmittance Behavior of Light-Transmitting Concrete with Optical Fiber Bundles. Materials, 16(21), 7037. https://doi.org/10.3390/ma16217037