Research on the Adhesion Properties of Fast-Melting SBS-Modified Asphalt–Aggregate Based on Surface Free Energy Theory

Abstract

:1. Introduction

2. Theoretical Background

3. Materials and Methodologies

3.1. Preparation of Quick-Melting SBS-Modified Asphalt

3.1.1. Matrix Asphalt

3.1.2. Asphalt Modifier

3.1.3. Modified Asphalt Preparation

3.2. Contact Angle Measurement Methods

3.2.1. Test Method

3.2.2. Asphalt Sample Preparation

3.2.3. Aggregate Sample Preparation

4. Results and Analysis

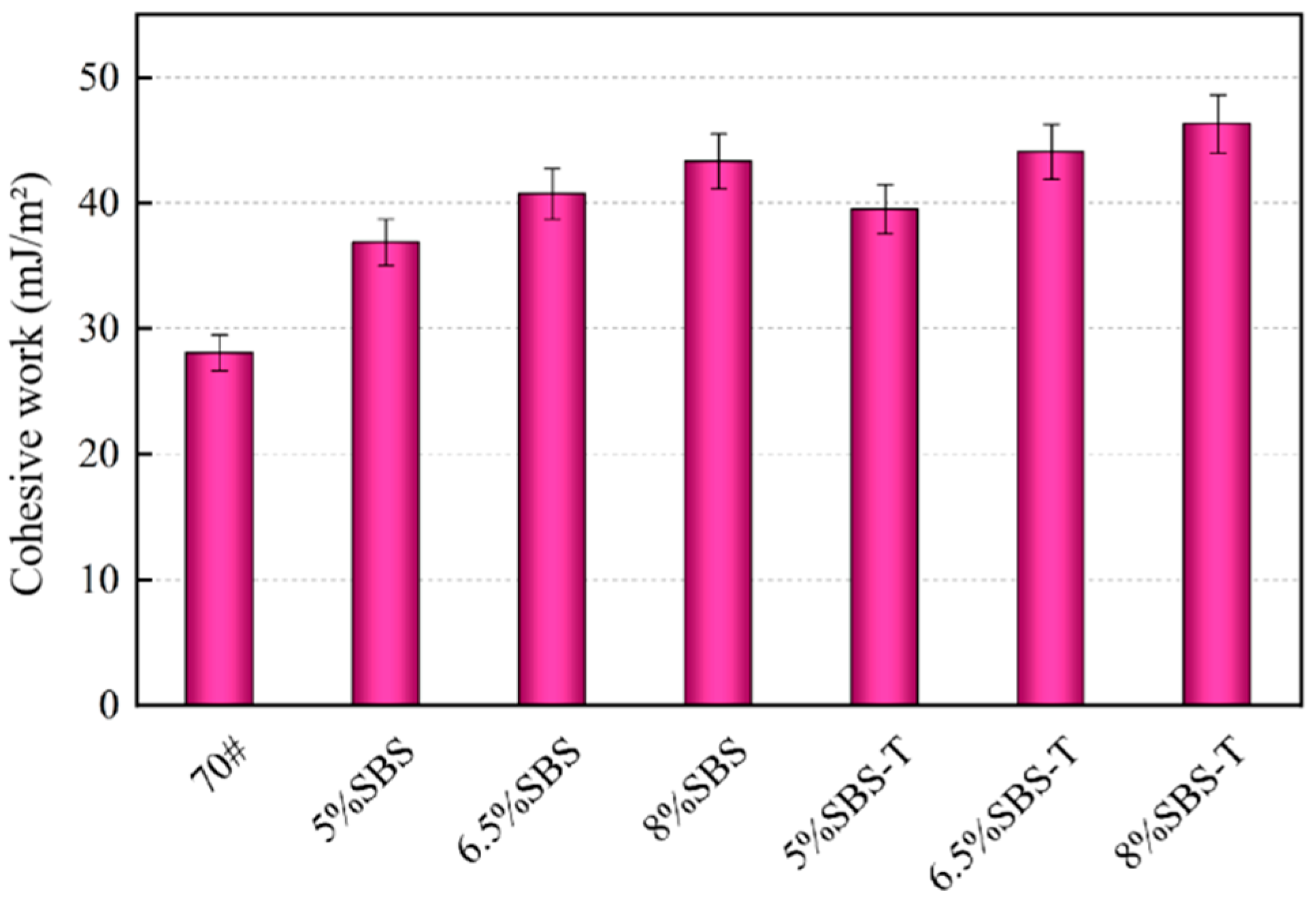

4.1. Cohesive Work

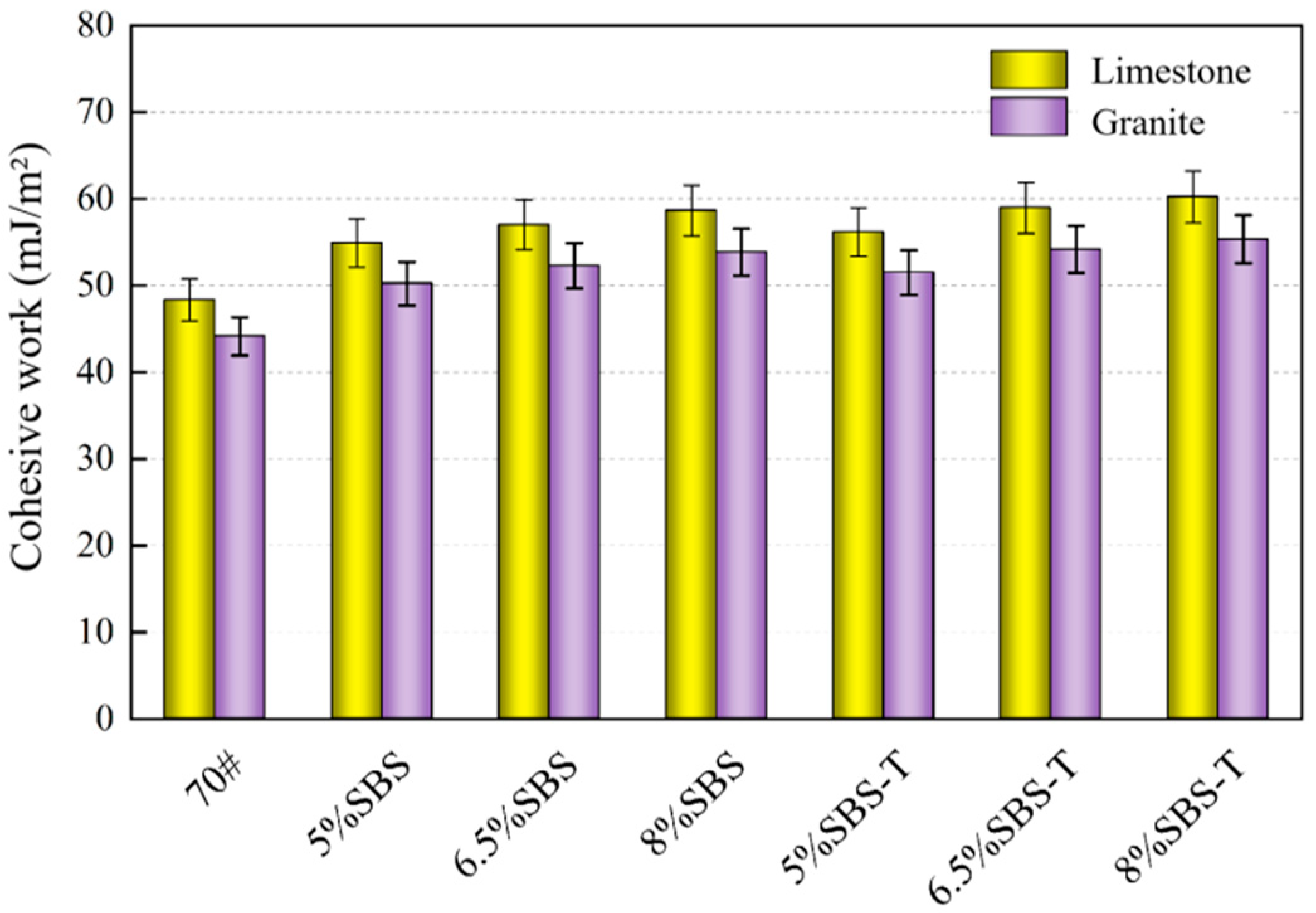

4.2. Adhesion Work

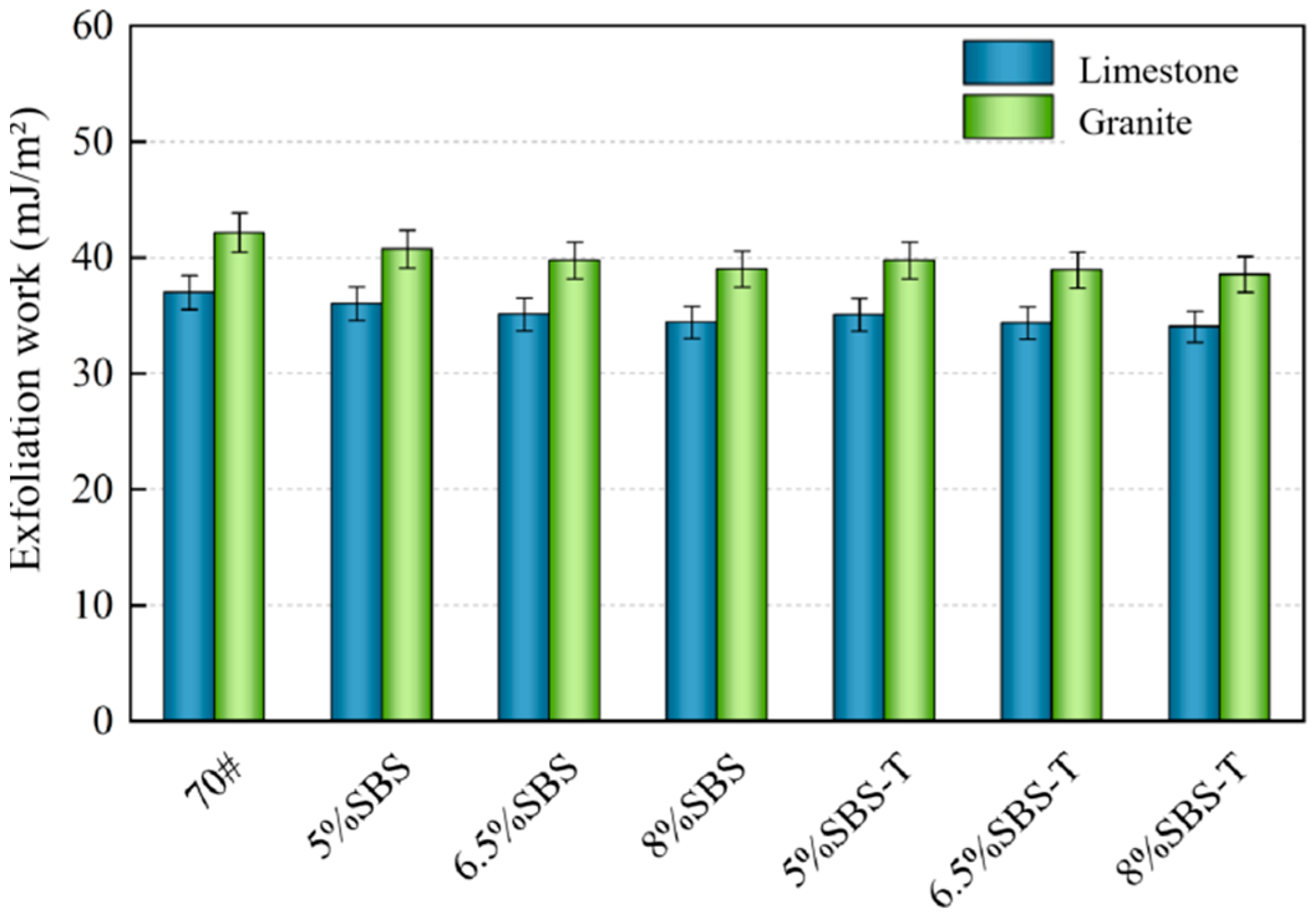

4.3. Stripping Work

4.4. Energy Ratio

5. Conclusions

- The cohesive energy of SBS-modified asphalt ranges from 36.91 to 42.83 mJ/m2, while for SBS-T asphalt, it ranges from 38.95 to 45.20 mJ/m2. This indicates that the addition of SBS-T had a significant positive impact on the thermomechanical properties of asphalt. As modifier dosage was increased, a more stable network structure was formed within the asphalt by the modifier. The cohesion work of asphalt also increased, leading to enhanced internal resistance against the cracking of asphalt material.

- For the limestone aggregate, the stripping work of SBS-modified asphalt ranges from 34.40 to 36.02 mJ/m2, and that of SBS-T-modified asphalt ranges from 34.03 to 35.04 mJ/m2. The stripping work of SBS-T-modified asphalt ranges from 39.74 to 38.53 mJ/m2, and that of SBS-modified asphalt ranges from 40.72 to 39.00 mJ/m2. As the dosage of SBS-T modifier increases, the adhesion work and energy ratio of the asphalt–aggregate system increases and the spalling work reduces. The best adhesion of SBS-T-modified asphalt and aggregate is achieved when the dosage reaches 8%, which corresponds to the strongest resistance to water damage within the asphalt and aggregate system.

- By analyzing the adhesion work, stripping work, and energy ratio of different asphalt–aggregate systems, the adhesion properties of different types of asphalt to aggregates can be ranked in the following order: SBS-T-modified bitumen > SBS-modified bitumen > matrix asphalt. The adhesion properties of the same bitumen to different aggregates can be ranked in the following order: limestone > granite. Among several combinations, the system consisting of SBS-T-modified asphalt and limestone has the best water resistance.

- In this study, the contact angle of the samples was measured using the lay drop method based on the micromechanical scale. The thermodynamic parameters of asphalt and aggregate were calculated using surface free energy theory. A method of evaluating the adhesion properties between new modified asphalt and aggregate at the microscopic scale was thus obtained.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, X.; Ren, D.; Tian, G.; Xu, J.; Ali, R.; Ai, C. Investigation on moisture damage resistance of asphalt pavement in salt and acid erosion environments based on Multi-scale analysis. Constr. Build. Mater. 2023, 366, 130177. [Google Scholar] [CrossRef]

- Cong, P.; Guo, X.; Ge, W. Effects of moisture on the bonding performance of asphalt-aggregate system. Constr. Build. Mater. 2021, 295, 123667. [Google Scholar] [CrossRef]

- Hu, M.; Sun, G.; Sun, D.; Zhang, Y.; Ma, J.; Lu, T. Effect of thermal aging on high viscosity modified asphalt binder: Rheological property, chemical composition and phase morphology. Constr. Build. Mater. 2020, 241, 118023. [Google Scholar] [CrossRef]

- Dong, F.; Yu, X.; Liu, S.; Wei, J. Rheological behaviors and microstructure of SBS/CR composite modified hard asphalt. Constr. Build. Mater. 2016, 115, 285–293. [Google Scholar] [CrossRef]

- Hassanpour-Kasanagh, S.; Ahmedzade, P.; Fainleib, A.M.; Behnood, A. Rheological properties of asphalt binders modified with recycled materials: A comparison with Styrene-Butadiene-Styrene (SBS). Constr. Build. Mater. 2020, 230, 117047. [Google Scholar] [CrossRef]

- Oreto, C.; Veropalumbo, R.; Viscione, N.; Biancardo, S.A.; Russo, F. Investigating the environmental impacts and engineering performance of road asphalt pavement mixtures made up of jet grouting waste and reclaimed asphalt pavement. Environ. Res. 2021, 198, 111277. [Google Scholar] [CrossRef] [PubMed]

- Oreto, C.; Veropalumbo, R.; Viscione, N.; Biancardo, S.A.; Botte, M.; Russo, F. Integration of life cycle assessment into a decision support system for selecting sustainable road asphalt pavement mixtures prepared with waste. Int. J. Life Cycle Assess. 2021, 26, 2391–2407. [Google Scholar] [CrossRef]

- Luo, H.; Zheng, C.; Yang, X.; Bao, C.; Liu, W.; Lin, Z. Development of technology to accelerate SBS-modified asphalts swelling in dry modification mode. Constr. Build. Mater. 2022, 314, 125703. [Google Scholar] [CrossRef]

- Zhuang, Y.; Yue, J.; Men, B.; Tang, G.; Wang, R. Experimental Study on Mechanism, Aging and Fatigue Performance of Warm Mixing Speed Melting SBS Modified Asphalt Binders. Coatings 2023, 13, 311. [Google Scholar] [CrossRef]

- Han, S.; Dong, S.; Liu, M.; Han, X.; Liu, Y. Study on improvement of asphalt adhesion by hydrated lime based on surface free energy method. Constr. Build. Mater. 2019, 227, 116794. [Google Scholar] [CrossRef]

- Howson, J.; Bhasin, A.; Masad, E.; Lytton, R.; Little, D. Development of a Database for Surface Energy of Aggregates and Asphalt Binders; No. FHWA/TX-09/5-4524-01-1; Texas Transportation Institute: College Station, TX, USA, 2009. [Google Scholar]

- Hefer, A.W. Adhesion in Bitumen-Aggregate Systems and Quantification of the Effects of Water on the Adhesive Bond; Texas A&M University: College Station, TX, USA, 2004. [Google Scholar]

- Little, D.N.; Bhasin, A. Using Surface Energy Measurements to Select Materials for Asphalt Pavement; Texas Transportation Institute: College Station, TX, USA, 2006. [Google Scholar]

- Li, N.; Wang, J.; Si, W.; Hu, D. Quantitative Analysis of Adhesion Characteristics between Crumb Rubber Modified Asphalt and Aggregate Using Surface Free Energy Theory. Materials 2022, 15, 5735. [Google Scholar] [CrossRef]

- Wang, R.; Qi, Z.; Li, R.; Yue, J. Investigation of the effect of aging on the thermodynamic parameters and the intrinsic healing capability of graphene oxide modified asphalt binders. Constr. Build. Mater. 2020, 230, 116984. [Google Scholar] [CrossRef]

- Bhasin, A.; Howson, J.; Masad, E.; Little, D.N.; Lytton, R.L. Effect of modification processes on bond energy of asphalt binders. Transp. Res. Rec. 2007, 1998, 29–37. [Google Scholar] [CrossRef]

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineer. MOT (Ministry of Transport of the People’s Republic of China): Beijing, China, 2011.

- Zhu, J.; Zhang, K.; Liu, K.; Shi, X. Adhesion characteristics of graphene oxide modified asphalt unveiled by surface free energy and AFM-scanned micro-morphology. Constr. Build. Mater. 2020, 244, 118404. [Google Scholar] [CrossRef]

- Kwok, D.Y.; Neumann, A.W. Contact angle measurement and contact angle interpretation. Adv. Colloid Interface Sci. 1999, 81, 167–249. [Google Scholar] [CrossRef]

- Jada, A.; Salou, M. Effects of the asphaltene and resin contents of the bitumens on the water-bitumen interface properties. J. Pet. Eng. 2002, 33, 185–193. [Google Scholar] [CrossRef]

- Lima, M.S.S.; Thives, L.P.; Haritonovs, V.; Gschösser, F. The Influence of Alternative Fillers on the Adhesive Properties of Mastics Fabricated with Red Mud. Materials 2020, 13, 484. [Google Scholar] [CrossRef]

- Moraes, R.; Velasquez, R.; Bahia, H. Using bond strength and surface energy to estimate moisture resistance of asphalt-aggregate systems. Constr. Build. Mater. 2017, 130, 156–170. [Google Scholar] [CrossRef]

- Grenfell, J.; Ahmad, N.; Liu, Y.; Apeagyei, A.; Large, D.; Airey, G. Assessing asphalt mixture moisture susceptibility through intrinsic adhesion, bitumen stripping and mechanical damage. Road Mater. Pavement Des. 2014, 15, 131–152. [Google Scholar] [CrossRef]

- Robertson, R.E. Chemical properties of asphalts and their effects on pavement performance. In Transportation Research Circular No. 499; Transportation Research Board, National Research Council: Washington, DC, USA, 2000; pp. 38–49. [Google Scholar]

| Technical Indicators | Unit | Measured Value | Test Methods a |

|---|---|---|---|

| Penetration (25 °C) | 0.1 mm | 66.9 | T0604-2011 |

| Ductility (15 °C, 5 cm/min) | cm | >100 | T0605-2011 |

| Softening point | °C | 53.2 | T0606-2011 |

| Brinell rotational viscosity (135 °C) | Pa·s | 0.61 | T0625-2011 |

| Modifier | Technical Indicator | Unit | Measured Value |

|---|---|---|---|

| SBS | Structure type | - | Linearity |

| Block ratio S/B | - | 40/60 | |

| Fracture elongation | % | ≥700 | |

| Melt flow rate | g/10 min | 0.1–5.0 | |

| SBS-T | Appearance | - | Granular, uniform |

| SBS content | % | ≥50 | |

| Ash content | % | ≤5.0 | |

| Melt index | g/10 min | ≥2.0 | |

| Dry mix dispersibility | - | No particle residue |

| Technical Indicator | Unit | 5% SBS-T | 6.5% SBS-T | 8% SBS-T |

|---|---|---|---|---|

| Penetration (25 °C) | 0.1 mm | 61.8 | 58.6 | 56.3 |

| Softening point | °C | 88.7 | 93.2 | 95.1 |

| Ductility (15 °C, 5 cm/min) | cm | 42.5 | 47.9 | 50.4 |

| Dynamic viscosity at 60 °C | Pa·s | 27,096 | 68,252 | 134,527 |

| Elastic recovery | % | 96.7 | 99.1 | 99.5 |

| Aggregate Type | Unit | |||||

|---|---|---|---|---|---|---|

| limestone | mJ/m2 | 42.17 | 32.72 | 9.45 | 1.55 | 14.39 |

| granite | mJ/m2 | 35.51 | 26.96 | 8.55 | 1.67 | 10.92 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Men, B.; Guo, F.; Kang, X.; Yue, J. Research on the Adhesion Properties of Fast-Melting SBS-Modified Asphalt–Aggregate Based on Surface Free Energy Theory. Materials 2023, 16, 7601. https://doi.org/10.3390/ma16247601

Men B, Guo F, Kang X, Yue J. Research on the Adhesion Properties of Fast-Melting SBS-Modified Asphalt–Aggregate Based on Surface Free Energy Theory. Materials. 2023; 16(24):7601. https://doi.org/10.3390/ma16247601

Chicago/Turabian StyleMen, Bo, Fei Guo, Xiaolong Kang, and Jinchao Yue. 2023. "Research on the Adhesion Properties of Fast-Melting SBS-Modified Asphalt–Aggregate Based on Surface Free Energy Theory" Materials 16, no. 24: 7601. https://doi.org/10.3390/ma16247601

APA StyleMen, B., Guo, F., Kang, X., & Yue, J. (2023). Research on the Adhesion Properties of Fast-Melting SBS-Modified Asphalt–Aggregate Based on Surface Free Energy Theory. Materials, 16(24), 7601. https://doi.org/10.3390/ma16247601