Effect of Waste Cooking Oil-Based Composite Materials on Radish Growth and Biochemical Responses

Abstract

:1. Introduction

2. Research Methodology

2.1. Production of Vegeblocks

2.2. Phytotoxicity Studies

3. Results and Discussion

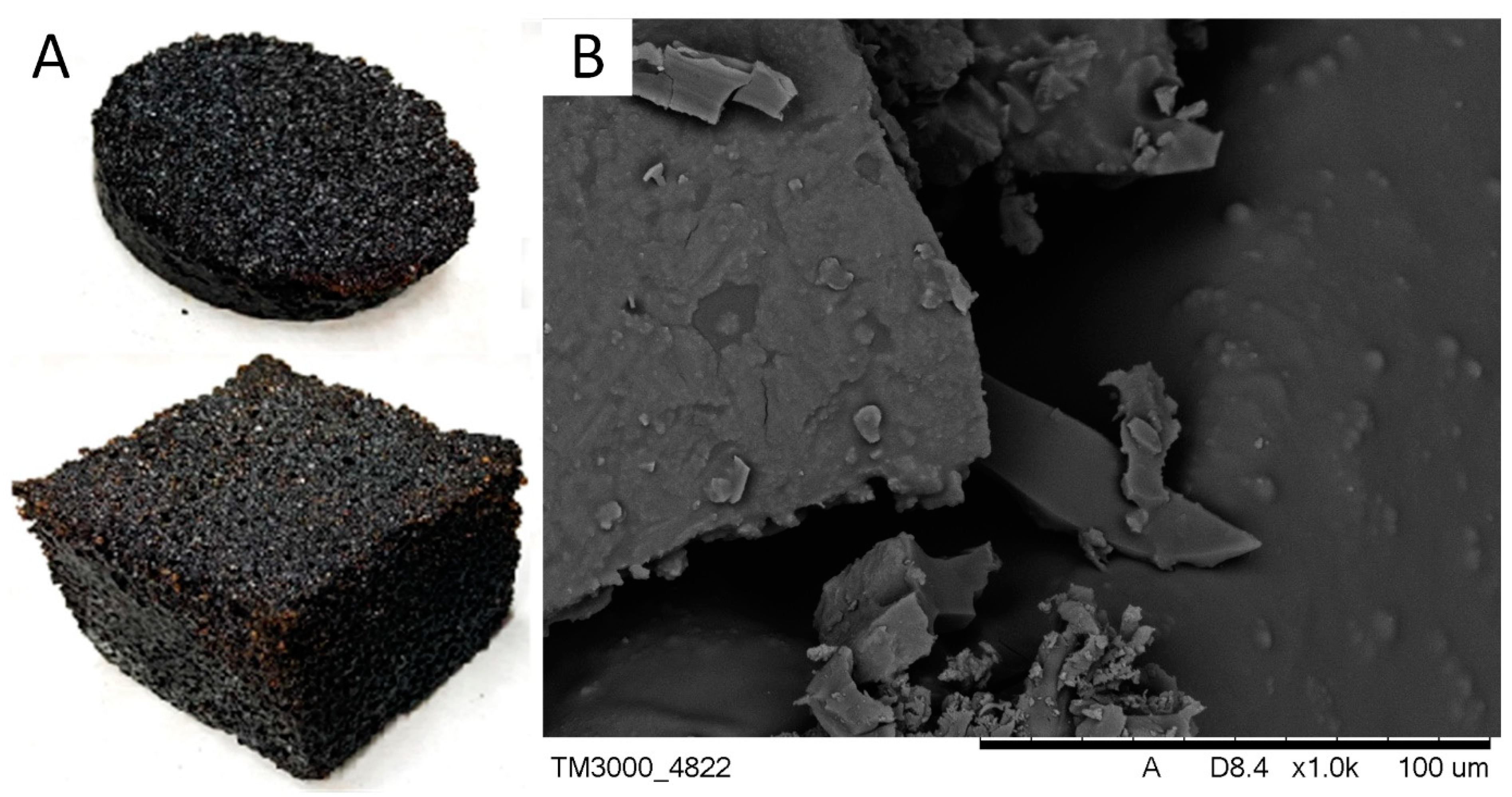

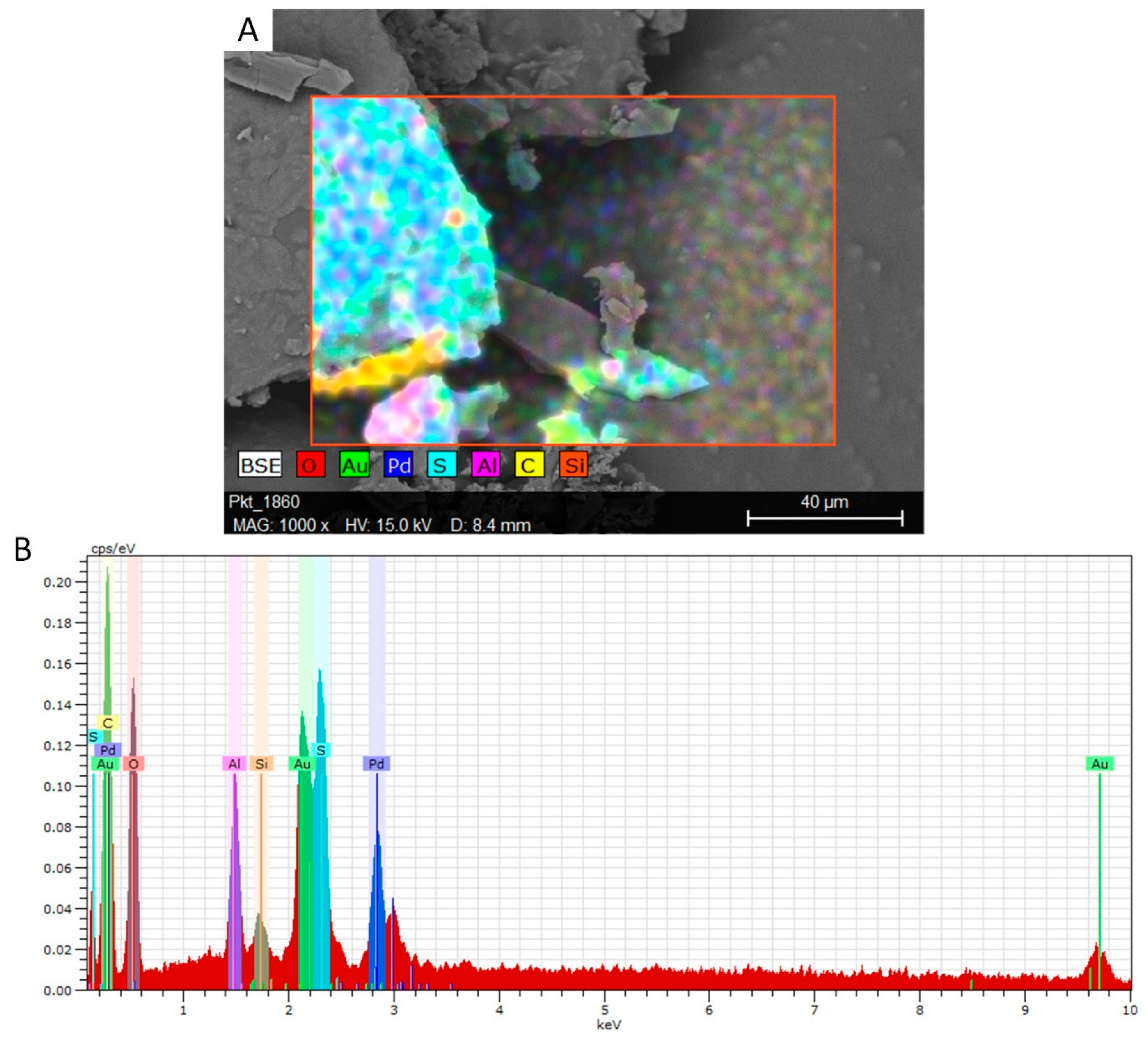

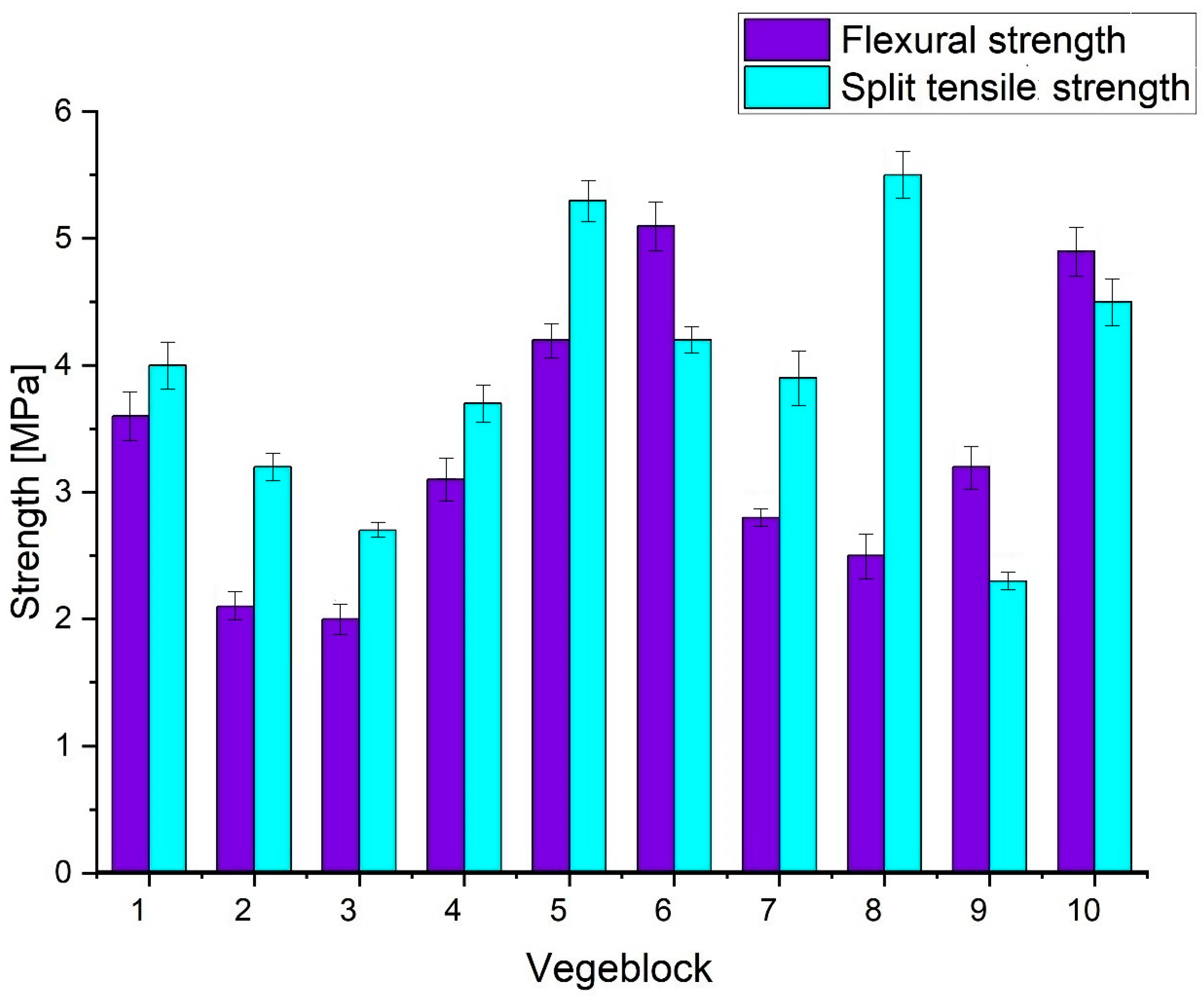

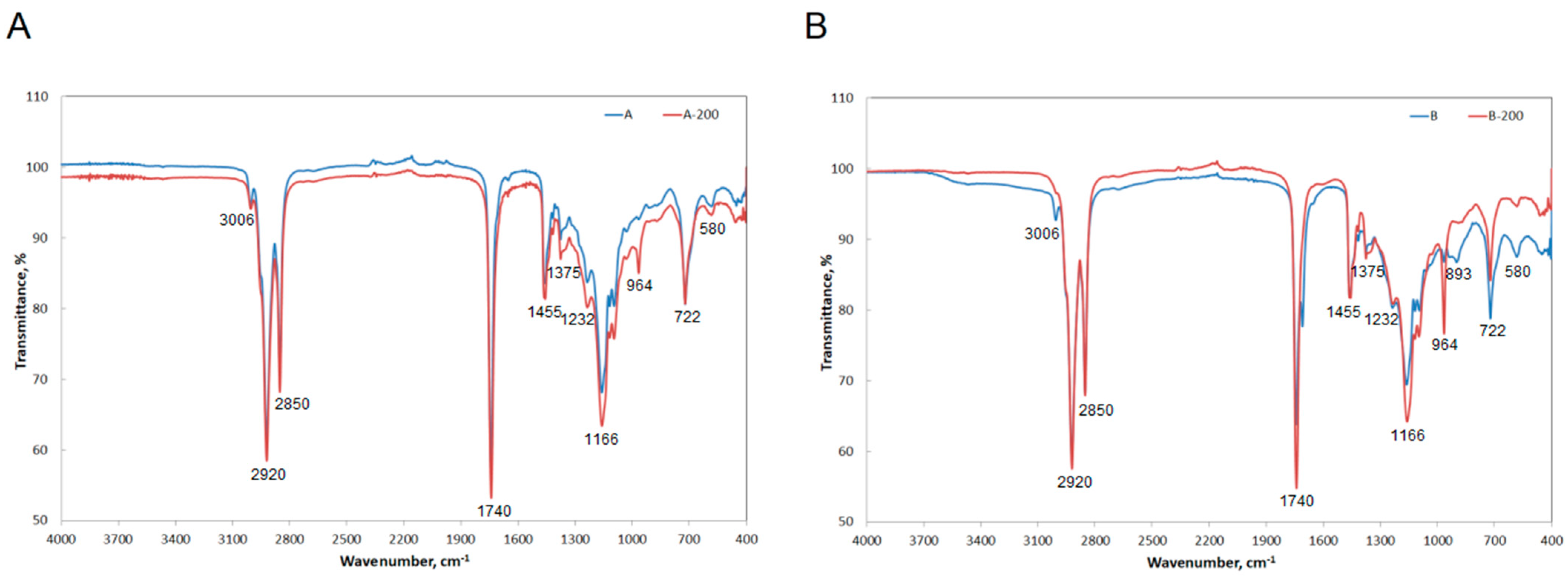

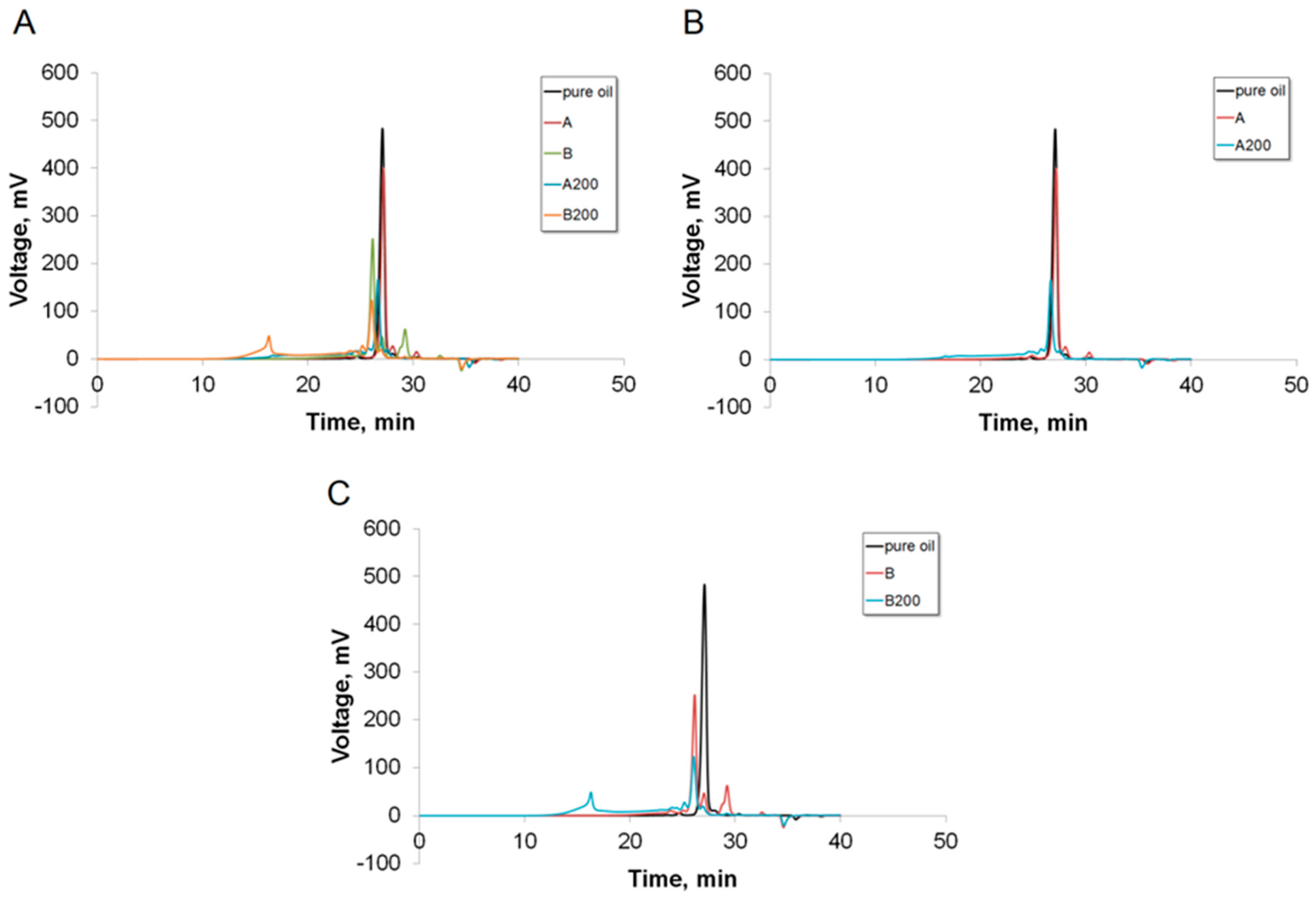

3.1. Vegeblocks

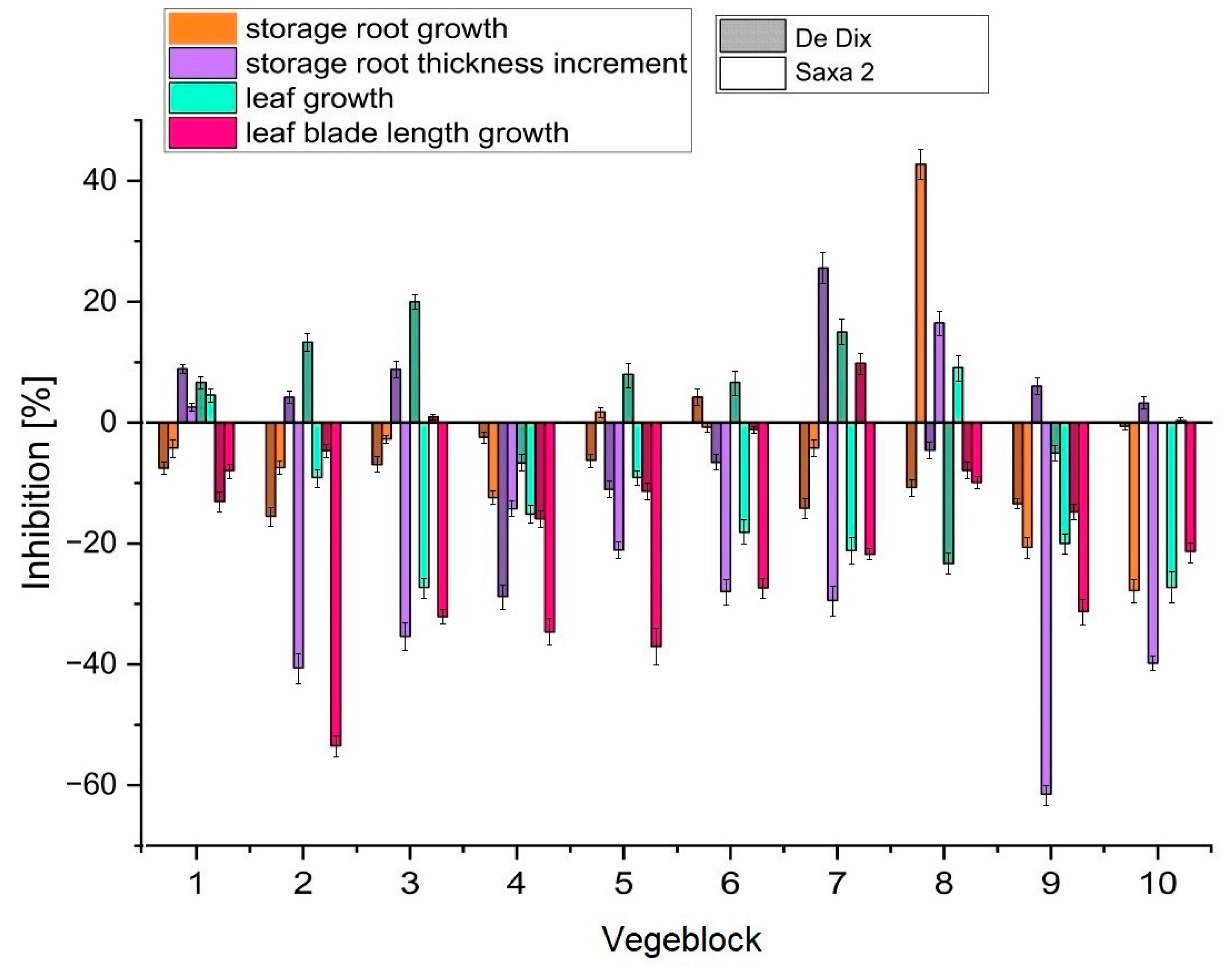

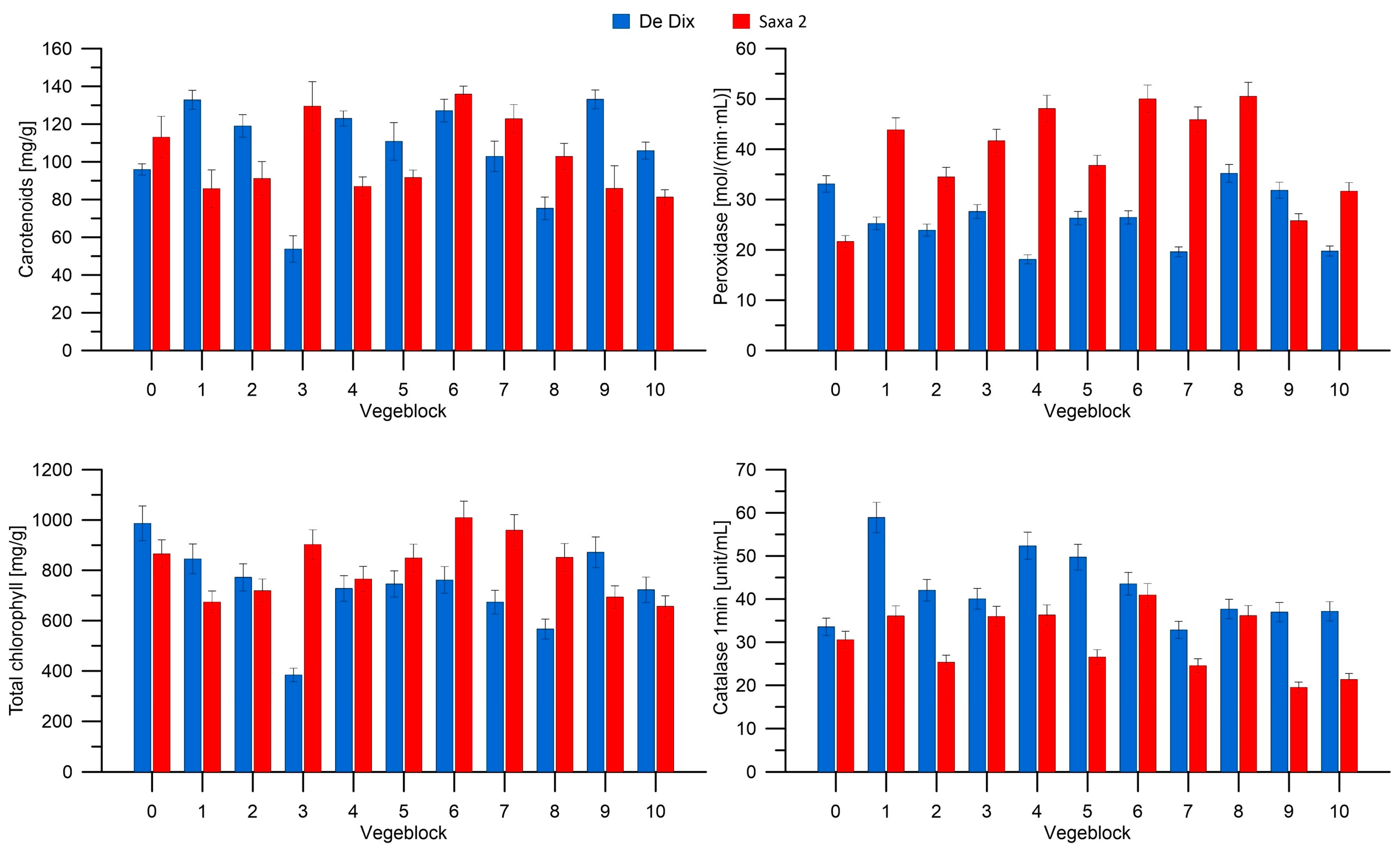

3.2. Phytotoxicity Studies

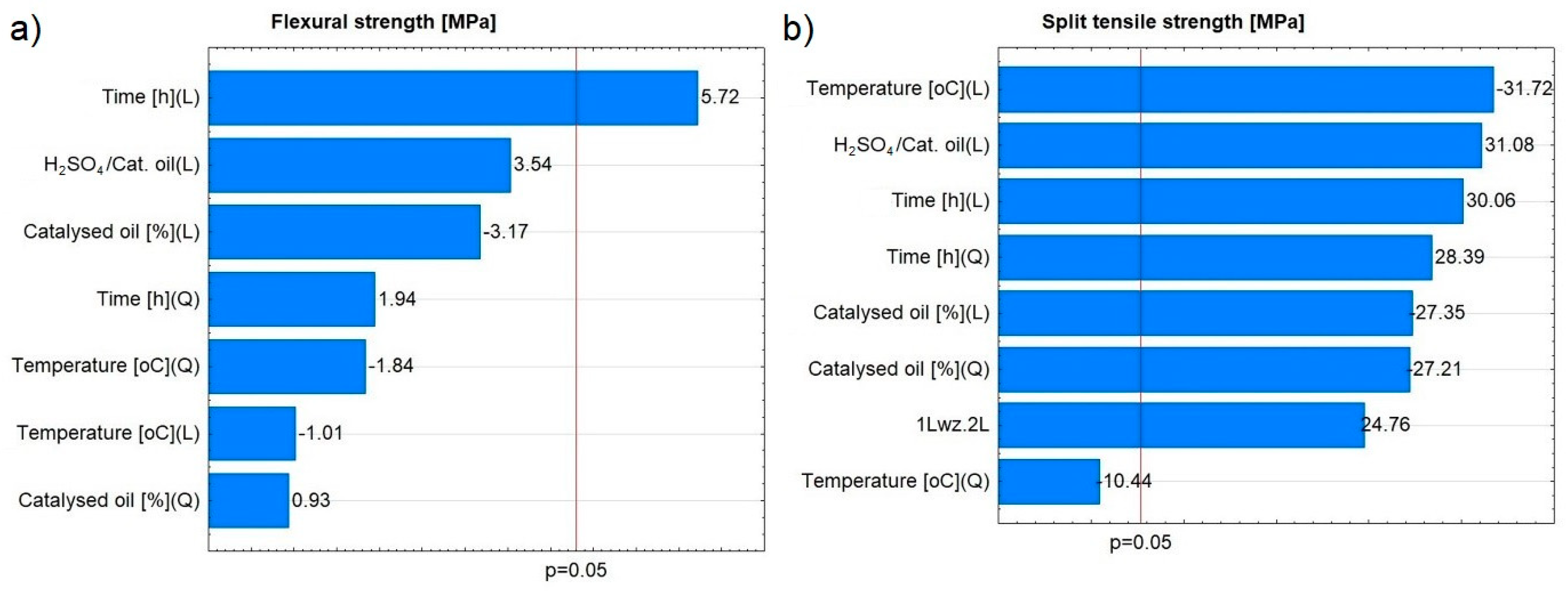

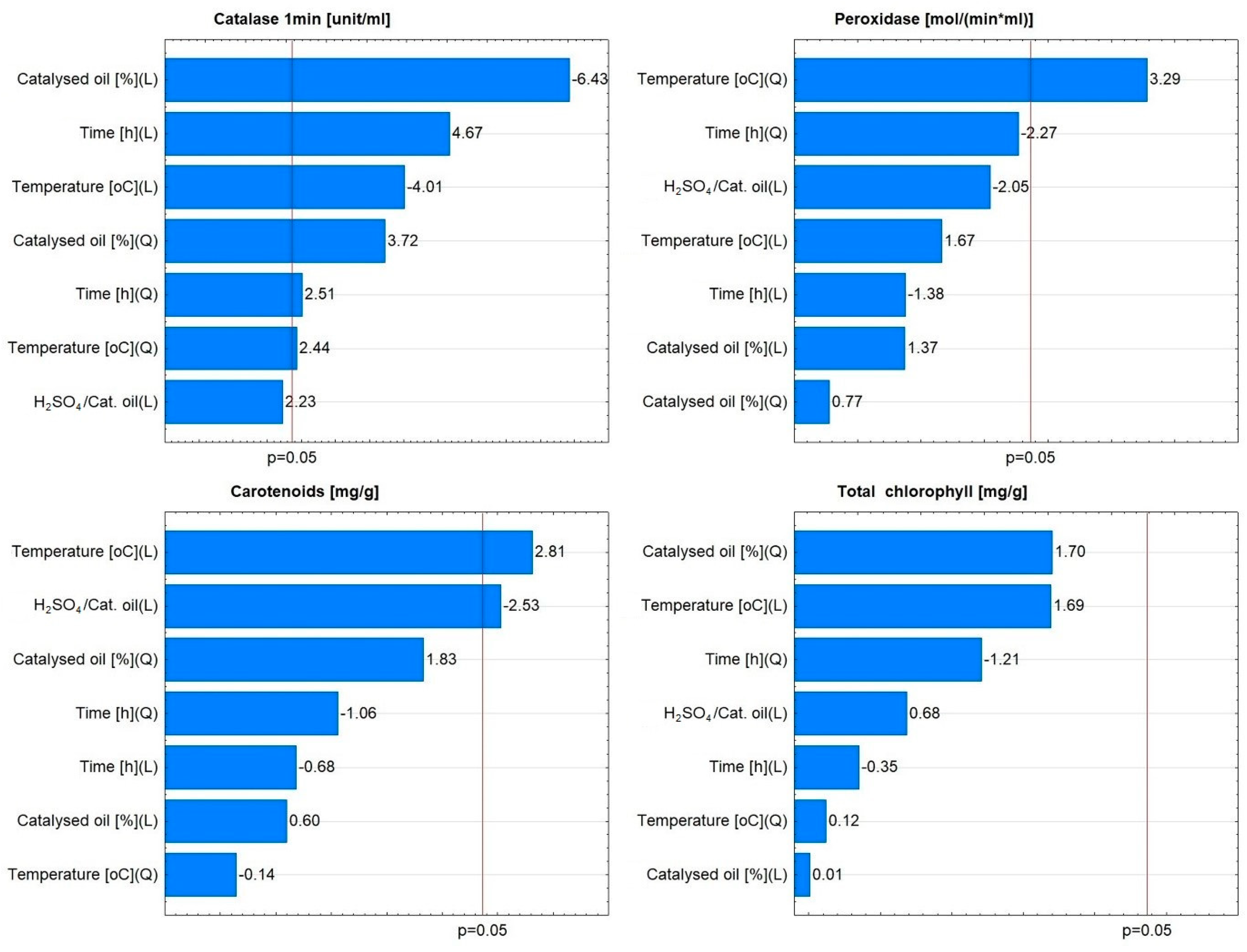

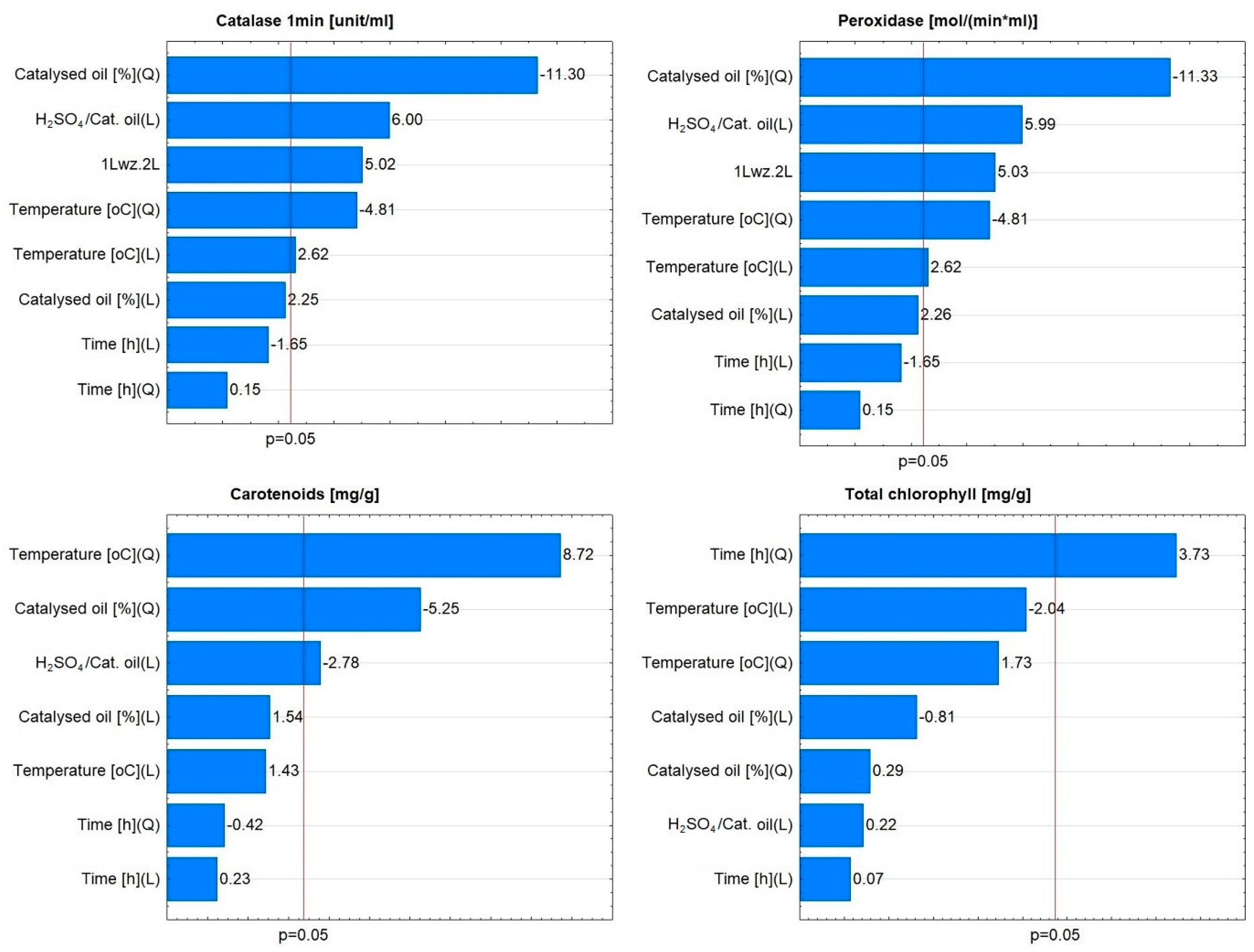

3.3. Evaluation of the Significance of Effects

4. Conclusions and Future Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| WCO | waste cooking oil |

| CO | catalysed oil |

| T | temperature |

| t | time |

| DSC | differential scanning calorimetry |

| TGA | thermogravimetric analysis |

| TA | thermal analysis |

| FT-IR | Fourier-transform infrared spectroscopy |

| SEM | scanning electron microscope |

| EDS | energy-dispersive X-ray spectroscopy |

| Mn | number average molecular weight |

| D | dispersity |

| GPC | gel permeation chromatography |

| Mw | average molecular weight |

| PAH | polycyclic aromatic hydrocarbon |

| LC-ESI-MS/MS | liquid chromatography-electrospray ionisation-tandem mass spectrometry |

| ANOVA | analysis of variance |

| chl a | chlorophyll a |

| chl b | chlorophyll b |

References

- Salmani, Y.; Mohammadi-Nasrabadi, F.; Esfarjani, F. A mixed-method study of edible oil waste from farm to table in Iran: SWOT analysis. J. Mater. Cycles Waste Manag. 2022, 24, 111–121. [Google Scholar] [CrossRef] [PubMed]

- Staroń, A. Composite Materials Based on Waste Cooking Oil for Construction Applications. Buildings 2023, 13, 994. [Google Scholar] [CrossRef]

- Hosseinzadeh-Bandbafha, H.; Nizami, A.S.; Kalogirou, S.A.; Gupta, V.K.; Park, Y.K.; Fallahi, A.; Sulaiman, A.; Ranjbari, M.; Rahnama, H.; Aghbashlo, M.; et al. Environmental Life Cycle Assessment of Biodiesel Production from Waste Cooking Oil: A Systematic Review. Renew. Sustain. Energy Rev. 2022, 161, 112411. [Google Scholar] [CrossRef]

- Versino, F.; Ortega, F.; Monroy, Y.; Rivero, S.; López, O.V.; García, M.A. Sustainable and Bio-Based Food Packaging: A Review on Past and Current Design Innovations. Foods 2023, 12, 1057. [Google Scholar] [CrossRef] [PubMed]

- Goh, B.H.H.; Chong, C.T.; Ge, Y.; Ong, H.C.; Ng, J.H.; Tian, B.; Ashokkumar, V.; Lim, S.; Seljak, T.; Józsa, V. Progress in utilisation of waste cooking oil for sustainable biodiesel and biojet fuel production. Energy Convers. Manag. 2020, 223, 113296. [Google Scholar] [CrossRef]

- Fazzino, F.; Pedullà, A.; Calabrò, P.S. Boosting the Circularity of Waste Management: Pretreated Mature Landfill Leachate Enhances the Anaerobic Digestion of Market Waste. Biofuel Res. J. 2023, 10, 1764–1773. [Google Scholar] [CrossRef]

- Suzihaque, M.U.H.; Alwi, H.; Kalthum Ibrahim, U.; Abdullah, S.; Haron, N. Biodiesel Production from Waste Cooking Oil: A Brief Review. Mater. Today Proc. 2022, 63, S490–S495. [Google Scholar] [CrossRef]

- Staroń, A.; Papla, A.; Midura, A.; Kijania-Kontak, M.; Świergosz, T.; Banach, M. Physicochemical properties, strength and phytotoxicity of building blocks with waste cooking oil as binder. J. Clean. Prod. 2022, 335, 130316. [Google Scholar] [CrossRef]

- Hájek, M.; Vávra, A.; de Paz Carmona, H.; Kocík, J. The catalysed transformation of vegetable oils or animal fats to biofuels and bio-lubricants: A review. Catalysts 2021, 11, 1118. [Google Scholar] [CrossRef]

- Kolář, M.; Machotová, J.; Hájek, M.; Honzíček, J.; Hájek, T.; Podzimek, Š. Application of Vegetable Oil-Based Monomers in the Synthesis of Acrylic Latexes via Emulsion Polymerization. Coatings 2023, 13, 262. [Google Scholar] [CrossRef]

- Thomas, J.; Patil, R. Enabling Green Manufacture of Polymer Products via Vegetable Oil Epoxides. Ind. Eng. Chem. Res. 2023, 62, 1725–1735. [Google Scholar] [CrossRef]

- Wang, G.; Yu, D.; Kelkar, A.D.; Zhang, L. Electrospun nanofiber: Emerging reinforcing filler in polymer matrix composite materials. Prog. Polym. Sci. 2017, 75, 73–107. [Google Scholar] [CrossRef]

- Almahri, G.; Madi, K.; Alkaabi, F.; Badran, Y.; Shehadeh, K.; ElHassan, A.; Ahmed, W.; Alzahmi, S. Characterization of Hybrid FRP Composite Produced from Recycled PET and CFRP. Polymers 2023, 15, 2946. [Google Scholar] [CrossRef] [PubMed]

- Wu, C.; Xu, F.; Wang, H.; Liu, H.; Yan, F.; Ma, C. Manufacturing Technologies of Polymer Composites—A Review. Polymers 2023, 15, 712. [Google Scholar] [CrossRef] [PubMed]

- Sagbansua, L.; Balo, F. Sustainable Insulation Materials for Green Strategy in Construction. Int. J. Comput. Trends Technol. 2016, 42, 66–71. [Google Scholar] [CrossRef]

- Sarmiento, A.M.; Guzmán, H.L.; Morales, G.; Romero, D.E.; Pataquiva-Mateus, A.Y. Expanded Polystyrene (EPS) and Waste Cooking Oil (WCO): From Urban Wastes to Potential Material of Construction. Waste Biomass Valorization 2016, 7, 1245–1254. [Google Scholar] [CrossRef]

- Vu, H.M.; Forth, J.P.; Toropov, V.V. The use of glycerol and cooking oil in masonry unit production. Proc. Inst. Civ. Eng.-Constr. Mater. 2017, 170, 77–90. [Google Scholar] [CrossRef]

- Attia, M.I.; Zoorob, S.; Hassan, K.; El-Husseini, H.; Reid, J.M.; Al Kuwari, M.S. Development of building blocks using vegetable oil and recycled aggregate. In Proceedings of the International Conference on Advances in Sustainable Construction Materials & Civil Engineering Systems, Sharjah, United Arab Emirates, 18–20 April 2021; Volume 120. [Google Scholar] [CrossRef]

- Adebayo, J.O.; Napiah, M.; Ibrahim, K.; Raduan Kabit, M. Evaluation of Waste Cooking Oil as Sustainable Binder for Building Blocks. In Proceedings of the International Conference on Civil and Environmental Engineering (ICCEE 2018), Kuala Lumpur, Malaysia, 2–5 October 2018; Volume 65, p. 05003. [Google Scholar] [CrossRef]

- Díez-Pascual, A.M.; Rahdar, A. Composites of Vegetable Oil-Based Polymers and Carbon Nanomaterials. Macromol 2021, 1, 276–292. [Google Scholar] [CrossRef]

- Dutta, T.K.; Phani, V. The pervasive impact of global climate change on plant-nematode interaction continuum. Front. Plant Sci. 2023, 14, 1143889. [Google Scholar] [CrossRef] [PubMed]

- Skendžić, S.; Zovko, M.; Živković, I.P.; Lešić, V.; Lemić, D. The Impact of Climate Change on Agricultural Insect Pests. Insects 2021, 12, 440. [Google Scholar] [CrossRef]

- Khare, E.; Mishra, J.; Arora, N.K. Multifaceted interactions between endophytes and plant: Developments and Prospects. Front. Microbiol. 2018, 9, 411604. [Google Scholar] [CrossRef]

- Trognitz, F.; Hackl, E.; Widhalm, S.; Sessitsch, A. The role of plant–microbiome interactions in weed establishment and control. FEMS Microbiol. Ecol. 2016, 92, 138. [Google Scholar] [CrossRef]

- Hadwan, M.H. Simple spectrophotometric assay for measuring catalase activity in biological tissues. BMC Biochem. 2018, 19, 7. [Google Scholar] [CrossRef] [PubMed]

- Kar, M.; Mishra, D. Catalase, Peroxidase, and Polyphenoloxidase Activities during Rice Leaf Senescence. Plant Physiol. 1976, 57, 315. [Google Scholar] [CrossRef] [PubMed]

- Oren, R.; Werk, K.S.; Buchmann, N.; Zimmermann, R. Chlorophyll–nutrient relationships identify nutritionally caused decline in Piceaabies stands. Can. J. For. Res. 2011, 23, 1187–1195. [Google Scholar] [CrossRef]

- Stanisz, A. An Affordable Statistics Course Using STATISTICA PL with Examples from Medicine—Volume II Linear and Nonlinear Models. StatSoft Polska: Kraków, Poland, 2007. [Google Scholar]

- STATISTICA (Data Analysis Software System), version 10; StatSoft, Inc.: Tulsa, OK, USA, 2011.

- Banchapattanasakda, W.; Asavatesanupap, C.; Santikunaporn, M. Conversion of Waste Cooking Oil into Bio-Fuel via Pyrolysis Using Activated Carbon as a Catalyst. Molecules 2023, 28, 3590. [Google Scholar] [CrossRef] [PubMed]

- Taleb, D.A.; Hamid, H.A.; Deris, R.R.R.; Zulkifli, M.; Khalil, N.A.; Ahmad Yahaya, A.N. Insights into pyrolysis of waste tire in fixed bed reactor: Thermal behavior. Mater. Today Proc. 2020, 31, 178–186. [Google Scholar] [CrossRef]

- Rodrigue Kaze, C.; Adesina, A.; Laure Lecomte-Nana, G.; Sontia Metekong, J.V.; Van Essa Kamga Samen, L.; Kamseu, E.; Melo, U.C. Synergetic Effect of Rice Husk Ash and Quartz Sand on Microstructural and Physical Properties of Laterite Clay Based Geopolymer. J. Build. Eng. 2021, 43, 103229. [Google Scholar] [CrossRef]

- Ezeh, E.M. Cone Calorimetric Fire Properties and Thermal Analysis of Polyester-Banana Peduncle Fibre Composite Fused with Bio-Fire Retardant Additive. Bull. Natl. Res. Cent. 2021, 45, 195. [Google Scholar] [CrossRef]

- Alves, C.T.; Peters, M.A.; Onwudili, J.A. Application of thermogravimetric analysis method for the characterisation of products from triglycerides during biodiesel production. J. Anal. Appl. Pyrolysis 2022, 168, 165–2370. [Google Scholar] [CrossRef]

- Dweck, J.; Sampaio, C.M.S. Analysis of the Thermal Decomposition of Commercial Vegetable Oils in Air by Simultaneous TG/DTA. J. Therm. Anal. Calorim. 2004, 75, 385–391. [Google Scholar] [CrossRef]

- Hein, D.K.; Eng, P. Pavement design for large element paving slabs. In Proceedings of the Innovations in Pavement Management, Engineering and Technologies, Toronto, ON, Canada, 25–28 September 2016. [Google Scholar]

- Yong, C.K.; Ching, Y.C.; Chuah, C.H.; Liou, N.S. Effect of fiber orientation on mechanical properties of kenaf-reinforced polymer composite. BioResources 2015, 10, 2597–2608. [Google Scholar] [CrossRef]

- Noor, Z.H.; Humayun, N.; Ng Choon, A.; Salah, E.Z.; Zahiraniza, M. Sustainable and Eco-Friendly Vege Roofing Tiles: An Innovative Bio-Composite. Mater. Sci. Forum 2017, 882, 71–76. [Google Scholar] [CrossRef]

- Staroń, A.; Kijania-Kontak, M.; Kozak, A.; Banach, M. Obtaining of oil blocks as a way to manage hazardous asbestos. Waste Manag. 2020, 105, 180–189. [Google Scholar] [CrossRef]

- Lim, S.Y.; Mutalib, M.S.A.; Khaza’ai, H.; Chang, S.K. Detection of fresh palm oil adulteration with recycled cooking oil using fatty acid composition and FTIR spectral analysis. Int. J. Food Prop. 2018, 21, 2428–2451. [Google Scholar] [CrossRef]

- García-Martínez, J.M.; Collar, E.P. Polymers and the Environment: Some Current Feature Trends. Polymers 2023, 15, 2093. [Google Scholar] [CrossRef] [PubMed]

- Liwarska-Bizukojc, E. Phytotoxicity assessment of biodegradable and non-biodegradable plastics using seed germination and early growth tests. Chemosphere 2022, 289, 133132. [Google Scholar] [CrossRef]

- Li, B.; Huang, S.; Wang, H.; Liu, M.; Xue, S.; Tang, D.; Cheng, W.; Fan, T.; Yang, X. Effects of plastic particles on germination and growth of soybean (Glycine max): A pot experiment under field condition. Environ. Pollut. 2021, 272, 116418. [Google Scholar] [CrossRef]

- Almajed, A.; Lemboye, K.; Moghal, A.A.B. A Critical Review on the Feasibility of Synthetic Polymers Inclusion in Enhancing the Geotechnical Behavior of Soils. Polymers 2022, 14, 5004. [Google Scholar] [CrossRef]

- Vinayagam, V.; Murugan, S.; Kumaresan, R.; Narayanan, M.; Sillanpää, M.; Dai Viet, N.V.; Kushwaha, O.S.; Jenis, P.; Potdar, P.; Gadiya, S. Sustainable adsorbents for the removal of pharmaceuticals from wastewater: A review. Chemosphere 2022, 300, 134597. [Google Scholar] [CrossRef]

- Gengmao, Z.; Yu, H.; Xing, S.; Shihui, L.; Quanmei, S.; Changhai, W. Salinity Stress Increases Secondary Metabolites and Enzyme Activity in Safflower. Ind. Crops Prod. 2015, 64, 175–181. [Google Scholar] [CrossRef]

- Ardila-Suárez, C.; Rojas-Avellaneda, D.; Ramirez-Caballero, G.E. Effect of Temperature and Catalyst Concentration on Polyglycerol during Synthesis. Int. J. Polym. Sci. 2015, 2015, 910249. [Google Scholar] [CrossRef]

- Aghbashlo, M.; Hosseinzadeh-Bandbafha, H.; Shahbeik, H.; Tabatabaei, M. The Role of Sustainability Assessment Tools in Realizing Bioenergy and Bioproduct Systems. Biofuel Res. J. 2022, 9, 1697–1706. [Google Scholar] [CrossRef]

- Gheewala, S.H. Life Cycle Assessment for Sustainability Assessment of Biofuels and Bioproducts. Biofuel Res. J. 2023, 10, 1810–1815. [Google Scholar] [CrossRef]

| Sample | CO [%] | H2SO4/CO [g/g] | T [°C] | t [h] |

|---|---|---|---|---|

| 1 | 20.0 | 0.240 | 210 | 18.0 |

| 2 | 25.0 | 0.240 | 190 | 18.0 |

| 3 | 22.5 | 0.140 | 200 | 20.0 |

| 4 | 25.0 | 0.240 | 210 | 20.0 |

| 5 | 22.5 | 0.240 | 190 | 19.0 |

| 6 | 25.0 | 0.240 | 210 | 20.0 |

| 7 | 22.5 | 0.240 | 210 | 16.0 |

| 8 | 22.5 | 0.240 | 190 | 17.0 |

| 9 | 22.5 | 0.240 | 210 | 19.0 |

| 10 | 22.5 | 0.240 | 200 | 19.0 |

| PAH ng/mL | Vegeblock No. 2 | Vegeblock No. 9 |

|---|---|---|

| naphthalene | 0.130 ± 0.001 | 0.211 ± 0.011 |

| acenaphthylene | 0.00530 ± 0.0001 | 0.00820 ± 0.00031 |

| acenaphthene | 0.0114 ± 0.0009 | 0.0385 ± 0.0015 |

| fluorene | 0.0221 ± 0.0010 | 0.0492 ± 0.0019 |

| phenanthrene | 0.111 ± 0.017 | 0.198 ± 0.006 |

| anthracene | 0.0251 ± 0.0024 | 0.0391 ± 0.0022 |

| fluoranthene | 0.0396 ± 0.0032 | 0.0584 ± 0.0022 |

| pyrene | 0.0265 ± 0.0014 | 0.0388 ± 0.0018 |

| benz(a)anthracene | 0.00710 ± 0.00037 | 0.00550 ± 0.00030 |

| chrysene | 0.0132 ± 0.0008 | 0.00320 ± 0.00024 |

| benzo(b)fluoranthene | 0.0132 ± 0.0011 | 0.00410 ± 0.00026 |

| benzo(k)fluoranthene | 0.00520 ± 0.00018 | <0.00176 ± 0.00011 |

| benzo(a)pyrene | 0.00390 ± 0.00020 | <0.00219 ± 0.00015 |

| indeno(1,2,3-cd)pyrene | 0.00360 ± 0.00019 | <0.000850 ± 0.000022 |

| dibenzo(ah)anthracene | 0.00210 ± 0.00011 | <0.000950 ± 0.000031 |

| benzo(ghi)perylene | 0.00420 ± 0.00017 | <0.00119 ± 0.00012 |

| Sum | 0.423 | 0.654 |

| Mn [g/mol] | Mw [g/mol] | D | |

|---|---|---|---|

| Oil | 620 | 632 | 1.02 |

| A | 577 | 659 | 1.14 |

| A200 | 987 | 3328 | 3.37 |

| B | 608 | 887 | 1.46 |

| B200 | 1542 | 9029 | 5.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Staroń, A.; Ciuruś, J.; Kijania-Kontak, M. Effect of Waste Cooking Oil-Based Composite Materials on Radish Growth and Biochemical Responses. Materials 2023, 16, 7350. https://doi.org/10.3390/ma16237350

Staroń A, Ciuruś J, Kijania-Kontak M. Effect of Waste Cooking Oil-Based Composite Materials on Radish Growth and Biochemical Responses. Materials. 2023; 16(23):7350. https://doi.org/10.3390/ma16237350

Chicago/Turabian StyleStaroń, Anita, Joanna Ciuruś, and Magda Kijania-Kontak. 2023. "Effect of Waste Cooking Oil-Based Composite Materials on Radish Growth and Biochemical Responses" Materials 16, no. 23: 7350. https://doi.org/10.3390/ma16237350

APA StyleStaroń, A., Ciuruś, J., & Kijania-Kontak, M. (2023). Effect of Waste Cooking Oil-Based Composite Materials on Radish Growth and Biochemical Responses. Materials, 16(23), 7350. https://doi.org/10.3390/ma16237350

.png)