The Laser Selective Sintering Controlled Forming of Flexible TPMS Structures

Abstract

:1. Introduction

2. Materials and Methods

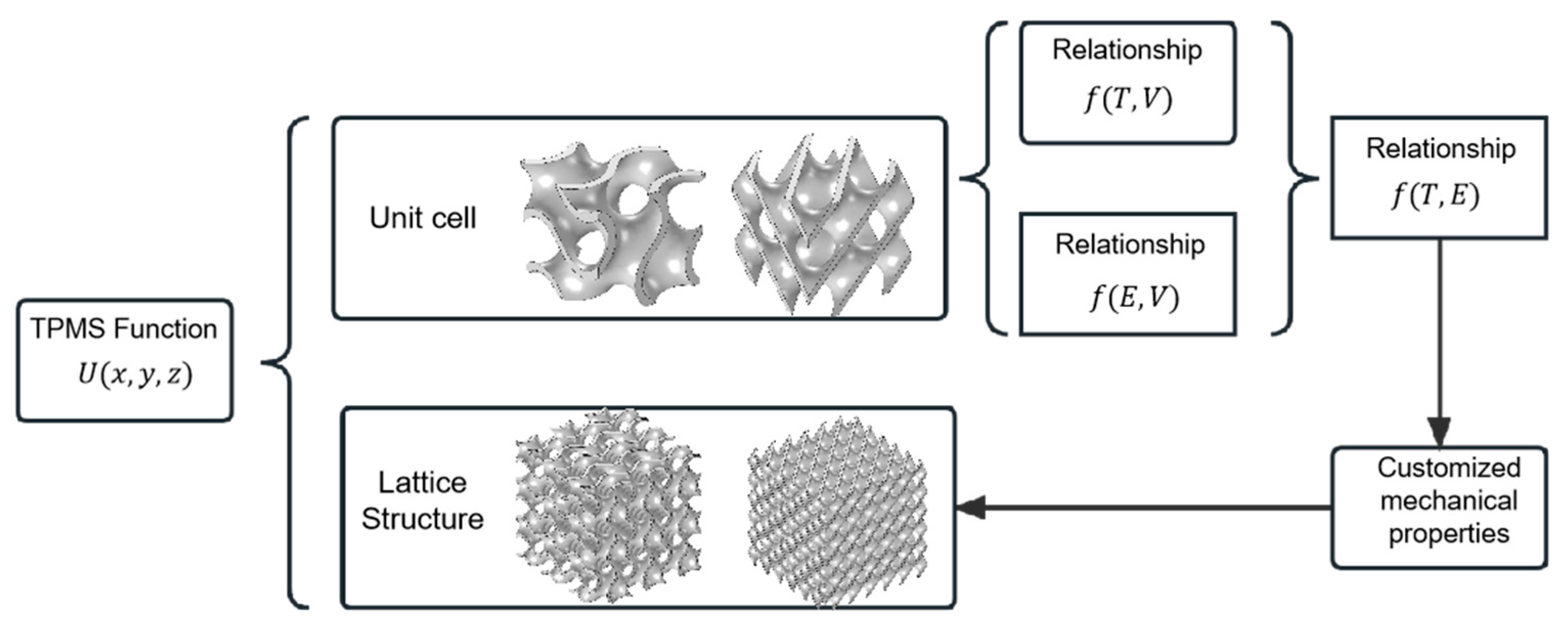

2.1. Parameterized Structural Design

2.1.1. TPMS Structural Design

2.1.2. Gradient and Hybrid TPMS Structure Design

2.2. Parametric Controlled Forming

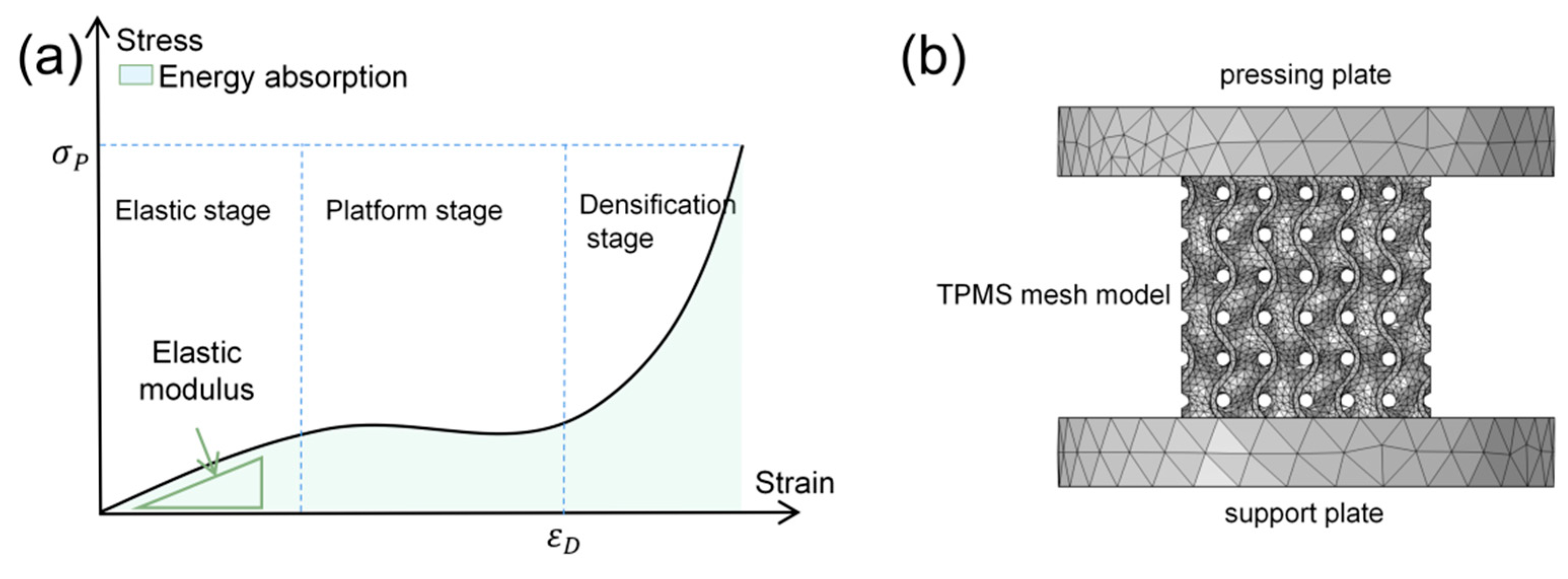

2.3. Quasi-Static Compression Experiment of TPMS Lattice Structure

2.4. Finite Element Analysis of TPMS Structure

3. Results

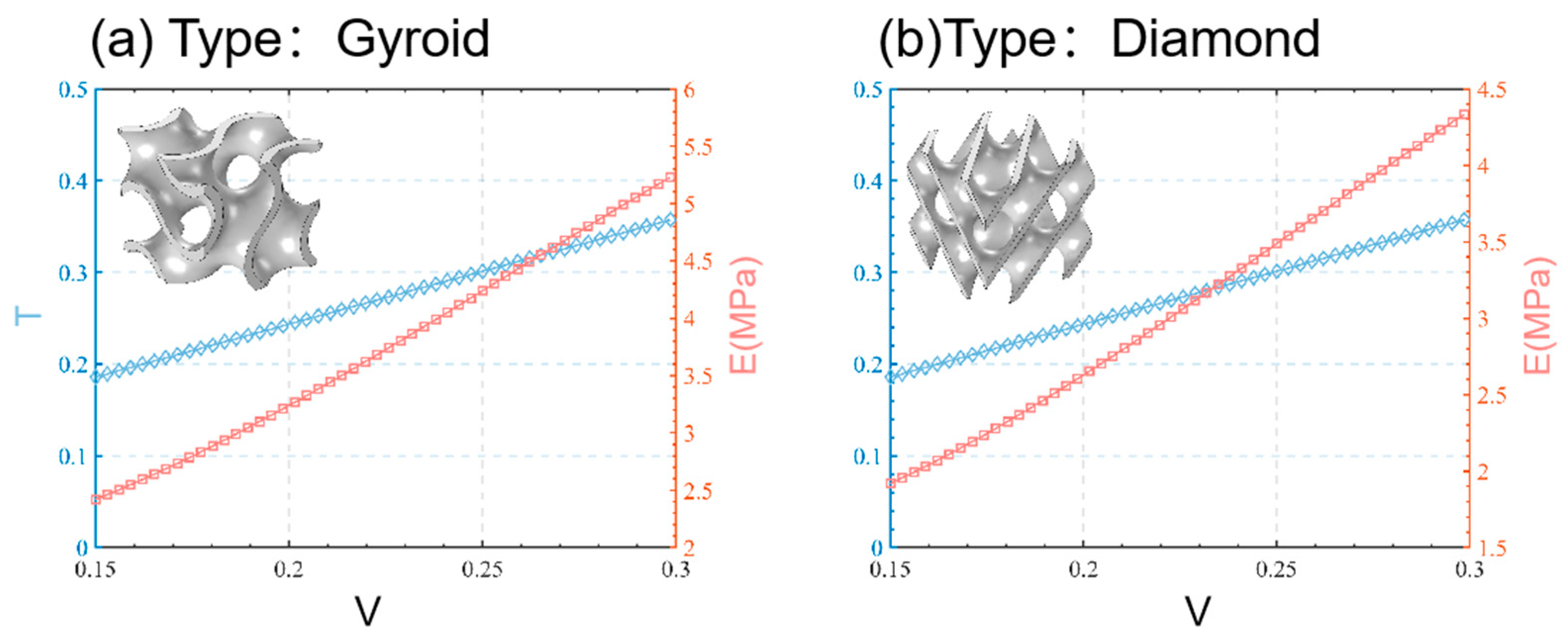

3.1. Parametric Design Model

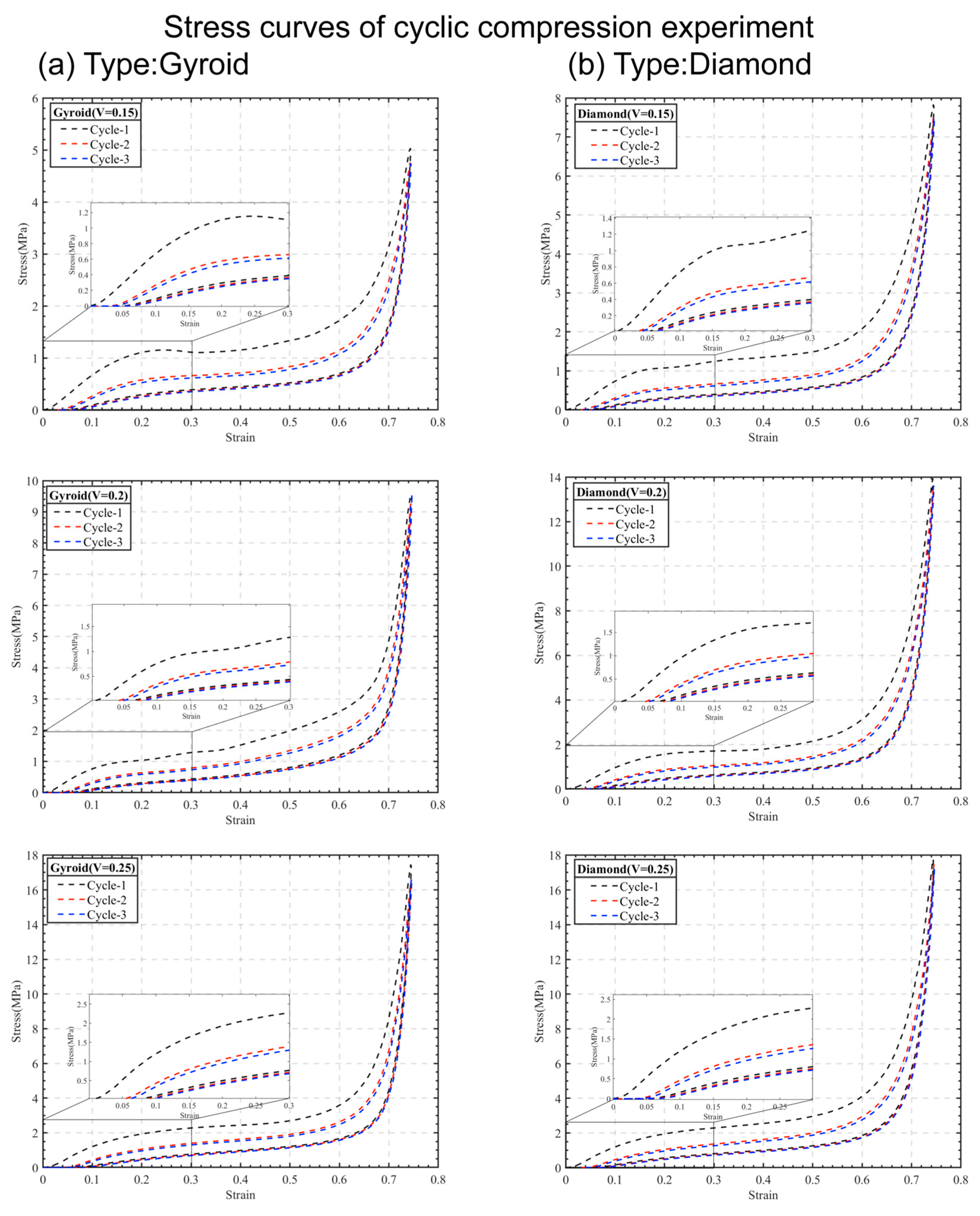

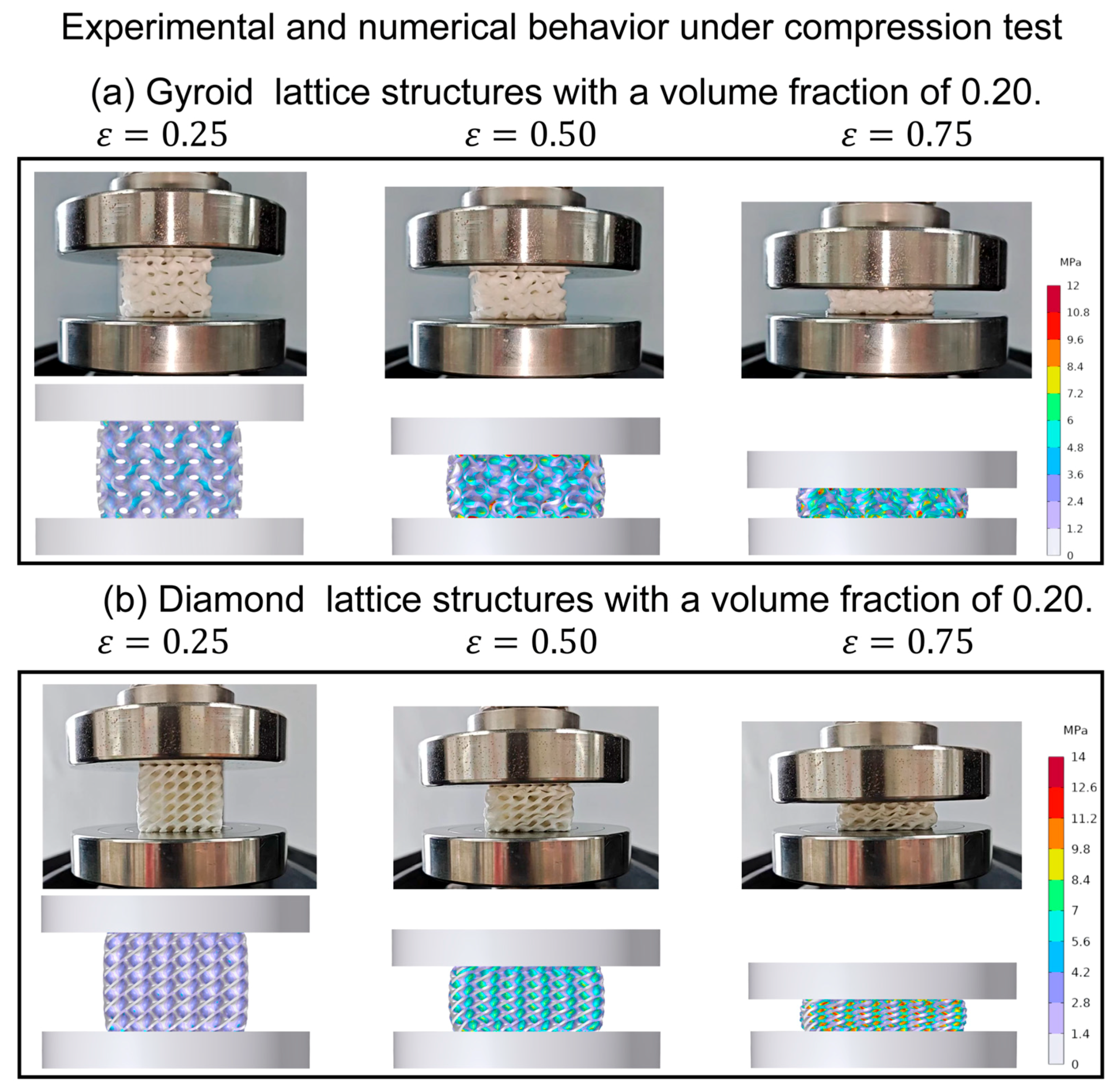

3.2. Uniform Flexible TPMS Lattice Structure

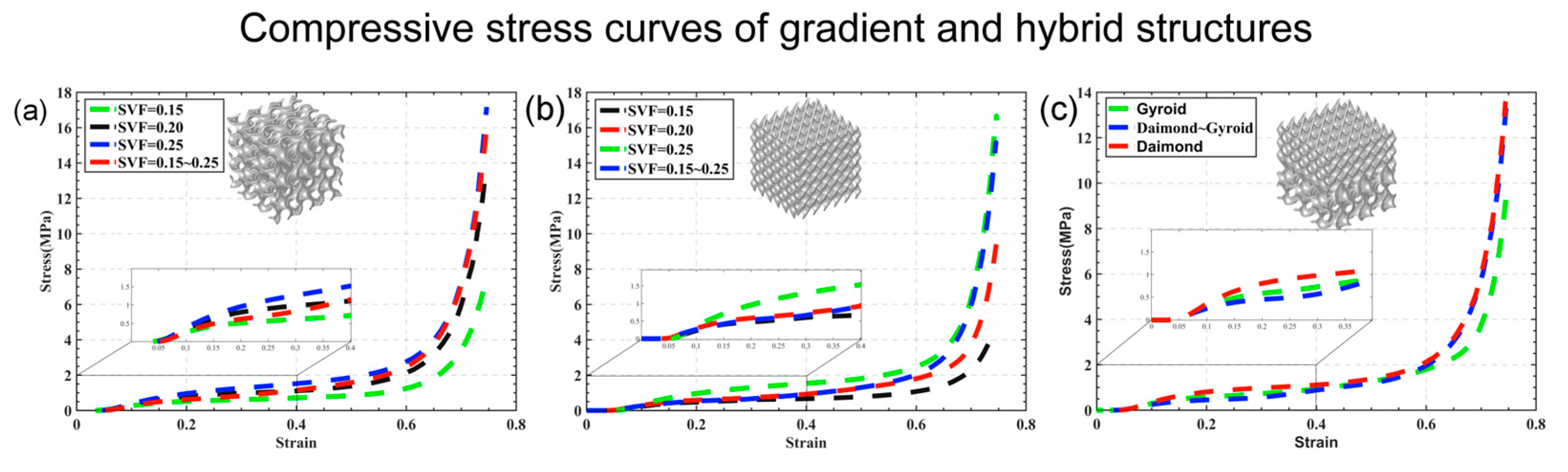

3.3. Flexible Gradient and Hybrid TPMS Lattice Structure

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, H.; Chen, L.; Zhou, Y.; Pan, X.; Zhu, S.; Li, W. Repeated Energy Absorption and Multiple Compressive Responses of Thermoplastic Composite Hierarchical Cylindrical Structures. Compos. Sci. Technol. 2022, 221, 109306. [Google Scholar] [CrossRef]

- Duran, M.M.; Moro, G.; Zhang, Y.; Islam, A. 3D Printing of Silicone and Polyurethane Elastomers for Medical Device Application: A Review. Adv. Ind. Manuf. Eng. 2023, 7, 100125. [Google Scholar] [CrossRef]

- Amjed, N.; Bhatti, I.A.; Simon, L.; Castel, C.D.; Zia, K.M.; Zuber, M.; Hafiz, I.; Murtaza, M.A. Preparation and Characterization of Thermoplastic Polyurethanes Blended with Chitosan and Starch Processed through Extrusion. Int. J. Biol. Macromol. 2022, 208, 37–44. [Google Scholar] [CrossRef] [PubMed]

- Ren, F.; Zhang, C.; Liao, W.; Liu, T.; Li, D.; Shi, X.; Jiang, W.; Wang, C.; Qi, J.; Chen, Y.; et al. Transition Boundaries and Stiffness Optimal Design for Multi-TPMS Lattices. Mater. Des. 2021, 210, 110062. [Google Scholar] [CrossRef]

- Arefin, A.M.E.; Khatri, N.R.; Kulkarni, N.; Egan, P.F. Polymer 3D Printing Review: Materials, Process, and Design Strategies for Medical Applications. Polymers 2021, 13, 1499. [Google Scholar] [CrossRef] [PubMed]

- Yuan, S.; Shen, F.; Bai, J.; Chua, C.K.; Wei, J.; Zhou, K. 3D Soft Auxetic Lattice Structures Fabricated by Selective Laser Sintering: TPU Powder Evaluation and Process Optimization. Mater. Des. 2017, 120, 317–327. [Google Scholar] [CrossRef]

- Holmes, D.W.; Singh, D.; Lamont, R.; Daley, R.; Forrestal, D.P.; Slattery, P.; Pickering, E.; Paxton, N.C.; Powell, S.K.; Woodruff, M.A. Mechanical Behaviour of Flexible 3D Printed Gyroid Structures as a Tuneable Replacement for Soft Padding Foam. Addit. Manuf. 2022, 50, 102555. [Google Scholar] [CrossRef]

- Jonnala, U.K.; Sankineni, R.; Ravi Kumar, Y. Design and Development of Fused Deposition Modeling (FDM) 3D-Printed Orthotic Insole by Using Gyroid Structure. J. Mech. Behav. Biomed. Mater. 2023, 145, 106005. [Google Scholar] [CrossRef]

- Teawdeswan, L.; Dong, G. Inverse Design of Multi-Material Gyroid Structures Made by Additive Manufacturing. Int. J. Mech. Sci. 2023, 108734. [Google Scholar] [CrossRef]

- Xi, H.; Zhou, Z.; Zhang, H.; Huang, S.; Xiao, H. Multi-Morphology TPMS Structures with Multi-Stage Yield Stress Platform and Multi-Level Energy Absorption: Design, Manufacturing, and Mechanical Properties. Eng. Struct. 2023, 294, 116733. [Google Scholar] [CrossRef]

- Cao, Y.; Lai, S.; Wu, W.; Sang, L.; Lin, Y.; Liu, T.; Liang, C.; Liu, W.; Zhao, Y. Design and Mechanical Evaluation of Additively-Manufactured Graded TPMS Lattices with Biodegradable Polymer Composites. J. Mater. Res. Technol. 2023, 23, 2868–2880. [Google Scholar] [CrossRef]

- Lal Lazar, P.J.; Subramanian, J.; Natarajan, E.; Markandan, K.; Ramesh, S. Anisotropic Structure-Property Relations of FDM Printed Short Glass Fiber Reinforced Polyamide TPMS Structures under Quasi-Static Compression. J. Mater. Res. Technol. 2023, 24, 9562–9579. [Google Scholar] [CrossRef]

- Tilton, M.; Borjali, A.; Griffis, J.C.; Varadarajan, K.M.; Manogharan, G.P. Fatigue Properties of Ti-6Al-4V TPMS Scaffolds Fabricated via Laser Powder Bed Fusion. Manuf. Lett. 2023, 37, 32–38. [Google Scholar] [CrossRef]

- Hussain, S.; Alagha, A.N.; Haidemenopoulos, G.N.; Zaki, W. Microstructural and Surface Analysis of NiTi TPMS Lattice Sections Fabricated by Laser Powder Bed Fusion. J. Manuf. Process. 2023, 102, 375–386. [Google Scholar] [CrossRef]

- Zhao, Z.; Wu, Z.; Yao, D.; Wei, Y.; Li, J. Mechanical Properties and Failure Mechanisms of Polyamide 12 Gradient Scaffolds Developed with Selective Laser Sintering. J. Mech. Behav. Biomed. Mater. 2023, 143, 105915. [Google Scholar] [CrossRef] [PubMed]

- Qiu, N.; Wan, Y.; Shen, Y.; Fang, J. Experimental and Numerical Studies on Mechanical Properties of TPMS Structures. Int. J. Mech. Sci. 2023, 108657. [Google Scholar] [CrossRef]

- Guo, W.; Yang, Y.; Liu, C.; Bu, W.; Guo, F.; Li, J.; Wang, E.; Peng, Z.; Mai, H.; You, H.; et al. 3D Printed TPMS Structural PLA/GO Scaffold: Process Parameter Optimization, Porous Structure, Mechanical and Biological Properties. J. Mech. Behav. Biomed. Mater. 2023, 142, 105848. [Google Scholar] [CrossRef]

- Liu, Z.; Gong, H.; Gao, J.; Liu, L. Bio-Inspired Design, Mechanical and Mass-Transport Characterizations of Orthotropic TPMS-Based Scaffold. Compos. Struct. 2023, 321, 117256. [Google Scholar] [CrossRef]

- Zeng, C.; Wang, W.; Hai, K.; Ma, S. Lightweight Airborne TPMS-Filled Reflective Mirror Design for Low Thermal Deformation. Compos. Struct. 2023, 327, 117665. [Google Scholar] [CrossRef]

- Yang, N.; Quan, Z.; Zhang, D.; Tian, Y. Multi-Morphology Transition Hybridization CAD Design of Minimal Surface Porous Structures for Use in Tissue Engineering. Comput.-Aided Des. 2014, 56, 11–21. [Google Scholar] [CrossRef]

- Abdullah, N.N.A.A.; Abdullah, A.H.; Ramlee, M.H. Current Trend of Lattice Structures Designed and Analysis for Porous Hip Implants: A Short Review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Kolakkattil, R.; Tsavdaridis, K.D.; Sanjeevi, A.J. A State-of-the-Art Review of Progressive Collapse Research and Guidelines for Single-Layer Lattice Shell Structures. Structures 2023, 56, 104945. [Google Scholar] [CrossRef]

- Song, W.; Feng, G.; Yu, G.; Shi, G.; Xiao, L. Dynamic Mechanical Behavior of Additively Manufactured Bio-Inspired Metallic Lattice Structure Subjected to High Strain Rate Impact Loading. Int. J. Impact Eng. 2023, 181, 104752. [Google Scholar] [CrossRef]

- Lu, D.; Zhang, L.; Cheng, S.; Shi, D.; Zhang, K.; Shao, W.; Lin, D.; Zeng, T. Microstructure Control of SiCw/SiC Composites Based on SLS Technology. J. Eur. Ceram. Soc. 2022, 42, 3747–3758. [Google Scholar] [CrossRef]

- Mei, H.; Li, H.; Jin, Z.; Li, L.; Yang, D.; Liang, C.; Cheng, L.; Zhang, L. 3D-Printed SiC Lattices Integrated with Lightweight Quartz Fiber/Silica Aerogel Sandwich Structure for Thermal Protection System. Chem. Eng. J. 2023, 454, 140408. [Google Scholar] [CrossRef]

- Novak, N.; Tanaka, S.; Hokamoto, K.; Mauko, A.; Yilmaz, Y.E.; Al-Ketan, O.; Vesenjak, M.; Ren, Z. High Strain Rate Mechanical Behaviour of Uniform and Hybrid Metallic TPMS Cellular Structures. Thin-Walled Struct. 2023, 191, 111109. [Google Scholar] [CrossRef]

- Feng, G.; Li, S.; Xiao, L.; Song, W. Mechanical Properties and Deformation Behavior of Functionally Graded TPMS Structures under Static and Dynamic Loading. Int. J. Impact Eng. 2023, 176, 104554. [Google Scholar] [CrossRef]

- Oleksandra, T.; Nataliya, Z.-L.; Yury, P.; Dmytro, V.; Oleksandr, T.; Ostap, Z.-L. The Role of Flexible Polymer Composite Materials Properties in Energy Absorption of Three-Dimensional Auxetic Lattice Structures. Mater. Today Commun. 2023, 37, 107370. [Google Scholar] [CrossRef]

- Luo, M.; Wu, Z.; Yang, C. Strongly Coupled Fluid–Structure Interaction Analysis of Aquatic Flapping Wings Based on Flexible Multibody Dynamics and the Modified Unsteady Vortex Lattice Method. Ocean Eng. 2023, 281, 114921. [Google Scholar] [CrossRef]

- Multi-Material Fused Filament Fabrication of Flexible 3D Piezoelectric Nanocomposite Lattices for Pressure Sensing and Energy Harvesting Applications—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S235294072200230X (accessed on 1 November 2023).

- BS EN ISO 3386-1:1997+A1:2010; Mechanical vibration—Measurement and Evaluation of Human Exposure to Hand-Transmitted Vibration—Part 1: General Requirements. International Organization for Standardization: Geneva, Switzerland, 2010.

- Yao, D.; Zhao, Z.; Wei, Y.; Li, J. Gradient Scaffolds Developed by Parametric Modeling with Selective Laser Sintering. Int. J. Mech. Sci. 2023, 248, 108221. [Google Scholar] [CrossRef]

- Dong, G.; Tang, Y.; Zhao, Y.F. A 149 Line Homogenization Code for Three-Dimensional Cellular Materials Written in Matlab. J. Eng. Mater. Technol. 2019, 141, 011005. [Google Scholar] [CrossRef]

- Design for Additive Manufacturing of Functionally Graded Lattice Structures: A Design Method with Process Induced Anisotropy Consideration|SpringerLink. Available online: https://link.springer.com/article/10.1007/s40684-019-00173-7 (accessed on 12 September 2023).

- Zhang, X.G.; Ren, X.; Jiang, W.; Zhang, X.Y.; Luo, C.; Zhang, Y.; Xie, Y.M. A Novel Auxetic Chiral Lattice Composite: Experimental and Numerical Study. Compos. Struct. 2022, 282, 115043. [Google Scholar] [CrossRef]

- Numerical Study on the Anisotropy in Thermo-Fluid Behavior of Triply Periodic Minimal Surfaces (TPMS)—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0017931023006865 (accessed on 1 November 2023).

- Khaleghi, S.; Dehnavi, F.N.; Baghani, M.; Safdari, M.; Wang, K.; Baniassadi, M. On the Directional Elastic Modulus of the TPMS Structures and a Novel Hybridization Method to Control Anisotropy. Mater. Des. 2021, 210, 110074. [Google Scholar] [CrossRef]

- Zhang, Z.; Jin, X. Study on the Energy Dissipation Mechanism of the Pyramidal Lattice Sandwich Panel Subjected to Underwater Explosion. Mar. Struct. 2022, 85, 103243. [Google Scholar] [CrossRef]

- Xu, T.; Shen, W.; Lin, X.; Xie, Y.M. Mechanical Properties of Additively Manufactured Thermoplastic Polyurethane (TPU) Material Affected by Various Processing Parameters. Polymers 2020, 12, 3010. [Google Scholar] [CrossRef] [PubMed]

- Mishra, A.K.; Chavan, H.; Kumar, A. Effect of Cell Size and Wall Thickness on the Compression Performance of Triply Periodic Minimal Surface Based AlSi10Mg Lattice Structures. Thin-Walled Struct. 2023, 193, 111214. [Google Scholar] [CrossRef]

- Novak, N.; Al-Ketan, O.; Borovinšek, M.; Krstulović-Opara, L.; Rowshan, R.; Vesenjak, M.; Ren, Z. Development of Novel Hybrid TPMS Cellular Lattices and Their Mechanical Characterisation. J. Mater. Res. Technol. 2021, 15, 1318–1329. [Google Scholar] [CrossRef]

- A Study of Multi-Stage Energy Absorption Characteristics of Hybrid Sheet TPMS Lattices—ScienceDirect. Available online: https://www.sciencedirect.com/science/article/abs/pii/S0263823123004676 (accessed on 1 November 2023).

- Ma, X.; Guo, C.; Hu, C.; Zhang, Z.; Shen, J. Study on the Topological Morphology and Mechanical Properties of Variable-Amplitude TPMS Structures. J. Mater. Res. Technol. 2023, 27, 3459–3472. [Google Scholar] [CrossRef]

- Singh, A.; Al-Ketan, O.; Karathanasopoulos, N. Highly Strain Rate Sensitive and Ductile Composite Materials Combining Soft with Stiff TPMS Polymer-Based Interpenetrating Phases. Compos. Struct. 2023, 328, 117646. [Google Scholar] [CrossRef]

- Novak, N.; Borovinšek, M.; Al-Ketan, O.; Ren, Z.; Vesenjak, M. Impact and Blast Resistance of Uniform and Graded Sandwich Panels with TPMS Cellular Structures. Compos. Struct. 2022, 300, 116174. [Google Scholar] [CrossRef]

- Santiago, R.; Ramos, H.; AlMahri, S.; Banabila, O.; Alabdouli, H.; Lee, D.-W.; Aziz, A.; Rajput, N.; Alves, M.; Guan, Z. Modelling and Optimisation of TPMS-Based Lattices Subjected to High Strain-Rate Impact Loadings. Int. J. Impact Eng. 2023, 177, 104592. [Google Scholar] [CrossRef]

- Zhang, C.; Qiao, H.; Yang, L.; Ouyang, W.; He, T.; Liu, B.; Chen, X.; Wang, N.; Yan, C. Vibration Characteristics of Additive Manufactured IWP-Type TPMS Lattice Structures. Compos. Struct. 2023, 327, 117642. [Google Scholar] [CrossRef]

| Process Parameter | Value |

|---|---|

| Laser power | 20 W |

| Laser scan speed | 2500 mm/s |

| Laser hatch spacing | 0.1 mm |

| Powder deposition thickness | 0.15 mm |

| Powder bed temperature | 125 °C |

| Type | Volume Fraction | Weight (g) | Dimension (X × Y × Z mm) |

|---|---|---|---|

| Uniform Gyroid structure | 0.15 | 7.69 | 35.38 × 35.44 × 36.51 |

| 0.20 | 10.65 | 35.33 × 35.55 × 36.50 | |

| 0.25 | 12.71 | 35.64 × 35.89 × 36.32 | |

| Uniform Diamond structure | 0.15 | 6.95 | 35.32 × 35.22 × 36.12 |

| 0.20 | 11.18 | 35.53 × 35.23 × 36.48 | |

| 0.25 | 13.51 | 35.25 × 35.64 × 36.33 | |

| Gradient structure | Average: 0.20 | 10.12 | 35.13 × 35.23 × 36.40 |

| Gradient structure | Average: 0.20 | 11.17 | 35.17 × 35.88 × 36.65 |

| Hybrid lattice structure | 0.20 | 11.38 | 35.77 × 35.46 × 36.76 |

| Type | Solid Volume Fraction | |||

|---|---|---|---|---|

| Gyroid | 15 | 2.28 | 0.64 | 0.23 |

| Gyroid | 20 | 3.03 | 1.03 | 0.37 |

| Gyroid | 25 | 3.44 | 1.6 | 0.59 |

| Diamond | 15 | 2.60 | 0.81 | 0.26 |

| Diamond | 20 | 3.25 | 1.35 | 0.44 |

| Diamond | 25 | 4.43 | 1.72 | 0.74 |

| Type (Volume: 36 × 36 × 36 mm3) | Solid Volume Fraction | Elastic Moulds E (MPa) | Energy Absorption | Dissipation of Energy |

|---|---|---|---|---|

| Gyroid (uniform) | 20% | 2.28 | 0.64 | 0.23 |

| Diamond (uniform) | 20% | 3.25 | 1.35 | 0.44 |

| Gyroid (gradient) | 20% | 2.66 | 1.26 | 0.43 |

| Diamond (gradient) | 20% | 3.51 | 1.61 | 0.52 |

| Gyroid~Diamond (hybrid) | 20% | 2.56 | 1.19 | 0.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xue, C.; Li, N.; Chen, S.; Liang, J.; Aiyiti, W. The Laser Selective Sintering Controlled Forming of Flexible TPMS Structures. Materials 2023, 16, 7565. https://doi.org/10.3390/ma16247565

Xue C, Li N, Chen S, Liang J, Aiyiti W. The Laser Selective Sintering Controlled Forming of Flexible TPMS Structures. Materials. 2023; 16(24):7565. https://doi.org/10.3390/ma16247565

Chicago/Turabian StyleXue, Chenhao, Nan Li, Shenggui Chen, Jiahua Liang, and Wurikaixi Aiyiti. 2023. "The Laser Selective Sintering Controlled Forming of Flexible TPMS Structures" Materials 16, no. 24: 7565. https://doi.org/10.3390/ma16247565