Jointing Achievement and Performance Evaluation of Bogie Crossmember Ring Joint Welded via Inertia Friction Welding

Abstract

:1. Introduction

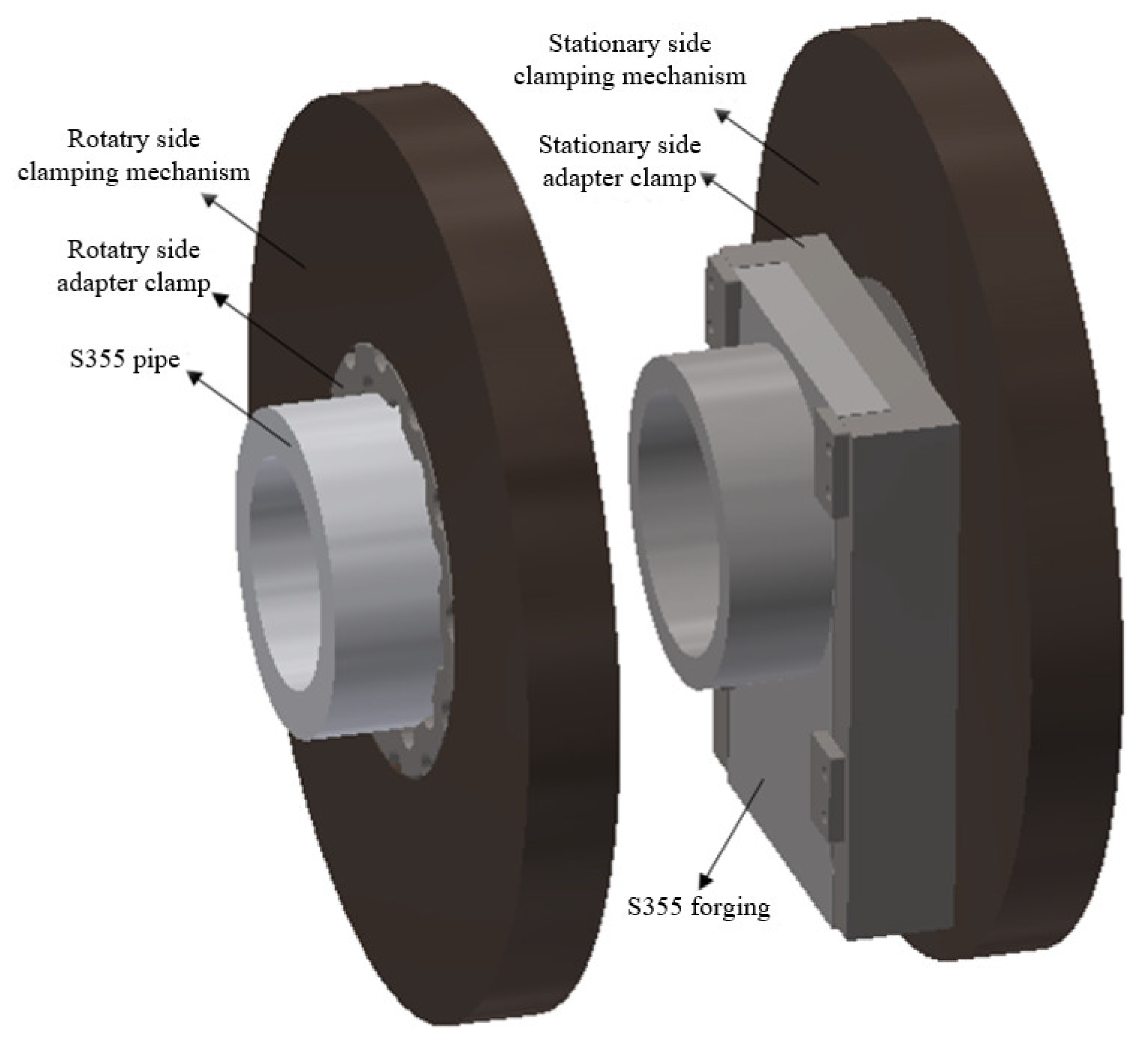

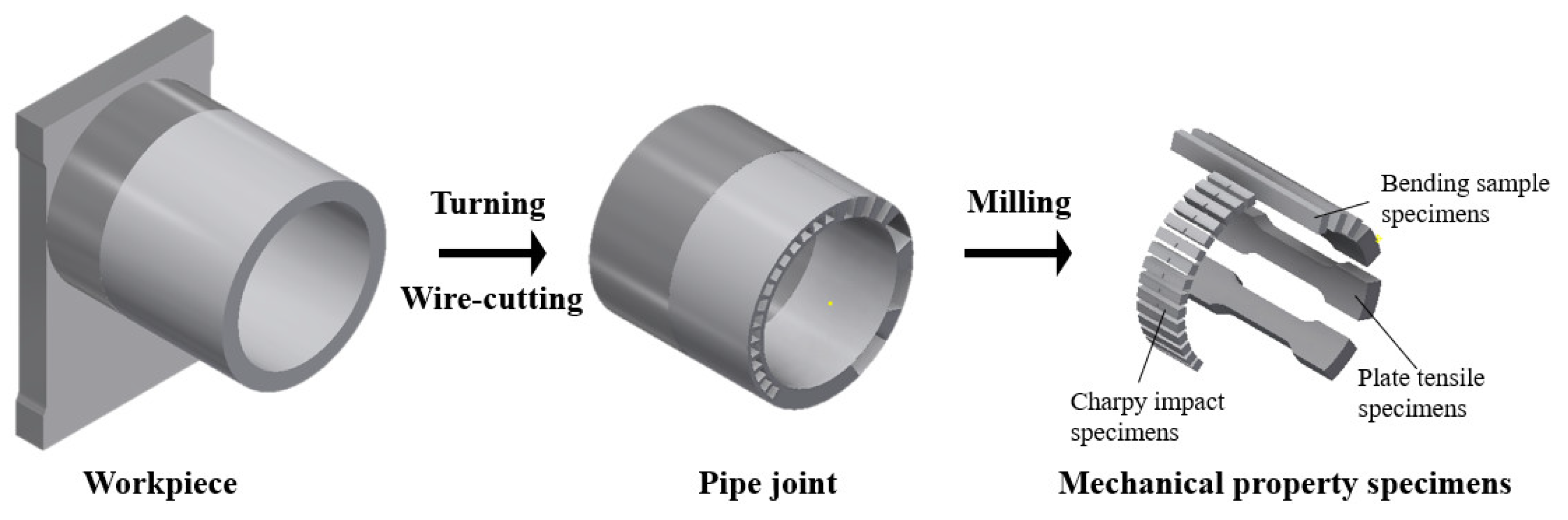

2. Materials and Methods

3. Results

3.1. Macroscopic and Microstructural

3.1.1. Flash Characteristics

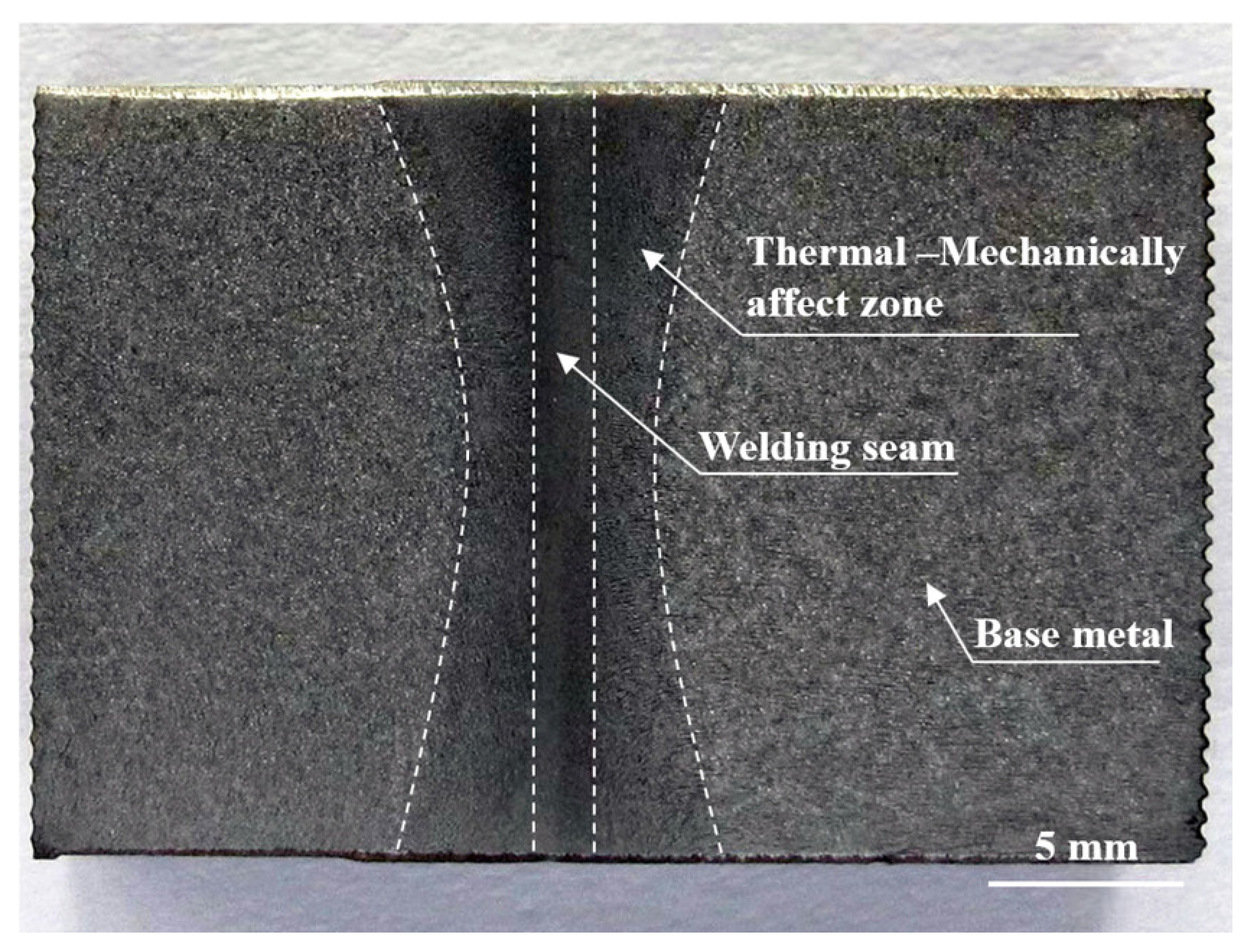

3.1.2. Macro Metallography

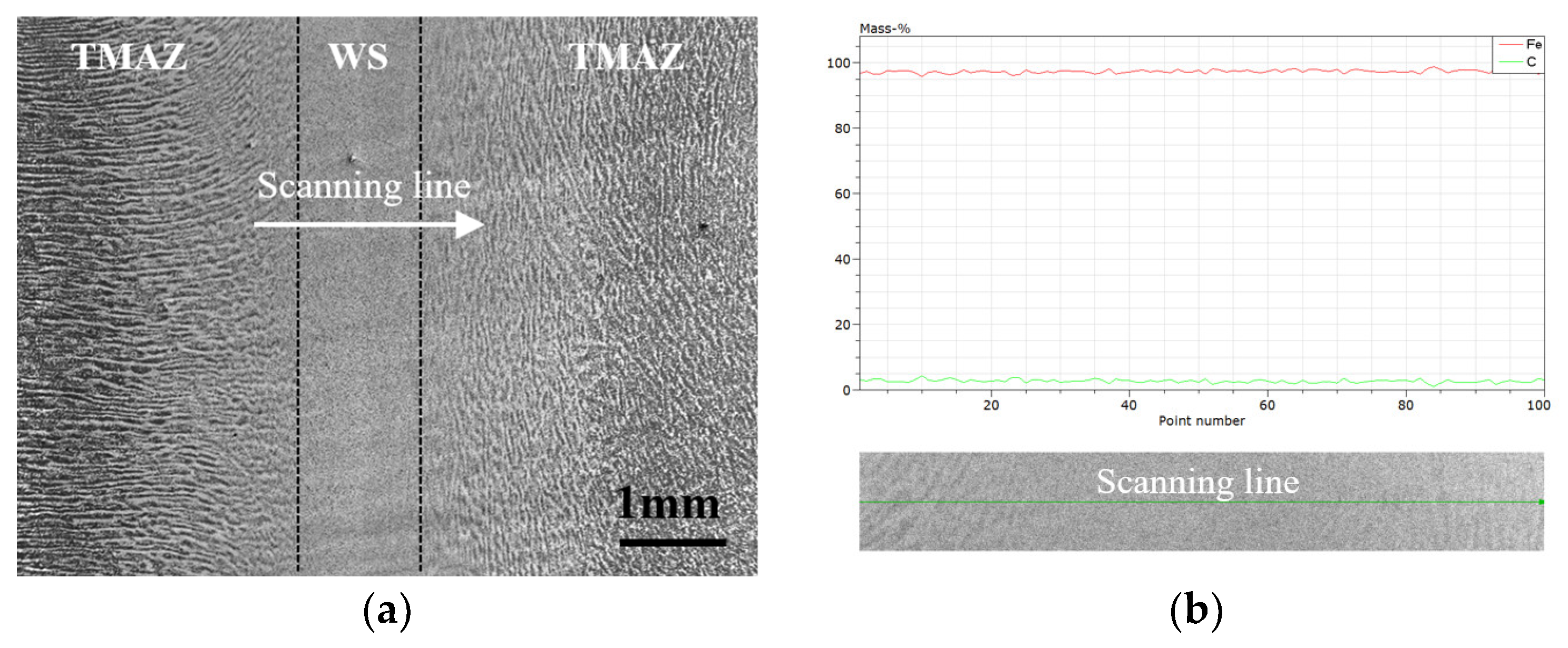

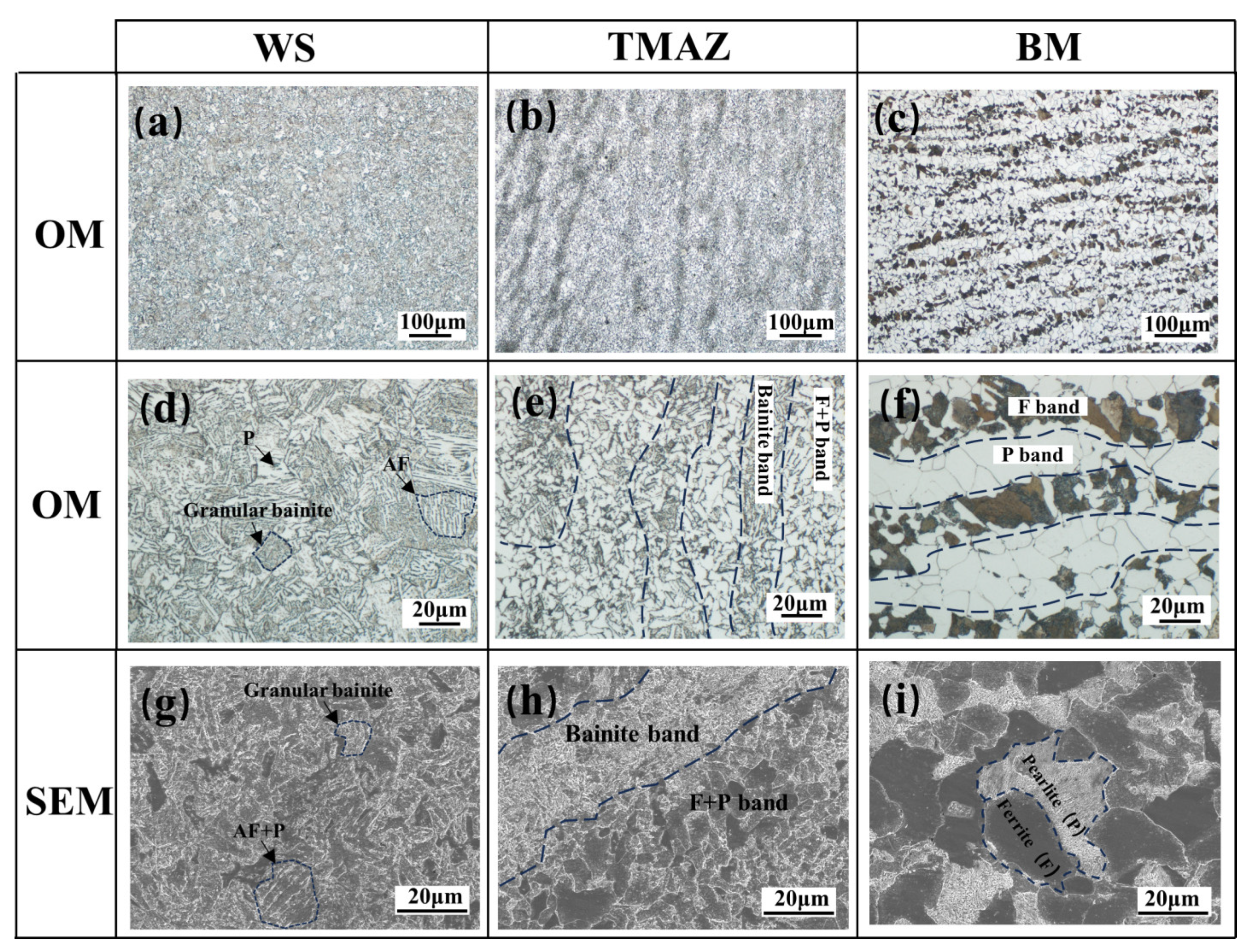

3.1.3. Microstructure

3.2. Mechanical Properties

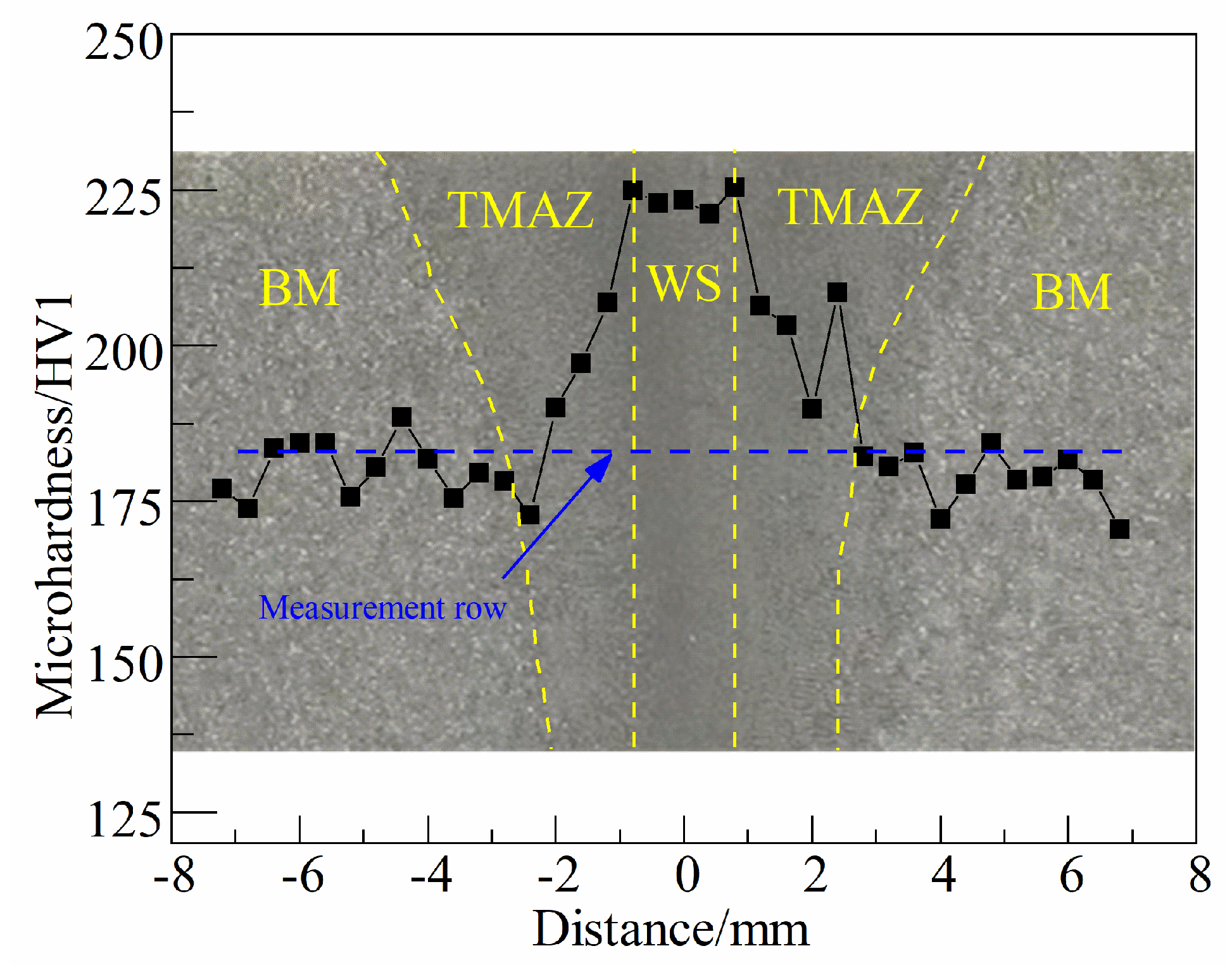

3.2.1. Microhardness Distribution

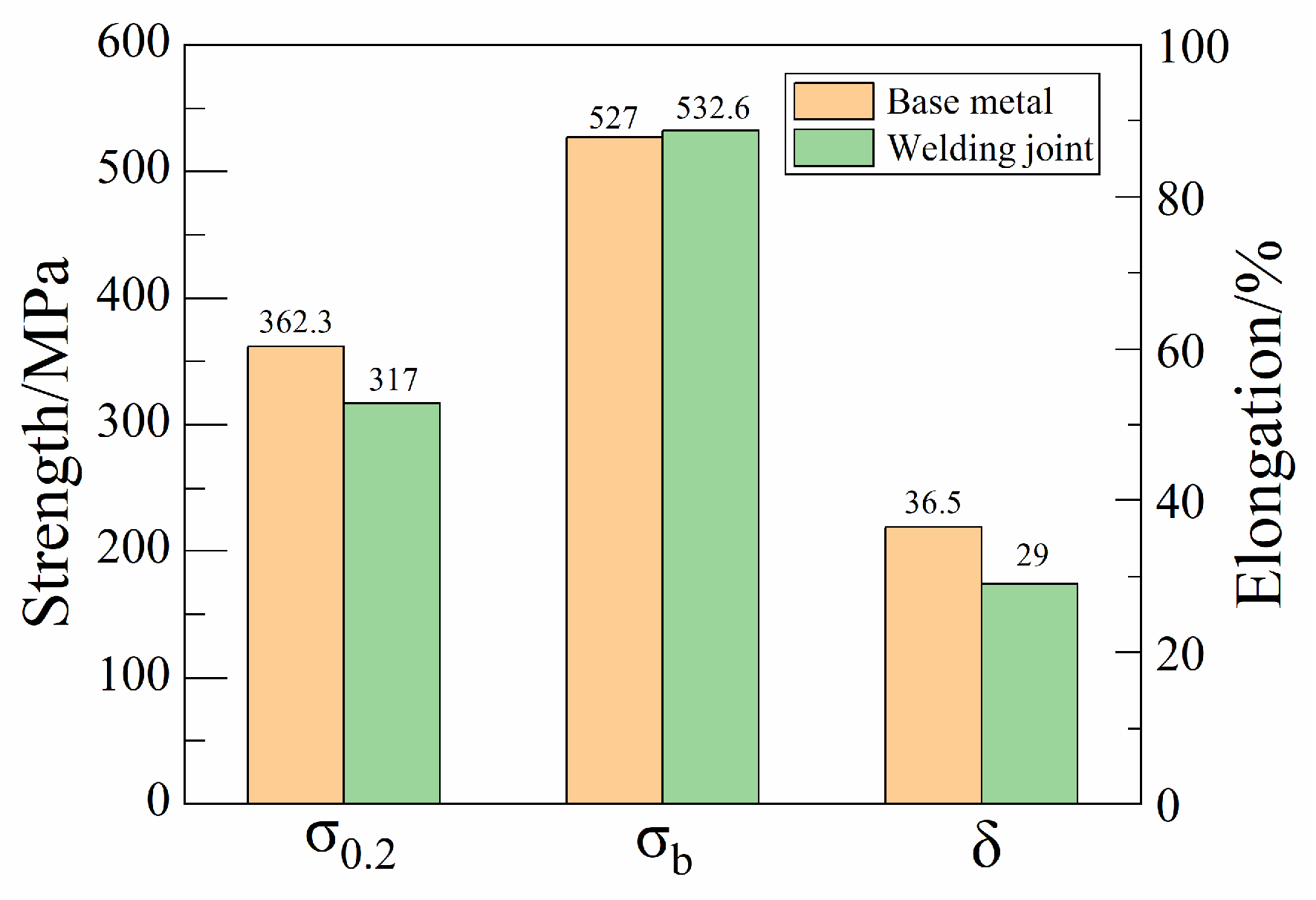

3.2.2. Tensile Strength

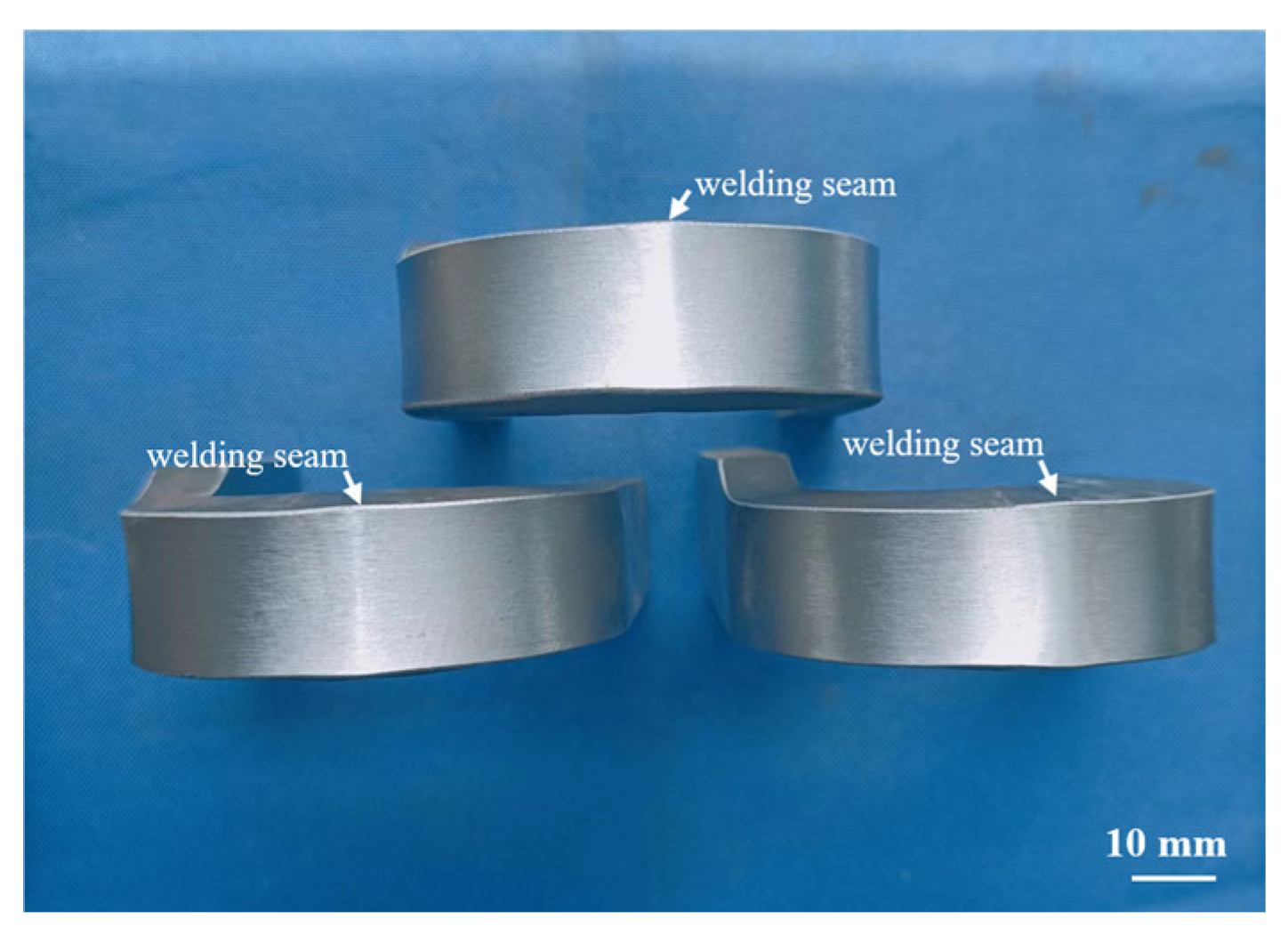

3.2.3. Bend Test

3.2.4. Impact Test

4. Discussion

5. Conclusions

- (1)

- The inertia friction welding method was used to achieve the one-step formation of a bogie crossmember ring joint with a diameter of 169 mm and a thickness of 20.5 mm, and the macroscopic metallurgical results show that there are no visible defects within the weld.

- (2)

- The WS undergoes a complete austenitization process, and the post-weld microstructure characteristics are mainly influenced by the degree of subcooling brought about by the cold source of the base metal, resulting in the formation of granular bainite and acicular ferrite, plus a small amount of pearlite.

- (3)

- The TMAZ microstructure is affected by the dual mechanism of austenitic phase transformation and recrystallization after plastic deformation, finally forming granular bainite bands and F+P bands.

- (4)

- Due to the presence of bainite in the welded joint, the strength and hardness of the joint exceed those of the base material, and the tensile strength reaches 532.6 MPa. But the elongation of and reduction in the area reduced compared with the base material, respectively, reach 87.5% and 79.5% of the base metal. Even so, the transverse side bending of the welded joints do not crack, indicating that the welded joint has sufficient ductility reserve.

- (5)

- The room-temperature impact toughness of WS is slightly lower than that of BM, but the −40 °C impact toughness exceeds that of BM. Compared to WS, the impact toughness of TMAZ is significantly lower than that of the parent material at both room and −40 °C low temperatures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ilesanmi, D.; Khumbulani, M.; Festus, F.; Adefemi, A. Numerical simulation and experimental validation of the welding operation of the railcar bogie frame to prevent distortion. Int. J. Adv. Manuf. Technol. 2020, 106, 5213–5224. [Google Scholar]

- Lu, Y.H.; Lu, C.; Zhang, D.; Chen, T.; Zeng, J.; Wu, P.B. Welding simulation of railway bogie frame side beam: Analyses of residual stresses, clamping forces, distortion and prediction of fatigue S-N curves. J. Manuf. Process. 2019, 38, 204–213. [Google Scholar] [CrossRef]

- Shukri, A.; Kaylan, M.; Kamen, U. Numerical computation methods of welding deformation and their application in bogie frame for high-speed trains. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2023, 237, 33–40. [Google Scholar]

- Gao, Y.H.; Zhao, W.Z. Adaptive optimization with weld fatigue constraints based on surrogate model for railway vehicles. Mech. Based Des. Struct. Mach. 2014, 42, 244–254. [Google Scholar] [CrossRef]

- Seo, J.W.; Kwon, S.J.; Lee, C.W.; Lee, D.H.; Goo, B.C. Fatigue strength and residual stress evaluation of repair welding of bogie frame for railway vehicles. Eng. Fail. Anal. 2021, 119, 104980. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Xie, S.Q.; Zhang, Y.L.; Li, Q.; Wang, W.J.; Wang, B.J. Fatigue reliability analysis of metro bogie frame based on effective notch stress method. Eng. Fail. Anal. 2022, 131, 105811. [Google Scholar] [CrossRef]

- Yang, G.X.; Wang, M.; Li, Q.; Li, Q.; Ding, R. Methodology to Evaluate Fatigue Damage of High-Speed Train Welded Bogie Frames Based on On-Track Dynamic Stress Test Data. Chin. J. Mech. Eng. 2019, 32, 51. [Google Scholar] [CrossRef]

- Mao, L.Y.; Wang, W.J.; Liu, Z.M.; Sha, M.; Zhang, D.Y. Investigation of the fatigue crack growth behavior of S355 steel weldments of motor hangers of high-speed trains. Eng. Fail. Anal. 2022, 140, 106425. [Google Scholar] [CrossRef]

- Dariusz, R.; Janusz, L.; Grzegorz, L.; Zbigniew, M.; Jose, A.C.; Wojciech, M. The energy approach to fatigue crack growth of S355 steel welded specimens subjected to bending. Theor. Appl. Fract. Mech. 2022, 121, 103470. [Google Scholar]

- Hassan, A.K. Material and residual stress improvement in S355 welded structural steel using mechanical and thermal post-weld treatment methods. Steel Constr. 2022, 15, 51–54. [Google Scholar]

- Boris, F.; Ivan, L.; Davor, S.; Mateo, G. Fatigue tests of as-welded and HFMI treated S355 details with longitudinal and transverse attachments. Weld. World 2022, 66, 2549–2561. [Google Scholar]

- Gu, B.P.; Wang, P.; Hu, X.; Jin, Z.D.; Lai, J.T.; Xu, G.H.; Yang, Z.S.; Huo, Z.P.; Wang, Z.S. Effects of High Frequency Impact Vibration Stress Relief on Residual Stress and Microstructure of a Laser Surface Treated S355 Steel. Lasers Eng. 2021, 51, 1–13. [Google Scholar]

- Wu, L.J.; Chen, J.; Xu, L.; Wu, X.Y.; Xia, C.Y.; Wu, C.S.; Wang, Z.S. Study on GMAW assisted by compound external magnetic fields in bogie manufacturing with T-joints and single-bevel grooves. Weld. World 2023, 67, 2017–2029. [Google Scholar] [CrossRef]

- Wang, F.X.; Yang, X.Q.; Yin, Y.Y.; Cui, L. Thermal process influence on microstructure and mechanical behavior for friction taper plug welding in structural steel S355. Int. J. Adv. Manuf. Technol. 2017, 88, 3459–3466. [Google Scholar] [CrossRef]

- Zhang, X.D.; Deng, C.Y.; Wang, D.P.; Wang, Z.J.; Teng, J.H.; Cao, J.; Xu, W.; Yang, F. Improving bonding quality of underwater friction stitch welds by selecting appropriate plug material and welding parameters and optimizing joint design. Mater. Des. 2016, 91, 398–410. [Google Scholar] [CrossRef]

- Cui, L.; Yang, X.Q.; Wang, D.P.; Hou, X.P.; Cao, J.; Xu, W. Friction taper plug welding for S355 steel in underwater wet conditions: Welding performance, microstructures and mechanical properties. Mater. Sci. Eng. A 2014, 611, 15–28. [Google Scholar] [CrossRef]

- ISO 6892-1:2019; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. International Organization for Standardization: Geneva, Switzerland, 2019. Available online: https://www.iso.org/obp/ui/#iso:std:iso:6892:-1:ed-3:v1:en (accessed on 1 October 2023).

- ISO 5173:2023; Destructive Tests on Welds in Metallic Materials—Bend Tests. International Organization for Standardization: Geneva, Switzerland, 2023. Available online: https://www.iso.org/obp/ui/#iso:std:iso:5173:ed-4:v1:en (accessed on 1 October 2023).

- ISO 9016:2022; Destructive Tests on Welds in Metallic Materials—Impact Tests—Test Specimen Location, Notch Orientation and Examination. International Organization for Standardization: Geneva, Switzerland, 2022. Available online: https://www.iso.org/obp/ui/en/#iso:std:iso:9016:ed-3:v1:en (accessed on 1 October 2023).

- Sun, J.M.; Hensel, J.; Klassen, J.; Nitschke-Pagel, T.; Dilger, K. Solid-state phase transformation and strain hardening on the residual stresses in S355 steel weldments. J. Mater. Process. Technol. 2019, 265, 173–184. [Google Scholar] [CrossRef]

- Rodrigues, D.M.; Leitao, C.; Balakrishnan, M.; Craveiro, H.D.; Santiago, A. Tensile properties of S355 butt welds after exposure to high temperatures. Constr. Build. Mater. 2021, 302, 124374. [Google Scholar] [CrossRef]

- Balakrishnan, M.; Leitao, C.; Craveiro, D.; Rodrigues, D.M.; Santiago, A.; Silva, L.S.; Subramanian, C. Post fire tensile properties of S355 J2 structural steel welded connections for construction industrial applications. Metall. Res. Technol. 2022, 119, 511. [Google Scholar] [CrossRef]

- Stornelli, G.; Gaggiotti, M.; Gattia, D.M.; Schmidt, R.; Sgambetterra, M.; Tselikova, A.; Zucca, G.; Di Schino, A. Vanadium Alloying in S355 Structural Steel: Effect on Residual Austenite Formation in Welded Joints Heat Affected Zone. Acta Metall. 2022, 28, 127–132. [Google Scholar] [CrossRef]

- Amborish, B.; Michail, N.; Laurie Da, S.; Ryan, O.; Salaheddin, R. Continuous Drive Friction Welding of AISI 8630 Low-Alloy Steel: Experimental Investigations on Microstructure Evolution and Mechanical Properties. J. Manuf. Sci. Eng. Trans. ASME 2022, 144, 7. [Google Scholar]

- Selvaraj, R.; Shanmugam, K.; Selvaraj, P.; Prasanna, N.B.; Balasubramanian, V. Optimization of mechanical properties of rotary friction welding parameters of low alloy steel tubes using design of experiments concept. Int. J. Interact. Des. Manuf. 2023. [Google Scholar] [CrossRef]

- Zhang, W.C.; Deng, Y.F.; Zhan, P.F.; Zeng, J.C.; Xiao, X.P. Effects of joint heat distribution on material flow and microstructure in continuous drive friction welding of 45 # steel. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2022, 236, 6635–6651. [Google Scholar]

- Kim, Y.; Kim, D.; Park, J.; Song, K. Implementation of Exceptional Microstructures and Mechanical Properties of Structural Carbon Steel Tubes by Friction Welding. Mater. Trans. 2022, 63, 1337–1344. [Google Scholar] [CrossRef]

| Element | C | Mn | Si | Cr | Ni | P | S | Fe | Rp0.2 /MPa | Rm /MPa |

|---|---|---|---|---|---|---|---|---|---|---|

| wt% | 0.05 | 1.60 | 0.25 | 0.04 | 0.03 | 0.018 | 0.004 | Ba | ≥300 | ≥490 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, F.; Zhang, X.; Zhang, C.; Wu, Y.; Liang, W.; Li, R.; Zhou, J. Jointing Achievement and Performance Evaluation of Bogie Crossmember Ring Joint Welded via Inertia Friction Welding. Materials 2023, 16, 7127. https://doi.org/10.3390/ma16227127

Qin F, Zhang X, Zhang C, Wu Y, Liang W, Li R, Zhou J. Jointing Achievement and Performance Evaluation of Bogie Crossmember Ring Joint Welded via Inertia Friction Welding. Materials. 2023; 16(22):7127. https://doi.org/10.3390/ma16227127

Chicago/Turabian StyleQin, Feng, Xinmeng Zhang, Chunbo Zhang, Yanquan Wu, Wu Liang, Rui Li, and Jun Zhou. 2023. "Jointing Achievement and Performance Evaluation of Bogie Crossmember Ring Joint Welded via Inertia Friction Welding" Materials 16, no. 22: 7127. https://doi.org/10.3390/ma16227127