Multiscale Modeling of a Chain Comprising Selective Laser Melting and Post-Machining toward Nanoscale Surface Finish

Abstract

:1. Introduction

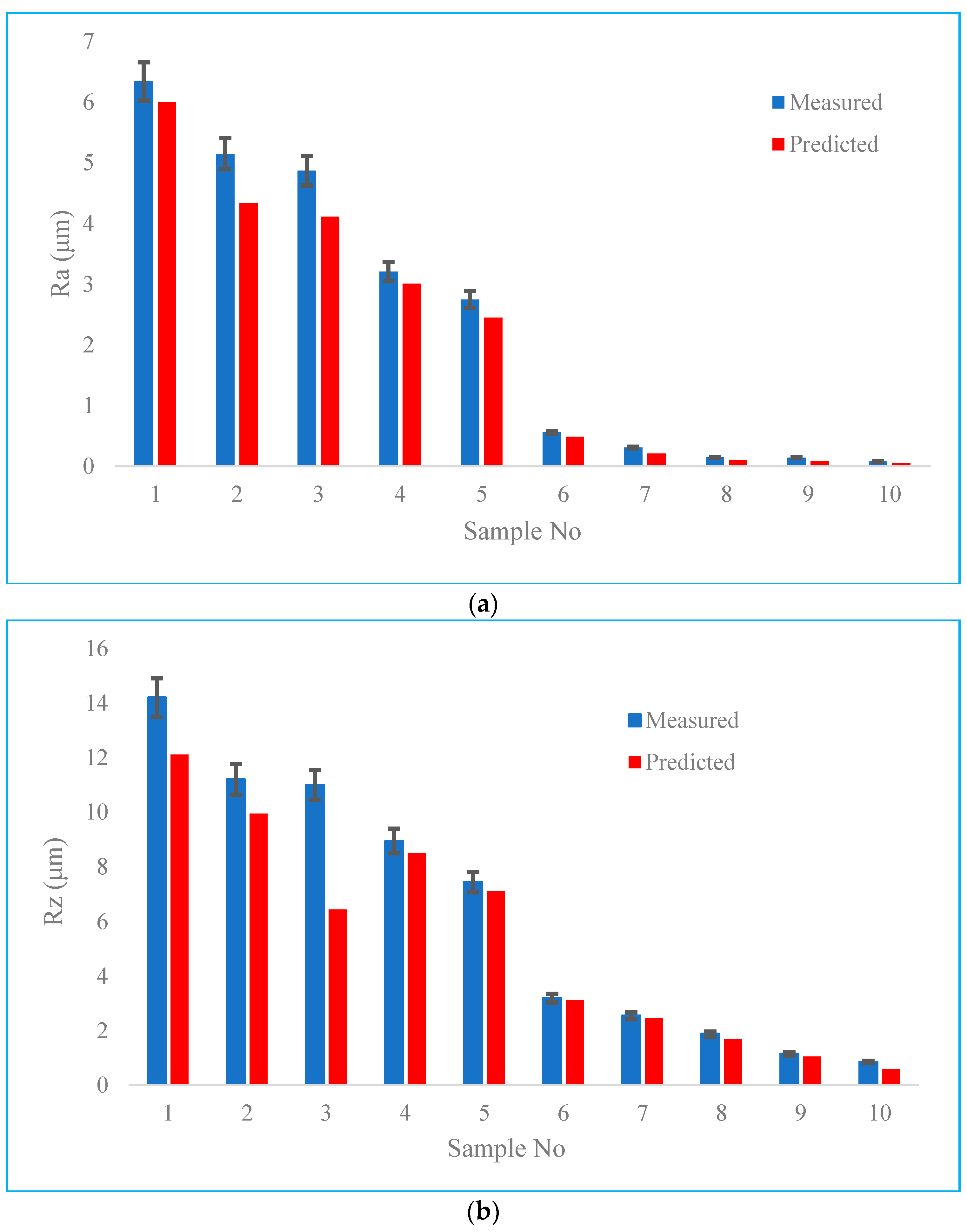

2. Materials and Methods

2.1. Simulation Framework

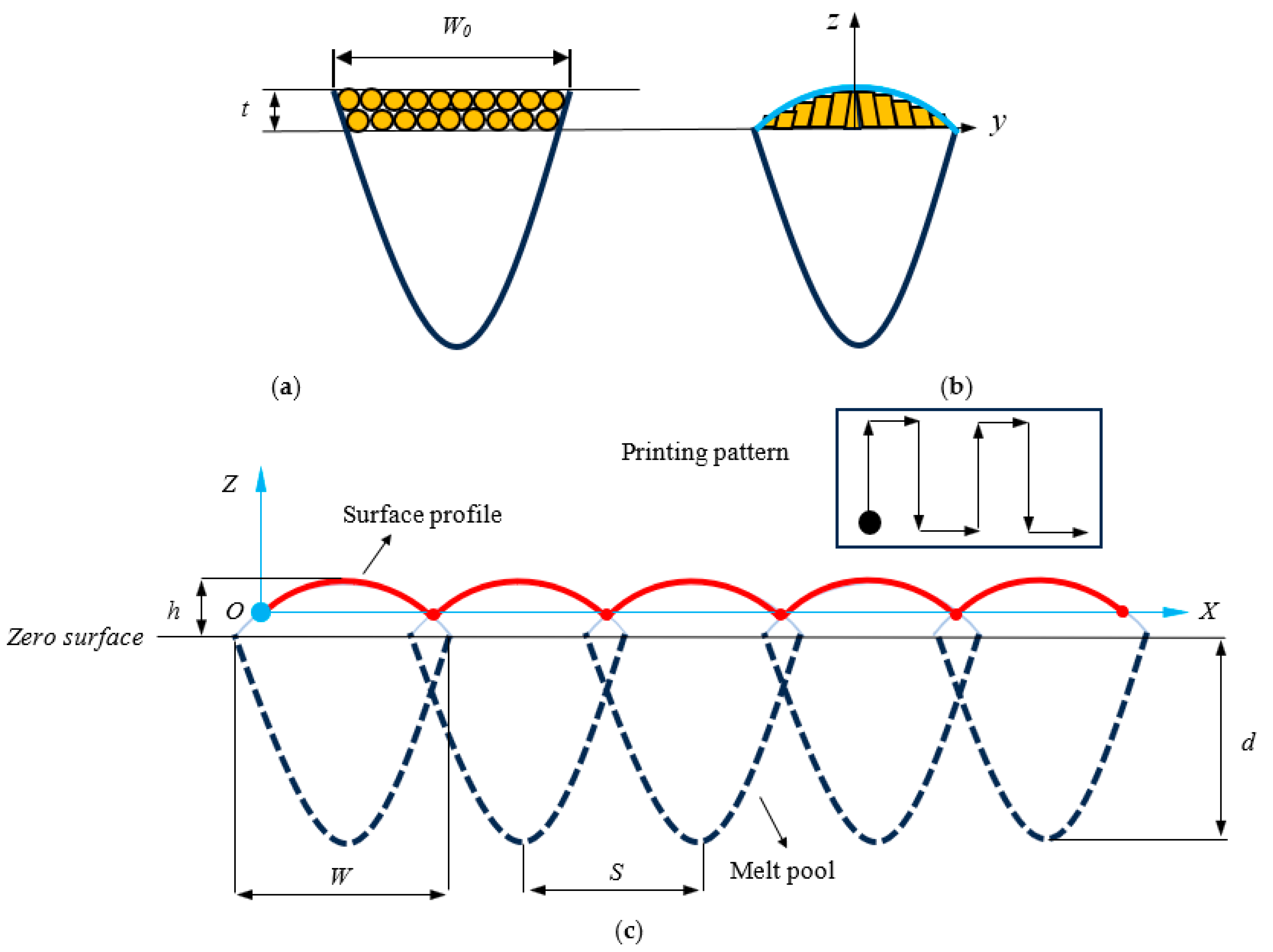

2.1.1. Analytical Modeling of Surface Generation in Selective Laser Melting

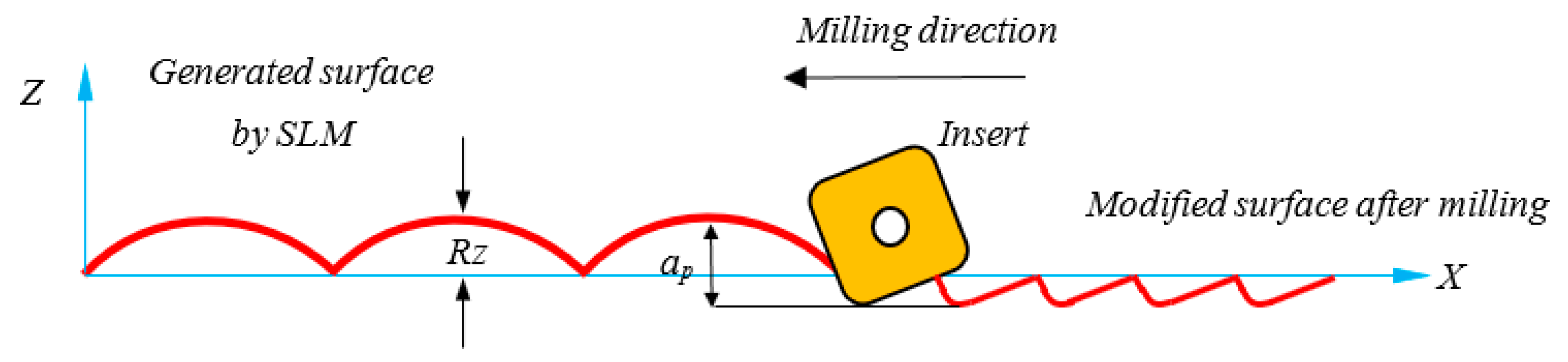

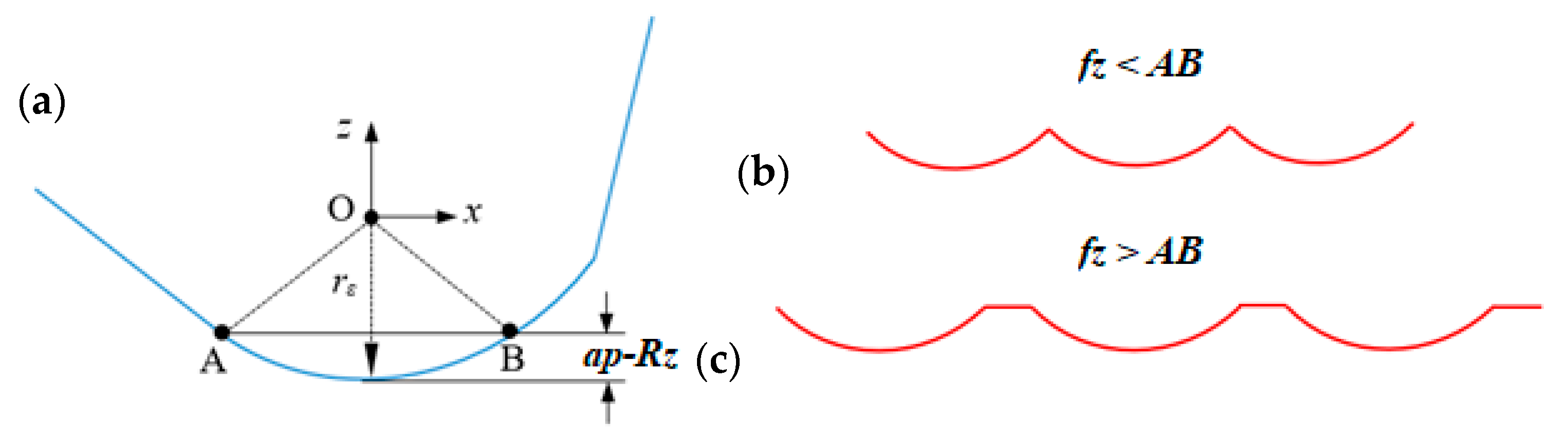

2.1.2. Analytical Modeling of Roughness Alternation by Milling

2.1.3. Analytical Modeling of Roughness Alternation by Burnishing

2.2. Experimental Work

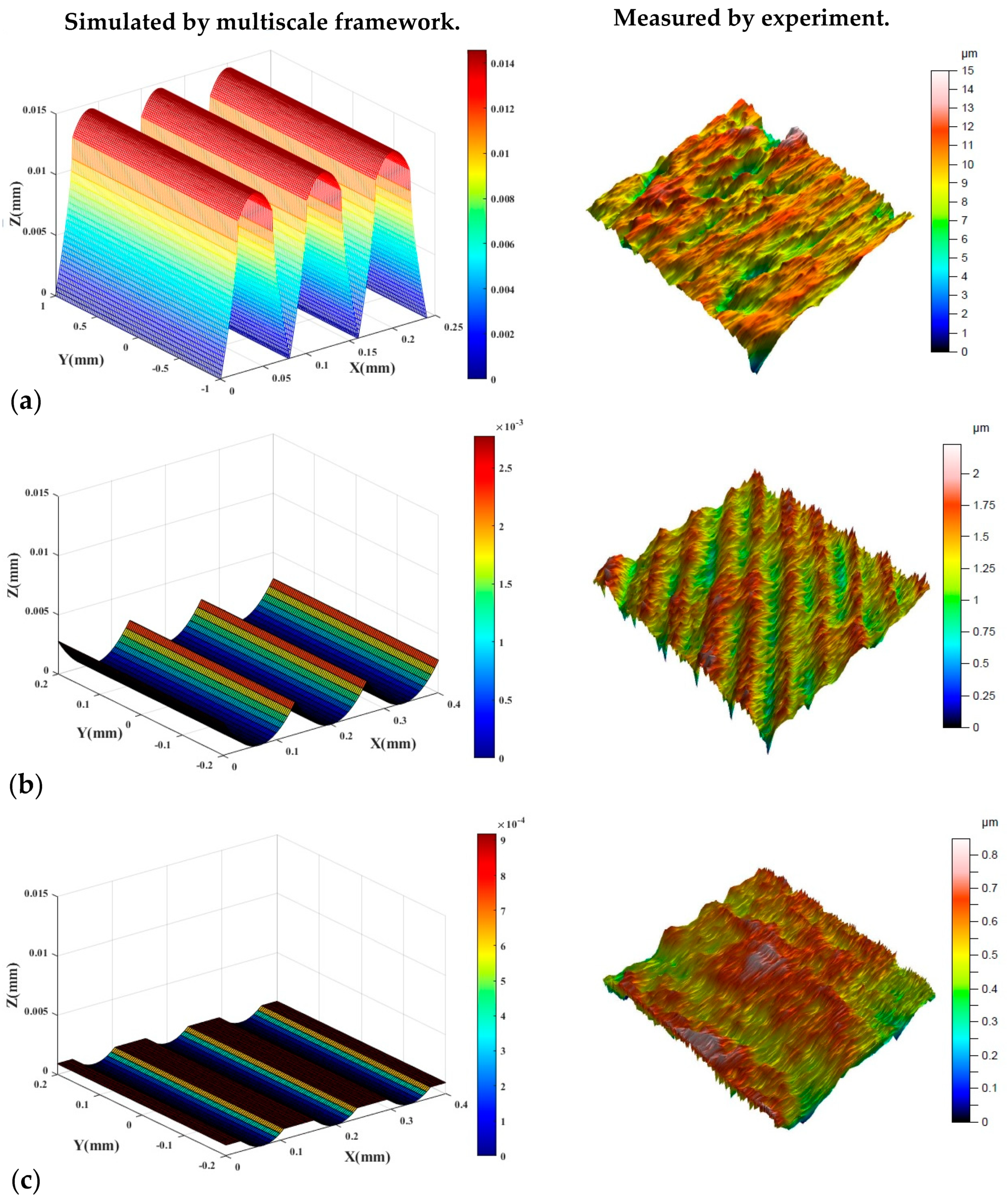

3. Results

4. Discussion

5. Conclusions

- The obtained results which were derived from the simulation framework were compatible with the experimental values, while the average error for prediction of the arithmetic roughness was 10.1% and for prediction of the maximum distance between roughness peaks and valleys was 7.3%.

- It was found that the simulated surface roughness which is modeled in a chain of SLM + Milling + Surface rolling has a lower prediction error than the chain of SLM + Burnishing because of existing finished milling processes.

- It was found that by eliminating milling from the chain the production time will significantly increase by three times and further forces and energy are required to obtain same roughness. Therefore, elimination of a process from the chain does not guarantee minimizing the production time.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Maleki, E.; Bagherifard, S.; Bandini, M.; Guagliano, M. Surface post-treatments for metal additive manufacturing: Progress, challenges, and opportunities. Addit. Manuf. 2021, 37, 101619. [Google Scholar] [CrossRef]

- Khan, H.M.; Karabulut, Y.; Kitay, O.; Kaynak, Y.; Jawahir, I.S. Influence of the post-processing operations on surface integrity of metal components produced by laser powder bed fusion additive manufacturing: A review. Mach. Sci. Technol. 2020, 25, 118–176. [Google Scholar] [CrossRef]

- Rotella, G.; Filice, L.; Micari, F. Improving surface integrity of additively manufactured GP1 stainless steel by roller burnishing. CIRP Ann. 2020, 69, 513–516. [Google Scholar] [CrossRef]

- Teimouri, R.; Sohrabpoor, H.; Grabowski, M.; Wyszynski, D.; Skoczypiec, S.; Raghavendra, R. Simulation of surface roughness evolution of additively manufactured material fabricated by laser powder bed fusion and post-processed by burnishing. J. Manuf. Process. 2022, 84, 10–27. [Google Scholar] [CrossRef]

- Zhang, P.; Liu, Z. Effect of sequential turning and burnishing on the surface integrity of Cr–Ni-based stainless steel formed by laser cladding process. Surf. Coat. Technol. 2015, 276, 327–335. [Google Scholar] [CrossRef]

- Varga, G.; Dezső, G.; Szigeti, F. Surface roughness improvement by sliding friction burnishing of parts produced by selective laser melting of Ti6Al4V titanium alloy. Machines 2022, 10, 400. [Google Scholar] [CrossRef]

- Sayadi, D.; Rangrizian, H.; Khodabandeh, A.; Nezarati, M.; Hemasian Etefagh, A.; Khajehzadeh, M.; Razfar, M.R. Using shot peening and burnishing to improve fatigue performance of additively manufactured 316L stainless steel. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 14644207231196266. [Google Scholar] [CrossRef]

- Zhang, C.; Shen, X.; Wang, J.; Xu, C.; He, J.; Bai, X. Improving surface properties of Fe-based laser cladding coating deposited on a carbon steel by heat assisted ultrasonic burnishing. J. Mater. Res. Technol. 2021, 12, 100–116. [Google Scholar] [CrossRef]

- Raaj, R.K.; Anirudh, V.; Karunakaran, C.; Kannan, C.; Jahagirdar, A.; Joshi, S.; Balan, A.S.S. Exploring grinding and burnishing as surface post-treatment options for electron beam additive manufactured Alloy 718. Surf. Coat. Technol. 2020, 397, 126063. [Google Scholar] [CrossRef]

- Yaman, N.; Sunay, N.; Kaya, M.; Kaynak, Y. Enhancing Surface Integrity of Additively Manufactured Inconel 718 by Roller Burnishing Process. Procedia CIRP 2022, 108, 681–686. [Google Scholar] [CrossRef]

- Hao, J.; Niu, Q.; Ji, H.; Liu, H. Effect of Ultrasonic Rolling on the Organization and Properties of a High-Speed Laser Cladding IN 718 Superalloy Coating. Crystals 2023, 13, 1214. [Google Scholar] [CrossRef]

- Sunny, S.; Mathews, R.; Yu, H.; Malik, A. Effects of microstructure and inherent stress on residual stress induced during powder bed fusion with roller burnishing. Int. J. Mech. Sci. 2022, 219, 107092. [Google Scholar] [CrossRef]

- Luo, Z.; Zhao, Y. A survey of finite element analysis of temperature and thermal stress fields in powder bed fusion Additive Manufacturing. Addit. Manuf. 2018, 21, 318–332. [Google Scholar] [CrossRef]

- Pinkerton, A.J. Advances in the modeling of laser direct metal deposition. J. Laser Appl. 2015, 27, S15001. [Google Scholar] [CrossRef]

- Ning, J.; Mirkoohi, E.; Dong, Y.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical modeling of 3D temperature distribution in selective laser melting of Ti-6Al-4V considering part boundary conditions. J. Manuf. Process. 2019, 44, 319–326. [Google Scholar] [CrossRef]

- Liu, B.; Fang, G.; Lei, L. An analytical model for rapid predicting molten pool geometry of selective laser melting (SLM). Appl. Math. Model. 2021, 92, 505–524. [Google Scholar] [CrossRef]

- Mirkoohi, E.; Sievers, D.E.; Garmestani, H.; Chiang, K.; Liang, S.Y. Three-dimensional semi-elliptical modeling of melt pool geometry considering hatch spacing and time spacing in metal additive manufacturing. J. Manuf. Process. 2019, 45, 532–543. [Google Scholar] [CrossRef]

- Zheng, J.; Shang, Y.; Guo, Y.; Deng, H.; Jia, L. Analytical model of residual stress in ultrasonic rolling of 7075 aluminum alloy. J. Manuf. Process. 2022, 80, 132–140. [Google Scholar] [CrossRef]

- Zhu, L.; Zheng, J.; Guo, Y.; Deng, H.; Shang, Y. Surface topography in two-dimensional ultrasonic rolling 2024-T3 Al-alloy. J. Manuf. Process. 2022, 76, 588–597. [Google Scholar] [CrossRef]

- Ravichander, B.B.; Jagdale, S.H.; Jabed, A.; Kumar, G. Mechanical and corrosion behavior of sheet-based 316L TPMS structures. Int. J. Mech. Sci. 2023, 254, 108439. [Google Scholar] [CrossRef]

- Revankar, G.D.; Shetty, R.; Rao, S.S.; Gaitonde, V.N. Analysis of surface roughness and hardness in ball burnishing of titanium alloy. Measurement 2014, 58, 256–268. [Google Scholar] [CrossRef]

- Zhuang, W.; Wicks, B. Multipass low-plasticity burnishing induced residual stresses: Three-dimensional elastic-plastic finite element modelling. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2004, 218, 663–668. [Google Scholar] [CrossRef]

| Properties | Symbol | Unit | Values |

|---|---|---|---|

| Density | ρ | kg/m3 | 7800 |

| Thermal conductivity | k | W/m°K | 14 |

| Specific heat | C | J/kg°K | 460 |

| Melting point | Tm | °K | 1678 |

| Absorptivity | η | - | 0.35 |

| Elasticity modulus | E | GPa | 210 |

| Yield strength | σs | MPa | 205 |

| Strength coefficient | K | MPa | 1356 |

| Poisson ratio | ν | - | 0.28 |

| Strain hardening exponent | m | - | 0.453 |

| Sample No | Initial Condition | Rolling Static Force | Pass Number |

|---|---|---|---|

| 1 | SLM | Not applicable | Not applicable |

| 2 | SLM | 750 | 1 |

| 3 | SLM | 750 | 3 |

| 4 | SLM | 1500 | 1 |

| 5 | SLM | 1500 | 3 |

| 6 | SLM + Milling | Not applicable | Not applicable |

| 7 | SLM + Milling | 750 | 1 |

| 8 | SLM + Milling | 1500 | 3 |

| 9 | SLM + Milling | 750 | 1 |

| 10 | SLM + Milling | 1500 | 3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Teimouri, R. Multiscale Modeling of a Chain Comprising Selective Laser Melting and Post-Machining toward Nanoscale Surface Finish. Materials 2023, 16, 7535. https://doi.org/10.3390/ma16247535

Teimouri R. Multiscale Modeling of a Chain Comprising Selective Laser Melting and Post-Machining toward Nanoscale Surface Finish. Materials. 2023; 16(24):7535. https://doi.org/10.3390/ma16247535

Chicago/Turabian StyleTeimouri, Reza. 2023. "Multiscale Modeling of a Chain Comprising Selective Laser Melting and Post-Machining toward Nanoscale Surface Finish" Materials 16, no. 24: 7535. https://doi.org/10.3390/ma16247535

APA StyleTeimouri, R. (2023). Multiscale Modeling of a Chain Comprising Selective Laser Melting and Post-Machining toward Nanoscale Surface Finish. Materials, 16(24), 7535. https://doi.org/10.3390/ma16247535