Exploring the Utilization of PHC Pile Waste Concrete as Filler in Asphalt Mastics

Abstract

:1. Introduction

2. Raw Materials and Preparation of Asphalt Mastics

2.1. Raw Materials

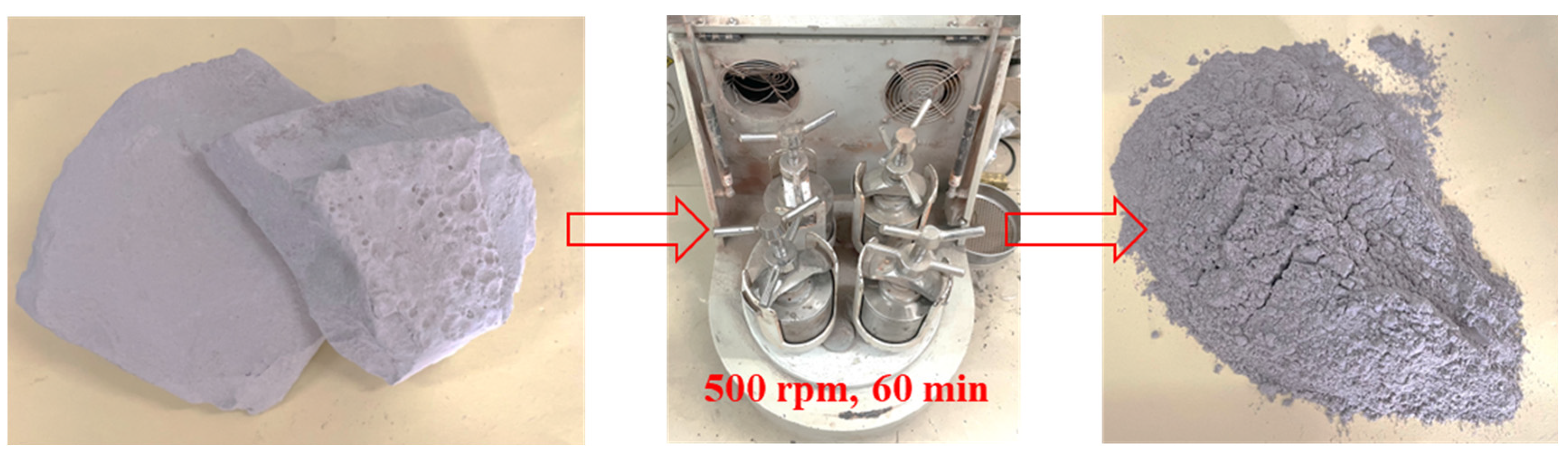

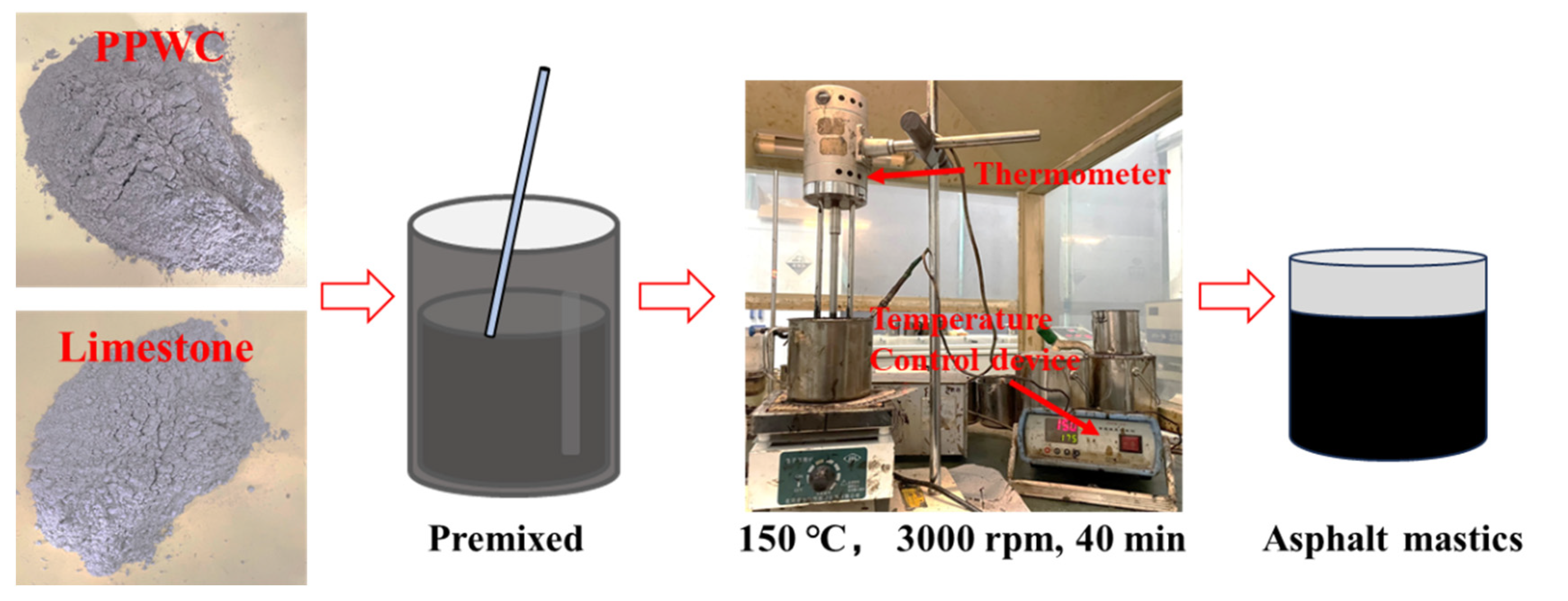

2.2. Preparation of Asphalt Mastics

3. Test Methods

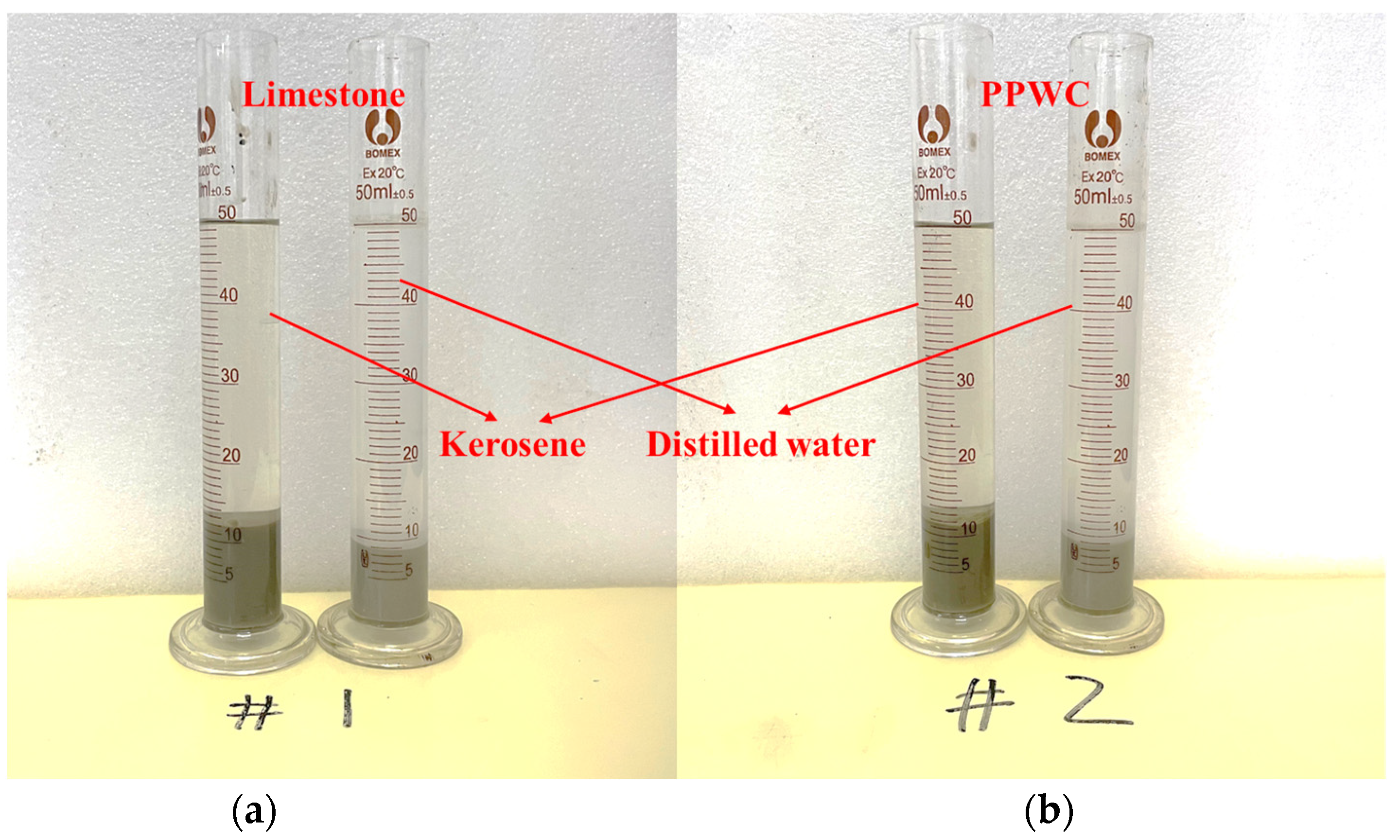

3.1. Particle Characteristics and Chemical Composition of Fillers

3.2. Physical Properties of Asphalt Mastics

3.3. Rheological Properties of Asphalt Mastics

3.4. Low-Temperature Crack Resistance of Mastics

4. Results and Discussions

4.1. Characteristics of Filler

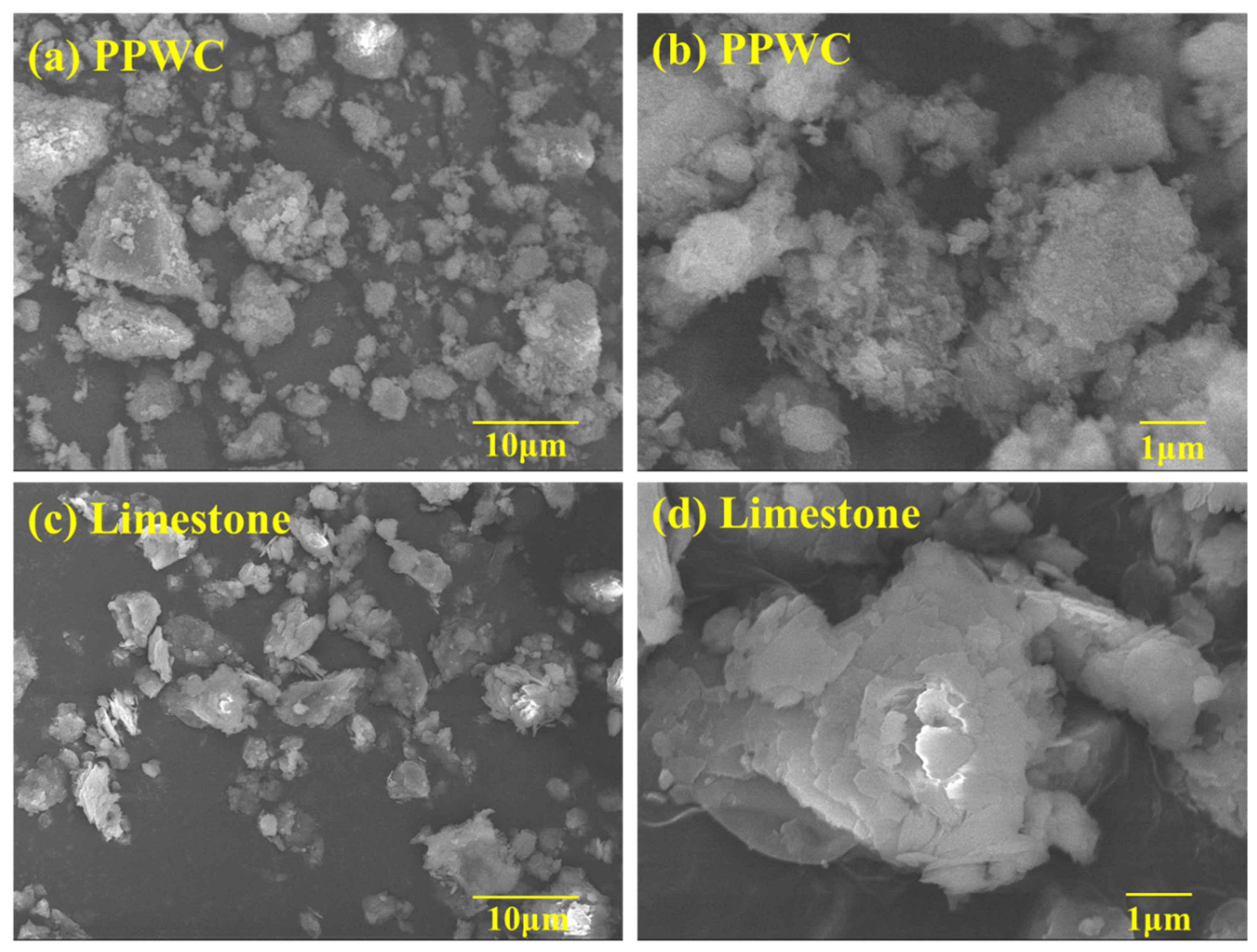

4.1.1. Surface Morphology of Filler

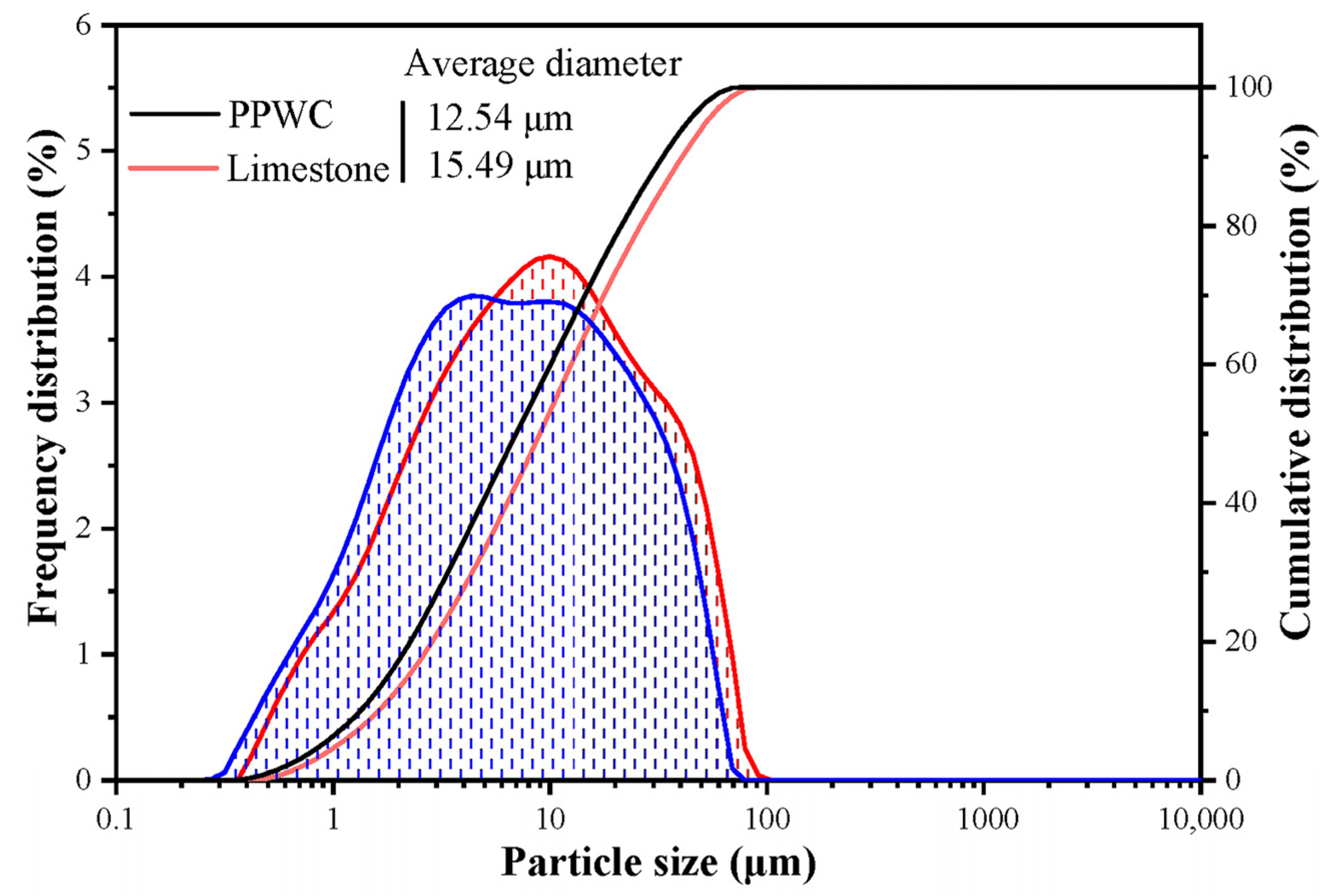

4.1.2. Particle Size Distribution of Filler

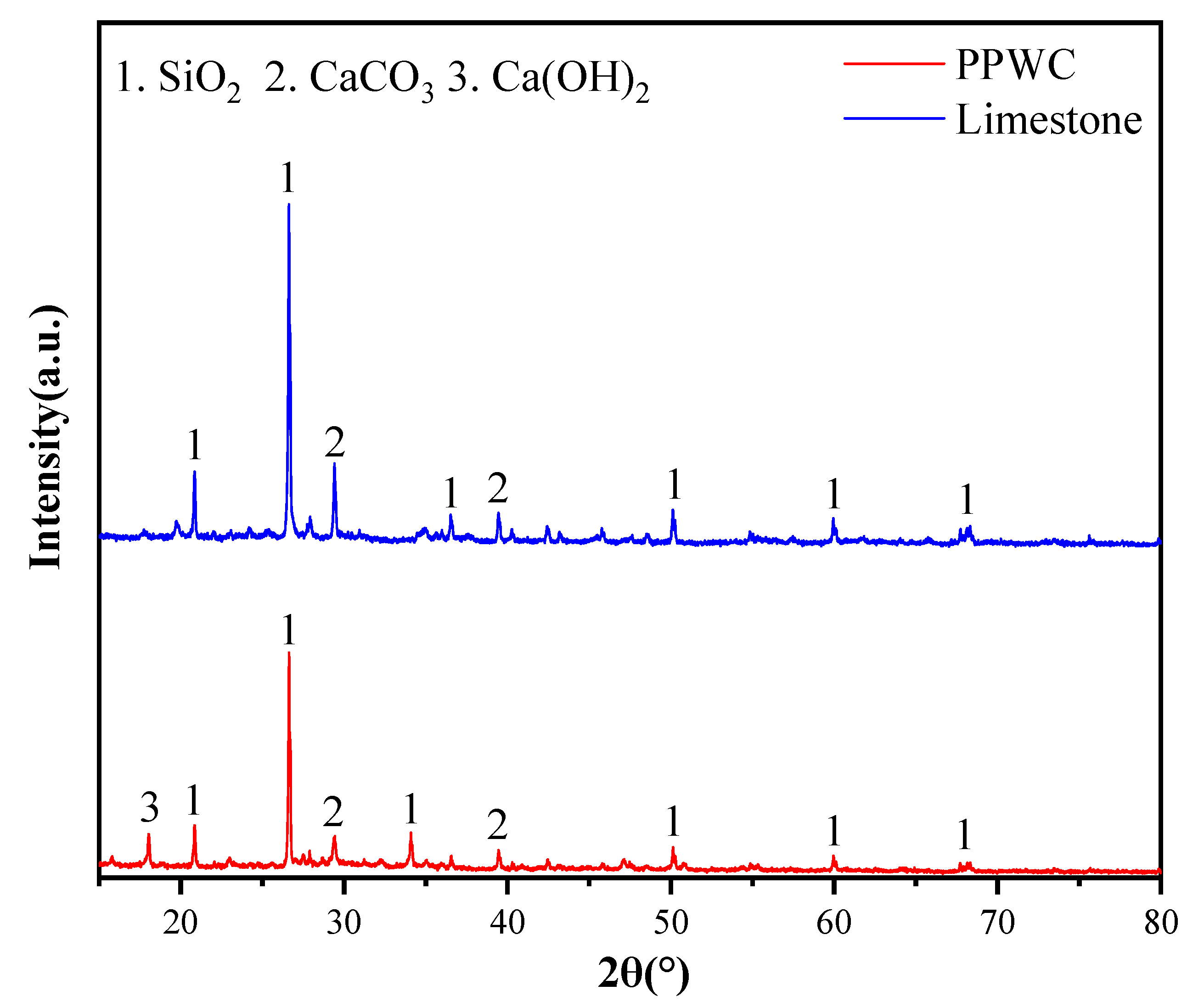

4.1.3. Chemical Composition of Filler

4.2. Physical Properties of Asphalt Mastics

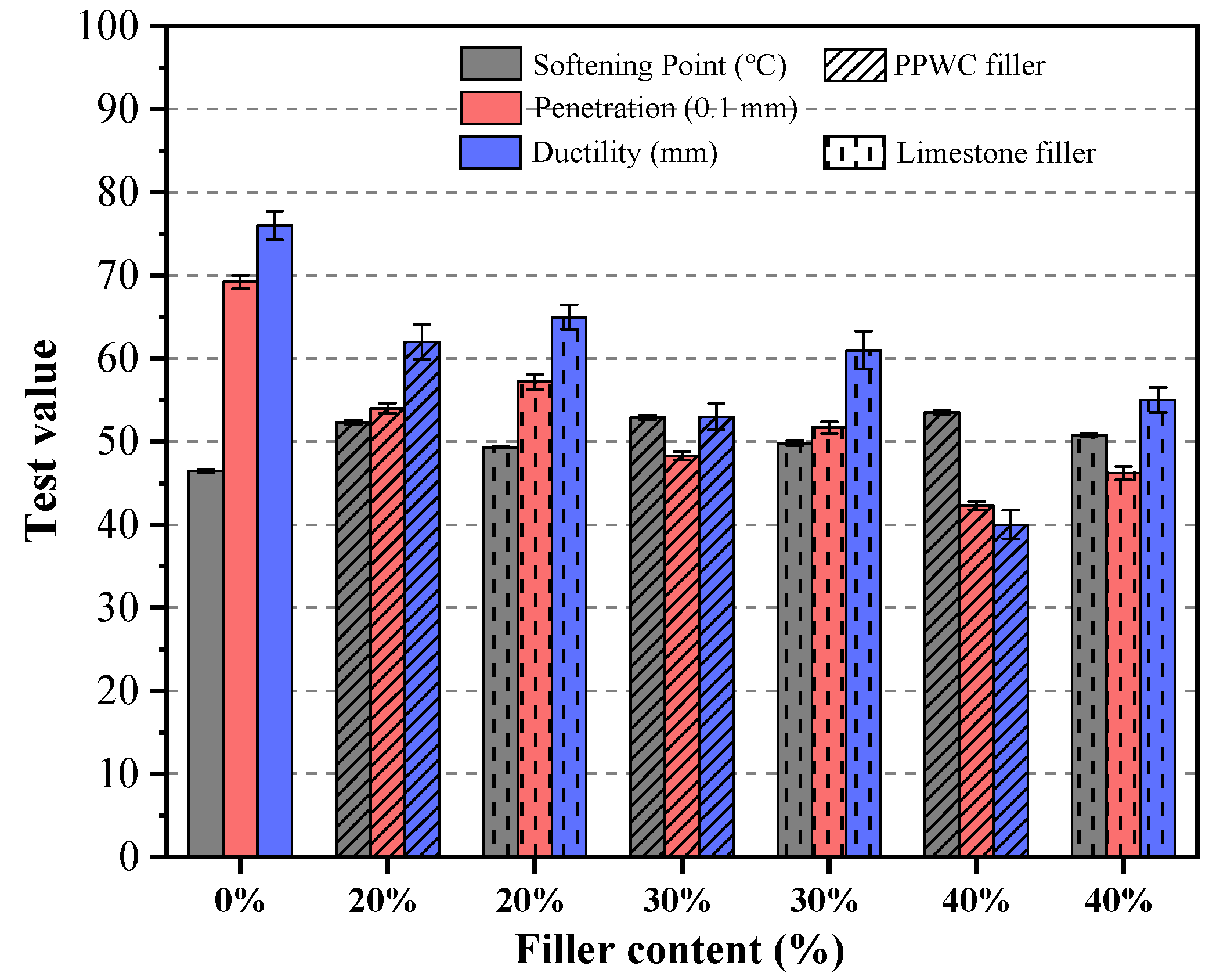

4.2.1. Softening Point, Penetration and Ductility of Asphalt Mastics

4.2.2. Viscosity of Asphalt Mastics

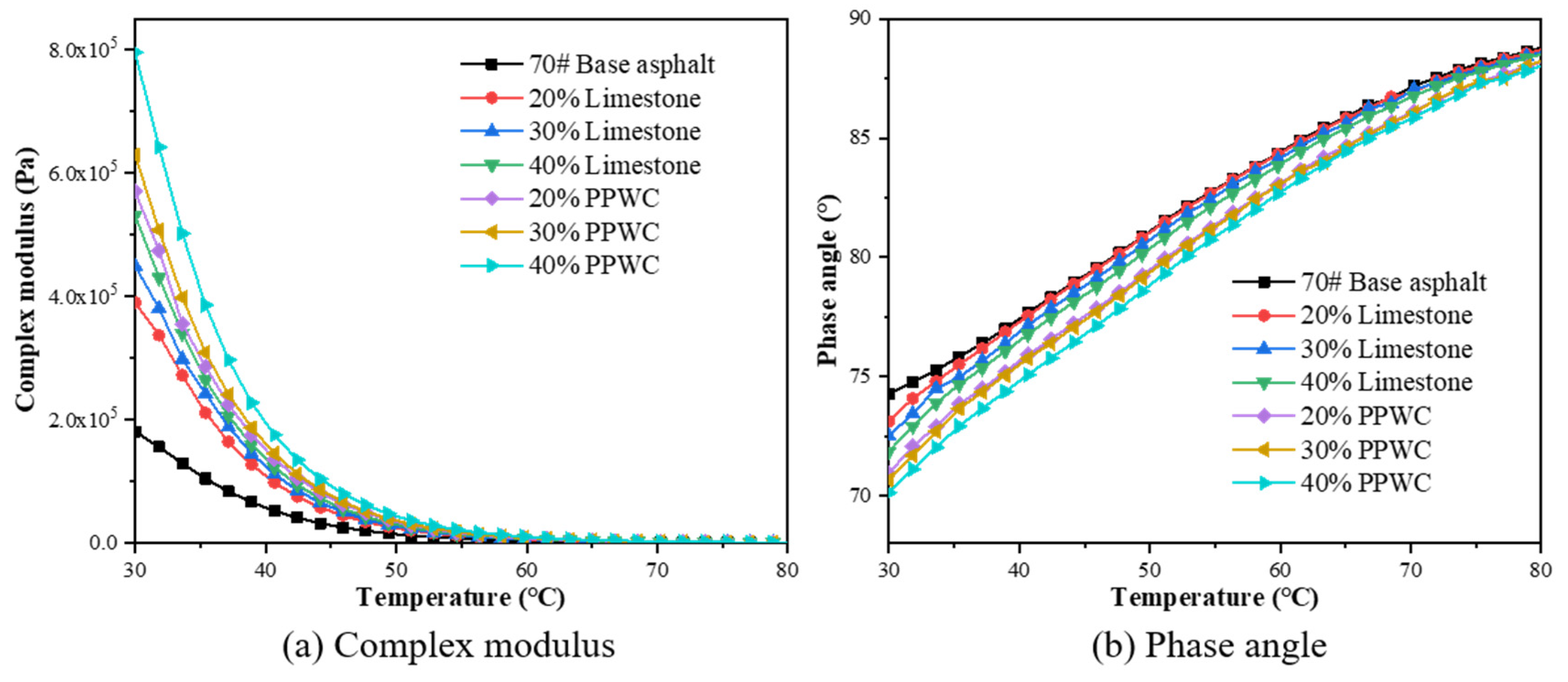

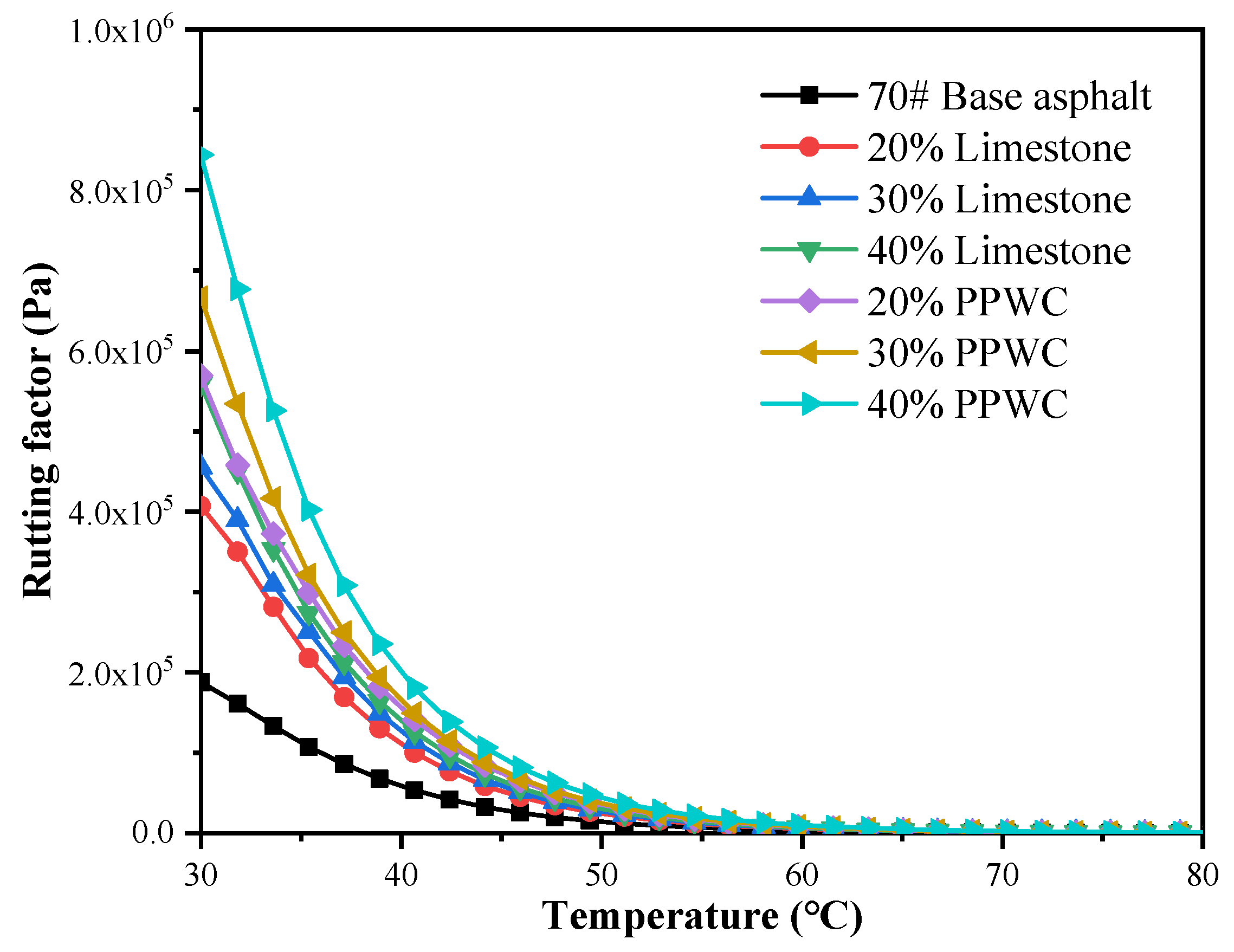

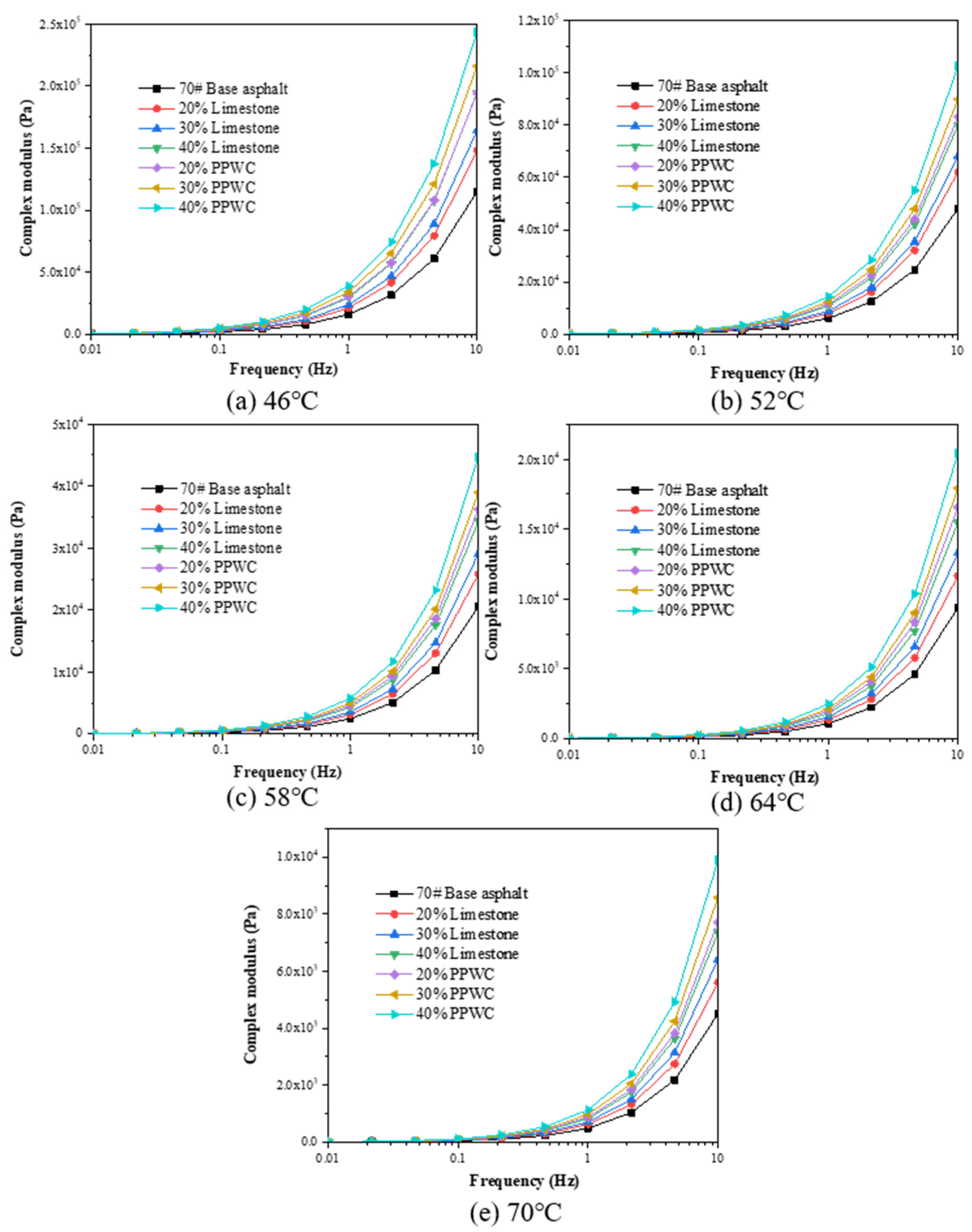

4.3. Rheological Properties of Asphalt Mortar

4.4. BBR Test Results

4.5. Economic Analysis of PPWC Filler

- (1)

- By grinding treatment, PPWC can be reused, reducing waste emissions and complying with environmental requirements. This not only reduces the cost of waste disposal but also maximizes resource utilization, thereby lowering overall costs.

- (2)

- PPWC, as a solid waste, does not require a mining process, whereas limestone extraction adds additional costs. Therefore, the processing and utilization costs of PPWC are lower, thus reducing the raw material costs.

- (3)

- PPWC is typically generated near construction sites. Therefore, using PPWC filler can reduce the transportation distance of raw materials, leading to decreased transportation costs.

- (4)

- In some regions, the government has policies and regulations related to waste management and resource utilization. Grinding PPWC for reuse complies with these policies and regulations. This approach might garner government support and incentives, ultimately lowering production costs.

5. Conclusions

- (1)

- Compared to limestone filler, PPWC filler has a lower density (2.67 g/cm3), smaller particle size (12.54 μm) and rougher surface, and its hydrophilicity coefficient (1.77) is higher than limestone filler (1.44).

- (2)

- As the filler-to-asphalt volume ratio increased from 0% to 40%, the softening point of the asphalt mastics containing PPWC filler improved by 15.1%, but the penetration and ductility decreased by 38.9% and 47.4%, respectively.

- (3)

- In comparison to the asphalt mastics with limestone filler, the performance of the asphalt mastics’ rutting resistance and high-temperature stability can both be greatly improved by PPWC filler. However, the performance of PPWC filler asphalt mastics at low temperatures is less impressive.

- (4)

- Considering that PPWC filler will reduce the low-temperature performance of asphalt mastics, it is suggested that the content of PPWC filler should not exceed 30% of asphalt volume.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, G.; Chen, X.; Zhang, Y.; Zhuang, Z.; Lv, Y. Studies of nano-SiO2 and subsequent water curing on enhancing the frost resistance of autoclaved PHC pipe pile concrete. J. Build. Eng. 2023, 69, 106209. [Google Scholar] [CrossRef]

- Li, L.; Yang, C.; Li, J. Corrosion initiation life of laterally loaded PHC pipe piles served in marine environment: Theoretical prediction and analysis. Constr. Build. Mater. 2021, 293, 123457. [Google Scholar] [CrossRef]

- Liu, Z.; Bu, L.; Wang, Z.; Hu, G. Durability and microstructure of steam cured and autoclaved PHC pipe piles. Constr. Build. Mater. 2019, 209, 679–689. [Google Scholar] [CrossRef]

- Zheng, C.; Bai, X.-Y.; Zhang, M.-Y.; Miao, D.-Z. Study on bearing behavior and Q-s curve model of rock-socketed PHC pipe piles based on ultimate load tests. J. Guangxi Univ. (Nat. Sci. Ed.) 2019, 44, 8. [Google Scholar]

- Yu, J.-L.; Zhou, J.-J.; Gong, X.-N.; Zhang, R.-H. Shaft capacity of prestressed high strength concrete (PHC) pile-cemented soil column embedded in clayey soil. Soils Found. 2021, 61, 1086–1098. [Google Scholar] [CrossRef]

- Sua-iam, G.; Makul, N. Recycling prestressed concrete pile waste to produce green self-compacting concrete. J. Mater. Res. Technol. 2023, 24, 4587–4600. [Google Scholar] [CrossRef]

- Yang, C.; Wu, S.; Xie, J.; Amirkhanian, S.; Zhao, Z.; Xu, H.; Wang, F.; Zhang, L. Development of blending model for RAP and virgin asphalt in recycled asphalt mixtures via a micron-Fe3O4 tracer. J. Clean. Prod. 2023, 383, 135407. [Google Scholar] [CrossRef]

- Amirbayev, Y.; Yelshibayev, A.; Nugmanova, A. Characterization of asphalt bitumens and asphalt concretes modified with carbon powder. Case Stud. Constr. Mater. 2022, 17, e01554. [Google Scholar] [CrossRef]

- Ren, M.; Gong, H.; Cong, L.; Sun, Y.; Zhang, Q.; Li, Z. Fatigue damage investigation on asphalt concrete under cyclic freeze–thaw using a combined energy and viscoelasticity method. Constr. Build. Mater. 2023, 388, 131707. [Google Scholar] [CrossRef]

- Xiao, F.; Xiao, X.; Li, J. Low-temperature fracture behavior of railway asphalt concretes under semi-circular bending: Experimental and numerical investigation. Constr. Build. Mater. 2023, 402, 132990. [Google Scholar] [CrossRef]

- Teixeira, J.E.S.L.; Amaecing Junior, C.M.; de Rezende, L.R.; Castelo Branco, V.T.F.; Kim, Y.-R. Evaluation of asphalt concrete’s fatigue behavior using cyclic semi-circular bending test. Constr. Build. Mater. 2023, 400, 132772. [Google Scholar] [CrossRef]

- Lin, Q.; Liu, Z.; Sun, J.; Yu, L. Comprehensive modification of emulsified asphalt on improving mechanical properties of crumb rubber concrete. Constr. Build. Mater. 2023, 369, 130555. [Google Scholar] [CrossRef]

- Karthikeyan, K.; Kothandaraman, S.; Sarang, G. Perspectives on the utilization of reclaimed asphalt pavement in concrete pavement construction: A critical review. Case Stud. Constr. Mater. 2023, 19, e02242. [Google Scholar] [CrossRef]

- Li, J.; Yu, J.; Wu, S.; Xie, J. The Mechanical Resistance of Asphalt Mixture with Steel Slag to Deformation and Skid Degradation Based on Laboratory Accelerated Heavy Loading Test. Materials 2022, 15, 911. [Google Scholar] [CrossRef]

- Xie, J.; Chen, J.; Hu, L.; Wu, S.; Wang, Z.; Li, M.; Yang, C. Preparation, thermochromic properties and temperature controlling ability of novel pellets in ultra-thin wearing course. Constr. Build. Mater. 2023, 389, 131797. [Google Scholar] [CrossRef]

- Mazalan, N.A.A.; Mohd Satar, M.K.I.; Mohamed, A.; Mohd Warid, M.N. Rheological properties of asphaltene-modified asphalt binder and mastic. Phys. Chem. Earth Parts A/B/C 2023, 131, 103422. [Google Scholar] [CrossRef]

- Jia, Y.; Liu, G.; Gao, Y.; Wang, S.; Li, Z.; Wang, X.; Yan, L. Micromechanics prediction of dynamic modulus for asphalt mastic considering filler distribution characteristic: A new perspective. Constr. Build. Mater. 2023, 364, 129916. [Google Scholar] [CrossRef]

- Meng, Y.; Lai, J.; Ling, L.; Zhang, C.; Chen, J.; Zhu, J. Preparation of an eco-friendly de-icing filler and its effects on the performance of different asphalt mastic. Constr. Build. Mater. 2023, 364, 129967. [Google Scholar] [CrossRef]

- Yang, C.; Wu, S.; Cui, P.; Amirkhanian, S.; Zhao, Z.; Wang, F.; Zhang, L.; Wei, M.; Zhou, X.; Xie, J. Performance characterization and enhancement mechanism of recycled asphalt mixtures involving high RAP content and steel slag. J. Clean. Prod. 2022, 336, 130484. [Google Scholar] [CrossRef]

- Wei, Z.; Jia, Y.; Wang, S.; Zhou, Z.; Zhang, Z.; Wang, X.; Huang, X.; Gao, Y. Influence of iron tailing filler on rheological behavior of asphalt mastic. Constr. Build. Mater. 2022, 352, 129047. [Google Scholar] [CrossRef]

- Belayali, F.; Maherzi, W.; Benzerzour, M.; Abriak, N.-E. Influence of the physical and chemical characteristics of sediment fillers on the properties of mastic asphalt. Powder Technol. 2023, 421, 118393. [Google Scholar] [CrossRef]

- Gong, X.; Liu, Q.; Wang, H.; Wan, P.; Chen, S.; Wu, J.; Wu, S. Synthesis of environmental-curable CO2-based polyurethane and its enhancement on properties of asphalt binder. J. Clean. Prod. 2023, 384, 135576. [Google Scholar] [CrossRef]

- Lv, Y.; Wu, S.; Li, N.; Cui, P.; Wang, H.; Amirkhanian, S.; Zhao, Z. Performance and VOCs emission inhibition of environmentally friendly rubber modified asphalt with UiO-66 MOFs. J. Clean. Prod. 2023, 385, 135633. [Google Scholar] [CrossRef]

- Lagos-Varas, M.; Movilla-Quesada, D.; Raposeiras, A.C.; Castro-Fresno, D.; Vega-Zamanillo, Á.; Cumian-Benavides, M. Use of Hydrated Ladle Furnace Slag as a filler substitute in asphalt mastics: Rheological analysis of filler/bitumen interaction. Constr. Build. Mater. 2022, 332, 127370. [Google Scholar] [CrossRef]

- Russo, F.; Veropalumbo, R.; Pontoni, L.; Oreto, C.; Biancardo, S.A.; Viscione, N.; Pirozzi, F.; Race, M. Sustainable asphalt mastics made up recycling waste as filler. J. Environ. Manag. 2022, 301, 113826. [Google Scholar] [CrossRef]

- Rieksts, K.; Pettinari, M.; Haritonovs, V. The influence of filler type and gradation on the rheological performance of mastics. Road Mater. Pavement Des. 2019, 20, 964–978. [Google Scholar] [CrossRef]

- Das, A.K.; Singh, D. Evaluation of fatigue performance of asphalt mastics composed of nano hydrated lime filler. Constr. Build. Mater. 2021, 269, 121322. [Google Scholar] [CrossRef]

- Zhang, J.; Li, P.; Liang, M.; Jiang, H.; Yao, Z.; Zhang, X.; Yu, S. Utilization of red mud as an alternative mineral filler in asphalt mastics to replace natural limestone powder. Constr. Build. Mater. 2020, 237, 117821. [Google Scholar] [CrossRef]

- Du, Y.; Xu, L.; Deng, H.; Deng, D.; Ma, C.; Liu, W. Characterization of thermal, high-temperature rheological and fatigue properties of asphalt mastic containing fly ash cenosphere. Constr. Build. Mater. 2020, 233, 117345. [Google Scholar] [CrossRef]

- Cui, P.; Wu, S.; Xiao, Y.; Hu, R.; Yang, T. Environmental performance and functional analysis of chip seals with recycled basic oxygen furnace slag as aggregate. J. Hazard. Mater. 2021, 405, 124441. [Google Scholar] [CrossRef]

- Gautam, L.; Kalla, P.; Jain, J.K.; Choudhary, R.; Jain, A. Robustness of self-compacting concrete incorporating bone china ceramic waste powder along with granite cutting waste for sustainable development. J. Clean. Prod. 2022, 367, 132969. [Google Scholar] [CrossRef]

- Mukhtar, N.; Mohd Hasan, M.R.; Mohd Ghazali, M.F.H.; Mohd Zin, Z.; Shariff, K.A.; Sani, A. Influence of concentration and packing of filler particles on the stiffening effect and shearing behaviour of asphalt mastic. Constr. Build. Mater. 2021, 295, 123660. [Google Scholar] [CrossRef]

- Wei, Z.; Jia, Y.; Wang, S.; Li, Z.; Li, Y.; Wang, X.; Gao, Y. Utilization of iron ore tailing as an alternative mineral filler in asphalt mastic: High-temperature performance and environmental aspects. J. Clean. Prod. 2022, 335, 130318. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, M.; Shao, L.; Chen, Z. Effect of volcanic ash filler on thermal viscoelastic property of SBS modified asphalt mastic. Constr. Build. Mater. 2018, 190, 495–507. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, S.; Liu, Q.; Xie, J.; Yang, C.; Wan, P.; Guo, S.; Ma, W. Characteristics of calcareous sand filler and its influence on physical and rheological properties of asphalt mastic. Constr. Build. Mater. 2021, 301, 124112. [Google Scholar] [CrossRef]

- Islam, S.S.; Ransinchung, G.D.; Choudhary, J. Analyzing the effect of waste jarosite as an alternative filler on the engineering properties of asphalt mixes. Constr. Build. Mater. 2021, 270, 121466. [Google Scholar] [CrossRef]

- Boateng, K.A.; Tuffour, Y.A.; Agyeman, S.; Boadu, F. Potential improvements in montmorillonite-nanoclay-modified Cold-Mix Asphalt. Case Stud. Constr. Mater. 2022, 17, e01331. [Google Scholar] [CrossRef]

- Akarsh, P.K.; Ganesh, G.O.; Marathe, S.; Rai, R. Incorporation of Sugarcane Bagasse Ash to investigate the mechanical behavior of Stone Mastic Asphalt. Constr. Build. Mater. 2022, 353, 129089. [Google Scholar] [CrossRef]

- Xu, P.; Chen, Z.; Cai, J.; Pei, J.; Gao, J.; Zhang, J.; Zhang, J. The effect of retreated coal wastes as filler on the performance of asphalt mastics and mixtures. Constr. Build. Mater. 2019, 203, 9–17. [Google Scholar] [CrossRef]

- Liu, N.; Liu, L.; Li, M.; Sun, L. Effects of zeolite on rheological properties of asphalt materials and asphalt-filler interaction ability. Constr. Build. Mater. 2023, 382, 131300. [Google Scholar] [CrossRef]

- Taherkhani, H.; Vahabi Kamsari, S. Evaluating the properties of zinc production wastes as filler and their effects on asphalt mastic. Constr. Build. Mater. 2020, 265, 120748. [Google Scholar] [CrossRef]

- Habibnejad Korayem, A.; Ziari, H.; Hajiloo, M.; Abarghooie, M.; Karimi, P. Laboratory evaluation of stone mastic asphalt containing amorphous carbon powder as filler material. Constr. Build. Mater. 2020, 243, 118280. [Google Scholar] [CrossRef]

- Das, A.K.; Singh, D. Investigation of rutting, fracture and thermal cracking behavior of asphalt mastic containing basalt and hydrated lime fillers. Constr. Build. Mater. 2017, 141, 442–452. [Google Scholar] [CrossRef]

- Ou, L.; Li, R.; Zhu, H.; Zhao, H.; Chen, R. Upcycling waste phosphogypsum as an alternative filler for asphalt pavement. J. Clean. Prod. 2023, 420, 138332. [Google Scholar] [CrossRef]

- Zhang, Q.; Luo, J.; Yang, Z.; Wang, J.; Zhao, Y.; Zhang, Y. Creep and fatigue properties of asphalt mastic with steel slag powder filler. Case Stud. Constr. Mater. 2023, 18, e01743. [Google Scholar] [CrossRef]

- Tahami, S.A.; Arabani, M.; Foroutan Mirhosseini, A. Usage of two biomass ashes as filler in hot mix asphalt. Constr. Build. Mater. 2018, 170, 547–556. [Google Scholar] [CrossRef]

- Lei, B.; Xiong, Q.; Zhao, H.; Dong, W.; Tam, V.W.Y.; Sun, Z.; Li, W. Performance of asphalt mortar with recycled concrete powder under different filler-to-asphalt weight ratios. Case Stud. Constr. Mater. 2023, 18, e01834. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Ministry of Transport: Beijing, China, 2011.

- JTG E42-2005; Test Methods of Aggregate for Highway Engineering. China Ministry of Transport: Beijing, China, 2005.

- Gautam, L.; Jain, J.K.; Jain, A.; Kalla, P. Recycling of bone china ceramic waste as cement replacement to produce sustainable self-compacting concrete. Structures 2022, 37, 364–378. [Google Scholar] [CrossRef]

- Xing, B.; Fan, W.; Zhuang, C.; Qian, C.; Lv, X. Effects of the morphological characteristics of mineral powder fillers on the rheological properties of asphalt mastics at high and medium temperatures. Powder Technol. 2019, 348, 33–42. [Google Scholar] [CrossRef]

- Han, X.; Du, Z.; Wang, P.; Zhang, R.; Gao, J.; Ling, Z.; Wei, D. Multi-scale microstructure quantitative characterization and anti-erosion performance of PHC pipe pile. Constr. Build. Mater. 2023, 406, 133464. [Google Scholar] [CrossRef]

- Chen, Z.; Leng, Z.; Jiao, Y.; Xu, F.; Lin, J.; Wang, H.; Cai, J.; Zhu, L.; Zhang, Y.; Feng, N.; et al. Innovative use of industrially produced steel slag powders in asphalt mixture to replace mineral fillers. J. Clean. Prod. 2022, 344, 131124. [Google Scholar] [CrossRef]

- AASHTO MP1-1998; Standard Specification for Performance Graded Asphalt Binder. ASTM International: West Conshohocken, PA, USA, 1998.

| Properties | Test Value | Standard Requirement JTG E20-2011 |

|---|---|---|

| Density/(g/cm3) | 1.034 | |

| Penetration (25 °C)/0.1 mm | 69.2 | 60–80 |

| Softening point/°C | 46.5 | ≥46 |

| Ductility 5 cm/min, (15 °C)/cm | 186 | ≥100 |

| Dynamic viscosity (60 °C)/(Pa·s) | 242.4 | ≥100 |

| Properties | Density/(g/cm3) | Hydrophilic Coefficient |

|---|---|---|

| Limestone | 2.71 | 0.74 |

| PPWC | 2.67 | 0.79 |

| Standard requirement | ≥2.50 | ≤1.00 |

| Filler | d (0.1) μm | d (0.5) μm | d (0.9) μm | Specific Surface Area (m2/g) |

|---|---|---|---|---|

| PPWC | 1.31 | 7.58 | 34.67 | 1.77 |

| Limestone | 1.66 | 8.71 | 39.81 | 1.44 |

| Oxide Type | Filler | CaO | SiO2 | MgO | Al2O3 | Na2O | SO3 | CO2 |

|---|---|---|---|---|---|---|---|---|

| Oxide content (%) | PPWC | 35.10 | 32.40 | 1.11 | 5.84 | 0.38 | 3.69 | 15.92 |

| Limestone | 56.92 | 18.35 | 1.73 | 7.62 | 0.13 | 2.12 | 8.82 |

| Samples | Fitting Line | R2 | Slope (Eη/R) | Eη (kJ/mol) |

|---|---|---|---|---|

| Base asphalt | y = 8763.1x − 22.3 | 0.9960 | 8763.1 | 72.78 |

| 20% PPWC | y = 8939.1x − 22.8 | 0.9966 | 8939.1 | 74.32 |

| 20% Limestone | y = 8973.7x − 22.7 | 0.9967 | 8973.7 | 74.61 |

| 30% PPWC | y = 8754.1x − 21.7 | 0.9890 | 8754.1 | 72.86 |

| 30% Limestone | y = 8807.8x − 22.1 | 0.9938 | 8807.8 | 73.23 |

| 40% PPWC | y = 8796.2x − 19.2 | 0.9840 | 8796.2 | 73.13 |

| 40% Limestone | y = 8940.8x − 22.3 | 0.9938 | 8940.8 | 74.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tu, B.; Yang, X.; Xu, S.; Liang, X.; Liu, C.; Jiang, J.; Fan, L.; Tu, L. Exploring the Utilization of PHC Pile Waste Concrete as Filler in Asphalt Mastics. Materials 2023, 16, 7158. https://doi.org/10.3390/ma16227158

Tu B, Yang X, Xu S, Liang X, Liu C, Jiang J, Fan L, Tu L. Exploring the Utilization of PHC Pile Waste Concrete as Filler in Asphalt Mastics. Materials. 2023; 16(22):7158. https://doi.org/10.3390/ma16227158

Chicago/Turabian StyleTu, Botao, Xinkui Yang, Shi Xu, Xuhui Liang, Chen Liu, Jian Jiang, Lulu Fan, and Liangliang Tu. 2023. "Exploring the Utilization of PHC Pile Waste Concrete as Filler in Asphalt Mastics" Materials 16, no. 22: 7158. https://doi.org/10.3390/ma16227158

APA StyleTu, B., Yang, X., Xu, S., Liang, X., Liu, C., Jiang, J., Fan, L., & Tu, L. (2023). Exploring the Utilization of PHC Pile Waste Concrete as Filler in Asphalt Mastics. Materials, 16(22), 7158. https://doi.org/10.3390/ma16227158