Additive Manufacturing of Fe-Mn-Si-Based Shape Memory Alloys: State of the Art, Challenges and Opportunities

Abstract

:1. Introduction

2. State of the Art and Challenges for AM of Fe-Mn-Si-Based SMA

- First, porosity must be reduced to obtain a fully compact alloy. This is a general requirement for the AM of alloys, but it is particularly relevant for SMA, in order that the microstructure will not be degraded by the local stresses associated with the phase transformation and its changes on cycling.

- Second, it becomes necessary to accurately master the concentration of each element of these complex alloys, because, as was previously discussed, the optimization of the properties requires very narrow ranges of each element concentration. This matching must be guaranteed along all processing routes, from atomization to the pool melting during AM.

- Third, in relation to the previous point, the control of the critical elements that may evaporate or react with crucibles generate important losses, in Mn or Si for instance, must be compensated. The use of pure metals and clean master alloys is strongly recommended.

- Fourth, the control of impurities, coming from the rough materials or unintentionally introduced during processing, must be a subject of special care. A relevant aspect for AM is the oxygen, because powders with an oxidized surface are being used.

3. Materials and Methods

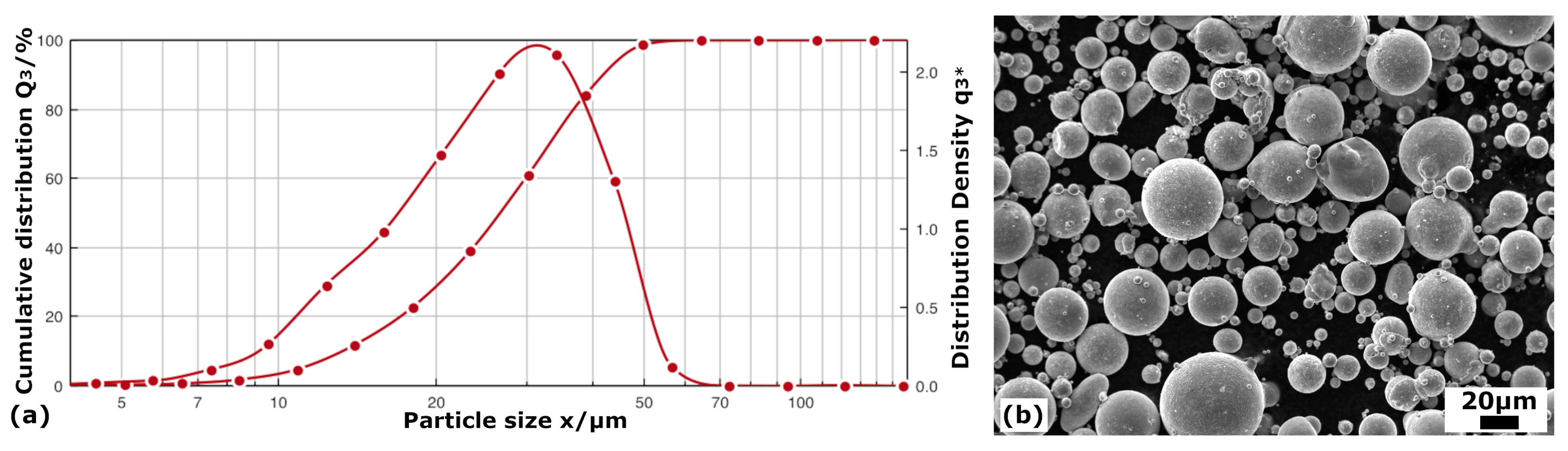

3.1. Powder Atomization

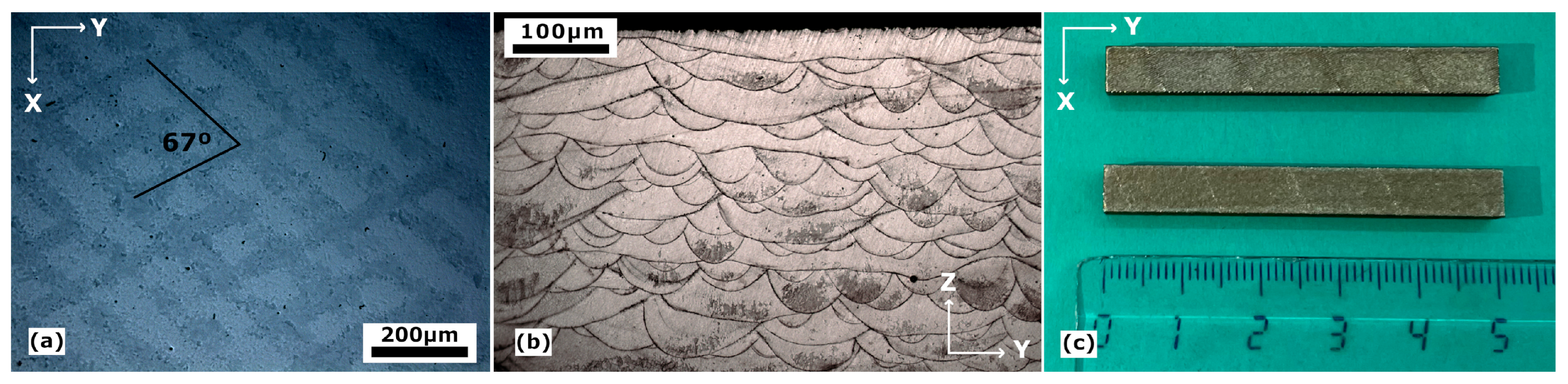

3.2. LPBF: Selective Laser Melting

3.3. Microstructural Characterization Methods

3.4. Phase Transformations Characterization Techniques

4. Experimental Results

4.1. Microstructure Characterization

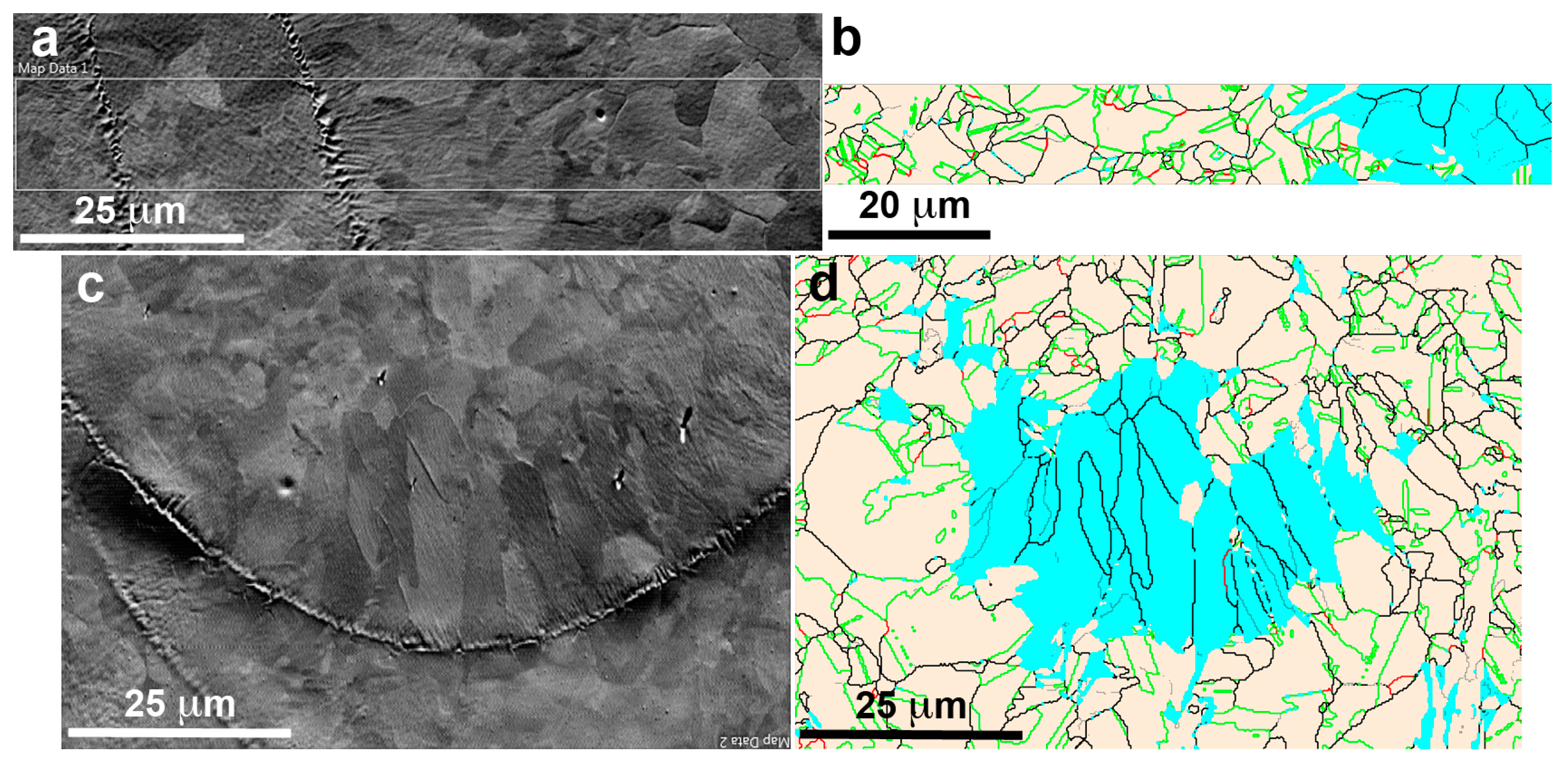

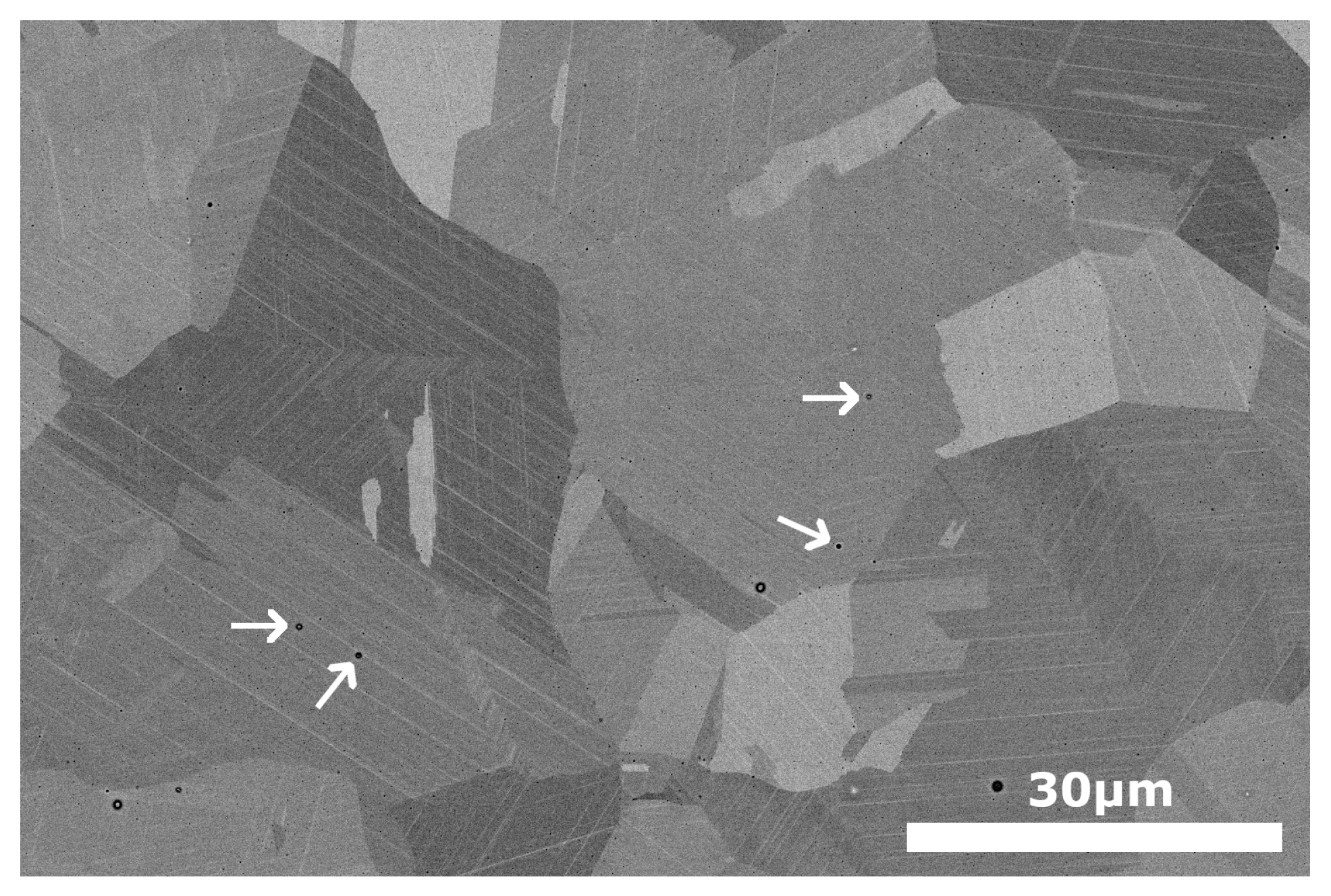

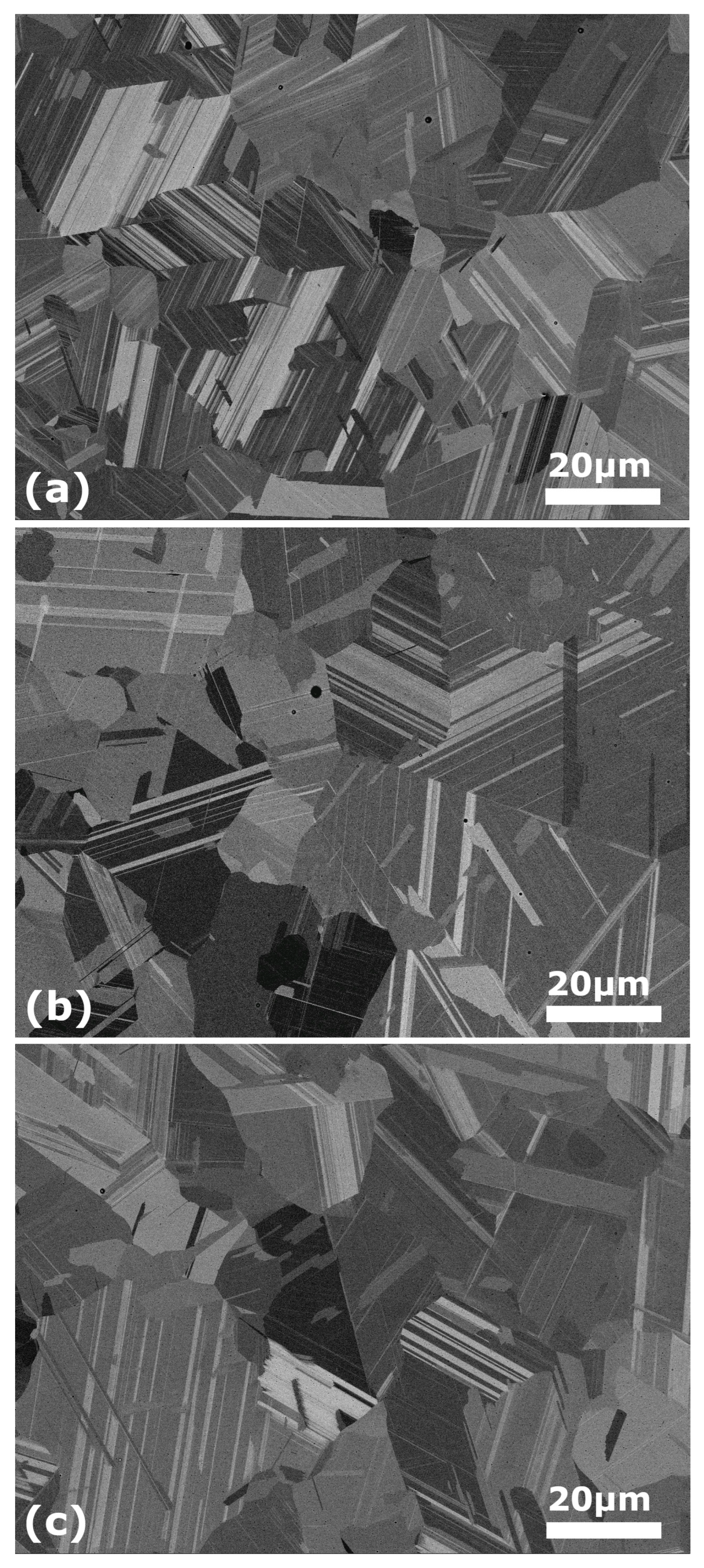

4.1.1. As-Built Microstructure

4.1.2. Microstructure after Thermal Treatment at 1200 K

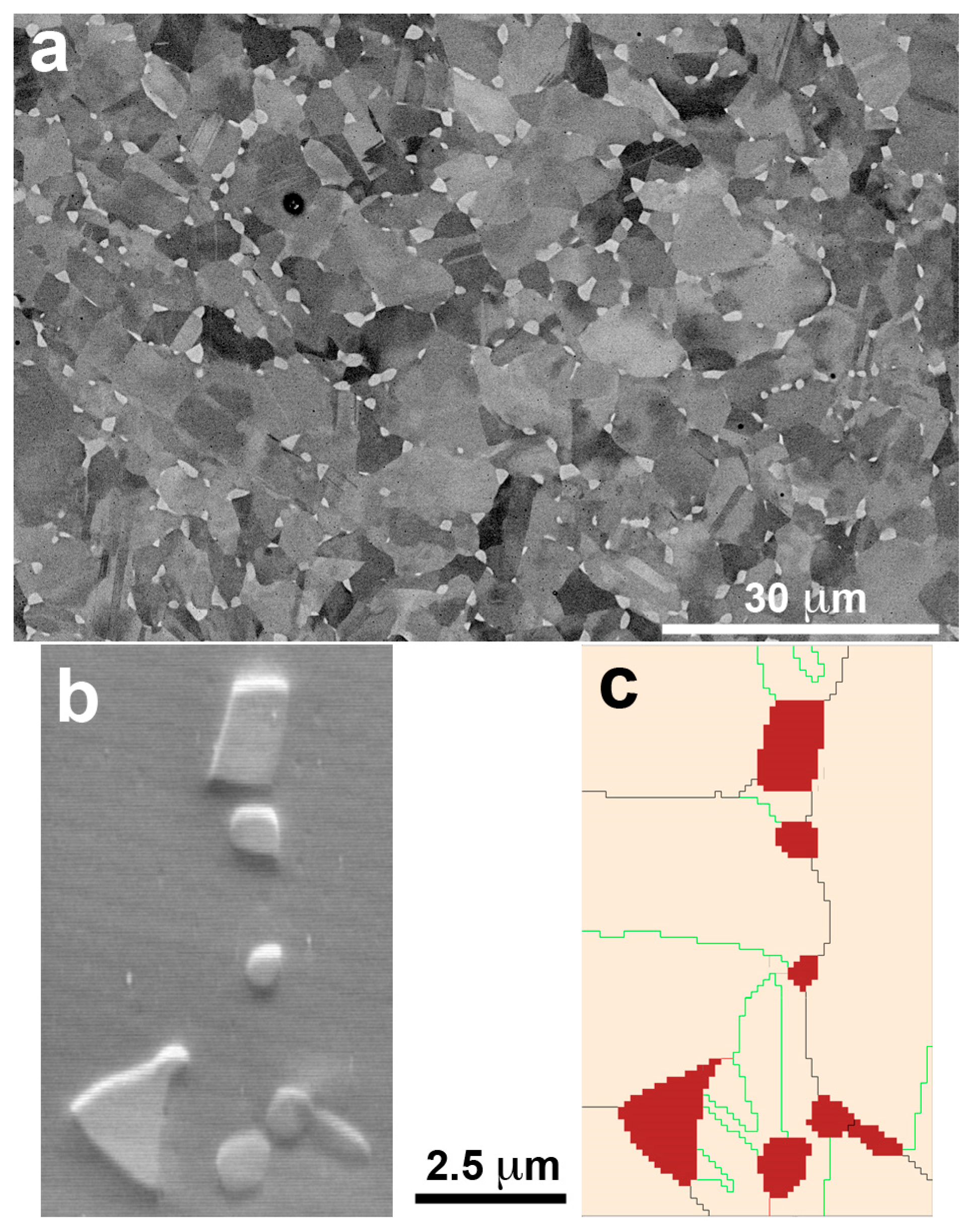

4.1.3. Microstructure after Thermal Treatment at 1350 K

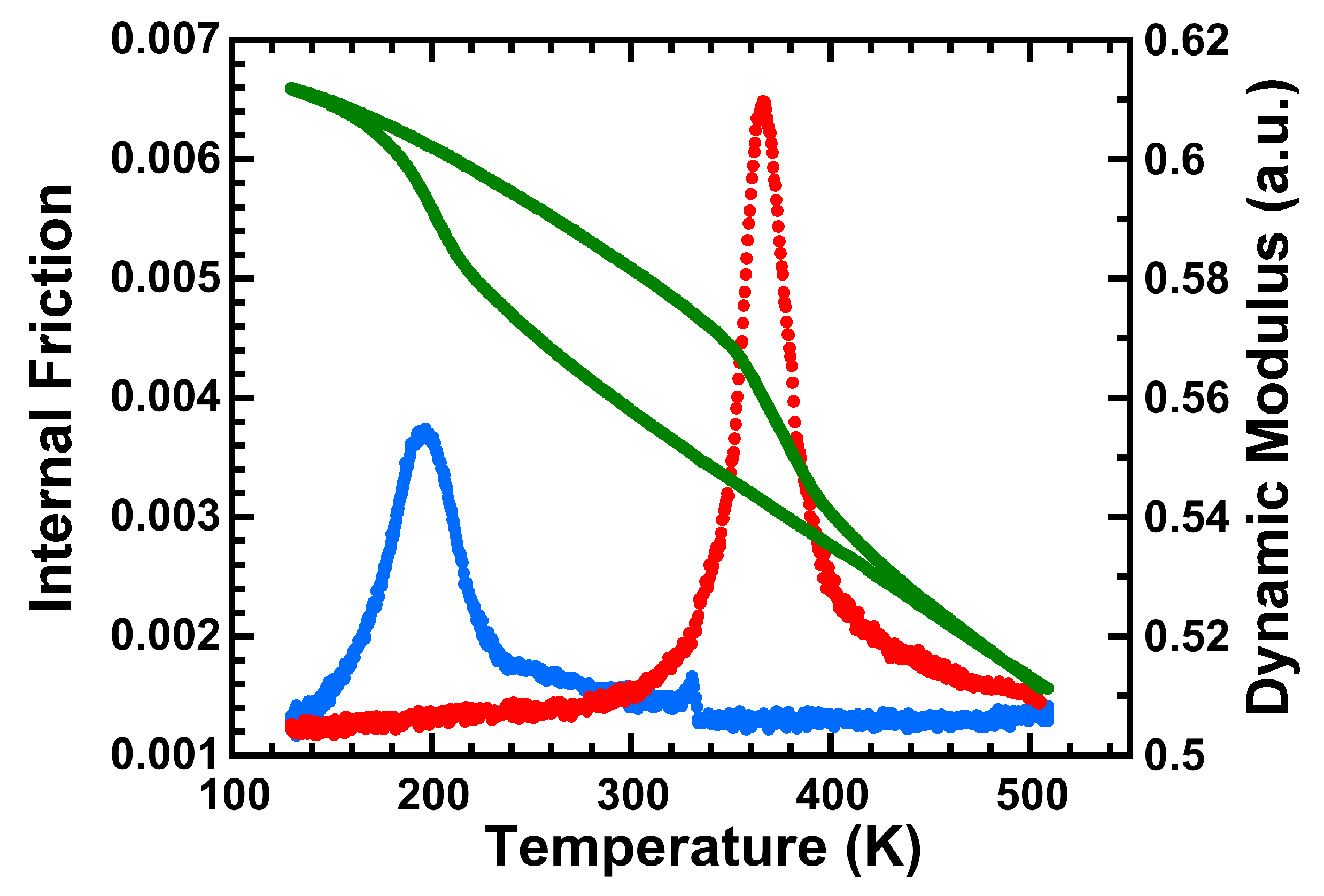

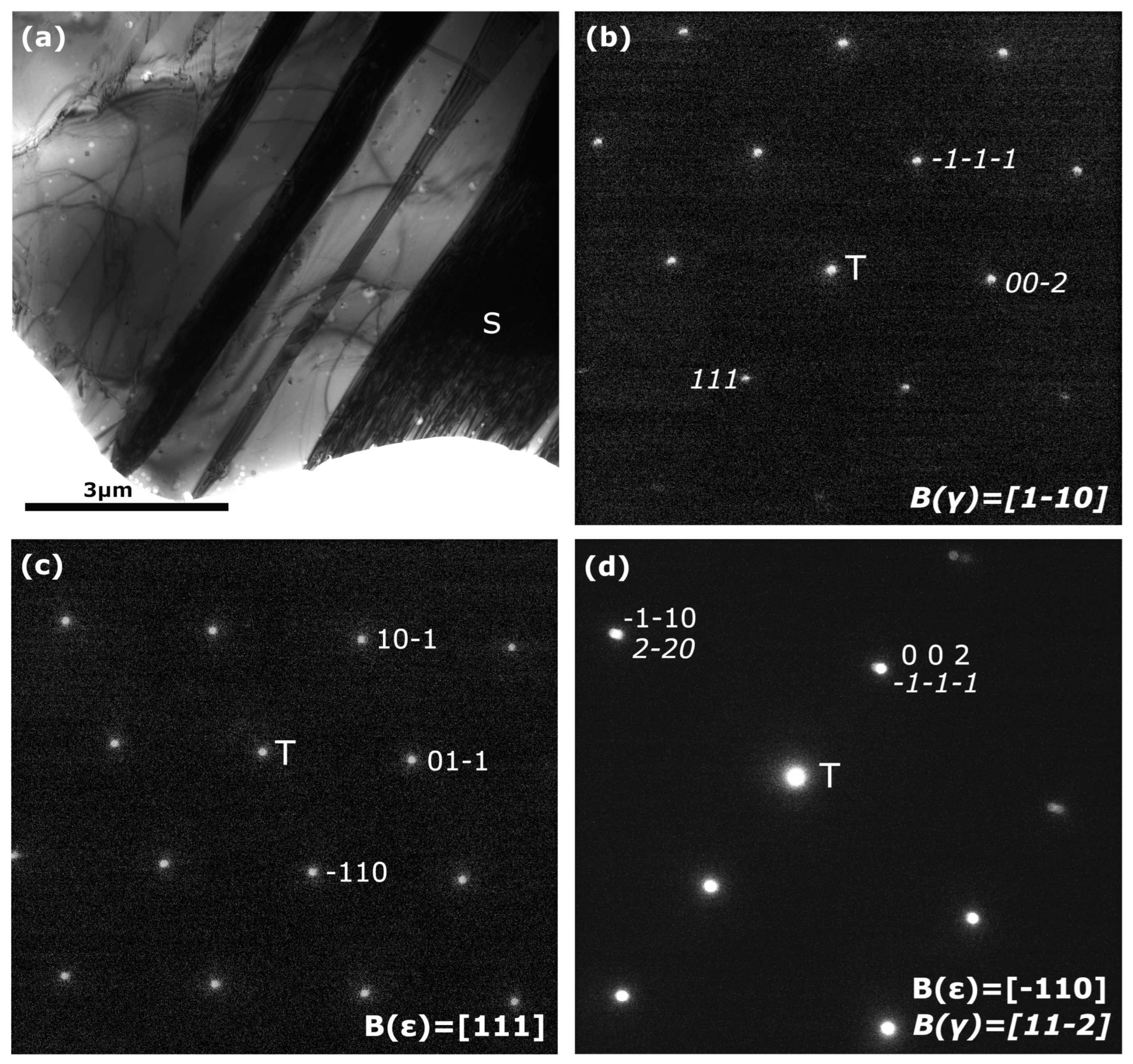

4.2. Martensitic Transformation

4.3. Thermal Cycling Behavior

5. Perspectives and Opportunities of AM in Fe-Mn-Si-Based SMA

6. Conclusions

- The use of pre-alloyed powders produced by gas atomization with diameters between 20 and 45 μm, allows the production of Fe-20Mn-6Si-9Cr-5Ni (wt%) shape memory alloys through additive manufacturing.

- The parameters of the additive manufacturing process, laser power and scan speed, were optimized and a remarkable 99.93% relative density was achieved by LPBF.

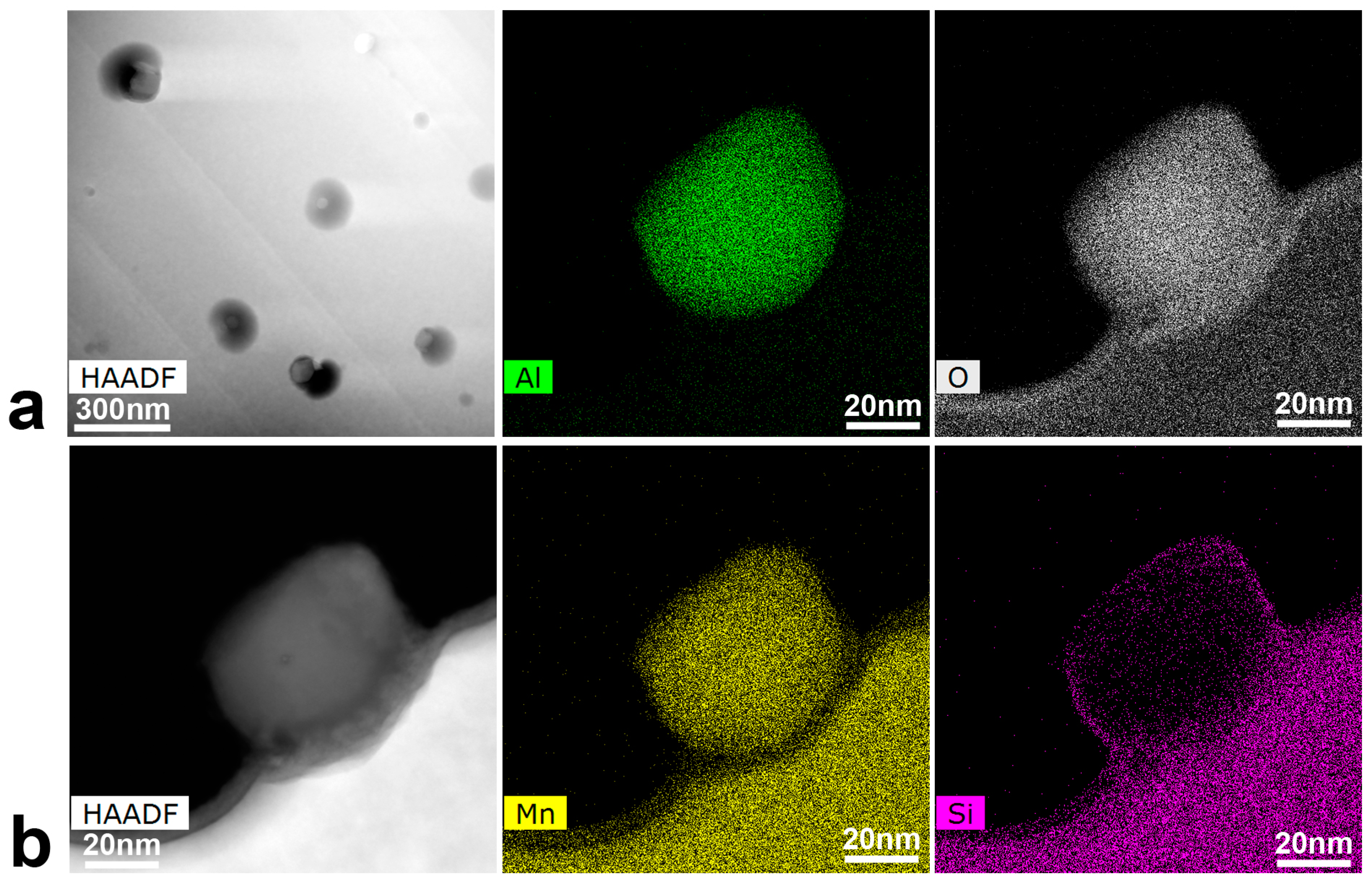

- The need of a further post-processing thermal treatment at 1350 K (or at least above 1273 K) was demonstrated through a detailed microstructural characterization by SEM, with EDX and EBSD and TEM, with HAADF and EDX, detectors.

- The design of the alloy composition succeeds in achieving a Neel temperature, TN, sufficiently low to not interact with the martensitic transformation.

- The presence of nano precipitates of (MnAl)2O3 mixed oxides has been reported in these SMA and its presence could be inherent to the additive manufacturing route of Mn-rich alloys.

- The LPBF processed and thermally treated samples exhibit a reproducible and fully reversible martensitic transformation between the γ austenite and the ε martensite. This reversibility stands over cycling, and the undesirable α′ martensite was not found.

- In the LPBF processed samples an ε transformed fraction above 14% was obtained, which is an outstanding result for a thermally induced transformation in non-strained samples.

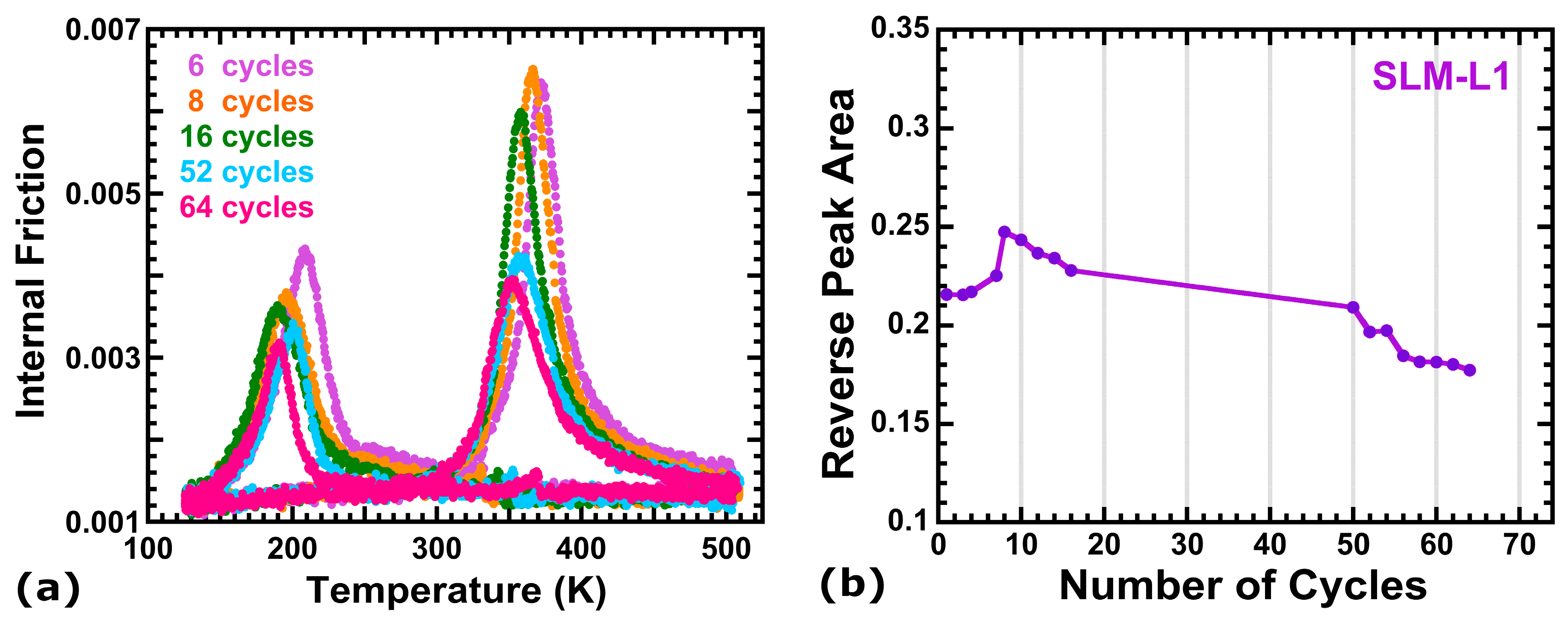

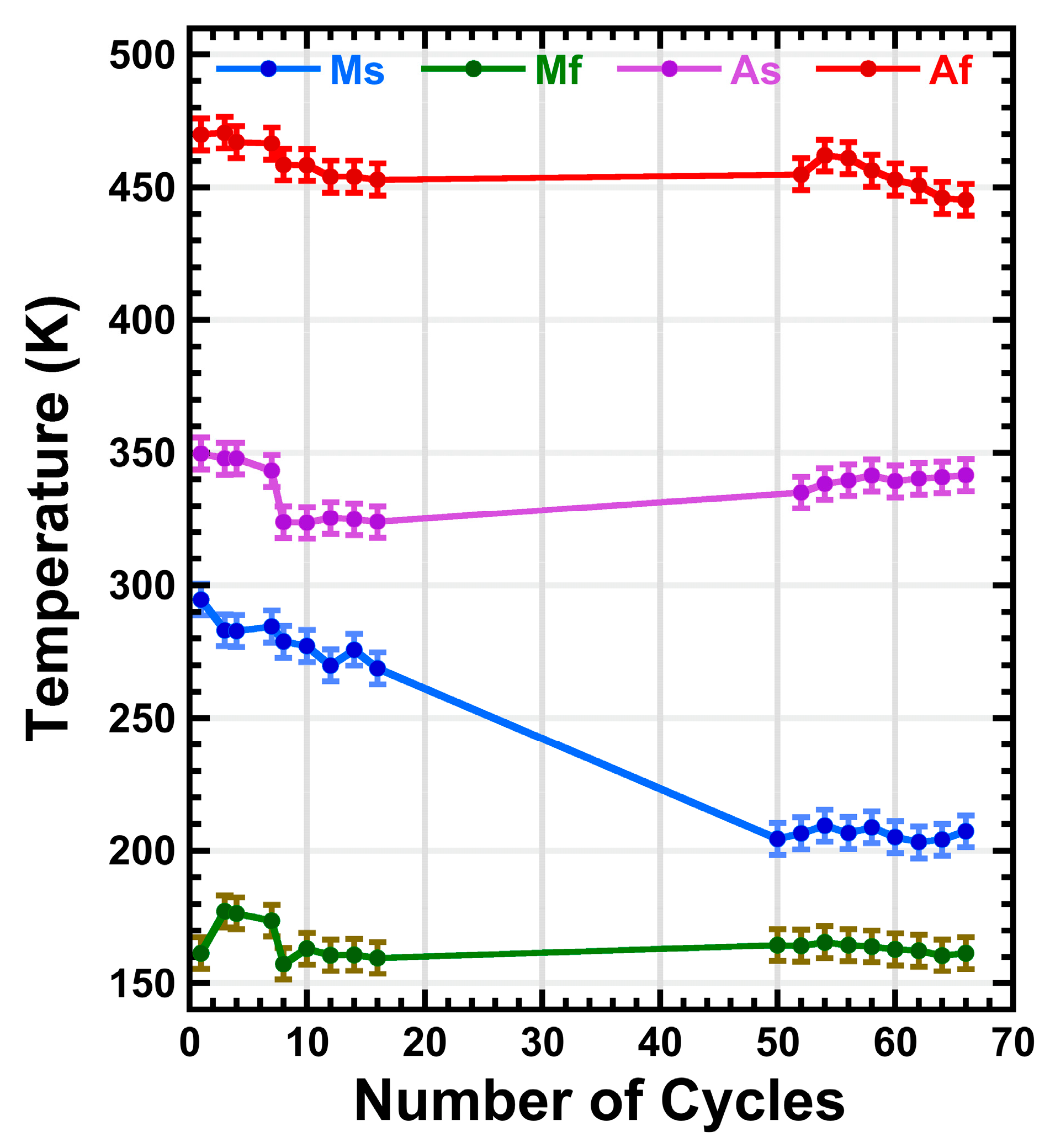

- The cycling behavior of the ε martensite transformation, in LPBF samples, is reproducible and stable after about 60 cycles, with a fully reversible thermally transformed ε fraction above 9%.

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Delaey, L. Diffusionless Transformations. In Materials Science and Technology V5; Cahn, R.W., Haasen, P., Kramer, E.J., Eds.; VCH: Weinheim, Germany, 1991; pp. 339–404. ISBN 3-527-30256-5. [Google Scholar]

- Otsuka, K.; Wayman, C.M. Shape Memory Materials; Cambridge University Press: Cambridge, UK, 1998; ISBN 0 521 44487 X. [Google Scholar]

- Yamauchi, K.; Ohkata, I.; Tsuchiya, K.; Miyazaki, S. Shape Memory and Superelastic Alloys; Woodhead Publishing: Cambridge, UK, 2011; ISBN 97800 810 17012. [Google Scholar]

- Jani, J.M.; Leary, M.; Subic, A.; Gibson, M.A. A review of shape memory alloy research, applications and opportunities. Mater. Design 2014, 56, 1078–1113. [Google Scholar] [CrossRef]

- Concilio, A.; Antonucci, V.; Aurichio, F.; Lecce, L.; Sacco, E. Shape Memory Alloy Engineering, 2nd ed.; Butterworth-Heinemann: Oxford, UK, 2021; ISBN 978-0-12-819264-1. [Google Scholar]

- Sato, A.; Chishima, E.; Soma, K.; Mori, T. Shape memory effect in γ-ε transformation in Fe-30Mn-1Si alloy single crystals. Acta Metall. 1982, 30, 1177–1183. [Google Scholar] [CrossRef]

- Sato, A.; Chishima, E.; Yamaji, Y.; Mori, T. Orientation and composition dependencies of shape memory effect in Fe-Mn-Si alloys. Acta Metall. 1984, 32, 539–547. [Google Scholar] [CrossRef]

- Sato, A.; Yamaji, Y.; Mori, T. Physical Properties controlling Shape Memory effect in Fe-Mn-Si Alloys. Acta Metall. 1986, 34, 287–294. [Google Scholar] [CrossRef]

- Murakami, M.; Suzuki, H.; Nakamura, Y. Effect of Si on the shape memory effect of polycrystalline Fe-Mn-Si alloys. J. Trans. Iron Steel Inst. Jpn. 1986, 27, 87–92. [Google Scholar]

- Otsuka, H.; Yamada, H.; Maruyama, T.; Tanahashi, H.; Matsuda, S.; Murakami, M. Effects of Alloying Additions on Fe-Mn-Si Shape Memory Alloys. Iron Steel Inst. Jpn. Int. 1990, 30, 674–679. [Google Scholar] [CrossRef]

- Rong, L.J.; Ping, D.H.; Li, Y.Y.; Shi, C.X. Improvement of Shape Memory Effect in Fe-Mn Alloy by Cr and Ni addition. Scr. Metall. Mater. 1995, 32, 1905–1909. [Google Scholar] [CrossRef]

- Söderberg, O.; Liu, X.W.; Yakovenko, P.G.; Ullakko, K.; Lindroos, V.K. Corrosion behavior of Fe-Mn-Si based shape memory steels trained by cold rolling. Mater. Sci. Eng. A 1990, 273–275, 543–548. [Google Scholar] [CrossRef]

- Maruyama, T.; Kurita, T. Ferrous shape memory alloys and their applications. Kinzoku 2004, 2, 48–51. [Google Scholar] [CrossRef]

- Janke, L.; Czaderski, C.; Motavalli, M.; Ruth, J. Applications of shape memory alloys in civil engineering structures—Overview, limits and new ideas. Mater. Struct. 2005, 38, 578–592. [Google Scholar] [CrossRef]

- Sato, A.; Kubo, H.; Maruyama, T. Mechanical Properties of Fe–Mn–Si Based SMA and the Application. Mater. Trans. 2006, 47, 571–579. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Kikuchi, T.; Ogawa, K.; Kajiwara, S.; Ikeo, Y.; Kojima, M.; Ogawa, T. Development of prestressed concrete using Fe-Mn-Si-based shape memory alloys containing NbC. Mater. Trans. 2006, 47, 580–583. [Google Scholar] [CrossRef]

- Maruyama, T.; Kurita, T.; Kozaki, S.; Andou, K.; Farjami, S.; Kubo, H. Innovation in producing crane rail fishplate using Fe-Mn-Si-Cr based shape memory alloy. Mater. Sci. Technol. 2008, 24, 908–912. [Google Scholar] [CrossRef]

- Cladera, A.; Weber, B.; Leinenbach, C.; Czaderski, C.; Shahverdi, M.; Motavalli, M. Iron-based shape memory alloys for civil engineering structures: An overview. Constr. Build. Mater. 2014, 63, 281–293. [Google Scholar] [CrossRef]

- Druker, A.V.; Perotti, A.; Esquivel, I.; Malarría, J. A manufacturing process for shaft and pipe couplings of Fe–Mn–Si–Ni–Cr shape memory alloys. Mater. Design 2014, 56, 878–888. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Maruyama, T.; Otsuka, H.; Kushibe, A.; Inoue, Y.; Tsuzaki, K. Design Concept and Applications of FeMnSi-Based Alloys—From Shape-Memory to Seismic Response Control. Mater. Trans. 2016, 57, 283–293. [Google Scholar] [CrossRef]

- Nikulin, I.; Nagashima, N.; Yoshinaka, F.; Sawaguchi, T. Superior fatigue life of Fe- 15Mn-10Cr-8Ni-4Si seismic damping alloy subjected to extremely high strain amplitudes. Mater. Lett. 2018, 230, 257–260. [Google Scholar] [CrossRef]

- Shahverdi, M.; Michels, J.; Czaderski, C.; Motavalli, M. Iron-based shape memory alloy strips for strengthening RC members: Material behavior and characterization. Constr. Build. Mater. 2018, 173, 586–599. [Google Scholar] [CrossRef]

- Hong, K.; Lee, S.; Han, S.; Yeon, Y. Evaluation of Fe-Based Shape Memory Alloy (Fe-SMA) as Strengthening Material for Reinforced Concrete Structures. Appl. Sci. 2018, 8, 730. [Google Scholar] [CrossRef]

- Sawaguchi, T.; Nikulin, I.; Ogawa, K.; Takamori, S.; Yoshinaka, F.; Chiba, Y.; Otsuka, H.; Inoue, Y.; Kushibe, A. Low-cycle fatigue life and plasticity mechanisms of a Fe-15Mn-10Cr-8Ni-4Si seismic damping alloy under cyclic loading at various temperatures. Acta Mater. 2021, 220, 117267. [Google Scholar] [CrossRef]

- Zhang, Z.X.; Zhang, J.; Wu, H.; Ji, Y.; Kumar, D.D. Iron-based shape memory alloys in construction: Research applications and opportunities. Materials 2022, 15, 1723. [Google Scholar] [CrossRef] [PubMed]

- Qiang, X.; Chen, L.; Jiang, X. Achievements and Perspectives on Fe-Based Shape Memory Alloys for Rehabilitation of Reinforced Concrete Bridges: An Overview. Materials 2022, 15, 8089. [Google Scholar] [CrossRef]

- Suzuki, T.; Motomura, S.; Kinoshita, T.; Inoue, Y.; Kushibe, A.; Iida, T. Shape optimization of Hourglass-shaped damper using Fe-Mn-Si-Based alloy considering target Load-displacement relationship and target fatigue characteristics. Constr. Build. Mater. 2023, 366, 130091. [Google Scholar] [CrossRef]

- Qiang, X.; Wu, Y.; Wang, Y.; Jiang, X. Research Progress and Applications of Fe-Mn-Si-Based Shape Memory Alloys on Reinforcing Steel and Concrete Bridges. Appl. Sci. 2023, 13, 3404. [Google Scholar] [CrossRef]

- Olson, G.; Cohen, M. A general mechanism of martensitic nucleation: Part, I. General concepts and the FCC-HCP transformation. Metall. Trans. A 1976, 7, 1897–1904. [Google Scholar] [CrossRef]

- Gu, Q.; Van Humbeeck, J.; Delaey, L. A review on the martensitic transformation and shape memory effect in Fe-Mn-Si alloys. J. Phys. IV 1994, 3, 135–144. [Google Scholar] [CrossRef]

- Nishiyama, Z. Martensitic Transformation; Academic Press: New York, NY, USA, 1978; ISBN 9780124145627. [Google Scholar]

- Sawaguchi, T.; Nikulin, I.; Ogawa, K.; Sekido, K.; Takamori, S.; Maruyama, T.; Chiba, Y.; Kushibe, A.; Inoue, Y.; Tsuzaki, K. Designing Fe–Mn–Si alloys with improved low-cycle fatigue lives. Scr. Mater. 2015, 99, 49–52. [Google Scholar] [CrossRef]

- Otsuka, K.; Ren, X. Physical Metallurgy of Ti-Ni-based shape memory alloys. Prog. Mater. Sci. 2005, 50, 511–678. [Google Scholar] [CrossRef]

- López-Ferreño, I.; Gómez-Cortés, J.F.; Breczewski, T.; Ruiz-Larrea, I.; Nó, M.L.; San Juan, J.M. High-temperature shape memory alloys based on the Cu-Al-Ni system: Design and thermomechanical characterization. J. Mater. Res. Technol. 2020, 9, 9972–9984. [Google Scholar] [CrossRef]

- Herzog, D.; Seyda, V.; Wycisk, E.; Emmelmann, C. Additive manufacturing of metals. Acta Mater. 2016, 117, 371–392. [Google Scholar] [CrossRef]

- Milewski, J.O. Additive Manufacturing of Metals; Springer International Publisher AG: Cham, Switzerland, 2017; ISBN 978-3319582047. [Google Scholar]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components—Process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Elahinia, M.; Moghaddam, N.S.; Andani, M.T.; Amerinatanzi, A.; Bimber, B.A.; Hamilton, R.F. Fabrication of NiTi through additive manufacturing: A review. Prog. Mater. Sci. 2016, 83, 630–663. [Google Scholar] [CrossRef]

- Van Humbeeck, J. Additive Manufacturing of Shape Memory Alloys. Shap. Mem. Superelasticity 2018, 4, 309–312. [Google Scholar] [CrossRef]

- Xue, L.; Atli, K.C.; Zhang, C.; Hite, N.; Srivastava, A.; Leff, A.C.; Wilson, A.A.; Sharar, D.J.; Elvany, A.; Arroyave, R.; et al. Laser Powder Bed Fusion of defect-free NiTi shape memory alloy parts with superior tensile superelasticity. Acta Mater. 2022, 229, 117781. [Google Scholar] [CrossRef]

- Tian, J.; Zhu, W.; Wei, Q.; Wen, S.; Li, S.; Song, B.; Shi, Y. Process optimization, microstructures and mechanical properties of a Cu-based shape memory alloy fabricated by selective laser melting. J. Alloys Compd. 2019, 785, 754–764. [Google Scholar] [CrossRef]

- Babacan, N.; Pauly, S.; Gustmann, T. Laser powder bed fusion of a superelastic Cu-Al-Mn shape memory alloy. Mater. Design 2021, 203, 109625. [Google Scholar] [CrossRef]

- Pérez-Cerrato, M.; Fraile, I.; Gómez-Cortés, J.F.; Urionabarrenetxea, E.; Ruiz-Larrea, I.; González, I.; Nó, M.L.; Burgos, N.; San Juan, J.M. Designing for Shape Memory in Additive Manufacturing of Cu-Al-Ni Shape Memory Alloy Processed by Laser Powder Bed Fusion. Materials 2022, 15, 6284. [Google Scholar] [CrossRef] [PubMed]

- Nilsén, F.; Ituarte, I.F.; Salmi, M.; Partanen, J.; Hannula, S.-P. Effect of process parameters on non-modulated Ni-Mn-Ga alloy manufactured using powder bed fusion. Addit. Manuf. 2019, 28, 464–474. [Google Scholar] [CrossRef]

- Laitinen, V.; Sozinov, A.; Saren, A.; Salminen, A.; Ullakko, K. Laser powder bed fusion of Ni-Mn-Ga magnetic shape memory alloy. Addit. Manuf. 2019, 30, 100891. [Google Scholar] [CrossRef]

- Sun, W.; Lu, X.; Wei, Z.; Li, Q.; Li, Z.; Zhang, Y.; Liu, J. Multicaloric effect in Ni-Mn-Sn metamagnetic shape memory alloy by laser powder bed fusion. Addit. Manuf. 2022, 59, 103125. [Google Scholar] [CrossRef]

- Rittinghaus, S.-K.; Shokri, H.; Shkodich, N.; Bruder, E.; Farle, M.; Gökce, B. Comparative insights into microstructure and magnetism of Ni-Mn-Sn Heusler alloys manufactured by electron beam and laser beam powder bed fusion. Addit. Manuf. Lett. 2023, 7, 100159. [Google Scholar] [CrossRef]

- Arabi-Hashemi, A.; Maeder, X.; Figi, R.; Schreiner, C.; Griffiths, S.; Leinenbach, C. 3D magnetic patterning in additive manufacturing via sit-specific in-situ alloy modification. Appl. Mater. Today 2020, 18, 100512. [Google Scholar] [CrossRef]

- Ferretto, I.; Kim, D.; Della-Ventura, N.M.; Shahverdi, M.; Lee, W.; Leinenbach, C. Laser powder bed fusion of a Fe–Mn–Si shape memory alloy. Add. Manuf. 2021, 46, 102071. [Google Scholar] [CrossRef]

- Kim, D.; Ferretto, I.; Jeon, J.B.; Leinenbach, C.; Lee, W. Formation of metastable bcc-δ phase and its transformation to fcc-γ in laser powder bed fusion of Fe–Mn–Si shape memory alloy. J. Mater. Res. Technol. 2021, 14, 2782–2788. [Google Scholar] [CrossRef]

- Kim, D.; Ferretto, I.; Kim, W.; Leinenbach, C.; Lee, W. Effect of post-heat treatment conditions on shape memory property in 4D printed Fe–17Mn–5Si–10Cr–4Ni shape memory alloy. Mater. Sci. Eng. A 2022, 852, 143689. [Google Scholar] [CrossRef]

- Ferretto, I.; Borzi, À.; Kim, D.; Della Ventura, N.M.; Hosseini, E.; Lee, W.J.; Leinenbach, C. Control of microstructure and shape memory properties of a Fe-Mn-Si-based shape memory alloy during laser powder bed fusion. Add. Manuf. Lett. 2022, 3, 100091. [Google Scholar] [CrossRef]

- Jafarabadi, A.; Ferretto, I.; Mohri, M.; Leinenbach, C.; Ghafoori, E. 4D printing of recoverable buckling-induced architected iron-based shape memory alloys. Mater. Design 2023, 233, 112216. [Google Scholar] [CrossRef]

- Del-Río, L.; Nó, M.L.; Sota, A.; Perez-Casero, I.; Gómez-Cortés, J.F.; Pérez-Cerrato, M.; Veiga, A.; Ruiz-Larrea, I.; Ausejo, S.; Burgos, N.; et al. Internal friction associated with ε martensite in shape memory steels produced by casting route and through additive manufacturing: Influence of thermal cycling on the martensitic transformation. J. Alloys Compd. 2022, 919, 165806. [Google Scholar] [CrossRef]

- Felice, I.O.; Shen, J.; Barragan, A.F.C.; Moura, I.A.B.; Li, B.; Wang, B.; Khodaverdi, H.; Mohri, M.; Schell, N.; Ghafoori, E.; et al. Wire and arc additive manufacturing of Fe-based shape memory alloys: Microstructure, mechanical and functional behavior. Mater. Design 2023, 231, 112004. [Google Scholar] [CrossRef]

- Chowdury, P.; Canadinc, D.; Seitoglu, H. On deformation behavior of Fe-Mn based structural alloys. Mater. Sci. Eng. R 2017, 122, 1–28. [Google Scholar] [CrossRef]

- Cotes, S.; Sade, M.; Fernández-Guillermet, A. Fcc/Hcp Martensitic Transformation in the Fe-Mn System: Experimental Study and Thermodynamic Analysis of Phase Stability. Metall. Mater. Trans. A 1995, 26, 1957–1969. [Google Scholar] [CrossRef]

- Hoshino, Y.; Nakamura, S.; Ishikawa, N.; Yamaji, Y.; Matsumoto, S.; Tanaka, Y.; Sato, A. In-situ observation of partial dislocation motion during γ → ε transformation in a Fe-Mn-Si shape memory alloy. Mater. Trans. 1992, 33, 253–262. [Google Scholar] [CrossRef]

- Tsuzaki, K.; Fukasaku, S.; Tomota, Y.; Maki, T. Effect of prior deformation of austenite on the γ–ε martensitic transformation. Mater. Trans. Jpn. Inst. Metals 1991, 32, 222–228. [Google Scholar]

- Jang, W.Y.; Gu, Q.; Van Humbeeck, J.; Delaey, L. Microscopic observation of γ-phase and ε- and α′-martensite in Fe Mn Si-based shape memory alloys. Mater. Charact. 1995, 34, 67–72. [Google Scholar] [CrossRef]

- Otubo, J.; Mei, P.R.; Koshimizu, S.; Shinohara, A.H.; Suzuki, C.K. Relationship between thermomechanical treatment, microstructure and α′ martensite in stainless Fe-based shape memory alloys. Mater. Sci. Eng. A 1999, 273–275, 533–537. [Google Scholar] [CrossRef]

- Dong, Z.Z.; Kajiwara, S.; Kikuchi, T.; Sawaguchi, T. Effect of pre-deformation at room temperature on shape memory properties of stainless type Fe-15Mn-5Si-9Cr-5Ni-(0.5–1.5)NbC alloys. Acta Mater. 2005, 53, 4009–4018. [Google Scholar] [CrossRef]

- Min, X.H.; Sawaguchi, T.; Ogawa, K.; Maruyama, T.; Yin, F.X.; Tsuzaki, K. Shape memory effect in Fe-Mn-Ni-Si-C alloys with low Mn contents. Mater. Sci. Eng. A 2011, 528, 5251–5258. [Google Scholar] [CrossRef]

- Peng, H.B.; Song, F.; Wang, S.L.; Zhang, C.Y.; Wen, Y.H. Role of carbon in improving the shape memory effect of Fe–Mn–Si–Cr–Ni alloys by thermo-mechanical treatments. Smart Mater. Struct. 2015, 24, 55010. [Google Scholar] [CrossRef]

- Pérez-Sáez, R.B.; Nó, M.L.; San Juan, J.M. Internal friction in Fe-Mn-Cr-Si-Ni shape memory alloys. J. Alloys Compd. 1994, 211/212, 212–215. [Google Scholar] [CrossRef]

- Chen, S.; Chung, C.Y.; Yan, C.; Hsu, T.Y. Effect of f.c.c. antiferromagnetism on martensitic transformation in Fe–Mn–Si based alloys. Mater. Sci. Eng. A 1999, 264, 262–268. [Google Scholar] [CrossRef]

- Wu, X.; Hsu, T.Y. Effect of the Neel temperature, TN, on martensitic transformation in Fe-Mn-Si-based shape memory alloys. Mater. Charact. 2000, 45, 137–142. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Lu, X.; Tian, X.; Qin, Z. Compositional dependence of the Neel transition, structural stability, magnetic properties and electrical resistivity in Fe–Mn–Al–Cr–Si alloys. Mater. Sci. Eng. A 2002, 334, 19–27. [Google Scholar] [CrossRef]

- Maki, T.; Tsuzaki, K. Transformation behavior of ε-martensite in Fe-Mn-Si shape memory alloys. In Proceedings of the International Conference on Martensitic Transformations (ICOMAT-92), Monterey, CA, USA, 20–24 July 1992; pp. 1151–1162. [Google Scholar]

- Sato, A.; Mori, T. Development of a shape memory alloy Fe Mn Si. Mater. Sci. Eng. A 1991, 146, 197–204. [Google Scholar] [CrossRef]

- Yang, J.; Wayman, C.M. Development of Fe-based shape memory alloys associated with face-centered cubic-hexagonal close-packed martensitic transformations: Part III. microstructures. Metall. Trans. A 1992, 23, 1445–1454. [Google Scholar] [CrossRef]

- Stanford, N.; Dunne, D.P. Effect of Si on the reversibility of stress-induced martensite in Fe–Mn–Si shape memory alloys. Acta Mater. 2010, 58, 6752–6762. [Google Scholar] [CrossRef]

- Guerrero, L.M.; La Roca, P.; Malamud, F.; Baruj, A.; Sade, M. Composition effects on the fcc-hcp martensitic tranbsformation and on the magnetic ordering of the fcc structure in Fe-Mn-Cr alloys. Mater. Design 2017, 116, 127–135. [Google Scholar] [CrossRef]

- Guerrero, L.M.; La Roca, P.; Malamud, F.; Baruj, A.; Sade, M. A short review on the effect of Cr on the fcc-hcp phase transition in Fe-Mn-based alloys. Shap. Mem. Superelasticity 2020, 6, 202–212. [Google Scholar] [CrossRef]

- Peng, H.; Chen, J.; Wang, Y.; Wen, Y. Key factors achieving large recovery strains in polycrystalline Fe-Mn-Si-Based shape memory alloys: A review. Adv. Eng. Mater. 2018, 20, 1700741. [Google Scholar] [CrossRef]

- Kim, R.; Bae, C.; Kim, J. Effects of Ni Content on Reversible Deformation-Induced Martensitic Transformation of Fe–Mn–Cr–Si–Ni Alloy Under Uniaxial Deformation. Metall. Mater. Trans A 2022, 53, 322–330. [Google Scholar] [CrossRef]

- Hamers, A.A.H.; Wayman, C.M. Shape memory behavior in FeMnCo alloys. Scr. Metall. Mater. 1991, 25, 2723–2728. [Google Scholar] [CrossRef]

- La Roca, P.; Marinelli, P.; Baruj, A.; Sade, M.; Fernández-Guillermet, A. Composition dependent of the Néel temperature and the entropy of the magnetic transition in the fcc phase of Fe-Mn and Fe-Mn-Co alloys. J. Alloys Compd. 2016, 688, 594–598. [Google Scholar] [CrossRef]

- Chen, J.; Sun, J.; Yang, Q.; Peng, H.; Wang, S.; Wen, Y. Thermodynamic explanation for the large difference in improving shape memory effect of Fe-Mn alloys by Co and Si addition. Adv. Eng. Mater. 2016, 18, 1426–1433. [Google Scholar] [CrossRef]

- Jiang, B.; Xu, K.; Qi, X.; Zhou, W. Effects of cobalt content on martensitic transformation and shape memory effect in Fe-Mn-Si-Cr-Ni alloys. J. Phys. IV France 2003, 112, 393–396. [Google Scholar] [CrossRef]

- Bliznuk, V.V.; Gavriljuk, V.G.; Kopista, G.P.; Grigoriev, S.V.; Runov, V.V. Fluctuations of chemical composition of austenite and their consequence on shape memory effect in Fe-Mn-(Si, Cr, Ni, C, N) alloys. Acta Mater. 2004, 52, 4791–4799. [Google Scholar] [CrossRef]

- Chen, J.; Peng, H.B.; Yang, Q.; Wang, S.L.; Song, F.; Wen, Y.H. Effect of carbon content on shape memory effect of Fe-Mn-Si-Cr-Ni-based alloys at different deformation temperatures. Mater. Sci. Eng. A 2016, 677, 133–139. [Google Scholar] [CrossRef]

- Li, H.; Dunne, D.; Kennon, N. Factors influencing shape memory effect and phase transformation behaviour of Fe–Mn–Si based shape memory alloys. Mater. Sci. Eng. A 1999, 273–275, 517–523. [Google Scholar] [CrossRef]

- Stanford, N.; Dunne, D. Thermo-mechanical processing and the shape memory effect in an Fe–Mn–Si-based shape memory alloy. Mater. Sci. Eng. A 2006, 422, 352–359. [Google Scholar] [CrossRef]

- Yang, C.H.; Lin, H.C.; Lin, K.M.; Tsai, H.K. Effects of thermo-mechanical treatment on a Fe–30Mn–6Si shape memory alloy. Mater. Sci. Eng. A 2008, 497, 445–450. [Google Scholar] [CrossRef]

- Wen, Y.H.; Peng, H.B.; Raabe, D.; Gutierrez-Urrutia, I.; Chen, J.; Du, Y.Y. Large recovery strain in Fe-Mn-Si-Based shape memory steels obtained by engineering annealing twin boundaries. Nat. Commun. 2014, 5, 4964. [Google Scholar] [CrossRef] [PubMed]

- Fuster, V.; Druker, A.V.; Baruj, A.; Malarria, J.; Bolmaro, R. Characterization of phases in an Fe–Mn–Si–Cr–Ni shape memory alloy processed by different thermomechanical methods. Mater. Charact. 2015, 109, 128–137. [Google Scholar] [CrossRef]

- Nikulin, I.; Sawaguchi, T.; Ogawa, K.; Tsuzaki, K. Effect of γ to ε martensitic transformation on low-cycle fatigue behaviour and fatigue microstructure of Fe-15Mn-10Cr-8Ni-xSi austenitic alloys. Acta Mater. 2016, 105, 207–218. [Google Scholar] [CrossRef]

- Balagurov, A.M.; Bobrikov, I.A.; Pons, J.; Cifre, J.; Sun, L.Y.; Golovin, I.S. Structure of the Fe-Mn-Si alloys submitted to γ ↔ ε thermocycling. Mater. Charact. 2018, 141, 223–228. [Google Scholar] [CrossRef]

- Peng, H.; Wang, G.; Wang, S.; Chen, J.; MacLaren, I.; Wen, Y. Key criterion for achieving giant recovery strains in polycrystalline Fe-Mn-Si based shape memory alloys. Mater. Sci. Eng. A 2018, 712, 37–49. [Google Scholar] [CrossRef]

- Arabi-Hashemi, A.; Lee, W.J.; Leinenbach, C. Recovery stress formation in FeMnSi based shape memory alloys: Impact of precipitates, texture and grain size. Mater. Design 2018, 139, 258–268. [Google Scholar] [CrossRef]

- Sun, L.; Cheng, W.C.; Balagurov, A.M.; Bobrikov, I.A.; Cifre, J.; Chudakov, I.B.; Jen, S.U.; Cheverikin, V.V.; Zadorozhnyy, M.Y.; Golovin, I.S. Effect of thermal cycling on microstructure and damping capacity of Fe–26Mn–4Si alloy. Mater. Charact. 2020, 159, 110001. [Google Scholar] [CrossRef]

- Arabi-Hashemi, A.; Polatidis, E.; Smid, M.; Panzner, T.; Leinenbach, C. Grain orientation dependence of the forward and reverse fcc ↔ hcp transformation in FeMnSi-based shape memory alloys studied by in situ neutron diffraction. Mater. Sci. Eng. A 2020, 782, 139261. [Google Scholar] [CrossRef]

- Urionabarrenechea, E. Estudio Experimental y Simulación del Proceso de Producción de Polvos Metálicos mediante Atomización con Gas. Ph.D. Thesis, Universidad de Navarra, Donostia-San Sebastian, Spain, 2015. [Google Scholar]

- Meier, H.; Haberland, C. Experimental studies on selective laser melting of metallic parts. Mat. Wiss Wekstoffen. 2008, 39, 665–670. [Google Scholar] [CrossRef]

- Gutierrez-Urrutia, I.; Nó, M.L.; Carreño-Morelli, E.; Guisolan, B.; Schaller, R.; San Juan, J.M. High performance very low frequency forced pendulum. Mater. Sci. Eng. A 2004, 370, 435–439. [Google Scholar] [CrossRef]

- San Juan, J.M.; Pérez-Sáez, R.B. Transitory effects. Mater. Sci. Forum. 2001, 366–368, 416–436. [Google Scholar] [CrossRef]

- Sato, A.; Ozaki, K.; Watanabe, Y.; Mori, T. Internal Friction due to ε → γ Reverse Transformation in an Fe-Mn-Si-Cr Shape Memory Alloy. Mater. Sci. Eng. A 1988, 101, 25–30. [Google Scholar] [CrossRef]

- Pérez-Sáez, R.B.; Recarte, V.; Nó, M.L.; San Juan, J.M. Anelastic contributions and transformed volume fraction during thermoelastic martensitic transformations. Phys. Rev. B 1998, 57, 5684–5692. [Google Scholar] [CrossRef]

- Robinson, J.S.; McCormick, P.G. Shape Memory in an Fe-Mn-Si Alloy. Mater. Sci. Forum 1990, 56–58, 649–654. [Google Scholar] [CrossRef]

- Federzoni, L.; Gex, D.; Gu, G.; Guénin, G.; Labrosse, D.; Mantel, M.; Van Humbeeck, J. Study of thermal ε-phase martensite in a Fe-Mn-Si-Cr-Ni shape memory alloy by X-ray diffraction and thermoelectric power. In Proceedings of the International Conference Martensitic Transformations, Monterey Institute Advanced Studies, Monterey, CA, USA, 20–24 July 1992; pp. 1175–1180. [Google Scholar]

- Liu, J.; Wen, P. Metal vaporization and its influence during laser powder bed fusion process. Mater. Des. 2022, 215, 110505. [Google Scholar] [CrossRef]

- Bollmann, W. (Ed.) Crystal Defects and Crystalline Interfaces; Springer: Berlin/Heilderberg, Germany, 1970; ISBN 978-3-642-49175-7. [Google Scholar] [CrossRef]

- Pond, R.C.; Bollmann, W. The symmetry and interfacial structure of bicrystals. Phil. Trans. R. Soc. Lond. A 1979, 292, 449–472. [Google Scholar] [CrossRef]

- Ferreto, I.; Sharma, A.; Kim, D.; Della Ventura, N.M.; Maeder, X.; Michler, J.; Hosseini, E.; Lee, W.J.; Leinenbach, C. Fabrication of FeMnSi-based shape memory alloy components with graded-microstructures by laser powder bed fusion. Addit. Manuf. 2023, 78, 103835. [Google Scholar] [CrossRef]

- Peng, H.; Wen, Y.; Du, Y.; Chen, J.; Yang, Q. A New Set of Creq and Nieq Equations for Predicting Solidification Modes of Cast Austenitic Fe-Mn-Si-Cr-Ni Shape Memory Alloys. Metall. Mater. Trans. B 2014, 45, 6–11. [Google Scholar] [CrossRef]

- Forsberg, A.; Ågren, J. Thermodynamic Evaluation of the Fe-Mn-Si System and the γ/ε Martensitic Transformation. J. Phase Equilibria 1993, 14, 354–363. [Google Scholar] [CrossRef]

- Zheng, W.; Lu, X.G.; He, Y.; Cui, Y.; Li, L. Thermodynamic assessment of the Fe–Mn–Si system and atomic mobility of its fcc phase. J. Alloys Compd. 2015, 632, 661–675. [Google Scholar] [CrossRef]

- Wen, Y.H.; Peng, H.B.; Sun, P.P.; Liu, G.; Li, N. A novel training-free cast Fe–18Mn–5.5Si–9.5Cr–4Ni shape memory alloy with lathy delta ferrite. Scr. Mater. 2010, 62, 55–58. [Google Scholar] [CrossRef]

- Zhang, X.; Yocom, C.J.; Mao, B.; Liao, Y. Microstructure evolution during selective laser melting of metallic materials: A review. J. Laser Appl. 2019, 31, 031201. [Google Scholar] [CrossRef]

- Jägle, E.A.; Sheng, Z.; Wu, L.; Lu, L.; Risse, J.; Weisheit, A.; Raabe, D. Precipitation Reactions in Age-Hardenable Alloys During Laser Additive Manufacturing. J. Alloys Compd. 2016, 68, 943–949. [Google Scholar] [CrossRef]

- Kraner, J.; Medved, J.; Godec, M.; Paulin, I. Thermodynamic Behavior of Fe-Mn and Fe-Mn-Ag Powder Mixtures during Selective Laser Melting. Metals 2021, 11, 234. [Google Scholar] [CrossRef]

- Putaux, J.L.; Chevalier, J.P. HREM study of self-accommodated thermal martensite in an Fe-Mn-Si-Cr-Ni shape memory alloy. Acta Mater. 1996, 44, 1701–1716. [Google Scholar] [CrossRef]

- Bergeon, N.; Guenin, G.; Esnouf, C. Characterization of the stress-induced martensite in a Fe–Mn–Si–Cr–Ni shape memory alloy: Microstructural observation at different scales, mechanism of formation and growth. Mater. Sci. Eng. A. 1997, 238, 309–316. [Google Scholar] [CrossRef]

- Jiang, B.; Tadaki, T.; Mori, H.; Hsu, T.Y. In situ TEM observation of Martensitic Transformation during Tensile Straining in an Fe-Mn-Si Shape Memory Alloy. Mater. Trans. JIM 1997, 38, 1072–1077. [Google Scholar] [CrossRef]

- Hong, J.S.; Lee, Y.K. The mechanism of dislocation multiplication during thermally induced γ ↔ ε transformations in the Fe-17Mn alloy. Scr. Mater. 2023, 225, 115157. [Google Scholar] [CrossRef]

- Nakada, N.; Ishibashi, Y.; Tsuchiyama, T.; Takaki, S. Self-stabilization of un- transformed austenite by hydrostatic pressure via martensitic transformation. Acta Mater. 2016, 110, 95–102. [Google Scholar] [CrossRef]

- Hong, J.S.; Choi, S.M.; Lee, Y.K. Stasis mechanism of γ → ε martensitic transformation in Fe-17Mn alloy. Acta Mater. 2021, 210, 116846. [Google Scholar] [CrossRef]

- Scheel, P.; Markovic, P.; Van Petegem, S.; Makowska, M.G.; Wrobel, R.; Mayer, T.; Leinenbach, C.; Mazza, E.; Hosseini, E. A close look at remperature profiles during laser powder bed fusion using operando X-ray diffraction and finite element simulations. Add. Manuf. Lett. 2023, 6, 100150. [Google Scholar] [CrossRef]

- Ferreto, I.; Kim, D.; Mohri, M.; Ghafoori, E.; Lee, W.J.; Leinenbach, C. Shape recovery performance of a (V,C)-containing Fe-Mn-Si-Ni-Cr shape memory alloy fabricated by laser powder bed fusion. J. Mater. Res. Technol. 2022, 20, 3969–3984. [Google Scholar] [CrossRef]

- Kim, D.; Ferreto, I.; Leinenbach, C.; Lee, W.; Kim, W. Effect of direct aging microstructure, mechanical properties and shape memory behavior of Fe-17Mn-5Si-10Cr-4Ni-(V,C) shape memory alloy fabricated by laser powder bed fusion. Mater. Charact. 2023, 197, 112705. [Google Scholar] [CrossRef]

- Rodríguez-Aseguinolaza, J.; Ruiz-Larrea, I.; Nó, M.L.; López-Echarri, A.; San Juan, J. A new quantitative approach to the thermoelastic martensitic transformation: The density of elastic states. Acta Mater. 2008, 56, 6283–6290. [Google Scholar] [CrossRef]

- Ruiz-Larrea, I.; López-Echarri, A.; Gómez-Cortés, J.F.; Nó, M.L.; Brown, D.W.; Balogh, L.; Breczewski, T.; San Juan, J. Strain relaxation in Cu-Al-Ni shape memory alloys studied by in situ neutron diffraction experiments. J. Appl. Phys. 2019, 125, 082536. [Google Scholar] [CrossRef]

- Bertoli, U.S.; Guss, G.; Wu, S.; Matthews, M.J.; Schoenung, J.M. In-situ characterization of laser-powder interaction and cooling rates through high-speed imaging of powder bed fusion additive manufacturing. Mater. Design 2017, 135, 385–396. [Google Scholar] [CrossRef]

- Tehumalla, S.; Seita, M.; Zaefferer, S. Delineating dislocation structures and residual stresses in additively manufactured alloys. Acta Mater. 2023, 262, 119413. [Google Scholar] [CrossRef]

- Köhnen, P.; Ewald, S.; Schleifenbaum, J.H.; Belyakov, A. Controlling microstructure and mechanical properties of additively manufactured high-strength steels by taylored solidification. Add. Manuf. 2020, 35, 101389. [Google Scholar] [CrossRef]

| Num. of Experiment | Laser Power (W) | Scanning Speed (mm/s) | VED (J/mm3) | Compactness (%) |

|---|---|---|---|---|

| 1 | 170 | 650 | 73 | 99.91 |

| 5 | 170 | 750 | 63 | 99.91 |

| 2 | 170 | 850 | 56 | 99.89 |

| 8 | 185 | 650 | 79 | 99.93 |

| 7 | 185 | 750 | 69 | 99.92 |

| 9 | 185 | 850 | 60 | 99.91 |

| 6 | 200 | 650 | 85 | 99.93 |

| 4 | 200 | 750 | 74 | 99.91 |

| 3 | 200 | 850 | 65 | 99.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Del-Río, L.; Nó, M.L.; Gómez, R.; García-Sesma, L.; Urionabarrenetxea, E.; Ortega, P.; Mancisidor, A.M.; San Sebastian, M.; Burgos, N.; San Juan, J.M. Additive Manufacturing of Fe-Mn-Si-Based Shape Memory Alloys: State of the Art, Challenges and Opportunities. Materials 2023, 16, 7517. https://doi.org/10.3390/ma16247517

Del-Río L, Nó ML, Gómez R, García-Sesma L, Urionabarrenetxea E, Ortega P, Mancisidor AM, San Sebastian M, Burgos N, San Juan JM. Additive Manufacturing of Fe-Mn-Si-Based Shape Memory Alloys: State of the Art, Challenges and Opportunities. Materials. 2023; 16(24):7517. https://doi.org/10.3390/ma16247517

Chicago/Turabian StyleDel-Río, Lucia, Maria L. Nó, Raul Gómez, Leire García-Sesma, Ernesto Urionabarrenetxea, Pablo Ortega, Ane M. Mancisidor, Maria San Sebastian, Nerea Burgos, and Jose M. San Juan. 2023. "Additive Manufacturing of Fe-Mn-Si-Based Shape Memory Alloys: State of the Art, Challenges and Opportunities" Materials 16, no. 24: 7517. https://doi.org/10.3390/ma16247517