Recent Advances in the Use of Green Corrosion Inhibitors to Prevent Chloride-Induced Corrosion in Reinforced Concrete

Abstract

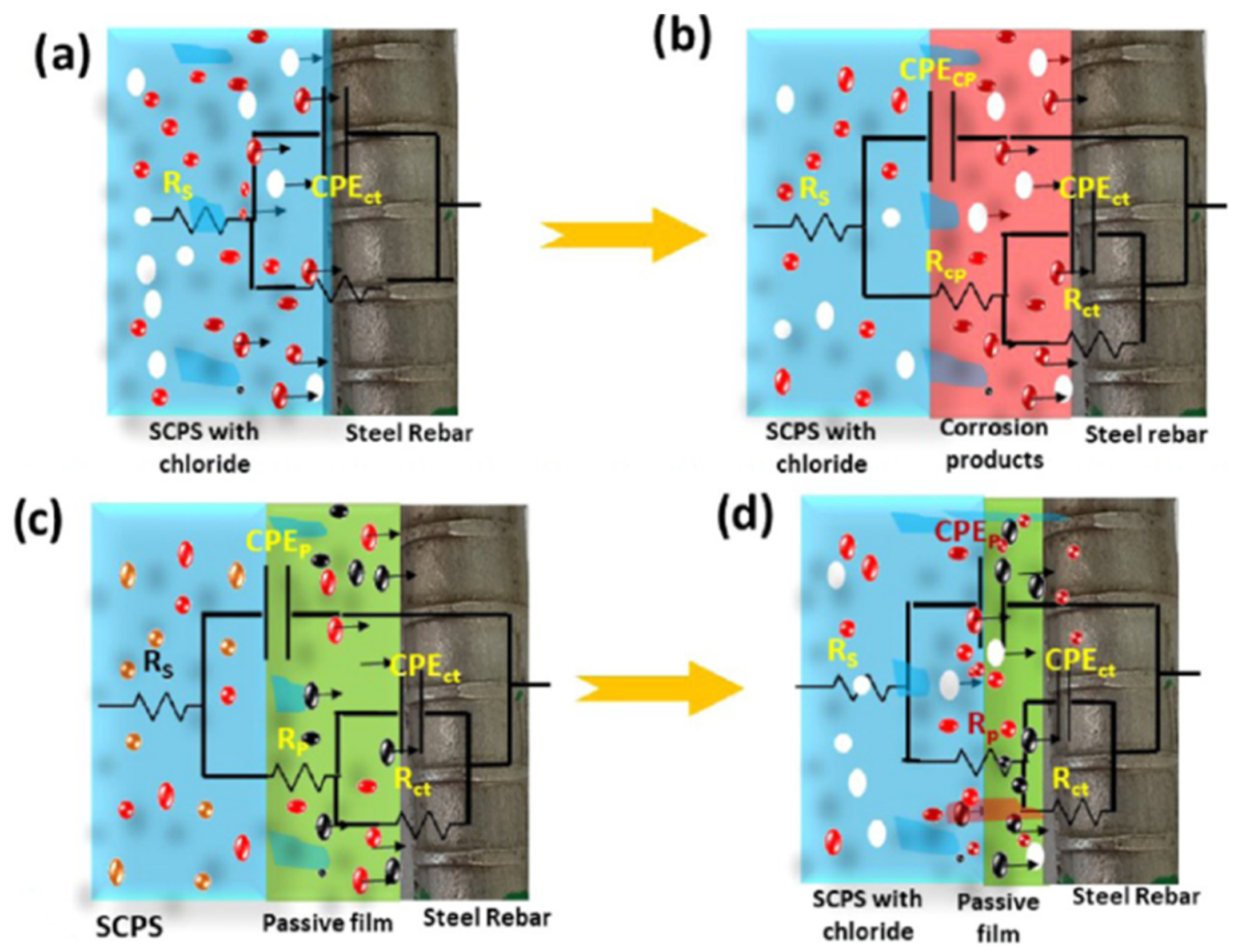

:1. Introduction

2. Botanical Green Inhibitors

2.1. Plant and Leaf Extracts

2.1.1. Tests in Solution

2.1.2. Tests in Concrete

2.2. Green Inhibitors from Agricultural Wastes

3. Microbial Green Inhibitors

| Substance | Test | Mix Design | IE% | [Inhibitor] | [Cl−] | Ref. |

|---|---|---|---|---|---|---|

| Rosa Damascena | SCP | / | 82 | 12 v/v% | 0.5 M NaCl | [26] |

| Morinda citrifolia (Noni) | Mortar | w/c = 0.45; cement/sand/gravel = 1:2:4 | 59 | 0.42 volume to cement wt.% | 3 wt.% NaCl | [28] |

| Olive leaf extract | NaOH 0.1 M solution | / | 91.9 | / | 0.5 M NaCl | [30] |

| Davidian involucrata | SCP | / | 80.3 | 0.1 g·L−1 | 3.5 wt.% NaCl | [32] |

| Prosopis juliflora | SCP | / | 91 | 100 ppm | 3.5 wt.% NaCl | [33] |

| Fatsia japonica | SCP | / | 91.2 | 100 mg·L−1 | 35 g·L−1 NaCl | [34] |

| Pinus resinosa extract | SCP | / | 80.64 | 1 g·L−1 | 30 g·L−1 NaCl | [35] |

| Pinus resinosa conifer cones | SCP | / | 80.64 | 1 g·L−1 | 30 g/L NaCl | [35] |

| Ginger extract | SCP | / | / | 2 wt.% | 0.1 M NaCl | [36] |

| Mango extract | SCP | / | 98 | 2 wt.% | 3.5 wt.% NaCl | [37] |

| Sodium phytate | SCP | / | 68.3 | 0.01 M | 0.3 M NaCl | [40] |

| Gossypol–indole | SCP | / | 96 | 100 mg·L−1 | 1 M NaCl | [41] |

| Cactus mucilage | SCP | / | >90 | 0.5 w/v | 16 g·L−1 NaCl | [42] |

| Bambusa Arundinacea | Mortar | w/c = 0.45; cement/sand/coarse aggregates = 1:1.2:2 | / | 2 cement wt.% | 0.94 cement wt.% NaCl | [43] |

| Ricinus communis | Mortar | w/c = 0.5; cement/fine aggregates/coarse aggregates = 1:1.2:2 | 87 | 100 ppm | 3.5 wt.% NaCl | [44] |

| Carboxylic acid 1 | Mortar | w/c = 0.5; cement/sand = 1:3 | 96 | 0.1 g·L−1 | 3 cement wt.% NaCl | [45] |

| Carboxylic acid 2 | Mortar | w/c = 0.5; cement/sand = 1:3 | 94 | 0.1 g·L−1 | 3 cement wt.% NaCl | [45] |

| Carboxylic acid 3 | Mortar | w/c = 0.5; cement/sand = 1:3 | 85 | 0.1 g·L−1 | 3 cement wt.% NaCl | [45] |

| Urtica Dioica extract | SCP | / | 77 | 0.075 wt.% | 1 wt.% NaCl | [47] |

| Ascorbic acid | Mortar | cement/sand/water: 1/3/0.5 | 97.3 | 0.009 cement wt.% | 3.29 cement wt.% NaCl | [48] |

| Maize gluten meal extract | Mortar | water/cement/sand: 0.6/1/3 | 99.72 | 3 cement wt.% | 3 cement wt.% NaCl | [49] |

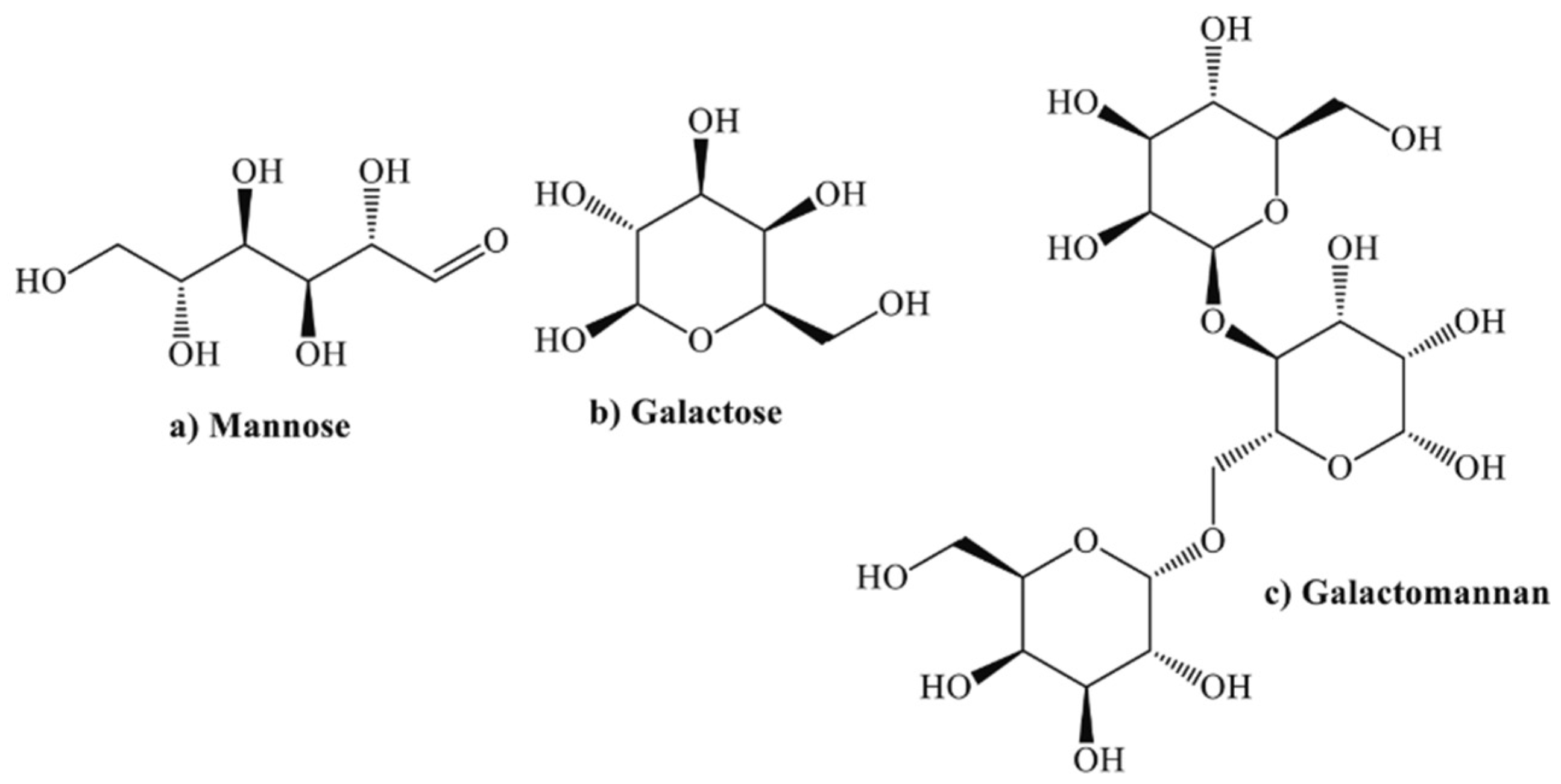

| Guar gum extract | Mortar | w/c = 0.45 | 71.1 | 1.4 cement wt.% | 3.5 wt.% NaCl | [50] |

| Reed leaves | Mortar | w/c = 0.55; cement/sand = 1:3 | 76.98 | 0.5 cement wt.% | 3.5 wt.% NaCl | [52] |

| Green tea antioxidants | Mortar | w/c = 0.54; cement/sand = 1:2.6 | 80 | 40 L·m−3 | 3.5 wt.% NaCl | [53] |

| Cymbopogon citratus | Mortar | w/c = 0.499; cement/sand = 1:3 | 99.35 | 0.0833 cement wt.% | 3.5 wt.% NaCl | [54] |

| Phyllanthus muellerianus | Mortar | / | 97.58 | 0.333 cement wt.% | 3.5 wt.% NaCl | [55] |

| Anthocleista djalonensis | Mortar | / | 97.43 | 0.417 cement wt.% | 3.5 wt.% NaCl | [56] |

| Rhizophora mangle | Mortar | w/c = 0.499; cement/sand/gravel = 1:2.97:3.69 | 99.08 | 0.467 cement wt.% | 3.5 wt.% NaCl | [57] |

| Opuntia ficus-indica | Mortar | cement/sand = 1:3 | >60% | From 1.5 to 95 water v.% | 3.5 wt.% NaCl | [58] |

| Platanus acerifolia leaves | SCP | / | 99 | 5 wt.% | 0.1 M NaCl | [59] |

| Platanus acerifolia leaves | SCP | / | 84.25 | 3 wt.% | 0.5 M NaCl | [60] |

| Bacillus subtilis in sugarcane-bagasse | Mortar | Cement/fine aggregates/coarse aggregates = 1:2.2:2.4; Water/binder = 0.4 | 97.5 | / | 5 wt.% NaCl | [68] |

| Lipoptide biomolecules | SCP | / | 58.6 | 1 g·L−1 | 29.25 g·L−1 NaCl | [69] |

| NO3− reducing bacteria | Mortar | Sand/cement/water = 3:1:0.5 | / | / | 0.5 M NaCl | [70] |

| Bacillus safensis, subtilis, pumilus, australimaris | SCP | / | 98.8 | / | 3.5 wt.% NaCl | [74] |

| Penicillium citrinum antioxidant | Chloride neutral solution | / | 58 | 10 v/v% | 0.9% NaCl | [75] |

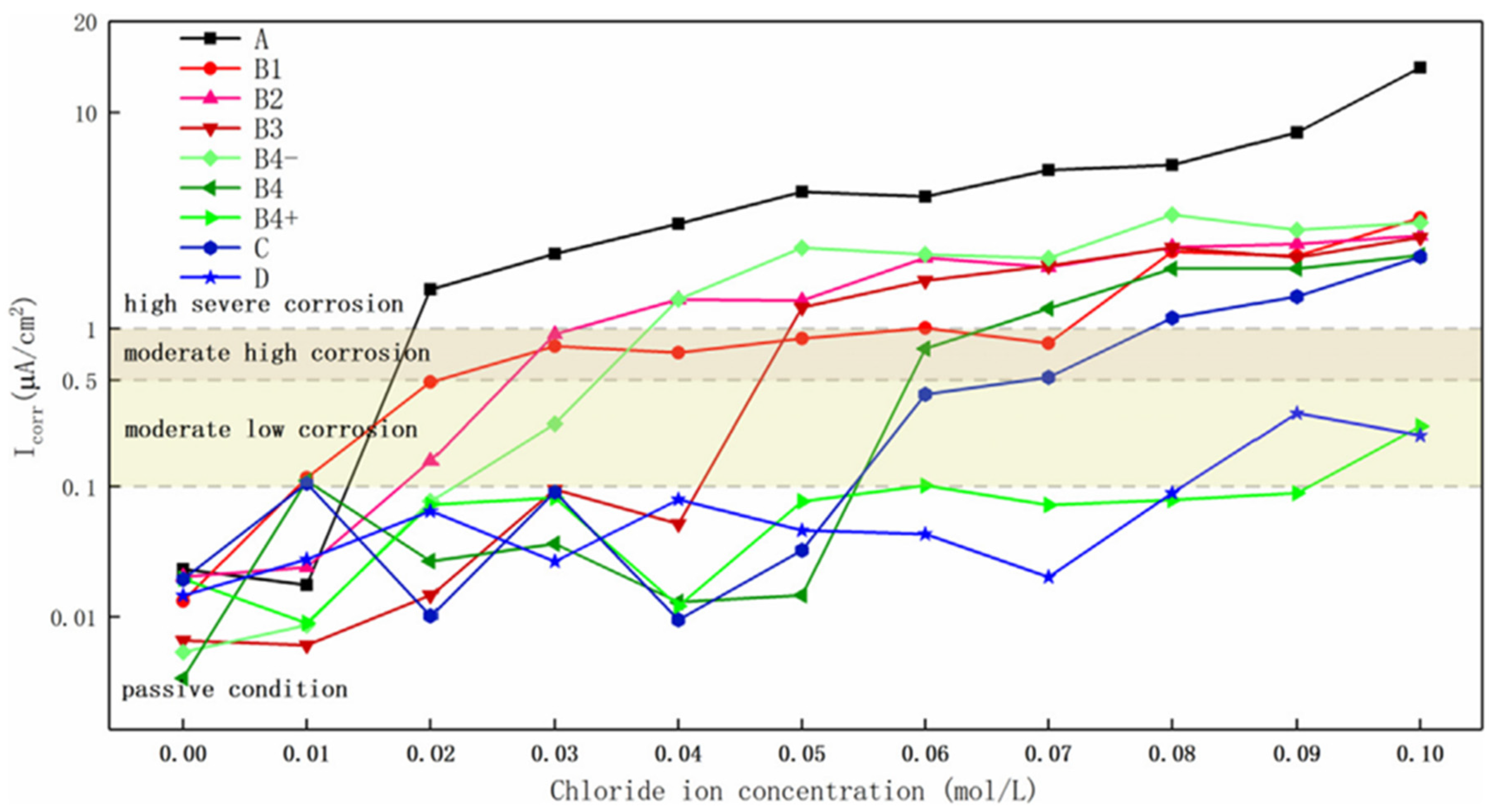

4. Discussion and Comparison with Nitrites

5. Conclusions

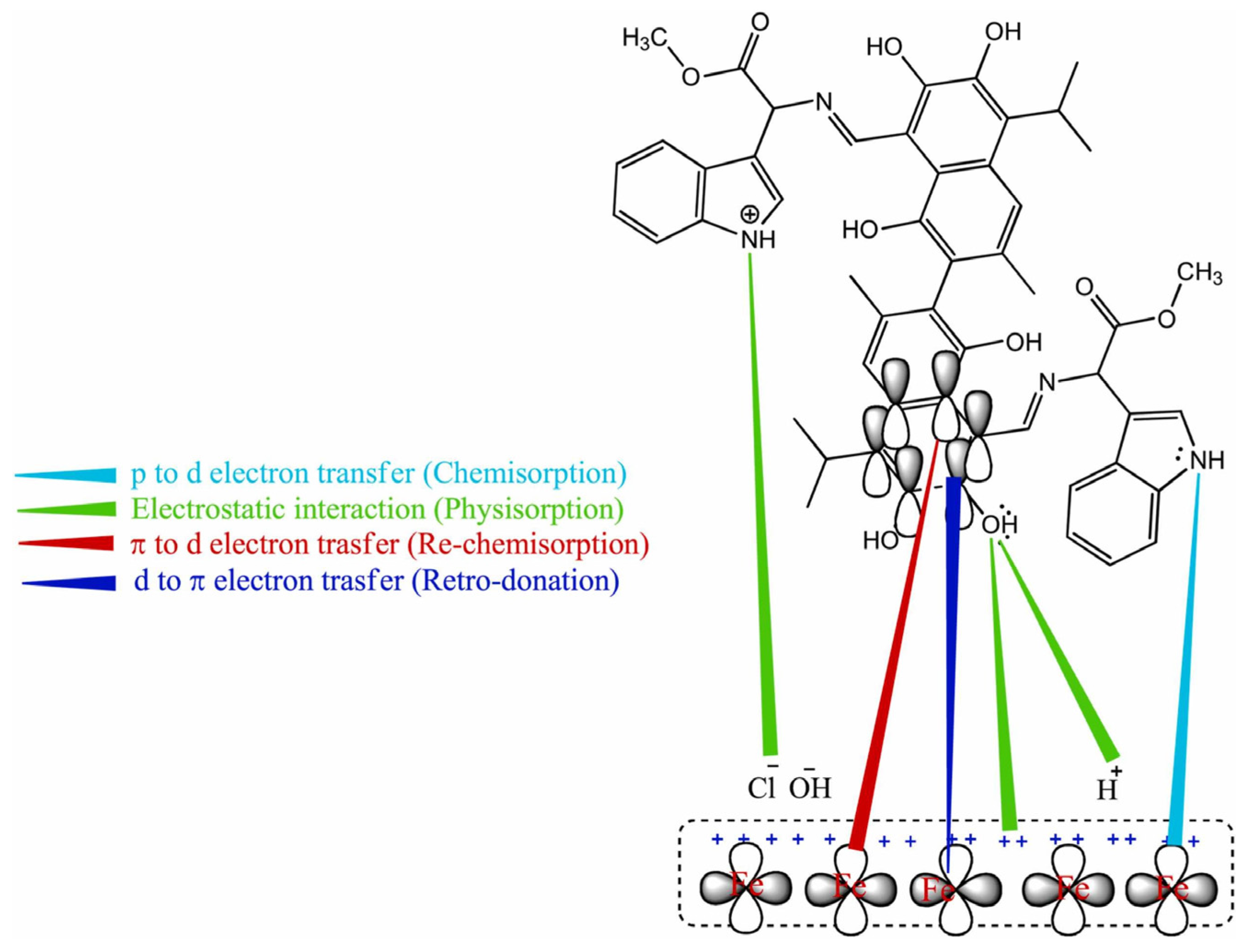

- Very recently, many organic molecules have been extracted from plants and leaves. Thanks to the presence of heteroatoms (O, S and N), aromatic rings and other polar groups, the majority of those substances have been found to donate electron density to the empty d-orbital of Fe, sometimes also accumulating in correspondence of defects or pits. Generally, all the molecules tested demonstrate mixed or at least anodic-inhibitive properties.

- Very few recent studies have compared the effectiveness of green inhibitors in a concrete pore solution (SCP) with carbon steel embodied in concrete or mortar. As a result, despite the declared inhibitive efficiency (IE%) seeming to well compete with nitrites, long term tests in cementitious materials should be performed for a reliable comparison.

- Various waste materials could be efficiently employed as stockpile to produce low-carbon-footprint mixed-type corrosion inhibitors for concrete. However, this kind of study still needs further development to evaluate, in more detail, the real effectiveness of these green inhibitors, which often display an underwhelming efficiency in terms of corrosion rate reduction.

- Based on the proposed inhibition efficiencies and completeness of the studies among all the chemicals collected, the following are considered as promising alternatives to nitrites: ascorbic acid, Cymbopogon citratus extract, licorice extract and maize gluten meal.

- Despite several solutions presenting inhibitory properties comparable to the ones of commercially available products like nitrites, often the high quantity of cement weight used poses a concern to the structural integrity of the mix, requiring mechanical tests to be performed. Moreover, some of the tested molecules, despite the environmental compatibility, do not guarantee an adequate level of protection, as the resulting corrosion rates are far from the levels compatible with the design life of common structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bertolini, L.; Elsener, B.; Redaelli, E.; Polder, R. Corrosion of Steel in Concrete: Prevention, Diagnosis, Repair, 2nd ed.; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Bertolini, L.; Bolzoni, F.; Pastore, T.; Pedeferri, P. Behaviour of Stainless Steel in Simulated Concrete Pore Solution. Br. Corros. J. 1996, 31, 218–222. [Google Scholar] [CrossRef]

- Liu, X.; Feng, P.; Cai, Y.; Yu, X.; Yu, C.; Ran, Q. Carbonation Behavior of Calcium Silicate Hydrate (C-S-H): Its Potential for CO2 Capture. Chem. Eng. J. 2022, 431, 134243. [Google Scholar] [CrossRef]

- Lv, Y.; Niu, D.; Liu, X.; Lin, M.; Li, Y.-C. Corrosion Damage and Life Prediction of Concrete Structure in the Coking Ammonium Sulfate Workshop of Iron and Steel Industry. Sci. Rep. 2023, 13, 2826. [Google Scholar] [CrossRef] [PubMed]

- Lazzari, L.; Pedeferri, P.; Ormellese, M. Cathodic Protection, 1st ed.; Polipress: Milan, Italy, 2006. [Google Scholar]

- Raupach, M. Chloride-Induced Macrocell Corrosion of Steel in Concrete—Theoretical Background and Practical Consequences. Constr. Build. Mater. 1996, 10, 329–338. [Google Scholar] [CrossRef]

- Tuutti, K. Service Life of Structures with Regard to Corrosion of Embedded Steel; ACI Special Publication; American Concrete Institute: Farmington Hills, MI, USA, 1980. [Google Scholar]

- Pedeferri, P. Cathodic Protection and Cathodic Prevention. Constr. Build. Mater. 1996, 10, 391–402. [Google Scholar] [CrossRef]

- Ormellese, M.; Lazzari, L.; Goidanich, S.; Fumagalli, G.; Brenna, A. A Study of Organic Substances as Inhibitors for Chloride-Induced Corrosion in Concrete. Corros. Sci. 2009, 62, 2959–2968. [Google Scholar] [CrossRef]

- Brenna, A.; Ormellese, M.; Pedeferri, M.P.; Bolzoni, F. Effect of Binary Mixtures on Chloride Induced Corrosion of Rebars in Concrete. Int. J. Corros. Scale Inhib. 2018, 7, 151–164. [Google Scholar]

- Bolzoni, F.; Brenna, A.; Ormellese, M. Recent Advances in the Use of Inhibitors to Prevent Chloride-Induced Corrosion in Reinforced Concrete. Cem. Concr. Res. 2022, 154, 106719. [Google Scholar] [CrossRef]

- Ormellese, M.; Bolzoni, F.; Brenna, A. Effect of a Nitrate-Based Corrosion Inhibitor on Carbonation-Induced Corrosion. Corrosion 2023, 79, 388–394. [Google Scholar] [CrossRef]

- Shehnazdeep; Pradhan, B. A Study on Effectiveness of Inorganic and Organic Corrosion Inhibitors on Rebar Corrosion in Concrete: A Review. Mater. Today Proc. 2022, 65, 1360–1366. [Google Scholar] [CrossRef]

- Sun, L.; Wang, C.; Zhang, C.; Yang, Z.; Li, C.; Qiao, P. Experimental Investigation on the Bond Performance of Sea Sand Coral Concrete with FRP Bar Reinforcement for Marine Environments. Adv. Struct. Eng. 2022, 26, 533–546. [Google Scholar] [CrossRef]

- Elsener, B.; Angst, U. Corrosion Inhibitors for Steel in Concrete—An Update. Metall. Ital. 2017, 7, 59–62. [Google Scholar]

- Söylev, T.A.; Richardson, M.G. Corrosion Inhibitors for Steel in Concrete: State-of-the-Art Report. Constr. Build. Mater. 2008, 22, 609–622. [Google Scholar] [CrossRef]

- Chen, L.; Chen, Z.; Xie, Z.; Wei, L.; Hua, J.; Huang, L.; Yap, P.S. Recent Developments on Natural Fiber Concrete: A Review of Properties, Sustainability, Applications, Barriers, and Opportunities. Dev. Built Environ. 2023, 16, 100255. [Google Scholar] [CrossRef]

- Al Shibli, F.S.Z.S.; Bose, S.; Kumar, P.S.; Rajasimman, M.; Rajamohan, N.; Vo, D.V.N. Green Technology for Sustainable Surface Protection of Steel from Corrosion: A Review. Environ. Chem. Lett. 2022, 20, 929–947. [Google Scholar] [CrossRef]

- Zhang, F.; Chen, C.; Hou, R.; Li, J.; Cao, Y.; Dong, S.; Lin, C.; Pan, J. Investigation and Application of Mussel Adhesive Protein Nanocomposite Film-Forming Inhibitor for Reinforced Concrete Engineering. Corros. Sci. 2019, 153, 333–340. [Google Scholar] [CrossRef]

- Chen, C.; Hou, R.; Zhang, F.; Dong, S.; Claesson, P.M.; Lin, C.; Pan, J. Heating-Induced Enhancement of Corrosion Protection of Carbon Steel by a Nanocomposite Film Containing Mussel Adhesive Protein. J. Electrochem. Soc. 2017, 164, C188–C193. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, F.; Lin, C.; Pan, J. Corrosion Protection and Self-Healing of a Nanocomposite Film of Mussel Adhesive Protein and CeO2 Nanoparticles on Carbon Steel. J. Electrochem. Soc. 2016, 163, C545–C552. [Google Scholar] [CrossRef]

- ElShami, A.A.; Bonnet, S.; Makhlouf, M.H.; Khelidj, A.; Leklou, N. Novel Green Plants Extract as Corrosion Inhibiting Coating for Steel Embedded in Concrete. Pigment Resin Technol. 2020, 49, 501–514. [Google Scholar] [CrossRef]

- López-León, L.D.; Juárez-Islas, M.A.; Bassam, A.; Pérez-Callejas, A.D.; Castaneda-Robles, I.E. Electrochemical Behavior of a Cactus Mucilage-Based Corrosion-Resistant Coating. Int. J. Electrochem. Sci. 2019, 14, 10016–10031. [Google Scholar] [CrossRef]

- Ahmed, N.M.; Mohamed, M.G.; Mabrouk, M.R.; Elshami, A.A. Novel Anticorrosive Pigments Based on Waste Material for Corrosion Protection of Reinforced Concrete Steel. Constr. Build. Mater. 2015, 98, 388–396. [Google Scholar] [CrossRef]

- Ahmed E S, J.; Ganesh, G.M. A Comprehensive Overview on Corrosion in RCC and Its Prevention Using Various Green Corrosion Inhibitors. Buildings 2022, 12, 1682. [Google Scholar] [CrossRef]

- Anitha, R.; Chitra, S.; Hemapriya, V.; Chung, I.M.; Kim, S.H.; Prabakaran, M. Implications of Eco-Addition Inhibitor to Mitigate Corrosion in Reinforced Steel Embedded in Concrete. Constr. Build. Mater. 2019, 213, 246–256. [Google Scholar]

- Donkor, S.; Song, Z.; Jiang, L.; Chu, H. An Overview of Computational and Theoretical Studies on Analyzing Adsorption Performance of Phytochemicals as Metal Corrosion Inhibitors. J. Mol. Liq. 2022, 359, 119260. [Google Scholar] [CrossRef]

- Limco, R.A.; Bacosa, H.P.; Lubguban, A.A.; Buluran, J.S. Morinda Citrifolia (Noni) Leaf Extract as Corrosion Inhibitor for Steel-Reinforced Concrete in Saline Environment. Int. J. Environ. Sci. Technol. 2020, 17, 4531–4540. [Google Scholar] [CrossRef]

- Miralrio, A.; Vázquez, A.E. Plant Extracts as Green Corrosion Inhibitors for Different Metal Surfaces and Corrosive Media: A Review. Processes 2020, 8, 942. [Google Scholar] [CrossRef]

- Ben Harb, M.; Abubshait, S.; Etteyeb, N.; Kamoun, M.; Dhouib, A. Olive Leaf Extract as a Green Corrosion Inhibitor of Reinforced Concrete Contaminated with Seawater. Arab. J. Chem. 2020, 13, 4846–4856. [Google Scholar] [CrossRef]

- Dehghani, A.; Bahlakeh, G.; Ramezanzadeh, B.; Ramezanzadeh, M. Applying Detailed Molecular/Atomic Level Simulation Studies and Electrochemical Explorations of the Green Inhibiting Molecules Adsorption at the Interface of the Acid Solution-Steel Substrate. J. Mol. Liq. 2020, 299, 112220. [Google Scholar] [CrossRef]

- Zhang, M. Davidian Involucrata Leaves Extract as Green Corrosion Inhibitor for Low Carbon Steel in Concrete Pore Solution Containing Chloride Ions. Int. J. Electrochem. Sci. 2021, 16, 21042. [Google Scholar] [CrossRef]

- Palanisamy, S.P.; Maheswaran, G.; Kamal, C.; Venkatesh, G. Prosopis Juliflora—A Green Corrosion Inhibitor for Reinforced Steel in Concrete. Res. Chem. Intermed. 2016, 42, 7823–7840. [Google Scholar] [CrossRef]

- Wang, Q.; Wu, X.; Zheng, H.; Liu, L.; Zhang, Q.; Zhang, A.; Yan, Z.; Sun, Y.; Li, Z.; Li, X. Evaluation for Fatsia Japonica Leaves Extract (FJLE) as Green Corrosion Inhibitor for Carbon Steel in Simulated Concrete Pore Solutions. J. Build. Eng. 2023, 63, 105568. [Google Scholar] [CrossRef]

- Subbiah, K.; Lee, H.S.; Mandal, S.; Park, T. Conifer Cone (Pinus resinosa) as a Green Corrosion Inhibitor for Steel Rebar in Chloride-Contaminated Synthetic Concrete Pore Solutions. ACS Appl. Mater. Interfaces 2021, 13, 43676–43695. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Song, Z.; Wang, W.; Jiang, L.; Zhang, Y.; Guo, M.; Song, F.; Xu, N. Effect of Ginger Extract as Green Inhibitor on Chloride-Induced Corrosion of Carbon Steel in Simulated Concrete Pore Solutions. J. Clean. Prod. 2019, 214, 298–307. [Google Scholar] [CrossRef]

- Rahmani, M.H.; Dehghani, A.; Salamati, M.; Bahlakeh, G.; Ramezanzadeh, B. Mango Extract Behavior as a Potent Corrosion Inhibitor against Simulated Chloride-Contaminated Concrete Pore Solution; Coupled Experimental and Computer Modeling Studies Abstract: Plants Extracts Are Nominated as Reliable Green Sources among All Classes. J. Ind. Eng. Chem. 2023. [Google Scholar] [CrossRef]

- Wang, Y.H.; He, J.B. Corrosion Inhibition of Copper by Sodium Phytate in NaOH Solution: Cyclic Voltabsorptometry for in Situ Monitoring of Soluble Corrosion Products. Electrochim. Acta 2012, 66, 45–51. [Google Scholar] [CrossRef]

- Gao, L.; Zhang, C.; Zhang, M.; Huang, X.; Jiang, X. Phytic Acid Conversion Coating on Mg-Li Alloy. J. Alloys Compd. 2009, 485, 789–793. [Google Scholar] [CrossRef]

- Liu, Y.; Shi, J. Corrosion Resistance of Carbon Steel in Alkaline Concrete Pore Solutions Containing Phytate and Chloride Ions. Corros. Sci. 2022, 205, 110451. [Google Scholar] [CrossRef]

- Berdimurodov, E.; Kholikov, A.; Akbarov, K.; Guo, L.; Kaya, S.; Katin, K.P.; Verma, D.K.; Rbaa, M.; Dagdag, O.; Haldhar, R. Novel Gossypol–Indole Modification as a Green Corrosion Inhibitor for Low–Carbon Steel in Aggressive Alkaline–Saline Solution. Colloids Surfaces A Physicochem. Eng. Asp. 2022, 637, 128207. [Google Scholar] [CrossRef]

- Hernández, E.F.; Cano-Barrita, P.F.D.J.; León-Martínez, F.M.; Torres-Acosta, A.A. Performance of Cactus Mucilage and Brown Seaweed Extract as a Steel Corrosion Inhibitor in Chloride Contaminated Alkaline Media. Anti-Corros. Methods Mater. 2017, 64, 529–539. [Google Scholar] [CrossRef]

- Asipita, S.A.; Ismail, M.; Majid, M.Z.A.; Majid, Z.A.; Abdullah, C.; Mirza, J. Green Bambusa Arundinacea Leaves Extract as a Sustainable Corrosion Inhibitor in Steel Reinforced Concrete. J. Clean. Prod. 2014, 67, 139–146. [Google Scholar] [CrossRef]

- Palanisamy, S.P.; Maheswaran, G.; Selvarani, A.G.; Kamal, C.; Venkatesh, G. Ricinus Communis—A Green Extract for the Improvement of Anti-Corrosion and Mechanical Properties of Reinforcing Steel in Concrete in Chloride Media. J. Build. Eng. 2018, 19, 376–383. [Google Scholar] [CrossRef]

- Matter, C.; Khanh, H.B.; Mittova, V.O.; Tien, N.A.; Thi, P.; Duyen, H. Evaluation of the Inhibitory Effect of Some Derivatives of Salts of Long-Chain Carboxylic Acids in Relation to Pitting Corrosion of Reinforcing Steel in Concrete. Condens. Matter Interphases 2022, 24, 109–115. [Google Scholar]

- Naderi, R.; Bautista, A.; Shagñay, S.; Velasco, F. Licorice (Glycyrrhiza glabra) as Corrosion Inhibitor of Carbon Steel Reinforcing Bars in Mortar and Its Synergic Effect with Nitrite. J. Ind. Eng. Chem. 2023. [Google Scholar] [CrossRef]

- Naderi, R.; Bautista, A.; Velasco, F.; Soleimani, M.; Pourfath, M. Green Corrosion Inhibition for Carbon Steel Reinforcement in Chloride-Polluted Simulated Concrete Pore Solution Using Urtica Dioica Extract. J. Build. Eng. 2022, 58, 105055. [Google Scholar] [CrossRef]

- Argiz, C.; Arroyo, C.; Bravo, A.; Moragues, A.; Andrade, C.; Bolzoni, F. L-Ascorbic Acid as an Efficient Green Corrosion Inhibitor of Steel Rebars in Chloride Contaminated Cement Mortar. Materials 2022, 15, 8005. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Yang, B.; Tai, B.; Zhu, Y. Effect of Maize Gluten Meal Extract as Natural Corrosion Inhibitor on Steel in Mortar Corroded by Chloride. J. Build. Eng. 2022, 62, 105394. [Google Scholar] [CrossRef]

- Venkatesh, G.; Kamal, C.; Vennila, P.; Kaya, S.; Annaamalai, M.G.L.; Ibrahimi, B.E. Sustainable Corrosion Inhibitor for Steel Embedded in Concrete by Guar Gum: Electrochemical and Theoretical Analyses. Appl. Surf. Sci. Adv. 2022, 12, 100328. [Google Scholar] [CrossRef]

- Valdez-salas, B.; Vazquez-delgado, R.; Salvador-carlos, J.; Beltran-partida, E.; Salinas-martinez, R.; Cheng, N.; Curiel-alvarez, M. Azadirachta Indica Leaf Extract as Green Corrosion Inhibitor for Reinforced Concrete Structures: Corrosion Effectiveness against Commercial Corrosion Inhibitors and Concrete Integrity. Materials 2021, 14, 3326. [Google Scholar] [CrossRef]

- Hadi, Z.A.; Mahdi, A.S.; Bahar, S.S. Reed Leaves Extract as Corrosion Inhibitor for Reinforcing Steel in Concrete. IOP Conf. Ser. Mater. Sci. Eng. 2020, 871, 012003. [Google Scholar] [CrossRef]

- Pradipta, I.; Kong, D.; Tan, J.B.L. Natural Organic Antioxidants from Green Tea Inhibit Corrosion of Steel Reinforcing Bars Embedded in Mortar. Constr. Build. Mater. 2019, 227, 117058. [Google Scholar] [CrossRef]

- Okeniyi, J.O.; Popoola, A.P.I.; Okeniyi, E.T. Cymbopogon Citratus and NaNO2 Behaviours in 3.5% NaCl-Immersed Steel-Reinforced Concrete: Implications for Eco-Friendly Corrosion Inhibitor Applications for Steel in Concrete. Int. J. Corros. 2018, 2018, 5949042. [Google Scholar] [CrossRef]

- Okeniyi, J.O.; Loto, C.A.; Popoola, A.P.I. Effects of Phyllanthus Muellerianus Leaf-Extract on Steel-Reinforcement Corrosion in 3.5% NaCl-Immersed Concrete. Metals 2016, 6, 255. [Google Scholar] [CrossRef]

- Okeniyi, J.O.; Loto, C.A.; Popoola, A.P.I. Electrochemical Performance of Anthocleista Djalonensis on Steel-Reinforcement Corrosion in Concrete Immersed in Saline/Marine Simulating-Environment. Trans. Indian Inst. Met. 2014, 67, 959–969. [Google Scholar] [CrossRef]

- Okeniyi, J.O.; Ikotun, J.O.; Akinlabi, E.T.; Okeniyi, E.T. Anticorrosion Behaviour of Rhizophora Mangle L. Bark-Extract on Concrete Steel-Rebar in Saline/Marine Simulating-Environment. Sci. World J. 2019, 2019, 6894714. [Google Scholar] [CrossRef] [PubMed]

- Martinez, W.; Torres, A.; Hernández, R.; Alonso, E.; Mendoza, I.; Martinez, I. The Inhibitive Properties of Nopal Slime on the Corrosion of Steel in Chloride-Contaminated Mortar. Anti-Corros. Methods Mater. 2016, 63, 65–71. [Google Scholar] [CrossRef]

- Song, Z.; Cai, H.; Liu, Q.; Jiang, L.; Chu, H. Performance of Corrosion Inhibitor Extracted from Enzymatic Hydrolysate of Waste Platanus Acerifolia Leaves. J. Ind. Eng. Chem. 2022, 111, 464–479. [Google Scholar] [CrossRef]

- Liu, Q.; Song, Z.; Han, H.; Donkor, S.; Jiang, L.; Wang, W.; Chu, H. A Novel Green Reinforcement Corrosion Inhibitor Extracted from Waste Platanus Acerifolia Leaves. Constr. Build. Mater. 2020, 260, 119695. [Google Scholar] [CrossRef]

- Ahamed, M.I.; Boddula, R.; Luqman, M. (Eds.) Theory and Applications of Green Corrosion Inhibitors; Materials Research Forum LLC: Millersville, PA, USA, 2021. [Google Scholar]

- Hammes, F.; Verstraete, W. Key Roles of PH and Calcium Metabolism in Microbial Carbonate Precipitation. Rev. Environ. Sci. Biotechnol. 2002, 1, 3–7. [Google Scholar] [CrossRef]

- Amer Algaifi, H.; Abu Bakar, S.; Rahman Mohd. Sam, A.; Ismail, M.; Razin Zainal Abidin, A.; Shahir, S.; Ali Hamood Altowayti, W. Insight into the Role of Microbial Calcium Carbonate and the Factors Involved in Self-Healing Concrete. Constr. Build. Mater. 2020, 254, 119258. [Google Scholar] [CrossRef]

- Khaliq, W.; Ehsan, M.B. Crack Healing in Concrete Using Various Bio Influenced Self-Healing Techniques. Constr. Build. Mater. 2016, 102, 349–357. [Google Scholar] [CrossRef]

- Mondal, S.; (Dey) Ghosh, A. Review on Microbial Induced Calcite Precipitation Mechanisms Leading to Bacterial Selection for Microbial Concrete. Constr. Build. Mater. 2019, 225, 67–75. [Google Scholar] [CrossRef]

- Jonkers, H.M.; Thijssen, A.; Muyzer, G.; Copuroglu, O.; Schlangen, E. Application of Bacteria as Self-Healing Agent for the Development of Sustainable Concrete. Ecol. Eng. 2010, 36, 230–235. [Google Scholar] [CrossRef]

- Reinhardt, H.W.; Jooss, M. Permeability and Self-Healing of Cracked Concrete as a Function of Temperature and Crack Width. Cem. Concr. Res. 2003, 33, 981–985. [Google Scholar] [CrossRef]

- Kanwal, M.; Khushnood, R.A.; Shahid, M.; Wattoo, A.G. An Integrated and Eco-Friendly Approach for Corrosion Inhibition and Microstructural Densification of Reinforced Concrete by Immobilizing Bacillus subtilis in Pyrolytic Sugarcane-Bagasse. J. Clean. Prod. 2022, 355, 131785. [Google Scholar] [CrossRef]

- Shubina, V.; Gaillet, L.; Chaussadent, T.; Meylheuc, T.; Creus, J. Biomolecules as a Sustainable Protection against Corrosion of Reinforced Carbon Steel in Concrete. J. Clean. Prod. 2016, 112, 666–671. [Google Scholar] [CrossRef]

- Erşan, Y.Ç.; Van Tittelboom, K.; Boon, N.; De Belie, N. Nitrite Producing Bacteria Inhibit Reinforcement Bar Corrosion in Cementitious Materials. Sci. Rep. 2018, 8, 14092. [Google Scholar] [CrossRef] [PubMed]

- Erşan, Y.Ç.; Verbruggen, H.; De Graeve, I.; Verstraete, W.; De Belie, N.; Boon, N. Nitrate Reducing CaCO3 Precipitating Bacteria Survive in Mortar and Inhibit Steel Corrosion. Cem. Concr. Res. 2016, 83, 19–30. [Google Scholar] [CrossRef]

- Shaheen, N.; Jalil, A.; Adnan, F.; Arsalan Khushnood, R. Isolation of Alkaliphilic Calcifying Bacteria and Their Feasibility for Enhanced CaCO3 Precipitation in Bio-Based Cementitious Composites. Microb. Biotechnol. 2021, 14, 1044–1059. [Google Scholar] [CrossRef]

- Yatish Reddy, P.V.; Ramesh, B.; Prem Kumar, L. Influence of Bacteria in Self Healing of Concrete—A Review. Mater. Today Proc. 2020, 33, 4212–4218. [Google Scholar] [CrossRef]

- Kanwal, M.; Khushnood, R.A.; Adnan, F.; Wattoo, A.G.; Jalil, A. Assessment of the MICP Potential and Corrosion Inhibition of Steel Bars by Biofilm Forming Bacteria in Corrosive Environment. Cem. Concr. Compos. 2023, 137, 104937. [Google Scholar] [CrossRef]

- Olivia, R.; Ang, C.H.; Clotilda, P.; Caroline, M.; Rudy, T.; Joe, N. Corrosion Inhibition of Mild Steel Bars by Biosurfactant Produced by Penicillium citrinum. IOP Conf. Ser. Earth Environ. Sci. 2023, 1135, 012057. [Google Scholar] [CrossRef]

- Song, Y.; Liu, J.; Wang, H.; Shu, H. Research Progress of Nitrite Corrosion Inhibitor in Concrete. Int. J. Corros. 2019, 2019, 3060869. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Casanova, L.; Ceriani, F.; Messinese, E.; Paterlini, L.; Beretta, S.; Bolzoni, F.M.; Brenna, A.; Diamanti, M.V.; Ormellese, M.; Pedeferri, M. Recent Advances in the Use of Green Corrosion Inhibitors to Prevent Chloride-Induced Corrosion in Reinforced Concrete. Materials 2023, 16, 7462. https://doi.org/10.3390/ma16237462

Casanova L, Ceriani F, Messinese E, Paterlini L, Beretta S, Bolzoni FM, Brenna A, Diamanti MV, Ormellese M, Pedeferri M. Recent Advances in the Use of Green Corrosion Inhibitors to Prevent Chloride-Induced Corrosion in Reinforced Concrete. Materials. 2023; 16(23):7462. https://doi.org/10.3390/ma16237462

Chicago/Turabian StyleCasanova, Luca, Federica Ceriani, Elena Messinese, Luca Paterlini, Silvia Beretta, Fabio Maria Bolzoni, Andrea Brenna, Maria Vittoria Diamanti, Marco Ormellese, and MariaPia Pedeferri. 2023. "Recent Advances in the Use of Green Corrosion Inhibitors to Prevent Chloride-Induced Corrosion in Reinforced Concrete" Materials 16, no. 23: 7462. https://doi.org/10.3390/ma16237462

APA StyleCasanova, L., Ceriani, F., Messinese, E., Paterlini, L., Beretta, S., Bolzoni, F. M., Brenna, A., Diamanti, M. V., Ormellese, M., & Pedeferri, M. (2023). Recent Advances in the Use of Green Corrosion Inhibitors to Prevent Chloride-Induced Corrosion in Reinforced Concrete. Materials, 16(23), 7462. https://doi.org/10.3390/ma16237462