Study on the Effect of Recycled Fine Aggregate Qualities on Fly Ash/GGBS-Based Geopolymer Mortar

Abstract

:1. Introduction

2. Materials and Experimental Programs

2.1. Materials

2.2. Mixing and Preparing the Specimens

2.3. Testing

3. Result and Discussion

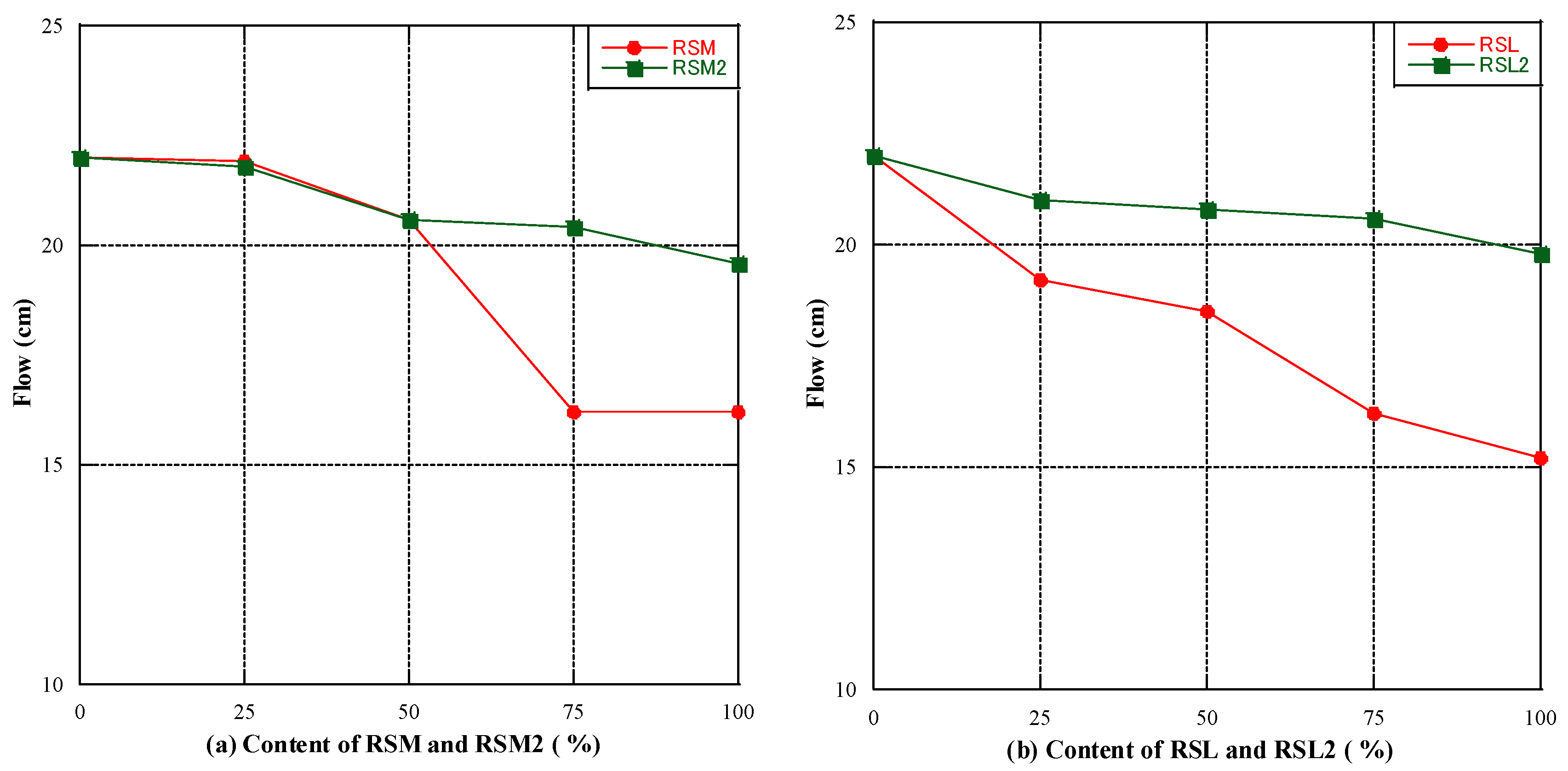

3.1. Fresh Properties

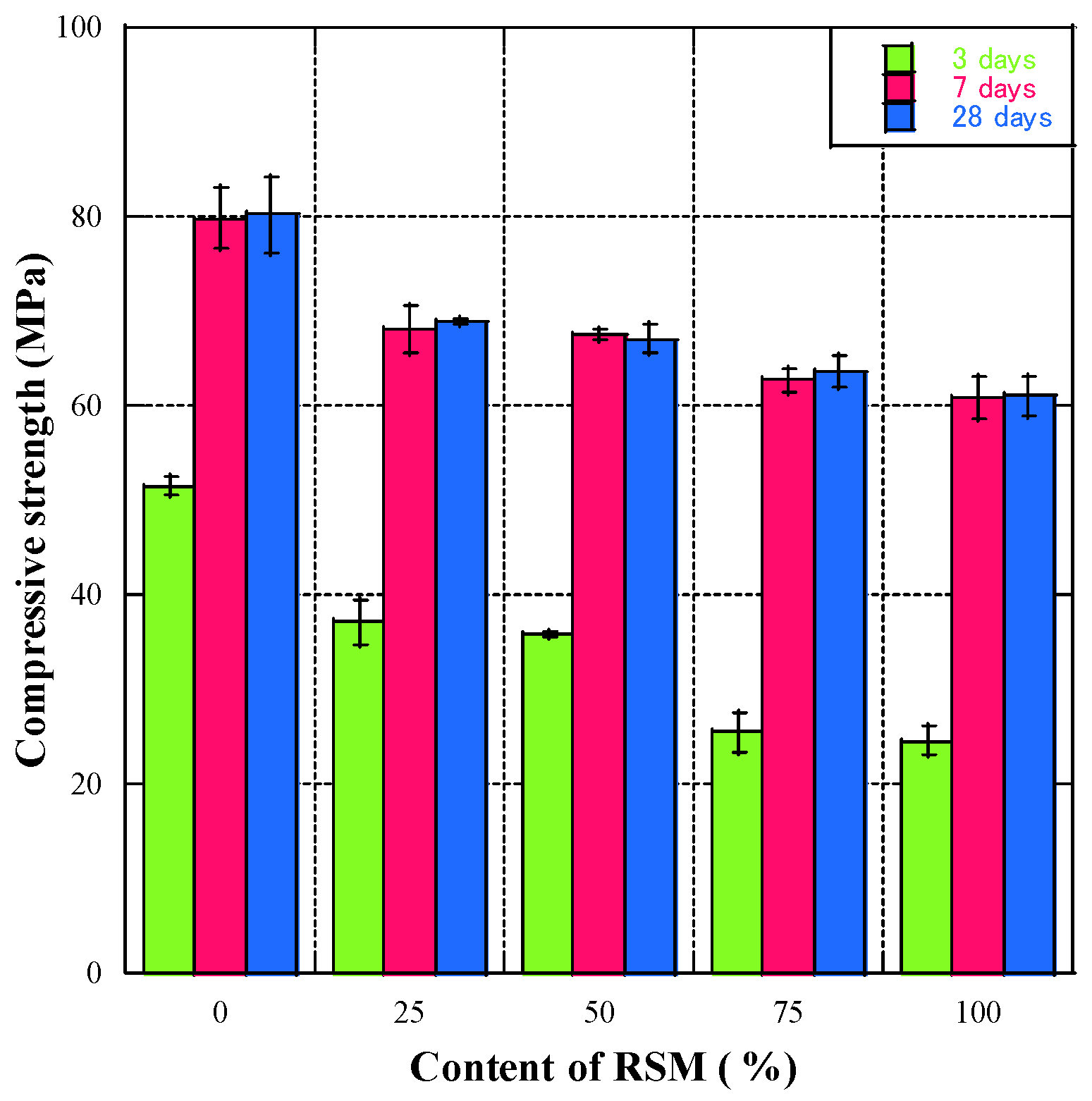

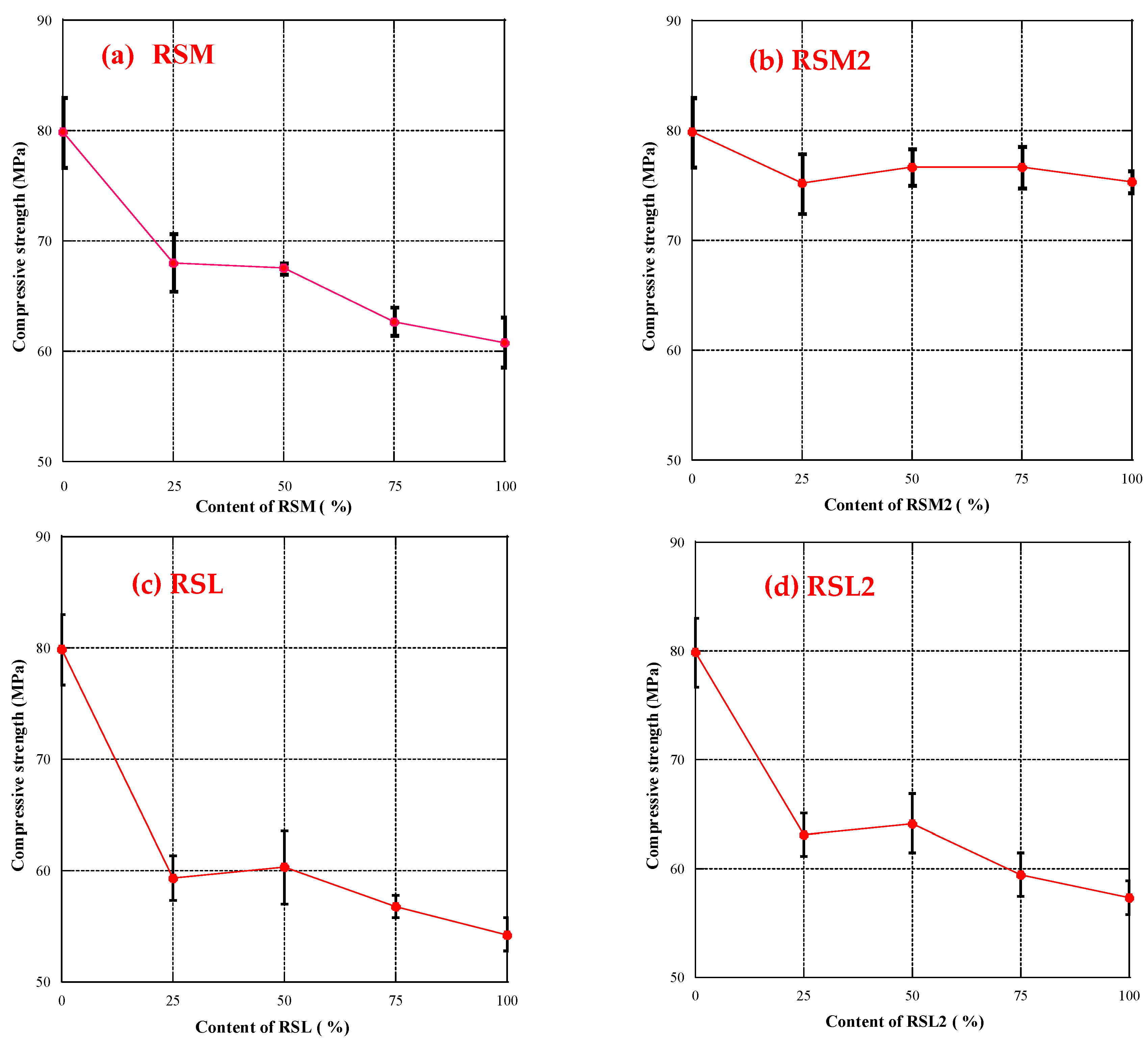

3.2. Compressive Strength

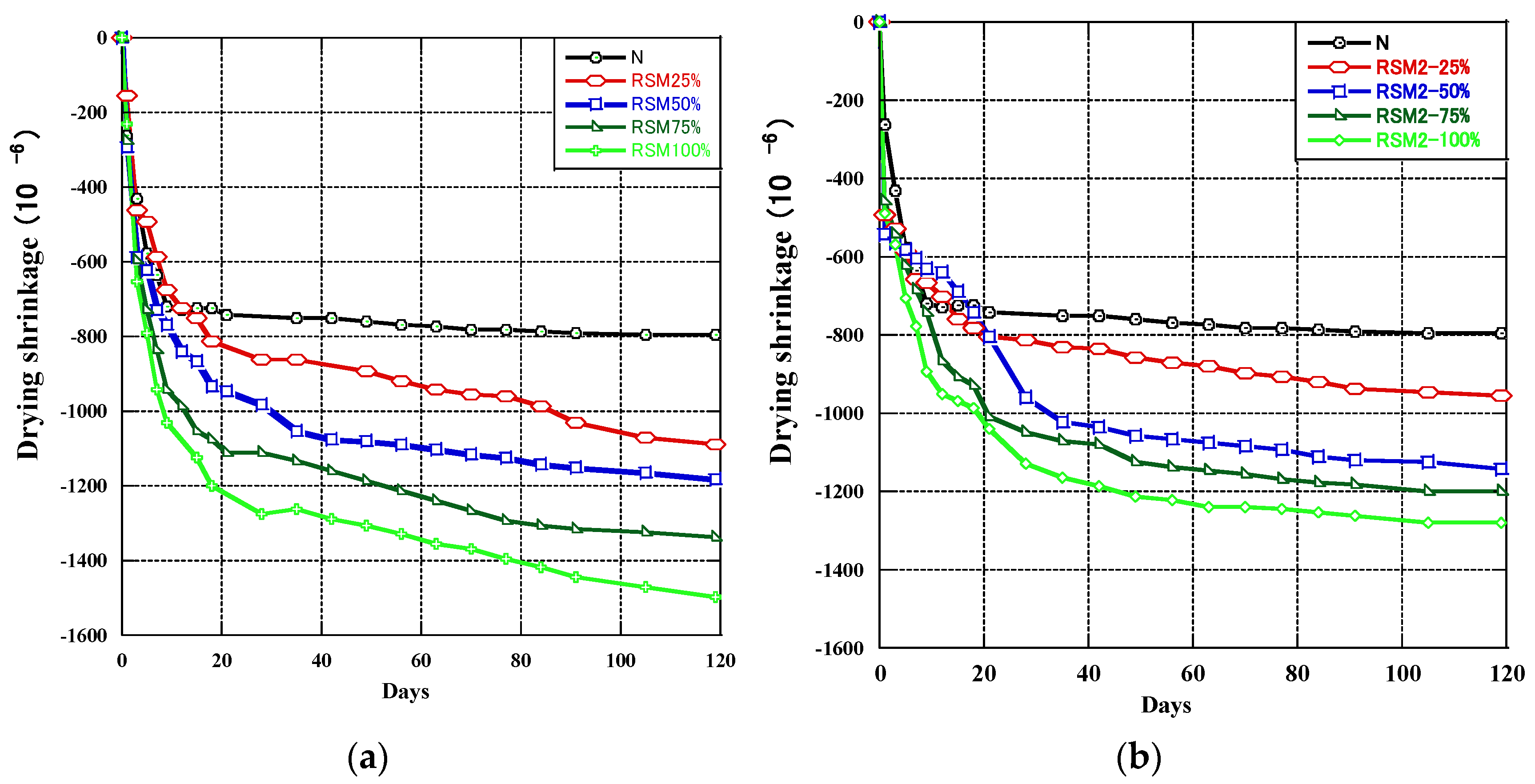

3.3. Drying Shrinkage

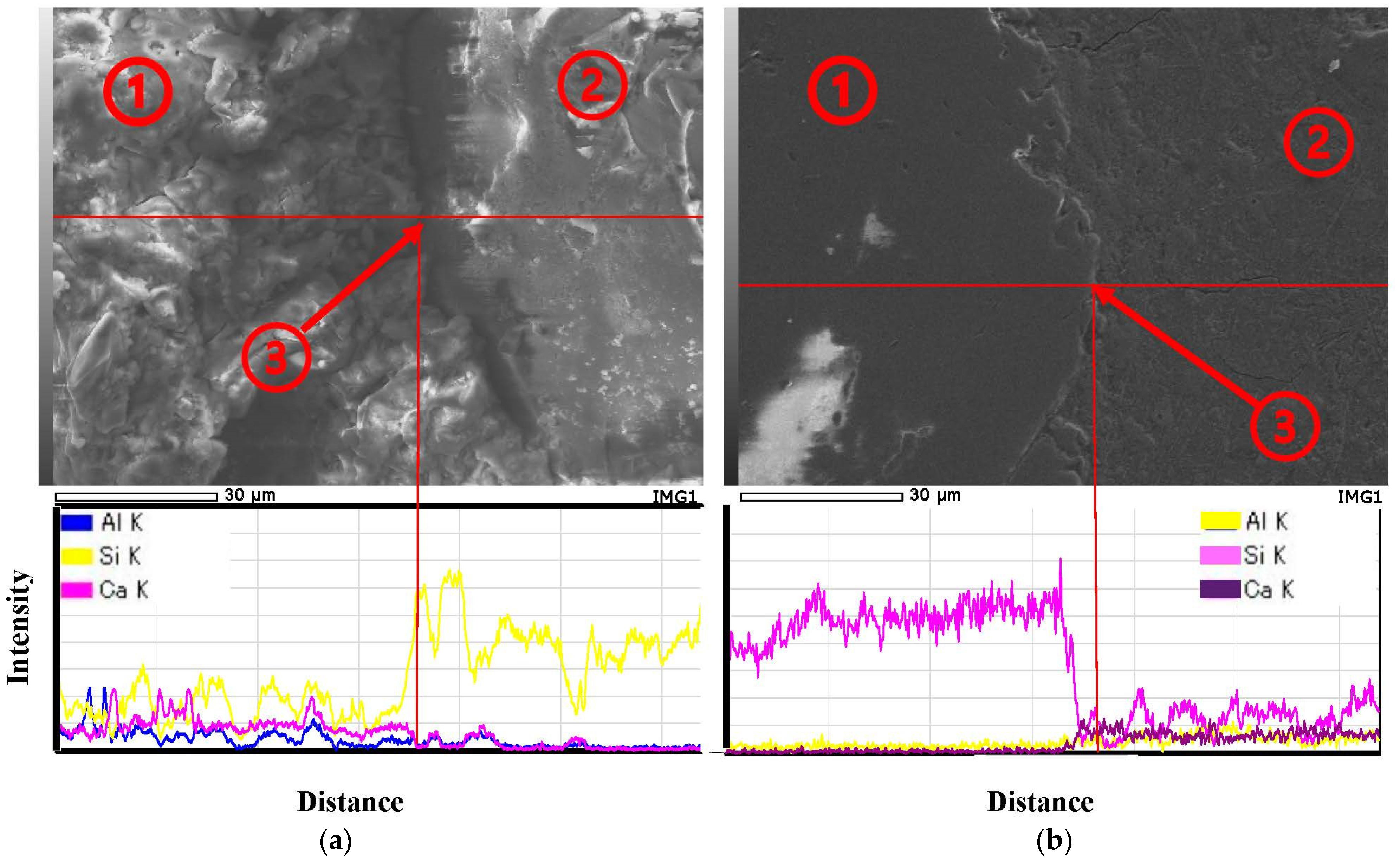

3.4. SEM

3.5. Correlation of Porosity and Compressive Strength of the Recycled Geopolymer Mortar

4. Conclusions

- RFA distinctly affects the flowability of geopolymer mortar. Opting for a higher-quality RFA, such as Class M, and administering appropriate preprocessing of RFA, such as by eliminating particles below 0.15 mm, can efficaciously augment the flowability of the mortar.

- The compressive strength growth of RGM is concentrated in the early curing stage. The addition of a certain amount of RFA leads to a decline in strength. The quality of the sand in the mortar has a great impact on the mechanical properties of the mortar. In the case of using the same dosage, the compressive strength of mortar using RSL is significantly lower than that of using RSM.

- Processing RFA by removing some fine particles of small diameter can effectively improve its performance in geopolymer mortar. The higher the inclusion level (above 75%), the more pronounced is the advantage in enhancing the compressive strength compared to unprocessed RFA.

- RFA adversely affects the drying shrinkage of geopolymer mortar. However, through proper processing, such as the removal of fine particles, its detrimental impact on the mortar’s drying shrinkage can be significantly mitigated.

- In RGM, RFA can result in a more compact ITZ than NA, which is one of the reasons why the compressive strength does not significantly decrease when the dosage of RFA increase.

- There is a positive correlation between the pore volume and the compressive strength of geopolymer mortar using RFA, in contrast to the conclusion in cement mortar.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete–A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar]

- Global Energy Review 2021, Global Energy Review 2021—Analysis—IEA. Available online: https://iea.blob.core.windows.net/assets/d0031107-401d-4a2f-a48b-9eed19457335/GlobalEnergyReview2021.pdf (accessed on 14 October 2023).

- Freedonia Group. World construction aggregates. Available online: https://cdn.cocodoc.com/cocodoc-form-pdf/pdf/58304896--World-Construction-.pdf (accessed on 17 February 2023).

- Evangelista, L.; Guedes, M.; de Brito, J.; Ferro, A.; Pereira, M. Physical, chemical and mineralogical properties of fine recycled aggregates made from concrete waste. Constr. Build. Mater. 2015, 86, 178–188. [Google Scholar] [CrossRef]

- Kim, J. Influence of quality of recycled aggregates on the mechanical properties of recycled aggregate concretes: An overview. Constr. Build. Mater. 2022, 328, 127071. [Google Scholar] [CrossRef]

- Peng, C.-L.; Grosskopf, K.R.; Kibert, C.J. Construction Waste Management and Recycling Strategies in the United States. In Proceedings of the First Conference of CIB TG 16 on Sustainable Construction, Tampa, FL, USA, 6–9 November 1994. [Google Scholar]

- Lu, W.; Webster, C.; Chen, K.; Zhang, X.; Chen, X. Computational Building Information Modelling for construction waste management: Moving from rhetoric to reality. Renew. Sustain. Energy Rev. 2017, 68, 587–595. [Google Scholar] [CrossRef]

- Klepa, R.B.; Medeiros, M.F.; Franco, M.A.C.; Tamberg, E.T.; Farias, T.M.D.B.; Paschoalin Filho, J.A.; Berssaneti, F.T.; Santana, J.C.C. Reuse of construction waste to produce thermoluminescent sensor for use in highway traffic control. J. Clean. Prod. 2019, 209, 250–258. [Google Scholar] [CrossRef]

- Liu, B.; Feng, C.; Deng, Z. Shear behavior of three types of recycled aggregate concrete. Constr. Build. Mater. 2019, 217, 557–572. [Google Scholar] [CrossRef]

- Kumar, G.S. Influence of fluidity on mechanical and permeation performances of recycled aggregate mortar. Constr. Build. Mater. 2019, 213, 404–412. [Google Scholar] [CrossRef]

- Kanadasan, J.; Razak, H.A. Utilization of palm oil clinker as cement replacement material. Materials 2015, 8, 8817–8838. [Google Scholar] [CrossRef]

- Karim, M.R.; Hashim, H.; Abdul Razak, H.; Yusoff, S. Characterization of palm oil clinker powder for utilization in cement-based applications. Constr. Build. Mater. 2017, 135, 21–29. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

- Kumar, M.L.; Revathi, V. Microstructural Properties of Alkali-Activated Metakaolin and Bottom Ash Geopolymer. Arab. J. Sci. Eng. 2020, 45, 4235–4246. [Google Scholar] [CrossRef]

- Imtiaz, L.; Rehman, S.K.U.; Memon, S.A.; Khan, M.K.; Javed, F. A review of recent developments and advances in eco-friendly geopolymer concrete. Appl. Sci. 2020, 10, 7838. [Google Scholar] [CrossRef]

- Haddad, R.H.; Alshbuol, O. Production of geopolymer concrete using natural pozzolan: A parametric study. Constr. Build. Mater. 2016, 114, 699–707. [Google Scholar] [CrossRef]

- Albidah, A.; Alqarni, A.S.; Abbas, H.; Almusallam, T.; Al-Salloum, Y. Behavior of Metakaolin-Based geopolymer concrete at ambient and elevated temperatures. Constr. Build. Mater. 2022, 317, 125910. [Google Scholar] [CrossRef]

- Dapena, E.; Alaejos, P.; Lobet, A.; Pérez, D. Effect of recycled sand content on characteristics of mortars and concretes. J. Mater. Civ. Eng. 2011, 23, 414–422. [Google Scholar] [CrossRef]

- Zhao, Z.; Remond, S.; Damidot, D.; Xu, W. Influence of fine recycled concrete aggregates on the properties of mortars. Constr. Build. Mater. 2015, 81, 179–186. [Google Scholar] [CrossRef]

- Braga, M.; De Brito, J.; Veiga, R. Incorporation of fine concrete aggregates in mortars. Constr. Build. Mater. 2012, 36, 960–968. [Google Scholar] [CrossRef]

- Neno, C.; Brito, J.; Veiga, R. Using fine recycled concrete aggregate for mortar production. Mater. Res. 2014, 17, 168–177. [Google Scholar] [CrossRef]

- Katz, A. Treatments for the improvement of recycled aggregate. J. Mater. Civ. Eng. 2004, 16, 597–603. [Google Scholar] [CrossRef]

- Luo, M.; Dai, J.; Ding, Z.; Liu, Y. Properties of Mortar Containing Recycled Fine Aggregate Modified by Microbial Mineralization. Buildings 2022, 12, 2035. [Google Scholar] [CrossRef]

- Tateyashiki, H.; Shima, H.; Matsumoto, Y.; Koga, Y. Properties of concrete with high quality recycled aggregate by heat and rubbing method. Proc. JCI 2001, 23, 61–66. [Google Scholar]

- Tam, V.W.Y.; Tam, C.M.; Le, K.N. Removal of cement mortar remains from recycled aggregate using pre-soaking approaches. Resour. Conserv. Recycl. 2007, 50, 82–101. [Google Scholar] [CrossRef]

- Zhang, J.; Shi, C.; Li, Y.; Pan, X.; Poon, C.-S.; Xie, Z. Influence of carbonated recycled concrete aggregate on properties of cement mortar. Constr. Build. Mater. 2015, 98, 1–7. [Google Scholar] [CrossRef]

- Li, B.; Hou, S.; Duan, Z.; Li, L.; Guo, W. Rheological behavior and compressive strength of concrete made with recycled fine aggregate of different size range. Constr. Build. Mater. 2021, 268, 12117. [Google Scholar] [CrossRef]

- Saba, M.; Assaad, J.J. Effect of recycled fine aggregates on performance of geopolymer masonry mortars. Constr. Build. Mater. 2021, 279, 122461. [Google Scholar] [CrossRef]

- Hasnaoui, A.; Ghorbel, E.; Wardeh, G. Performance of metakaolin/slag-based geopolymer concrete made with recycled fine and coarse aggregates. J. Build. Eng. 2021, 42, 102813. [Google Scholar] [CrossRef]

- Lyu, B.-C.; Guo, L.-P.; Fei, X.-P.; Wu, J.-D.; Bian, R.-S. Preparation and properties of green high ductility geopolymer composites incorporating recycled fine brick aggregate. Cem. Concr. Compos. 2023, 139, 105054. [Google Scholar] [CrossRef]

- Zhu, P.; Hua, M.; Liu, H.; Wang, X.; Chen, C. Interfacial evaluation of geopolymer mortar prepared with recycled geopolymer fine aggregates. Constr. Build. Mater. 2020, 259, 119849. [Google Scholar] [CrossRef]

- JIS A 6201; Fly Ash for Use in Concrete. Japanese Industrial Standard Committee: Tokyo, Japan, 2015.

- JIS A 6206; Ground Granulated Blast-Furnace Slag for Concrete. Japanese Industrial Standard Committee: Tokyo, Japan, 2013.

- Hadi, M.N.S.; Al-Azzawi, M.; Yu, T. Effects of fly ash characteristics and alkaline activator components on compressive strength of fly ash-based geopolymer mortar. Constr. Build. Mater. 2018, 175, 41–54. [Google Scholar] [CrossRef]

- JIS A 5022; Recycled Aggregate Concrete-Class M. Japanese Industrial Standard Committee: Tokyo, Japan, 2018.

- Narayanan, A.; Shanmugasundaram, P. An experimental investigation on flyash-based geopolymer mortar under different curing regime for thermal analysis. Energy Build. 2017, 138, 539–545. [Google Scholar] [CrossRef]

- JIS R 5201; Physical Testing Methods for Cement. Japanese Industrial Standard Committee: Tokyo, Japan, 2013.

- JIS A 1108; Method of Test for Compressive Strength of Concrete and Mortar. Japanese Industrial Standard Committee: Tokyo, Japan, 2018.

- JIS A 1129-2; Method of Measurement for Length Change of Mortar and Concrete—Part 2: Method with Contact-Type Strain Gauge. Japanese Industrial Standard Committee: Tokyo, Japan, 2010.

- Hassan, I.O.; Ismail, M.; Forouzani, P.; Majid, Z.A.; Mirza, J. Flow characteristics of ternary blended self-consolidating cement mortars incorporating palm oil fuel ash and pulverised burnt clay. Constr. Build. Mater. 2014, 64, 253–260. [Google Scholar] [CrossRef]

- Lachemi, M.; Hossain, K.M.A.; Patel, R.; Shehata, M.; Bouzoubaâ, N. Influence of paste/mortar rheology on the flow characteristics of high-volume fly ash self-consolidating concrete. Mag. Concr. Res. 2007, 59, 517–528. [Google Scholar] [CrossRef]

- Butler, L.J.; West, J.S.; Tighe, S.L. Towards the classification of recycled concrete aggregates: Influence of fundamental aggregate properties on recycled concrete performance. J. Sustain. Cement-Based Mater. 2014, 3, 140–163. [Google Scholar] [CrossRef]

- Kirthika, S.K.; Singh, S.; Chourasia, A. Alternative fine aggregates in production of sustainable concrete—A review. J. Clean. Prod. 2020, 268, 122089. [Google Scholar]

- De Vargas, A.S.; Dal Molin, D.C.; Vilela, A.C.; Silva, F.J.D.; Pavão, B.; Veit, H. The effects of Na2O/SiO2 molar ratio, curing temperature and age on compressive strength, morphology and microstructure of alkali-activated fly ash-based geopolymers. Cement Concr. Compos. 2011, 33, 653–660. [Google Scholar] [CrossRef]

- Görhan, G.; Kürklü, G. The influence of the NaOH solution on the properties of the fly ash-based geopolymer mortar cured at different temperatures. Compos. Part B Eng. 2014, 58, 371–377. [Google Scholar] [CrossRef]

- Behera, M.; Minocha, A.K.; Bhattacharyya, S.K. Flow behavior, microstructure, strength and shrinkage properties of self-compacting concrete incorporating recycled fine aggregate. Constr. Build. Mater. 2019, 228, 116819. [Google Scholar] [CrossRef]

- Thomas, B.S.; Yang, J.; Bahurudeen, A.; Chinnu, S.N.; Abdalla, J.A.; Hawileh, R.A.; Hamada, H.M. Geopolymer concrete incorporating recycled aggregates: A comprehensive review. Clean. Mater. 2022, 3, 100056. [Google Scholar] [CrossRef]

- Sáez, P.V.; Osmani, M. A diagnosis of construction and demolition waste generation and recovery practice in the European Union. J. Clean. Prod. 2019, 241, 118400. [Google Scholar] [CrossRef]

- Katz, A.; Kulisch, D. Performance of mortars containing recycled fine aggregate from construction and demolition waste. Mater. Struct. 2017, 50, 199. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete; Longman: London, UK, 1995. [Google Scholar]

- Neville, A.M.; Brooks, J.J. Concrete Technology; Longman Scientific & Technical: London, UK, 1987. [Google Scholar]

- Silva, R.V.; De Brito, J.; Dhir, R.K. Prediction of the shrinkage behavior of recycled aggregate concrete: A review. Constr. Build. Mater. 2015, 77, 327–339. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Lehman, D.E.; Geng, Y.; Kuder, K. Time-dependent drying shrinkage model for concrete with coarse and fine recycled aggregate. Cement Concr. Compos. 2020, 105, 103426. [Google Scholar] [CrossRef]

- Medjigbodo, S.; Bendimerad, A.Z.; Rozière, E.; Loukili, A. How do recycled concrete aggregates modify the shrinkage and self-healing properties? Cement Concr. Compos. 2018, 86, 72–86. [Google Scholar] [CrossRef]

- Duan, Z.H.; Poon, C.S. Properties of recycled aggregate concrete made with recycled aggregates with different amounts of old adhered mortars. Mater. Des. 2014, 58, 19–29. [Google Scholar] [CrossRef]

- Pedro, D.D.; De Brito, J.; Evangelista, L. Structural concrete with simultaneous incorporation of fine and coarse recycled concrete aggregates: Mechanical, durability and long-term properties. Constr. Build. Mater. 2017, 154, 294–309. [Google Scholar] [CrossRef]

- Wang, Q.; Geng, Y.; Wang, Y.; Zhang, H. Drying shrinkage model for recycled aggregate concrete accounting for the influence of parent concrete. Eng. Struct. 2020, 202, 109888. [Google Scholar] [CrossRef]

- Wu, H.; Wang, C.; Ma, Z. Drying shrinkage, mechanical and transport properties of sustainable mortar with both recycled aggregate and powder from concrete waste. J. Build. Eng. 2022, 49, 104048. [Google Scholar] [CrossRef]

- Mao, Y.; Liu, J.; Shi, C. Autogenous shrinkage and drying shrinkage of recycled aggregate concrete: A review. J. Clean. Prod. 2021, 295, 126435. [Google Scholar] [CrossRef]

- Diamond, S.; Huang, J. The ITZ in concrete—A different view based on image analysis and SEM observations. Cement Concr. Compos. 2001, 23, 179–188. [Google Scholar] [CrossRef]

- Liu, Q.; Xiao, J.; Sun, Z. Experimental study on the failure mechanism of recycled concrete. Cement Concr. Res. 2011, 41, 1050–1057. [Google Scholar] [CrossRef]

- Colangelo, F.; Messina, F.; Cioffi, R. Recycling of MSWI fly ash by means of cementitious double step cold bonding pelletization: Technological assessment for the production of lightweight artificial aggregates. J. Hazard. Mater. 2015, 299, 181–191. [Google Scholar] [CrossRef] [PubMed]

- Almadani, M.; Razak, R.A.; Abdullah, M.M.A.B.; Mohamed, R. Geopolymer-based artificial aggregates: A review on methods of producing, properties, and improving techniques. Materials 2022, 15, 5516. [Google Scholar] [CrossRef] [PubMed]

- Poolman, K.D.; Kruger, D. International Congress on Polymers in Concrete (ICPIC 2018); Springer: Berlin/Heidelberg, Germany, 2018. [Google Scholar]

- Liu, Z.; Takasu, K.; Suyama, H.; Koyamada, H.; Liu, S.; Hao, Q. The Effect of Cementitious Materials on the Engineering Properties and Pore Structure of Concrete with Recycled Fine Aggregate. Materials 2022, 16, 305. [Google Scholar] [CrossRef] [PubMed]

- Kuri, J.C.; Hosan, A.; Shaikh, F.U.A.; Biswas, W.K. The Effect of Recycled Waste Glass as a Coarse Aggregate on the Properties of Portland Cement Concrete and Geopolymer Concrete. Buildings 2023, 13, 586. [Google Scholar] [CrossRef]

| Alkaline activator | Distilled water | AL | |

| Sodium hydroxide (NaOH) | The concentrations of 12 M | ||

| Sodium silicate (Na2SiO3) | 12.97% Na2O, 29.03% SiO2 and 58% H2O | ||

| Admixture | Fly ash (adapted to JISⅡ) | Density 2.30 (g/cm3), LOI 1.3% specific surface area 4000 (g/cm3) | FA |

| Ground granulated blast-furnace slag (adapted to JIS) | Density 2.91 (g/cm3), LOI 0.04% specific surface area 4100 (g/cm3) | GGBS |

| SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | CaO (%) | SO3 (%) | MgO (%) | |

|---|---|---|---|---|---|---|

| Fly ash | 53.8 | 13.5 | 13 | 8.99 | 0.49 | 1.48 |

| GGBS | 32.7 | 13.4 | 0.5 | 41.6 | 6.9 | 0.3 |

| Type | Symbol | Summary | Range of Particle Size (mm) | Absolute Dry Density (g/cm3) | Water Absorption (%) | Fine Particle Content (%) |

|---|---|---|---|---|---|---|

| Class M | RSM | Fine aggregate processed by crushing and grinding the original concrete, with particle size distribution adjusted as necessary. | <5 | >2.2 | <7 | <8 |

| Class L | RSL | Fine aggregate produced by processing the original concrete through crushing | <5 | - | <13 | <10 |

| Properties | S | RSM | REM2 | RSL | RSL2 | JIS A5022(M) | JIS A5022(L) |

|---|---|---|---|---|---|---|---|

| Absolute dry density (g/cm3) | 2.64 | 2.29 | 2.25 | 2.09 | 2.08 | >2.3 | - |

| Fineness modulus | 2.2 | 3.09 | 3.09 | 3.15 | 2.2 | - | - |

| Water absorption (%) | 1.06 | 6.98 | 6.35 | 9.91 | 9.79 | <7.0 | <13.0 |

| Saturated surface dry density (g/cm3) | 2.67 | 2.46 | 2.402 | 2.32 | 2.30 |

| Type | Unit Mass (kg/m3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| AL/P | AL | FA | GGBS | S | RSM | RSM2 | RSL | RSL2 | |

| N | 0.60 | 388 | 162 | 492 | 1322 | 0 | 0 | 0 | 0 |

| RSM-25 | 0.60 | 388 | 162 | 492 | 992 | 287 | 0 | 0 | 0 |

| RSM-50 | 0.60 | 388 | 162 | 492 | 661 | 574 | 0 | 0 | 0 |

| RSM-75 | 0.60 | 388 | 162 | 492 | 331 | 860 | 0 | 0 | 0 |

| RSM-100 | 0.60 | 388 | 162 | 492 | 0 | 1147 | 0 | 0 | 0 |

| RSM2-25 | 0.60 | 388 | 162 | 492 | 992 | 0 | 282 | 0 | 0 |

| RSM2-50 | 0.60 | 388 | 162 | 492 | 661 | 0 | 564 | 0 | 0 |

| RSM2-75 | 0.60 | 388 | 162 | 492 | 331 | 0 | 845 | 0 | 0 |

| RSM2-100 | 0.60 | 388 | 162 | 492 | 0 | 0 | 1127 | 0 | 0 |

| RSL-25 | 0.60 | 388 | 162 | 492 | 992 | 0 | 0 | 262 | 0 |

| RSL-50 | 0.60 | 388 | 162 | 492 | 661 | 0 | 0 | 524 | 0 |

| RSL-75 | 0.60 | 388 | 162 | 492 | 331 | 0 | 0 | 785 | 0 |

| RSL-100 | 0.60 | 388 | 162 | 492 | 0 | 0 | 0 | 1047 | 0 |

| RSL2-25 | 0.60 | 388 | 162 | 492 | 992 | 0 | 0 | 0 | 261 |

| RSL2-50 | 0.60 | 388 | 162 | 492 | 661 | 0 | 0 | 0 | 521 |

| RSL2-75 | 0.60 | 388 | 162 | 492 | 331 | 0 | 0 | 0 | 782 |

| RSL2-100 | 0.60 | 388 | 162 | 492 | 0 | 0 | 0 | 0 | 1042 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Liu, Z.; Takasu, K.; Koyamada, H.; Suyama, H. Study on the Effect of Recycled Fine Aggregate Qualities on Fly Ash/GGBS-Based Geopolymer Mortar. Materials 2023, 16, 7289. https://doi.org/10.3390/ma16237289

Liu S, Liu Z, Takasu K, Koyamada H, Suyama H. Study on the Effect of Recycled Fine Aggregate Qualities on Fly Ash/GGBS-Based Geopolymer Mortar. Materials. 2023; 16(23):7289. https://doi.org/10.3390/ma16237289

Chicago/Turabian StyleLiu, Shilun, Zihao Liu, Koji Takasu, Hidehiro Koyamada, and Hiroki Suyama. 2023. "Study on the Effect of Recycled Fine Aggregate Qualities on Fly Ash/GGBS-Based Geopolymer Mortar" Materials 16, no. 23: 7289. https://doi.org/10.3390/ma16237289

APA StyleLiu, S., Liu, Z., Takasu, K., Koyamada, H., & Suyama, H. (2023). Study on the Effect of Recycled Fine Aggregate Qualities on Fly Ash/GGBS-Based Geopolymer Mortar. Materials, 16(23), 7289. https://doi.org/10.3390/ma16237289