Tailored Time–Temperature Transformation Diagram for IN718 Alloy Obtained via Powder Bed Fusion Additive Manufacturing: Phase Behavior and Precipitation Dynamic

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

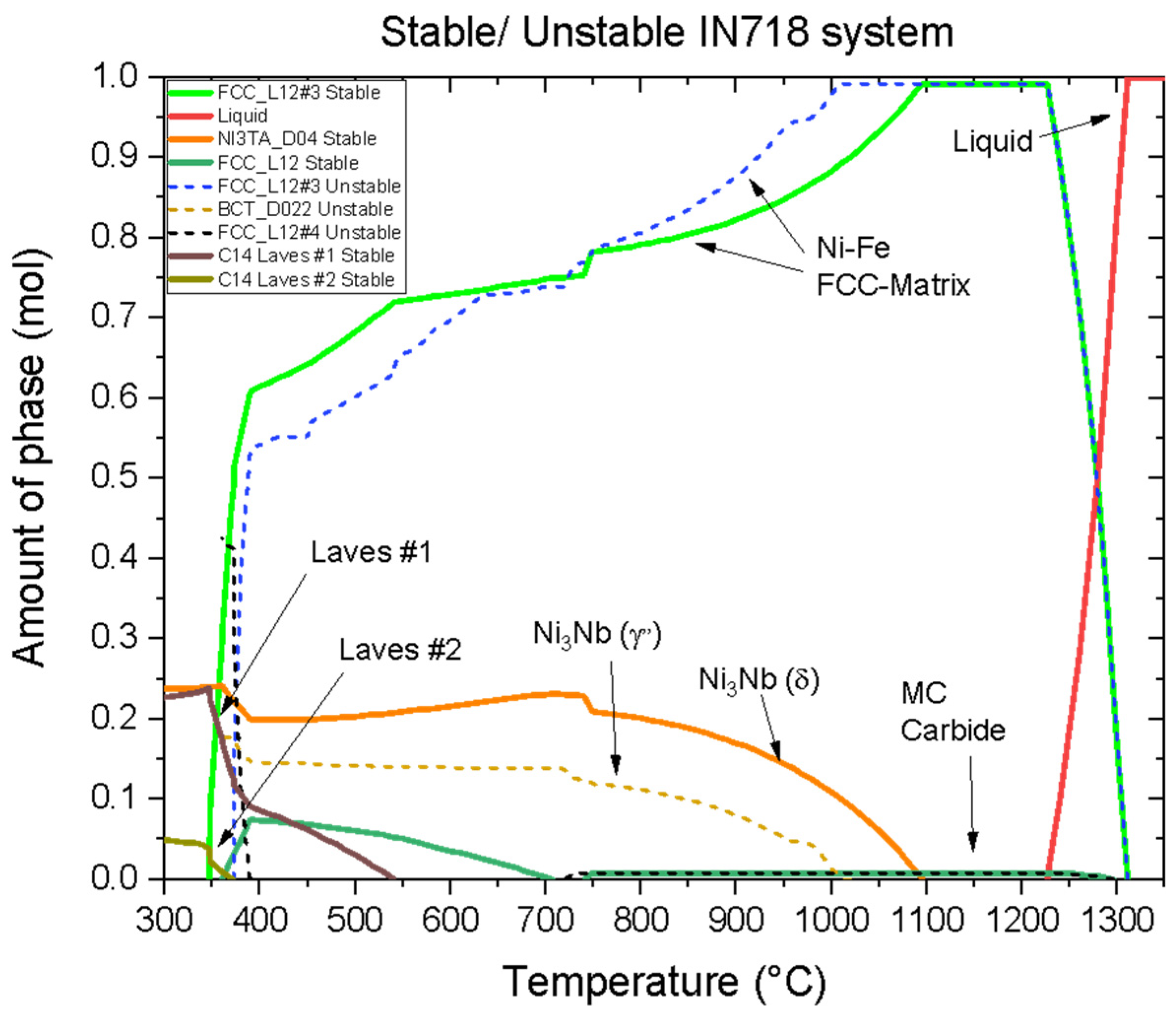

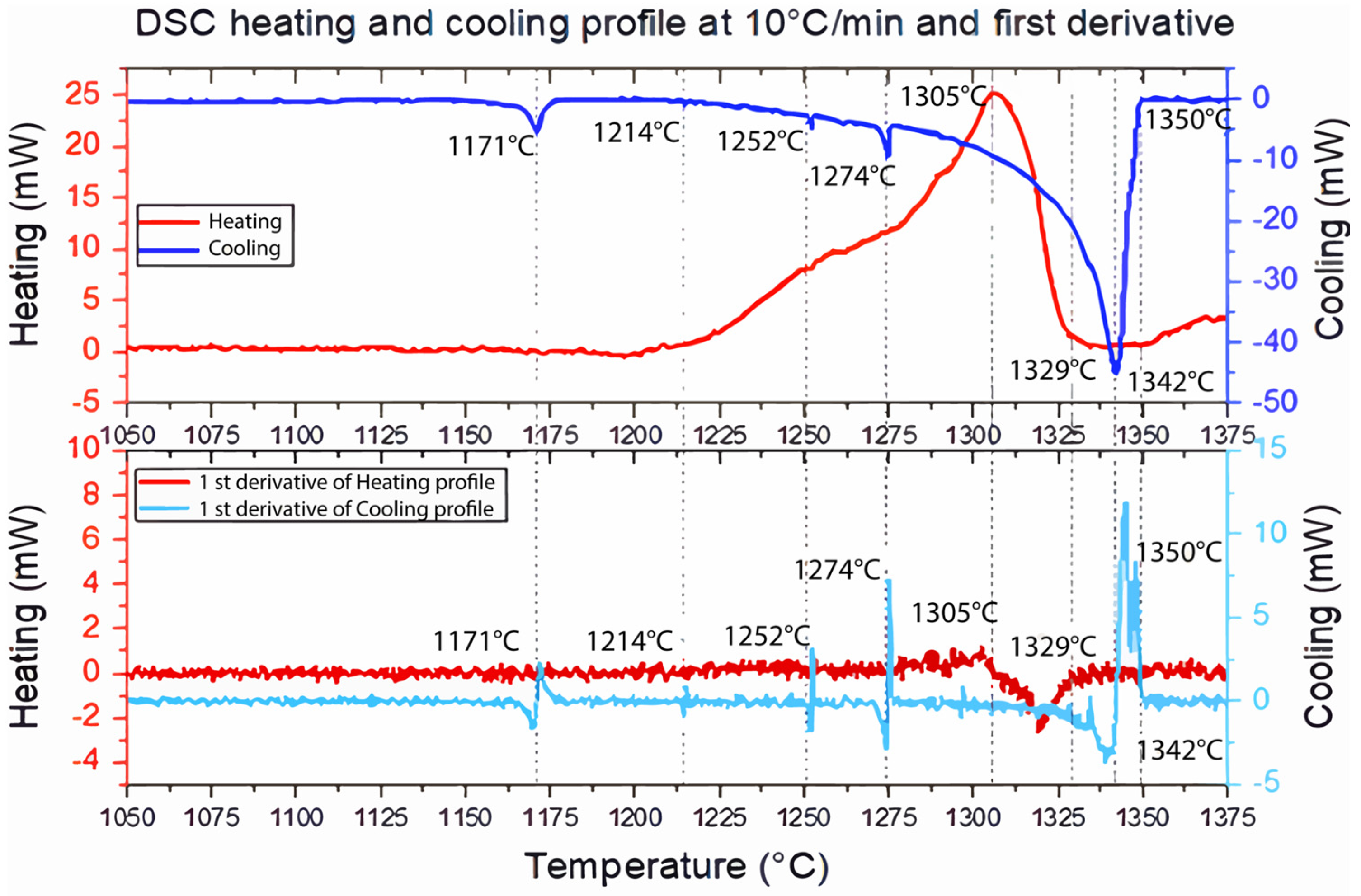

3.1. Phase Dynamics versus Temperature

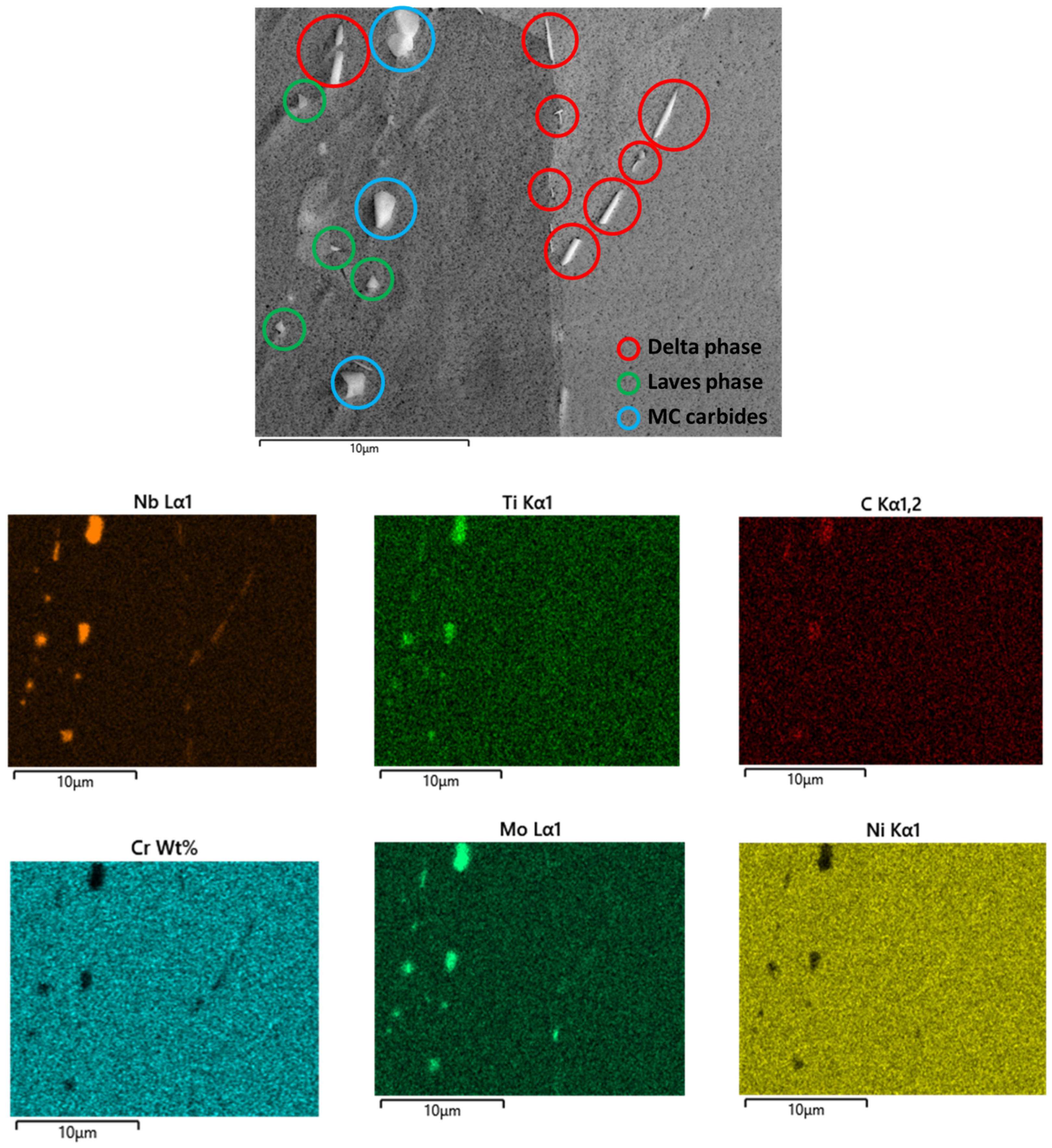

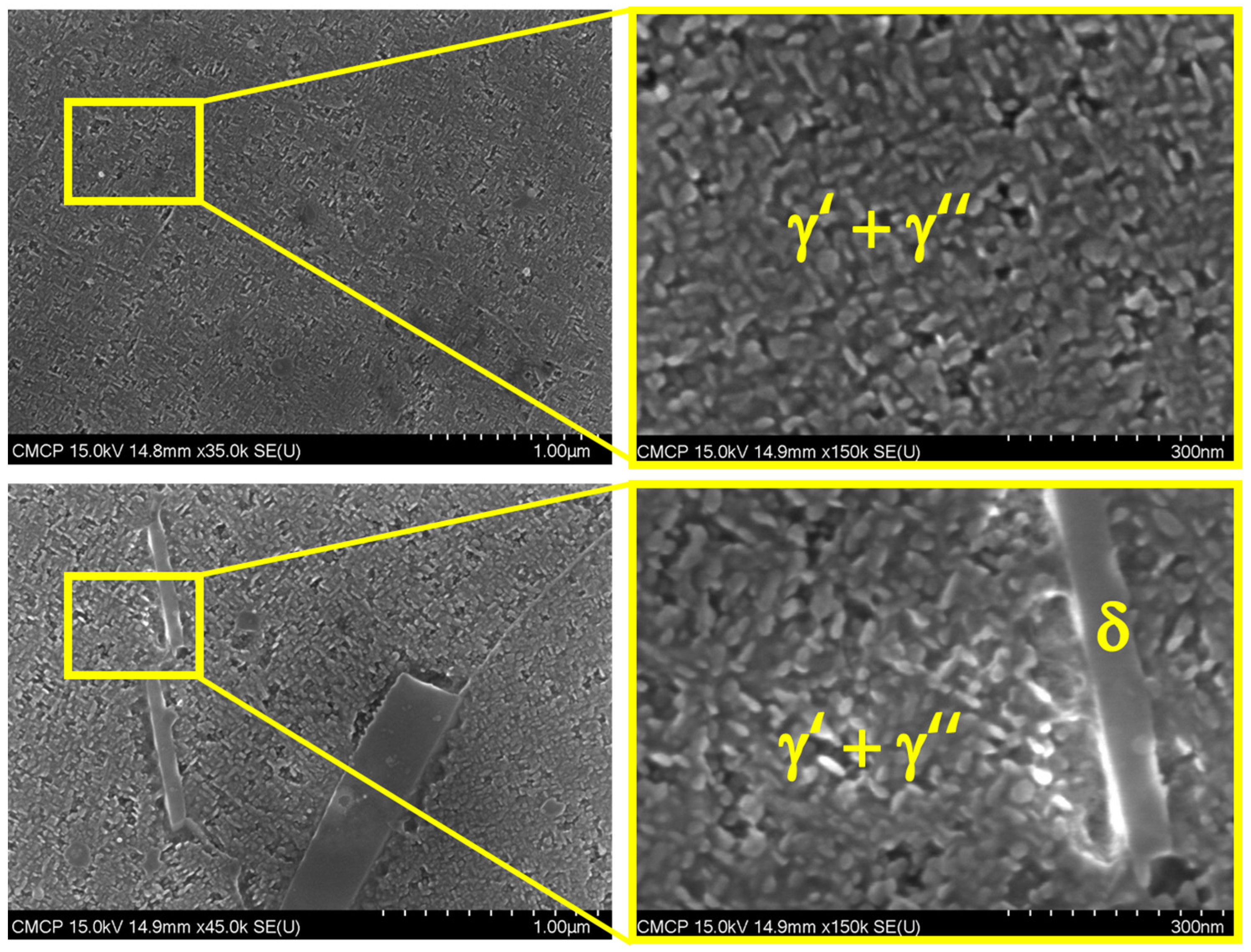

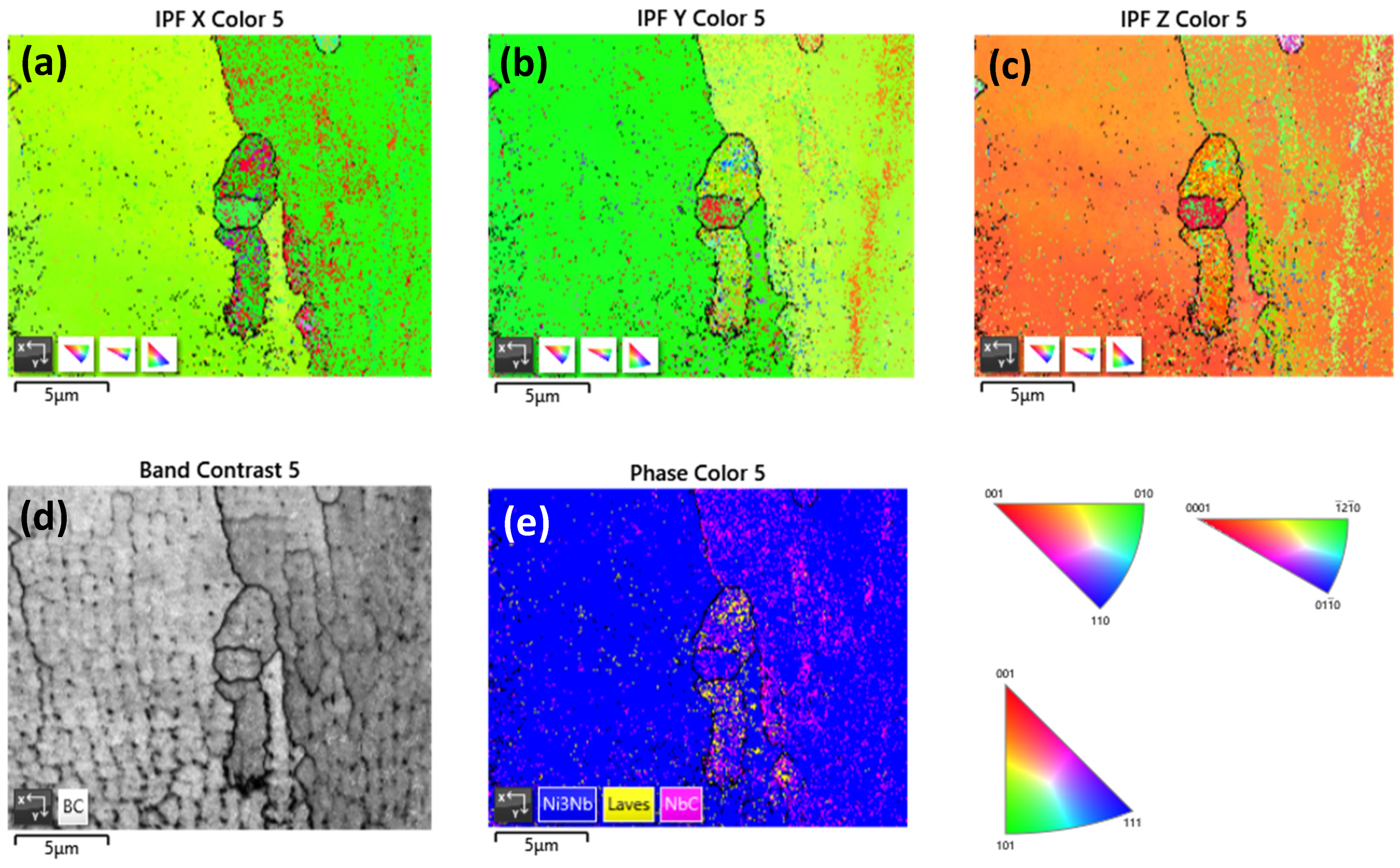

3.2. Microstructural Characterization

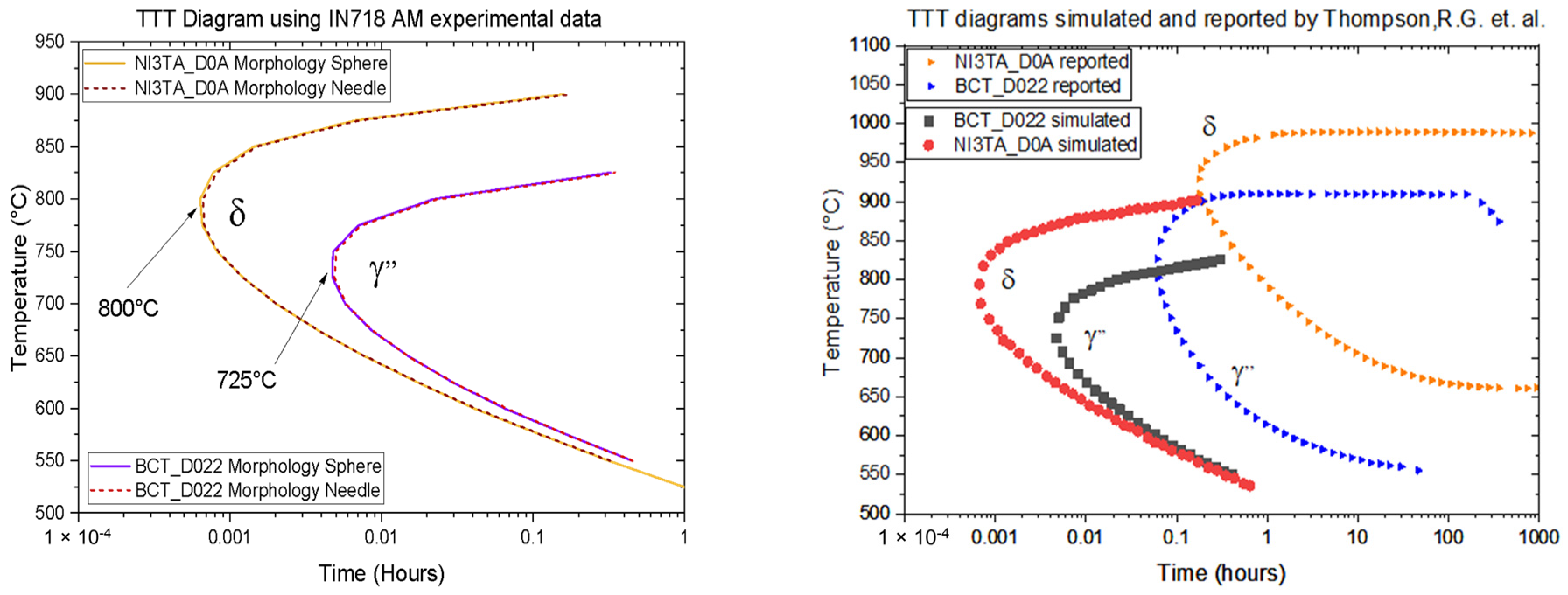

3.3. TTT Diagram

4. Conclusions

- The study successfully predicted the presence of stable and metastable phases and precipitates for a specific chemical composition of the alloy. However, the complex PBF manufacturing process induced intricate phase formations, including Laves phases, which competed with stable and metastable phases such as δ and γ′′, ultimately influencing the chemical composition of the matrix.

- Using DSC analysis and correlation with the Scheil–Gulliver solidification model, we highlighted the predominant formation of MC carbides, a result that was further supported by experimental findings. The presence of Laves phases had significant implications for the availability of chemical elements. Although quantifying the exact proportions of γ′′ and δ phases in a specific range proved challenging, the correlations provided valuable insights.

- Using SEM/EDX/EBSD, it was possible to successfully morphologically identify phases and precipitates based on their distinctive shapes, chemical compositions, and spatial distribution within the microstructure. The complexity of the AM production process significantly influenced the microstructure’s morphological and crystalline features, emphasizing the need for a thorough understanding of these conditions to assess the mechanical properties accurately. The confirmation of Laves, MC carbides, and δ phases through various analytical techniques underscored the complexity of the microstructure.

- Furthermore, we showed that a TTT diagram accurately predicts the solidification process of the δ and γ′′ for IN718 superalloy under AM conditions. The comparison between the precipitation of the stable δ phase and the metastable γ′′ highlighted the limitations of relying solely on TTT diagrams to depict the complete kinetic behavior of AM-produced samples. Local variations in chemical composition and other factors influenced thermal gradients and dendritic growth in the microstructure, calling for further research to comprehensively understand additive manufacturing and accurately evaluate its mechanical properties.

- The tailored TTT diagram provides critical information about the phase transformations and microstructural evolution that occur during the heat treatment of components produced by additive manufacturing. With this knowledge, engineers can design heat treatment cycles specifically suited for the AM-produced components. By adjusting the temperature, holding times, and cooling rates based on the TTT diagram, they can optimize the microstructure to achieve the desired material properties, such as strength, hardness, and ductility.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Tan, C.; Weng, F.; Sui, S.; Chew, Y.; Bi, G. Progress and perspectives in laser additive manufacturing of critical aeroengine materials. Int. J. Mach. Tools Manuf. 2021, 170, 103804. [Google Scholar] [CrossRef]

- Ghanavati, R.; Naffakh-Moosavy, H. Additive manufacturing of functionally graded metallic materials: A review of experimental and numerical studies. J. Mater. Res. Technol. 2021, 13, 1628–1664. [Google Scholar] [CrossRef]

- Chen, S.G.; Gao, H.J.; Wu, Q.; Gao, Z.H.; Zhou, X. Review on residual stresses in metal additive manufacturing: Formation mechanisms, parameter dependencies, prediction and control approaches. J. Mater. Res. Technol. 2022, 17, 2950–2974. [Google Scholar] [CrossRef]

- Cooke, S.; Ahmadi, K.; Willerth, S.; Herring, R. Metal additive manufacturing: Technology, metallurgy, and modeling. J. Manuf. Process. 2020, 57, 978–1003. [Google Scholar] [CrossRef]

- Lindwall, G.; Campbell, C.E.; Lass, E.A.; Zhang, F.; Stoudt, M.R.; Allen, A.J.; Levine, L.E. Simulation of TTT curves for additively manufactured Inconel 625. Metall. Mater. Trans. A Phys. 2019, 50, 457–467. [Google Scholar] [CrossRef]

- Paulonis, D.F.; Schirra, J.J. Alloy 718 at Pratt & Whitney-Historical Perspective and Future Challenges. In Superalloys 718, 625, 706 and Various Derivatives; TMS (The Minerals, Metals & Materials Society): Warrendale, PA, USA, 2001; pp. 13–23. [Google Scholar] [CrossRef]

- AMS 5662; Nickel Alloy, Corrosion and Heat-Resistant, Bars, Forgings, and Rings 52.5Ni-19Cr-3.0Mo-5.1Cb (Nb)-0.90Ti-0.50AI-18Fe Consumable Electrode or Vacuum Induction Melted 1775 °F (968 °C) Solution Heat Treated, Precipitation Hardenable—UNS N07718. SAE International: Warrendale, PA, USA, 2016. [CrossRef]

- AMS5383F; Nickel Alloy, Corrosion and Heat-Resistant, Investment Castings 52.5Ni-19Cr-3.0Mo-5.1Cb(Nb)-0.90Ti-0.60Al-18Fe Vacuum Melted Homogenization and Solution Heat Treated. SAE International: Warrendale, PA, USA, 2018. [CrossRef]

- Trosch, T.; Strößner, J.; Völkl, R.; Glatzel, U. Microstructure and Mechanical Properties of Selective Laser Melted Inconel 718 Compared to Forging and Casting. Mater. Lett. 2016, 164, 428–431. [Google Scholar] [CrossRef]

- Sanchez, S.; Smith, P.; Xu, Z.; Gaspard, G.; Hyde, C.J.; Wits, W.W.; Ashcroft, I.A.; Chen, H.; Clare, A.T. Powder Bed Fusion of nickel-based superalloys: A review. Int. J. Mach. Tools Manuf. 2021, 165, 103729. [Google Scholar] [CrossRef]

- Gallmeyer, T.G.; Moorthy, S.; Kappes, B.B.; Mills, M.J.; Amin-Ahmadi, B.; Stebner, A.P. Knowledge of process-structure-property relationships to engineer better heat treatments for laser powder bed fusion additive manufactured Inconel 718. Addit. Manuf. 2020, 31, 100977. [Google Scholar] [CrossRef]

- Xi, N.; Ni, Z.; Fang, X.; Zhou, Y.; Tang, K.; Zhang, H.; Huang, K. Role of δ-phase on Mechanical Behaviors of Additive Manufactured Inconel 718: Detailed Microstructure Analysis and Crystal Plasticity Modelling. Int. J. Plast. 2023, 168, 103708. [Google Scholar] [CrossRef]

- Franco-Correa, J.C.; Martínez-Franco, E.; Alvarado-Orozco, J.M.; Cáceres-Díaz, L.A.; Espinosa-Arbelaez, D.G.; Villada, J.A. Effect of Conventional Heat Treatments on the Microstructure and Microhardness of IN718 Obtained by Wrought and Additive Manufacturing. J. Mater. Eng. Perform. 2021, 30, 7035–7045. [Google Scholar] [CrossRef]

- De Jaeger, J.; Solas, D.; Baudin, T.; Fandeur, O.; Schmitt, J.H.; Rey, C. Inconel 718 single and multipass modelling of hot forging. In Proceedings of the Superalloys 2012: 12th International Symposium on Superalloys, Champion, PA, USA, 9 September 2012; John Wiley&Sons Inc.: Hoboken, NJ, USA, 2012; pp. 663–672. Available online: https://hal.science/hal-00771436 (accessed on 1 August 2023).

- Han, W.; Wan, M.; Zhao, R.; Kang, H.; Rao, Y. Microstructural evolution and mechanical properties of brazed IN718 ultrathin-walled capillary structure using different particulate reinforced filler alloy. Chin. J. Aero. 2022, 35, 550–564. [Google Scholar] [CrossRef]

- ASTM D3418; 12 Standard Test Method for Transition Temperatures and Enthalpies of Fusion and Crystallization of Polymers by Differential Scanning Calorimetry. ASTM International: West Conshohocken, PA, USA, 2021.

- ASTM E407-07(2015)e1; Standard Practice for Microetching Metals and Alloys. ASTM International: West Conshohocken, PA, USA, 2015. [CrossRef]

- Rayner, A.J.; Corbin, S.F. Grain growth activation during supersolidus liquid phase sintering in a metal injection molded nickel-base superalloy. Mater. Today Commun. 2021, 26, 101769. [Google Scholar] [CrossRef]

- Shafiee, A.; Moon, J.; Kim, H.S.; Jahazi, M.; Nili-Ahmadabadi, M. Precipitation behaviour and mechanical properties of a new wrought high entropy superalloy. Mater. Sci. Eng. A 2019, 749, 271–280. [Google Scholar] [CrossRef]

- Shi, X.; Duan, S.; Yang, W.; Guo, H.; Guo, J. Solidification and segregation behaviors of superalloy IN718 at a slow cooling rate. Materials 2018, 11, 2398. [Google Scholar] [CrossRef]

- Miao, Z.J.; Shan, A.D.; Wu, Y.B.; Jun, L.U.; Ying, H.U.; Liu, J.L.; Song, H.W. Effects of P and B addition on as-cast microstructure and homogenization parameter of Inconel 718 alloy. Trans. Nonferrous Met. Soc. China 2012, 22, 318–323. [Google Scholar] [CrossRef]

- Vyazovkin, S.; Koga, N.; Schick, C. Handbook of Thermal Analysis and Calorimetry: Recent Advances, Techniques, and Applications; Elsevier: Amsterdam, The Netherland, 2018. [Google Scholar]

- Rielli, V.V.; Piglione, A.; Pham, M.S.; Primig, S. On the detailed morphological and chemical evolution of phases during laser powder bed fusion and common post-processing heat treatments of IN718. Addit. Manuf. 2022, 50, 102540. [Google Scholar] [CrossRef]

- Knorovsky, G.A.; Cieslak, M.J.; Headley, T.J.; Romig, A.D.; Hammetter, W.F. Inconel 718: A solidification diagram. Metall. Mater. Trans. A Phys. 1989, 20, 2149–2158. [Google Scholar] [CrossRef]

- Tang, Y.T.; Panwisawas, C.; Ghoussoub, J.N.; Gong, Y.; Clark, J.W.; Németh, A.A.; McCartney, D.G.; Reed, R.C. Alloys-by-design: Application to new superalloys for additive manufacturing. Acta Mater. 2021, 202, 417–436. [Google Scholar] [CrossRef]

- Zhao, Z.; Li, L.; Yang, W.; Zeng, Y.; Lian, Y.; Yue, Z. A comprehensive study of the anisotropic tensile properties of laser additive manufactured Ni-based superalloy after heat treatment. Int. J. Plast. 2022, 148, 103147. [Google Scholar] [CrossRef]

- Hasani, N.; Dharmendra, C.; Sanjari, M.; Fazeli, F.; Amirkhiz, B.S.; Pirgazi, H.; Janaki-Ram, G.D.; Mohammadi, M. Laser powder bed fused Inconel 718 in stress-relieved and solution heat-treated conditions. Mater. Charact. 2021, 181, 111499. [Google Scholar] [CrossRef]

- Cao, M.; Zhang, D.; Gao, Y.; Chen, R.; Huang, G.; Feng, Z.; Poprawe, R.; Schleifenbaum, J.H.; Ziegler, S. The effect of homogenization temperature on the microstructure and high temperature mechanical performance of SLM-fabricated IN718 alloy. Mater. Sci. Eng. A 2021, 801, 140427. [Google Scholar] [CrossRef]

- Qin, H.; Bi, Z.; Yu, H.; Feng, G.; Zhang, R.; Guo, X.; Chi, H.; Du, J.; Zhang, J. Assessment of the stress-oriented precipitation hardening designed by interior residual stress during aging in IN718 superalloy. Mater. Sci. Eng. A 2018, 728, 183–195. [Google Scholar] [CrossRef]

- Lin, Y.Y.; Schleifer, F.; Fleck, M.; Glatzel, U. On the interaction between γ″ precipitates and dislocation microstructures in Nb containing single crystal nickel-base alloys. Mater. Charact. 2020, 165, 110389. [Google Scholar] [CrossRef]

- Zhang, S.; Wang, L.; Lin, X.; Yang, H.; Li, M.; Lei, L.; Huang, W. Precipitation behavior of δ phase and its effect on stress rupture properties of selective laser-melted Inconel 718 superalloy. Composites Part B Eng. 2021, 224, 109202. [Google Scholar] [CrossRef]

- Jang, J.; Van, D.; Lee, S.H. Precipitation kinetics of secondary phases induced by heat accumulation in the deposit of Inconel 718. Addit. Manuf. 2022, 55, 102831. [Google Scholar] [CrossRef]

- Yu, X.; Lin, X.; Tan, H.; Hu, Y.; Zhang, S.; Liu, F.; Yang, H.; Huang, W. Microstructure and fatigue crack growth behavior of Inconel 718 superalloy manufactured by laser directed energy deposition. Int. J. Fatigue 2021, 143, 106005. [Google Scholar] [CrossRef]

- Thompson, R.G.; Dobbs, J.; Mayo, D. The effect of heat treatment on microfissuring in alloy 718. Weld J. 1986, 65, 299–304. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Franco-Correa, J.C.; Martínez-Franco, E.; Cruz-González, C.E.; Salgado-López, J.M.; Villada-Villalobos, J.A. Tailored Time–Temperature Transformation Diagram for IN718 Alloy Obtained via Powder Bed Fusion Additive Manufacturing: Phase Behavior and Precipitation Dynamic. Materials 2023, 16, 7280. https://doi.org/10.3390/ma16237280

Franco-Correa JC, Martínez-Franco E, Cruz-González CE, Salgado-López JM, Villada-Villalobos JA. Tailored Time–Temperature Transformation Diagram for IN718 Alloy Obtained via Powder Bed Fusion Additive Manufacturing: Phase Behavior and Precipitation Dynamic. Materials. 2023; 16(23):7280. https://doi.org/10.3390/ma16237280

Chicago/Turabian StyleFranco-Correa, Julio Cesar, Enrique Martínez-Franco, Celso Eduardo Cruz-González, Juan Manuel Salgado-López, and Jhon Alexander Villada-Villalobos. 2023. "Tailored Time–Temperature Transformation Diagram for IN718 Alloy Obtained via Powder Bed Fusion Additive Manufacturing: Phase Behavior and Precipitation Dynamic" Materials 16, no. 23: 7280. https://doi.org/10.3390/ma16237280

APA StyleFranco-Correa, J. C., Martínez-Franco, E., Cruz-González, C. E., Salgado-López, J. M., & Villada-Villalobos, J. A. (2023). Tailored Time–Temperature Transformation Diagram for IN718 Alloy Obtained via Powder Bed Fusion Additive Manufacturing: Phase Behavior and Precipitation Dynamic. Materials, 16(23), 7280. https://doi.org/10.3390/ma16237280