Growth and Dispersion Control of SnO2 Nanocrystals Employing an Amino Acid Ester Hydrochloride in Solution Synthesis: Microstructures and Photovoltaic Applications

Abstract

:1. Introduction

2. Materials and Methods

2.1. Chemicals

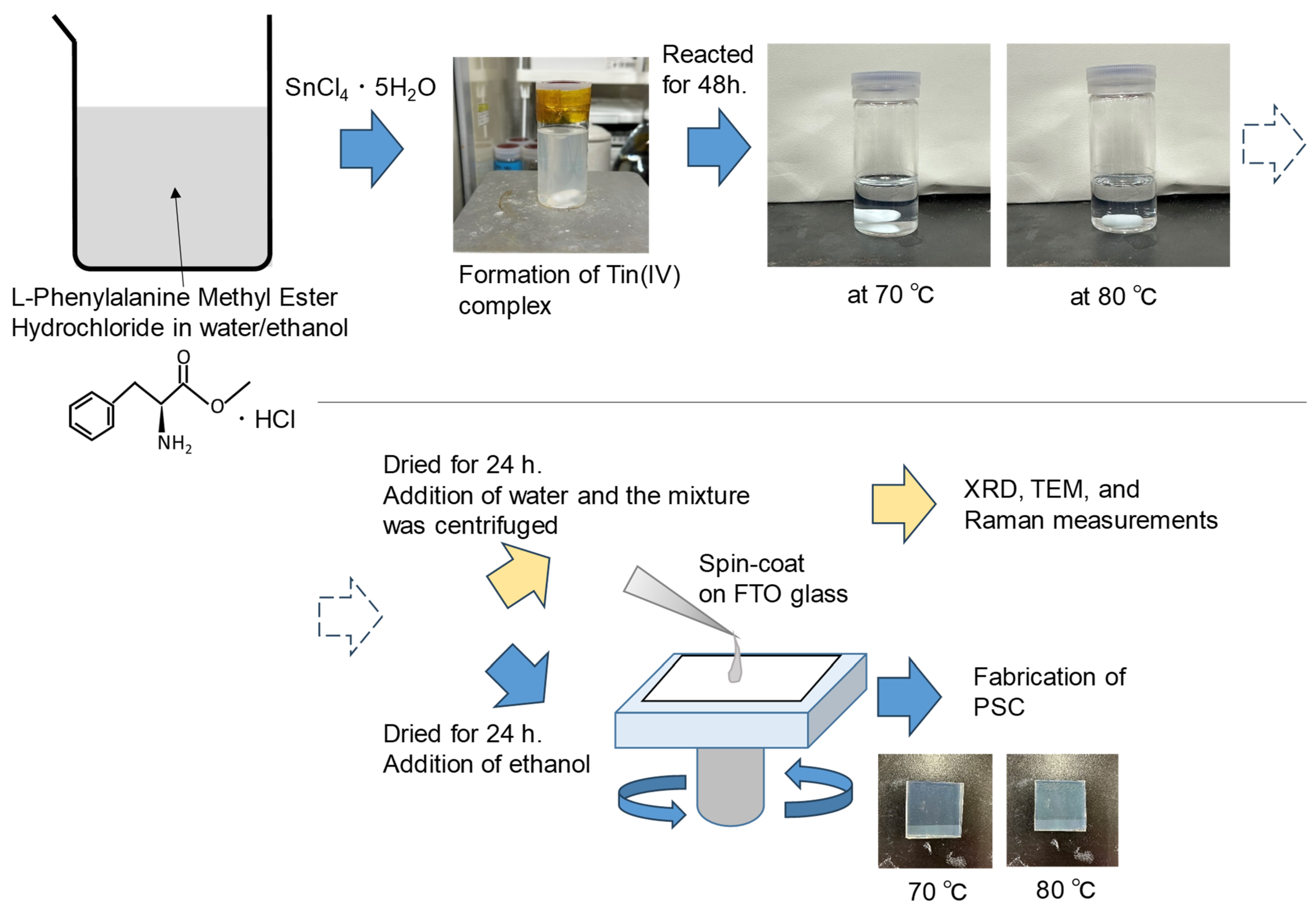

2.2. Synthesis of SnO2 Nanocrystals

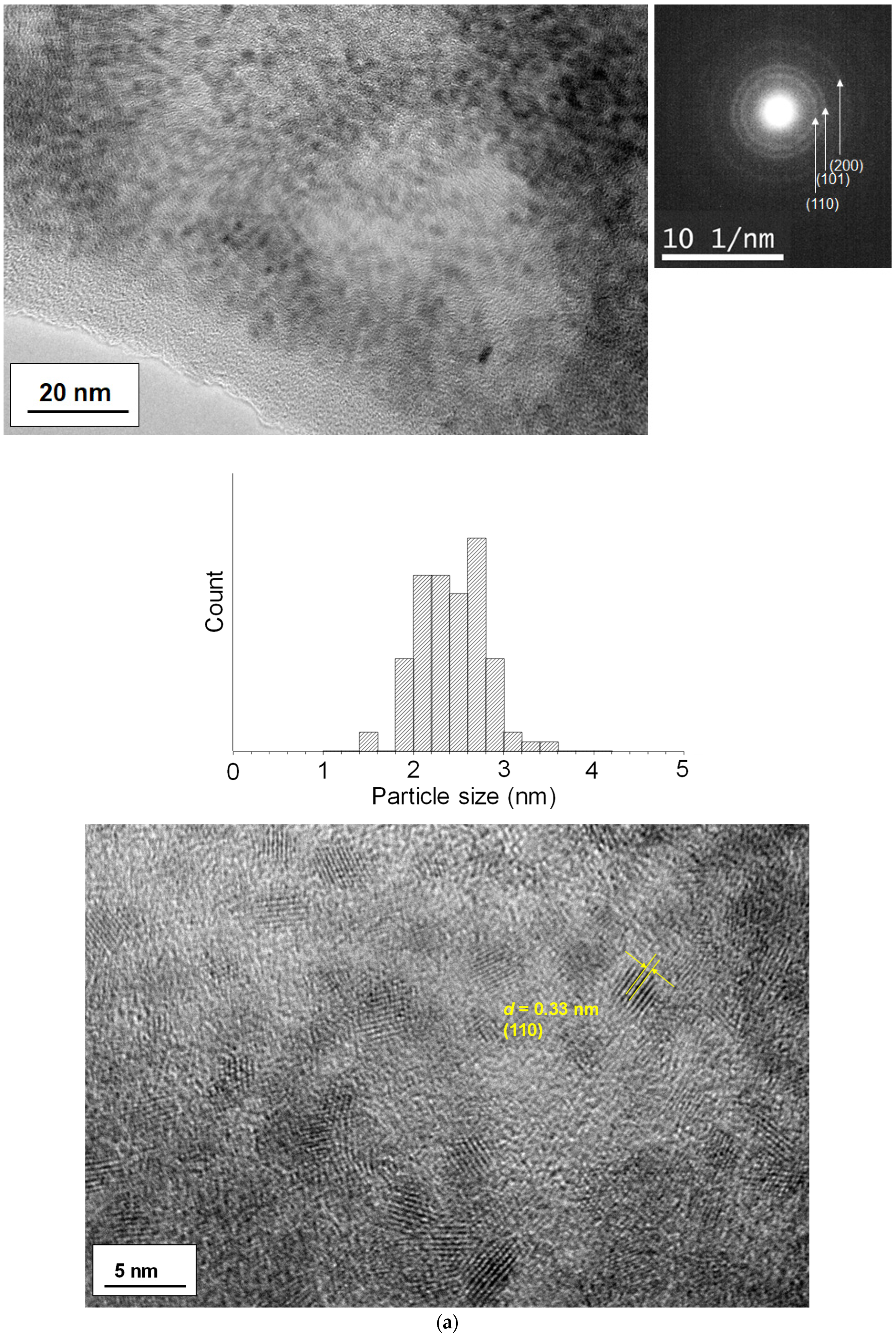

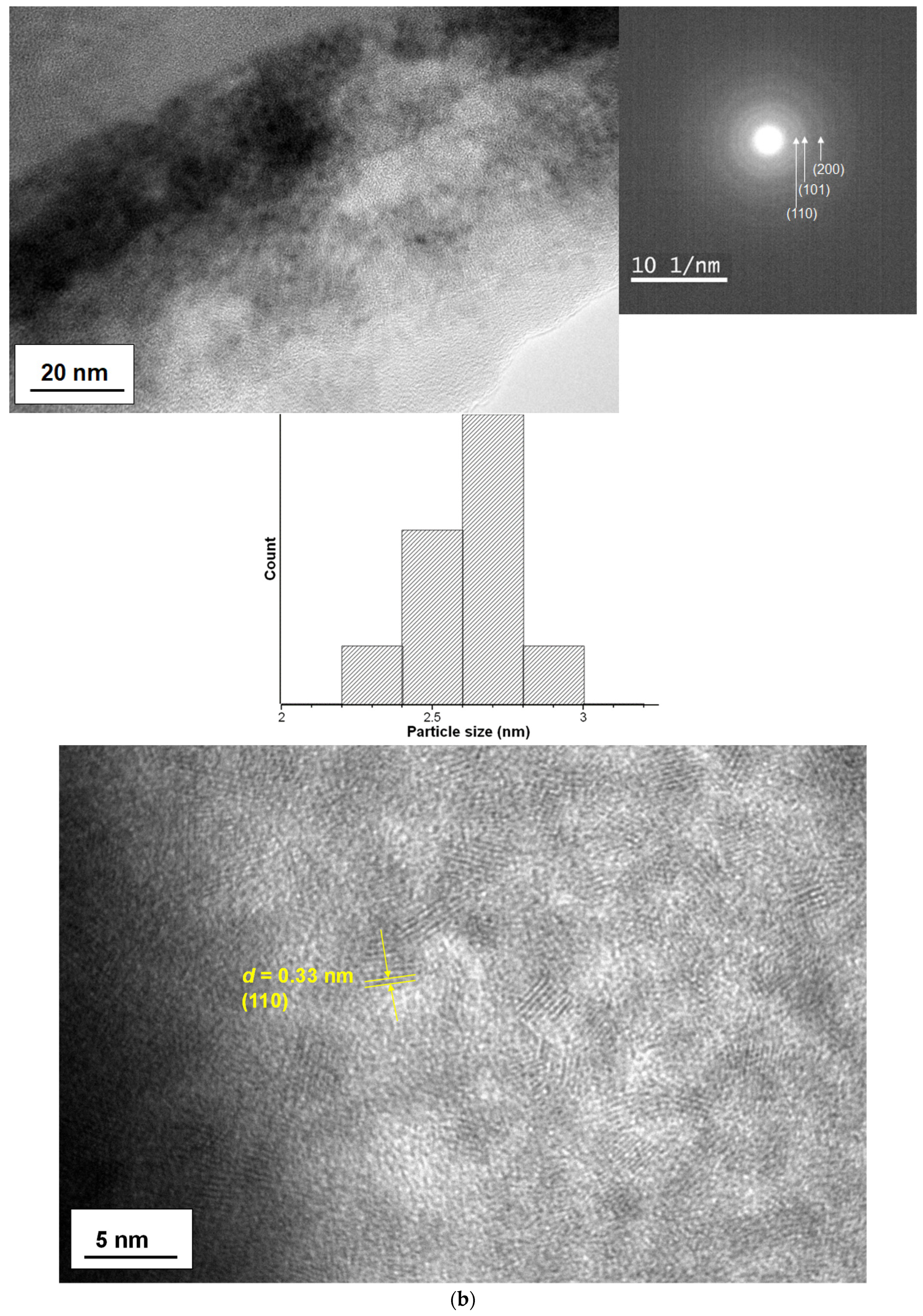

2.3. Characterization of SnO2 Nanocrystals

2.4. Preparation and Structural Characterization of SnO2 Thin Films

2.5. Fabrication and Evaluation of Perovskite Solar Cells

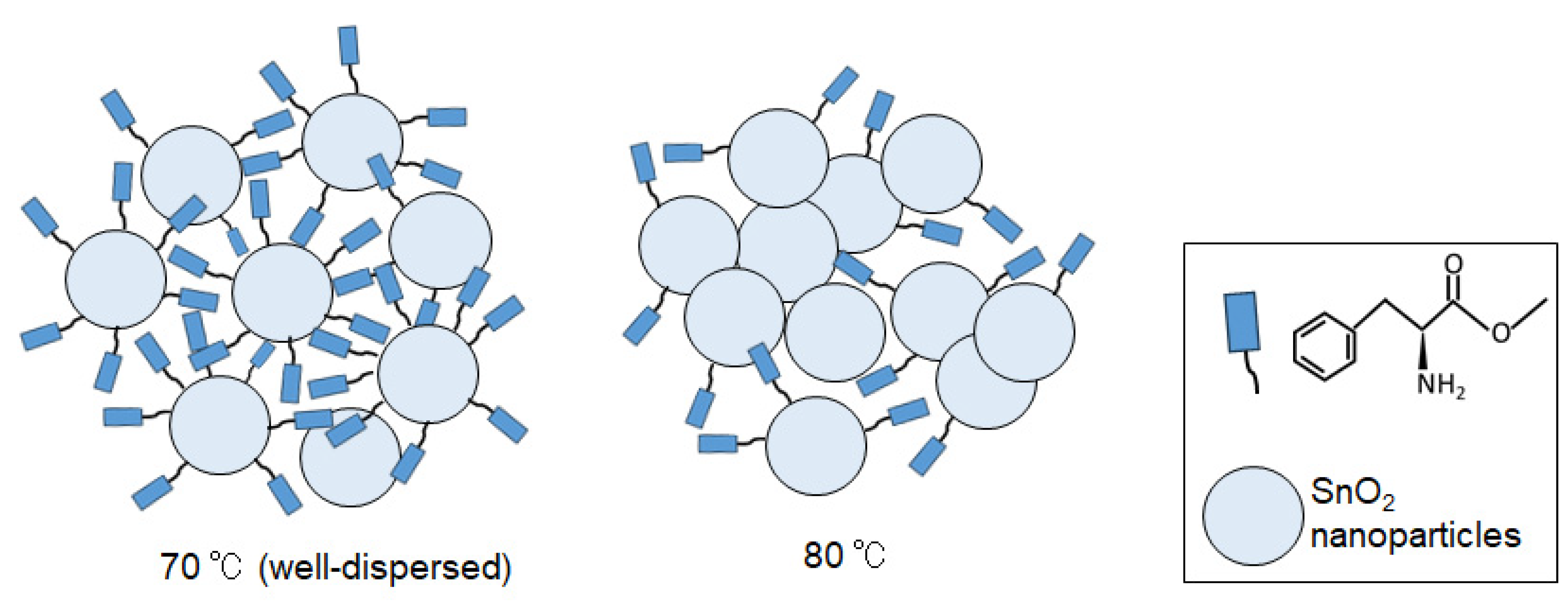

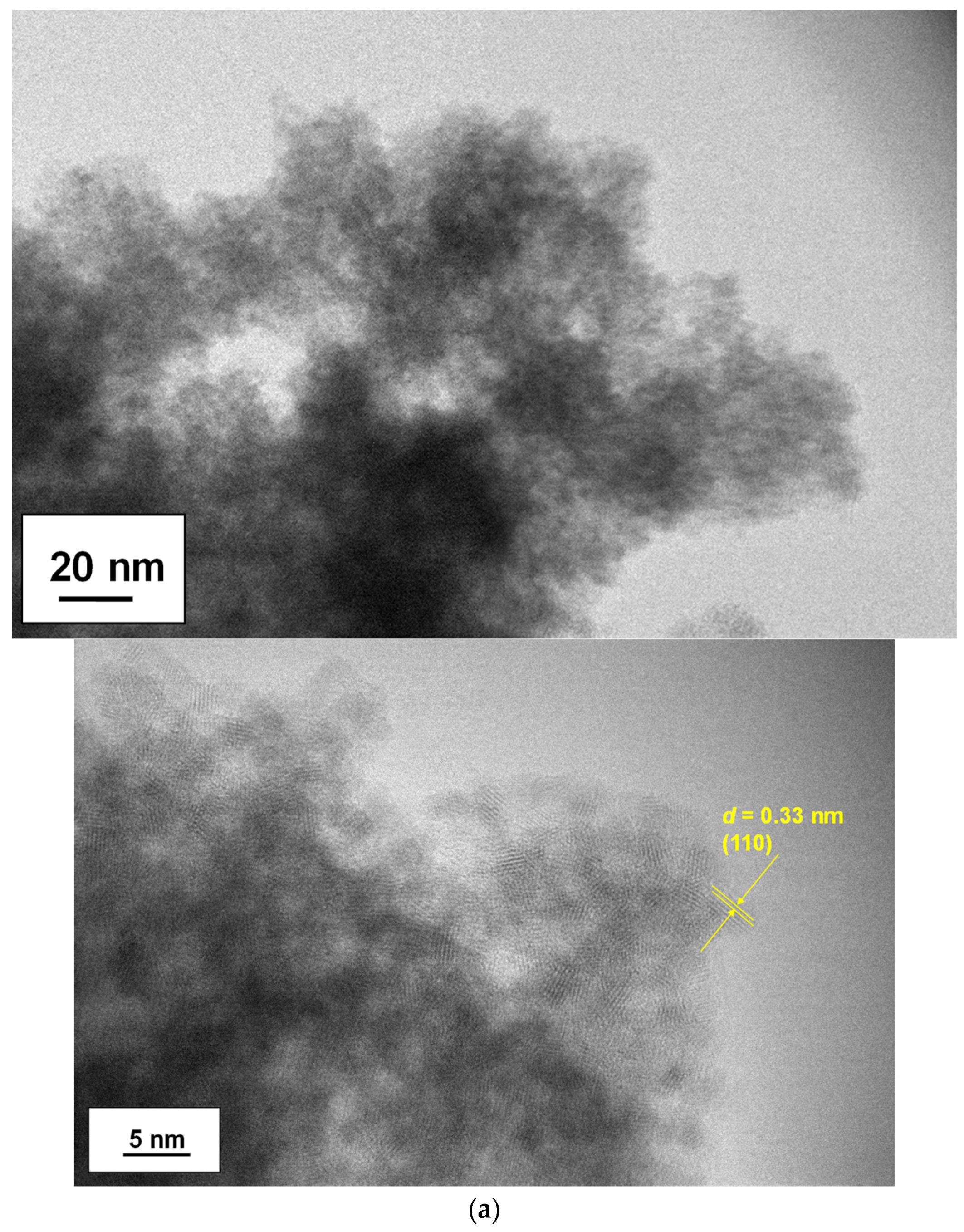

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Grätzel, M. Recent Advances in Sensitized Mesoporous Solar Cells. Acc. Chem. Res. 2009, 42, 1788–1798. [Google Scholar] [CrossRef] [PubMed]

- Jena, A.-K.; Kulkarni, A.; Miyasaka, T. Halide perovskite photovoltaics: Background, status, and future prospects. Chem. Rev. 2019, 119, 3036–3103. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.; Park, N.-G. A realistic methodology for 30% efficient perovskite solar cells. Chem 2020, 6, 1254–1256. [Google Scholar] [CrossRef]

- Keshtmand, R.; Zamani-Meymian, M.R.; Mohamadkhani, F.; Taghavinia, N. Smoothing and coverage improvement of SnO2 electoron transporting layer by NH4F treatment: Enhanced fill factor and efficiency of perovskite solar cells. Sol. Energy 2021, 228, 253–262. [Google Scholar] [CrossRef]

- Gil, B.; Yun, A.J.; Lim, J.; Cho, J.; Kim, B.; Ryu, S.; Kim, J.; Park, B. Design of SnO2 Electron Transport Layer in Perovskite Solar Cells to Achieve 2000 h Stability Under 1 Sun Illumination and 85 °C. Adv. Mater. Interfaces 2023, 10, 2202148. [Google Scholar] [CrossRef]

- Sun, Q.; Li, H.; Gong, X.; Ban, H.; Shen, Y.; Wang, M. Interconnected SnO2 Nanocrystals Electron Transport Layer for Highly Flexible Perovskite Solar Cells. Sol. RRL 2020, 4, 1900229. [Google Scholar] [CrossRef]

- Chen, Y.; Zuo, X.; He, Y.; Qian, F.; Zuo, S.; Zhang, Y.; Liang, L.; Chen, Z.; Zhao, K.; Liu, Z.; et al. Dual Passivation of perovskite and SnO2 for High-Efficiency MAPbI3 Perovskite Solar Cells. Adv. Sci. 2021, 8, 2001466. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Du, Y.; Fang, S.; Chen, X.; Li, X.; Guo, Y.; Gu, B.; Lu, H. Regulating Lewis Acid-Base Interactions to Enhance Stability of Tin Oxide for High-Performance Perovskite Solar Cells. Adv. Mater. Interfaces 2023, 10, 2300328. [Google Scholar] [CrossRef]

- Zhang, L.; Fu, C.; Wang, S.; Wang, M.; Wang, R.; Xiang, S.; Wang, Z.; Liu, J.; Ma, H.; Wang, Y.; et al. Amorphous F-doped TiOx Caulked SnO2 Electron Transport Layer for Flexible Perovskite Solar Cells with efficiency Exceeding 22.5%. Adv. Mater. 2023, 33, 2213961. [Google Scholar] [CrossRef]

- Deng, K.; Chen, Q.; Li, L. Modification Engineering in SnO2 Electron Transport Layer toward Perovskite Solar Cells: Efficiency and Stability. Adv. Funct. Mater. 2020, 30, 2004209. [Google Scholar] [CrossRef]

- Ghasemi, F.; Keshtmand, R.; Taghavinia, N. SnO2 Layer Treatment with Tthioacetamide in Perovskite Solar Cell. Nanochem. Res. 2023, 8, 299–305. [Google Scholar]

- Chai, N.; Chen, X.; Zeng, Z.; Yu, R.; Yue, Y.; Mai, B.; Wu, J.; Mai, L.; Cheng, Y.; Wang, X. Photoexcitation-induced passivation of SnO2 thin film for efficient perovskite solar cells. Nat. Sci. Rev. 2023, 10, 245. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Xing, C.; Bao, Q.; Zhang, L.; Huang, S.; Wang, D.; Zhang, T. An Interface Strategy on SnO2 for Stable Planar Perovskite Solar Cells. Energy Technol. 2023, 11, 230016. [Google Scholar] [CrossRef]

- Huang, Y.; Li, S.; Wu, C.; Wang, S.; Wang, C.; Ma, R. Introduction of SnO2 electron transport layer for efficient planar perovskite solar cells. Chem. Phys. Lett. 2020, 745, 137220. [Google Scholar] [CrossRef]

- Xie, H.; Yin, X.; Liu, J.; Guo, Y.; Chen, P.; Que, W.; Wang, G.; Gao, B. Low temperature solution-derived TiO2-SnO2 bilayered electron transport layer for high performance perovskite solar cells. Appl. Surf. Sci. 2019, 464, 700–707. [Google Scholar] [CrossRef]

- Chen, Y.; Xu, C.; Xiong, J.; Zhang, Z.; Yang, J.; Xue, X.; Yang, D.; Zhang, J. Benefits of fullerene/SnO2 bilayers as electron transport layer for efficient planar perovskite solar cells. Org. Electron. 2018, 58, 294–300. [Google Scholar] [CrossRef]

- Zhang, J.; Bai, C.; Dong, Y.; Shen, W.; Zhang, Q.; Huang, F.; Cheng, Y.-B.; Zhong, J. Batch chemical bath deposition of large-area SnO2 film with mercaptosuccinic acid decoration for homogenized and efficient perovskite solar cells. Chem. Eng. J. 2021, 425, 131444. [Google Scholar] [CrossRef]

- Suo, J.; Yang, B.; Mosconi, E.; Choi, H.-S.; Kim, Y.; Zakeeruddin, S.M.; Angelis, F.D.; Grätzel, M.; Kim, H.-S.; Hagfeldt, A. Surface Reconstruction Engineering with Synergistic Effect of Mixed-Salt Passivation Treatment toward Efficient and Stable Perovskite Solar Cells. Adv. Funct. Mater. 2021, 31, 2102902. [Google Scholar] [CrossRef]

- Quy, H.V.; Bark, C.W. Ni-doped SnO2 as an Electron Transport Layer by a Low-Temperature Process in Planar Perovskite Solar Cells. ACS Omega 2022, 7, 22256–22262. [Google Scholar] [CrossRef]

- Lee, S.-U.; Park, H.; Shin, H.; Park, N.-G. Atomic layer deposition of SnO2 using hydrogen peroxide improves the efficiency and stability of perovskite solar cells. Nanoscale 2023, 15, 5044–5052. [Google Scholar] [CrossRef]

- Zakaria, Y.; Aïssa, B.; Fix, T.; Ahzi, S.; Mansour, S.; Slaoui, A. Moderate temperature deposition of RF magnetron sputtered SnO2 based electron transporting layer for triple cation perovskite solar cells. Sci. Rep. 2023, 13, 9100. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.; Lee, H.B.; Tyagi, B.; Ovhal, M.M.; Cho, S.; Lee, J.-S.; Oh, J.-W.; Kang, J.-W. Spray-Deposited, Virus-Templated SnO2 Mesoporous Electron Transport Layer for High-Efficiency, Sequential -Deposited Perovskite Solar Cells. Sol. RRL 2023, 7, 2300065. [Google Scholar] [CrossRef]

- Wu, Z.; Su, J.; Chai, N.; Cheng, S.; Wang, X.; Zhang, Z.; Liu, X.; Zhong, H.; Yang, J.; Wang, Z.; et al. Periodic Acid Modification of Chemical-Bath Deposited SnO2 Electron Transport Layers for Perovskite Solar Cells and Mini Modules. Adv. Sci. 2023, 10, 2300010. [Google Scholar] [CrossRef] [PubMed]

- Zeng, W.; He, X.; Bian, H.; Guo, P.; Wang, M.; Xu, C.; Xu, G.; Zhong, Y.; Lu, D.; Sofer, Z.; et al. Multi-functional Strategy: Ammonium Citrate-Modified SnO2 ETL for Efficient and Stable Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2022, 14, 43975–43986. [Google Scholar] [CrossRef] [PubMed]

- Muthukrishnan, A.P.; Lee, J.; Kim, J.; Kim, C.S.; Jo, S. Low-temperature solution-processed SnO2 electron transport layer modified by oxygen plasma for planar perovskite solar cells. RSC Adv. 2022, 12, 4883–4890. [Google Scholar] [CrossRef] [PubMed]

- Kumar, N.; Lee, H.B.; Sahani, R.; Tyagi, B.; Cho, S.; Lee, J.-S.; Kang, J.-W. Room-Temperature Spray Deposition of Large-Area SnO2 Electron Transport Layer for High Performance, Stable FAPbI3-Based Perovskite Solar Cells. Small Methods 2021, 6, 2101127. [Google Scholar] [CrossRef] [PubMed]

- Eliwi, A.A.; Byranvand, M.M.; Fassl, P.; Khan, M.R.; Hossain, I.M.; Frericks, M.; Ternes, S.; Abzieher, T.; Schwenzer, J.A.; Mayer, T.; et al. Optimization of SnO2 electron transport layer for efficient planar perovskite solar cells with very low hysteresis. Mater. Adv. 2023, 3, 456–466. [Google Scholar] [CrossRef]

- Bi, H.; Zuo, X.; Liu, B.; He, D.; Bai, L.; Wang, W.; Li, X.; Xiao, Z.; Sun, K.; Song, Q.; et al. Multifunctional organic ammo nium salt-modified SnO2 nanoparticles toward efficient and stable planar perovskite solar cells. J. Mater. Chem. A 2021, 9, 3940–3951. [Google Scholar] [CrossRef]

- Zhang, X.; Zhou, Y.; Chen, M.; Wang, D.; Chao, L.; Lv, Y.; Zhang, H.; Xia, Y.; Li, M.; Hu, Z.; et al. Novel Bilayer SnO2 Electron Transport Layers with Atomic Layer Deposition for High-Performance α-FAPbI3 Perovskite Solar Cells. Small 2023, 19, 2303254. [Google Scholar] [CrossRef]

- Yang, Y.; Yang, L.; Feng, S.; Niu, Y.; Li, X.; Cheng, L.; Li, L.; Qin, W.; Wang, T.; Xu, Q.; et al. Active SnO2 Crystal Planes Enable Efficient and Ultra-Bendable n-i-p Perovskite Solar Cells with Record Certificated Power Conversion Efficiency. Adv. Energy Mater. 2023, 13, 2302661. [Google Scholar] [CrossRef]

- Liu, T.; Guo, X.; Liu, Y.; Hou, M.; Yuan, Y.; Mai, X.; Fedorovich, K.V.; Wang, N. 4-Trifluorophenylammonium Iodide-Based Dual Interfacial Modification Engineering toward Improved Efficiency and Stability of SnO2-Based Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2023, 15, 6777–6787. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Wu, J.; Liu, X.; Wang, S.; Yan, Z.; Chen, L.; Li, G.; Zhang, X.; Sun, W.; Lan, Z. High-effective SnO2-based perovskite solar cells by multifunctional molecular additive engineering. J. Alloys Compd. 2021, 886, 161352. [Google Scholar] [CrossRef]

- Yang, Y.; Lu, H.; Feng, S.; Yang, L.; Dong, H.; Wang, J.; Tian, C.; Li, L.; Lu, H.; Jeong, J.; et al. Modulation of perovskite crystallization processes towards highly efficient and stable perovskite solar cells with MXene quantum dot-modified SnO2. Energy Environ. Sci. 2021, 14, 3447–3454. [Google Scholar] [CrossRef]

- Qian, Z.; Chen, L.; Wang, J.; Wang, L.; Xia, Y.; Ran, X.; Li, P.; Zhong, Q.; Song, L.; Müller-Buschbaum, P.; et al. Manipulating SnO2 Growth for Efficient Electron Transport in Perovskite Solar Cells. Adv. Mater. Interfaces 2021, 8, 2100128. [Google Scholar] [CrossRef]

- Bai, Y.; Xing, D.; Luo, H.; Jiang, Q.-S.; Yuan, L.; Ge, X.; Yang, X.; Zhang, Y.; Xie, F.; Yan, K. Facilitating the formation of SnO2 film via hydroxyl groups for efficient perovskite solar cells. Appl. Surf. Sci. 2021, 552, 149459. [Google Scholar] [CrossRef]

- Shekargoftar, M.; Pospisil, J.; Kratochvíl, M.; Vida, J.; Souček, P.; Homola, T. Low-Temperature and Rapid Deposition of an SnO2 Layer from a Colloidal Nanoparticle Dispersion for Use in Planar Perovskite Solar Cells. Energy Technol. 2021, 9, 2001076. [Google Scholar] [CrossRef]

- Zhuang, J.; Mao, P.; Luan, Y.; Chen, N.; Cao, X.; Niu, G.; Jia, F.; Wang, F.; Cao, S.; Wan, J. Rubidium Fluoride Modified SnO2 for Planar n-i-p Perovskite Solar Cells. Adv. Funct. Mater. 2021, 31, 2010385. [Google Scholar] [CrossRef]

- Zhang, W.; Zheng, X.; Li, Y.; He, L.; Li, X. Gourmet powder functionalization of SnO2 for high-performance perovskite solar cells made in air. Electrochim. Acta 2021, 371, 137812. [Google Scholar] [CrossRef]

- Gao, B.; Cao, Q.; Pu, X.; Yang, J.; Han, J.; Wang, S.; Li, T.; He, Z.; Li, X. Bi-Directional functionalization of urea-complexed SnO2 for efficient planar perovskite solar cells. Appl. Surf. Sci. 2021, 546, 148711. [Google Scholar] [CrossRef]

- Xu, C.; Liu, Z.; Sun, Q.; Lee, E.-C. Morphology control of SnO2 layer by solvent engineering for efficient perovskite solar cells. Sol. Energy 2020, 214, 280–287. [Google Scholar] [CrossRef]

- Cao, J.-J.; Wang, K.-L.; Dong, C.; Li, X.-M.; Yang, W.-F.; Wang, Z.-K. Bottom-contact passivation for high-performance perovskite solar cells using TaCl5-doped SnO2 as electron-transporting layer. Org. Electron. 2021, 88, 105972. [Google Scholar] [CrossRef]

- Xu, Z.; Teo, S.H.; Gao, L.; Guo, Z.; Kamata, Y.; Hayase, S.; Ma, T. La-doped SnO2 as ETL for efficient planar-structure hybrid perovskite solar cells. Org. Electron. 2019, 73, 62–68. [Google Scholar] [CrossRef]

- Ko, Y.; Kim, Y.; Lee, C.; Kim, T.; Kim, S.; Yun, Y.J.; Gwon, H.-J.; Lee, N.-H.; Jun, Y. Self-Aggregation-Controlled Rapid Chemical Bath Deposition of SnO2 Layers and Stable Dark Depolarization Process for Highly Efficient Planar Perovskite Solar Cells. ChemSusChem 2020, 13, 4051–4063. [Google Scholar] [CrossRef] [PubMed]

- Zhang, S.; Si, H.; Fan, W.; Shi, M.; Li, M.; Xu, C.; Zhang, Z.; Liao, Q.; Sattar, A.; Kang, Z.; et al. Graphdiyne: Bridging SnO2 and Perovskite in Planar Solar Cells. Angew. Chem. Int. Ed. 2020, 59, 11573–11582. [Google Scholar] [CrossRef] [PubMed]

- Vafaei, S.; Wolosz, A.; Ethridge, C.; Schnupf, U.; Hattori, N.; Sugiura, T.; Manseki, K. Elucidation of the Crystal Growth Characteristics of SnO2 Nanoaggregates Formed by Sequential Low-Temperature Sol-Gel Reaction and Freeze Drying. Nanomaterials 2021, 11, 1738. [Google Scholar] [CrossRef] [PubMed]

- Kulandaisamy, A.J.; Rayappan, J.B.B. Significance of Nanoparticles and the Role of Amino Acids in Structuring Them-A Review. J. Nanosci. Nanotechnol. 2018, 18, 5222–5233. [Google Scholar] [CrossRef] [PubMed]

- Skwierczynski, R.D.; Connors, K.A. Demethylation Kinetics of Aspartame and L-Phenylalanine Methyl Ester in Aqueous Solution. Pharm. Res. 1993, 10, 1174–1180. [Google Scholar] [CrossRef] [PubMed]

- Jiang, K.-J.; Manseki, K.; Yu, Y.-H.; Masaki, N.; Suzuki, K.; Song, Y.-L.; Yanagida, S. Photovoltaics Based on Hybridization of Effective Dye-Sensitized Titanium Oxide and Hole-Conductive Polymer P3HT. Adv. Funct. Mater. 2009, 19, 2481–2485. [Google Scholar] [CrossRef]

- Vafaei, S.; Boddu, V.K.; Jala, S.; Bezawada, P.K.; Hattori, N.; Higashi, S.; Sugiura, T.; Manseki, K. Preparation of Nanostructured Sn/Ti Oxide Hybrid Films with Terpineol/PEG-Based Nanofluids: Perovskite Solar Cell Applications. Materials 2023, 16, 3136. [Google Scholar] [CrossRef]

- Griffith, E.C.; Vaida, V. Ionization state of L-Phenylalanine at the Air–Water Interface. J. Am. Chem. Soc. 2013, 135, 710–716. [Google Scholar] [CrossRef]

- Geng, Q.; Jia, X.; He, Z.; Hu, Y.; Gao, Y.; Yang, S.; Yao, C.; Zhang, S. Interface Engineering via Amino Acid for Efficient and Stable Perovskite Solar Cells. Adv. Mater. Interfaces 2022, 9, 2201641. [Google Scholar] [CrossRef]

- Du, J.; Feng, L.; Huang, X.; Lin, Z.; Su, J.; Hu, Z.; Zhang, J.; Chang, J.; Hao, Y. Enhanced efficiency and stability of planar perovskite solar cells by introducing amino acid to SnO2/perovskite interface. J. Sources 2020, 455, 227974. [Google Scholar] [CrossRef]

- Begum, S.; Devi, T.B.; Ahmaruzzaman, M. L-lysine monohydrate mediated facile and environment friendly synthesis of SnO2 nanoparticles and their prospective applications as a catalyst for reduction and photodegradation of aromatic compounds. J. Environ. Chem. Eng. 2016, 4, 2976–2989. [Google Scholar] [CrossRef]

- Tammina, S.K.; Mandal, B.K. Tyrosine mediated synthesis of SnO2 nanoparticles and their photocatalytic activity towards Violet 4 BSN dye. J. Mol. Liq. 2016, 221, 415–421. [Google Scholar] [CrossRef]

- Cheng, B.; Russell, J.M.; Shi, W.; Zhang, L.; Samulski, E.T. Large-Scale, Solution-Phase Growth of Single-Crystalline SnO2 Nanorods. J. Am. Chem. Soc. 2004, 126, 5972–5973. [Google Scholar] [CrossRef]

- Liu, L.Z.; Li, T.H.; Wu, X.L.; Shen, J.C.; Chu, P.K. Identification of oxygen vacancy types from Raman spectra of SnO2 nanocrystals. J. Raman Spectrosc. 2012, 43, 1423–1426. [Google Scholar] [CrossRef]

- Kaur, J.; Shah, J.; Kotnala, R.K.; Verma, K.C. Raman spectra, photoluminescence and ferromagnetism of pure, Co and Fe doped SnO2 nanoparticles. Ceram. Int. 2012, 38, 5563–5570. [Google Scholar] [CrossRef]

- Matysiak, W.; Tański, T.; Smok, W.; Polishchuk, O. Synthesis of hybrid amorphous/crystalline SnO2 1D nanostructures: Investigation of morphology, structure and optical properties. Sci. Rep. 2020, 10, 10842. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hattori, N.; Vafaei, S.; Narita, R.; Nagaya, N.; Yoshida, N.; Sugiura, T.; Manseki, K. Growth and Dispersion Control of SnO2 Nanocrystals Employing an Amino Acid Ester Hydrochloride in Solution Synthesis: Microstructures and Photovoltaic Applications. Materials 2023, 16, 7649. https://doi.org/10.3390/ma16247649

Hattori N, Vafaei S, Narita R, Nagaya N, Yoshida N, Sugiura T, Manseki K. Growth and Dispersion Control of SnO2 Nanocrystals Employing an Amino Acid Ester Hydrochloride in Solution Synthesis: Microstructures and Photovoltaic Applications. Materials. 2023; 16(24):7649. https://doi.org/10.3390/ma16247649

Chicago/Turabian StyleHattori, Nagisa, Saeid Vafaei, Ryoki Narita, Naohide Nagaya, Norimitsu Yoshida, Takashi Sugiura, and Kazuhiro Manseki. 2023. "Growth and Dispersion Control of SnO2 Nanocrystals Employing an Amino Acid Ester Hydrochloride in Solution Synthesis: Microstructures and Photovoltaic Applications" Materials 16, no. 24: 7649. https://doi.org/10.3390/ma16247649