Microwaved-Assisted Synthesis of Starch-Based Biopolymer Membranes for Novel Green Electrochemical Energy Storage Devices

Abstract

:1. Introduction

2. Materials and Methods

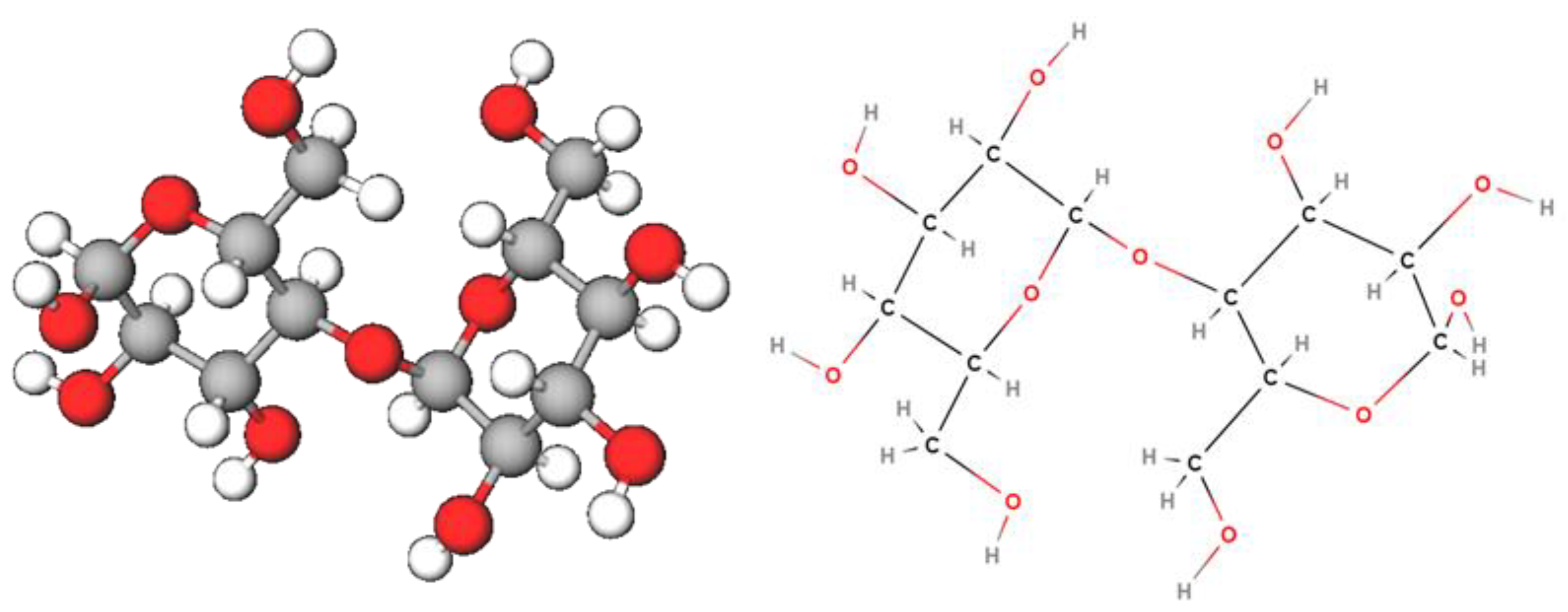

2.1. Starch-Based Membrane Preparation Procedure

2.2. Assembling the Swagelok Cells

2.3. Assays for Electrochemical Testing

2.4. Raman and Infrared Spectroscopy

2.5. LF NMR Relaxometry

3. Results and Discussion

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Forysenkova, A.A.; Fadeeva, I.V.; Deyneko, D.V.; Gosteva, A.N.; Mamin, G.V.; Shurtakova, D.V.; Davydova, G.A.; Yankova, V.G.; Antoniac, I.V.; Rau, J.V. Polyvinylpyrrolidone—Alginate—Carbonate Hydroxyapatite Porous Composites for Dental Applications. Materials 2023, 16, 4478. [Google Scholar] [CrossRef] [PubMed]

- Katrilaka, C.; Karipidou, N.; Petrou, N.; Manglaris, C.; Katrilakas, G.; Tzavellas, A.N.; Pitou, M.; Tsiridis, E.E.; Choli-Papadopoulou, T.; Aggeli, A. Freeze-Drying Process for the Fabrication of Collagen-Based Sponges as Medical Devices in Biomedical Engineering. Materials 2023, 16, 4425. [Google Scholar] [CrossRef] [PubMed]

- Stefanowska, K.; Woźniak, M.; Dobrucka, R.; Ratajczak, I. Chitosan with Natural Additives as a Potential Food Packaging. Materials 2023, 16, 1579. [Google Scholar] [CrossRef]

- Madej-Kiełbik, L.; Gzyra-Jagieła, K.; Jóźwik-Pruska, J.; Dziuba, R.; Bednarowicz, A. Biopolymer Composites with Sensors for Environmental and Medical Applications. Materials 2022, 15, 7493. [Google Scholar] [CrossRef]

- Hernández, V.; Ibarra, D.; Triana, J.F.; Martínez-Soto, B.; Faúndez, M.; Vasco, D.A.; Gordillo, L.; Herrera, F.; García-Herrera, C.; Garmulewicz, A. Agar Biopolymer Films for Biodegradable Packaging: A Reference Dataset for Exploring the Limits of Mechanical Performance. Materials 2022, 15, 3954. [Google Scholar] [CrossRef]

- Su, Q.; Wang, H.; Wang, Y.; Liang, S.; Pang, S.; Zhao, X.; Sun, X.; Shi, X.; Zhao, J. Flame-Retardant Foamed Material Based on Modified Corn Straw Using Two Nitrogenous Layers. Materials 2023, 16, 952. [Google Scholar] [CrossRef] [PubMed]

- Santos, D.; Baptista, R.M.F.; Handa, A.; Almeida, B.; Rodrigues, P.V.; Torres, A.R.; Machado, A.; Belsley, M.; de Matos Gomes, E. Bioinspired Cyclic Dipeptide Functionalized Nanofibers for Thermal Sensing and Energy Harvesting. Materials 2023, 16, 2477. [Google Scholar] [CrossRef]

- Teng, C.P.; Tan, M.Y.; Toh, J.P.W.; Lim, Q.F.; Wang, X.; Ponsford, D.; Lin, E.M.J.; Thitsartarn, W.; Tee, S.Y. Advances in Cellulose-Based Composites for Energy Applications. Materials 2023, 16, 3856. [Google Scholar] [CrossRef] [PubMed]

- Jeżowski, P.; Kowalczewski, P.Ł. Isinglass as an Alternative Biopolymer Membrane for Green Electrochemical Devices: Initial Studies of Application in Electric Double-Layer Capacitors and Future Perspectives. Polymers 2023, 15, 3557. [Google Scholar] [CrossRef]

- Kötz, R.; Carlen, M. Principles and applications of electrochemical capacitors. Electrochim. Acta 2000, 45, 2483–2498. [Google Scholar] [CrossRef]

- Simon, P.; Gogotsi, Y. Materials for electrochemical capacitors. Nat. Mater. 2008, 7, 845–854. [Google Scholar] [CrossRef]

- Miller, J.R.; Burke, A.F. Electrochemical capacitors: Challenges and opportunities for real-world applications. Electrochem. Soc. Interface 2008, 17, 53–57. [Google Scholar] [CrossRef]

- Miller, J.R. Engineering electrochemical capacitor applications. J. Power Sources 2016, 326, 726–735. [Google Scholar] [CrossRef]

- Fic, K.; Platek, A.; Piwek, J.; Frackowiak, E. Sustainable materials for electrochemical capacitors. Mater. Today 2018, 21, 437–454. [Google Scholar] [CrossRef]

- Jeżowski, P.; Crosnier, O.; Deunf, E.; Poizot, P.; Béguin, F.; Brousse, T. Safe and recyclable lithium-ion capacitors using sacrificial organic lithium salt. Nat. Mater. 2018, 17, 167–173. [Google Scholar] [CrossRef]

- Jeżowski, P.; Fic, K.; Crosnier, O.; Brousse, T.; Béguin, F. Lithium rhenium(VII) oxide as a novel material for graphite pre-lithiation in high performance lithium-ion capacitors. J. Mater. Chem. A 2016, 4, 12609–12615. [Google Scholar] [CrossRef]

- Jeżowski, P.; Chojnacka, A.; Pan, X.; Béguin, F. Sodium amide as a “zero dead mass” sacrificial material for the pre-sodiation of the negative electrode in sodium-ion capacitors. Electrochim. Acta 2021, 375, 137980. [Google Scholar] [CrossRef]

- Chojnacka, A.; Pan, X.; Jeżowski, P.; Béguin, F. High performance hybrid sodium-ion capacitor with tin phosphide used as battery-type negative electrode. Energy Storage Mater. 2019, 22, 200–206. [Google Scholar] [CrossRef]

- Jeżowski, P.; Crosnier, O.; Brousse, T. Sodium borohydride (NaBH4) as a high-capacity material for next-generation sodium-ion capacitors. Open Chem. 2021, 19, 432–441. [Google Scholar] [CrossRef]

- Kasprzak, D.; Stępniak, I.; Galiński, M. Electrodes and hydrogel electrolytes based on cellulose: Fabrication and characterization as EDLC components. J. Solid State Electrochem. 2018, 22, 3035–3047. [Google Scholar] [CrossRef]

- Nunes, W.G.; Freitas, B.G.A.; Beraldo, R.M.; Filho, R.M.; Da Silva, L.M.; Zanin, H. A rational experimental approach to identify correctly the working voltage window of aqueous-based supercapacitors. Sci. Rep. 2020, 10, 19195. [Google Scholar] [CrossRef]

- Zang, X.; Shen, C.; Sanghadasa, M.; Lin, L. High-Voltage Supercapacitors Based on Aqueous Electrolytes. ChemElectroChem 2019, 6, 976–988. [Google Scholar] [CrossRef]

- Roberts, A.J.; Danil de Namor, A.F.; Slade, R.C.T. Low temperature water based electrolytes for MnO2/carbon supercapacitors. Phys. Chem. Chem. Phys. 2013, 15, 3518. [Google Scholar] [CrossRef] [PubMed]

- Rajasekaran, S.J.; Grace, A.N.; Jacob, G.; Alodhayb, A.; Pandiaraj, S.; Raghavan, V. Investigation of Different Aqueous Electrolytes for Biomass-Derived Activated Carbon-Based Supercapacitors. Catalysts 2023, 13, 286. [Google Scholar] [CrossRef]

- Ishikawa, M.; Ihara, M.; Morita, M.; Matsuda, Y. Electric double layer capacitors with new gel electrolytes. Electrochim. Acta 1995, 40, 2217–2222. [Google Scholar] [CrossRef]

- Morita, M.; Ishikawa, M.; Matsuda, Y. Ionic conductivities of polymeric solid electrolyte films containing rare earth ions. J. Alloys Compd. 1997, 250, 524–527. [Google Scholar] [CrossRef]

- Le Bideau, J.; Viau, L.; Vioux, A. Ionogels, ionic liquid based hybrid materials. Chem. Soc. Rev. 2011, 40, 907–925. [Google Scholar] [CrossRef]

- Senthilkumar, S.T.; Selvan, R.K.; Ponpandian, N.; Melo, J.S. Redox additive aqueous polymer gel electrolyte for an electric double layer capacitor. RSC Adv. 2012, 2, 8937–8940. [Google Scholar] [CrossRef]

- Yamagata, M.; Soeda, K.; Ikebe, S.; Yamazaki, S.; Ishikawa, M. Chitosan-based gel electrolyte containing an ionic liquid for high-performance nonaqueous supercapacitors. Electrochim. Acta 2013, 100, 275–280. [Google Scholar] [CrossRef]

- Ye, W.; Wang, H.; Ning, J.; Zhong, Y.; Hu, Y. New types of hybrid electrolytes for supercapacitors. J. Energy Chem. 2021, 57, 219–232. [Google Scholar] [CrossRef]

- Prontera, C.T.; Gallo, N.; Giannuzzi, R.; Pugliese, M.; Primiceri, V.; Mariano, F.; Maggiore, A.; Gigli, G.; Sannino, A.; Salvatore, L.; et al. Collagen Membrane as Water-Based Gel Electrolyte for Electrochromic Devices. Gels 2023, 9, 310. [Google Scholar] [CrossRef]

- Armand, M. Polymers with Ionic Conductivity. Adv. Mater. 1990, 2, 278–286. [Google Scholar] [CrossRef]

- Gadjourova, Z.; Andreev, Y.G.; Tunstall, D.P.; Bruce, P.G. Ionic conductivity in crystalline polymer electrolytes. Nature 2001, 412, 520–523. [Google Scholar] [CrossRef] [PubMed]

- Epps, T.; Bailey, T.; Pham, H.; Bates, F. Phase Behavior of Lithium Perchlorate-Doped Poly(styrene-b-isoprene-b-ethylene oxide) Triblock Copolymers. Chem. Mater. 2002, 14, 1706–1714. [Google Scholar] [CrossRef]

- Lewandowski, A.; Zajder, M.; Frąckowiak1, E.; Béguin, F. Supercapacitor based on activated carbon and polyethylene oxide–KOH–H2O polymer electrolyte. Electrochim. Acta 2001, 46, 2777–2780. [Google Scholar] [CrossRef]

- Yu, H.; Wu, J.; Fan, L.; Xu, K.; Zhong, X.; Lin, Y.; Lin, J. Improvement of the performance for quasi-solid-state supercapacitor by using PVA–KOH–KI polymer gel electrolyte. Electrochim. Acta 2011, 56, 6881–6886. [Google Scholar] [CrossRef]

- Wu, Z.; Parvez, K.; Feng, X.; Müllen, K. Graphene-based in-plane micro-supercapacitors with high power and energy densities. Nat. Commun. 2013, 4, 2487. [Google Scholar] [CrossRef]

- Morita, M.; Qiao, J.-L.; Yoshimoto, N.; Ishikawa, M. Application of proton conducting polymeric electrolytes to electrochemical capacitors. Electrochim. Acta 2004, 50, 837–841. [Google Scholar] [CrossRef]

- Yamagata, M.; Ikebe, S.; Kasai, Y.; Soeda, K.; Ishikawa, M. Dramatic Improvements in Electric Double-Layer Capacitors by Using Polysaccharides. ECS Trans. 2013, 50, 27–36. [Google Scholar] [CrossRef]

- Yamagata, M.; Soeda, K.; Yamazaki, S.; Ishikawa, M. Charge-Discharge Behavior of Electric Double-Layer Capacitor with Alginate/Ionic Liquid Gel Electrolyte. ECS Trans. 2019, 25, 193–200. [Google Scholar] [CrossRef]

- Armelin, E.; Pérez-Madrigal, M.M.; Alemán, C.; Díaz, D.D. Current status and challenges of biohydrogels for applications as supercapacitors and secondary batteries. J. Mater. Chem. A 2016, 4, 8952–8968. [Google Scholar] [CrossRef]

- Nowacki, K.; Galiński, M.; Stępniak, I. Synthesis and characterization of modified chitosan membranes for applications in electrochemical capacitor. Electrochim. Acta 2019, 320, 134632. [Google Scholar] [CrossRef]

- Wysokowski, M.; Nowacki, K.; Jaworski, F.; Niemczak, M.; Bartczak, P.; Sandomierski, M.; Piasecki, A.; Galiński, M.; Jesionowski, T. Ionic liquid-assisted synthesis of chitin–ethylene glycol hydrogels as electrolyte membranes for sustainable electrochemical capacitors. Sci. Rep. 2022, 12, 8861. [Google Scholar] [CrossRef] [PubMed]

- Skunik-Nuckowska, M.; Wisińska, N.H.; Garbacz, P.; Dyjak, S.; Wieczorek, W.; Kulesza, P.J. Polysaccharide-Based Hydrogel Electrolytes Enriched with Poly(Norepinephrine) for Sustainable Aqueous Electrochemical Capacitors. SSRN Electron. J. 2022. [Google Scholar] [CrossRef]

- Aziz, S.B.; Hamsan, M.H.; Nofal, M.M.; San, S.; Abdulwahid, R.T.; Raza Saeed, S.R.; Brza, M.A.; Kadir, M.F.Z.; Mohammed, S.J.; Al-Zangana, S. From Cellulose, Shrimp and Crab Shells to Energy Storage EDLC Cells: The Study of Structural and Electrochemical Properties of Proton Conducting Chitosan-Based Biopolymer Blend Electrolytes. Polymers 2020, 12, 1526. [Google Scholar] [CrossRef]

- Aziz, S.B.; Hadi, J.M.; Dannoun, E.M.A.; Abdulwahid, R.T.; Saeed, S.R.; Shahab Marf, A.; Karim, W.O.; Kadir, M.F.Z. The Study of Plasticized Amorphous Biopolymer Blend Electrolytes Based on Polyvinyl Alcohol (PVA): Chitosan with High Ion Conductivity for Energy Storage Electrical Double-Layer Capacitors (EDLC) Device Application. Polymers 2020, 12, 1938. [Google Scholar] [CrossRef]

- Huang, H.; Zeng, X.; Li, W.; Wang, H.; Wang, Q.; Yang, Y. Reinforced conducting hydrogels prepared from the in situ polymerization of aniline in an aqueous solution of sodium alginate. J. Mater. Chem. A 2014, 2, 16516–16522. [Google Scholar] [CrossRef]

- Pérez-Madrigal, M.M.; Estrany, F.; Armelin, E.; Díaz, D.D.; Alemán, C. Towards sustainable solid-state supercapacitors: Electroactive conducting polymers combined with biohydrogels. J. Mater. Chem. A 2016, 4, 1792–1805. [Google Scholar] [CrossRef]

- Zeng, J.; Wei, L.; Guo, X. Bio-inspired high-performance solid-state supercapacitors with the electrolyte, separator, binder and electrodes entirely from: Kelp. J. Mater. Chem. A 2017, 5, 25282–25292. [Google Scholar] [CrossRef]

- Moon, W.G.; Kim, G.P.; Lee, M.; Song, H.D.; Yi, J. A biodegradable gel electrolyte for use in high-performance flexible supercapacitors. ACS Appl. Mater. Interfaces 2015, 7, 3503–3511. [Google Scholar] [CrossRef]

- Pal, R.K.; Kundu, S.C.; Yadavalli, V.K. Fabrication of Flexible, Fully Organic, Degradable Energy Storage Devices Using Silk Proteins. ACS Appl. Mater. Interfaces 2018, 10, 9620–9628. [Google Scholar] [CrossRef]

- Menzel, J.; Frąckowiak, E.; Fic, K. Agar-based aqueous electrolytes for electrochemical capacitors with reduced self-discharge. Electrochim. Acta 2020, 332, 135435. [Google Scholar] [CrossRef]

- Fic, K.; Płatek, A.; Piwek, J.; Menzel, J.; Ślesiński, A.; Bujewska, P.; Galek, P.; Frąckowiak, E. Revisited insights into charge storage mechanisms in electrochemical capacitors with Li2SO4-based electrolyte. Energy Storage Mater. 2019, 22, 1–14. [Google Scholar] [CrossRef]

- Kim, B.C.; Hong, J.Y.; Wallace, G.G.; Park, H.S. Recent Progress in Flexible Electrochemical Capacitors: Electrode Materials, Device Configuration, and Functions. Adv. Energy Mater. 2015, 5, 1500959. [Google Scholar] [CrossRef]

- Mohamad Yazid, N.S.; Abdullah, N.; Muhammad, N.; Matias-Peralta, H.M. Application of Starch and Starch-Based Products in Food Industry. J. Sci. Technol. 2018, 10, 144–174. [Google Scholar] [CrossRef]

- Raguin, A.; Ebenhöh, O. Design starch: Stochastic modeling of starch granule biogenesis. Biochem. Soc. Trans. 2017, 45, 885–893. [Google Scholar] [CrossRef]

- Parker, R.; Ring, S.G. Aspects of the physical chemistry of starch. J. Cereal Sci. 2001, 34, 1–17. [Google Scholar] [CrossRef]

- Carvalho, A.J.F.; Job, A.E.; Alves, N.; Curvelo, A.A.S.; Gandini, A. Thermoplastic starch/natural rubber blends. Carbohydr. Polym. 2003, 53, 95–99. [Google Scholar] [CrossRef]

- Leja, K.; Lewandowicz, G. Polymer Biodegradation and Biodegradable Polymers—A Review. Polish J. Environ. Stud. 2010, 19, 255–266. [Google Scholar]

- Lewandowicz, J.; Le Thanh-Blicharz, J.; Szwengiel, A. The Effect of Chemical Modification on the Rheological Properties and Structure of Food Grade Modified Starches. Processes 2022, 10, 938. [Google Scholar] [CrossRef]

- Le Thanh-Blicharz, J.; Lewandowicz, J. Functionality of Native Starches in Food Systems: Cluster Analysis Grouping of Rheological Properties in Different Product Matrices. Foods 2020, 9, 1073. [Google Scholar] [CrossRef]

- Jeżowski, P.; Kowalczewski, P.Ł. Starch as a Green Binder for the Formulation of Conducting Glue in Supercapacitors. Polymers 2019, 11, 1648. [Google Scholar] [CrossRef] [PubMed]

- Zhao, C.; Wang, Y.; Zheng, J.; Xu, S.; Rui, P.; Zhao, C. Improved supercapacitor performance of α-starch-derived porous carbon through gelatinization. J. Power Sources 2022, 521, 230942. [Google Scholar] [CrossRef]

- Kasturi, P.R.; Ramasamy, H.; Meyrick, D.; Sung Lee, Y.; Kalai Selvan, R. Preparation of starch-based porous carbon electrode and biopolymer electrolyte for all solid-state electric double layer capacitor. J. Colloid Interface Sci. 2019, 554, 142–156. [Google Scholar] [CrossRef] [PubMed]

- Weingarth, D.; Noh, H.; Foelske-Schmitz, A.; Wokaun, A.; Kötz, R. A reliable determination method of stability limits for electrochemical double layer capacitors. Electrochim. Acta 2013, 103, 119–124. [Google Scholar] [CrossRef]

- Zhao, J.; Burke, A.F. Electrochemical Capacitors: Performance Metrics and Evaluation by Testing and Analysis. Adv. Energy Mater. 2021, 11, 2002192. [Google Scholar] [CrossRef]

- de Almeida, M.R.; de Sá Oliveira, K.; Stephani, R.; Cappa de Oliveira, L.F. Application of FT-Raman Spectroscopy and Chemometric Analysis for Determination of Adulteration in Milk Powder. Anal. Lett. 2012, 45, 2589–2602. [Google Scholar] [CrossRef]

- Sapkal, R.T.; Shinde, S.S.; Rajpure, K.Y.; Bhosale, C.H. Photoelectrocatrocatalytic hydrolysis of starch by using sprayed ZnO thin films. J. Semicond. 2013, 34, 053001. [Google Scholar] [CrossRef]

- Lasia, A. Impedance of porous electrodes. J. Electroanal. Chem. 1995, 397, 27–33. [Google Scholar] [CrossRef]

- Wu, T.-H.; Hsu, C.-T.; Hu, C.-C.; Hardwick, L.J. Important parameters affecting the cell voltage of aqueous electrical double-layer capacitors. J. Power Sources 2013, 242, 289–298. [Google Scholar] [CrossRef]

- Shao, J.-H.; Deng, Y.-M.; Song, L.; Batur, A.; Jia, N.; Liu, D.-Y. Investigation the effects of protein hydration states on the mobility water and fat in meat batters by LF-NMR technique. LWT—Food Sci. Technol. 2016, 66, 1–6. [Google Scholar] [CrossRef]

- Resende, M.T.; Osheter, T.; Linder, C.; Wiesman, Z. Proton Low Field NMR Relaxation Time Domain Sensor for Monitoring of Oxidation Stability of PUFA-Rich Oils and Emulsion Products. Foods 2021, 10, 1385. [Google Scholar] [CrossRef]

- Ezeanaka, M.C.; Nsor-Atindana, J.; Zhang, M. Online Low-field Nuclear Magnetic Resonance (LF-NMR) and Magnetic Resonance Imaging (MRI) for Food Quality Optimization in Food Processing. Food Bioprocess Technol. 2019, 12, 1435–1451. [Google Scholar] [CrossRef]

- Kamal, T.; Cheng, S.; Khan, I.A.; Nawab, K.; Zhang, T.; Song, Y.; Wang, S.; Nadeem, M.; Riaz, M.; Khan, M.A.U.; et al. Potential uses of LF-NMR and MRI in the study of water dynamics and quality measurement of fruits and vegetables. J. Food Process. Preserv. 2019, 43, e14202. [Google Scholar] [CrossRef]

- Brosio, E.; Gianferri, R.R. Low-resolution NMR—An analytical tool in foods characterization and traceability. In Basic NMR in Foods Characterization; Brosio, E., Ed.; Research Signpost: Kerala, India, 2009; pp. 9–37. ISBN 978-81-308-0303-6. [Google Scholar]

- Baranowska, H.M.; Sikora, M.; Krystyjan, M.; Dobosz, A.; Tomasik, P.; Walkowiak, K.; Masewicz, Ł.; Borczak, B. Analysis of the Retrogradation Processes in Potato Starches Blended with Non-Starchy Polysaccharide Hydrocolloids by LF NMR. Food Biophys. 2020, 15, 64–71. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jeżowski, P.; Menzel, J.; Baranowska, H.M.; Kowalczewski, P.Ł. Microwaved-Assisted Synthesis of Starch-Based Biopolymer Membranes for Novel Green Electrochemical Energy Storage Devices. Materials 2023, 16, 7111. https://doi.org/10.3390/ma16227111

Jeżowski P, Menzel J, Baranowska HM, Kowalczewski PŁ. Microwaved-Assisted Synthesis of Starch-Based Biopolymer Membranes for Novel Green Electrochemical Energy Storage Devices. Materials. 2023; 16(22):7111. https://doi.org/10.3390/ma16227111

Chicago/Turabian StyleJeżowski, Paweł, Jakub Menzel, Hanna Maria Baranowska, and Przemysław Łukasz Kowalczewski. 2023. "Microwaved-Assisted Synthesis of Starch-Based Biopolymer Membranes for Novel Green Electrochemical Energy Storage Devices" Materials 16, no. 22: 7111. https://doi.org/10.3390/ma16227111

APA StyleJeżowski, P., Menzel, J., Baranowska, H. M., & Kowalczewski, P. Ł. (2023). Microwaved-Assisted Synthesis of Starch-Based Biopolymer Membranes for Novel Green Electrochemical Energy Storage Devices. Materials, 16(22), 7111. https://doi.org/10.3390/ma16227111